Exploring Barriers to Unmanned Aerial Vehicle (UAV) Technology for Construction Safety Management Using Mixed-Methods Approach

Abstract

1. Introduction

2. Contextual Background

2.1. Safety Problems and Issues in the Construction Industry

2.2. Application of UAVs in Construction Safety

2.2.1. Pre-Construction Applications

2.2.2. Construction Applications

2.2.3. Post-Construction Application

2.3. Opportunities and Barriers of UAVs in Construction Safety Management

2.3.1. Opportunities of UAVs in Construction Safety

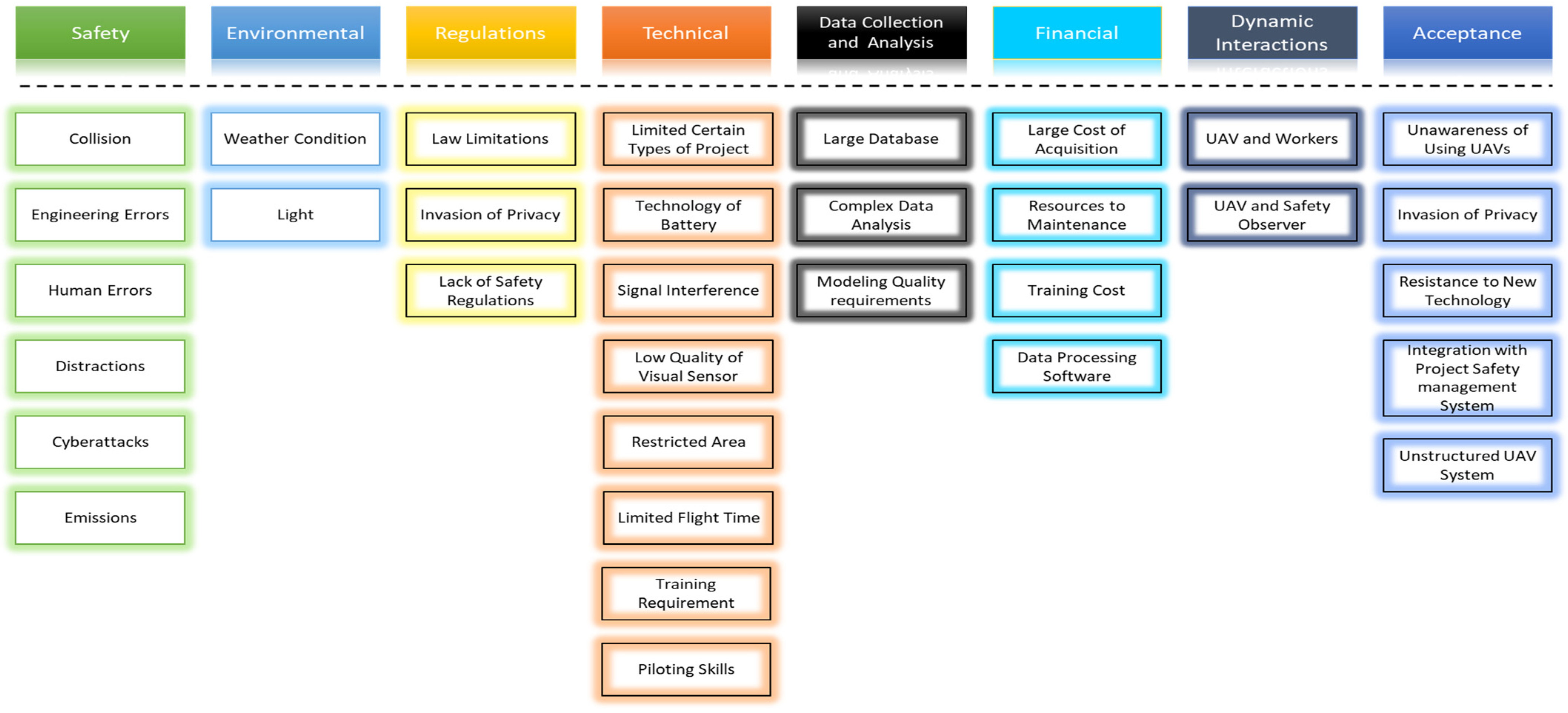

2.3.2. Barriers to UAVs in Construction Safety Management

2.4. Point of Departure

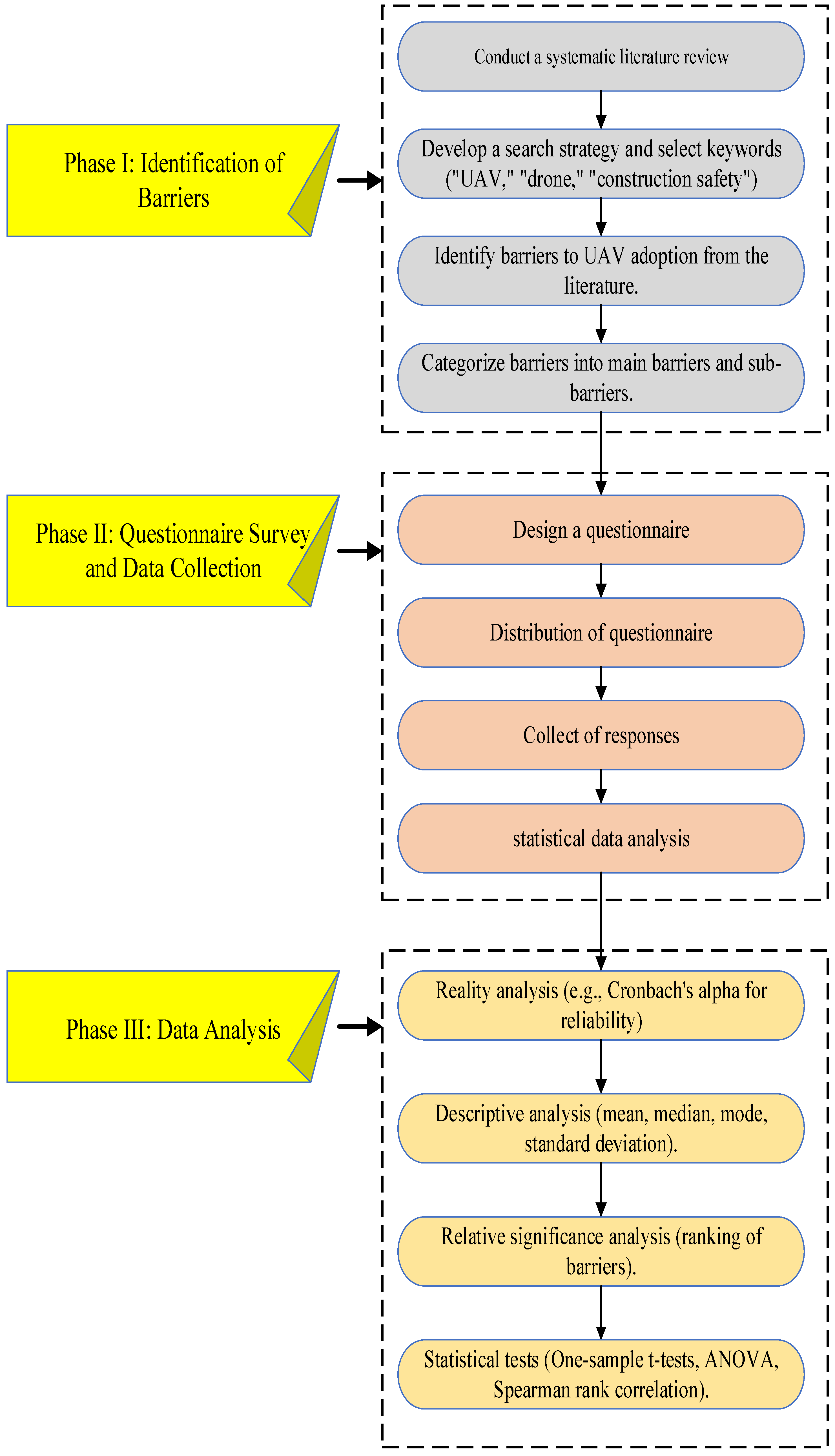

3. Methodology

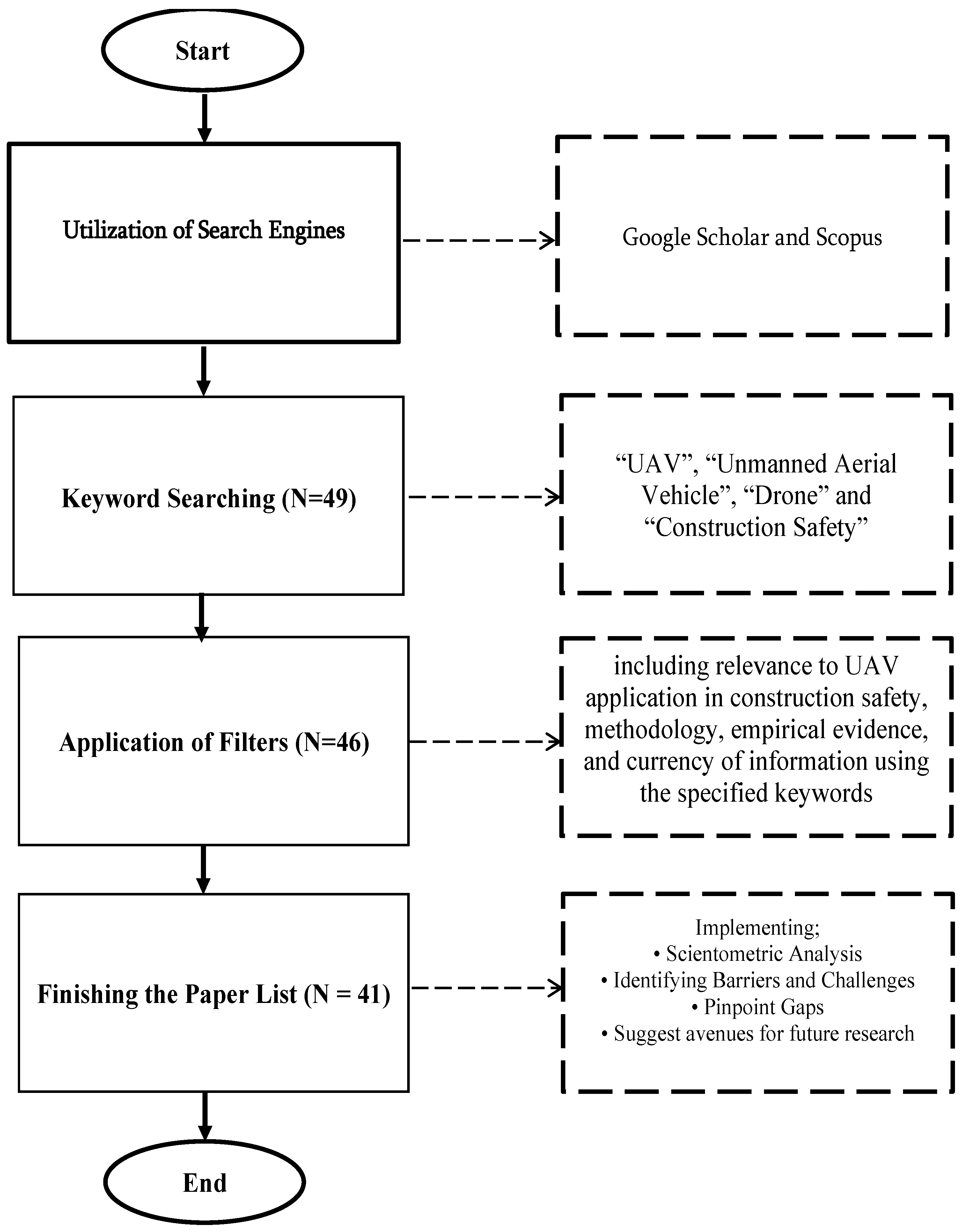

3.1. Phase I: Identification of Barriers

3.2. Phase II: Questionnaire Survey and Data Collection

3.3. Phase III: Data Analysis

4. Result Analysis

4.1. Findings of Questionnaire Survey

4.1.1. Reliability Analysis to Data

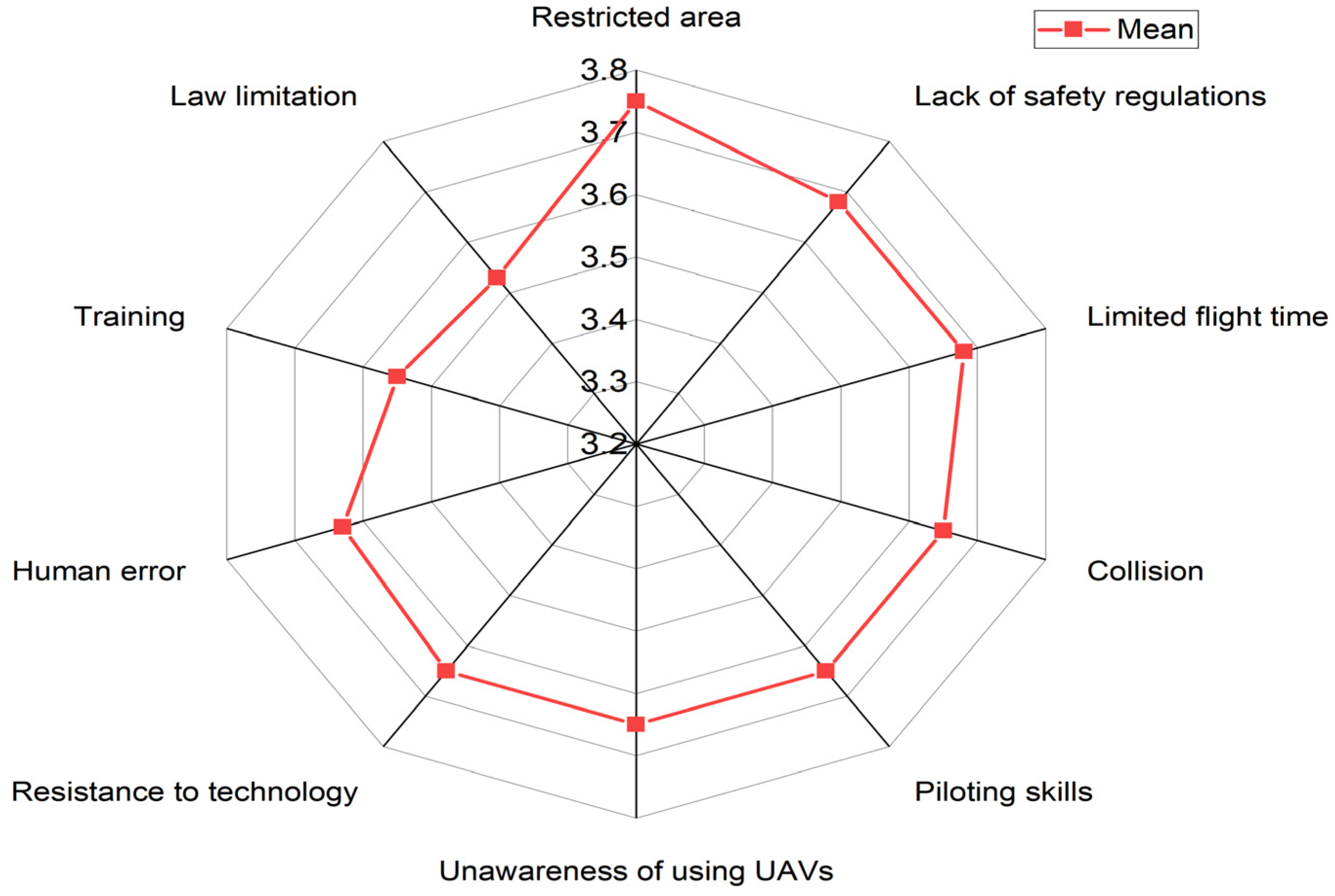

4.1.2. Descriptive Analysis

4.1.3. Differences Test

4.1.4. Relationship Among Barriers

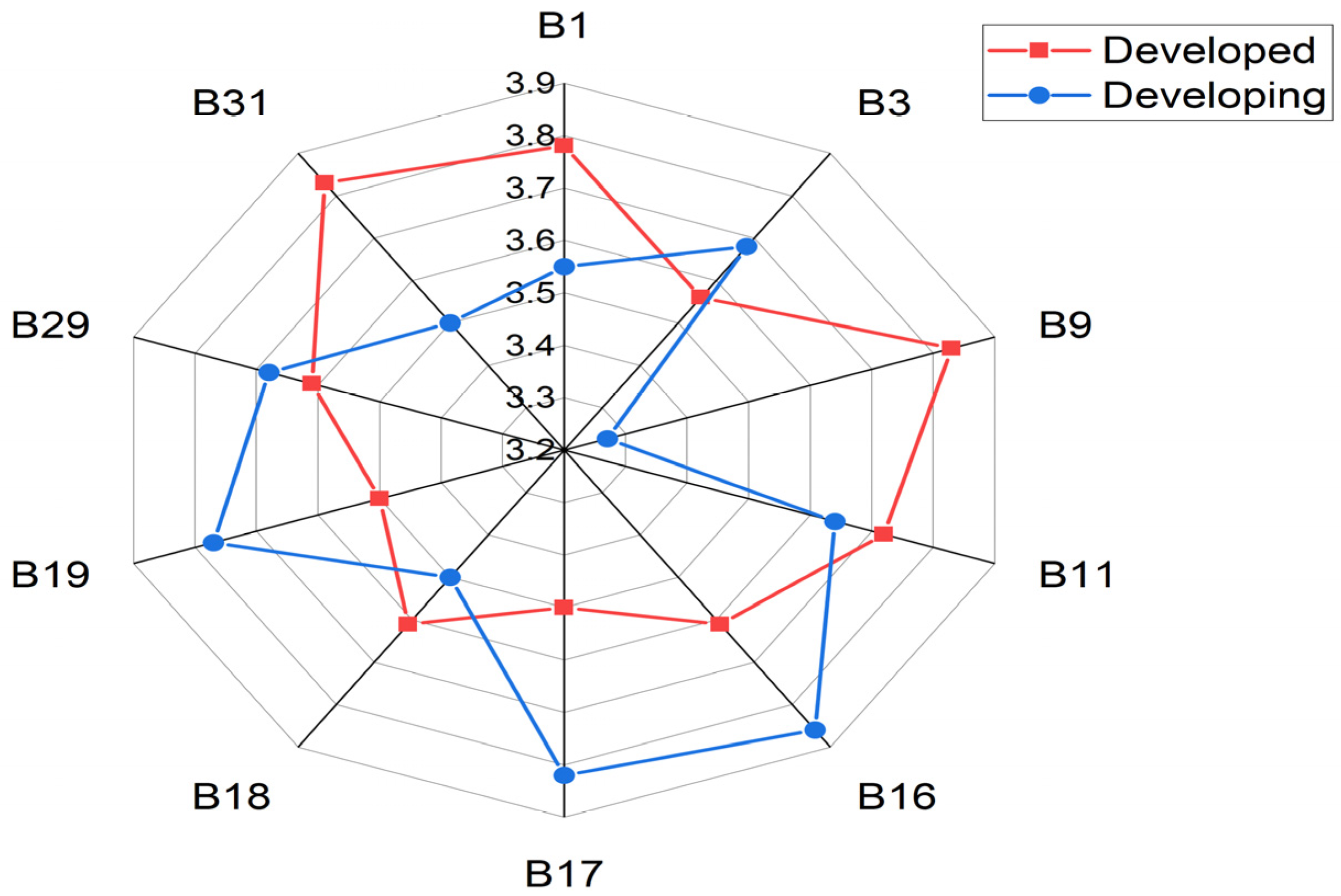

4.1.5. Differences Between Countries

4.1.6. Differences Among Company Sizes

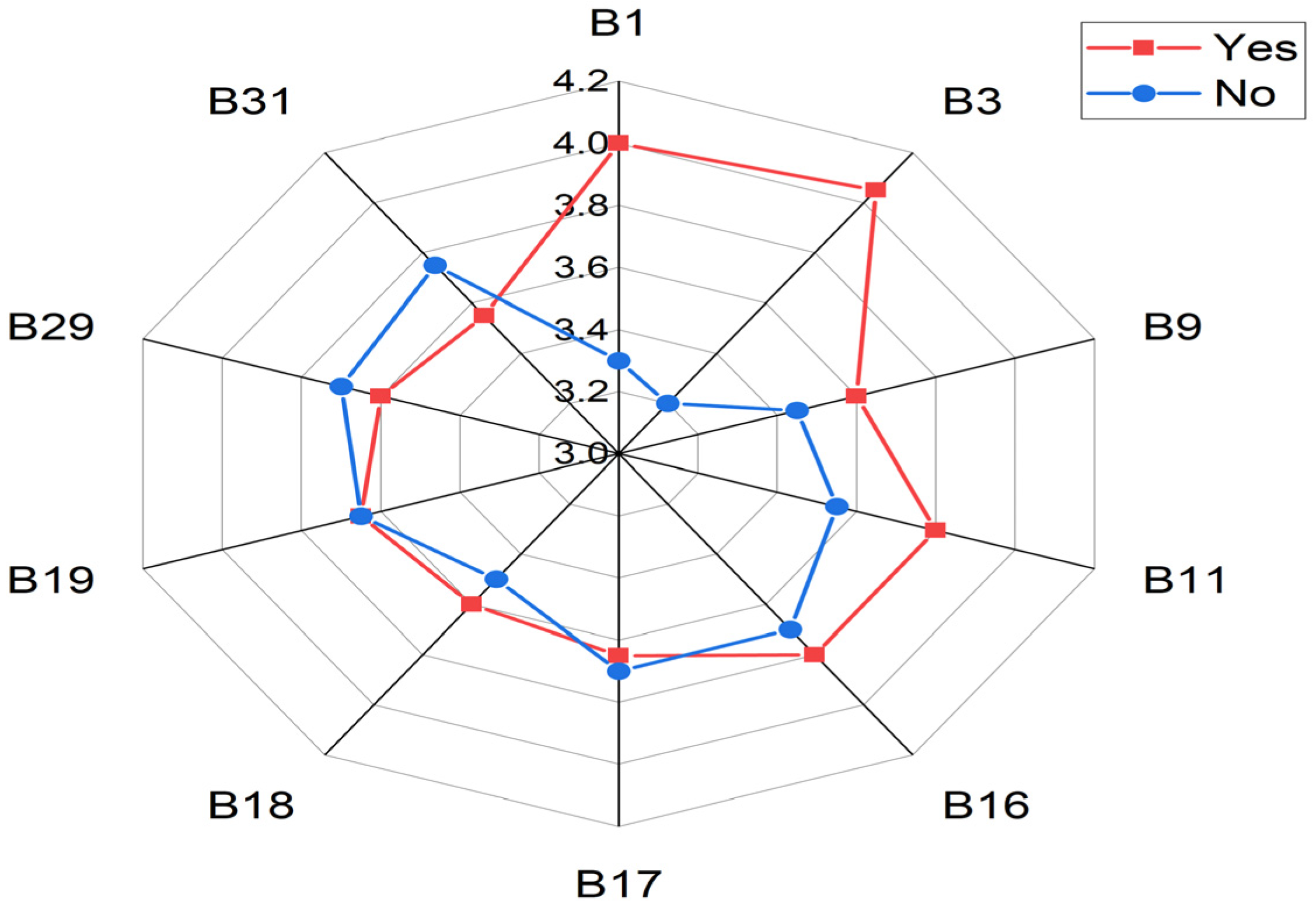

4.1.7. Differences in UAV Project Involvement

5. Discussion

5.1. Implications

5.1.1. Theoretical Implications

5.1.2. Practical Implications

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ikudayisi, A.E.; Chan, A.P.; Darko, A.; Adedeji, Y.M. Integrated practices in the Architecture, Engineering, and Construction industry: Current scope and pathway towards Industry 5.0. J. Build. Eng. 2023, 73, 106788. [Google Scholar] [CrossRef]

- Tijani, B.; Falana, J.N.; Jin, X.; Osei-Kyei, R. Suicide in the construction industry: Literature review. Int. J. Constr. Manag. 2023, 23, 1684–1693. [Google Scholar] [CrossRef]

- Buniya, M.K.; Othman, I.; Durdyev, S.; Sunindijo, R.Y.; Ismail, S.; Kineber, A.F. Safety Program Elements in the Construction Industry: The Case of Iraq. Int. J. Environ. Res. Public Health 2021, 18, 411. [Google Scholar] [CrossRef]

- Jalaei, F.; Jrade, A. Construction Research Congress 2014 ©ASCE 2014 140. Constr. Res. Congr. 2014, 2014, 140–149. [Google Scholar]

- Forteza, F.J.; Carretero-Gómez, J.M.; Sesé, A. Safety in the construction industry: Accidents and precursors. Rev. De La Construcción 2020, 19, 271–281. [Google Scholar] [CrossRef]

- Anthony, R.; Anandh, K.S.; Prasanna, K.; Sawhney, A. An Exploratory Study on the Application of Digital Twins in the Indian Construction Industry. Int. J. Constr. Manag. 2024, 1–12. [Google Scholar] [CrossRef]

- Getuli, V.; Capone, P.; Bruttini, A.; Isaac, S. BIM-based immersive Virtual Reality for construction workspace planning: A safety-oriented approach. Autom. Constr. 2020, 114, 103160. [Google Scholar] [CrossRef]

- Alruqi, W.M.; Hallowell, M.R. Critical Success Factors for Construction Safety: Review and Meta-Analysis of Safety Leading Indicators. J. Constr. Eng. Manag. 2019, 145, 4019005. [Google Scholar] [CrossRef]

- Ikuabe, M.; Aigbavboa, C.; Akinradewo, O.; Adekunle, S.; Adeniyi, A. Hindering Factors to the Utilisation of UAVs for Construction Projects in South Africa. Modul. Offsite Constr. (moc) Summit Proc. 2022, 154–160. [Google Scholar] [CrossRef]

- Onososen, A.O.; Musonda, I.; Onatayo, D.; Tjebane, M.M.; Saka, A.B.; Fagbenro, R.K. Impediments to Construction Site Digitalisation Using Unmanned Aerial Vehicles (UAVs). Drones 2023, 7, 45. [Google Scholar] [CrossRef]

- Liang, H.; Lee, S.-C.; Bae, W.; Kim, J.; Seo, S. Towards UAVs in Construction: Advancements, Challenges, and Future Directions for Monitoring and Inspection. Drones 2023, 7, 202. [Google Scholar] [CrossRef]

- Jeelani, I.; Gheisari, M. Safety challenges of UAV integration in construction: Conceptual analysis and future research roadmap. Saf. Sci. 2021, 144, 105473. [Google Scholar] [CrossRef]

- Gupta, S.; Nair, S. A review of the emerging role of UAVs in construction site safety monitoring. Mater. Today Proc. 2024, in press. [Google Scholar] [CrossRef]

- Alizadehsalehi, S.; Yitmen, I.; Celik, T.; Arditi, D. The effectiveness of an integrated BIM/UAV model in managing safety on construction sites. Int. J. Occup. Saf. Ergon. 2018, 26, 829–844. [Google Scholar] [CrossRef]

- Martinez, J.G.; Gheisari, M.; Alarcón, L.F. UAV Integration in Current Construction Safety Planning and Monitoring Processes: Case Study of a High-Rise Building Construction Project in Chile. J. Manag. Eng. 2022, 36. [Google Scholar] [CrossRef]

- Xu, Y.; Turkan, Y. The development of a safety assessment model for using Unmanned aerial systems (UAS) in construction. Saf. Sci. 2022, 155, 105893. [Google Scholar] [CrossRef]

- Xu, Z.; Luo, M.; Vijayakumar, P.; Peng, C.; Wang, L. Efficient certificateless designated verifier proxy signature scheme using UAV network for sustainable smart city. Sustain. Cities Soc. 2022, 80, 103771. [Google Scholar] [CrossRef]

- Kanchana, S.; Sivaprakash, P.; Joseph, S. Studies on Labour Safety in Construction Sites. Sci. World J. 2015, 2015, 590810. [Google Scholar] [CrossRef]

- Irizarry, J.; Gheisari, M.; Walker, B.N. Usability assessment of drone technology as safety inspection tools. ITcon 2012, 17, 194–212. [Google Scholar]

- Melo, R.; Costa, D. Reducing the gap between work as done and work as imagined on construction safety supported by UAS. In Proceedings: 8th REA Symposium on Resilience Engineering: Scaling up and Speeding up Linnaeus Univerity, Kalmar, Sweden, 24–27 June 2019; Lnu Press: Kalmar, Sweden, 2020. [Google Scholar] [CrossRef]

- Gheisari, M.; Esmaeili, B. Applications and requirements of unmanned aerial systems (UASs) for construction safety. Saf. Sci. 2019, 118, 230–240. [Google Scholar] [CrossRef]

- de Melo, R.R.S.; Costa, D.B. Integrating resilience engineering and UAS technology into construction safety planning and control. Eng. Constr. Arch. Manag. 2019, 26, 2705–2722. [Google Scholar] [CrossRef]

- de Melo, R.R.S.; Costa, D.B.; Álvares, J.S.; Irizarry, J. Applicability of unmanned aerial system (UAS) for safety inspection on construction sites. Saf. Sci. 2017, 98, 174–185. [Google Scholar] [CrossRef]

- Albeaino, G.; Gheisari, M. Trends, benefits, and barriers of unmanned aerial systems in the construction industry: A survey study in the United States. J. Inf. Technol. Constr. 2021, 26, 84–111. [Google Scholar] [CrossRef]

- Poderytė, I.; Banaitienė, N.; Banaitis, A. Life Cycle Sustainability Assessment of Buildings: A Scientometric Analysis. Buildings 2025, 15, 381. [Google Scholar] [CrossRef]

- Xu, J.; Cheung, C.; Manu, P.; Ejohwomu, O.; Too, J. Implementing safety leading indicators in construction: Toward a proactive approach to safety management. Saf. Sci. 2022, 157, 105929. [Google Scholar] [CrossRef]

- Aiyetan, A.O.; Das, D.K. Use of Drones for construction in developing countries: Barriers and strategic interventions. Int. J. Constr. Manag. 2022, 23, 2888–2897. [Google Scholar] [CrossRef]

- Rashidian, S.; Drogemuller, R.; Omrani, S. Building Information Modelling, Integrated Project Delivery, and Lean Construction Maturity Attributes: A Delphi Study. Buildings 2023, 13, 281. [Google Scholar] [CrossRef]

- Oppong, G.D.; Chan, A.P.-C.; Chan, M.-W.; Darko, A.; Adabre, M.A. Success Evaluation Index Model for Running Healthcare Projects in Hong Kong: A Delphi Approach. Buildings 2025, 15, 332. [Google Scholar] [CrossRef]

- Mohandes, S.R. Towards Improvements to the Occupational Health and Safety in Construction Industry; Hong Kong University of Science and Technology: Hong Kong, China, 2020. [Google Scholar]

- Zhang, X.; Mohandes, S.R. Occupational Health and Safety in green building construction projects: A holistic Z-numbers-based risk management framework. J. Clean. Prod. 2020, 275, 122788. [Google Scholar] [CrossRef]

- Phuriwa, U.R.; Liphadzi, M.; Oguntona, O.A.; Aigbavboa, C. Exploring Barriers Hindering the Applications of Unmanned Aerial Vehicles Within the South African Construction Industry. In Proceedings of the 28th International Symposium on Advancement of Construction Management and Real Estate, CRIOCM 2023, Nanjing, China, 4–6 August 2023; Li, D., Zou, P.X.W., Yuan, J., Wang, Q., Peng, Y., Eds.; Lecture Notes in Operations Research. Springer: Singapore, 2024. [Google Scholar]

- Gyamfi, T.A.; Adjei, K.O.; Bonney, S.O. Strategies to Improve Building Construction Sustainability Through Utilization of Drones in the Building Construction Sector. Procedia Comput. Sci. 2024, 236, 209–216. [Google Scholar] [CrossRef]

- Szóstak, M.; Nowobilski, T.; Mahamadu, A.-M.; Pérez, D.C. Unmanned aerial vehicles in the construction industry—Towards a protocol for safe preparation and flight of drones. Int. J. Intell. Unmanned Syst. 2023, 11, 296–316. [Google Scholar] [CrossRef]

- Sah, B.; Gupta, R.; Bani-Hani, D. Analysis of barriers to implement drone logistics. Int. J. Logist. Res. Appl. 2021, 24, 531–550. [Google Scholar] [CrossRef]

- Singh, A.K.; Kumar, V. Establishing the relationship between the strategic factors influencing blockchain technology deployment for achieving SDG and ESG objectives during infrastructure development: An ISM-MICMAC approach. Smart Sustain. Built Environ. 2024, 13, 711–736. [Google Scholar] [CrossRef]

- Singh, A.K.; Kumar, V.P.; Shoaib, M.; Adebayo, T.S.; Irfan, M. A strategic roadmap to overcome blockchain technology barriers for sustainable construction: A deep learning-based dual-stage SEM-ANN approach. Technol. Forecast. Soc. Chang. 2023, 194, 122716. [Google Scholar] [CrossRef]

- Singh, A.K.; Kumar, V.P. Analyzing the barriers for blockchain-enabled BIM adoption in facility management using best-worst method approach. Built Environ. Proj. Asset Manag. 2023, 14, 164–183. [Google Scholar] [CrossRef]

- Singh, A.K.; Kumar, V.P. Integrating blockchain technology success factors in the supply chain of circular economy-driven construction materials: An environmentally sustainable paradigm. J. Clean. Prod. 2024, 460, 142577. [Google Scholar] [CrossRef]

- Palinkas, L.A.; Horwitz, S.M.; Green, C.A.; Wisdom, J.P.; Duan, N.; Hoagwood, K. Purposeful Sampling for Qualitative Data Collection and Analysis in Mixed Method Implementation Research. Adm. Policy Ment. Health Ment. Health Serv. Res. 2015, 42, 533–544. [Google Scholar] [CrossRef]

- Wagner, W.E., III; Gillespie, B.J. How to Sample and Collect Data for Analysis. In 3 How to Sample and Collect Data for Analysis; SAGE Publications, Inc.: Thousand Oaks, CA, USA, 2019. [Google Scholar] [CrossRef]

- Mosly, I. Construction Cost-Influencing Factors: Insights from a Survey of Engineers in Saudi Arabia. Buildings 2024, 14, 3399. [Google Scholar] [CrossRef]

- Samaratunga, M.; Kamardeen, I. Modelling Work–Study Conflict Effects on Built Environment Students’ Well-Being, Health, and Academic Performance. Buildings 2025, 15, 406. [Google Scholar] [CrossRef]

- Chaaya, M.L.; Sarkis, L.M.; Tahmasebinia, F. Integration of Emerging Technologies with Construction Practices in Australia. Buildings 2025, 15, 396. [Google Scholar] [CrossRef]

- Slil, E.; Iyiola, K.; Alzubi, A.; Aljuhmani, H.Y. Impact of Safety Leadership and Employee Morale on Safety Performance: The Moderating Role of Harmonious Safety Passion. Buildings 2025, 15, 186. [Google Scholar] [CrossRef]

- Moore, L.L.; Wurzelbacher, S.J.; Chen, I.-C.; Lampl, M.P.; Naber, S.J. Reliability and validity of an employer-completed safety hazard and management assessment questionnaire. J. Saf. Res. 2022, 81, 283–296. [Google Scholar] [CrossRef]

- Singh, A.K.; Kumar, V.G.R.P.; Hu, J.; Irfan, M. Investigation of barriers and mitigation strategies to blockchain technology implementation in construction industry: An interpretive structural modeling approach. Environ. Sci. Pollut. Res. 2023, 30, 89889–89909. [Google Scholar] [CrossRef] [PubMed]

- Yuan, K.; Wu, R.; Bentler, P.M. Ridge structural equation modelling with correlation matrices for ordinal and continuous data. Br. J. Math. Stat. Psychol. 2011, 64, 107–133. [Google Scholar] [CrossRef] [PubMed]

- Deepa, N.; Pham, Q.-V.; Nguyen, D.C.; Bhattacharya, S.; Prabadevi, B.; Gadekallu, T.R.; Maddikunta, P.K.R.; Fang, F.; Pathirana, P.N. A survey on blockchain for big data: Approaches, opportunities, and future directions. Futur. Gener. Comput. Syst. 2022, 131, 209–226. [Google Scholar] [CrossRef]

- Manjourides, J.; Dennerlein, J.T. Testing the associations between leading and lagging indicators in a contractor safety pre-qualification database. Am. J. Ind. Med. 2019, 62, 317–324. [Google Scholar] [CrossRef]

- Statistics. Statistics. 2023. Available online: https://www.bls.gov/opub/ted/2021/fatal-and-nonfatal-falls-slips-and-trips-in-the-construction-industry.htm (accessed on 30 March 2024).

- Xu, J.; Cheung, C.; Manu, P.; Ejohwomu, O. Safety leading indicators in construction: A systematic review. Saf. Sci. 2021, 139, 105250. [Google Scholar] [CrossRef]

- Zhu, Z.; Jeelani, I.; Rinker, M.M.G. Safety Risk Assessment of Drones on Construction Sites using 4D Simulation. In Proceedings of the International Symposium on Automation and Robotics in Construction (IAARC), Bogota, Colombia, 12–15 July 2022. [Google Scholar]

- Umar, T. Applications of drones for safety inspection in the Gulf Cooperation Council construction. Eng. Constr. Arch. Manag. 2021, 28, 2337–2360. [Google Scholar] [CrossRef]

- Cheng, J.-Y.; Gheisari, M.; Jeelani, I. Using 360-Degree Virtual Reality Technology for Training Construction Workers about Safety Challenges of Drones. J. Comput. Civ. Eng. 2023, 23, 2337–2360. [Google Scholar] [CrossRef]

- Hussain, R.; Sabir, A.; Lee, D.-Y.; Alam Zaidi, S.F.; Pedro, A.; Abbas, M.S.; Park, C. Conversational AI-based VR system to improve construction safety training of migrant workers. Autom. Constr. 2024, 160, 105315. [Google Scholar] [CrossRef]

- Singh, A.K.; Kumar, V.R.P.; Irfan, M.; Mohandes, S.R.; Awan, U. Revealing the Barriers of Blockchain Technology for Supply Chain Transparency and Sustainability in the Construction Industry: An Application of Pythagorean FAHP Methods. Sustainability 2023, 15, 10681. [Google Scholar] [CrossRef]

- Yoo, J.W.; Park, J.S.; Park, H.J. Understanding VR-Based Construction Safety Training Effectiveness: The Role of Telepresence, Risk Perception, and Training Satisfaction. Appl. Sci. 2023, 13, 1135. [Google Scholar] [CrossRef]

- Singh, A.K.; Kumar, V.P.; Dehdasht, G.; Mohandes, S.R.; Manu, P.; Pour Rahimian, F. Investigating the barriers to the adoption of blockchain technology in sustainable construction projects. J. Clean. Prod. 2023, 403, 136840. [Google Scholar] [CrossRef]

- Singh, A.K.; Kumar, V.P.; Dehdasht, G.; Mohandes, S.R.; Manu, P.; Pour Rahimian, F. Investigating barriers to blockchain adoption in construction supply chain management: A fuzzy-based MCDM approach. Technol. Forecast. Soc. Chang. 2023, 196, 122849. [Google Scholar] [CrossRef]

- Yuvaraj, D.; Anandh, K.S. A Rapid Review on the Application of Unmanned Aerial Vehicles in Construction Safety. In Intelligent Systems Design and Applications; Abraham, A., Pllana, S., Casalino, G., Ma, K., Bajaj, A., Eds.; ISDA 2022. Lecture Notes in Networks and Systems; Springer: Cham, Switzerland, 2023; Volume 646. [Google Scholar]

| Background | Experience | Count | Percentage |

|---|---|---|---|

| Years of experience | 6–10 | 20 | 50.00% |

| 11–15 | 14 | 35.00% | |

| 16–20 | 2 | 5.00% | |

| 20+ | 4 | 10.00% | |

| Professional Roles | Construction project manager | 3 | 7.50% |

| Civil/project engineer | 5 | 12.50% | |

| Academician | 23 | 57.50% | |

| Quantity surveyor | 2 | 5.00% | |

| Planning engineer | 2 | 5.00% | |

| Drone pilot/technical engineer | 1 | 2.50% | |

| Contract engineer | 2 | 5.00% | |

| Innovation manager | 1 | 2.50% | |

| Consultant | 1 | 2.50% | |

| Countries in which | United States/Canada/Australia/Hong Kong/United Kingdom | 18 | 45.00% |

| respondents practice(d) | |||

| Pakistan/Brazil/Russia/China/South Africa/Turkey/Poland/India/Nepal | 22 | 55.00% | |

| Level of education of respondents | Bachelor’s degree | 1 | 2.50% |

| Master’s degree | 15 | 37.50% | |

| PhD degree | 24 | 60.00% | |

| The company size of the respondents | Small (1–49 employees) | 11 | 27.50% |

| Medium (50–249 employees) | 5 | 12.50% | |

| Large (250+ employees) | 24 | 60.00% |

| Barriers | Count | Weighted | Relative Significance Index | Mean Score | Median | Mode | Normalized Value | Std. Deviation | Std. Error | Rank |

|---|---|---|---|---|---|---|---|---|---|---|

| B16 | 40 | 150 | 0.75 | 3.75 | 4 | 4 | 1.00 | 1.032 | 0.163 | 1 |

| B11 | 40 | 147 | 0.735 | 3.68 | 4 | 4 | 0.95 | 1.047 | 0.166 | 2 |

| B17 | 40 | 147 | 0.735 | 3.68 | 4 | 4 | 0.95 | 1.141 | 0.18 | 3 |

| B1 | 40 | 146 | 0.73 | 3.65 | 4 | 4 | 0.94 | 1.027 | 0.162 | 4 |

| B19 | 40 | 146 | 0.73 | 3.65 | 4 | 4 | 0.94 | 0.975 | 0.154 | 5 |

| B29 | 40 | 146 | 0.73 | 3.65 | 4 | 4 | 0.94 | 0.975 | 0.154 | 6 |

| B31 | 40 | 146 | 0.73 | 3.65 | 4 | 4 | 0.94 | 1.027 | 0.162 | 7 |

| B3 | 40 | 145 | 0.725 | 3.63 | 3.5 | 3 | 0.92 | 1.079 | 0.171 | 8 |

| B18 | 40 | 142 | 0.71 | 3.55 | 4 | 3 | 0.88 | 1.061 | 0.168 | 9 |

| B9 | 40 | 141 | 0.705 | 3.53 | 4 | 4 | 0.86 | 0.96 | 0.152 | 10 |

| B7 | 40 | 140 | 0.7 | 3.5 | 4 | 4 | 0.85 | 0.877 | 0.139 | 11 |

| B32 | 40 | 139 | 0.695 | 3.48 | 4 | 4 | 0.83 | 1.086 | 0.172 | 12 |

| B33 | 40 | 139 | 0.695 | 3.47 | 3 | 3 | 0.83 | 1.132 | 0.179 | 13 |

| B4 | 40 | 136 | 0.68 | 3.4 | 3 | 3 | 0.78 | 1.057 | 0.167 | 14 |

| B2 | 40 | 134 | 0.67 | 3.35 | 3 | 4 | 0.75 | 1.145 | 0.181 | 15 |

| B30 | 40 | 133 | 0.665 | 3.32 | 3 | 4 | 0.74 | 1.095 | 0.173 | 16 |

| B23 | 40 | 131 | 0.655 | 3.28 | 4 | 4 | 0.71 | 1.261 | 0.199 | 17 |

| B24 | 40 | 131 | 0.655 | 3.28 | 3 | 3 | 0.71 | 0.96 | 0.152 | 18 |

| B14 | 40 | 130 | 0.65 | 3.25 | 3 | 3 | 0.69 | 1.006 | 0.159 | 19 |

| B25 | 40 | 130 | 0.65 | 3.25 | 3.5 | 4 | 0.69 | 1.149 | 0.182 | 20 |

| B26 | 40 | 130 | 0.65 | 3.25 | 3 | 3 | 0.69 | 1.08 | 0.171 | 21 |

| B10 | 40 | 129 | 0.645 | 3.23 | 3 | 4 | 0.68 | 1.097 | 0.174 | 22 |

| B12 | 40 | 128 | 0.64 | 3.2 | 3.5 | 4 | 0.66 | 1.244 | 0.197 | 23 |

| B22 | 40 | 126 | 0.63 | 3.15 | 3 | 3 | 0.63 | 1.189 | 0.188 | 24 |

| B13 | 40 | 124 | 0.62 | 3.1 | 3 | 3 | 0.60 | 1.257 | 0.199 | 25 |

| B15 | 40 | 124 | 0.62 | 3.1 | 3 | 4 | 0.60 | 1.257 | 0.199 | 26 |

| B8 | 40 | 123 | 0.615 | 3.08 | 3 | 3 | 0.58 | 1.023 | 0.162 | 27 |

| B21 | 40 | 123 | 0.615 | 3.08 | 3 | 4 | 0.58 | 1.228 | 0.194 | 28 |

| B27 | 40 | 123 | 0.615 | 3.07 | 3 | 3,4 | 0.58 | 1.095 | 0.173 | 29 |

| B28 | 40 | 122 | 0.61 | 3.05 | 3 | 3 | 0.57 | 1.176 | 0.186 | 30 |

| B20 | 40 | 117 | 0.585 | 2.92 | 3 | 4 | 0.49 | 1.328 | 0.21 | 31 |

| B5 | 40 | 115 | 0.575 | 2.87 | 3 | 3 | 0.46 | 1.067 | 0.169 | 32 |

| B6 | 40 | 85 | 0.425 | 2.13 | 2 | 1 | 0.00 | 1.09 | 0.172 | 33 |

| Barriers | t | df | Sig. (2-Tailed) | Mean Difference | 95% Confidence Interval of the Difference | |

|---|---|---|---|---|---|---|

| Lower | Upper | |||||

| B16 | 4.57 | 40 | 0 | 0.732 | 0.41 | 1.06 |

| B11 | 4.057 | 40 | 0 | 0.659 | 0.33 | 0.99 |

| B17 | 3.726 | 40 | 0.001 | 0.659 | 0.3 | 1.02 |

| B1 | 3.986 | 40 | 0 | 0.634 | 0.31 | 0.96 |

| B19 | 4.193 | 40 | 0 | 0.634 | 0.33 | 0.94 |

| B29 | 4.193 | 40 | 0 | 0.634 | 0.33 | 0.94 |

| B31 | 3.986 | 40 | 0 | 0.634 | 0.31 | 0.96 |

| B3 | 3.651 | 40 | 0.001 | 0.61 | 0.27 | 0.95 |

| B18 | 3.269 | 40 | 0.002 | 0.537 | 0.2 | 0.87 |

| B9 | 3.445 | 40 | 0.001 | 0.512 | 0.21 | 0.81 |

| B7 | 3.592 | 40 | 0.001 | 0.488 | 0.21 | 0.76 |

| B32 | 2.761 | 40 | 0.009 | 0.463 | 0.12 | 0.8 |

| B33 | 2.649 | 40 | 0.012 | 0.463 | 0.11 | 0.82 |

| B4 | 2.389 | 40 | 0.022 | 0.39 | 0.06 | 0.72 |

| B2 | 1.932 | 40 | 0.06 | 0.341 | −0.02 | 0.7 |

| B30 | 1.875 | 40 | 0.068 | 0.317 | −0.02 | 0.66 |

| B23 | 1.379 | 40 | 0.175 | 0.268 | −0.12 | 0.66 |

| B24 | 1.81 | 40 | 0.078 | 0.268 | −0.03 | 0.57 |

| B14 | 1.57 | 40 | 0.124 | 0.244 | −0.07 | 0.56 |

| B25 | 1.376 | 40 | 0.177 | 0.244 | −0.11 | 0.6 |

| B26 | 1.463 | 40 | 0.151 | 0.244 | −0.09 | 0.58 |

| B10 | 1.296 | 40 | 0.202 | 0.22 | −0.12 | 0.56 |

| B12 | 1.016 | 40 | 0.316 | 0.195 | −0.19 | 0.58 |

| B22 | 0.798 | 40 | 0.429 | 0.146 | −0.22 | 0.52 |

| B13 | 0.503 | 40 | 0.617 | 0.098 | −0.29 | 0.49 |

| B15 | 0.503 | 40 | 0.617 | 0.098 | −0.29 | 0.49 |

| B8 | 0.464 | 40 | 0.645 | 0.073 | −0.25 | 0.39 |

| B21 | 0.386 | 40 | 0.701 | 0.073 | −0.31 | 0.46 |

| B27 | 0.433 | 40 | 0.667 | 0.073 | −0.27 | 0.41 |

| B28 | 0.269 | 40 | 0.789 | 0.049 | −0.32 | 0.42 |

| B20 | −0.357 | 40 | 0.723 | −0.073 | −0.49 | 0.34 |

| B5 | −0.741 | 40 | 0.463 | −0.122 | −0.45 | 0.21 |

| B6 | −5.036 | 40 | 0 | −0.854 | −1.2 | −0.51 |

| Barriers | Spearman Rank Test | B1 | B3 | B11 | B16 | B17 | B18 | B19 | B29 | B31 |

|---|---|---|---|---|---|---|---|---|---|---|

| B1 | Correlation Coefficient | 1 | 0.655 ** | 0.477 ** | −0.05 | −0.009 | 0.128 | −0.05 | 0.123 | 0.119 |

| Sig. (2-tailed) | . | 0 | 0.002 | 0.76 | 0.957 | 0.433 | 0.76 | 0.45 | 0.465 | |

| N | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 40 | |

| B3 | Correlation Coefficient | 0.655 ** | 1 | 0.377 * | 0.021 | 0.097 | 0.126 | 0.2 | 0.306 | 0.084 |

| Sig. (2-tailed) | 0 | . | 0.016 | 0.899 | 0.55 | 0.439 | 0.216 | 0.055 | 0.608 | |

| N | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 40 | |

| B11 | Correlation Coefficient | 0.477 ** | 0.377 * | 1 | 0.07 | 0.214 | 0.462 ** | 0.407 ** | 0.393 * | 0.541 ** |

| Sig. (2-tailed) | 0.002 | 0.016 | . | 0.667 | 0.185 | 0.003 | 0.009 | 0.012 | 0 | |

| N | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 40 | |

| B16 | Correlation Coefficient | −0.05 | 0.021 | 0.07 | 1 | 0.649 ** | 0.296 | 0.409 ** | 0.084 | 0.05 |

| Sig. (2-tailed) | 0.76 | 0.899 | 0.667 | . | 0 | 0.064 | 0.009 | 0.608 | 0.759 | |

| N | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 40 | |

| B17 | Correlation Coefficient | −0.009 | 0.097 | 0.214 | 0.649 ** | 1 | 0.312 | 0.411 ** | 0.006 | 0.013 |

| Sig. (2-tailed) | 0.957 | 0.55 | 0.185 | 0 | . | 0.05 | 0.008 | 0.971 | 0.937 | |

| N | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 40 | |

| B18 | Correlation Coefficient | 0.128 | 0.126 | 0.462 ** | 0.296 | 0.312 | 1 | 0.688 ** | 0.332 * | 0.431 ** |

| Sig. (2-tailed) | 0.433 | 0.439 | 0.003 | 0.064 | 0.05 | . | 0 | 0.037 | 0.006 | |

| N | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 40 | |

| B19 | Correlation Coefficient | −0.05 | 0.2 | 0.407 ** | 0.409 ** | 0.411 ** | 0.688 ** | 1 | 0.341 * | 0.389 * |

| Sig. (2-tailed) | 0.76 | 0.216 | 0.009 | 0.009 | 0.008 | 0 | . | 0.031 | 0.013 | |

| N | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 40 | |

| B29 | Correlation Coefficient | 0.123 | 0.306 | 0.393 * | 0.084 | 0.006 | 0.332 * | 0.341 * | 1 | 0.362 * |

| Sig. (2-tailed) | 0.45 | 0.055 | 0.012 | 0.608 | 0.971 | 0.037 | 0.031 | . | 0.022 | |

| N | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 40 | |

| B31 | Correlation Coefficient | 0.119 | 0.084 | 0.541 ** | 0.05 | 0.013 | 0.431 ** | 0.389 * | 0.362 * | 1 |

| Sig. (2-tailed) | 0.465 | 0.608 | 0 | 0.759 | 0.937 | 0.006 | 0.013 | 0.022 | . | |

| N | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 40 |

| Barriers | Country | N | Mean | Std. Deviation | Std. Error Mean | t | Sig. (2-Tailed) |

|---|---|---|---|---|---|---|---|

| B1 | developed country | 18 | 3.78 | 1.114 | 0.263 | 0.707 | 0.484 |

| developing country | 22 | 3.55 | 0.963 | 0.205 | |||

| B2 | developed country | 18 | 3.17 | 1.2 | 0.283 | −0.914 | 0.366 |

| developing country | 22 | 3.5 | 1.102 | 0.235 | |||

| B3 | developed country | 18 | 3.56 | 1.247 | 0.294 | −0.364 | 0.718 |

| developing country | 22 | 3.68 | 0.945 | 0.202 | |||

| B4 | developed country | 18 | 3.56 | 0.984 | 0.232 | 0.838 | 0.407 |

| developing country | 22 | 3.27 | 1.12 | 0.239 | |||

| B5 | developed country | 18 | 2.67 | 1.085 | 0.256 | −1.121 | 0.269 |

| developing country | 22 | 3.05 | 1.046 | 0.223 | |||

| B6 | developed country | 18 | 1.83 | 1.043 | 0.246 | −1.558 | 0.128 |

| developing country | 22 | 2.36 | 1.093 | 0.233 | |||

| B7 | developed country | 18 | 3.56 | 0.922 | 0.217 | 0.358 | 0.722 |

| developing country | 22 | 3.45 | 0.858 | 0.183 | |||

| B8 | developed country | 18 | 2.83 | 1.098 | 0.259 | −1.367 | 0.18 |

| developing country | 22 | 3.27 | 0.935 | 0.199 | |||

| B9 | developed country | 18 | 3.83 | 0.786 | 0.185 | 1.897 | 0.065 |

| developing country | 22 | 3.27 | 1.032 | 0.22 | |||

| B10 | developed country | 18 | 3.39 | 1.037 | 0.244 | 0.851 | 0.4 |

| developing country | 22 | 3.09 | 1.151 | 0.245 | |||

| B11 | developed country | 18 | 3.72 | 0.958 | 0.226 | 0.255 | 0.8 |

| developing country | 22 | 3.64 | 1.136 | 0.242 | |||

| B12 | developed country | 18 | 3.06 | 1.392 | 0.328 | −0.659 | 0.514 |

| developing country | 22 | 3.32 | 1.129 | 0.241 | |||

| B13 | developed country | 18 | 2.83 | 1.339 | 0.316 | −1.221 | 0.229 |

| developing country | 22 | 3.32 | 1.171 | 0.25 | |||

| B14 | developed country | 18 | 3.11 | 1.132 | 0.267 | −0.786 | 0.437 |

| developing country | 22 | 3.36 | 0.902 | 0.192 | |||

| B15 | developed country | 18 | 2.94 | 1.11 | 0.262 | −0.703 | 0.486 |

| developing country | 22 | 3.23 | 1.378 | 0.294 | |||

| B16 | developed country | 18 | 3.61 | 1.145 | 0.27 | −0.766 | 0.448 |

| developing country | 22 | 3.86 | 0.941 | 0.201 | |||

| B17 | developed country | 18 | 3.5 | 1.295 | 0.305 | −0.875 | 0.387 |

| developing country | 22 | 3.82 | 1.006 | 0.215 | |||

| B18 | developed country | 18 | 3.61 | 0.979 | 0.231 | 0.326 | 0.746 |

| developing country | 22 | 3.5 | 1.144 | 0.244 | |||

| B19 | developed country | 18 | 3.5 | 0.924 | 0.218 | −0.877 | 0.386 |

| developing country | 22 | 3.77 | 1.02 | 0.218 | |||

| B20 | developed country | 18 | 2.5 | 1.339 | 0.316 | −1.89 | 0.066 |

| developing country | 22 | 3.27 | 1.241 | 0.265 | |||

| B21 | developed country | 18 | 2.61 | 1.29 | 0.304 | −2.274 | 0.029 |

| developing country | 22 | 3.45 | 1.057 | 0.225 | |||

| B22 | developed country | 18 | 2.89 | 1.323 | 0.312 | −1.266 | 0.213 |

| developing country | 22 | 3.36 | 1.049 | 0.224 | |||

| B23 | developed country | 18 | 2.89 | 1.41 | 0.332 | −1.75 | 0.09 |

| developing country | 22 | 3.59 | 1.054 | 0.225 | |||

| B24 | developed country | 18 | 2.89 | 1.079 | 0.254 | −2.442 | 0.019 |

| developing country | 22 | 3.59 | 0.734 | 0.157 | |||

| B25 | developed country | 18 | 2.72 | 1.127 | 0.266 | −2.859 | 0.007 |

| developing country | 22 | 3.68 | 0.995 | 0.212 | |||

| B26 | developed country | 18 | 2.72 | 1.074 | 0.253 | −3.086 | 0.004 |

| developing country | 22 | 3.68 | 0.894 | 0.191 | |||

| B27 | developed country | 18 | 3.06 | 0.998 | 0.235 | −0.1 | 0.921 |

| developing country | 22 | 3.09 | 1.192 | 0.254 | |||

| B28 | developed country | 18 | 2.78 | 1.06 | 0.25 | −1.338 | 0.189 |

| developing country | 22 | 3.27 | 1.241 | 0.265 | |||

| B29 | developed country | 18 | 3.61 | 0.85 | 0.2 | −0.225 | 0.823 |

| developing country | 22 | 3.68 | 1.086 | 0.232 | |||

| B30 | developed country | 18 | 3.17 | 1.043 | 0.246 | −0.824 | 0.415 |

| developing country | 22 | 3.45 | 1.143 | 0.244 | |||

| B31 | developed country | 18 | 3.83 | 0.924 | 0.218 | 1.022 | 0.313 |

| developing country | 22 | 3.5 | 1.102 | 0.235 | |||

| B32 | developed country | 18 | 3.39 | 1.092 | 0.257 | −0.449 | 0.656 |

| developing country | 22 | 3.55 | 1.101 | 0.235 | |||

| B33 | developed country | 18 | 3.17 | 1.2 | 0.283 | −1.588 | 0.12 |

| developing country | 22 | 3.73 | 1.032 | 0.22 |

| Barriers | Company Sizes | N | Mean | Std. Deviation | Std. Error | 95% Confidence Interval for Mean | Min | Max | Sig | |

|---|---|---|---|---|---|---|---|---|---|---|

| Lower | Upper | |||||||||

| B1 | small | 10 | 3.5 | 0.85 | 0.269 | 2.89 | 4.11 | 2 | 5 | 0.219 |

| medium | 5 | 3 | 1 | 0.447 | 1.76 | 4.24 | 2 | 4 | ||

| large | 25 | 3.84 | 1.068 | 0.214 | 3.4 | 4.28 | 1 | 5 | ||

| Total | 40 | 3.65 | 1.027 | 0.162 | 3.32 | 3.98 | 1 | 5 | ||

| B2 | small | 10 | 3.4 | 1.075 | 0.34 | 2.63 | 4.17 | 2 | 5 | 0.775 |

| medium | 5 | 3 | 1.414 | 0.632 | 1.24 | 4.76 | 1 | 4 | ||

| large | 25 | 3.4 | 1.155 | 0.231 | 2.92 | 3.88 | 1 | 5 | ||

| Total | 40 | 3.35 | 1.145 | 0.181 | 2.98 | 3.72 | 1 | 5 | ||

| B3 | small | 10 | 3.6 | 0.843 | 0.267 | 3 | 4.2 | 3 | 5 | 0.931 |

| medium | 5 | 3.8 | 1.304 | 0.583 | 2.18 | 5.42 | 2 | 5 | ||

| large | 25 | 3.6 | 1.155 | 0.231 | 3.12 | 4.08 | 1 | 5 | ||

| Total | 40 | 3.63 | 1.079 | 0.171 | 3.28 | 3.97 | 1 | 5 | ||

| B4 | small | 10 | 3.3 | 0.823 | 0.26 | 2.71 | 3.89 | 2 | 5 | 0.581 |

| medium | 5 | 3 | 1.581 | 0.707 | 1.04 | 4.96 | 1 | 5 | ||

| large | 25 | 3.52 | 1.046 | 0.209 | 3.09 | 3.95 | 2 | 5 | ||

| Total | 40 | 3.4 | 1.057 | 0.167 | 3.06 | 3.74 | 1 | 5 | ||

| B5 | small | 10 | 3 | 1.155 | 0.365 | 2.17 | 3.83 | 1 | 5 | 0.652 |

| medium | 5 | 3.2 | 1.483 | 0.663 | 1.36 | 5.04 | 1 | 5 | ||

| large | 25 | 2.76 | 0.97 | 0.194 | 2.36 | 3.16 | 1 | 4 | ||

| Total | 40 | 2.88 | 1.067 | 0.169 | 2.53 | 3.22 | 1 | 5 | ||

| B6 | small | 10 | 2.4 | 1.35 | 0.427 | 1.43 | 3.37 | 1 | 5 | 0.478 |

| medium | 5 | 2.4 | 1.342 | 0.6 | 0.73 | 4.07 | 1 | 4 | ||

| large | 25 | 1.96 | 0.935 | 0.187 | 1.57 | 2.35 | 1 | 4 | ||

| Total | 40 | 2.13 | 1.09 | 0.172 | 1.78 | 2.47 | 1 | 5 | ||

| B7 | small | 10 | 3.7 | 0.823 | 0.26 | 3.11 | 4.29 | 2 | 5 | 0.584 |

| medium | 5 | 3.2 | 1.095 | 0.49 | 1.84 | 4.56 | 2 | 4 | ||

| large | 25 | 3.48 | 0.872 | 0.174 | 3.12 | 3.84 | 2 | 5 | ||

| Total | 40 | 3.5 | 0.877 | 0.139 | 3.22 | 3.78 | 2 | 5 | ||

| B8 | small | 10 | 3.5 | 0.972 | 0.307 | 2.8 | 4.2 | 2 | 5 | 0.171 |

| medium | 5 | 3.4 | 1.342 | 0.6 | 1.73 | 5.07 | 1 | 4 | ||

| large | 25 | 2.84 | 0.943 | 0.189 | 2.45 | 3.23 | 1 | 4 | ||

| Total | 40 | 3.08 | 1.023 | 0.162 | 2.75 | 3.4 | 1 | 5 | ||

| B9 | small | 10 | 3.6 | 0.843 | 0.267 | 3 | 4.2 | 2 | 5 | 0.437 |

| medium | 5 | 4 | 0.707 | 0.316 | 3.12 | 4.88 | 3 | 5 | ||

| large | 25 | 3.4 | 1.041 | 0.208 | 2.97 | 3.83 | 1 | 5 | ||

| Total | 40 | 3.53 | 0.96 | 0.152 | 3.22 | 3.83 | 1 | 5 | ||

| B10 | small | 10 | 3.4 | 1.075 | 0.34 | 2.63 | 4.17 | 1 | 5 | 0.541 |

| medium | 5 | 3.6 | 1.14 | 0.51 | 2.18 | 5.02 | 2 | 5 | ||

| large | 25 | 3.08 | 1.115 | 0.223 | 2.62 | 3.54 | 1 | 5 | ||

| Total | 40 | 3.23 | 1.097 | 0.174 | 2.87 | 3.58 | 1 | 5 | ||

| B11 | small | 10 | 3.5 | 1.269 | 0.401 | 2.59 | 4.41 | 1 | 5 | 0.193 |

| medium | 5 | 3 | 0.707 | 0.316 | 2.12 | 3.88 | 2 | 4 | ||

| large | 25 | 3.88 | 0.971 | 0.194 | 3.48 | 4.28 | 2 | 5 | ||

| Total | 40 | 3.68 | 1.047 | 0.166 | 3.34 | 4.01 | 1 | 5 | ||

| B12 | small | 10 | 3.1 | 1.287 | 0.407 | 2.18 | 4.02 | 1 | 5 | 0.315 |

| medium | 5 | 4 | 0.707 | 0.316 | 3.12 | 4.88 | 3 | 5 | ||

| large | 25 | 3.08 | 1.288 | 0.258 | 2.55 | 3.61 | 1 | 5 | ||

| Total | 40 | 3.2 | 1.244 | 0.197 | 2.8 | 3.6 | 1 | 5 | ||

| B13 | small | 10 | 3.7 | 1.252 | 0.396 | 2.8 | 4.6 | 1 | 5 | 0.219 |

| medium | 5 | 3 | 1.581 | 0.707 | 1.04 | 4.96 | 1 | 5 | ||

| large | 25 | 2.88 | 1.166 | 0.233 | 2.4 | 3.36 | 1 | 5 | ||

| Total | 40 | 3.1 | 1.257 | 0.199 | 2.7 | 3.5 | 1 | 5 | ||

| B14 | small | 10 | 3.6 | 1.075 | 0.34 | 2.83 | 4.37 | 2 | 5 | 0.435 |

| medium | 5 | 3 | 1.225 | 0.548 | 1.48 | 4.52 | 2 | 5 | ||

| large | 25 | 3.16 | 0.943 | 0.189 | 2.77 | 3.55 | 1 | 5 | ||

| Total | 40 | 3.25 | 1.006 | 0.159 | 2.93 | 3.57 | 1 | 5 | ||

| B15 | small | 10 | 3.5 | 1.179 | 0.373 | 2.66 | 4.34 | 1 | 5 | 0.283 |

| medium | 5 | 2.4 | 1.342 | 0.6 | 0.73 | 4.07 | 1 | 4 | ||

| large | 25 | 3.08 | 1.256 | 0.251 | 2.56 | 3.6 | 1 | 5 | ||

| Total | 40 | 3.1 | 1.257 | 0.199 | 2.7 | 3.5 | 1 | 5 | ||

| B16 | small | 10 | 3.4 | 0.966 | 0.306 | 2.71 | 4.09 | 2 | 5 | 0.1 |

| medium | 5 | 4.6 | 0.548 | 0.245 | 3.92 | 5.28 | 4 | 5 | ||

| large | 25 | 3.72 | 1.061 | 0.212 | 3.28 | 4.16 | 1 | 5 | ||

| Total | 40 | 3.75 | 1.032 | 0.163 | 3.42 | 4.08 | 1 | 5 | ||

| B17 | small | 10 | 3.7 | 1.337 | 0.423 | 2.74 | 4.66 | 1 | 5 | 0.959 |

| medium | 5 | 3.8 | 1.304 | 0.583 | 2.18 | 5.42 | 2 | 5 | ||

| large | 25 | 3.64 | 1.075 | 0.215 | 3.2 | 4.08 | 1 | 5 | ||

| Total | 40 | 3.68 | 1.141 | 0.18 | 3.31 | 4.04 | 1 | 5 | ||

| B18 | small | 10 | 3.6 | 1.174 | 0.371 | 2.76 | 4.44 | 1 | 5 | 0.473 |

| medium | 5 | 3 | 0.707 | 0.316 | 2.12 | 3.88 | 2 | 4 | ||

| large | 25 | 3.64 | 1.075 | 0.215 | 3.2 | 4.08 | 1 | 5 | ||

| Total | 40 | 3.55 | 1.061 | 0.168 | 3.21 | 3.89 | 1 | 5 | ||

| B19 | small | 10 | 3.7 | 1.059 | 0.335 | 2.94 | 4.46 | 1 | 5 | 0.98 |

| medium | 5 | 3.6 | 0.548 | 0.245 | 2.92 | 4.28 | 3 | 4 | ||

| large | 25 | 3.64 | 1.036 | 0.207 | 3.21 | 4.07 | 2 | 5 | ||

| Total | 40 | 3.65 | 0.975 | 0.154 | 3.34 | 3.96 | 1 | 5 | ||

| B20 | small | 10 | 3.5 | 1.08 | 0.342 | 2.73 | 4.27 | 1 | 5 | 0.26 |

| medium | 5 | 3 | 1.414 | 0.632 | 1.24 | 4.76 | 1 | 4 | ||

| large | 25 | 2.68 | 1.376 | 0.275 | 2.11 | 3.25 | 1 | 5 | ||

| Total | 40 | 2.93 | 1.328 | 0.21 | 2.5 | 3.35 | 1 | 5 | ||

| B21 | small | 10 | 3.5 | 1.179 | 0.373 | 2.66 | 4.34 | 1 | 5 | 0.299 |

| medium | 5 | 3.4 | 0.894 | 0.4 | 2.29 | 4.51 | 2 | 4 | ||

| large | 25 | 2.84 | 1.281 | 0.256 | 2.31 | 3.37 | 1 | 5 | ||

| Total | 40 | 3.08 | 1.228 | 0.194 | 2.68 | 3.47 | 1 | 5 | ||

| B22 | small | 10 | 3.4 | 1.075 | 0.34 | 2.63 | 4.17 | 1 | 5 | 0.6 |

| medium | 5 | 3.4 | 1.517 | 0.678 | 1.52 | 5.28 | 1 | 5 | ||

| large | 25 | 3 | 1.19 | 0.238 | 2.51 | 3.49 | 1 | 5 | ||

| Total | 40 | 3.15 | 1.189 | 0.188 | 2.77 | 3.53 | 1 | 5 | ||

| B23 | small | 10 | 3.9 | 1.197 | 0.379 | 3.04 | 4.76 | 1 | 5 | 0.033 |

| medium | 5 | 4 | 1 | 0.447 | 2.76 | 5.24 | 3 | 5 | ||

| large | 25 | 2.88 | 1.201 | 0.24 | 2.38 | 3.38 | 1 | 4 | ||

| Total | 40 | 3.28 | 1.261 | 0.199 | 2.87 | 3.68 | 1 | 5 | ||

| B24 | small | 10 | 3.8 | 0.919 | 0.291 | 3.14 | 4.46 | 2 | 5 | 0.057 |

| medium | 5 | 3.6 | 0.894 | 0.4 | 2.49 | 4.71 | 3 | 5 | ||

| large | 25 | 3 | 0.913 | 0.183 | 2.62 | 3.38 | 1 | 4 | ||

| Total | 40 | 3.28 | 0.96 | 0.152 | 2.97 | 3.58 | 1 | 5 | ||

| B25 | small | 10 | 3.6 | 1.174 | 0.371 | 2.76 | 4.44 | 1 | 5 | 0.199 |

| medium | 5 | 3.8 | 0.837 | 0.374 | 2.76 | 4.84 | 3 | 5 | ||

| large | 25 | 3 | 1.155 | 0.231 | 2.52 | 3.48 | 1 | 5 | ||

| Total | 40 | 3.25 | 1.149 | 0.182 | 2.88 | 3.62 | 1 | 5 | ||

| B26 | small | 10 | 3.7 | 1.059 | 0.335 | 2.94 | 4.46 | 2 | 5 | 0.035 |

| medium | 5 | 4 | 0.707 | 0.316 | 3.12 | 4.88 | 3 | 5 | ||

| large | 25 | 2.92 | 1.038 | 0.208 | 2.49 | 3.35 | 1 | 5 | ||

| Total | 40 | 3.25 | 1.08 | 0.171 | 2.9 | 3.6 | 1 | 5 | ||

| B27 | small | 10 | 3.1 | 1.101 | 0.348 | 2.31 | 3.89 | 1 | 5 | 0.986 |

| medium | 5 | 3 | 1.414 | 0.632 | 1.24 | 4.76 | 1 | 4 | ||

| large | 25 | 3.08 | 1.077 | 0.215 | 2.64 | 3.52 | 1 | 5 | ||

| Total | 40 | 3.08 | 1.095 | 0.173 | 2.72 | 3.43 | 1 | 5 | ||

| B28 | small | 10 | 3.3 | 1.059 | 0.335 | 2.54 | 4.06 | 1 | 5 | 0.669 |

| medium | 5 | 3.2 | 1.643 | 0.735 | 1.16 | 5.24 | 1 | 5 | ||

| large | 25 | 2.92 | 1.152 | 0.23 | 2.44 | 3.4 | 1 | 5 | ||

| Total | 40 | 3.05 | 1.176 | 0.186 | 2.67 | 3.43 | 1 | 5 | ||

| B29 | small | 10 | 3.5 | 1.08 | 0.342 | 2.73 | 4.27 | 2 | 5 | 0.655 |

| medium | 5 | 4 | 1.225 | 0.548 | 2.48 | 5.52 | 2 | 5 | ||

| large | 25 | 3.64 | 0.907 | 0.181 | 3.27 | 4.01 | 2 | 5 | ||

| Total | 40 | 3.65 | 0.975 | 0.154 | 3.34 | 3.96 | 2 | 5 | ||

| B30 | small | 10 | 3.7 | 0.949 | 0.3 | 3.02 | 4.38 | 2 | 5 | 0.09 |

| medium | 5 | 4 | 1 | 0.447 | 2.76 | 5.24 | 3 | 5 | ||

| large | 25 | 3.04 | 1.098 | 0.22 | 2.59 | 3.49 | 1 | 5 | ||

| Total | 40 | 3.33 | 1.095 | 0.173 | 2.97 | 3.68 | 1 | 5 | ||

| B31 | small | 10 | 3.6 | 0.843 | 0.267 | 3 | 4.2 | 2 | 5 | 0.115 |

| medium | 5 | 2.8 | 1.643 | 0.735 | 0.76 | 4.84 | 1 | 5 | ||

| large | 25 | 3.84 | 0.898 | 0.18 | 3.47 | 4.21 | 2 | 5 | ||

| Total | 40 | 3.65 | 1.027 | 0.162 | 3.32 | 3.98 | 1 | 5 | ||

| B32 | small | 10 | 3.5 | 1.08 | 0.342 | 2.73 | 4.27 | 1 | 5 | 0.761 |

| medium | 5 | 3.8 | 0.837 | 0.374 | 2.76 | 4.84 | 3 | 5 | ||

| large | 25 | 3.4 | 1.155 | 0.231 | 2.92 | 3.88 | 1 | 5 | ||

| Total | 40 | 3.48 | 1.086 | 0.172 | 3.13 | 3.82 | 1 | 5 | ||

| B33 | small | 10 | 3.5 | 0.707 | 0.224 | 2.99 | 4.01 | 3 | 5 | 0.045 |

| medium | 5 | 4.6 | 0.548 | 0.245 | 3.92 | 5.28 | 4 | 5 | ||

| large | 25 | 3.24 | 1.234 | 0.247 | 2.73 | 3.75 | 1 | 5 | ||

| Total | 40 | 3.48 | 1.132 | 0.179 | 3.11 | 3.84 | 1 | 5 | ||

| Barriers | Independent Samples | N | Mean | Std. Deviation | Std. Error Mean | t | Sig. (2-Tailed) |

|---|---|---|---|---|---|---|---|

| B1 | Yes | 20 | 4 | 0.973 | 0.218 | 2.268 | 0.029 |

| No | 20 | 3.3 | 0.979 | 0.219 | |||

| B2 | Yes | 20 | 3.5 | 1.1 | 0.246 | 0.825 | 0.414 |

| No | 20 | 3.2 | 1.196 | 0.268 | |||

| B3 | Yes | 20 | 4.05 | 0.999 | 0.223 | 2.683 | 0.011 |

| No | 20 | 3.2 | 1.005 | 0.225 | |||

| B4 | Yes | 20 | 3.6 | 1.188 | 0.266 | 1.203 | 0.236 |

| No | 20 | 3.2 | 0.894 | 0.2 | |||

| B5 | Yes | 20 | 2.75 | 1.209 | 0.27 | −0.737 | 0.466 |

| No | 20 | 3 | 0.918 | 0.205 | |||

| B6 | Yes | 20 | 1.85 | 1.089 | 0.244 | −1.628 | 0.112 |

| No | 20 | 2.4 | 1.046 | 0.234 | |||

| B7 | Yes | 20 | 3.3 | 0.923 | 0.206 | −1.463 | 0.152 |

| No | 20 | 3.7 | 0.801 | 0.179 | |||

| B8 | Yes | 20 | 3.05 | 1.05 | 0.235 | −0.153 | 0.879 |

| No | 20 | 3.1 | 1.021 | 0.228 | |||

| B9 | Yes | 20 | 3.6 | 0.94 | 0.21 | 0.489 | 0.628 |

| No | 20 | 3.45 | 0.999 | 0.223 | |||

| B10 | Yes | 20 | 3.2 | 1.24 | 0.277 | −0.142 | 0.888 |

| No | 20 | 3.25 | 0.967 | 0.216 | |||

| B11 | Yes | 20 | 3.8 | 1.196 | 0.268 | 0.751 | 0.457 |

| No | 20 | 3.55 | 0.887 | 0.198 | |||

| B12 | Yes | 20 | 3.15 | 1.387 | 0.31 | −0.251 | 0.803 |

| No | 20 | 3.25 | 1.118 | 0.25 | |||

| B13 | Yes | 20 | 3 | 1.487 | 0.332 | −0.498 | 0.621 |

| No | 20 | 3.2 | 1.005 | 0.225 | |||

| B14 | Yes | 20 | 3.35 | 1.089 | 0.244 | 0.623 | 0.537 |

| No | 20 | 3.15 | 0.933 | 0.209 | |||

| B15 | Yes | 20 | 2.9 | 1.447 | 0.324 | −1.007 | 0.32 |

| No | 20 | 3.3 | 1.031 | 0.231 | |||

| B16 | Yes | 20 | 3.8 | 1.24 | 0.277 | 0.303 | 0.764 |

| No | 20 | 3.7 | 0.801 | 0.179 | |||

| B17 | Yes | 20 | 3.65 | 1.348 | 0.302 | −0.137 | 0.892 |

| No | 20 | 3.7 | 0.923 | 0.206 | |||

| B18 | Yes | 20 | 3.6 | 1.188 | 0.266 | 0.295 | 0.77 |

| No | 20 | 3.5 | 0.946 | 0.212 | |||

| B19 | Yes | 20 | 3.65 | 1.182 | 0.264 | 0 | 1 |

| No | 20 | 3.65 | 0.745 | 0.167 | |||

| B20 | Yes | 20 | 2.6 | 1.392 | 0.311 | −1.577 | 0.123 |

| No | 20 | 3.25 | 1.209 | 0.27 | |||

| B21 | Yes | 20 | 2.8 | 1.281 | 0.287 | −1.436 | 0.159 |

| No | 20 | 3.35 | 1.137 | 0.254 | |||

| B22 | Yes | 20 | 3.1 | 1.252 | 0.28 | −0.263 | 0.794 |

| No | 20 | 3.2 | 1.152 | 0.258 | |||

| B23 | Yes | 20 | 3.2 | 1.576 | 0.352 | −0.372 | 0.712 |

| No | 20 | 3.35 | 0.875 | 0.196 | |||

| B24 | Yes | 20 | 3.25 | 1.118 | 0.25 | −0.163 | 0.872 |

| No | 20 | 3.3 | 0.801 | 0.179 | |||

| B25 | Yes | 20 | 3.25 | 1.293 | 0.289 | 0 | 1 |

| No | 20 | 3.25 | 1.02 | 0.228 | |||

| B26 | Yes | 20 | 3.1 | 1.071 | 0.24 | −0.876 | 0.387 |

| No | 20 | 3.4 | 1.095 | 0.245 | |||

| B27 | Yes | 20 | 2.85 | 1.348 | 0.302 | −1.311 | 0.2 |

| No | 20 | 3.3 | 0.733 | 0.164 | |||

| B28 | Yes | 20 | 3 | 1.451 | 0.324 | −0.266 | 0.792 |

| No | 20 | 3.1 | 0.852 | 0.191 | |||

| B29 | Yes | 20 | 3.6 | 1.095 | 0.245 | −0.32 | 0.75 |

| No | 20 | 3.7 | 0.865 | 0.193 | |||

| B30 | Yes | 20 | 3.25 | 1.209 | 0.27 | −0.429 | 0.671 |

| No | 20 | 3.4 | 0.995 | 0.222 | |||

| B31 | Yes | 20 | 3.55 | 1.099 | 0.246 | −0.611 | 0.545 |

| No | 20 | 3.75 | 0.967 | 0.216 | |||

| B32 | Yes | 20 | 3.45 | 1.276 | 0.285 | −0.144 | 0.886 |

| No | 20 | 3.5 | 0.889 | 0.199 | |||

| B33 | Yes | 20 | 3.65 | 1.268 | 0.284 | 0.977 | 0.335 |

| No | 20 | 3.3 | 0.979 | 0.219 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Singh, A.K.; Mohandes, S.R.; Muhodir, S.H.; Zhang, W.; Antwi-Afari, M.F.; Shakor, P. Exploring Barriers to Unmanned Aerial Vehicle (UAV) Technology for Construction Safety Management Using Mixed-Methods Approach. Buildings 2025, 15, 2092. https://doi.org/10.3390/buildings15122092

Singh AK, Mohandes SR, Muhodir SH, Zhang W, Antwi-Afari MF, Shakor P. Exploring Barriers to Unmanned Aerial Vehicle (UAV) Technology for Construction Safety Management Using Mixed-Methods Approach. Buildings. 2025; 15(12):2092. https://doi.org/10.3390/buildings15122092

Chicago/Turabian StyleSingh, Atul Kumar, Saeed Reza Mohandes, Sabih Hashim Muhodir, Wanqing Zhang, Maxwell Fordjour Antwi-Afari, and Pshtiwan Shakor. 2025. "Exploring Barriers to Unmanned Aerial Vehicle (UAV) Technology for Construction Safety Management Using Mixed-Methods Approach" Buildings 15, no. 12: 2092. https://doi.org/10.3390/buildings15122092

APA StyleSingh, A. K., Mohandes, S. R., Muhodir, S. H., Zhang, W., Antwi-Afari, M. F., & Shakor, P. (2025). Exploring Barriers to Unmanned Aerial Vehicle (UAV) Technology for Construction Safety Management Using Mixed-Methods Approach. Buildings, 15(12), 2092. https://doi.org/10.3390/buildings15122092