Abstract

Loess, predominantly distributed in arid and semi-arid regions of central and western China, exhibits low shear strength and structural instability, rendering it prone to geological hazards such as landslides and collapses, which pose significant threats to local infrastructure and safety. This study evaluated the urease activity of soybean and sword bean at different temperatures to screen the optimal enzyme source for enzyme-induced carbonate precipitation (EICP). Methods including single EICP, EICP combined with nano-SiO2, and EICP combined with both nano-SiO2 and soil stabilizer (SS) were adopted to enhance the surface strength of loess. The results showed that the EICP technique significantly improved the surface strength of loess, especially with the addition of nano-SiO2 and soil stabilizer. This study confirmed that using sword bean urease treated at −20 °C for 24 h in combination with 1.5% nano-SiO2 was both cost-effective and efficient in reinforcement. The incorporation of 5% soil stabilizer further enhanced the surface strength, and the accuracy was further verified by combining the results of SEM and XRD. Future research will focus on optimizing the material ratio to maximize the improvement of surface strength, providing an economical and feasible solution for rapid loess solidification, and evaluating the long-term durability under cyclic wet and dry conditions.

1. Introduction

Loess is predominantly composed of silt particles (0.05–0.005 mm), forming a “skeleton–pore” open framework structure through cementation by clay minerals, calcium carbonate, and organic matter. Characterized by a high void ratio (typically 0.8–1.5), its structure remains inherently loose and porous. Upon water infiltration, clay minerals swell while soluble salts like calcium carbonate dissolve, diminishing the cementing strength of bonding agents. This degradation disrupts inter-particle connections, ultimately leading to structural collapse. Loess, predominantly found in central and western China, represents a common soil type in northwestern China and various arid and semi-arid regions. Its inherent characteristics of a low shear strength and instability render it susceptible to geological hazards such as landslides and collapses, posing a significant risk to local infrastructure and inhabitants. Consequently, numerous researchers have undertaken extensive investigations into this matter. For instance, Liu et al. [1] investigated the flow instability of intact and reconstituted silty loess from the Loess Plateau of China under undrained monotonic loading through conventional triaxial tests, and Wang et al. [2] examined the critical moisture content that initiates flow failure in silty loess to enhance liquefaction risk management. Establishing the suitable saturation (Sr) criterion is crucial for comprehending the mechanical mechanism behind loess flow failure. Tao et al. [3] utilized Geo-Studio finite element software (2022) to assess the enduring effects of water infiltration on loess slopes. Wang et al. [4] employed dynamic triaxial tests to examine the mechanisms underlying earthquake-triggered loess landslides. Additionally, Zhao et al. [5] scrutinized the distribution density of contact forces and the peak pore throat diameter in air-fall specimens subjected to vertical consolidation pressures through precise 3D digital models and the discrete element method.

Ma et al. [6] investigated the impact of loess saturation, liquefaction, and tunnel structures on seismic intensity, whether amplifying or attenuating it. Li et al. [7] utilized the finite discrete element method to validate the slurry diffusion pattern and examined the diffusion laws by considering factors like the tunnel burial depth, slurry viscosity, and elastic modulus. Liu et al. [8] performed triaxial creep tests to study the stress–strain–time behavior of fissured loess, identifying long-term strength variations and discussing the creep deformation characteristics of fissured loess samples [FLS]. Zhang et al. [9] elucidated the influence of the strain rate [0.005–0.3 mm/min] on the strength envelope, deformation modulus, pore pressure, and shear properties of unsaturated and quasi-saturated loess.

Yang et al. [10] investigated the wetting mechanism of the loess microstructure through the lens of unsaturated soil theory. Zhao et al. [11] examined the seepage–mechanical response and crack evolution characteristics of high-fill loess slopes under the combined effects of consolidation, rainfall, and evaporation. Li et al. [12] focused on the Jing Jiang and Gan Jiang River basins in northwestern China as representative study areas to analyze the spatial variability of soil permeability in loess regions. Li et al. [13] demonstrated that land use types have a significant impact on soil erosion resistance, with varying degrees of influence on different erosion resistance indicators. Meng et al. [14] developed a comprehensive understanding of the geological deformation and failure patterns of loess fill slopes. Zhou et al. [15] employed ring shear tests, image analysis, and numerical simulations to conduct a detailed investigation of the failure behavior of loess at a continuous scale. Dai et al. [16] explored the structural evolution and anisotropic stiffness of saturated and compacted loess under isotropic compression. Consequently, research on reinforcing loess is essential for improving its engineering characteristics and ensuring the safety of infrastructure.

The collapsibility resistance of loess can be achieved through multiple approaches: incorporating fine-grained soils (such as clay), sand, or mineral powders (e.g., fly ash, silica fume) to fill the open framework pores of loess, reduce the void ratio, and form a denser structure. Curing agents like lime and cement have been used to perform hydration reactions with clay minerals in loess, generating cementitious substances such as ettringite and calcium silicate to fill pores and enhance inter-particle bonding. In recent studies, various approaches to reinforcing loess have been investigated. Wang et al. [17] modified loess using lignin, while Zhu et al. [18] demonstrated that the addition of sodium hydroxide effectively increased its shear strength. Wang et al. [19] utilized HPMC (Hydroxy Propyl Methyl Cellulose) to notably improve the strength, stiffness, and ductility of loess, and Chen et al. [20] employed calcium carbonate to enhance the loess structure by augmenting effective bonding areas. Niu et al. [21] observed a significant enhancement in the unconfined compressive strength of CFIL (cement and polypropylene fiber composite improved loess) with an increased polypropylene fiber content. Nonetheless, these methods often entail high costs. Consequently, several scholars [22,23,24,25,26] have turned to EICP (Enzyme-induced calcium carbonate precipitation) for stabilizing and rehabilitating loess to enhance its stability. The urease solution and cementation solution, comprising urea and anhydrous calcium chloride, initially generate unstable ammonia (NH3) and carbamate. Subsequently, carbamate degrades to yield an additional ammonia molecule and carbonic acid (H2CO3), which hydrolyzes to produce bicarbonate, ammonium, and hydroxide ions. These ions then react with bicarbonate to form carbonate ions. In the presence of calcium ions in the solution, carbonate ions will precipitate with calcium ions to form calcium carbonate, solidifying the loess, filling gaps, and enhancing the bonding between particles, thereby increasing the surface strength of the loess. The mechanisms of void filling and particle bonding have also been reported to improve the strength and liquefaction resistance of coarser materials (sand, silty sands), such as when induced by way of colloidal silica stabilization (Triantafyllos et al., 2022) [27].

EICP utilizes urease derived from soybean and sword bean, both of which are more cost-effective compared to previous materials. While existing research predominantly focuses on soybean urease, there are limited comparative analyses of the urease activity between soybean and sword bean, and few explorations of sword bean as a urease source. Additionally, studies on the reinforcement effect of EICP combined with other materials on the surface strength of loess are sparse; for example, Samuel Ng [28] suggested that storing urease at −20 °C not only prolonged its storage life but also notably enhanced the efficacy and efficiency of enzyme-induced carbonate precipitation (EICP) for soil enhancement. Almajed et al. [29] investigated the impact of EICP, along with lime treatments, on two distinct soils with varying mineralogical and plastic characteristics. They assessed the influence of these treatments on the strength and swelling properties of the soils.

EICP utilizes urease derived from soybean and sword bean, both of which are more cost-effective compared to previous materials. While existing research predominantly focuses on soybean urease, there is limited comparative analysis of the urease activity between soybean and sword bean, and scant exploration of sword bean as a urease source. Additionally, studies on the reinforcement effect of EICP combined with other materials on loess surface strength are sparse. This study first compares the urease activity from both sources, identifying sword bean as the superior choice for urease production. Nano-silica (nano-SiO2) consists of nanoscale particles in amorphous or crystalline states, with an abundance of hydroxyl groups (-OH) on the surface that readily form aggregates. Composed primarily of silica (SiO2) at high purity (typically > 99%), it exhibits stable chemical properties and resistance to acid/alkali corrosion. Surface hydroxyl groups form hydrogen bonds with metal ions (e.g., Ca2+, Mg2+) and polar molecules in soil, enhancing adsorption to soil particles. By filling soil pores, refining pore size distribution, reducing permeability, and improving compactness, nano-SiO2’s high specific surface area (100–400 m2/g) adsorbs urease and Ca2+, boosting the contact efficiency between urea hydrolysis products (CO32−) and Ca2+ to accelerate CaCO3 precipitation. And the Ca2+ released by the soil stabilizer (SS) can supplement the calcium source in the EICP system. Subsequently, EICP is combined with nano-SiO2 and SS (soil stabilizer) to consolidate loess, examining three dry densities (1.4, 1.5, 1.6 g/cm3) across four treatment methods: plain soil, EICP alone, EICP with nano-SiO2, and EICP with both nano-SiO2 and SS. The efficacy coefficient method is employed to determine the optimal approach for enhancing the loess surface strength, offering practical applications and guidance for improving the surface strength of loess in high-fill projects.

2. Materials and Methods

2.1. Loess

The Q3 loess samples analyzed in this research were sourced from the high-fill engineering site at Yan’an University in Yan’an City, Shaanxi Province. Characterized by a light gray color, the loess demonstrated an optimal moisture content of 16.7% and a maximum dry density of 1.79 g/cm3. It is predominantly composed of silt particles (0.005–0.075 mm), accounting for 50–70% of the total composition, with clay particles (<0.005 mm) comprising 10–25% and sand particles (>0.075 mm) typically less than 10%. The silt fraction consists mainly of primary minerals like quartz and feldspar, exhibiting a single-grain structure, whereas the clay fraction is dominated by hydrophilic clay minerals such as illite and montmorillonite, falling under the classification of loose silt loam.

2.2. Urease from Soybean and Sword Bean

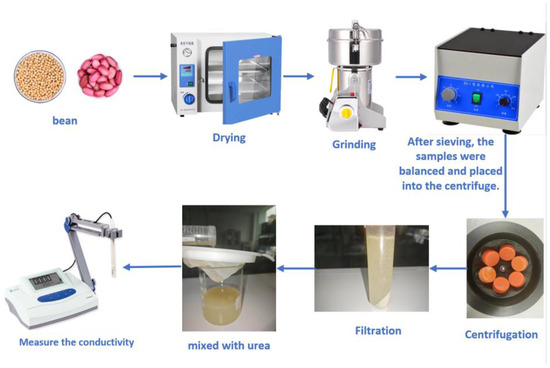

To assess the urease activity of sword bean and soybeans at room temperature and after 24 h of freezing at −20 °C, the following procedures were conducted for urease extraction and activity determination:

- (1)

- The sword bean and soybeans were dried in an oven.

- (2)

- Subsequently, the dried beans were ground into powder using a grinder.

- (3)

- A portion of the powdered samples was sieved through a No 100 sieve (0.15 mm) [30] and then frozen at −20 °C for 24 h.

- (4)

- The powders of soybeans and sword bean, stored at room temperature and frozen at −20 °C for 24 h, were mixed with water to achieve predetermined concentrations.

- (5)

- The mixture was homogenized using a stirring cup and combined with 30 mL of 1.1 mol/L urea solution at a ratio of 1:9.

- (6)

- The electrical conductivity was continuously monitored at 5 min intervals using a conductivity meter with a resolution of 1 μS/cm and an accuracy of ±0.5% to ±2% of the reading. The meter was calibrated via multi-point calibration using (a) a near-zero standard solution and (b) standard solutions close to the expected measurement values, and the urease activity was determined using the following formula [31]:

In the formula, U represents the urease solution activity (U, where 1 U = 1 μmol of urea hydrolyzed per minute), E is the solution’s conductivity (mS/cm), t is the time (min), and m is the dilution factor of the urease solution.

2.3. Activity Test

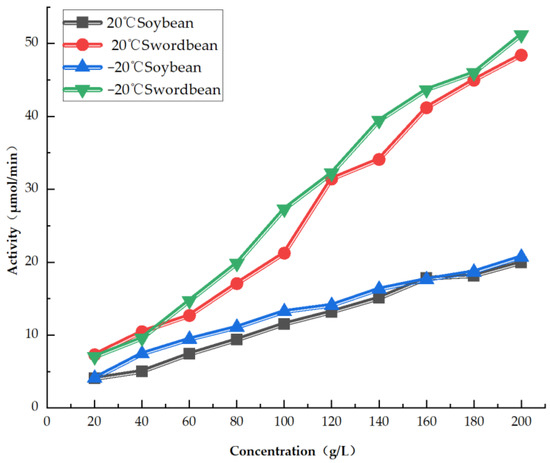

The experiment investigated the variation in urease activity between soybean and sword bean extracts at different concentrations and temperatures. Various groups of bean powder solutions were prepared with concentrations ranging from 20 g/L to 200 g/L. The urease activity in sword bean and soybean was assessed at room temperature and following 24 h of freezing at −20 °C using established methods for urease extraction and activity quantification (Figure 1) [32]:

Figure 1.

Activity test.

2.4. Surface Strength Determination

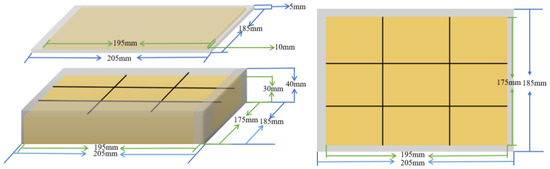

Samples were fabricated using acrylic molds measuring 205 × 185 × 40 mm3. To maintain precise internal geometry and a consistent dry density, a 195 × 175 × 10 mm3 compact plate was placed atop the mold, yielding a final sample size of 195 × 175 × 30 mm3 (Figure 2). Three target dry densities (1.4, 1.5, and 1.6 g/cm3), labeled A, B, and C, respectively, were systematically tested across four material formulations: natural loess (1), loess treated with enzyme-induced calcite precipitation (EICP) (2), EICP with 1.5% nano-SiO2 (3), and EICP with 1.5% nano-SiO2 and 5% soil stabilizer (4). For instance, natural loess with a dry density of 1.4 g/cm3 is denoted as A1.

Figure 2.

Sample size control and area division.

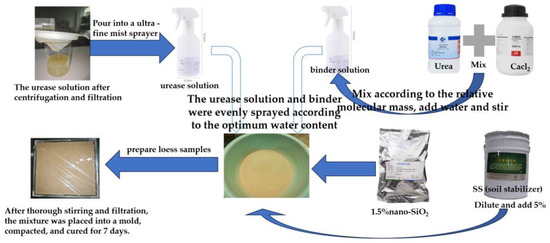

The loess samples were prepared using a premixing technique [33] to mitigate the swift reaction between the urease solution and cementing solution (comprising urea and anhydrous calcium chloride). The refined protocol entails:

- (1)

- Dispensing filtered urease solution and cementing solution into an ultrafine mist sprayer;

- (2)

- Evenly spraying the amalgamated solution onto loess powder (pre-sifted through a 2 mm mesh) in a mixing basin at the optimal moisture content of 16.7%;

- (3)

- Thoroughly blending the mixture via mechanical stirring;

- (4)

- Sifting the treated loess through a 2 mm mesh to eliminate clumped aggregates;

- (5)

- Compacting the prepared blend into molds using a compaction plate. Detailed methodologies and procedures are delineated in Figure 3.

Figure 3. Prepare experimental loess samples.

Figure 3. Prepare experimental loess samples.

The subsequent addition of nano-SiO2 and soil stabilizer followed the same procedure.

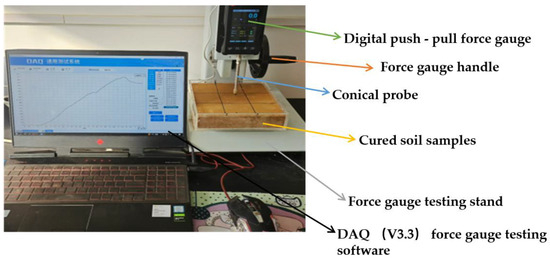

After 7 days of curing at room temperature, the surface strength of the loess was assessed using a digital push–pull force gauge (Figure 4) with a conical probe (20 mm length, 10 mm diameter). The testing involved dividing each sample surface into nine regions, followed by inserting the probe into these regions at a constant speed of 2 mm/s by rotating the force gauge’s handle to record the penetration force in each region. Subsequently, the average penetration force was determined for the top, middle, and bottom sections of each sample to ascertain the peak penetration force at different positions and times. The penetration strength, calculated as the ratio of penetration force to the base area of the cone, was then computed to derive the penetration strength and peak penetration strength (surface strength) at each time point.

Figure 4.

Schematic diagram of experimental loading.

3. Results and Discussion

3.1. Urease Activity Comparison

The measured urease activities under various conditions are shown in Figure 5.

Figure 5.

Urease activity.

- 1.

- Comparing the urease activity in soybean and sword bean across various concentrations reveals distinct patterns. At 20 g/L, the activity difference was 0.03 μmol/min, favoring soybean. This difference peaked at 2.40 μmol/min at 120 g/L. By 160 g/L, soybean’s urease surpassed sword bean by 0.17 μmol/min. Between 160 g/L and 200 g/L, sword bean exhibited higher activity, with differences remaining under 1 μmol/min. For samples stored at −20 °C, soybean showed higher activity at 20 g/L, with differences under 1 μmol/min. However, from 60 g/L to 200 g/L, sword bean’s activity exceeded soybean’s, peaking at a 7.78 μmol/min difference at 120 g/L, highlighting sword bean’s increasing activity with concentration.

- 2.

- At a constant soybean concentration, differences in the urease activity between 20 °C and −20 °C expanded from 20 g/L to 200 g/L, with a peak difference of 28.48 μmol/min. Similarly, the disparity in urease activity between these temperatures increased, peaking at 30.48 μmol/min at 200 g/L. Lower temperatures enhanced urease activity.

- 3.

- As the concentration increased, urease activity also rose. At 100 g/L, sword bean exhibited higher urease activity than soybean. Given their comparable market prices and the enhanced activity following freezing at −20 °C for 24 h, the 100 g/L urease, frozen under these conditions, was chosen for this study based on economic considerations, experimental design, and prior experience [34,35].

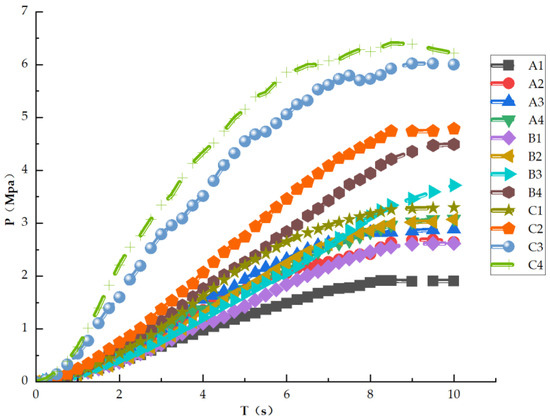

3.2. Analysis of Penetration Intensity Variation with Time

Figure 6 illustrates distinct penetration strength development patterns across varying dry densities and treatment methods. Untreated loess samples, irrespective of the dry density, exhibit a gradual increase in penetration strength before stabilizing. For EICP-treated samples, those with dry densities of 1.4 g/cm3 and 1.5 g/cm3 display a similar pattern of slow growth stabilization, albeit with minor fluctuations prior to stabilization. In contrast, samples treated with EICP combined with nano-SiO2 and those further enhanced with soil stabilizer show significant fluctuations. Specifically, samples with a dry density of 1.4 g/cm3 maintain stable growth, while those with densities of 1.5 g/cm3 and 1.6 g/cm3 undergo considerable fluctuations during consolidation before stabilizing.

Figure 6.

Penetration intensity changes with time.

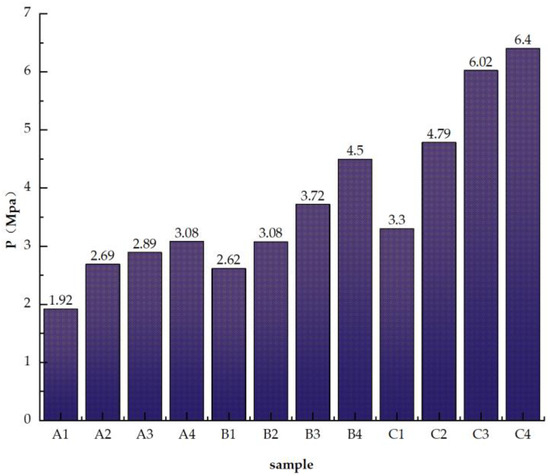

Table 1 and Figure 7 show that the soil dry density markedly influences the penetration strength and growth rate. The data reveal that increasing the dry density from 1.4 g/cm3 to 1.6 g/cm3 leads to a positive increase in the intensities of S2s (strength of digital push–pull dynamometer when the push–pull dynamometer penetrates soil for 2 s), S5s (strength of digital push–pull dynamometer when the push–pull dynamometer penetrates soil for 5 s), and S10s (strength of digital push–pull dynamometer when the push–pull dynamometer penetrates soil for 10 s) across all treated soil samples. Specifically, the S2s strength of plain soil rises by 38.5% (from 0.39 to 0.54 MPa), and the S10s strength increases by 72.8% (from 1.91 to 3.30 MPa). Soils treated with EICP, EICP + SiO2, and EICP + SiO2 + SS exhibit more pronounced improvements, particularly with the addition of EICP + SiO2 + SS, which elevates the S10s strength to 6.40 MPa at 1.6 g/cm3. This represents a 107.8% increase from 3.08 MPa at 1.4 g/cm3, indicating that soils with a higher dry density are significantly more responsive to additives.

Table 1.

Comparison of penetration strength development parameters of each group of samples.

Figure 7.

Comparison of surface strength of each group.

Increasing the dry density of soil samples treated with EICP + SiO2 and EICP + SiO2 + SS from 1.4 g/cm3 to 1.6 g/cm3 increases the β value from 0.46 MPa/s and 0.41 MPa/s to 0.98 MPa/s, respectively. This corresponds to an increase rate of 139% and 113%, indicating that the strength development rate per unit time is more than double. This demonstrates the fundamental role of dry density in enhancing the development of soil strength.

The intensity of S2s → S5s → S10s in soil samples, solidified through various treatment methods, consistently increased. For example, with EICP treatment at a density of 1.5 g/cm3, the strength progression of 0.38 → 1.75 → 3.08 MPa exhibits a typical three-stage growth. Notably, the strength increase of 1.33 MPa from S5s to S10s accounts for 97% of the 1.37 MPa increase from S2s to S5s, demonstrating significantly enhanced strength development at later stages with a high dry density.

The analysis of surface strength variations among different additive groups revealed distinct strengthening effects across varying dry density categories. The EICP treatment enhanced the strength of groups B and C by 17.6% (from 2.62 to 3.08 MPa) and 45.2% (from 3.30 to 4.79 MPa), respectively. Nano SiO2 yielded the highest strength increase in group C, elevating the post-treatment strength to 6.02 MPa, a 25.7% improvement over EICP treatment alone. The addition of soil stabilizer further increased the peak strength of C4 to 6.40 MPa. Under a dry density of 1.6 g/cm3, the S10 strength of EICP combined with SiO2 and SS reached 194%, and with SiO2 alone, the strength was 182% that of untreated soil, highlighting the advantages of composite treatment technology and the impact of additive efficiency and the dry density on performance.

3.3. Analysis of Influence Factors on Surface Strength by Efficacy Coefficient Method

Table 2 illustrates how various dry densities and additives yield distinct strategies for enhancing the surface strength of loess. The efficacy coefficient method, a mathematical approach rooted in multi-objective programming, is employed to identify the optimal strategy. In this study, the average intensity, intensity growth rate, and maximum intensity serve as evaluation indices d1, d2, and d3. This method synthesizes these indicators to evaluate their collective effect and ascertain the best option.

Table 2.

Efficacy coefficient calculation table of EICP-treated loess with additives.

The efficacy coefficient method assigns an efficacy coefficient of 1 to the index with the highest evaluation value, while other indices receive a coefficient calculated as the ratio of their evaluation value to the highest index value. The calculation method [36] for the total efficacy system D is , where D represents the overall assessment index. A larger D indicates greater influence and a more favorable scheme. According to the table analysis, although group C3 and group C4 have the same d2 efficacy coefficient, group C4 achieves the highest total efficacy coefficient (D = 1) when the dry density is 1.6 g/cm3, with the addition of nano-SiO2 and soil stabilizer to EICP. Therefore, the optimal scheme involves incorporating nano-SiO2 and a soil stabilizer into EICP at a dry density of 1.6 g/cm3.

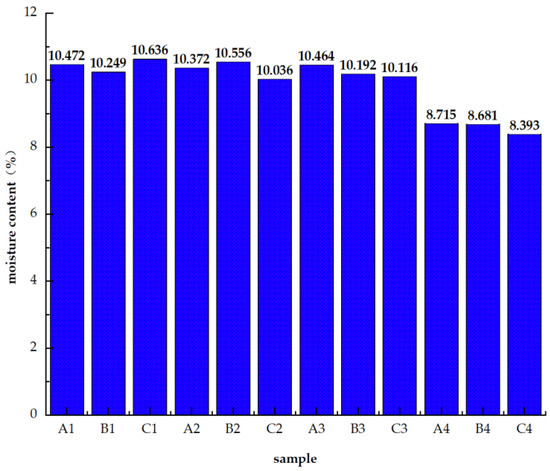

Soil stabilizer effectively enhances the surface strength of loess, likely by reducing the water content (the soil stabilizer undergoes a hydration reaction with the moisture in the soil, consuming part of the free water and thus reducing the water content). To assess this, the moisture content of nine regions per sample was measured and averaged (Figure 8). The results indicate that samples with soil stabilizer exhibited a water content 1.321% to 2.243% lower than those without.

Figure 8.

Moisture content.

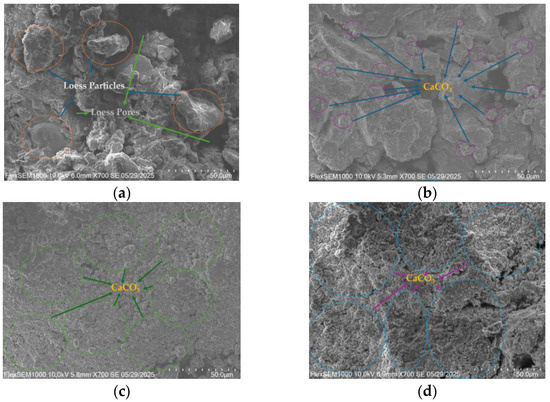

3.4. Microstructural Analysis by Scanning Electron Microscopy (SEM)

Figure 9 presents SEM images at 700× magnification, where “Loess Particles” denote the large grains within the soil matrix, and “Loess Pores” represent the voids characteristic of loess. In Figure 9a, the inter-particle connections appear weak, with the pronounced development of both macroscopic pores and micro-cracks, indicating a loose soil structure.

Figure 9.

Microstructures of various samples. (a) Loess. (b) EICP. (c) EICP + SiO2. (d) EICP + SiO2 + SS.

A comparative analysis of Figure 9b–d reveals a progressive improvement: EICP treatment initiates the formation of calcium carbonate (CaCO3) precipitates, effectively filling the inter-particle pores. With the addition of nano-SiO2, the yield of CaCO3 significantly increases, leading to a gradual reduction in pore size. Notably, when SS is incorporated, CaCO3 precipitates extensively coat both the pore surfaces and the outer layer of loess particles. The adhesive property of calcium carbonate promotes particle cementation, thereby enhancing the surface strength of the loess matrix. This sequential enhancement demonstrates the synergistic effect of EICP, nano-SiO2, and SS in stabilizing the loess microstructure.

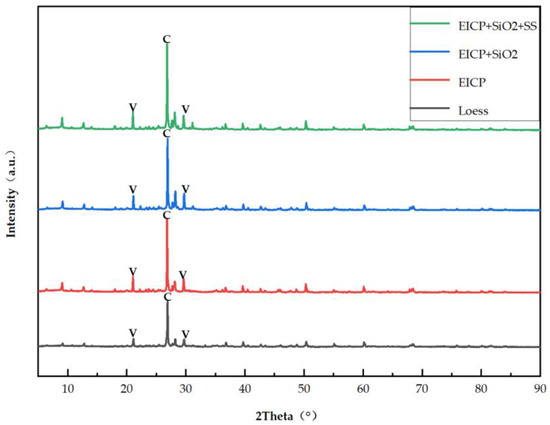

3.5. Compositional Analysis by X-Ray Diffraction (XRD)

In Figure 10, “C” and “V” denote the diffraction peaks corresponding to the mineral components of the specimens, where “C” represents calcite and “V” represents vaterite. As shown, calcite diffraction peaks are primarily distributed between 26 and 28°, while vaterite characteristic peaks concentrate in the ranges of 20–22° and 29–30°. An analysis of the XRD patterns reveals:

Figure 10.

XRD patterns and analysis results.

Single EICP addition leads to a slight increase in the diffraction peak intensity of both calcite and vaterite.

The incorporation of nano-SiO2 into EICP significantly enhances the relative content of both minerals.

The combined addition of EICP, nano-SiO2, and SS results in the maximum content of calcite and vaterite, indicating a synergistic promotion effect of nano-SiO2 and SS on the EICP reaction. Notably, SS demonstrates a more pronounced promoting effect, inducing a significantly higher amount of CaCO3 precipitation than the single EICP system. This enhanced carbonate precipitation effectively fills the loess pores, thereby improving the compressive strength of the specimens, which forms a good mutual verification with the previous SEM microstructural observations.

4. Conclusions

The soybean urease and concanavalin urease used commonly in the enzyme-induced carbonate precipitation method (EICP) were compared in the solidification of loess. Concanavalin urease was added to nano-SiO2 and soil fixative for EICP. The surface strength of loess samples cured at room temperature for 7 days was measured with a digital push–pull tester and cone probe. The parameters were a penetration strength–time curve, the surface strength value of each sample and a comparison curve. The moisture content of the specimens after 7 days of curing at room temperature was measured, and SEM and XRD analyses were performed to determine the structure and composition of the samples:

- 1.

- While soybean and sword bean prices are comparable, their urease activities vary substantially, particularly after being frozen at −20 °C for 24 h, with sword bean demonstrating superior activity. Considering the economic costs, experimental design, and previous experience, sword bean urease at 100 g/L, frozen at −20 °C for 24 h, was chosen as the EICP raw material for this study.

- 2.

- The penetration strength curves demonstrate that the superior performance of the composite system stems from the synergistic interplay among enzyme-induced carbonate precipitation, the nano-SiO2 enhancement effect, and soil stabilizer. This synergy markedly enhances the structural stability of loess, improves its engineering mechanical properties, and enhances its soil-bearing capacity through diverse mechanisms.

- 3.

- The surface strength analysis reveals a significant enhancement in the strength of loess with the application of EICP. Supplementation with a small quantity of nano-SiO2 can yield further improvements in a cost-effective manner. Thus, the synergistic utilization of EICP and nano-SiO2 proves advantageous for reinforcing loess. The rate of strength enhancement when EICP is combined with nano-SiO2 matches that achieved by incorporating an extra curing agent. The choice of employing a supplementary curing agent can be made selectively based on the specific construction requirements to optimize cost-effectiveness.

- 4.

- SEM and XRD show that nano-SiO2 and SS enhance the generation of CaCO3 through enzyme-induced carbonate precipitation (EICP) and seal pores in loess. This is consistent with surface strength tests and confirms that nano-SiO2 and SS enhance EICP collaboratively.

Author Contributions

Conceptualization: X.W. and B.W.; Methodology: X.W. and Y.Y.; Software: G.D.; Validation: Y.Y. and T.Y.; Formal analysis: T.Y.; Investigation: B.W. and C.S.; Resources: Y.Y.; Data curation: X.W. and G.D.; Writing—original draft preparation: B.W.; Writing—review and editing: X.W.; Visualization: C.S. and G.D.; Supervision: X.W. and Y.Y.; Project administration: B.W.; Funding acquisition: Y.Y. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Youth Program of the National Natural Science Foundation of China (sponsored by the National Natural Science Foundation of China, Grant No. 52408393), the Key Research and Development Program of Shaanxi Province (sponsored by the Shaanxi Provincial Department of Science and Technology, 2024SF-YBXM-624), and the Scientific Research and Development Project of the Department of Housing and Urban-Rural Development of Shaanxi Province (sponsored by the Department of Housing and Urban-Rural Development of Shaanxi Province, 2023-K46).

Data Availability Statement

The original data supporting the conclusion of this paper will be provided by the authors as needed.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Liu, F.; Xu, Q.; Zhang, Y.; Frost, J.D.; Zhang, X. State-dependent flow instability of a silty loess. Géotech. Lett. 2019, 9, 22–27. [Google Scholar] [CrossRef]

- Wang, J.; Liu, W.; Lin, G. Saturation effects on the undrained shear behavior of loess: Application to static liquefaction. Nat. Hazards 2025, 1–22. [Google Scholar] [CrossRef]

- Tao, H.; Wang, Y.; Zhao, Y.; Li, J. Study on the cumulative effect of drip irrigation on the stability of loess slopes. Geomat. Nat. Hazards Risk 2024, 16, 2434612. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, T.; Liu, K.; Zhou, B. Mechanism of seismic-collapsed loess landslides induced by the Ms6.2 earthquake in Jishishan County, Gansu Province, China. Geomat. Nat. Hazards Risk 2025, 16, 2457997. [Google Scholar] [CrossRef]

- Zhao, Y.; Xu, L.; Qin, C.; Huang, X.; Wu, Y. Tracking the evolution of loess microstructure using micro-CT 3D reconstruction based on a soil-particle-aware model. Comput. Geotech. 2025, 182, 107176. [Google Scholar] [CrossRef]

- Ma, W.; Wang, L.; Chen, W.; Wang, P.; Pu, X. Investigation of the liquefying characteristics of saturated loess surrounding tunnels under seismic loading based on large-scale shaking table tests. Tunn. Undergr. Space Technol. 2025, 159, 106465. [Google Scholar] [CrossRef]

- Li, S.; Ye, F.; Zhang, C.; Yang, Y.; Xia, T.; Jiang, Y.; Han, X. Diffusion law and diffusion model for backfill grouting in loess shield tunnel at different soil moisture. Undergr. Space 2025, 21, 313–330. [Google Scholar] [CrossRef]

- Liu, K.; Wang, X.; Zhan, H.; Lian, B.; Xue, C.; Hu, S.; Wang, D.; Gu, C. An experimental study of creep characteristics of fissured loess based on triaxial tests. CATENA 2025, 250, 108768. [Google Scholar] [CrossRef]

- Zhang, T.; Li, S.; Lan, H.; Zhang, H.; Zhang, F. Influences of strain rate on mechanical behaviors of unsaturated and quasi-saturated loess under varying drainage conditions. J. Rock Mech. Geotech. Eng. 2025, 17, 1163–1181. [Google Scholar] [CrossRef]

- Yang, R.; Gan, L.; Liuxin Wang, Z.; Chen, Q. Micro-mechanism and permeability of wetting of unsaturated loesses. Chem. Technol. Fuels Oils 2025, 60, 1653–1667. [Google Scholar] [CrossRef]

- Zhao, Z.; Zhu, Y.; Ye, S. Experimental study on the failure characteristics of the loess high slope under the coupled effects of soil Consolidation, Rainfall, and evaporation. Eng. Fail. Anal. 2025, 171, 109383. [Google Scholar] [CrossRef]

- Li, J.; Wu, J.; Li, P.; Zhang, L.; Liu, Y. Spatial variability of soil permeability in a loess-covered area, China and its influencing factors. Geosci. J. 2025, 29, 116–133. [Google Scholar] [CrossRef]

- Li, J.; Liu, S.; Yang, D.; Suo, F.; Yu, Y.; Wang, Z.; Liao, Q. The impact of land use types on the soil erosion resistance in the arid valley region of Southwest China. Agriculture 2025, 15, 386. [Google Scholar] [CrossRef]

- Meng, S.; Lv, D.; Liu, R.; Yu, M.; Zhang, J. The formation mechanism of geological disasters on loess fill slopes revealed by the deformation characteristics of remolded loess under different stress paths. Front. Earth Sci. 2025, 12, 1512248. [Google Scholar] [CrossRef]

- Zhou, B.; Li, X.-A. Particle breakage behavior of silty loess: Insights based on experimental tests, image analysis, and numerical simulation. Eng. Geol. 2025, 346, 107904. [Google Scholar] [CrossRef]

- Dai, B.-L.; Zhou, C.; Mu, Q.-Y.; Peng, J.-B. Evolution of structure and anisotropic shear stiffness of compacted loess during compression. Can. Geotech. J. 2025, 62, 1–13. [Google Scholar] [CrossRef]

- Wang, Z.; Bai, Z.; Lu, W.; Wu, X.; Yin, Y.; Li, D. Experimental study on the dynamic response of lignin-modified loess under traffic vibration and seepage wetting. Case Stud. Constr. Mater. 2025, 22, e04419. [Google Scholar] [CrossRef]

- Zhu, G.; Zhang, Y.; Zhang, Y.; Wu, M.; Zhang, J.; Wang, Z.; Fan, D.; Chen, J. Study on the mechanical properties of sodium hydroxide activated steel slag for loess improvement. Mater. Lett. 2025, 385, 138179. [Google Scholar] [CrossRef]

- Wang, X.; Sun, H. Effect of hydroxypropyl methylcellulose (HPMC) modified microbial induced carbonate precipitation on strength and water stability of loess. Bull. Eng. Geol. Environ. 2025, 84, 183. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, R.; Zi, J.; Wang, L.; Liu, H. Evaluation of the treatment variables on the shear strength of loess treated by microbial induced carbonate precipitation. J. Mt. Sci. 2025, 22, 1075–1086. [Google Scholar] [CrossRef]

- Niu, Y.; Li, Q.; Wang, X.; Cheng, Y.; Zhang, Y.; Li, T. Study on mechanical properties and constitutive model of cement and polypropylene fiber improved loess considering freeze-thaw cycles. Constr. Build. Mater. 2025, 462, 140011. [Google Scholar] [CrossRef]

- Gao, J.; Wang, J.; Zhang, D.; Wang, F.; Qi, L. Enzyme-Induced Calcium Carbonate Precipitation Treated Loess Fly Ash-Based Geopolymer for Airport Slope Stabilization: Evaluation of Wetting Deformation and Vibratory Disintegration. Case Stud. Constr. Mater. 2025, 22, e04345. [Google Scholar] [CrossRef]

- Bian, Z.-W.; Cheng, W.-C.; Xie, Y.-X.; Rahman, M.M.; He, W. Nano-hydroxyapatite-assisted enzyme-induced carbonate precipitation enhances Pb-contaminated aqueous solution and loess remediation. Front. Bioeng. Biotechnol. 2024, 12, 1410203. [Google Scholar] [CrossRef]

- Wang, L.; Cheng, W.-C.; Xue, Z.-F.; Xie, Y.-X.; Lv, X.-J. Feasibility study of applying electrokinetic technology coupled with enzyme-induced carbonate precipitation treatment to Cu- and Pb-contaminated loess remediation. J. Clean. Prod. 2023, 401, 136734. [Google Scholar] [CrossRef]

- Shen, D.; Liu, Z.; Song, Z.; Wu, C. Reinforcement Mechanism and Erosion Resistance of Loess Slope Using Enzyme Induced Calcite Precipitation Technique. Sustainability 2023, 15, 1044. [Google Scholar] [CrossRef]

- Chen, Y.; Chai, S.; Cai, D.; Wang, W.; Li, X.; Liu, J. Experimental study on shear mechanical properties of improved loess based on rubber particle incorporation and EICP technology. Front. Earth Sci. 2023, 11, 1270102. [Google Scholar] [CrossRef]

- Triantafyllos, P.K.; Georgiannou, V.N.; Pavlopoulou, E.M.; Dafalias, Y.F. Strength and dilatancy of sand before and after stabilisation with colloidal-silica gel. Géotechnique 2022, 72, 471–485. [Google Scholar] [CrossRef]

- Ng, S.; Chu, J. Frozen enzyme EICP method for more effective soil improvement. Acta Geotech. 2024, 19, 7117–7124. [Google Scholar] [CrossRef]

- Almajed, A.; Moghal, A.A.B.; Mohammed, S.A.S.; Nuruddin, M. Comparative Studies on the Strength and Swell Characteristics of Cohesive Soils Using Lime and Modified Enzyme-Induced Calcite Precipitation Technique. Buildings 2024, 14, 909. [Google Scholar] [CrossRef]

- Roksana, K.; Hewage, S.A.; Lomboy, M.M.; Tang, C.; Xue, W.; Zhu, C. Desiccation cracking remediation through enzyme induced calcite precipitation in fine-grained soils under wetting drying cycles. Biogeotechnics 2023, 1, 100049. [Google Scholar] [CrossRef]

- Whiffin, V.S. Microbial CaCO3 Precipitation for the Production of Biocement. Ph.D. Thesis, Murdoch University, Perth, Australia, 2004. [Google Scholar]

- Zhang, J.; Yin, Y.; Shi, W.; Song, D.; Yu, L.; Shi, L.; Han, Z. Experimental study on the calcium carbonate production rates and crystal size of EICP under multi-factor coupling. Case Stud. Constr. Mater. 2023, 18, e01802. [Google Scholar] [CrossRef]

- Shuang, S.; Yan, B.; Meng, H.; Bian, X. Comparative study of EICP treatment methods on the mechanical properties of sandy soil. Soils Found. 2022, 62, 101246. [Google Scholar] [CrossRef]

- Xu, K.; Huang, M.; Zhen, J.; Xu, C.; Cui, M. Field implementation of enzyme-induced carbonate precipitation technology for reinforcing a bedding layer beneath an underground cable duct. J. Rock Mech. Geotech. Eng. 2023, 15, 1011–1022. [Google Scholar] [CrossRef]

- Huang, M.; Xu, K.; Liu, Z.; Xu, C.; Cui, M. Effect of drying-wetting cycles on pore characteristics and mechanical properties of enzyme-induced carbonate precipitation-reinforced sea sand. J. Rock Mech. Geotech. Eng. 2024, 16, 291–302. [Google Scholar] [CrossRef]

- Deng, J.-X.; Li, X.; Li, X.-J.; Wei, T.-B. Analysis of the performance of recycled insulation concrete and optimal mix ratio design based on orthogonal testing. Materials 2023, 16, 5688. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).