Research on the Bending Behavior of Concrete Beams Reinforced with CFRP Sheets Bonded Using BMSC

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. BMSC

2.1.2. Concrete

2.1.3. Cement Mortar

2.1.4. Reinforcements

2.1.5. FRP Sheet

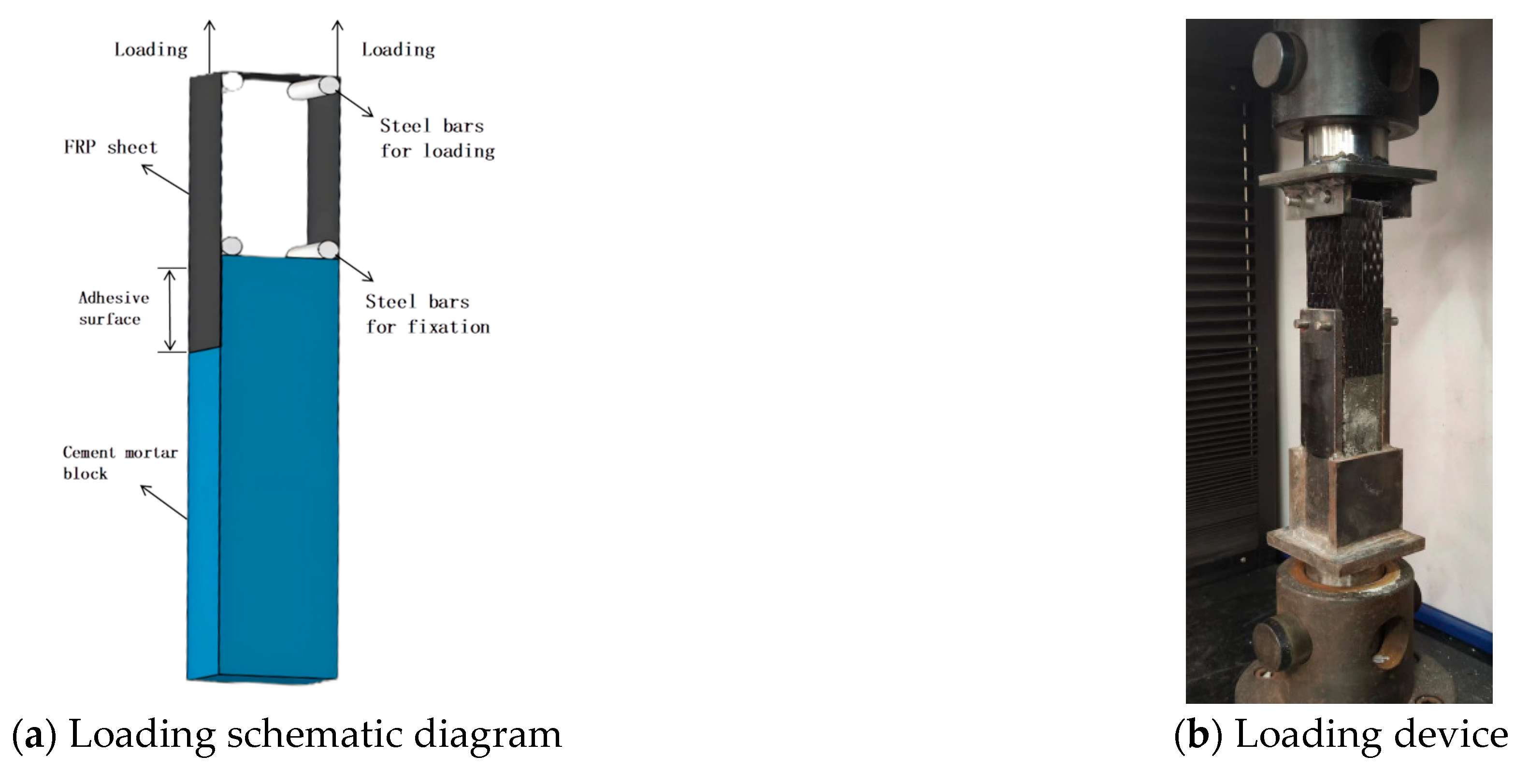

2.2. Double-Shear Test Method for Interfacial Bonding Performance

2.3. Bending Test Method for Concrete Beams Reinforced with FRP Sheets

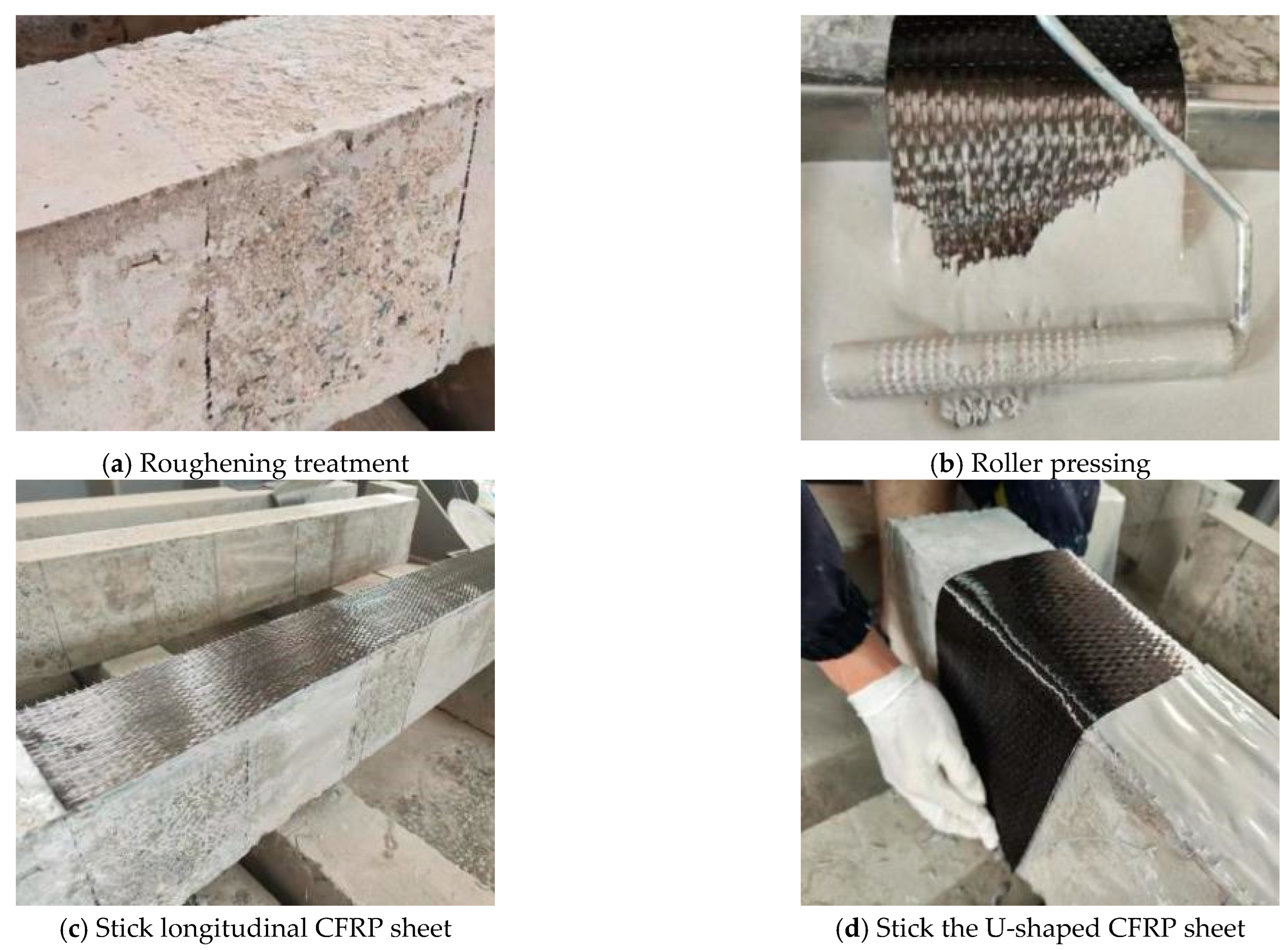

2.3.1. The Construction Process of Adhering FRP Sheets to the Test Beam

- (1)

- According to the set FRP sheet bonding area, grind off the floating slurry on the surface of the beam, and use a chiseling hammer to roughen the corresponding positions on the surface of the test beam to increase the surface roughness of the beam body and enhance the adhesion between the BMSC and concrete. Then rinse thoroughly with clean water.

- (2)

- Pour the prepared BMSC into the container, spread the cut CFRP sheet flat, immerse it in the BMSC, and repeatedly roll the CFRP sheet with a roller to ensure that the BMCS is fully impregnated into the interior of the CFRP sheet before bonding.

- (3)

- First, apply a layer of BMSC as a base adhesive in the treated CFRP sheet bonding area to prevent the dry concrete surface from absorbing moisture from the BMSC and affecting the bonding performance. The soaked FRP sheet is then attached to the surface of the test beam, and a roller is repeatedly rolled on the surface of the CFRP sheet to ensure that the CFRP sheets are fully bonded to the surface concrete of the test beam. U-shaped hoops are stuck to the corresponding positions on the side of the test beam, and finally a layer of BMSC surface adhesive is applied on the surface of the CFRP sheet as a protective layer.

- (4)

- After the BMSC surface adhesive has initially set, cover the CFRP sheet surface with plastic film and water it for curing at room temperature to keep the beam moist. After 14 days, conduct the bending test on the test beam.

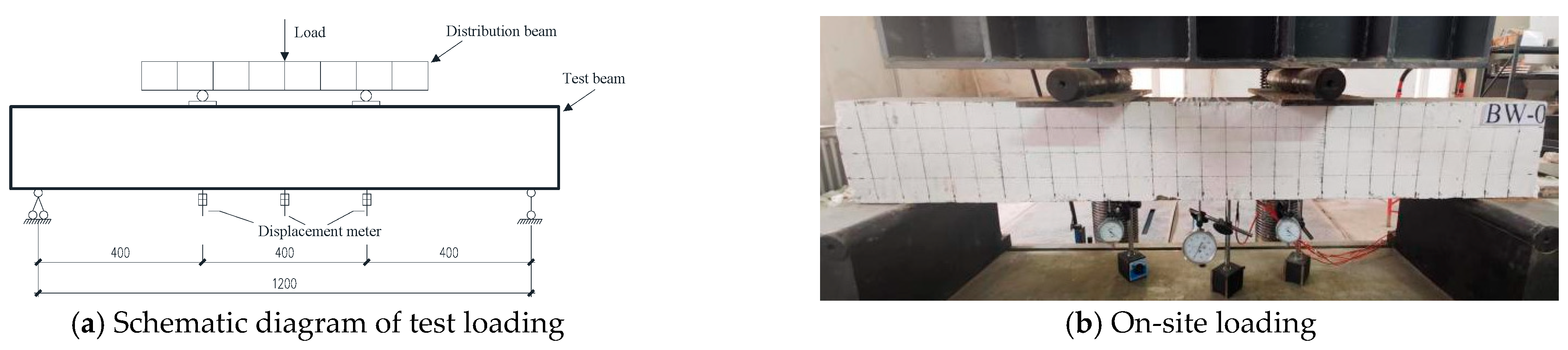

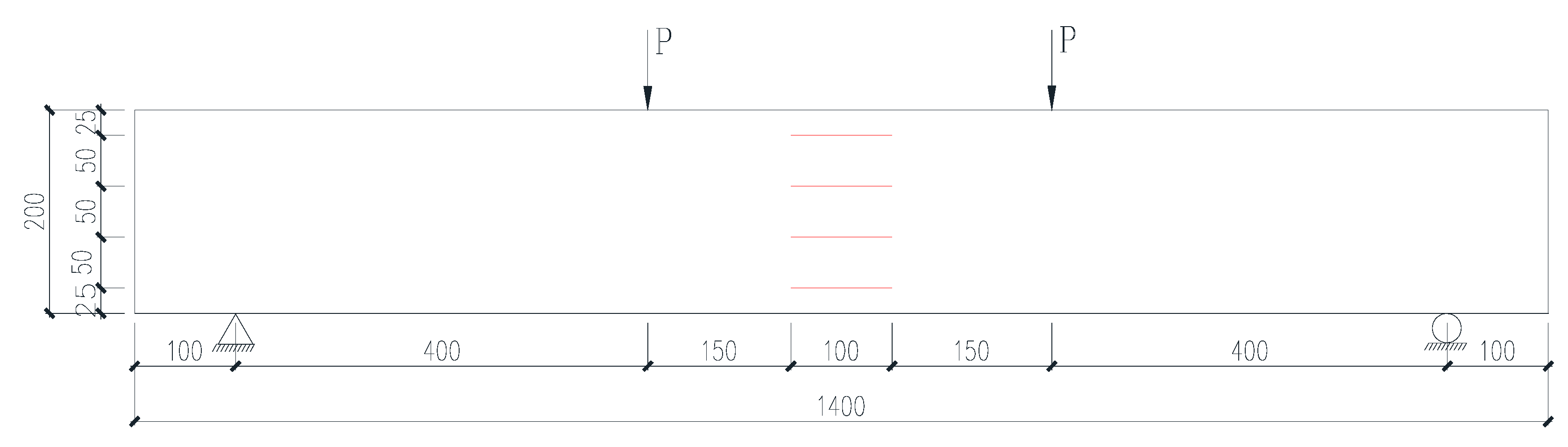

2.3.2. Test Beam Loading Method

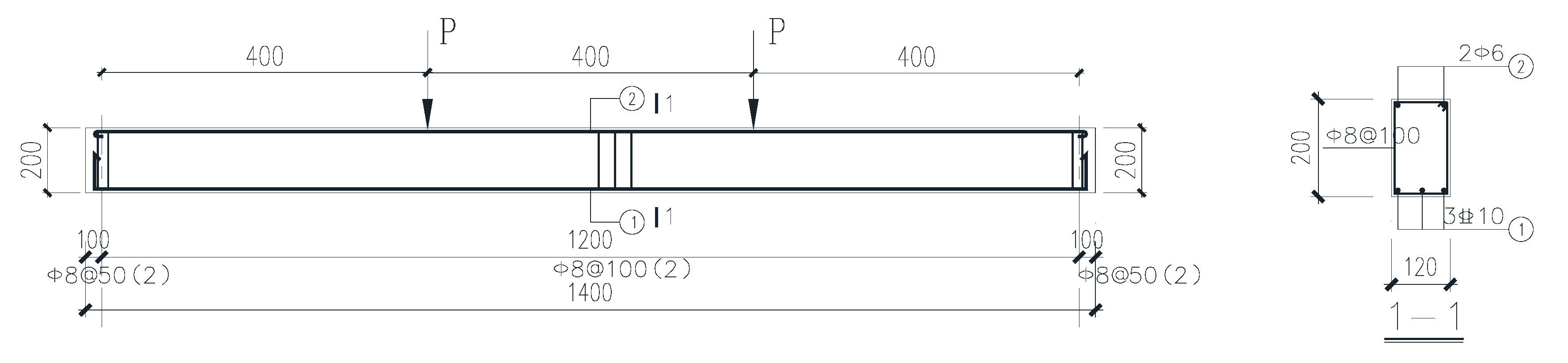

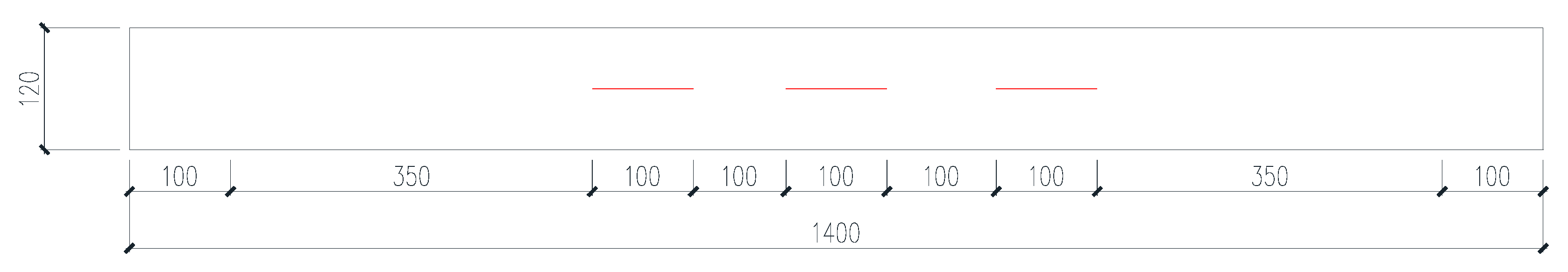

2.4. Test Beam Parameters

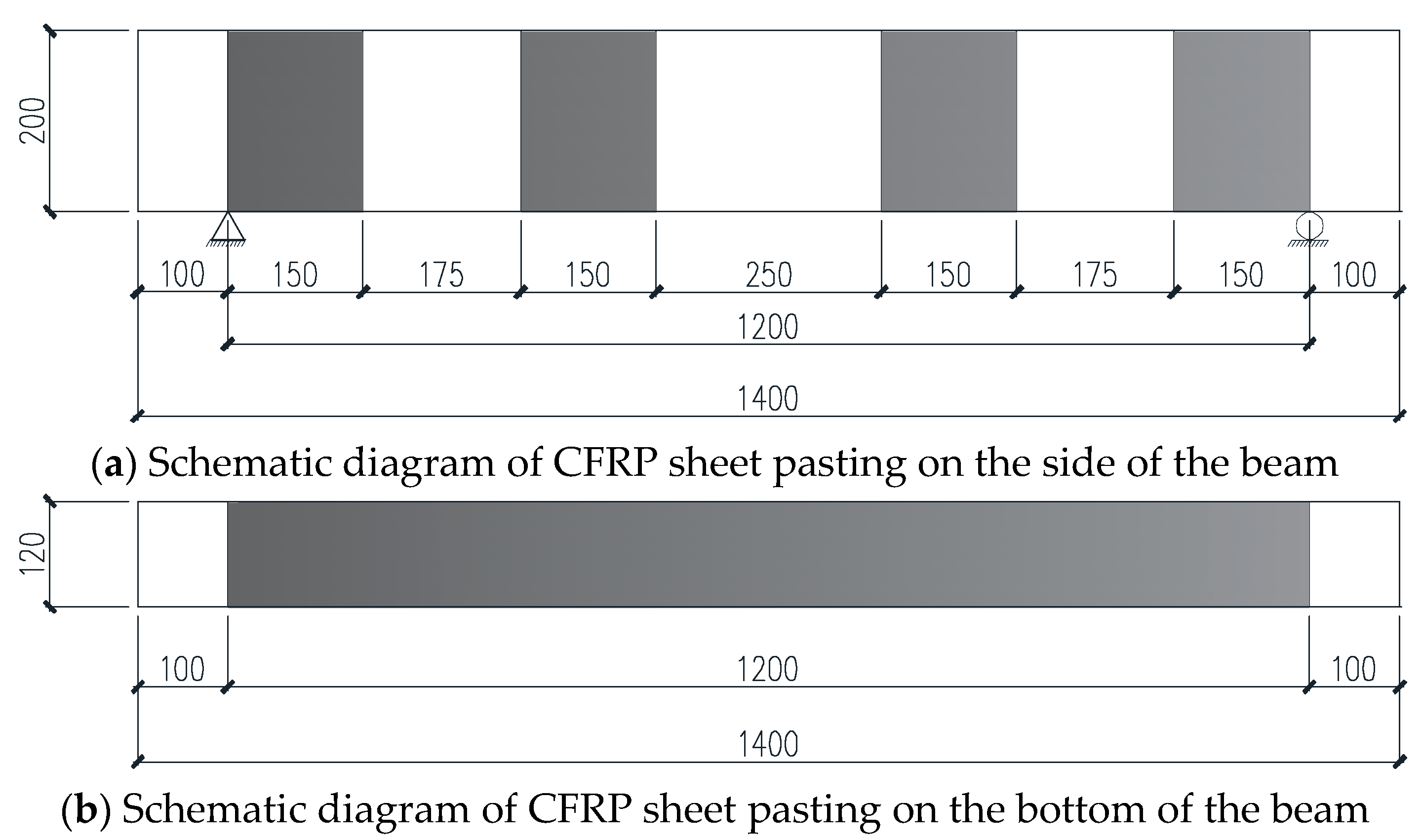

2.5. The Position for Pasting the CFRP Sheet

2.6. Test Data Collection

2.6.1. Concrete Strain

2.6.2. Beam Deflection

2.6.3. CFRP Sheet Strain

2.6.4. Observation of Cracks

3. Results and Discussions

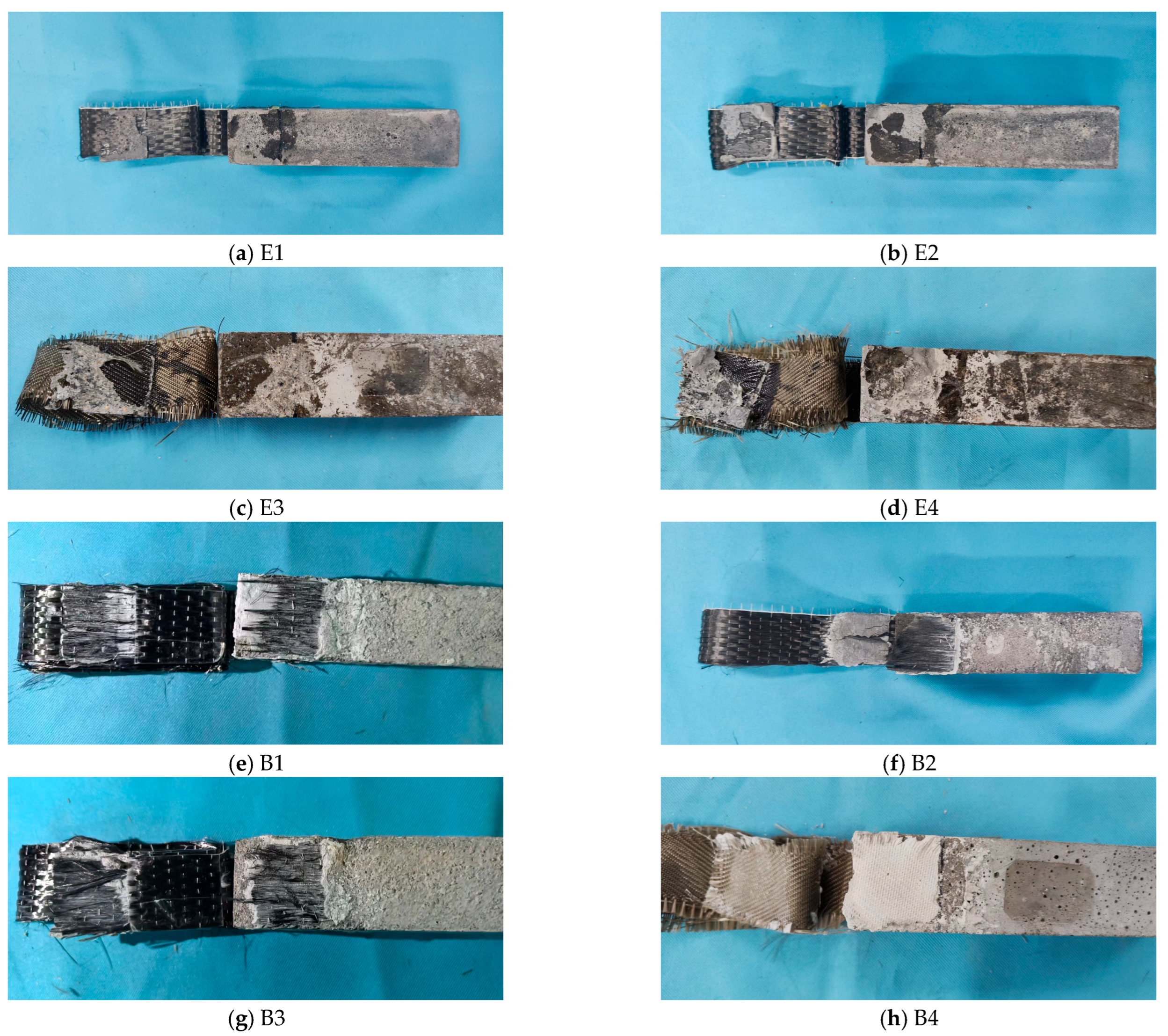

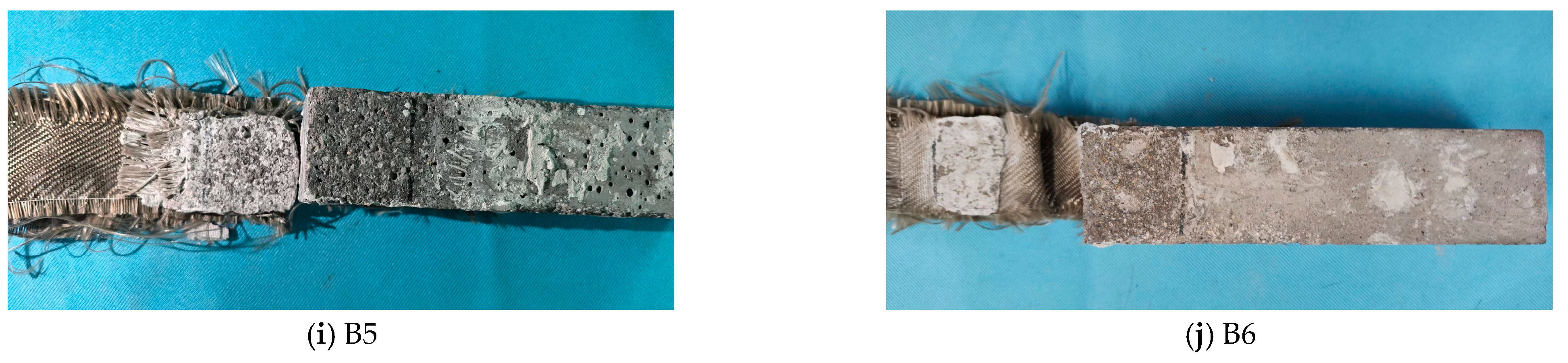

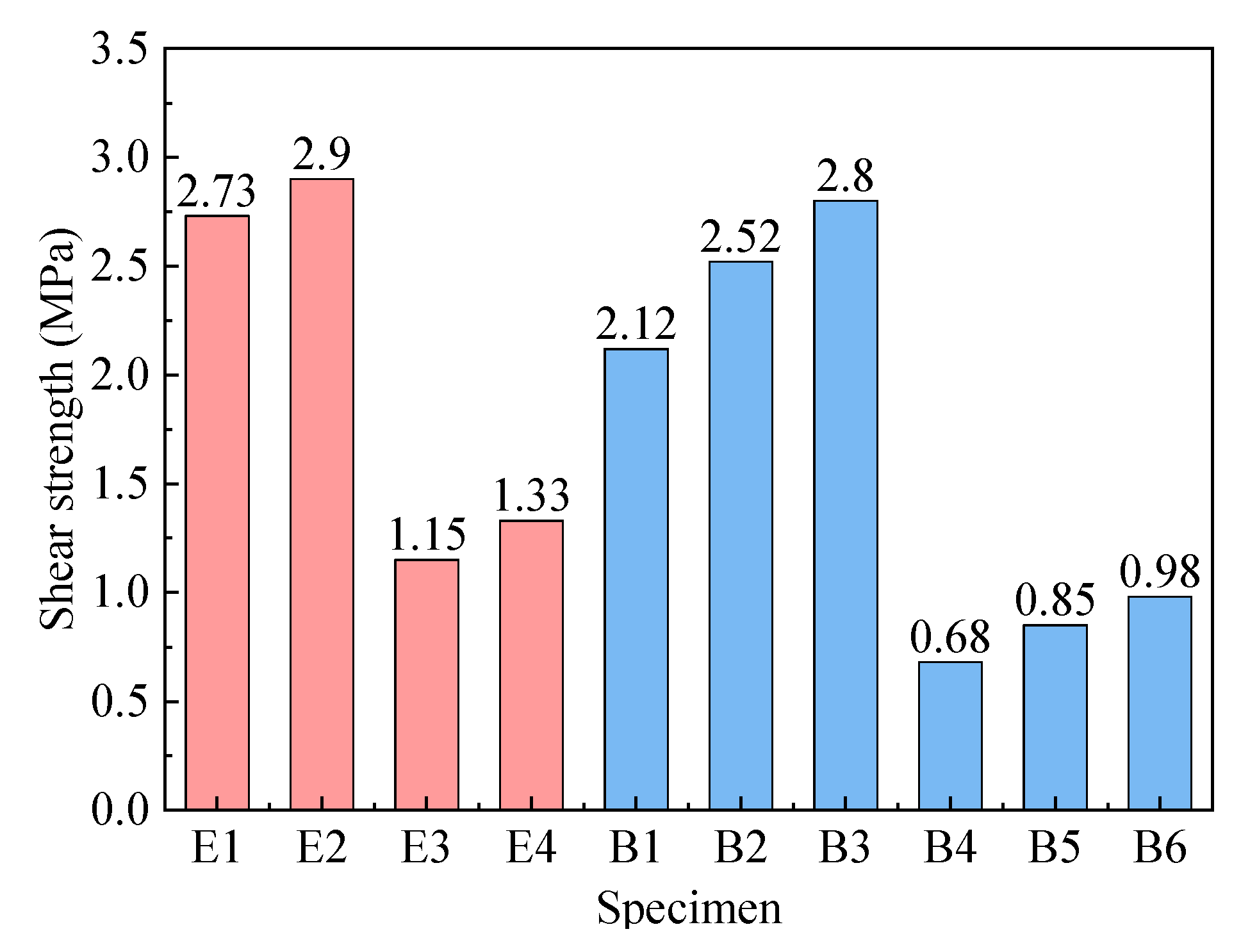

3.1. Double-Shear Test Results of CFRP Adhered with BMSC

3.2. Bending Test Results

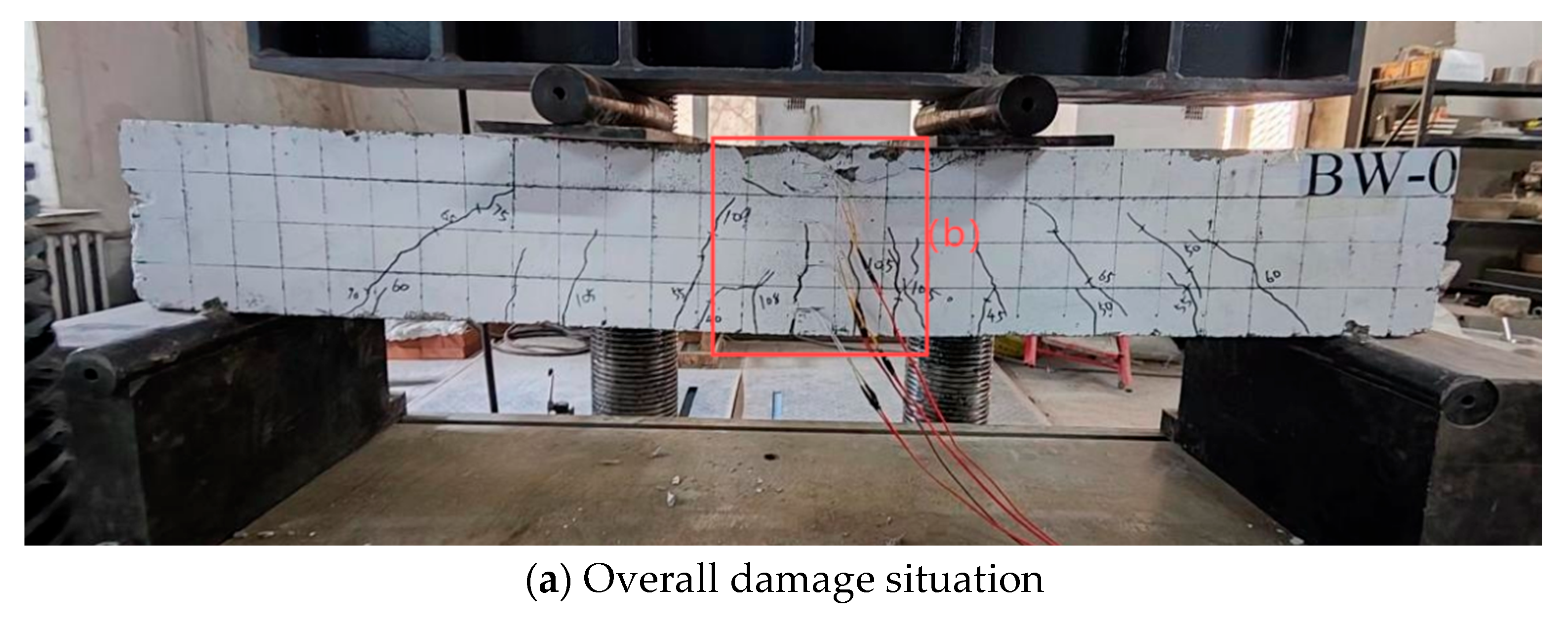

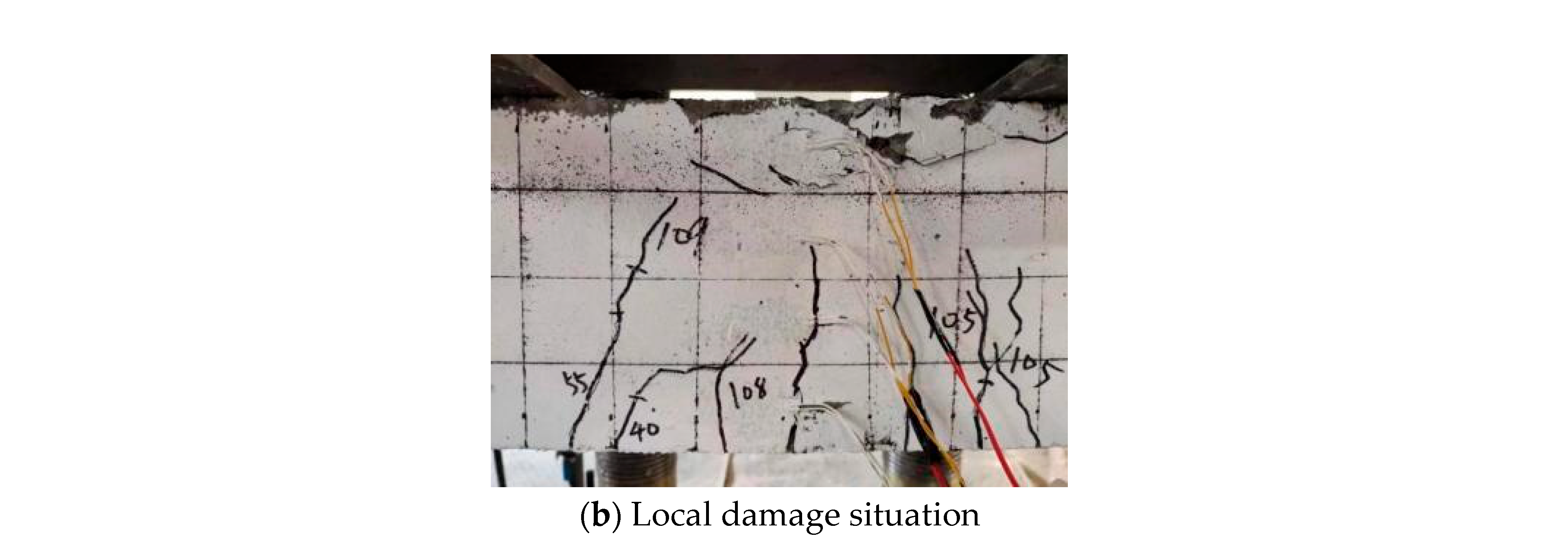

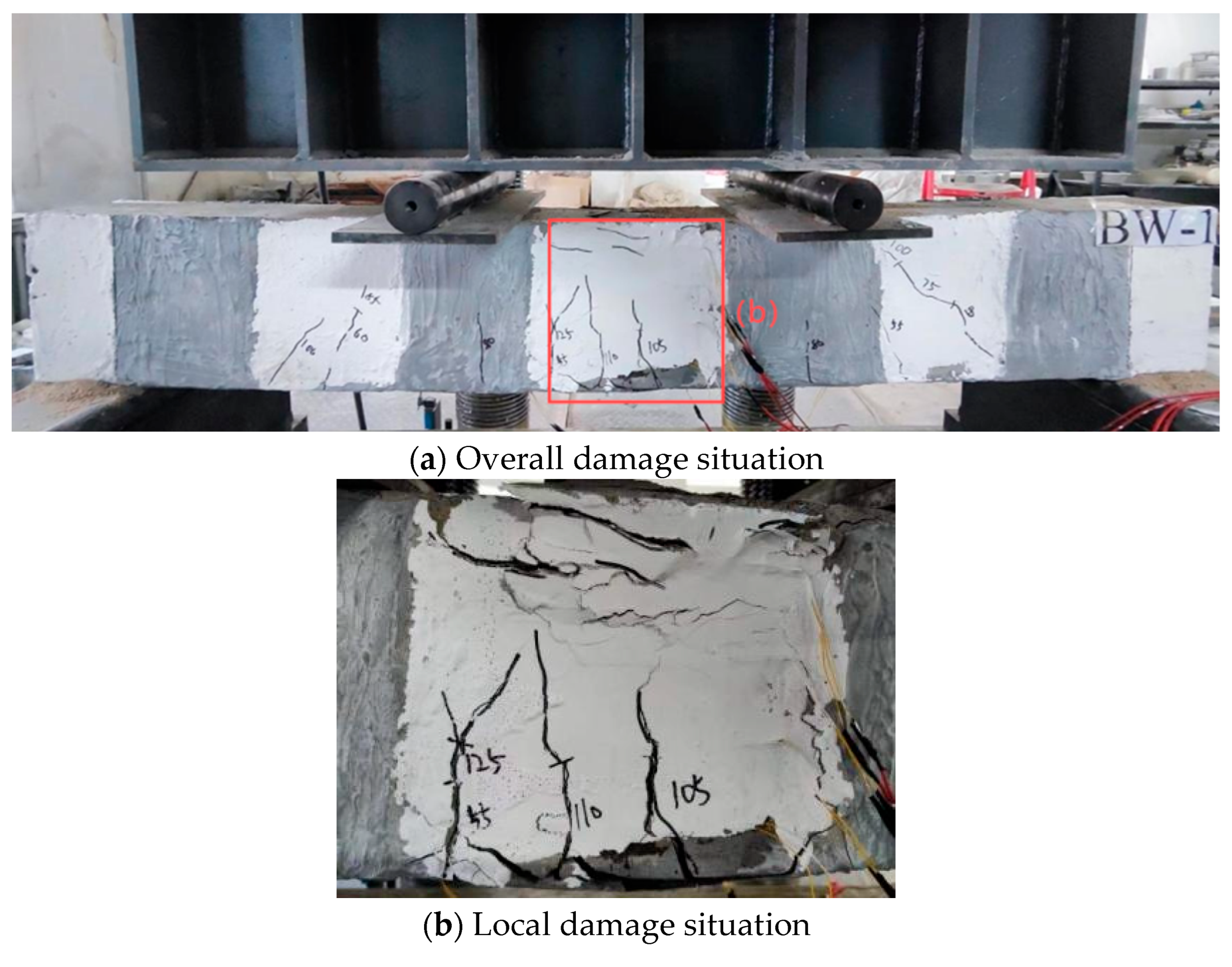

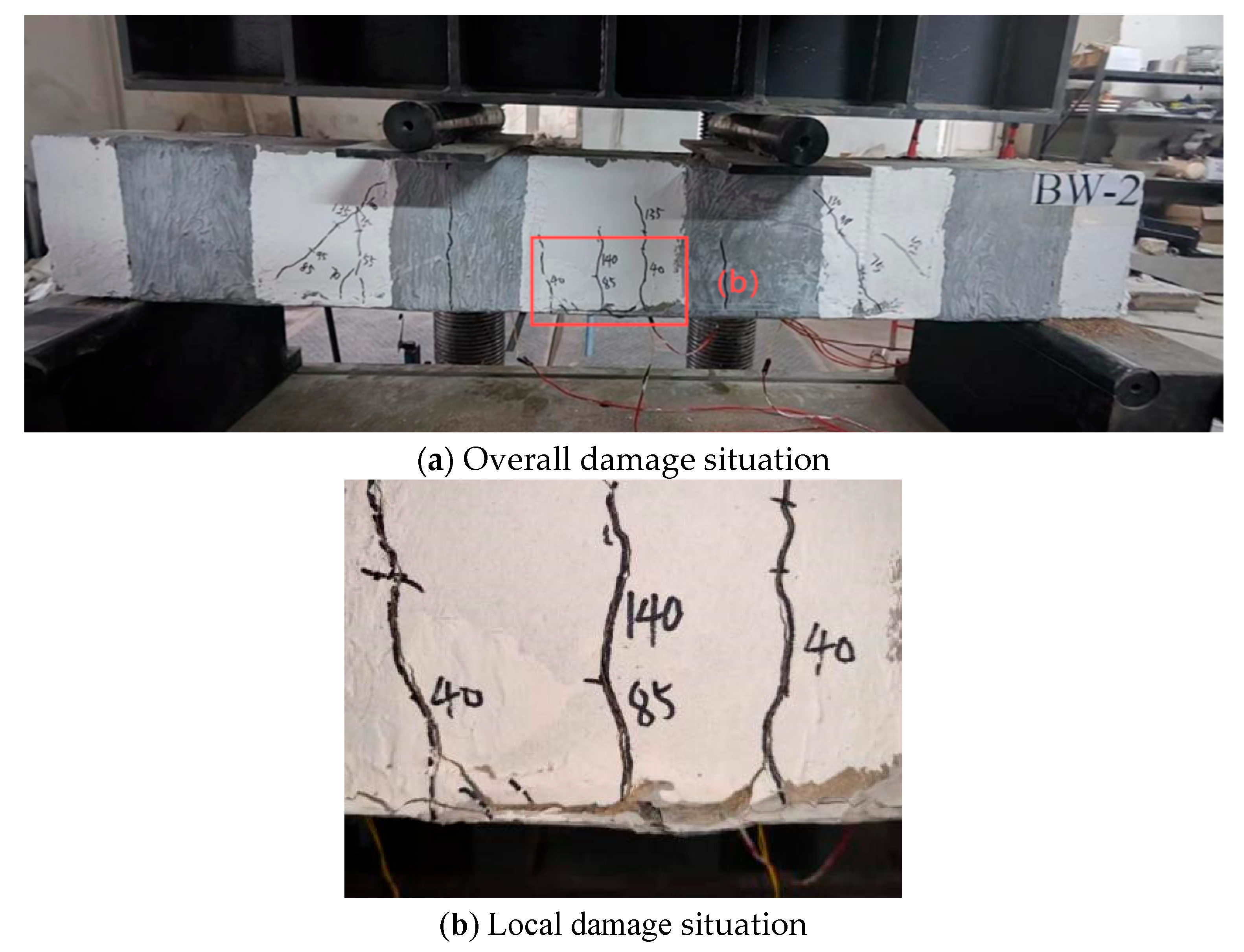

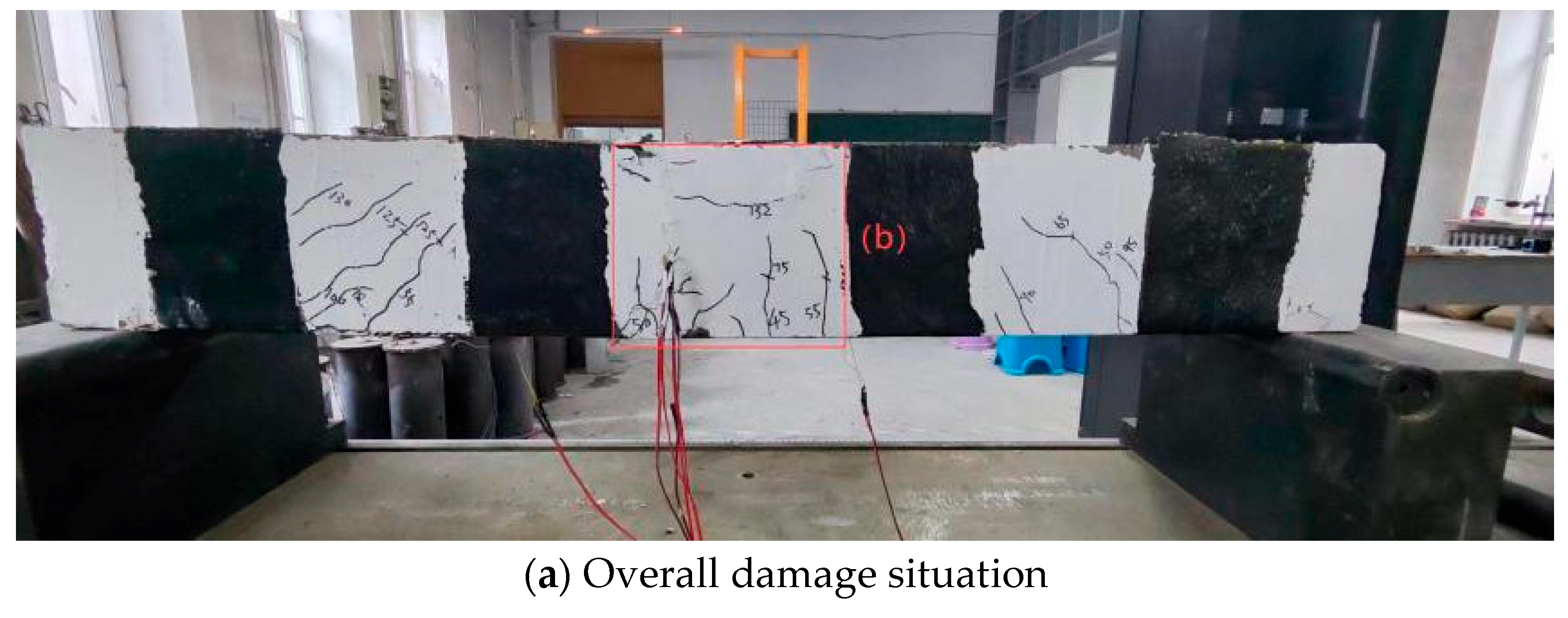

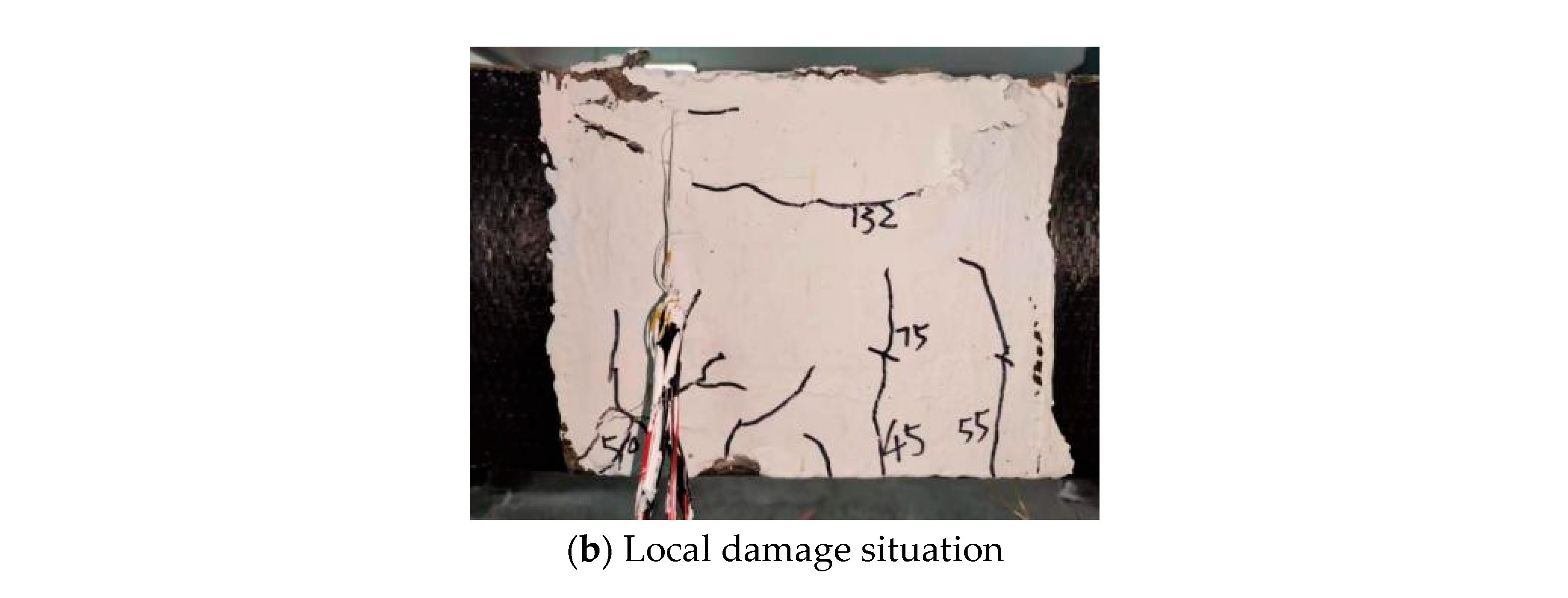

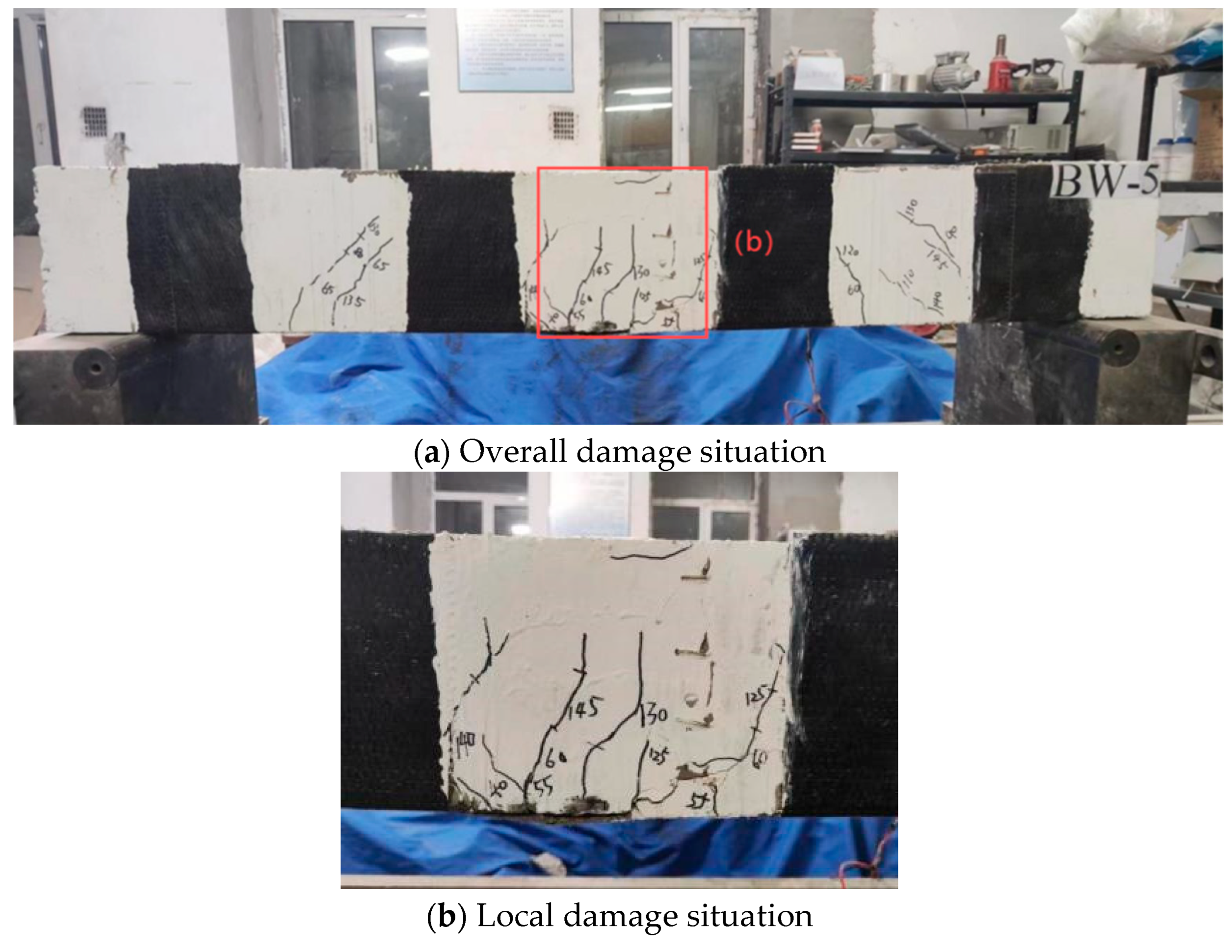

3.2.1. Experimental Phenomena

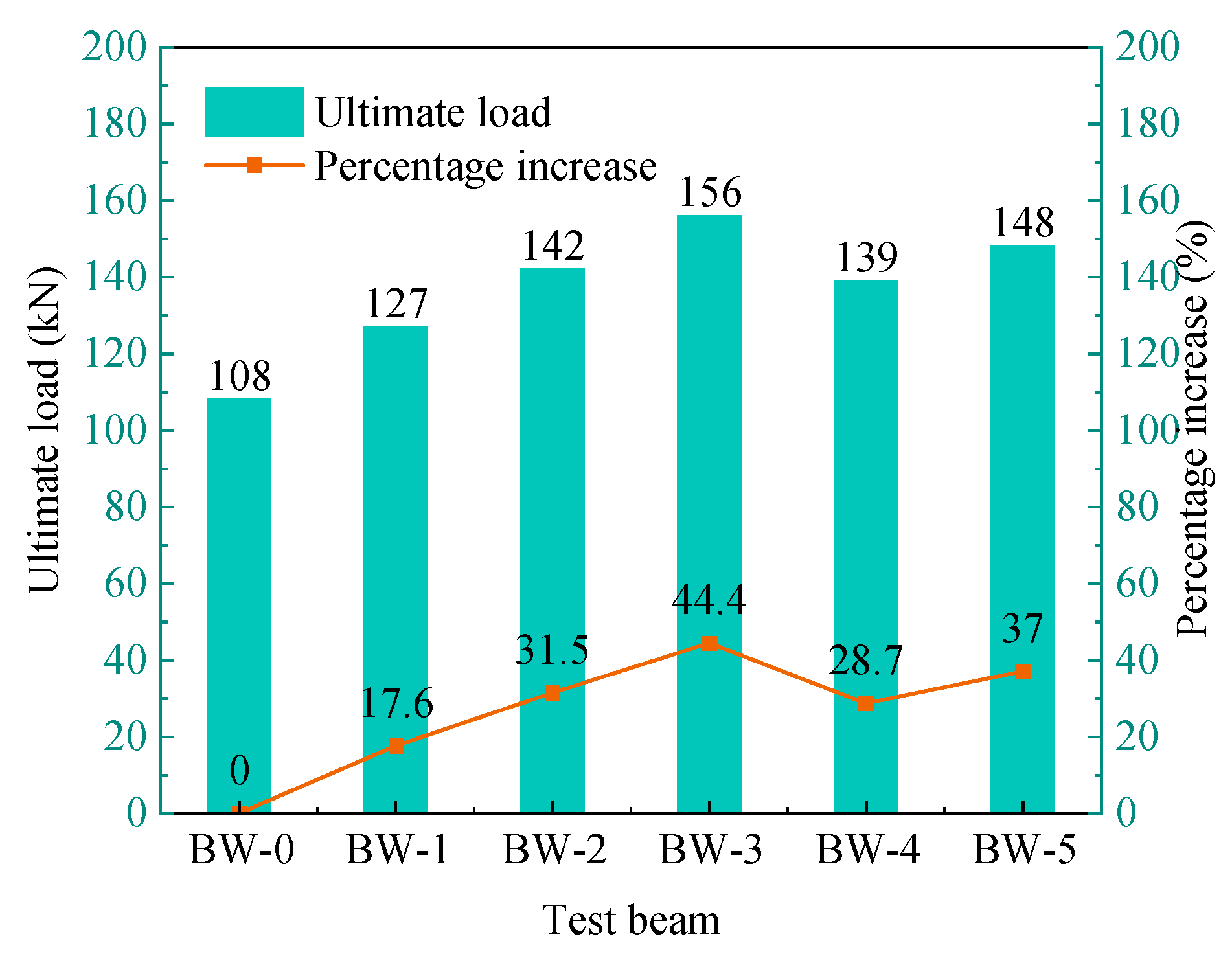

3.2.2. FBC Analysis

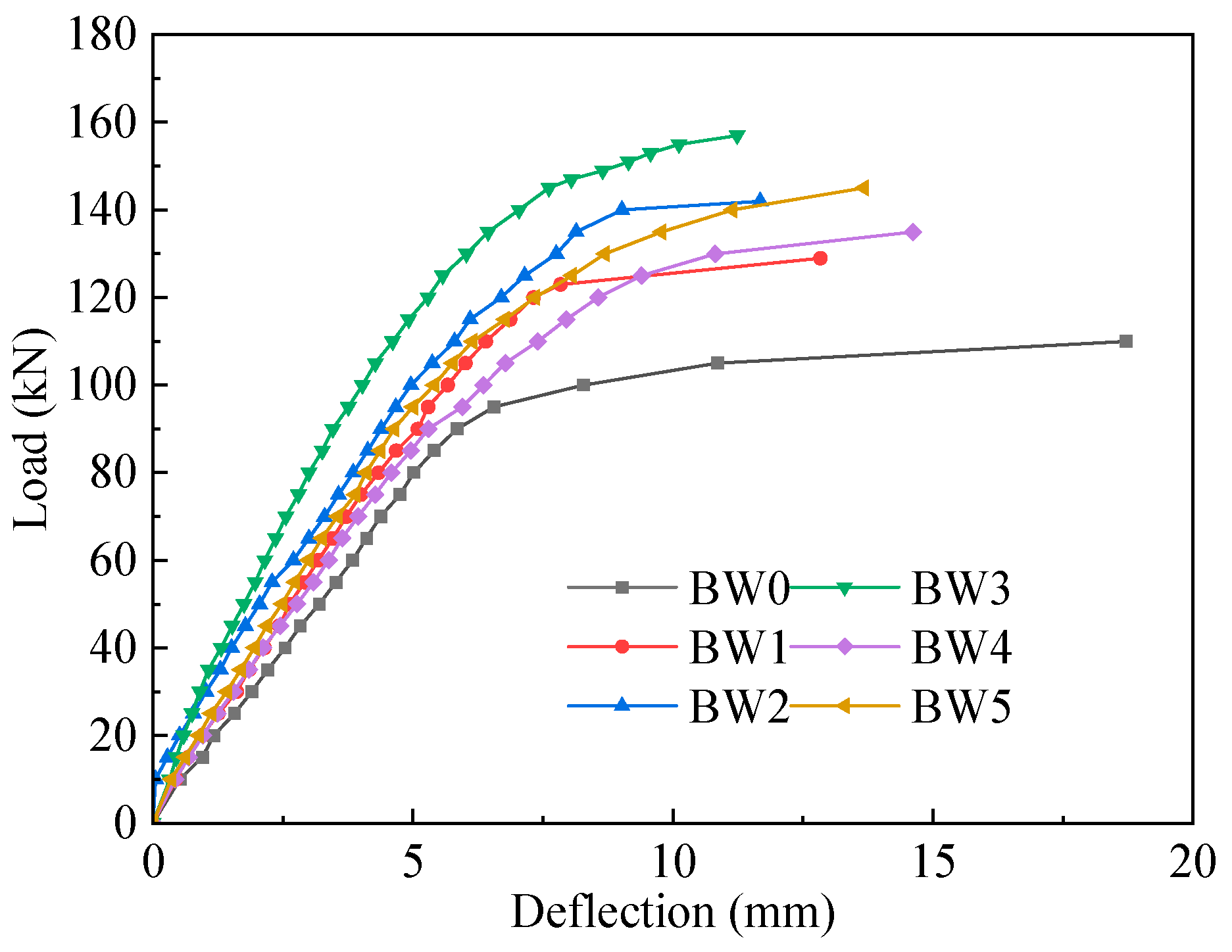

3.2.3. Deflection Analysis

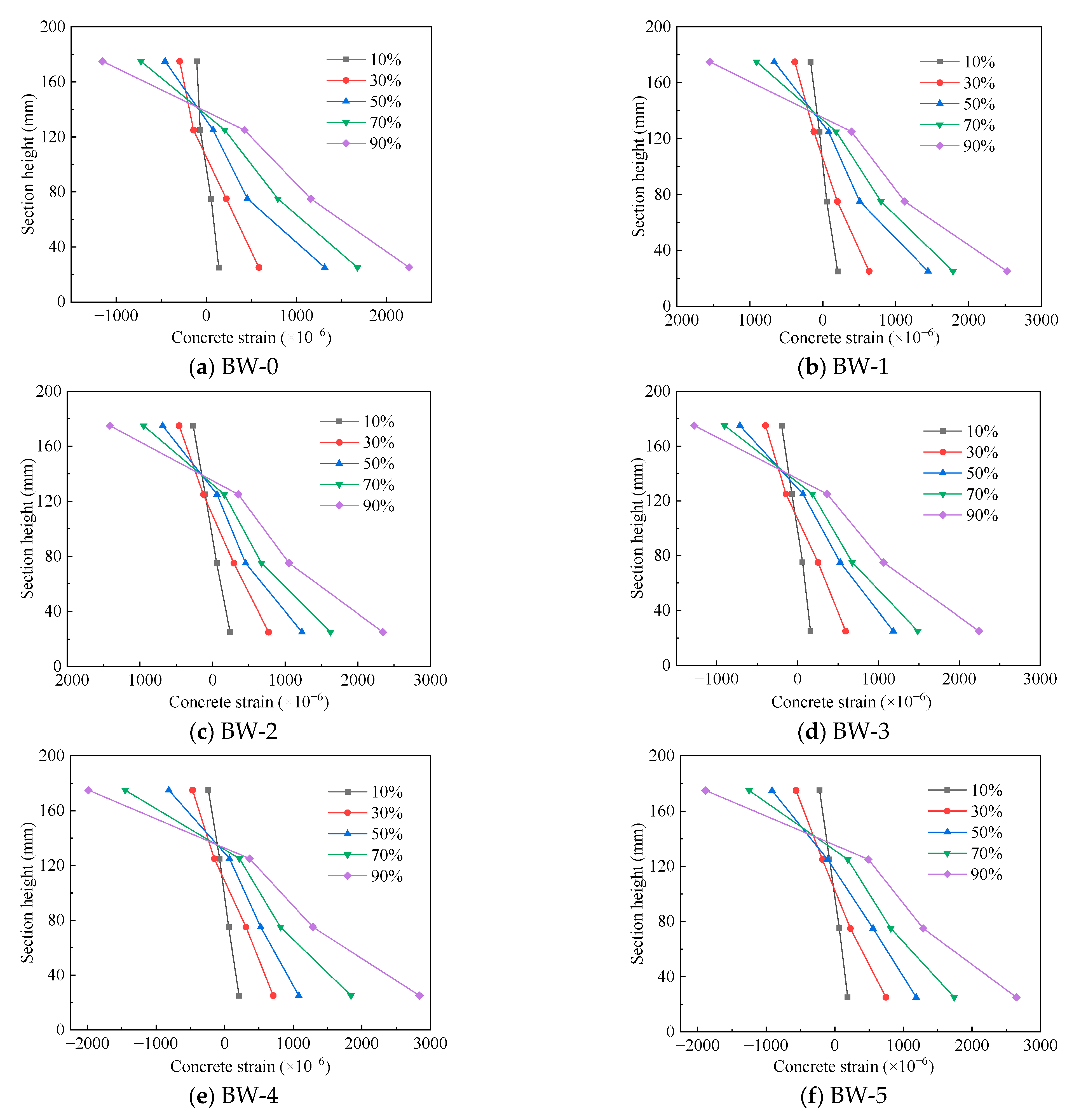

3.2.4. Concrete Strain Analysis

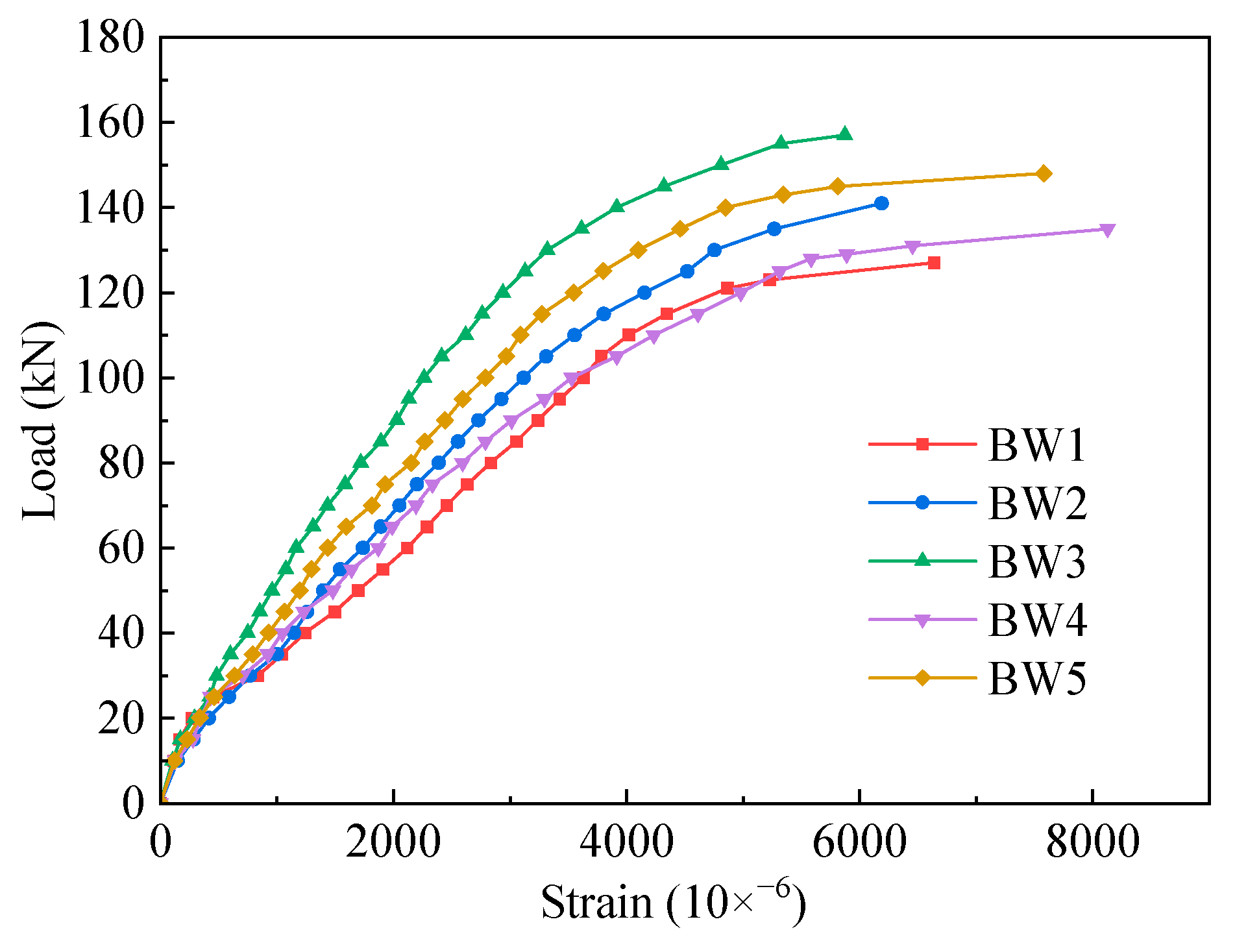

3.2.5. Strain Analysis of CFRP Sheets

4. Calculation Formula for FBC of Reinforced Beams

4.1. Failure Forms of CFRP Sheet-Reinforced Beams

4.2. Establishment of the Calculations

4.2.1. Basic Assumptions

- (1)

- Plane cross-section assumption: The test beams basically conform to the plane cross-section assumption.

- (2)

- The tensile strength of concrete is not considered.

- (3)

- Stress calculation of concrete: The formula recommended in “Code for Design of Concrete Structures” GB50010-2010 [39] is adopted, as shown in Equation (1).where σc and εc are the compressive stress and compressive strain of concrete, respectively; fc is the axial compressive strength of concrete; ε0 and εcu are, respectively, the strain corresponding to the peak stress and the ultimate strain.

- (4)

- Reinforcement stress calculation: Assuming that reinforcing bars are ideal elastoplastic materials, the calculation is shown in Equation (2).

- (5)

- Stress–strain relationship of CFRP sheet: Assuming that the stress–strain relationship of the CFRP sheet is linear, the calculation is shown in Equation (3).

- (6)

- Before the test beam reaches the ultimate load, the CFRP sheet remains effectively bonded to the surface of the concrete beam.

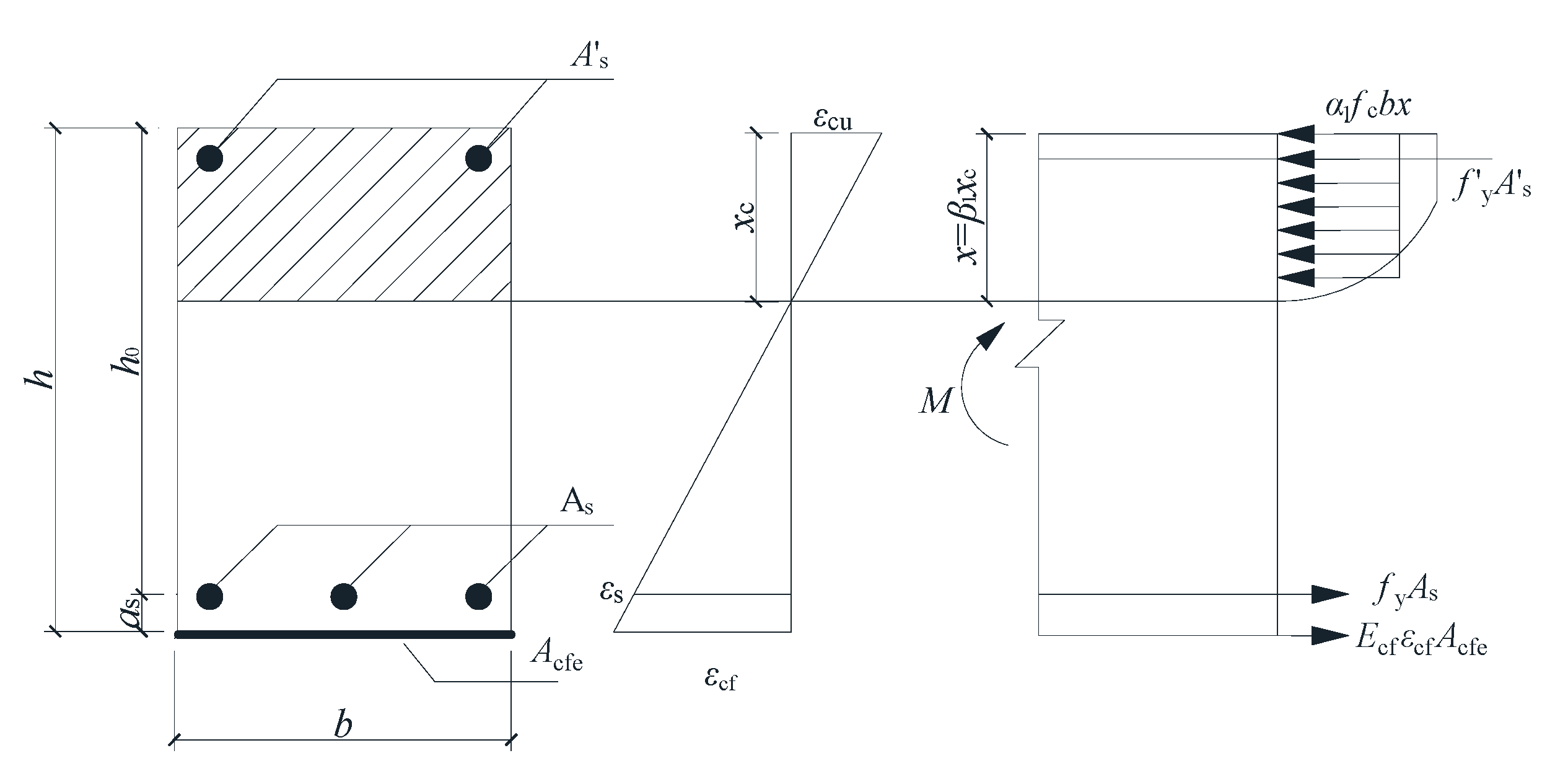

4.2.2. Calculation and Analysis of Flexural Capacity

- (1)

- According to the force and moment balance in Figure 19, Equations (4) and (5) can be obtained, respectively.

- (2)

- Acfe takes into account the influence of multi-layer CFRP sheets on the FBC, which can be calculated by Equation (6), where Acf is the actual area of the CFRP sheet. In Equation (6), km is the thickness reduction coefficient of the CFRP sheet, which can be calculated according to GB 50367-2013 “Code for Design of Reinforcement of Concrete Structures” [40], as shown in Equation (7). In Equation (7), tf1 represents the single-layer thickness of the CFRP sheet; nf represents the number of layers of the CFRP sheet.

- (3)

- The theoretical strain value of CFRP can be obtained by assuming the planar section, as shown in Equation (8). Among them, β1 is the ratio of x to the actual height xc of the concrete compression zone.

- (4)

- Since Equation (8) is obtained based on the idealized plan and section theory, and the thickness reduction coefficient of CFRP sheet in Equation (7) is derived from the test results of organic adhesives, in order to improve the calculation accuracy of the FBC formula, this paper introduces the influence coefficient γp of BMSC on the FBC to correct the FBC formula. Combining Equations (6)–(8), Equations (4) and (5) were, respectively, revised to Equations (9) and (10).

- (5)

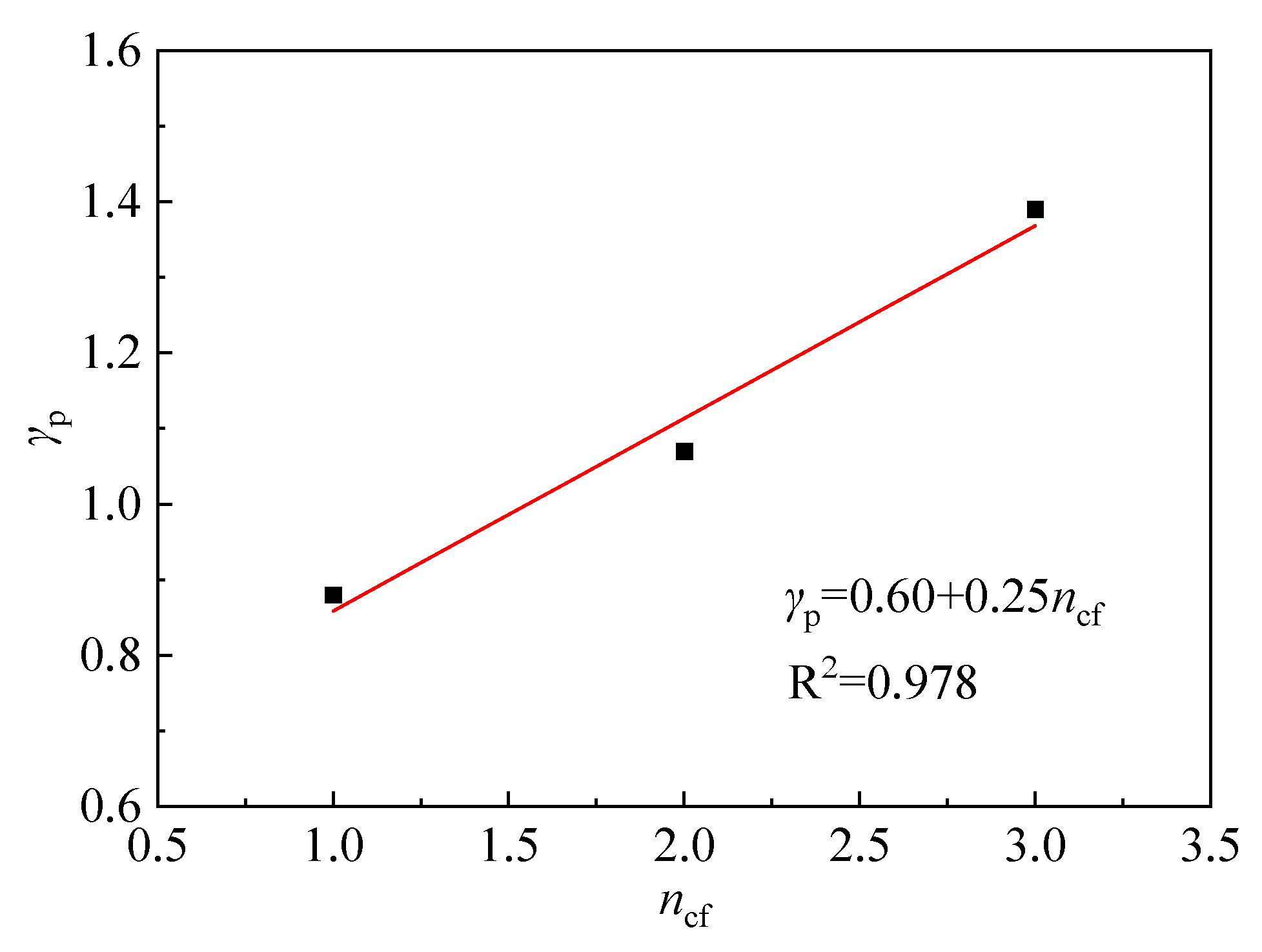

- According to the test results of the reinforced beams BW-1, BW-2, and BW-3, with different numbers of layers of sheet materials pasted by BMSC in this paper, the γp values can be solved simultaneously by Equations (9) and (10), which are 0.88, 1.07, and 1.39, respectively. Taking the number of CFRP sheet bonding layers as the independent variable, the γp values of the reinforced beams BW-1, BW-2, and BW-3 were linearly fitted with the number of CFRP sheet bonding layers, as shown in Figure 21. The calculation formula of γp can be obtained as shown in Equation (11).

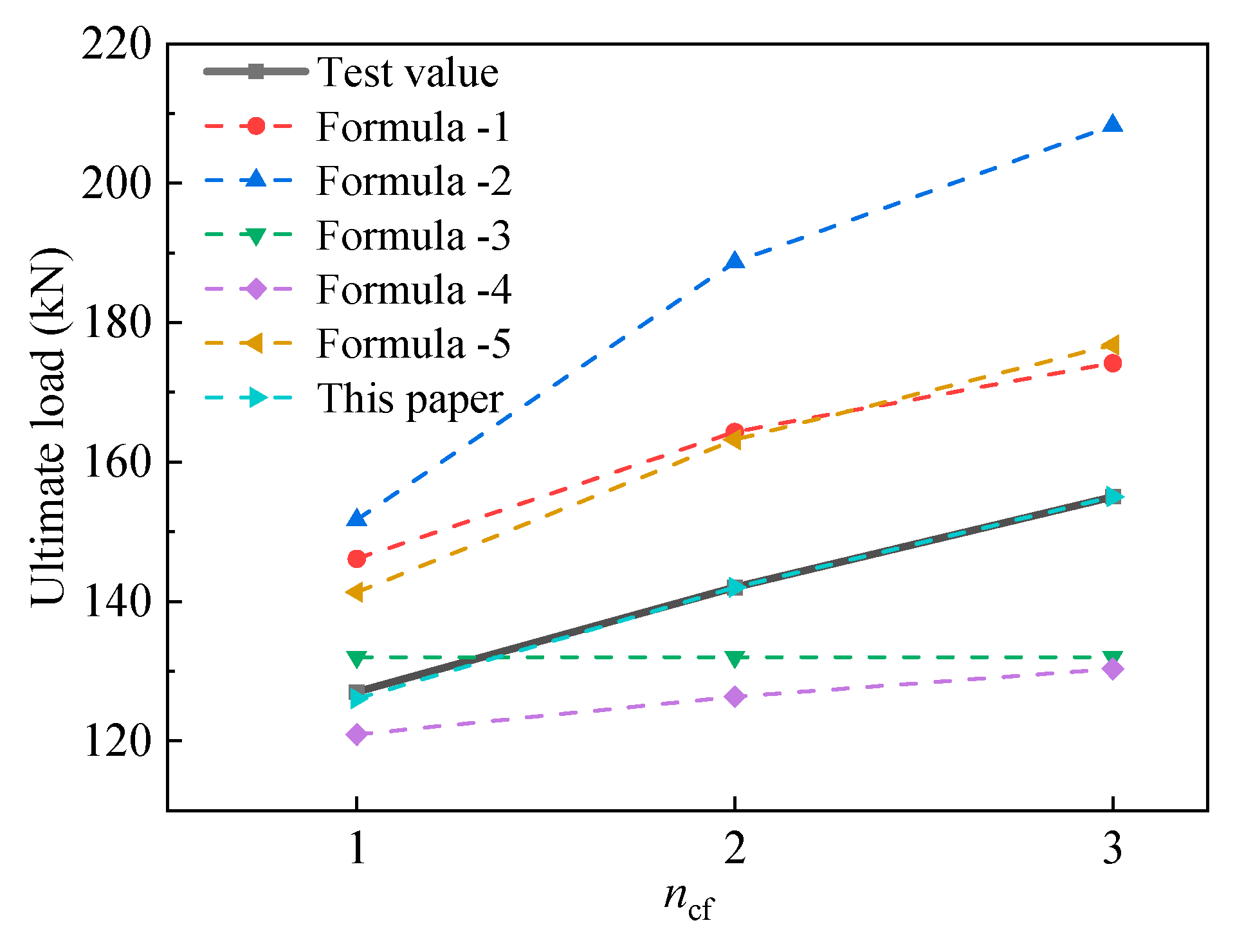

4.3. Accuracy Analysis of the Calculation Formula

4.3.1. Verification of the Calculation Results of the Formulas in This Paper

4.3.2. Comparison of Existing Calculation Formulas

- (1)

- Formula (1): recommended in GB 50367-2013 “Code for Design of Reinforcement of Concrete Structures”.

- (2)

- Formula (2): recommended by the American Concrete Institute ACI 440 [41].

- (3)

- Formula (3): proposed by Huang et al. [42].

- (4)

- Formula (4): proposed by Teng et al. [43].

- (5)

- Formula (5): proposed by Zhang et al. [45].

5. Conclusions

- (1)

- The interface double-shear test results of BMSC adhering CFRP sheets and cement mortar test blocks show that BMSC has good adhesion to CFRP sheets and cement mortar test blocks. When BMSC was used as the binder, the shear strengths at the interfaces between single-layer CFRP sheets and two-layer CFRP sheets and cement mortar test blocks reached 77.6% and 86.9%, respectively, when epoxy resin was used as the binder. Moreover, the shear strength at the interface between BMSC and cement mortar test blocks when three layers of CFRP sheets were adhered was 11.1% higher than that when two layers of CFRP sheets were adhered. It is indicated that BMSC can effectively impregnate CFRP sheets and can be used for reinforcing CFRP sheets.

- (2)

- The bending failure test results of concrete beams reinforced with CFRP sheets bonded with BMSC and epoxy resin show that bonding CFRP sheets can effectively enhance the FBC and flexural stiffness of the beams and limit the development of cracks. When the BMSC-adhered CFRP sheet-reinforced beam was damaged, the concrete at the bonding area between the middle and bottom of the beam span and the CFRP sheet cracked. Immediately, the concrete protective layer in some areas peeled off, and the concrete was crushed. When the CFRP sheet was one layer, the FBC of the beam reinforced with BMSC as the binder was 17.4% higher than that of the unreinforced beam, reaching 91.4% of the beam reinforced with epoxy resin as the binder. When the CFRP sheet was two layers, the FBC of the beam reinforced with BMSC as the binder was 31.5% higher than that of the unreinforced beam, reaching 96% of that of the beam reinforced with epoxy resin as the binder.

- (3)

- By introducing the influence coefficient γp of BMSC on the FBC, a calculation formula for the FBC of concrete beams reinforced with CFRP sheets bonded by BMSC was established based on the test results. The empirical calculation shows that the maximum relative error between the calculated value and the test value of this formula is 0.8%. By comparing it with the existing calculation methods, this paper proposes that the calculated value of the FBC of the formula is the closest to the test value, verifying the reliability of the formula in this paper when used to calculate the FBC of concrete beams reinforced with CFRP sheets bonded by BMSC. It has reference significance for actual reinforcement projects.

- (4)

- The next step should be to continue the research on the shear performance of the inclined section of concrete beams reinforced with BMSC and CFRP sheets and the mechanical performance under extremely high temperature conditions.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Michel, Q.; Orozco, G.; Carter, A.; Vaillancourt, M. Influences of type and concentration of recycled mineral construction, renovation and demolition waste on the linear viscoelastic behavior of bituminous mastics. Constr. Build. Mater. 2023, 371, 130668. [Google Scholar] [CrossRef]

- Niu, G.; Jin, Z.; Zhang, W.; Huang, Y. Investigation of FRP and SFRC Technologies for Efficient Tunnel Reinforcement Using the Cohesive Zone Model. Struct. Durab. Health. Monit. 2024, 18, 161–179. [Google Scholar] [CrossRef]

- Kabashi, N.; Muhaxheri, M.; Krasniqi, E.; Murati, Y.; Latifi, F. Advancements in Fiber-Reinforced Polymer (FRP) Retrofitting Techniques for Seismic Resilience of Reinforced Concrete Structures. Buildings 2025, 15, 587. [Google Scholar] [CrossRef]

- Du, H.; Xian, G.; Tian, J.; Ma, Z.; Li, C.; Xin, M.; Zhang, Y. Effect of fiber surface treatment with silane coupling agents and carbon nanotubes on mechanical properties of carbon fiber reinforced polyamide 6 composites. Polym. Compos. 2024, 46, 1267–1283. [Google Scholar] [CrossRef]

- Yu, Y.; Liu, S.; Pan, Y.; Miu, X.; Liu, J. Durability of glass fiber-reinforced polymer bars in water and simulated concrete pore solution. Constr. Build. Mater. 2021, 299, 123995. [Google Scholar] [CrossRef]

- Li, C.; Xian, G. Novel wedge-shaped bond anchorage system for pultruded CFRP plates. Mater. Struct. 2018, 51, 162. [Google Scholar] [CrossRef]

- Wang, Y.; Jia, Q.; Surahman, R.; He, X. Static and seismic strengthening of RC frame joints by using CFRP sheets with various anchoring methods. J. Build. Eng. 2024, 82, 108309. [Google Scholar] [CrossRef]

- Işık, E.; Radu, D.; Harirchian, E.; Avcil, F.; Arkan, E.; Büyüksaraç, A.; Hadzima-Nyarko, M. Failures in Reinforced-Concrete Columns and Proposals for Reinforcement Solutions: Insights from the 2023 Kahramanmaraş Earthquakes. Buildings 2025, 15, 1535. [Google Scholar] [CrossRef]

- Eshghi, S.; Zanjanizadeh, V. Repair of Earthquake-Damaged Square R/C Columns with Glass Fiber-Reinforced Polymer. Int. J. Civ. Eng. 2007, 5, 210–223. [Google Scholar]

- Fukuyama, K.; Higashibata, Y.; Miyauchi, Y. Studies on repair and strengthening methods of damaged reinforced concrete columns. Cem. Concr. Compos. 2000, 22, 81–88. [Google Scholar] [CrossRef]

- Tsonos, A.G. Effectiveness of CFRP-jackets and RC-jackets in post-earthquake and pre-earthquake retrofitting of beam–column subassemblages. Eng. Struct. 2008, 30, 777–793. [Google Scholar] [CrossRef]

- Yao, Q. Experimental Study and Numerical Simulation of Seismic Strengthening for Earthquake-Damaged Piers. Master’s Thesis, Qingdao Technological University, Qingdao, China, 2023. [Google Scholar]

- Baloch, W.L.; Siad, H.; Lachemi, M.; Sahmaran, M. A review on the durability of concrete-to-concrete bond in recent rehabilitated structures. J. Build. Eng. 2021, 44, 103315. [Google Scholar] [CrossRef]

- Harle, S.M. Durability and long-term performance of fiber reinforced polymer (FRP) composites: A review. Structures 2024, 60, 105881. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, G.; Shen, Z.; Gao, Y.; Zhou, H.; Wang, Z. A comprehensive study on the effect of reinforcing methods on the flexural behaviour of Concrete-RUHTCC composite beams. Eng. Struct. 2023, 292, 116524. [Google Scholar] [CrossRef]

- Fang, X.; Zhang, B.; Li, J.; Hu, L.; Chen, W. A significant comparison between magnesium-based binder and other inorganic cementitious materials for the restoration of brick-carved cultural relics. Constr. Build. Mater. 2024, 411, 134788. [Google Scholar] [CrossRef]

- Goufi, N.; Kaid, N.; Kerdal, D.E.D.; Idir, R. Sustainable cementitious materials: Exploring alkali-activated binders. Proc. Inst. Civ. Eng.-Constr. Mater. 2024, 177, 233–248. [Google Scholar] [CrossRef]

- Huang, W.; Zheng, W.; Wang, Y. Experimental study on high-temperature resistance of alkali-activated slag concrete block masonry. Adv. Struct. Eng. 2024, 27, 105–118. [Google Scholar] [CrossRef]

- Wang, B. Ultrahigh Toughness Cementitious Composite: Its Bond Behavior with Concrete and Structural Application for Flexural Strengthening of RC Beams. Ph.D. Thesis, Dalian University of Technology, Dalian, China, 2011. [Google Scholar]

- Hou, L.J.; Xu, R.; Zhang, X.F.; Zheng, R.F.; Xu, S.L.; Chen, D.; Ou, Y.F. Seismic behavior of reinforced concrete columns strengthened by textile-UHTCC. J. Build. Struct. 2022, 12, 59–69. [Google Scholar] [CrossRef]

- Wu, B.; Fang, S.; Feng, W. Experimental study on concrete beams strengthened with carbon fiber sheet using geopolymer. J. Build. Struct. 2012, 33, 111–118. [Google Scholar] [CrossRef]

- Qi, S. Experimental Study on Ambient Temperature and High Temperature Behaviors of RC Beams Strengthened with Carbon Fiber Sheet Using Geopolymers as Adhesive Agent. Master’s Thesis, South China University of Technology, Guangzhou, China, 2015. [Google Scholar]

- Zhang, A. Study on High Temperature Resistance Modification of Magnesium Phosphate Cement and In-Plane Shear Between CFRP Sheets and Concrete. Ph.D. Thesis, Harbin Institute of Technology, Harbin, China, 2017. [Google Scholar]

- Ren, J. Experimental Study on Modification of Magnesium Phosphate Cement and Reinforcement of Concrete Beams by Bonding Carbon Fiber Sheet. Master’s Thesis, Shandong Jianzhu University, Jinan, China, 2022. [Google Scholar]

- Fang, Y.; Zhang, L.; Hu, T.; Sun, H.; Yu, F.; Li, C. A comprehensive review on shrinkage behaviors of alkali-activated metakaolin-blast furnace slag cementitious materials: Shrinkage mechanism, properties and mitigate strategies. Case Stud. Constr. Mater. 2025, 22, e04391. [Google Scholar] [CrossRef]

- Yazid, M.H.; Faris, M.A.; Abdullah, M.M.A.B.; Nabiałek, M.; Rahim, S.Z.A.; Salleh, M.A.A.M.; Kheimi, M.; Sandu, A.V.; Rylski, A.; Jeż, B. Contribution of Interfacial Bonding towards Geopolymers Properties in Geopolymers Reinforced Fibers: A Review. Materials 2022, 15, 1496. [Google Scholar] [CrossRef] [PubMed]

- Meng, X.; Jiang, Y.; Chen, B.; Wang, L. Modification of magnesium phosphate cement with steel slag powder and ground blast furnace slag: Mechanism of hydration and electrical conductivity. Constr. Build. Mater. 2024, 438, 137305. [Google Scholar] [CrossRef]

- Xiao, Y.; Wang, C.; Chen, B. Understanding the role of MgO fineness on the performance of magnesium phosphate cement through multi-scale study. Constr. Build. Mater. 2024, 455, 139095. [Google Scholar] [CrossRef]

- Mei, Q.; Yu, H.; Ma, H.; Tan, Y.; Wu, Z. Experimental and Numerical Simulation on the Penetration for Basic Magnesium Sulfate Cement Concrete. Materials 2023, 16, 4024. [Google Scholar] [CrossRef] [PubMed]

- Zhao, J.; Xu, J.; Cui, C.; Yu, C.; Chang, J.; Hu, Z.; Bi, W. Stability and phase transition of 5·1·7 phase in alkaline solutions. Constr. Build. Mater. 2020, 258, 119683. [Google Scholar] [CrossRef]

- You, J.-J.; Song, Q.-Y.; Tan, D.; Yang, C.; Liu, Y.-F. Mechanical properties and microstructure of basalt fiber-biobased- basic magnesium sulfate cement. Cem. Concr. Compos. 2023, 137, 104934. [Google Scholar] [CrossRef]

- Xu, X.; Li, Y.; Sun, Y.; Yu, B.; Hu, H.; Li, D.; Hu, Z.; Wang, S.; Meng, J.; Yu, B. Investigation of the performance of basic magnesium sulfate cement mortar. Adv. Cem. Res. 2023, 35, 432–451. [Google Scholar] [CrossRef]

- Zhang, X.; Wu, C. Influence of Magnesium Oxide Activity on Water Resistance of Basic Magnesium Sulfate Cement. J. Adv. Concr. Technol. 2022, 20, 212–221. [Google Scholar] [CrossRef]

- Zhang, N.; Yu, H.; Ma, H.; Ba, M. Effects of different pH chemical additives on the hydration and hardening rules of basic magnesium sulfate cement. Constr. Build. Mater. 2021, 305, 124696. [Google Scholar] [CrossRef]

- Fu, Y.; Yao, X. A review on manufacturing defects and their detection of fiber reinforced resin matrix composites. Compos. Part C Open Access 2022, 8, 100276. [Google Scholar] [CrossRef]

- Wang, A.; Huang, M.; Chu, Y.; Zhu, Y.; Liu, K.; Guo, L.; Liu, P.; Sun, D. Optimization of mix proportion of basic magnesium sulfate cement-based high-strength coral concrete. Constr. Build. Mater. 2022, 341, 127709. [Google Scholar] [CrossRef]

- GB/T 17671-2021; Test method for Strength of Cement mortar (ISO Method). China Cement Standardization Technical Committee: Beijing, China, 2021.

- Pekgökgöz, R.K.; İzol, G.; Avcil, F.; Gürel, M.A. Experimental and Numerical Investigation of the Tendon Layout Effect on Flexural Capacity in Post-Tensioning Beams. Tehnički vjesnik 2024, 31, 1553–1560. [Google Scholar] [CrossRef]

- GB50010-2010; Code for Design of Concrete Structures. China Academy of Building Research: Beijing, China, 2010.

- GB 50367-2013; Code for Design of Reinforcement of Concrete Structures. Sichuan Provincial Academy of Building Research: Beijing, China, 2013.

- ACI440.2R-17; Guide for the Design and Construction of Externally Bonded FRP Systems for Strengthening Concrete Structures. American Concrete Institute: Farmington Hills, MI, USA, 2017.

- Huang, Y.; Ye, L. Nonlinear fem analysis of bond behavior of rc beams strengthened with bottom bonded CFRP sheets. J. Eng. Mech. 2004, 21, 54–61. [Google Scholar] [CrossRef]

- Teng, J.; Smith, S.; Yao, J.; Chen, J. Intermediate crack-induced debonding in RC beams and slabs. Constr. Build. Mater. 2003, 17, 447–462. [Google Scholar] [CrossRef]

- Chen, J.F.; Teng, J.G. Anchorage Strength Models for FRP and Steel Plates Bonded to Concrete. J. Struct. Eng. 2001, 127, 784–791. [Google Scholar] [CrossRef]

- Zhang, X.; Li, S.; Yang, L. Experimental study on flexural behavior of RC beams strengthened with inorganic adhesive CFRP sheets. J. Build. Struct. 2010, 31, 249–254. [Google Scholar] [CrossRef]

| Curing Days (Day) | Compressive Strength (MPa) | Flexural Strength (MPa) |

|---|---|---|

| 3 | 65 | 11.6 |

| 7 | 70 | 12.6 |

| 28 | 80.5 | 14 |

| Type | Yield Strength (MPa) | Tensile Strength (MPa) | Elastic Modulus (GPa) |

|---|---|---|---|

| C12 | 430 | 651 | 202 |

| A8 | 330 | 520 | 205 |

| A6 | 332 | 523 | 205 |

| Fiber Type | Thickness (mm) | Tensile Strength (MPa) | Elastic Modulus (MPa) | Elongation (%) |

|---|---|---|---|---|

| CFRP | 0.17 | 3400 | 2.3 × 105 | 1.6 |

| BFRP | 0.24 | 1870 | 1.0 × 105 | 2.7 |

| Number | Adhesive Type | FRP Type | Number of Layers |

|---|---|---|---|

| E1 | Epoxy resin | CFRP | 1 |

| E2 | Epoxy resin | CFRP | 2 |

| E3 | Epoxy resin | BFRP | 1 |

| E4 | Epoxy resin | BFRP | 2 |

| B1 | BMSC | CFRP | 1 |

| B2 | BMSC | CFRP | 2 |

| B3 | BMSC | CFRP | 3 |

| B4 | BMSC | BFRP | 1 |

| B5 | BMSC | BFRP | 2 |

| B6 | BMSC | BFRP | 3 |

| Test Beam Number | Adhesive Type | Number of CFRP Sheet Layers | Thickness of CFRP Sheet (mm) |

|---|---|---|---|

| BW-0 | No (unreinforced beams) | / | / |

| BW-1 | BMSC | 1 | 0.17 |

| BW-2 | BMSC | 2 | 0.33 |

| BW-3 | BMSC | 3 | 0.50 |

| BW-4 | Epoxy resin | 1 | 0.17 |

| BW-5 | Epoxy resin | 2 | 0.33 |

| Test Beam Number | (kN) | (kN) | / | Relative Error (%) |

|---|---|---|---|---|

| BW-1 | 126 | 127 | 0.992 | 0.8 |

| BW-2 | 143 | 142 | 1.007 | 0.7 |

| BW-3 | 155 | 156 | 0.993 | 0.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Z.; Jiang, L.; Li, Z.; Yang, C. Research on the Bending Behavior of Concrete Beams Reinforced with CFRP Sheets Bonded Using BMSC. Buildings 2025, 15, 1980. https://doi.org/10.3390/buildings15121980

Yang Z, Jiang L, Li Z, Yang C. Research on the Bending Behavior of Concrete Beams Reinforced with CFRP Sheets Bonded Using BMSC. Buildings. 2025; 15(12):1980. https://doi.org/10.3390/buildings15121980

Chicago/Turabian StyleYang, Zhenzhong, Lili Jiang, Zhenguo Li, and Chenggen Yang. 2025. "Research on the Bending Behavior of Concrete Beams Reinforced with CFRP Sheets Bonded Using BMSC" Buildings 15, no. 12: 1980. https://doi.org/10.3390/buildings15121980

APA StyleYang, Z., Jiang, L., Li, Z., & Yang, C. (2025). Research on the Bending Behavior of Concrete Beams Reinforced with CFRP Sheets Bonded Using BMSC. Buildings, 15(12), 1980. https://doi.org/10.3390/buildings15121980