From Profit to Preservation: A Review of Digital Technology Enabling Sustainable Prefabricated Building Supply Chain Management

Abstract

1. Introduction

1.1. Background

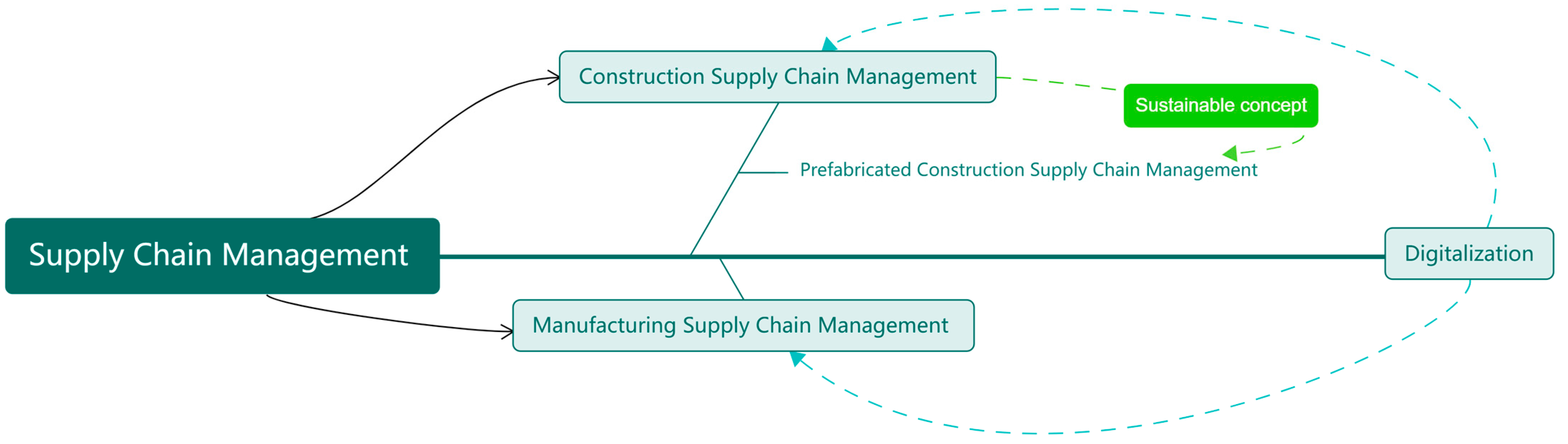

1.1.1. Supply Chain Management and Construction Supply Chain Management

1.1.2. Environmental Issues Give Rise to PCSCM

1.1.3. Current Digital Technology Widely Used in PCSCM

1.2. Objectives and Structure

2. Methodology

2.1. Process Framework

2.2. Detailed Literature Search Process

2.2.1. Main Data Sources

2.2.2. Principles of Literature Search and Screening

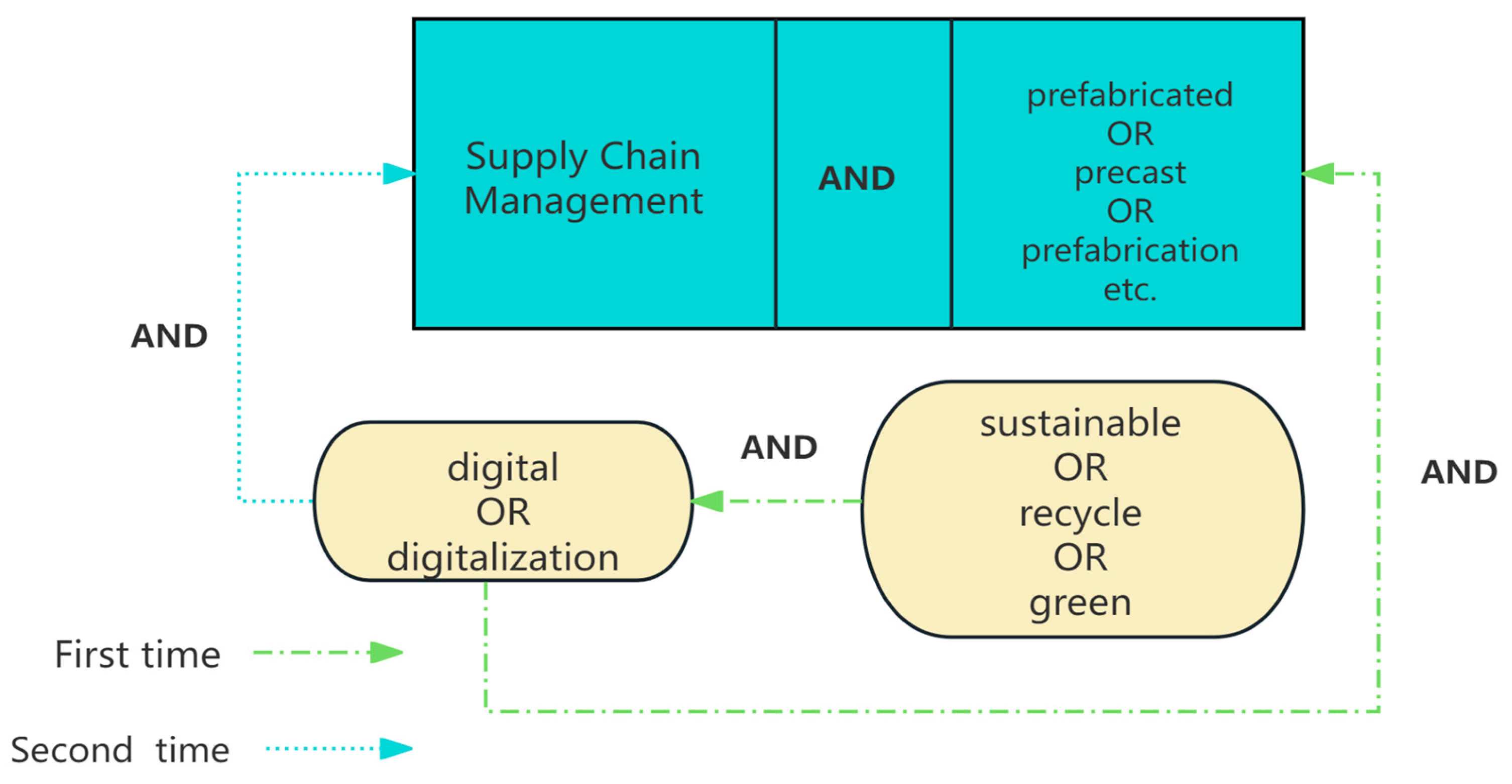

2.2.3. Keywords and Data in Literature Search

2.2.4. Using Scientific Bibliometric Tools

2.2.5. Supplementary Searches

3. Results of Visual Analysis

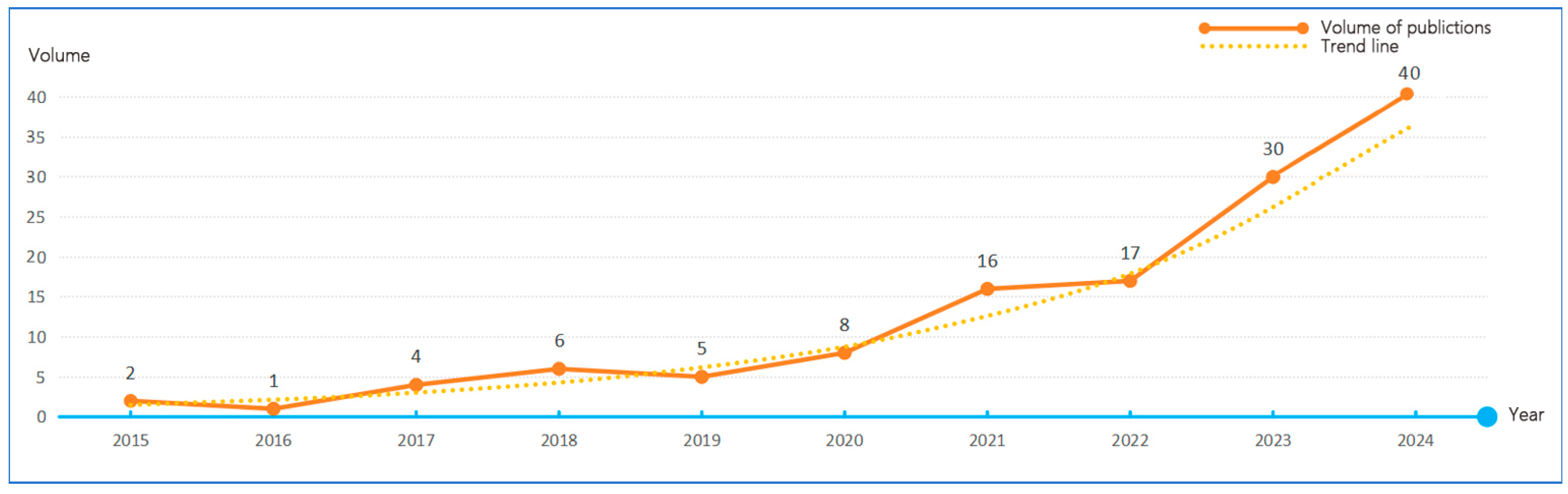

3.1. Statistics of Relevant Literature Documents

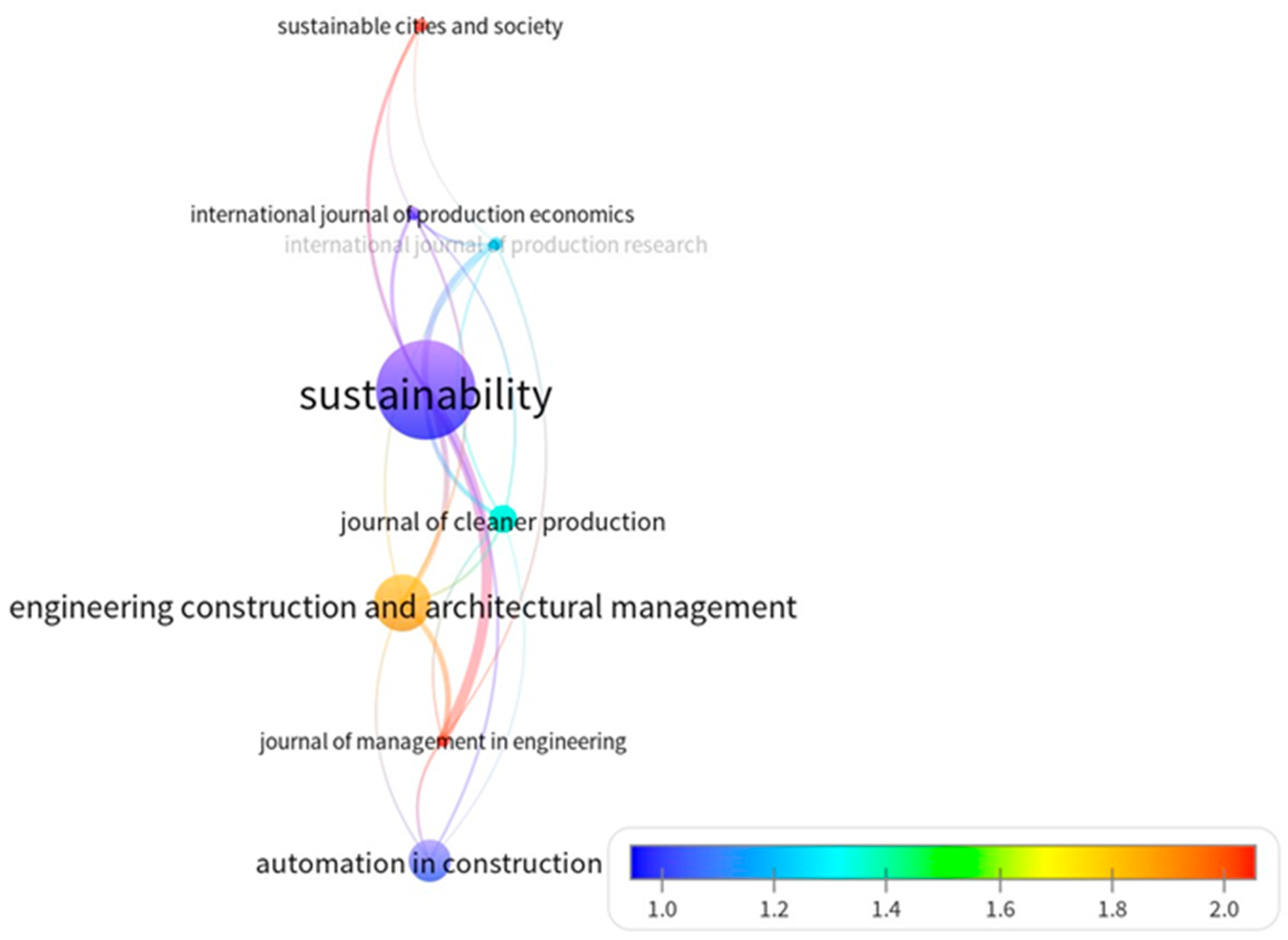

3.2. Publication and Citations Analysis

Research Themes of the Journals

3.3. Major Country Analysis

- 1.

- Market Demand

- 2.

- Policy Support

- 3.

- Technological Development

- 4.

- International Exchange

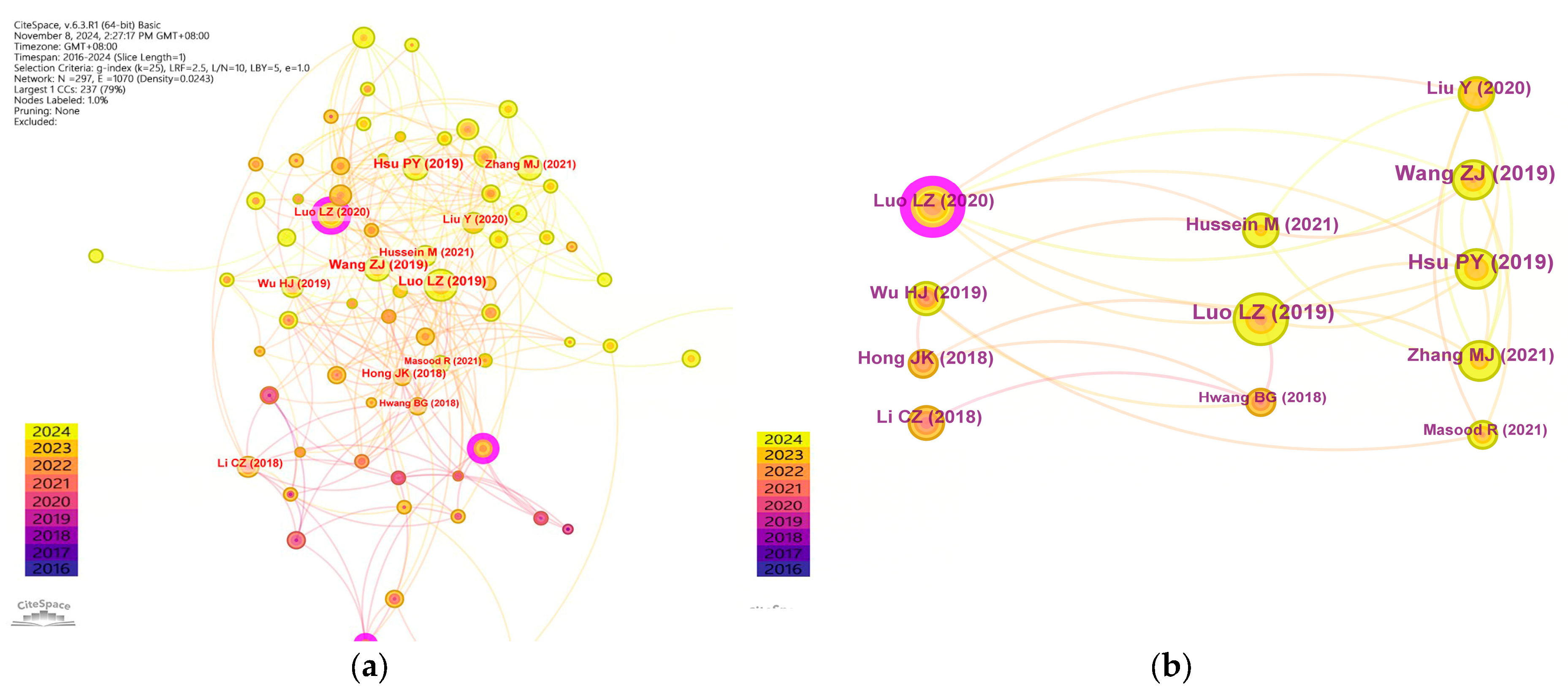

3.4. Author Analysis

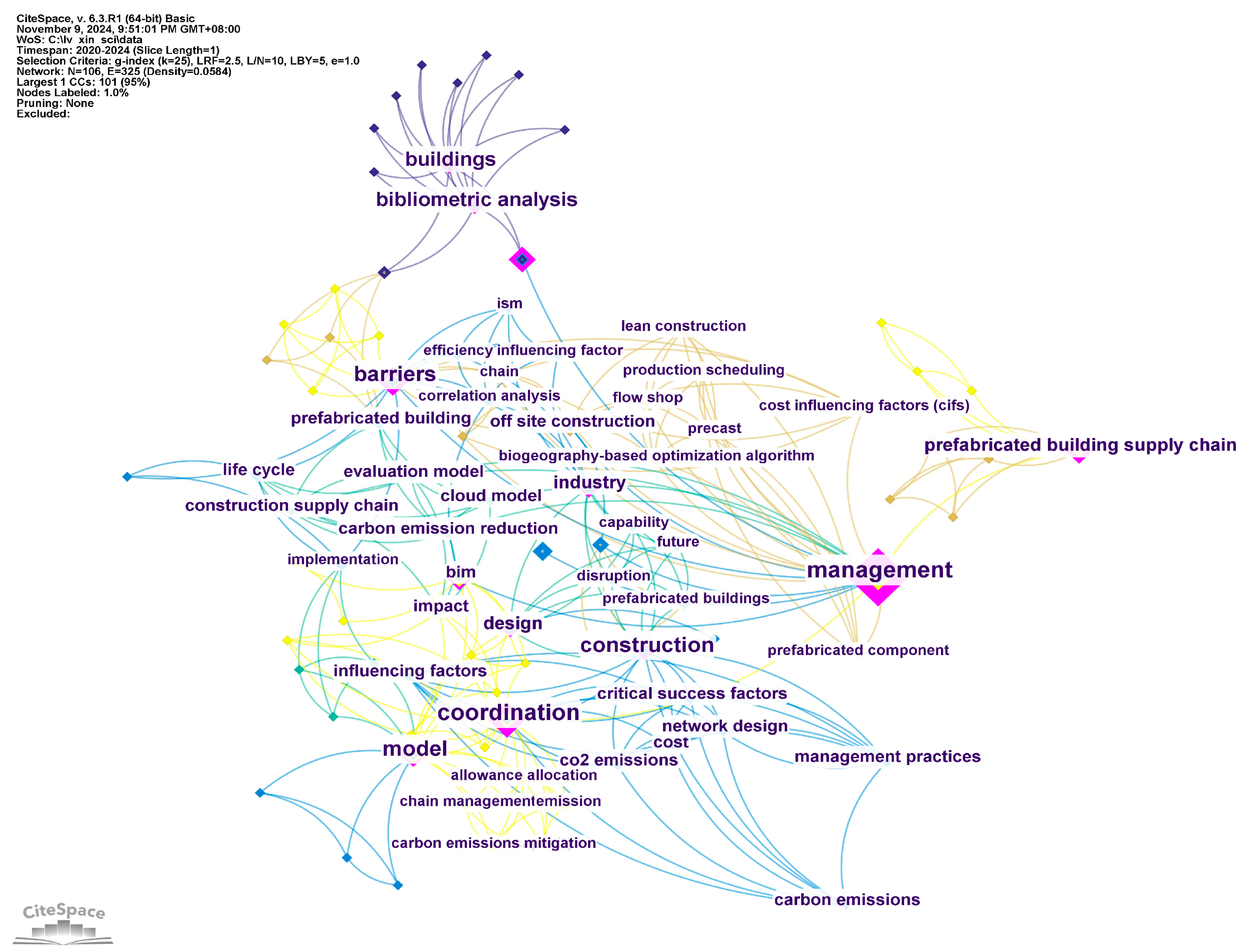

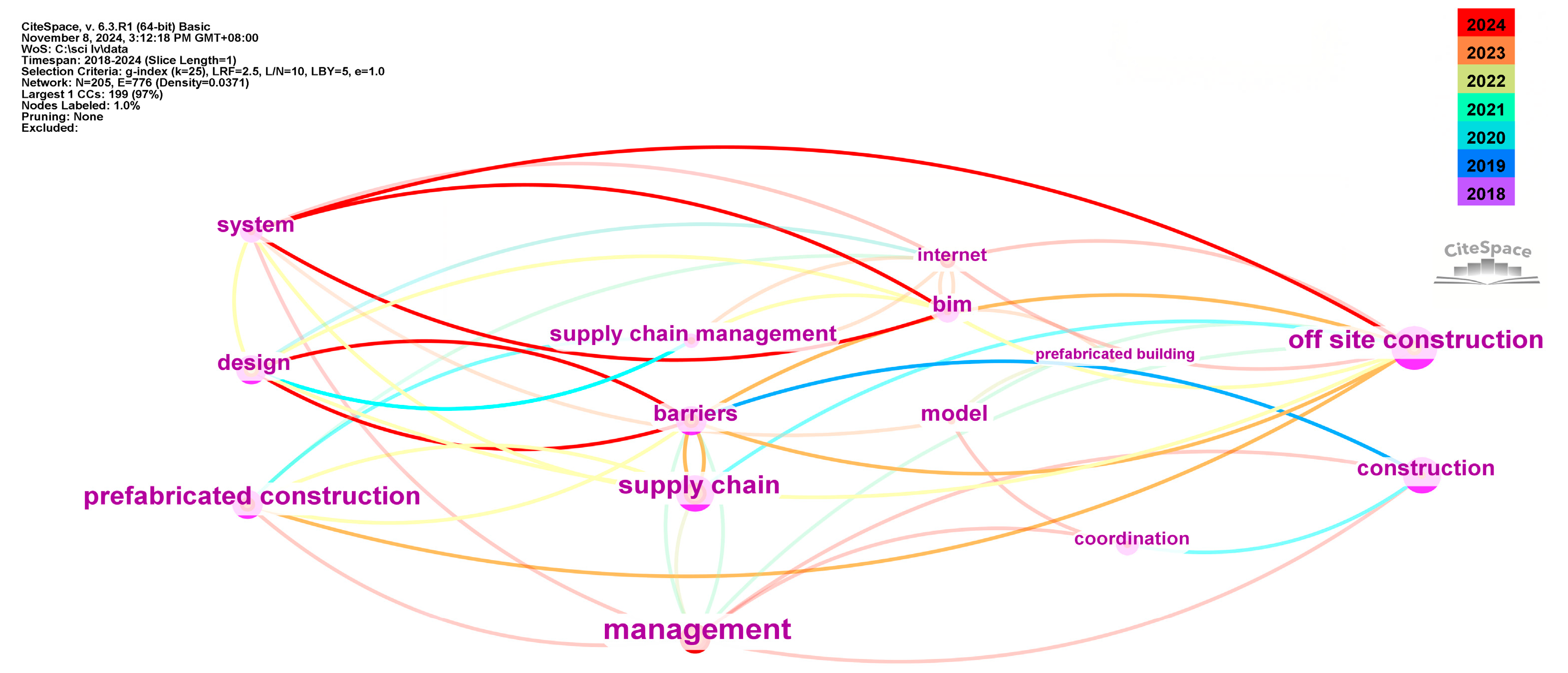

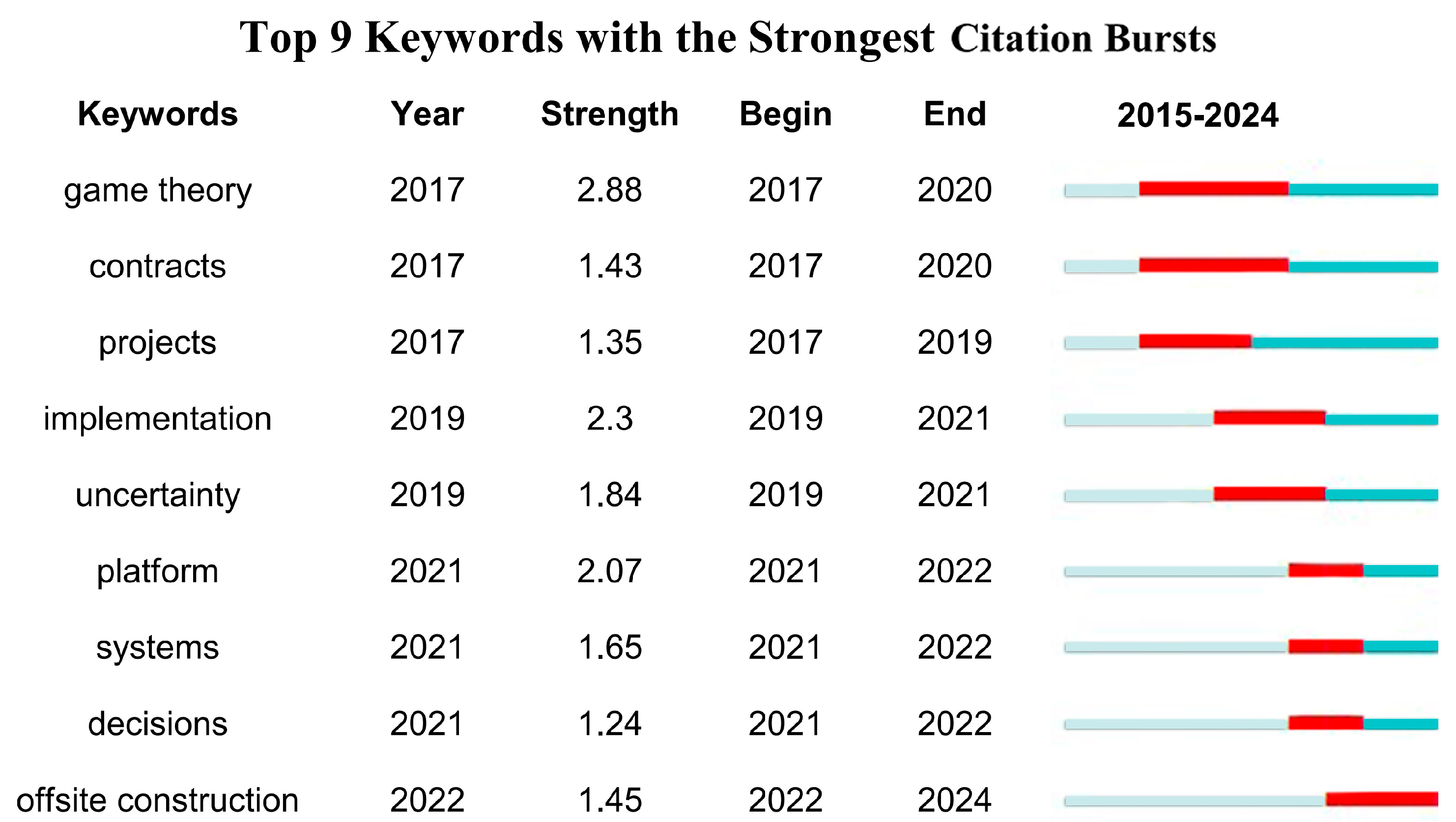

3.5. Key Word Analysis

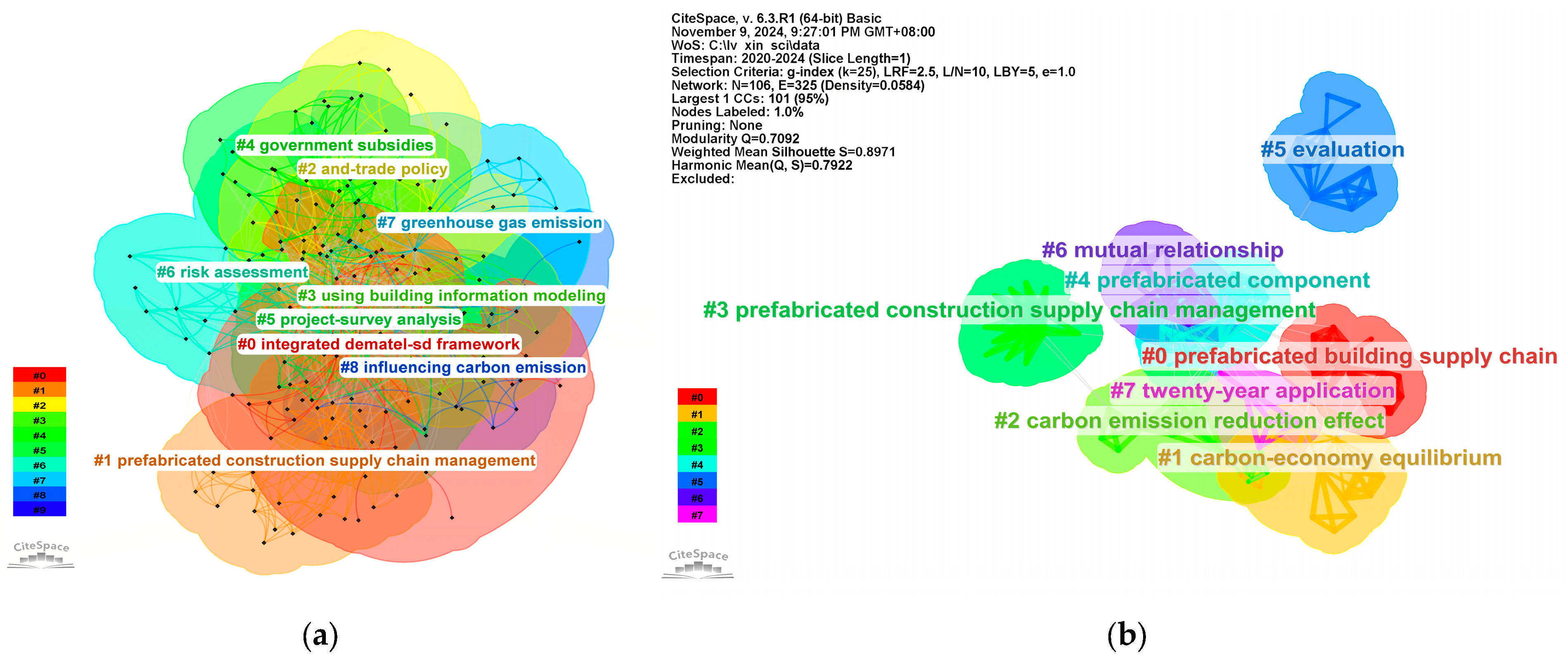

3.5.1. Cluster Analysis

- 1.

- Supply Chain Management

- 2.

- Environmental Economics

- 3.

- Long-Term Planning

- 4.

- Relevant Relationships

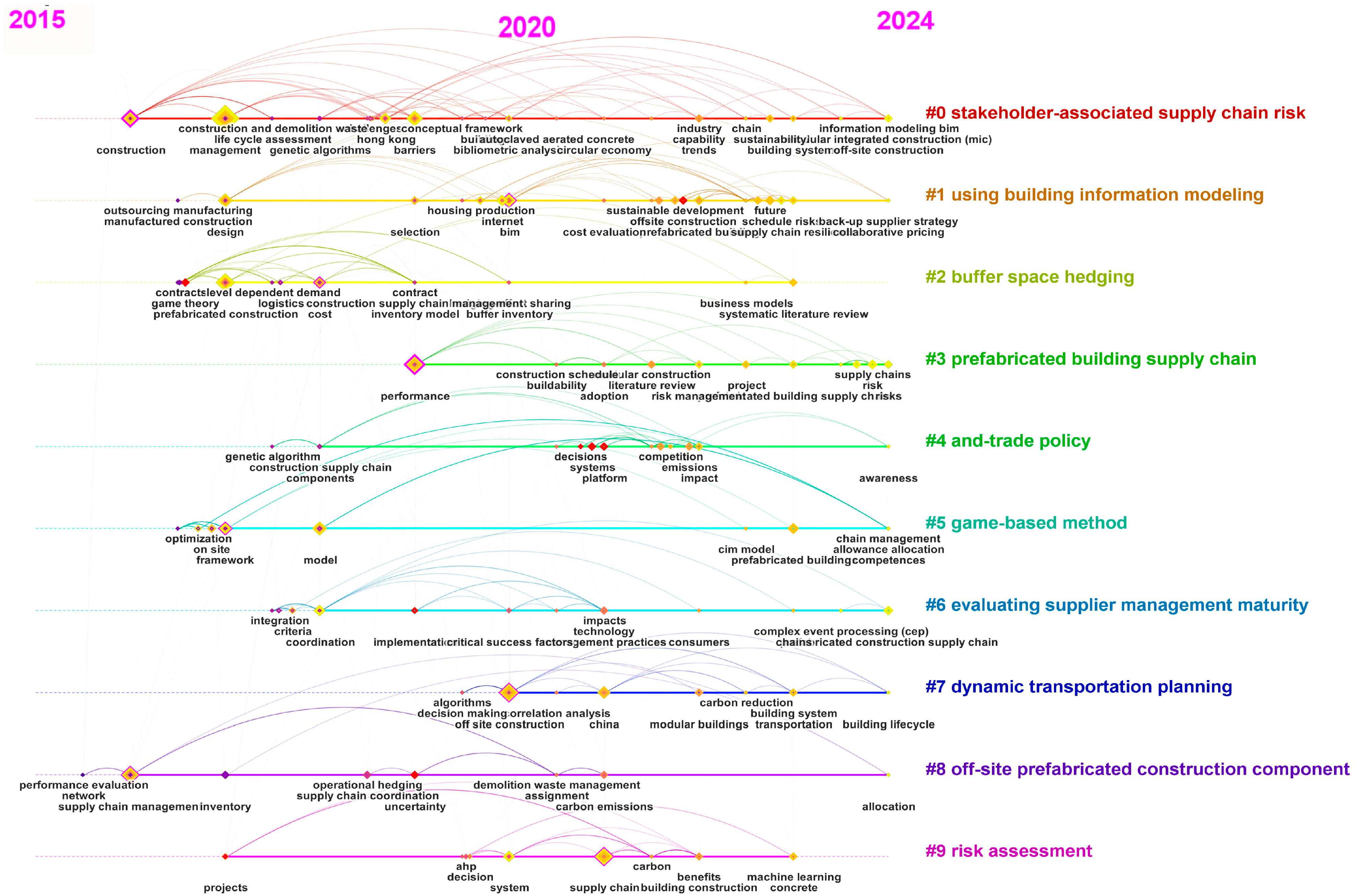

3.5.2. Timeline Analysis

3.5.3. Summary of Visual Analysis

4. Qualitative Discussion

4.1. Challenges of Achieving Digital Transformation in PCSCM

4.2. Applying Digital Technologies to Adress Digital Transformation in PCSCM

4.2.1. Current Status of Most Research Applying Digital Technologies to Enhance Profits

- 1.

- Using BIM and IOT Technology

- 2.

- Using Big Data and Cloud Computing Technology

- 3.

- Using Artificial Intelligence Technology

4.2.2. Integration of Digital Technology with Sustainable Concepts in PCSCM

- 1.

- Carbon Emissions

| Year | Title | Citations | Author | Research Topics | Methods |

|---|---|---|---|---|---|

| 2023 | An exploratory analysis of low-carbon transitions in China’s construction industry based on multi-level perspective | 11 | Xu, PP et al. [51] | Low-carbon transitions in the construction industry | Interpretative structural model and cross-impact matrix multiplication |

| 2021 | Critical factors influencing carbon emissions of prefabricated building supply chains in China | 62 | Du, Q et al. [52] | Formulate low-carbon strategies | A hypothesis model |

| 2022 | An Evaluation Model of Carbon Emission Reduction Effect of Prefabricated Building Based on Cloud Model from the Perspective of Construction Supply Chain | 18 | Sun, SN et al. [53] | Reduce carbon emissions and achieve the “dual carbon” goal | Continuous ordered weighted averaging operator cloud model |

| 2023 | Research on Resilience Evaluation of Green Building Supply Chain Based on ANP-Fuzzy Model | 16 | Wang, YX et al. [54] | Evaluate resilience level | Interpretative structural model and ANP-Fuzzy comprehensive evaluation model |

| 2022 | Artificial Neural Networks for Sustainable Development of the Construction Industry | 18 | Ahmed, M et al. [55] | Sustainable development of construction industry | Artificial neural networks |

| 2022 | A dynamic simulation study on the sustainability of prefabricated buildings | 52 | Liu, S et al. [56] | PC efficiently and sustainably | System dynamics |

- 2.

- Comprehensive Benefits

- 3.

- Resilient in Terms of Sustainability

- 4.

- Quality Management

- 5.

- Risk Prediction

- 6.

- Green Materials and Recycling

- 7.

- Green Transportation

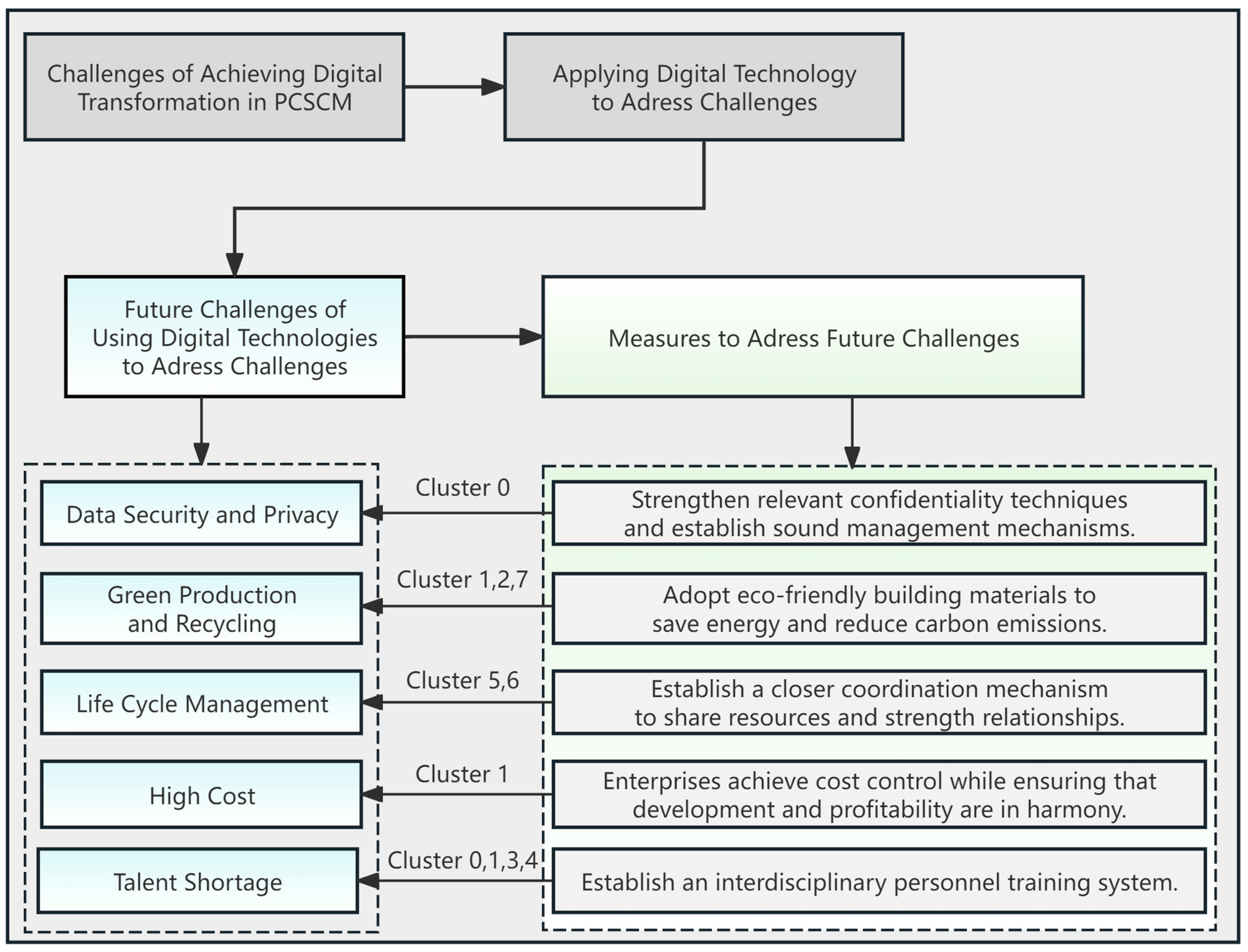

4.3. Future Challenges of Using Digital Technologies to Achieve Sustainable Development in PCSCM

- 1.

- Data Security and Privacy

- 2.

- Green Production and Recycling

- 3.

- Life Cycle Management

- 4.

- High Cost

- 5.

- Talent Shortage

5. Measures to Address Future Challenges in PCSCM

- 1.

- Data Security and Encryption

- 2.

- Green Materials

- 3.

- Standard System

- 4.

- Cost Control

- 5.

- Talent Cultivation

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Dian, J.; Song, T.; Li, S. Facilitating or Inhibiting? Spatial Effects of the Digital Economy Affecting Urban Green Technology Innovation. Energy Econ. 2024, 129, 107223. [Google Scholar] [CrossRef]

- Huang, C.; Liu, W.; Iqbal, W.; Shah, S.A.R. Does Digital Governance Matter for Environmental Sustainability? The Key Challenges and Opportunities under the Prism of Natural Resource Management. Resour. Policy 2024, 91, 104812. [Google Scholar] [CrossRef]

- Na, Y.; Palikhe, S.; Lim, C.; Kim, S. Health Performance and Cost Management Model for Sustainable Healthy Buildings. Indoor Built Environ. 2015, 25, 799–808. [Google Scholar] [CrossRef]

- Kussl, S.; Wald, A.; Flak, L.S. Change Must Come from Within: Study of Digital Transformation in Construction Client Organizations. J. Constr. Eng. Manag. 2025, 151. [Google Scholar] [CrossRef]

- Avotra, A.A.R.N.; Chenyun, Y.; Yongmin, W.; Lijuan, Z.; Nawaz, A. Conceptualizing the State of the Art of Corporate Social Responsibility (CSR) in Green Construction and Its Nexus to Sustainable Development. Front. Environ. Sci. 2021, 9, 774822. [Google Scholar] [CrossRef]

- Schniederjans, D.G.; Curado, C.; Khalajhedayati, M. Supply Chain Digitisation Trends: An Integration of Knowledge Management. Int. J. Prod. Econ. 2019, 220, 107439. [Google Scholar] [CrossRef]

- Gao, C.M.; Wong, K.Y. Key Factors Influencing Building Components’ Remanufacturing Strategy: A Comprehensive Literature Review. Buildings 2025, 15, 934. [Google Scholar] [CrossRef]

- Han, Y.; Yan, X.; Piroozfar, P. An Overall Review of Research on Prefabricated Construction Supply Chain Management. Eng. Constr. Archit. Manag. 2022, 22, 51. [Google Scholar] [CrossRef]

- Nasir, M.H.A.; Genovese, A.; Acquaye, A.A.; Koh, S.C.L.; Yamoah, F. Comparing Linear and Circular Supply Chains: A Case Study from the Construction Industry. Int. J. Prod. Econ. 2017, 183, 443–457. [Google Scholar] [CrossRef]

- Marsden, J. Systematic Approaches to a Successful Literature Review. Nurse Res. 2014, 21, 46. [Google Scholar] [CrossRef]

- Bornmann, L.; Marx, W. The Journal Impact Factor and Alternative Metrics. EMBO Rep. 2016, 17, 1094–1097. [Google Scholar] [CrossRef] [PubMed]

- Harzing, A.-W.; Alakangas, S. Google Scholar, Scopus and the Web of Science: A Longitudinal and Cross-Disciplinary Comparison. Scientometrics 2015, 106, 787–804. [Google Scholar] [CrossRef]

- Waltman, L.; van Eck, N.J. A New Methodology for Constructing a Publication-Level Classification System of Science. J. Am. Soc. Inf. Sci. Technol. 2012, 63, 2378–2392. [Google Scholar] [CrossRef]

- Binali, N.; Tanveer, B. A Comparison of Citation Sources for Reference and Citation-Based Search in Systematic Literature Reviews. E-Inform. Softw. Eng. J. 2022, 16, 220106. [Google Scholar] [CrossRef]

- Keshavarz-Ghorabaee, M.; Amiri, M.; Hashemi-Tabatabaei, M.; Zavadskas, E.K.; Kaklauskas, A. A New Decision-Making Approach Based on Fermatean Fuzzy Sets and WASPAS for Green Construction Supplier Evaluation. Mathematics 2020, 8, 2202. [Google Scholar] [CrossRef]

- Fan, W.; Wu, X.; He, Q. Digitalization Drives Green Transformation of Supply Chains: A Two-Stage Evolutionary Game Analysis. Ann. Oper. Res. 2024. [Google Scholar] [CrossRef]

- Li, J.; Greenwood, D.; Kassem, M. Blockchain in the Built Environment and Construction Industry: A Systematic Review, Conceptual Models and Practical Use Cases. Autom. Constr. 2019, 102, 288–307. [Google Scholar] [CrossRef]

- Jiang, W.; Hua, Y.; Yuan, M.; Martek, I.; Jiang, W. Pricing Models under Three-Echelon Prefabricated Construction Supply Chains with Consumer Preferences. Sustainability 2024, 16, 727. [Google Scholar] [CrossRef]

- Zhang, X.; Yang, Q.; Song, T.; Xu, Y. Collaborative Pricing of Green Supply Chain of Prefabricated Construction. Sustainability 2024, 16, 5579. [Google Scholar] [CrossRef]

- Wang, D.-Y.; Wang, X. Supply Chain Consequences of Government Subsidies for Promoting Prefabricated Construction and Emissions Abatement. J. Manag. Eng. 2023, 39. [Google Scholar] [CrossRef]

- Zhong, R.Y.; Peng, Y.; Fang, J.; Xu, G.; Xue, F.; Zou, W.; Huang, G.Q. Towards Physical Internet-Enabled Prefabricated Housing Construction in Hong Kong. IFAC-PapersOnLine 2015, 48, 1079–1086. [Google Scholar] [CrossRef]

- Luo, L.; Qiping Shen, G.; Xu, G.; Liu, Y.; Wang, Y. Stakeholder-Associated Supply Chain Risks and Their Interactions in a Prefabricated Building Project in Hong Kong. J. Manag. Eng. 2019, 35, 05018015. [Google Scholar] [CrossRef]

- Chen, K.; Lu, W.; Peng, Y.; Rowlinson, S.; Huang, G.Q. Bridging BIM and Building: From a Literature Review to an Integrated Conceptual Framework. Int. J. Proj. Manag. 2015, 33, 1405–1416. [Google Scholar] [CrossRef]

- Zhai, Y.; Zhong, R.Y.; Li, Z.; Huang, G. Production Lead-Time Hedging and Coordination in Prefabricated Construction Supply Chain Management. Int. J. Prod. Res. 2016, 55, 3984–4002. [Google Scholar] [CrossRef]

- Li, C.Z.; Lai, X.; Xiao, B.; Vivian, W.Y.T.; Guo, S.; Zhao, Y. A Holistic Review on Life Cycle Energy of Buildings: An Analysis from 2009 to 2019. Renew. Sustain. Energy Rev. 2020, 134, 110372. [Google Scholar] [CrossRef]

- Du, Q.; Deng, Y.; Zhou, J.; Wu, J.; Pang, Q. Spatial Spillover Effect of Carbon Emission Efficiency in the Construction Industry of China. Environ. Sci. Pollut. Res. 2021, 29, 2466–2479. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, T.; Hu, H.; Gong, J.; Ren, X.; Xiao, Q. Blockchain-Based Framework for Improving Supply Chain Traceability and Information Sharing in Precast Construction. Autom. Constr. 2020, 111, 103063. [Google Scholar] [CrossRef]

- Ogunmakinde, O.E.; Egbelakin, T.; Sher, W. Contributions of the Circular Economy to the UN Sustainable Development Goals through Sustainable Construction. Resour. Conserv. Recycl. 2022, 178, 106023. [Google Scholar] [CrossRef]

- Ghaffarianhoseini, A.; Tookey, J.; Ghaffarianhoseini, A.; Naismith, N.; Azhar, S.; Efimova, O.; Raahemifar, K. Building Information Modelling (BIM) Uptake: Clear Benefits, Understanding Its Implementation, Risks and Challenges. Renew. Sustain. Energy Rev. 2017, 75, 1046–1053. [Google Scholar] [CrossRef]

- Li, Z.; Shen, G.Q.; Xue, X. Critical Review of the Research on the Management of Prefabricated Construction. Habitat Int. 2014, 43, 240–249. [Google Scholar] [CrossRef]

- Zhang, J.; Ouyang, Y.; Ballesteros-Pérez, P.; Li, H.; Philbin, S.P.; Li, Z.; Skitmore, M. Understanding the Impact of Environmental Regulations on Green Technology Innovation Efficiency in the Construction Industry. Sustain. Cities Soc. 2021, 65, 102647. [Google Scholar] [CrossRef]

- Yin, S.; Zhao, Y. An Agent-Based Evolutionary System Model of the Transformation from Building Material Industry (BMI) to Green Intelligent BMI under Supply Chain Management. Humanit. Soc. Sci. Commun. 2024, 11, 468. [Google Scholar] [CrossRef]

- Gao, X.; Pishdad-Bozorgi, P. BIM-Enabled Facilities Operation and Maintenance: A Review. Adv. Eng. Inform. 2019, 39, 227–247. [Google Scholar] [CrossRef]

- Hossain, M.U.; Ng, S.T.; Antwi-Afari, P.; Amor, B. Circular Economy and the Construction Industry: Existing Trends, Challenges and Prospective Framework for Sustainable Construction. Renew. Sustain. Energy Rev. 2020, 130, 109948. [Google Scholar] [CrossRef]

- Pan, Y.; Zhang, L. Integrating BIM and AI for Smart Construction Management: Current Status and Future Directions. Arch. Comput. Methods Eng. 2022, 30, 1081–1110. [Google Scholar] [CrossRef]

- Chen, Z.; Hammad, A.W.A.; Alyami, M. Building Construction Supply Chain Resilience under Supply and Demand Uncertainties. Autom. Constr. 2024, 158, 105190. [Google Scholar] [CrossRef]

- Luo, L.; Li, Y.; Wang, X.; Jin, X.; Qin, Z. Supply Chain Vulnerability in Prefabricated Building Projects and Digital Mitigation Technologies. IEEE Trans. Eng. Manag. 2024, 71, 10686–10698. [Google Scholar] [CrossRef]

- Zhou, J.X.; Shen, G.Q.; Yoon, S.H.; Jin, X. Customization of On-Site Assembly Services by Integrating the Internet of Things and BIM Technologies in Modular Integrated Construction. Autom. Constr. 2021, 126, 103663. [Google Scholar] [CrossRef]

- Li, C.Z.; Xue, F.; Li, X.; Hong, J.; Shen, G.Q. An Internet of Things-Enabled BIM Platform for On-Site Assembly Services in Prefabricated Construction. Autom. Constr. 2018, 89, 146–161. [Google Scholar] [CrossRef]

- Chen, Q.; Adey, B.T.; Haas, C.T.; Hall, D.M. Exploiting Digitalization for the Coordination of Required Changes to Improve Engineer-To-Order Materials Flow Management. Constr. Innov. 2021, 22. [Google Scholar] [CrossRef]

- Xie, L.; Chen, Y.; Chang, R. Scheduling Optimization of Prefabricated Construction Projects by Genetic Algorithm. Appl. Sci. 2021, 11, 5531. [Google Scholar] [CrossRef]

- Yan, X.; Zhang, H. Computer Vision-Based Disruption Management for Prefabricated Building Construction Schedule. J. Comput. Civ. Eng. 2021, 35, 04021027. [Google Scholar] [CrossRef]

- Dong, T.; Yin, S.; Zhang, N. The Interaction Mechanism and Dynamic Evolution of Digital Green Innovation in the Integrated Green Building Supply Chain. Systems 2023, 11, 122. [Google Scholar] [CrossRef]

- Moshood, T.D.; Rotimi, J.O.B.; Shahzad, W.; Bamgbade, J.A. Infrastructure Digital Twin Technology: A New Paradigm for Future Construction Industry. Technol. Soc. 2024, 77, 102519. [Google Scholar] [CrossRef]

- Chen, L.; Huang, L.; Hua, J.; Chen, Z.; Wei, L.; Osman, A.I.; Fawzy, S.; Rooney, D.W.; Dong, L.; Yap, P.-S. Green Construction for Low-Carbon Cities: A Review. Environ. Chem. Lett. 2023, 21, 1627–1657. [Google Scholar] [CrossRef]

- Hanifa, M.; Agarwal, R.; Sharma, U.; Thapliyal, P.C.; Singh, L.P. A Review on CO2 Capture and Sequestration in the Construction Industry: Emerging Approaches and Commercialised Technologies. J. CO2 Util. 2023, 67, 102292. [Google Scholar] [CrossRef]

- Liang, H.; Bian, X.; Dong, L. Towards Net Zero Carbon Buildings: Accounting the Building Embodied Carbon and Life Cycle-Based Policy Design for Greater Bay Area, China. Geosci. Front. 2023, 101760. [Google Scholar] [CrossRef]

- Piracha, A.; Chaudhary, M.T. Urban Air Pollution, Urban Heat Island and Human Health: A Review of the Literature. Sustainability 2022, 14, 9234. [Google Scholar] [CrossRef]

- Mustafa, M.N.; Mohd Abdah, M.A.A.; Numan, A.; Moreno-Rangel, A.; Radwan, A.; Khalid, M. Smart Window Technology and Its Potential for Net-Zero Buildings: A Review. Renew. Sustain. Energy Rev. 2023, 181, 113355. [Google Scholar] [CrossRef]

- Liu, J.-B.; Yuan, X.-Y.; Lee, C.-C. Prediction of Carbon Emissions in China’s Construction Industry Using an Improved Grey Prediction Model. Sci. Total Environ. 2024, 938, 173351. [Google Scholar] [CrossRef]

- Xu, P.; Wang, Y.; Yao, H.; Hou, H.C. An Exploratory Analysis of Low-Carbon Transitions in China’s Construction Industry Based on Multi-Level Perspective. Sustain. Cities Soc. 2023, 92, 104460. [Google Scholar] [CrossRef]

- Du, Q.; Pang, Q.; Bao, T.; Guo, X.; Deng, Y. Critical Factors Influencing Carbon Emissions of Prefabricated Building Supply Chains in China. J. Clean. Prod. 2021, 280, 124398. [Google Scholar] [CrossRef]

- Sun, S.; Chen, Y.; Wang, A.; Liu, X. An Evaluation Model of Carbon Emission Reduction Effect of Prefabricated Buildings Based on Cloud Model from the Perspective of Construction Supply Chain. Buildings 2022, 12, 1534. [Google Scholar] [CrossRef]

- Wang, Y.; Ren, J.; Zhang, L.; Liu, D. Research on Resilience Evaluation of Green Building Supply Chain Based on ANP-Fuzzy Model. Sustainability 2022, 15, 285. [Google Scholar] [CrossRef]

- Henderson, I.; Ubando, A.T.; Tseng, M.-L.; Tan, R.R. Artificial Neural Networks for Sustainable Development: A Critical Review. Clean Technol. Environ. Policy 2020, 22, 1449–1465. [Google Scholar] [CrossRef]

- Liu, S.; Li, Z.; Teng, Y.; Dai, L. A Dynamic Simulation Study on the Sustainability of Prefabricated Buildings. Sustain. Cities Soc. 2022, 77, 103551. [Google Scholar] [CrossRef]

- Li, C.Z.; Chen, Z.; Xue, F.; Kong, X.T.R.; Xiao, B.; Lai, X.; Zhao, Y. A Blockchain- and IoT-Based Smart Product-Service System for the Sustainability of Prefabricated Housing Construction. J. Clean. Prod. 2021, 286, 125391. [Google Scholar] [CrossRef]

- Zhang, K.; Tsai, J.-S. Identification of Critical Factors Influencing Prefabricated Construction Quality and Their Mutual Relationship. Sustainability 2021, 13, 11081. [Google Scholar] [CrossRef]

- Zhu, T.; Liu, G. A Novel Hybrid Methodology to Study the Risk Management of Prefabricated Building Supply Chains: An Outlook for Sustainability. Sustainability 2022, 15, 361. [Google Scholar] [CrossRef]

- Ferrández-Vega, D.; Diaz-Velilla, J.P.; Zaragoza-Benzal, A.; Zúñiga-Vicente, J.A. Use of Composite Plaster Material for the Development of sustainable prefabricated: Study of its manufacturing process, properties and supply chain. Dyna 2023, 98, 391–396. [Google Scholar] [CrossRef]

- Zhang, H.; Yu, L. Dynamic Transportation Planning for Prefabricated Component Supply Chain. Eng. Constr. Archit. Manag. 2020, 27, 2553–2576. [Google Scholar] [CrossRef]

- Anvari, B.; Angeloudis, P.; Ochieng, W.Y. A Multi-Objective GA-Based Optimisation for Holistic Manufacturing, Transportation and Assembly of Precast Construction. Autom. Constr. 2016, 71, 226–241. [Google Scholar] [CrossRef]

- Hsu, P.-Y.; Aurisicchio, M.; Angeloudis, P. Risk-Averse Supply Chain for Modular Construction Projects. Autom. Constr. 2019, 106, 102898. [Google Scholar] [CrossRef]

- Bortolini, R.; Formoso, C.T.; Viana, D.D. Site Logistics Planning and Control for Engineer-To-Order Prefabricated Building Systems Using BIM 4D Modeling. Autom. Constr. 2019, 98, 248–264. [Google Scholar] [CrossRef]

- Liu, Y.; Chang, R.-D.; Zuo, J.; Xiong, F.; Dong, N. What Leads to the High Capital Cost of Prefabricated Construction in China: Perspectives of Stakeholders. Eng. Constr. Archit. Manag. 2022. [Google Scholar] [CrossRef]

- Fan, C.; Binchao, D.; Yin, Y. Hierarchical Structure and Transfer Mechanism to Assess the Scheduling-Related Risk in Construction of Prefabricated Buildings: An Integrated ISM–MICMAC Approach. Eng. Constr. Archit. Manag. 2022, 30, 7. [Google Scholar] [CrossRef]

- Asif, M.; Naeem, G.; Khalid, M. Digitalization for Sustainable Buildings: Technologies, Applications, Potential, and Challenges. J. Clean. Prod. 2024, 405, 141814. [Google Scholar] [CrossRef]

- Nilimaa, J. Smart Materials and Technologies for Sustainable Concrete Construction. Dev. Built Environ. 2023, 15, 100177. [Google Scholar] [CrossRef]

- Datta, S.D.; Islam, M.; Rahman Sobuz, M.H.; Ahmed, S.; Kar, M. Artificial Intelligence and Machine Learning Applications in the Project Lifecycle of the Construction Industry: A Comprehensive Review. Heliyon 2024, 10, e26888. [Google Scholar] [CrossRef]

- Ghaffar, S.H.; Burman, M.; Braimah, N. Pathways to Circular Construction: An Integrated Management of Construction and Demolition Waste for Resource Recovery. J. Clean. Prod. 2020, 244, 118710. [Google Scholar] [CrossRef]

- Bag, S.; Wood, L.C.; Xu, L.; Dhamija, P.; Kayikci, Y. Big Data Analytics as an Operational Excellence Approach to Enhance Sustainable Supply Chain Performance. Resour. Conserv. Recycl. 2020, 153, 104559. [Google Scholar] [CrossRef]

| Source Title | Total Link Strength | Number of Articles | Avg. Pub. Year | Total Citations | Avg. Citations |

|---|---|---|---|---|---|

| Journal of Management in Engineering | 39 | 2 | 2020 | 253 | 127 |

| Automation in Construction | 13 | 6 | 2022 | 187 | 31 |

| Engineering Construction and Architectural Management | 36 | 8 | 2023 | 150 | 19 |

| International Journal of Production Research | 23 | 2 | 2018 | 104 | 52 |

| Sustainable Cities and Societies | 11 | 2 | 2022 | 67 | 34 |

| Journal of Cleaner Production | 24 | 4 | 2021 | 63 | 59 |

| Sustainability | 76 | 14 | 2022 | 201 | 14 |

| International Journal of Production Research Economics | 15 | 2 | 2019 | 65 | 33 |

| Citations | Centrality | Year | Country |

|---|---|---|---|

| 95 | 0.53 | 2015 | China |

| 17 | 0.4 | 2015 | Australia |

| 10 | 0.1 | 2017 | England |

| 9 | 0.19 | 2016 | USA |

| 6 | 0.14 | 2017 | New Zealand |

| 5 | 0.04 | 2021 | Canada |

| 3 | 0.04 | 2019 | India |

| Year | Title | Author | Centrality | Citations |

|---|---|---|---|---|

| 2019 | Stakeholder-Associated Supply Chain Risks and Their Interactions in a Prefabricated Building Project in Hong Kong | Luo, Lizi [22] | 0.01 | 175 |

| 2015 | Towards Physical Internet-enabled Prefabricated Housing Construction in Hong Kong | Zhong, Ray Y and Xu, Gangyan [21] | 0.01 | 24 |

| 2015 | Bridging BIM and building: From a literature review to an integrated conceptual framework | Huang, George Q [23] | 0.01 | 150 |

| 2017 | Production lead-time hedging and coordination in prefabricated construction supply chain management | Zhai, Yue [24] | 0 | 76 |

| 2020 | A holistic review on life cycle energy of buildings: An analysis from 2009 to 2019 | Li, CZ [25] | 0.01 | 41 |

| 2021 | Spatial spillover effect of carbon emission efficiency in the construction industry of China | Du, Qiang [26] | 0 | 81 |

| Year | Title | Citation | Author | Research Topics | Methods |

|---|---|---|---|---|---|

| 2023 | An overall review of research on prefabricated construction supply chain management | 74 | Han, YH et al. [8] | Overview of the PCSC | Visualization maps and quantitative analysis |

| 2021 | Customization of on-site assembly services by integrating the internet of things and BIM technologies in modular integrated construction | 60 | Zhou JX et al. [38] | On-site assembly services | IOT, enabled smart BIM platform |

| 2018 | An Internet of Things-enabled BIM platform for on-site assembly services in prefabricated construction | 265 | Li CZ et al. [39] | Improve PC efficiently | BIM |

| 2022 | Exploiting digitalization for the coordination of required changes to improve engineer-to-order materials flow management | 20 | Chen, Q et al. [40] | Improve PC efficiently | Integrated management framework through digital data sharing |

| 2021 | Scheduling Optimization of Prefabricated Construction Projects by Genetic Algorithm | 30 | Xie, LL et al. [41] | Improve PC project | Scheduling model and genetic algorithms |

| 2021 | Computer Vision-Based Disruption Management for Prefabricated Building Construction Schedule | 17 | Yan, XZ et al. [42] | Prefabricated building construction schedules | Computer-vision-based |

| Year | Title | Citations | Author | Research Topics | Methods |

|---|---|---|---|---|---|

| 2021 | A blockchain and IoT-based smart product service system for the sustainability of prefabricated housing construction | 126 | Li, CZ et al. [57] | Sustainable prefabricated housing construction SC | IOT, Cyber-Physical System and BIM |

| 2021 | Identification of Critical Factors Influencing Prefabricated Construction Quality and Their Mutual Relationship | 18 | Zhang, K et al. [58] | PC quality and safety | Interpretation structure model-matrix cross-reference multiplication |

| 2023 | A Novel Hybrid Methodology to Study the Risk Management of Prefabricated Building Supply Chains: An Outlook for Sustainability | 15 | Zhu, T et al. [59] | Risk prediction and evaluation of its SCM | BP neural network and machine learning |

| 2023 | Use of composite plaster material for the development of sustainable prefabricated: study of its manufacturing process, properties and supply chain | 4 | Ferrández-Vega, D et al. [60] | Development of new, more sustainable construction materials | Use the FlexSim Simulation Software |

| Year | Title | Citations | Author | Research Topics | Methods |

|---|---|---|---|---|---|

| 2020 | Dynamic transportation planning for prefabricated component supply chain | 44 | Zhang, H; Yu, L [61] | Transportation planning problem | Dynamic optimization model and the PSO algorithm |

| 2016 | A multi-objective GA-based optimisation for holistic manufacturing, transportation and assembly of precast construction | 80 | Anvari B et al. [62] | Manufacturing, transportation | Enetic-algorithm-based |

| 2019 | Risk-averse supply chain for modular construction projects | 70 | Hsu PY et al. [63] | Risk-averse logistics configurations | Mathematical model |

| 2019 | Site logistics planning and control for engineer-to-order prefabricated building systems using BIM 4D modeling | 141 | Bortolini R et al. [64] | Logistics planning and control | BIM 4D model |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Li, H.; Shen, K.; Yang, S. From Profit to Preservation: A Review of Digital Technology Enabling Sustainable Prefabricated Building Supply Chain Management. Buildings 2025, 15, 2004. https://doi.org/10.3390/buildings15122004

Wang Y, Li H, Shen K, Yang S. From Profit to Preservation: A Review of Digital Technology Enabling Sustainable Prefabricated Building Supply Chain Management. Buildings. 2025; 15(12):2004. https://doi.org/10.3390/buildings15122004

Chicago/Turabian StyleWang, Yuelin, Hongyang Li, Kaicheng Shen, and Su Yang. 2025. "From Profit to Preservation: A Review of Digital Technology Enabling Sustainable Prefabricated Building Supply Chain Management" Buildings 15, no. 12: 2004. https://doi.org/10.3390/buildings15122004

APA StyleWang, Y., Li, H., Shen, K., & Yang, S. (2025). From Profit to Preservation: A Review of Digital Technology Enabling Sustainable Prefabricated Building Supply Chain Management. Buildings, 15(12), 2004. https://doi.org/10.3390/buildings15122004