Digital Twin Framework for Bridge Slab Deterioration: From 2D Inspection Data to Predictive 3D Maintenance Modeling

Abstract

1. Introduction

1.1. Background

1.2. Problem Statement

2. Literature Review

2.1. Digitalized Data Delivery for Bridges

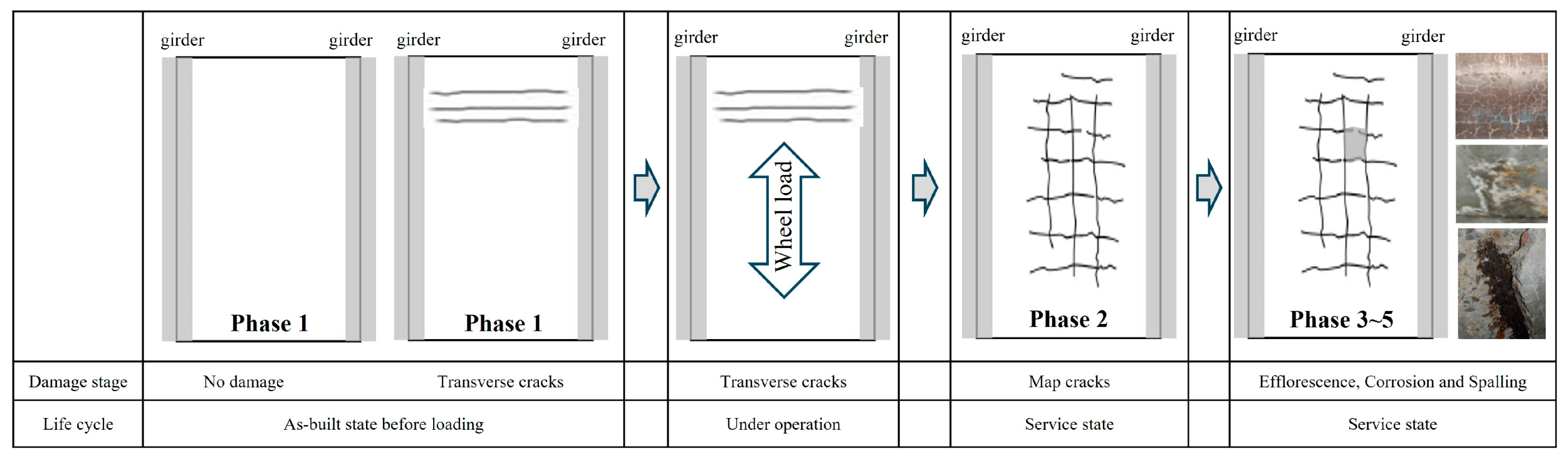

2.2. Service Life Design of Bridge Slab

3. Methodology

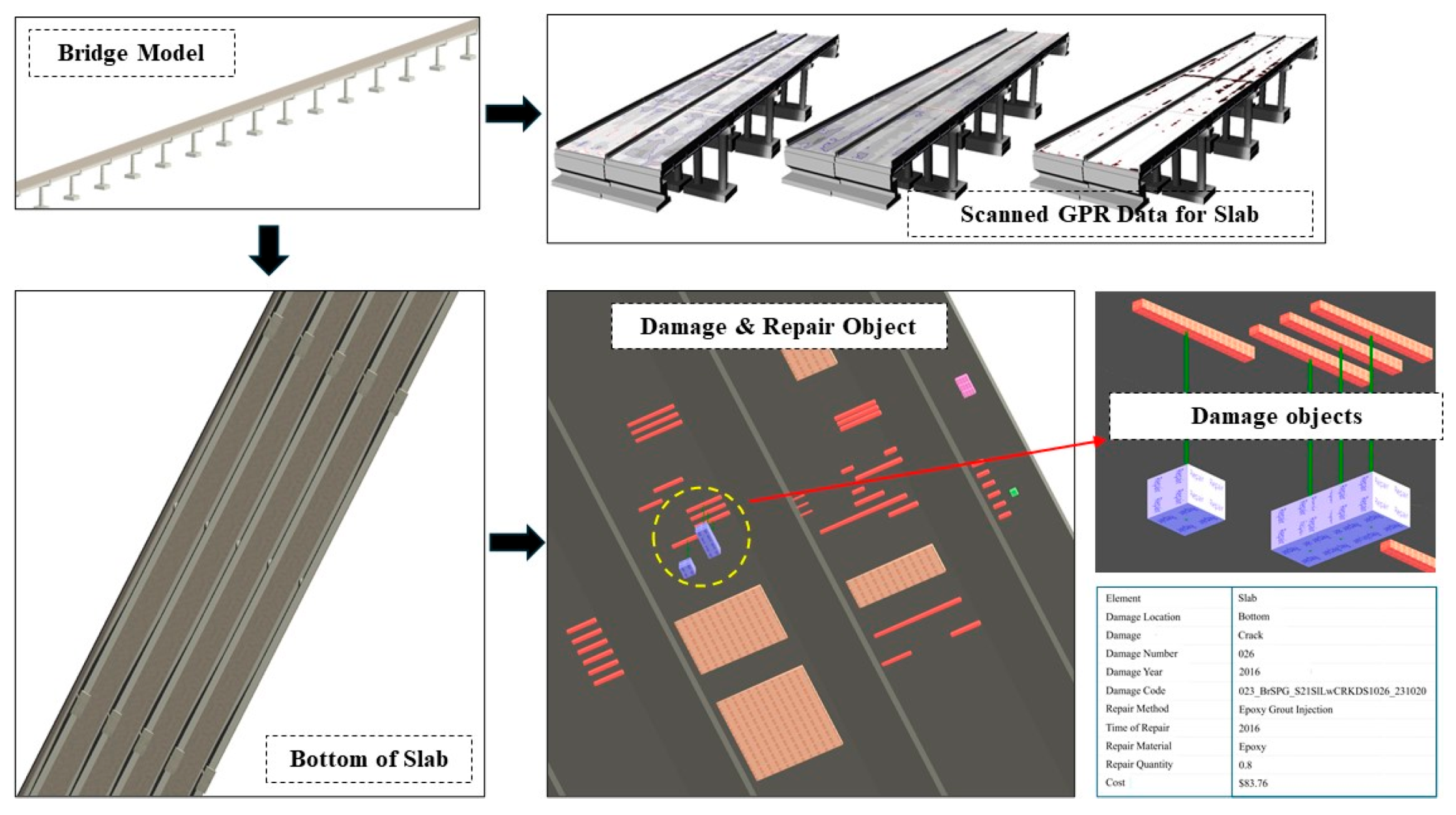

3.1. Definition of a Digital Twin Model Framework for Bridge Slabs

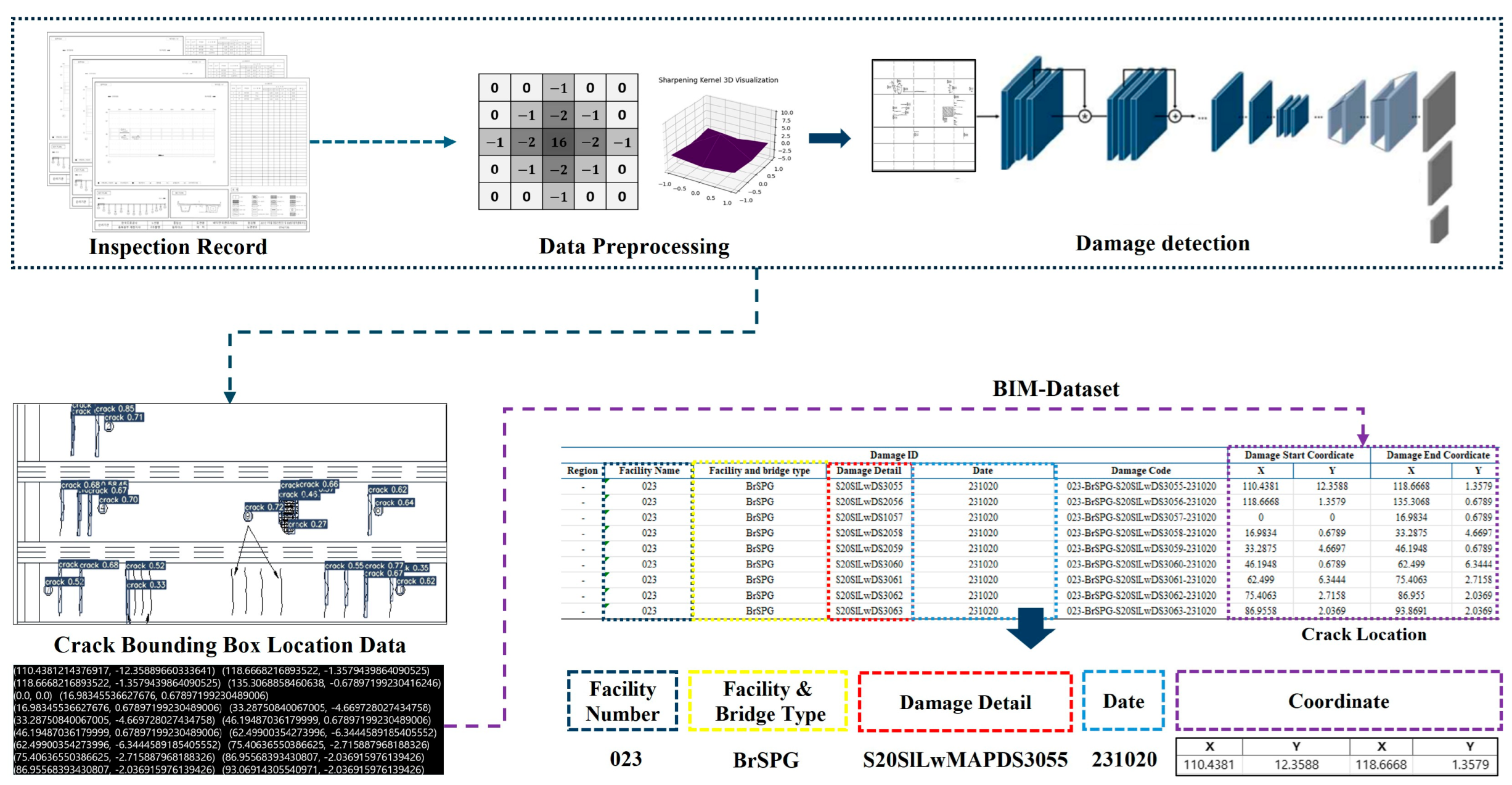

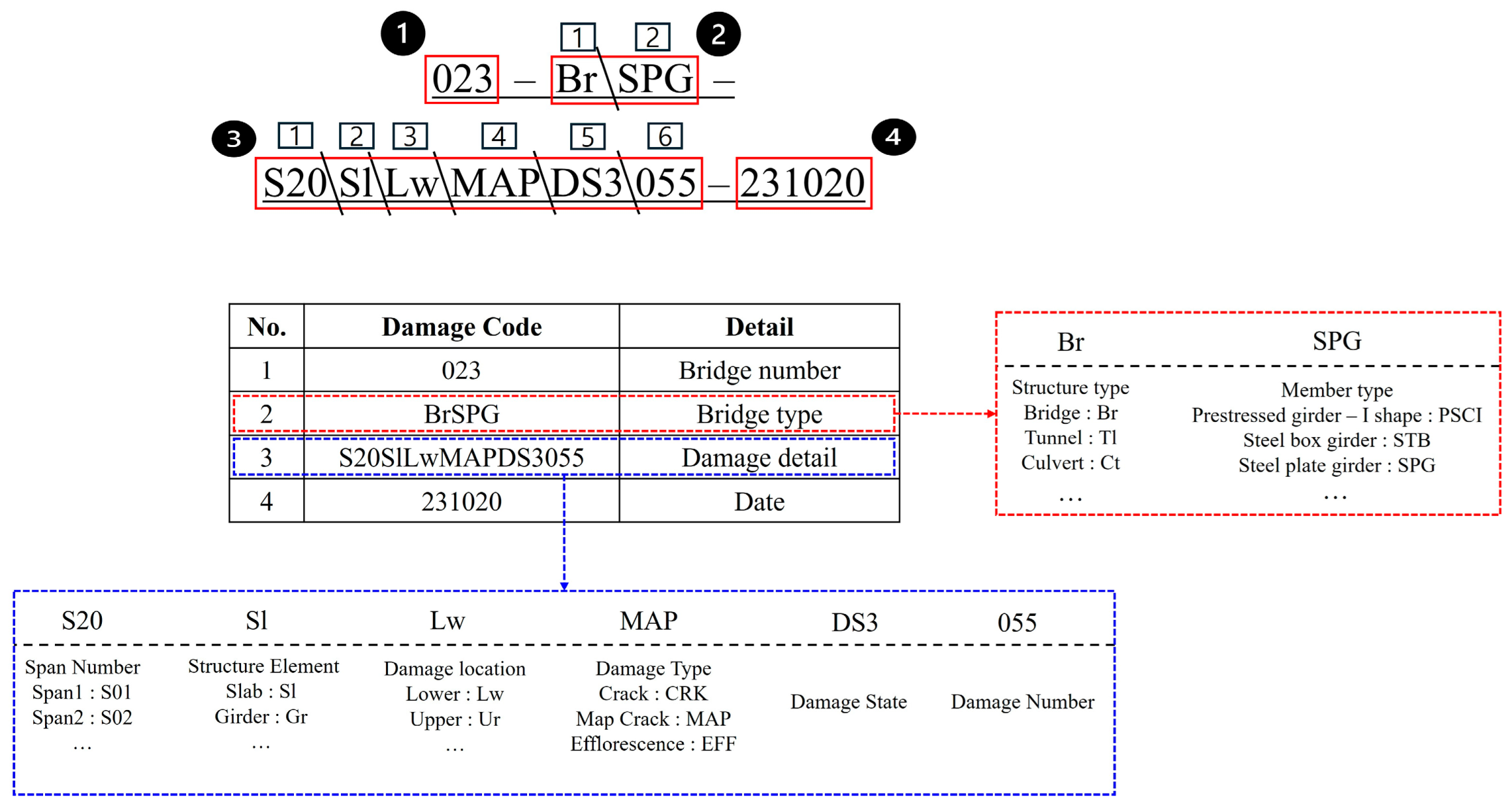

3.2. Digitalization of the Damage Report of the Bridge Slab

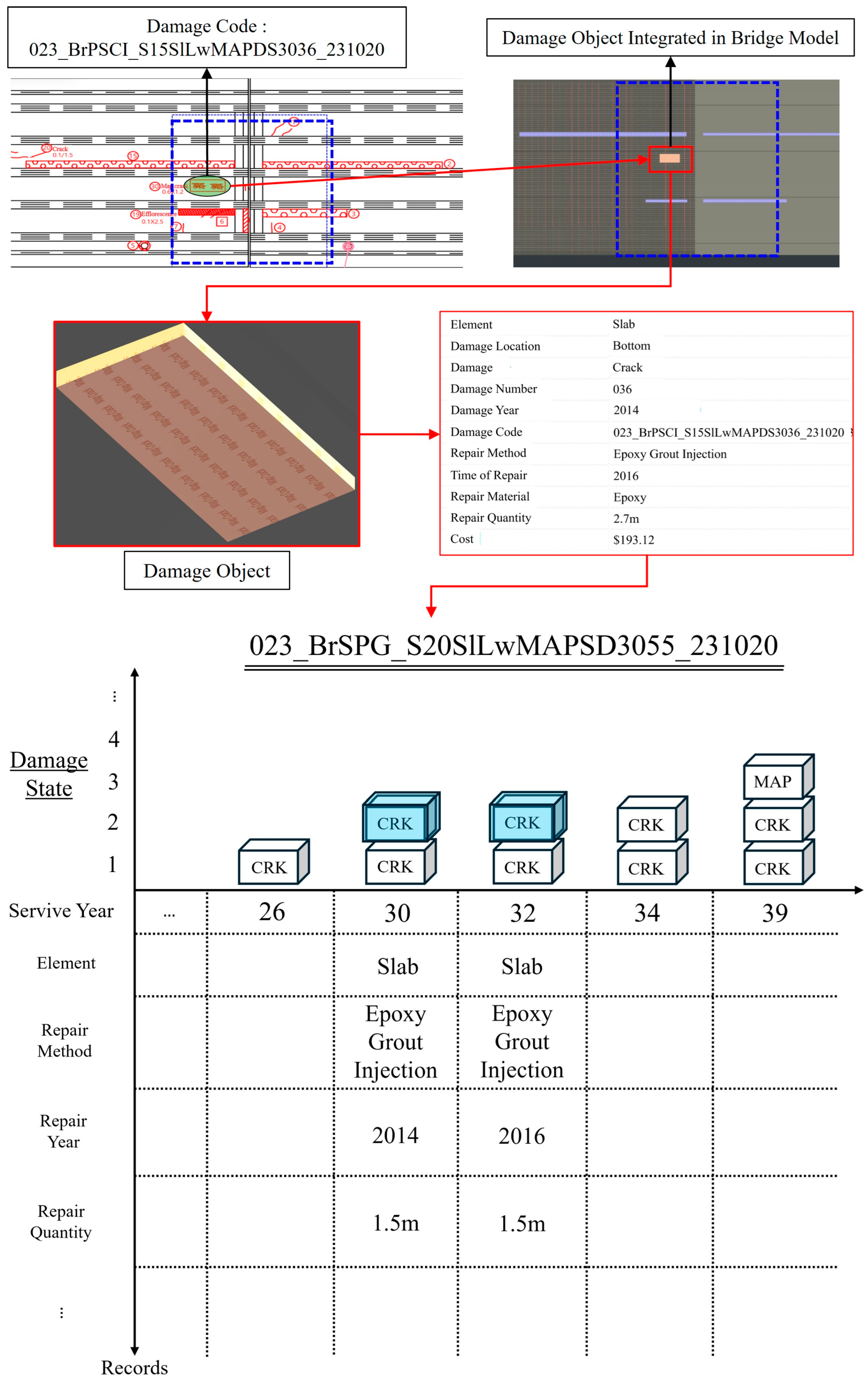

3.3. Maintenance Model for Damage Objects

4. Case Study

4.1. Deteriorated Bridge Slab with Different Girder Types

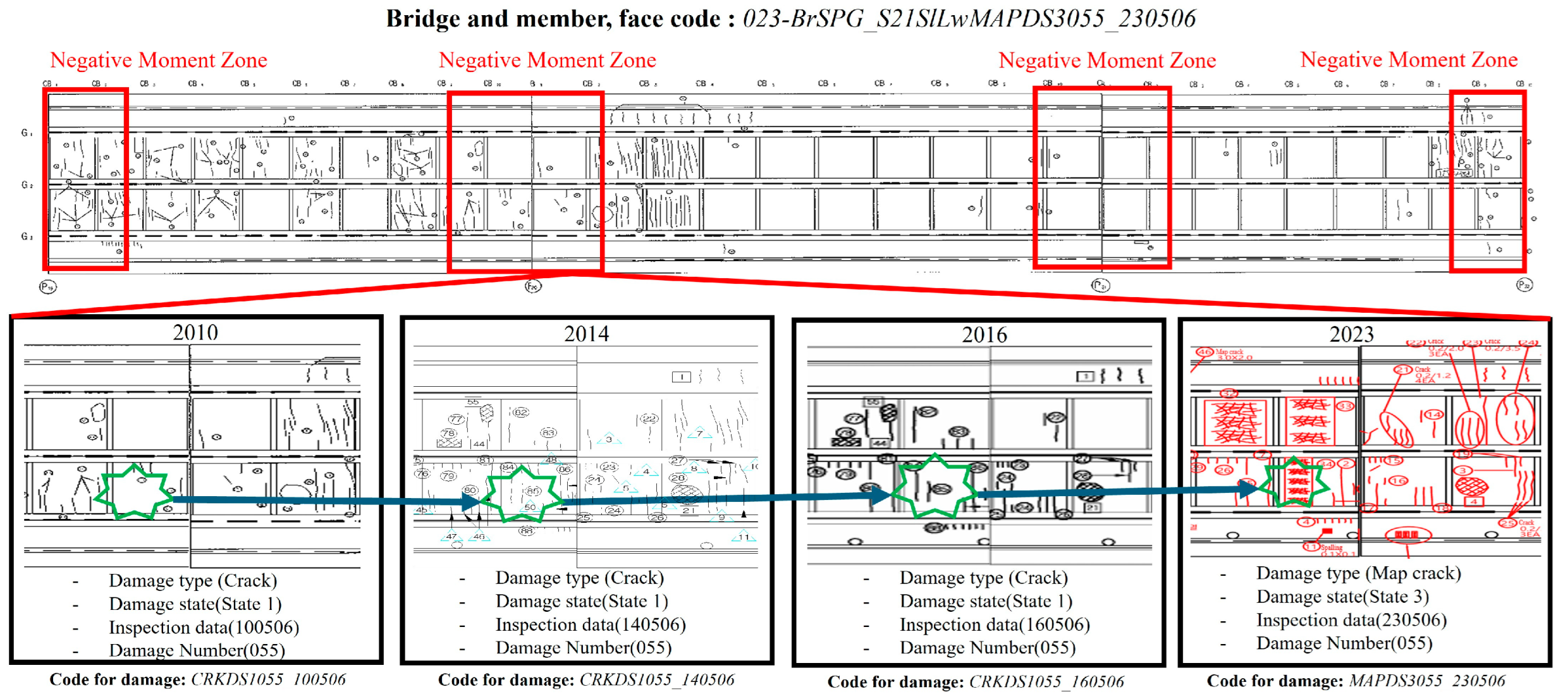

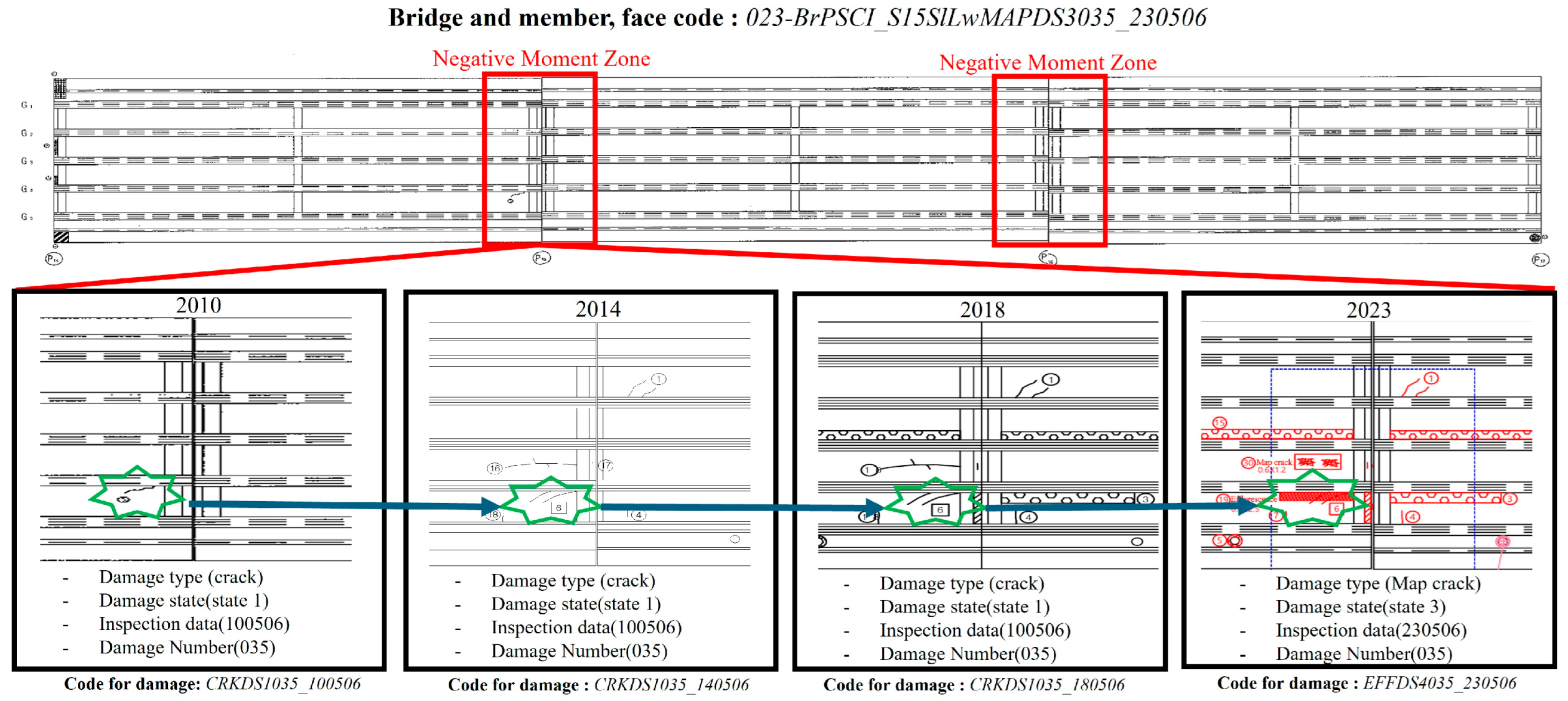

4.2. Definition of Crack Damage and Repair History in Negative Moment Region

4.3. Damage and Repair Objects in BIM Models

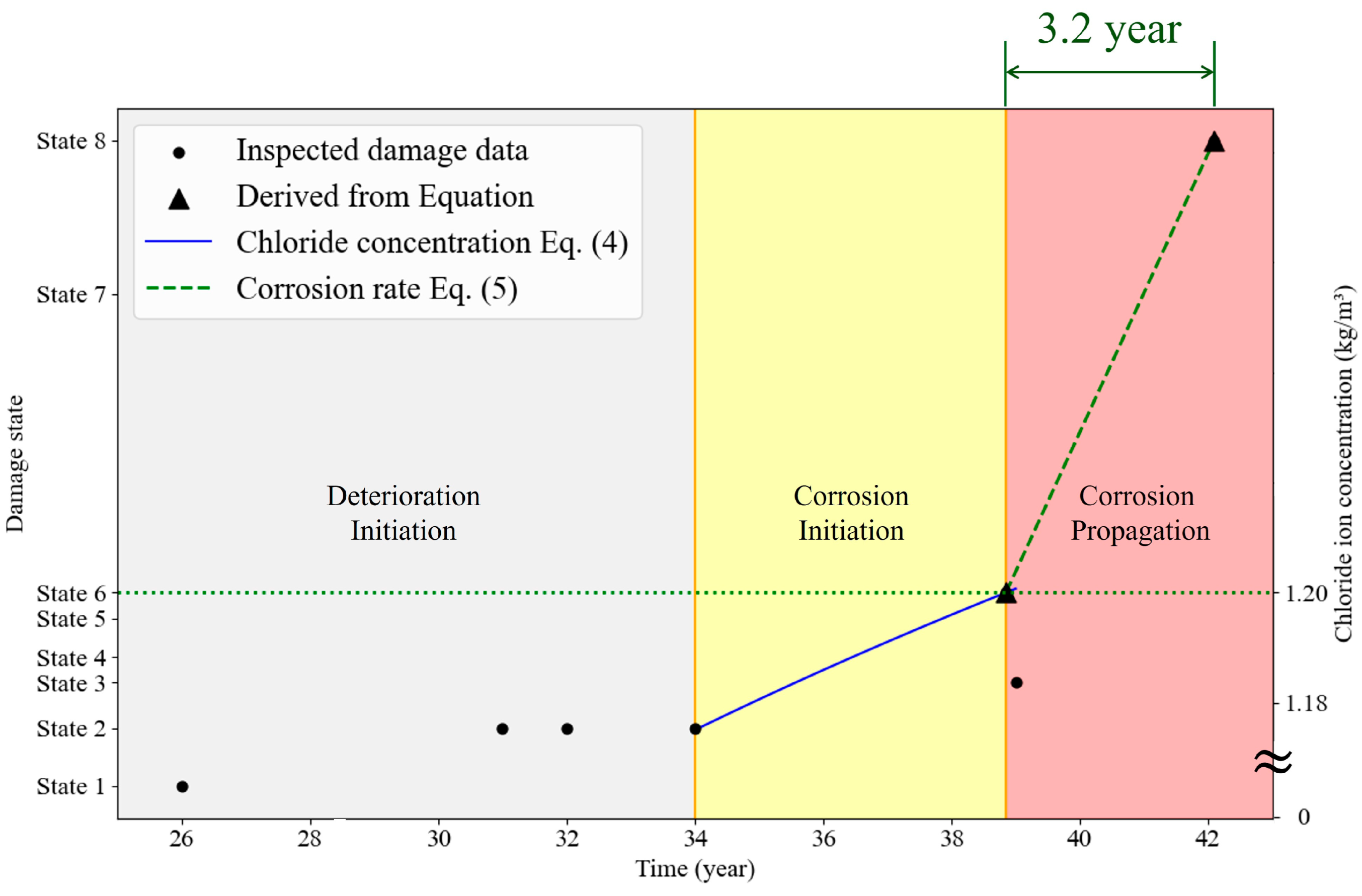

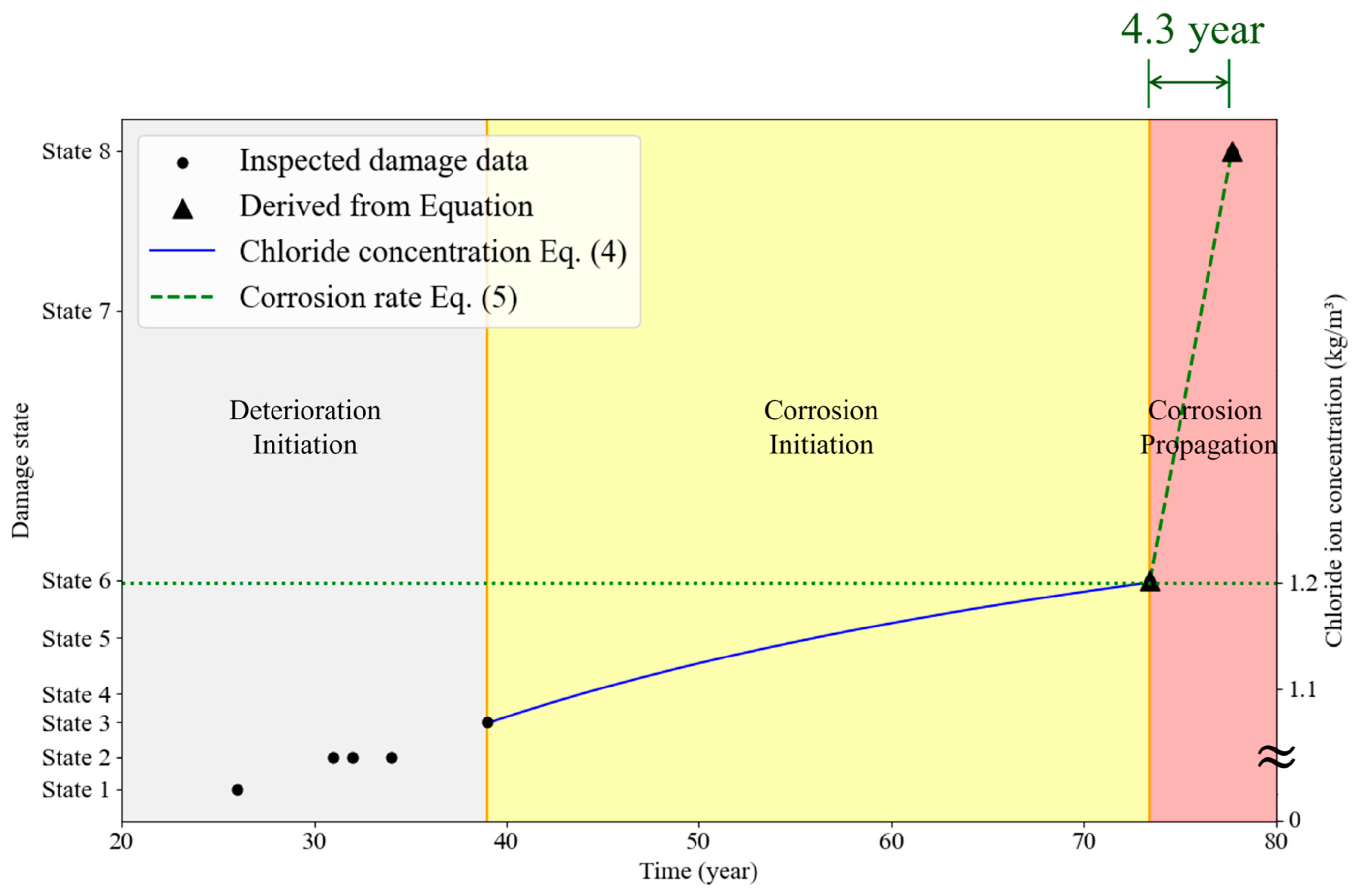

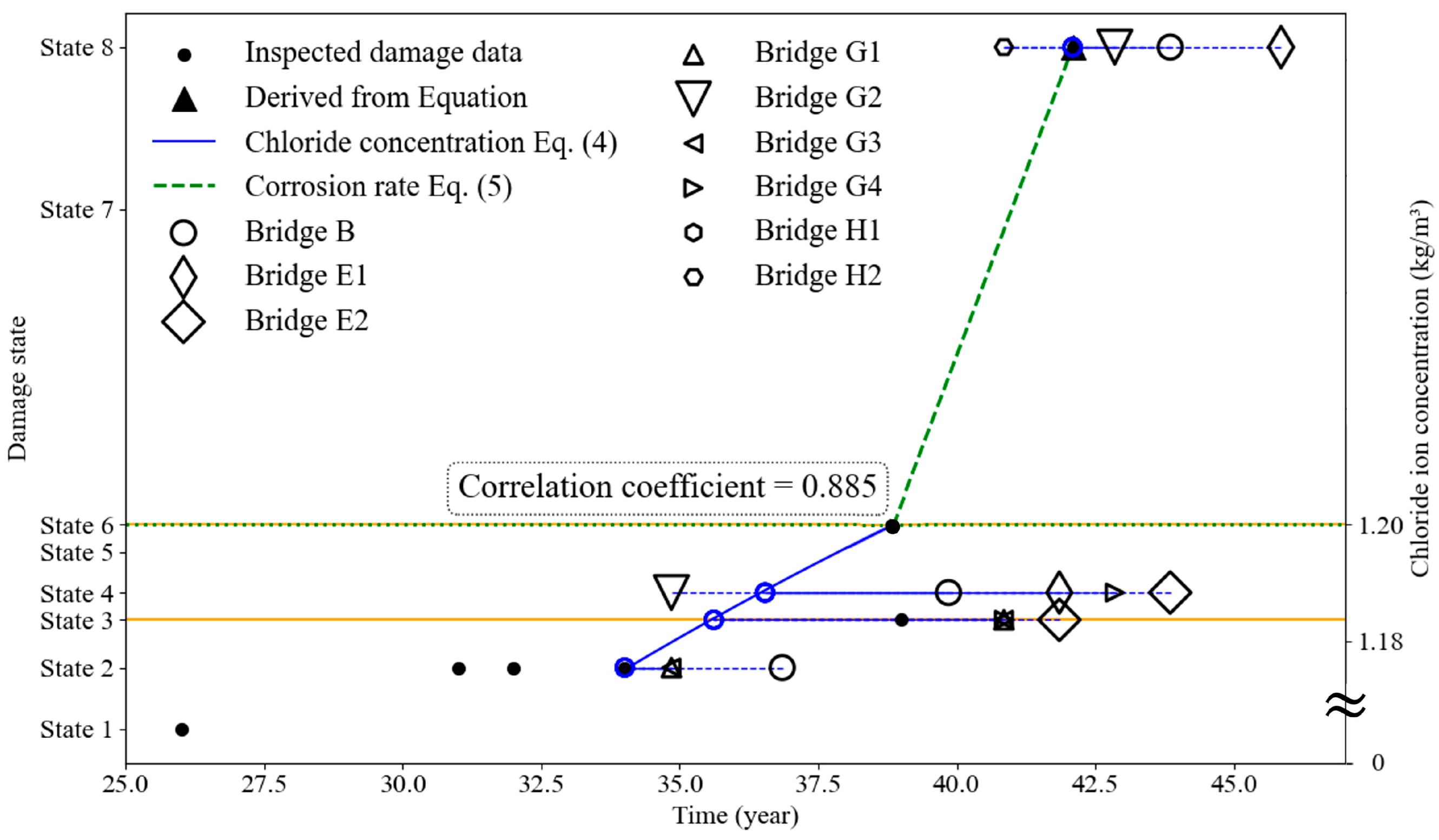

4.4. Digital Twin Model for Predicting the Service Life of the Bridge Slab

5. Conclusions

5.1. Summary of Findings

5.2. Contributions to the Field

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| BIM | Building Information Modeling |

| CDT | Construction Digital Twin |

| FM | facility management |

| ADTT | average daily truck traffic |

References

- Kanavaris, F.; Coelho, M.; Ferreira, N.; Azenha, M.; Andrade, C. A review on the effects of cracking and crack width on corrosion of reinforcement in concrete. Struct. Concr. 2023, 24, 7272–7294. [Google Scholar] [CrossRef]

- Pape, J.F. Impact of Bridge Deck Cracking on Durability. Master’s Thesis, Iowa State University, Ames, IA, USA, 1998. [Google Scholar]

- National Academies of Sciences, Engineering, and Medicine. Guide Specification for Service Life Design of Highway Bridges; The National Academies Press: Washington, DC, USA, 2020. [Google Scholar] [CrossRef]

- Federal Highway Administration (FHWA). Performance of Concrete Highway Bridge Decks Using Nation-Wide Condition Data; FHWA-HIF-18-082; FHWA: Washington, DC, USA, 2018. [Google Scholar]

- Nguyen, D.C.; Jeon, C.H.; Roh, G.; Shim, C.S. BIM-based preassembly analysis for design for manufacturing and assembly of prefabricated bridges. Autom. Constr. 2024, 160, 105338. [Google Scholar] [CrossRef]

- Jang, D.H.; Roh, G.T.; Jeon, C.H.; Shim, C.S. Simulation-based optimization of crane lifting position and capacity using a construction digital twin for prefabricated bridge deck assembly. Buildings 2025, 15, 475. [Google Scholar] [CrossRef]

- BS EN ISO 19650–1; Organization and Digitization of Information About Buildings and Civil Engineering Works, Including BIM—Information Management Using Building Information Modelling. Part 1: Concepts and Principles. British Standards Institution (BSI): London, UK, 2018. Available online: https://www.iso.org/standard/68078.html (accessed on 14 April 2025).

- BS EN ISO 19650–2; Organization and Digitization of Information About Buildings and Civil Engineering Works, Including BIM—Information Management Using BIM. Part 2: Delivery Phase of the Assets. British Standards Institution (BSI): London, UK, 2018. Available online: https://www.iso.org/standard/68080.html (accessed on 14 April 2025).

- BS EN ISO 19650–3; Organization and Digitization of Information About Buildings and Civil Engineering Works, Including BIM—Information Management Using BIM. Part 3: Operational Phase of the Assets. British Standards Institution (BSI): London, UK, 2020. Available online: https://www.iso.org/standard/75109.html (accessed on 15 April 2025).

- Nicał, A.K.; Wodyński, W. Enhancing facility management through BIM 6D. Procedia Eng. 2016, 164, 299–306. [Google Scholar] [CrossRef]

- Lu, Q.; Xie, X.; Parlikad, A.K.; Schooling, J.M.; Konstantinou, E. Moving from building information models to digital twins for operation and maintenance. Proc. Inst. Civ. Eng. Smart Infrastruct. Constr. 2021, 174, 46–56. [Google Scholar] [CrossRef]

- Fang, Z.; Lu, Q.; Xie, X.; Parlikad, A.K.; Schooling, J.; Pitt, M. Definitions and principles of digital twins. In Digital Twins in the Built Environment; ICE Publishing: Leeds, UK, 2022; pp. 5–27. [Google Scholar] [CrossRef]

- Jeon, C.H.; Shim, C.S.; Lee, Y.H.; Schooling, J. Prescriptive maintenance of prestressed concrete bridges considering digital twin and key performance indicator. Eng. Struct. 2024, 302, 117383. [Google Scholar] [CrossRef]

- Roh, G.; Park, J.; Jeon, C.H.; Shim, C.S. Development of a baseline digital twin model as a prerequisite for the digital twin definition of a PSC-I bridge with model updating considering member stiffness. Buildings 2025, 15, 17. [Google Scholar] [CrossRef]

- Holt, R. Concrete bridge deck service-life prediction tools. ASPIRE Winter 2019, 30–31. Available online: https://www.aspirebridge.com/magazine/2019Winter/winter-2019.pdf (accessed on 14 April 2025).

- Ghonima, O.; Schumacher, T.; Unnikrishnan, A.; Fleischhacker, A. Advancing Bridge Technology, Task 10: Statistical Analysis and Modeling of US Concrete Highway Bridge Deck Performance; Portland State University: Portland, OR, USA, 2018; Available online: https://pdxscholar.library.pdx.edu/cengin_fac/443 (accessed on 14 April 2025).

- Gode, K. Predicting the service life of concrete bridges based on quantitative research. Constr. Sci. 2014, 15, 11–18. [Google Scholar] [CrossRef][Green Version]

- Shim, C.-S.; Chang, S.-P. Cracking of continuous composite beams with precast decks. J. Constr. Steel Res. 2003, 59, 201–214. [Google Scholar] [CrossRef]

- Li, S. Analysis of influence of bridge deck damage on first order natural frequency of simply supported T-beam bridge. Vibroeng. Procedia 2021, 36, 43–48. [Google Scholar] [CrossRef]

- Gheitasi, A.; Harris, D.K. Performance assessment of steel–concrete composite bridges with subsurface deck deterioration. Structures 2015, 2, 8–20. [Google Scholar] [CrossRef]

- Hopper, T.; Manafpour, A.; Radlinska, A.; Warn, G.; Rajabipour, F.; Morian, D.; Jahangirnejad, S. Bridge Deck Cracking: Effects on In-Service Performance, Prevention, and Remediation; FHWA-PA-2015-006-120103; FHWA: Washington, DC, USA, 2015. [Google Scholar]

- Fanous, F.; Wu, H.; Pape, J. Impact of Deck Cracking on Durability; Iowa State University: Ames, IA, USA, 2000. [Google Scholar]

- Yang, J.W. A Study on Evaluation of Probability Based Service Life in Carbonated RC Structure; Hanyang University: Seoul, Republic of Korea, 2011. (In Korean) [Google Scholar]

- Nordic Council of Ministers. NT Build 492: Concrete, Mortar and Cement-Based Repair Materials—Chloride Migration Coefficient from Non-Steady-State Migration Experiment. 1999. Available online: https://www.nordtest.info/wp/1999/11/21/concrete-mortar-and-cement-based-repair-materials-chloride-migration-coefficient-from-non-steady-state-migration-experiments-nt-build-492/ (accessed on 14 April 2025).

- Liu, Y. Modeling time-to-corrosion cracking in chloride contaminated reinforced concrete structures. ACI Mater. J. 1999, 96, 611–613. [Google Scholar]

- Ouzaa, K.; Oucif, C. Numerical model for prediction of corrosion of steel reinforcements in reinforced concrete structures. Undergr. Space 2019, 4, 72–77. [Google Scholar] [CrossRef]

- Sapkota, R.; Ahmed, D.; Karkee, M. Comparing YOLOv8 and Mask R-CNN for instance segmentation in complex orchard environments. Artif. Intell. Agric. 2024, 13, 100233. [Google Scholar] [CrossRef]

- Gonzalez, R.C.; Woods, R.E. Digital Image Processing; Pearson: London, UK, 2018. [Google Scholar]

- Shalev-Shwartz, S.; Ben-David, S. Understanding Machine Learning: From Theory to Algorithms; Cambridge University Press: Cambridge, UK, 2014. [Google Scholar]

- Fang, X.; Wang, H.; Liu, G.; Tian, X.; Ding, G.; Zhang, H. Industry application of digital twin: From concept to implementation. Int. J. Adv. Manuf. Technol. 2022, 121, 4289–4312. [Google Scholar] [CrossRef]

| Damage Stage | Description | Remarks |

|---|---|---|

| State 1 | Transverse crack (width is less than 0.1 mm) | |

| State 2 | Transverse crack (width is less than 0.3 mm) | |

| State 3 | Map crack or transverse crack greater than 0.5 mm | |

| State 4 | Efflorescence near cracks | |

| State 5 | Corrosion condition | Leakage, chloride (>0.4%), carbonation depth (>cover) |

| State 6 | Corrosion initiation | Rust stains on the concrete surface |

| State 7 | Severe corrosion | Calculation under given conditions (chloride, carbonation depth) |

| State 8 | Delamination and Spalling | Service life limit |

| Parameter | Value |

|---|---|

| Density of rebar | 7.85 |

| Density of corrosion products | 4.00 |

| Poisson’s ratio of the concrete | 0.18 |

| Ratio between the molecular weights of steel and corrosion products | 0.57 |

| Tensile strength of concrete | 29.2 |

| Elastic modulus of concrete | 280,624.3 |

| Thickness of pore band around the steel/concrete interface | 12.5 |

| Parameter | Value |

|---|---|

| Number of epochs | 300 |

| Batch size | 4 |

| Image resolution | 640 × 640 |

| Initial learning rate | 0.005 |

| Bridge | Girder Type | Span Length (m) | Girder Spacing (m) | Slab Thickness (mm) |

|---|---|---|---|---|

| A | PSC-I | 30.0 | 2.30 | 200 |

| B | PSC-I | 25.0 | 2.45 | 200 |

| C | PSC-I | 30.0 | 2.10 | 200 |

| D | PSC-I | 30.0 | 2.48 | 250 |

| E | PSC-I | 24.2 | 2.30 | 180 |

| F | PSC-I | 32.0 | 2.0 | 250 |

| G | PSC-I | 30.0 | 2.18 | 200 |

| H | PSC-I | 30.0 | 2.0 | 200 |

| I | PSC-I | 29.25 | 2.2 | 200 |

| J | PSC-I | 39.9 | 2.4 | 200 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, H.; Kim, K.; Shin, J.; Roh, G.; Shim, C. Digital Twin Framework for Bridge Slab Deterioration: From 2D Inspection Data to Predictive 3D Maintenance Modeling. Buildings 2025, 15, 1979. https://doi.org/10.3390/buildings15121979

Song H, Kim K, Shin J, Roh G, Shim C. Digital Twin Framework for Bridge Slab Deterioration: From 2D Inspection Data to Predictive 3D Maintenance Modeling. Buildings. 2025; 15(12):1979. https://doi.org/10.3390/buildings15121979

Chicago/Turabian StyleSong, Hyunhye, Kiyeol Kim, Jihun Shin, Gitae Roh, and Changsu Shim. 2025. "Digital Twin Framework for Bridge Slab Deterioration: From 2D Inspection Data to Predictive 3D Maintenance Modeling" Buildings 15, no. 12: 1979. https://doi.org/10.3390/buildings15121979

APA StyleSong, H., Kim, K., Shin, J., Roh, G., & Shim, C. (2025). Digital Twin Framework for Bridge Slab Deterioration: From 2D Inspection Data to Predictive 3D Maintenance Modeling. Buildings, 15(12), 1979. https://doi.org/10.3390/buildings15121979