1. Introduction

Cement is the essential binder in mortar and concrete. With its excellent compressive strength and low cost, concrete is widely used in the construction of infrastructure and civil and military works. However, concrete, in particular, and cement-based materials, in general, have low tensile strength and brittle properties [

1]. Therefore, improving these properties to minimize the negative impacts of these drawbacks has been a subject of research. Methods to improve the brittleness and tensile strength of concrete primarily focus on adding additives or reinforcement materials such as steel fibers, polymer fibers, FRP, and other polymers. Among these, the incorporation of polymers as additives into concrete has received significant attention.

Styrene–butadiene rubber (SBR) is a copolymer made from two monomers, styrene and butadiene, and is widely used in the construction industry [

2]. Numerous studies have been conducted to assess the effects of SBR latex on concrete. Observations show that adding SBR latex to concrete and cement mortar improves tensile strength and enhances flexural strength while slightly reducing compressive strength [

3,

4,

5,

6,

7,

8]. An experimental study tested five grades of concrete from M20 to M60, with polymer emulsion dosages from 5% to 10%, and found that adding polymer to concrete can improve compressive strength, tensile strength, and flexural strength, with significant improvements at a 10% polymer content. Specifically, compressive strength increased by 16.25% to 33.4%, tensile strength increased by 5.1% to 19.8%, and flexural strength increased by 13.2% to 18.4%. Additionally, water permeability decreased by up to 32.40%, while the elastic modulus increased by 6.21% to 10.91% when using 10% polymer in the concrete. These results indicate that adding polymer not only improves the mechanical properties of concrete but also reduces water permeability and enhances the material’s elasticity, especially for low- and medium-strength concrete. Moreover, Li et al. [

9] also showed that the optimal polymer SBR content is 5%, which significantly improves flexural strength without significantly reducing compressive strength, with similar improvements in permeability and load-bearing capacity. Rossignolo and Agnesini (2002) [

10] demonstrated that adding SBR to concrete could increase flexural strength by up to 32% compared to unmodified concrete, particularly when the SBR content was 3% and 5% by weight. Their study also showed that combining SBR and steel fibers in concrete improves overall mechanical properties, especially flexural strength and load-bearing capacity, opening up possibilities for developing concrete materials with higher elasticity and better load resistance, which are highly beneficial for dynamic load applications. Although compressive strength slightly decreases, adding SBR enhances energy absorption and the toughness of concrete, particularly after reaching the ultimate load. According to this study, adding SBR to concrete improves the microstructure, creating a stronger bond between the concrete components (steel fibers, aggregates, and cement), thereby enhancing the flexural strength and overall durability of the concrete.

In another study, Rossignolo and Agnesini (2004) [

11] focused on evaluating the durability of lightweight concrete (LWAC) modified with SBR, with tests on corrosion resistance, chemical resistance, and water absorption. They found that LWAC modified with SBR exhibited superior corrosion resistance and chemical attack resistance compared to unmodified concrete, particularly in resisting acid attacks and reducing water absorption. Specifically, adding SBR reduced the water absorption of concrete from 10% to 2.3% when the polymer/cement ratio reached 10%. These results suggest that LWAC modified with SBR could be an ideal choice for construction in harsh environments, especially in marine environments.

While previous studies mainly focused on improving the mechanical and physical properties of polymer-modified concrete, Cao et al. [

12] performed a microstructural analysis to understand the mechanisms by which polymers alter physical properties and improve the bending toughness of concrete. They pointed out that cross-linked polymers encapsulate the cement matrix to form a robust network structure that fills and partially fixes discontinuities, thus altering the microstructure of the hardened concrete. This helps to improve the cohesion and reduce microfailures. Moreover, the thickness of the transition zone was reduced, and the transition zone’s micro-hardness was improved by the reaction consuming Ca(OH)

2, leading to improved mechanical behaviors of concrete, especially its bending toughness.

It can be seen that combining concrete with polymers exploits the advantages of both materials. Evaluations of compressive strength, flexural strength, and physical properties such as permeability from the above studies confirm this. Another crucial factor for assessing the effectiveness of SBR latex in improving concrete’s drawbacks is the material’s toughness, which is reflected in its energy absorption capabilities, such as fracture energy (G

F) or Charpy impact energy. These are essential factors for evaluating a material’s ability to withstand sudden mechanical impacts or dynamic loads. The Charpy test is one of the most common methods for testing the durability and energy absorption of materials. This test is widely applied to various materials such as metals, plastics, composites, and ceramics. Nguyen, D-H et al. [

13] and Nguyen, Tri NM et al. [

14] evaluated the impact of SBR latex on cement mortar with different proportions ranging from 0% to 20%. Both authors confirmed that SBR latex improved the impact resistance of cement mortar. However, previous studies were limited because the Charpy test for cement paste had not been standardized and lacked specific guidelines. Moreover, in their studies, the support span—an important parameter influencing test results—was not explained. Specifically, in the study by Nguyen, D-H et al. [

13], Charpy testing was performed with two support spans, 40 mm and 20 mm, but the rationale and necessary recommendations were not provided. In contrast, the study by Nguyen, Tri NM et al. [

14] did not mention this parameter at all.

In this study, I use the Charpy test to evaluate the energy absorption capacity of cement paste modified with SBR latex with a more comprehensive approach. Specifically, I will investigate different sample support spans and assess the failure modes of the specimens. Additionally, I will calculate the fracture energy (GF) value to compare with the Charpy test results, establishing a correlation between the two. This will provide further grounds for evaluating the effectiveness of the Charpy test for cement paste, a material for which no standardized testing method currently exists.

Fracture energy is an important parameter in fracture mechanics, helping to predict crack behavior and understand the mechanisms of crack formation and development from micro-cracks to material failure. Moreover, fracture energy can also be used as a parameter in detailed simulation analyses, such as in commercial finite element analysis program to determine structural behavior, such as crack propagation and impact energy calculations. This will help engineers predict and improve the fracture resistance of concrete, especially in applications requiring materials with good toughness and energy absorption, such as in structures subjected to dynamic loads or sudden impacts.

The most direct method to determine fracture energy (G

F) is by performing a stable uniaxial tensile test. However, performing tensile tests with high stability and representativeness is very challenging. A simpler method, proposed by the RILEM TC-50 FMC Technical Committee on Fracture Mechanics of Concrete Testing Methods [

15], is based on calculating the total work of fracture from three-point bending tests on specimens with a central U-notch. Hillerborg [

16] analyzed the effectiveness of this test method by comparing results from approximately 700 concrete beam samples of different sizes tested in 14 laboratories. He concluded that the method is suitable for use in laboratories with standard equipment, although a dependence of fracture energy (G

F) on specimen size was detected. However, this size dependence was not considered more significant than the size dependence observed in standard compressive strength tests when calculating structural strength.

Recently, the digital image correlation (DIC) technique has often been used to directly investigate crack behavior and crack propagation in concrete or cement-based materials. DIC allows real-time tracking of strain fields and displacement distributions with high accuracy, as demonstrated in the works of Choi et al. [

17], Kozicki et al. [

18], Shah et al. [

19], and Wu et al. [

20]. However, within the scope of this study, where fracture mechanics focuses on quantifying fracture energy, the three-point bending test method proposed by the RILEM TC-50 Technical Committee on Fracture Mechanics of Concrete Testing Methods will be adopted.

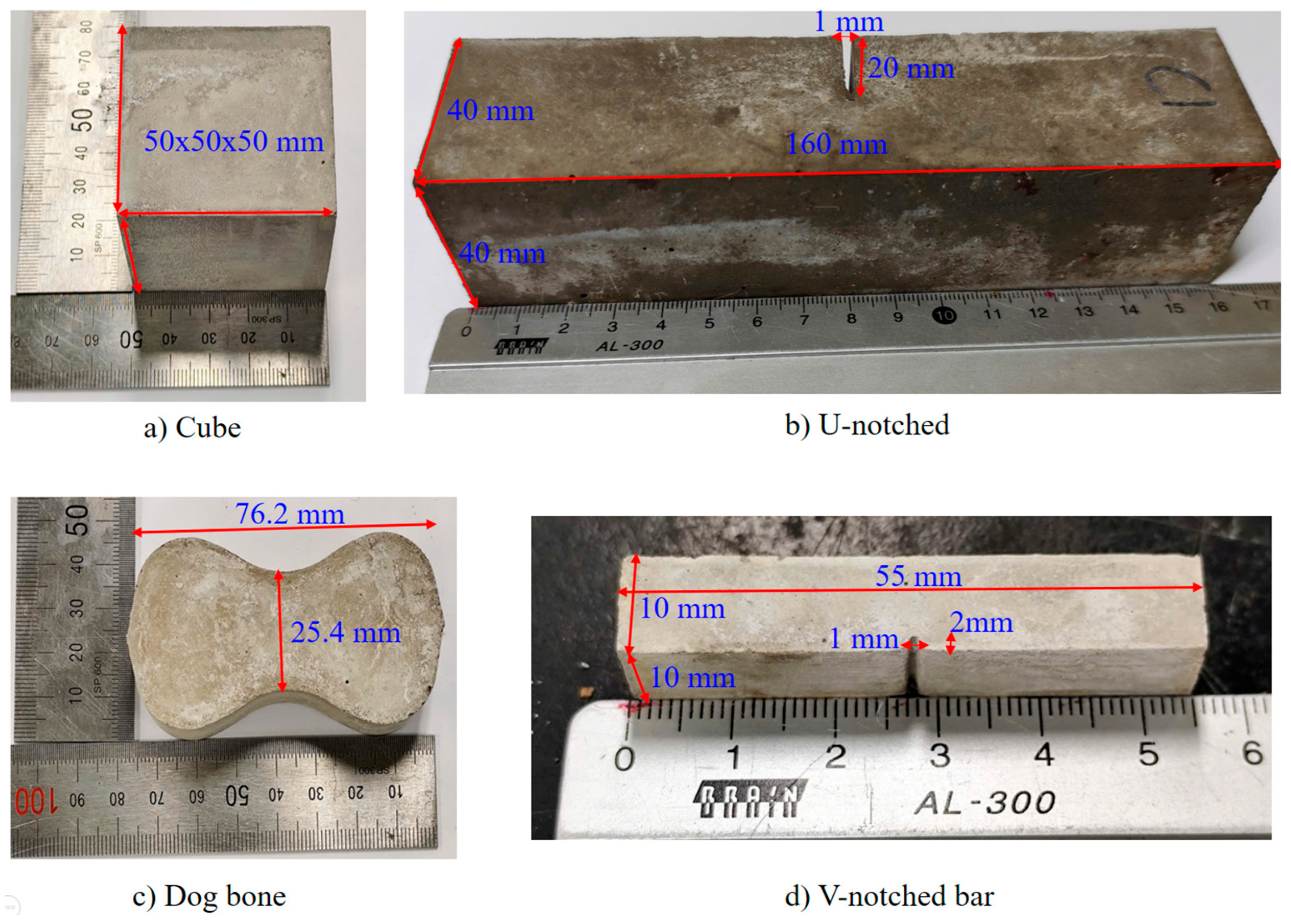

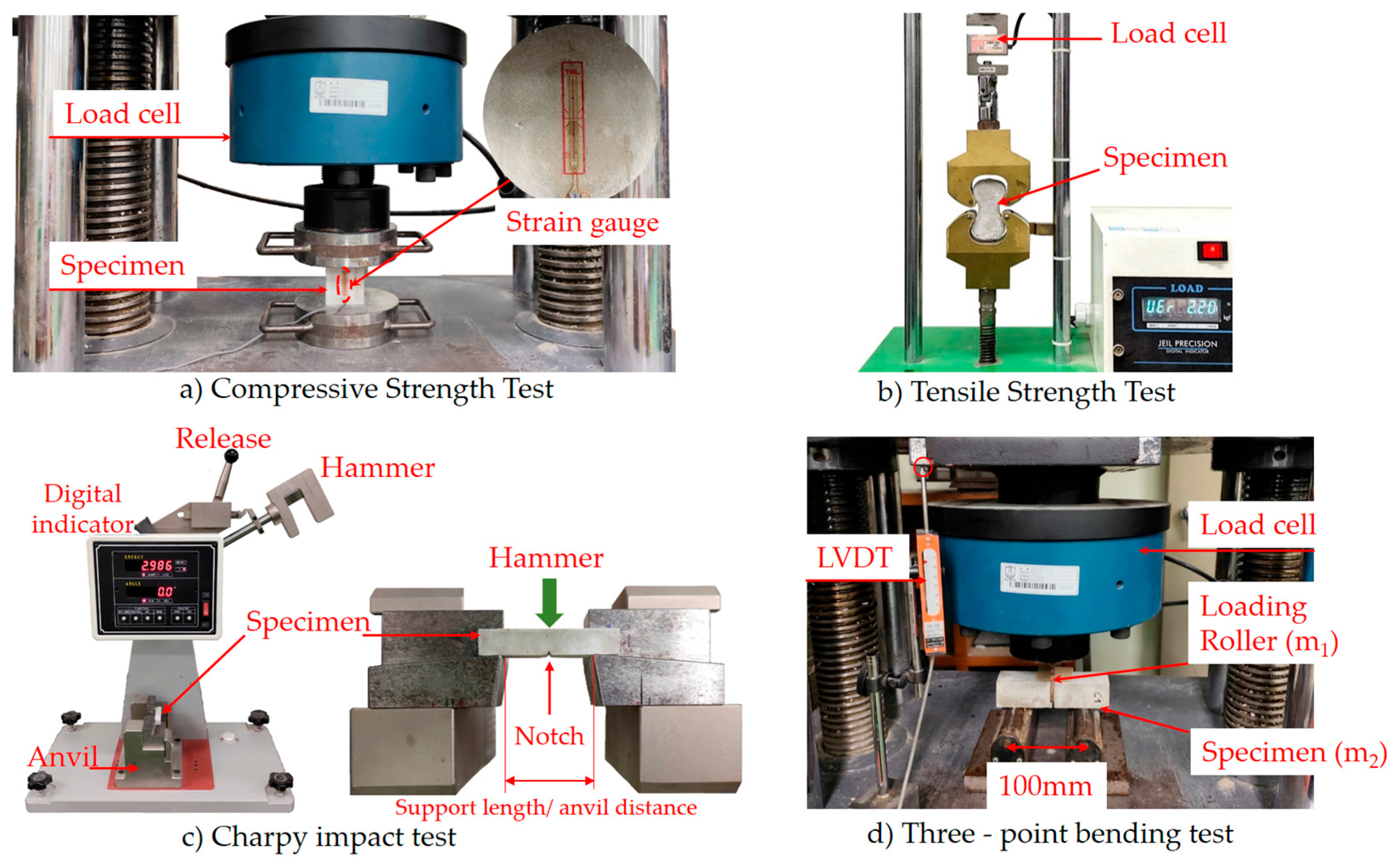

In this study, cement paste modified with SBR latex at polymer-to-water (P/W) ratios of 0%, 5%, 10%, 15%, and 20% was tested through a series of experiments, including Charpy impact tests, three-point bending tests, tensile strength tests, and compressive strength tests. The Charpy impact test was performed on samples cured at different times, 7, 14, and 28 days, while the three-point bending, tensile strength, and compressive strength tests were performed on samples at 28 days.

3. Results and Discussion

3.1. Compressive Strength and Tensile Strength

The results of the compressive strength and tensile strength tests of the cement paste at 28 days of curing are presented in

Figure 3 and

Table 3. The experimental results show several trends when evaluating the effect of the polymer-to-water (P/W) ratio on the mechanical properties of the cement paste. In general, the compressive strength of the cement paste tends to decrease, while the tensile strength tends to increase when using modified SBR latex in the cement paste.

Compressive Strength

The compressive strength of the cement paste decreases from 42.82 MPa (at 0% P/W) to 39.75 MPa (at 20% P/W). Although this change is not significant, the clear decreasing trend at higher polymer ratios can be explained by the polymer’s interference with the cement structure, reducing the bond density between cement particles and resulting in a decreased compressive strength. This could be due to the formation of a polymer network in the concrete structure, which alters the mechanical properties of the cement paste and makes the material more susceptible to compression. These results are reflected in the compressive strength graph in

Figure 3a, which shows a slight but stable change as the P/W ratio increases.

This decreasing trend in compressive strength is consistent with the findings of Wang et al. [

6,

7], who demonstrated that SBR latex reduces compressive strength due to its lower mechanical strength compared to cement. Additionally, the incorporation of SBR latex increases the porosity of the matrix, which contributes to a reduction in strength. These findings also align with the report by Wang [

27], which emphasized that a higher P/W ratio leads to increased ettringite content and a reduction in calcium hydroxide concentration. Both of these changes significantly impact the compressive strength of the material.

Tensile Strength

As shown in

Figure 3b, the tensile strength of the cement paste increased across all polymer-to-water (P/W) ratios tested (5%, 10%, 15%, and 20%). This increase is attributed to the cross-linked polymers encapsulating the cement matrix, creating a robust structure that helps reduce microfailures while enhancing the microhardness interface transition zone [

12].

The increase in tensile strength of the cement paste, when combined with SBR latex, follows a clear trend with a limited SBR latex content in the mix. Specifically, when the P/W ratio is below 10%, tensile strength increases, with the largest increase of 42.1% observed at the P/W ratio of 10%. Beyond this point, the tensile strength gradually decreases from P/W 10% to 20%. This result is consistent with the findings of Idrees and Nazar [

28], who reported that the indirect (split) flexural and tensile strengths of concrete improved as the SBR content increased, with optimal performance observed at a polymer-to-cement ratio of around 5%, corresponding to a P/W ratio of 10% in this study.

Overall, the basic properties of the cement paste, including tensile and compressive strength, have been clarified in this study. These results not only confirm the stability of the samples but also provide a solid foundation for further evaluation of energy absorption and fracture energy, the primary objectives of this study. These assessments highlight the advantages of SBR latex-modified cement paste in practical applications, particularly in improving toughness and impact resistance.

3.2. Impact Resistance

The Charpy impact test was conducted to evaluate the energy absorption capacity of SBR latex-modified cement paste. As expected, all the samples were completely fractured during the test, confirming the validity of the observations from the Charpy test.

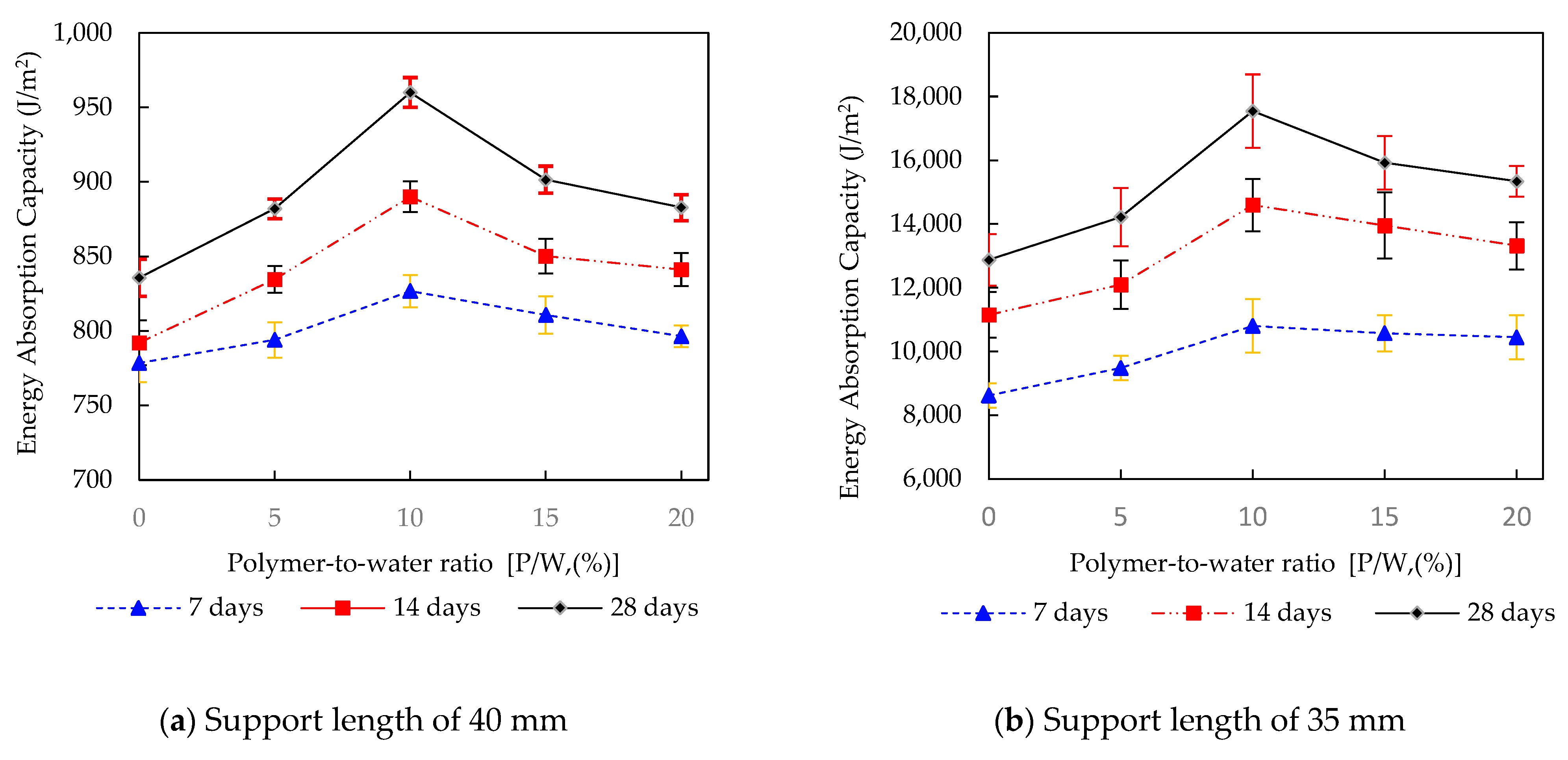

Figure 4 and

Table 4 present the results of energy absorption (J/m

2), calculated as the average value from six samples for each P/W ratio. The results show that the energy absorption capacity of SBR latex-modified cement paste significantly increases with longer curing times. This improvement can be attributed to the combined effects of polymer film formation and the hydration process of the cement.

With a support length of 40 mm,

Figure 4a and

Table 4 show the increase in energy absorption over curing time and the polymer-to-water (P/W) ratio. After 7 days of curing, the energy absorption of the SBR latex-modified cement paste increased slightly by 2 to 6.2%. After 14 days, the increase in energy absorption was more significant, with a 12.4% rise at a 10% P/W ratio. After 28 days of curing, the crystalline structure of the cement paste was further optimized with the use of SBR latex, and the increase in energy absorption reached 14.9% at a 10% P/W ratio. Similar to the samples of cement paste cured at 7 days and 14 days, the energy absorption of the cement paste at 28 days tended to decrease when the P/W ratio exceeded 10%. This suggests that excessive use of SBR may negatively affect the gel structure and the mechanical performance of the material, as noted by Li et al. [

9].

The effect of SBR latex on the energy absorption capacity of the cement paste is clearly demonstrated in the experimental results with a 35 mm support length (

Figure 4b and

Table 4). The results show a significant increase in energy absorption at various P/W ratios compared to the 40 mm support length. All samples at the three curing stages showed nearly double the energy absorption and increase compared to the results obtained at the 40 mm anvil distance. The highest increase in energy absorption at a 10% P/W ratio occurred at 7 days, 14 days, and 28 days, with increases of 25.3%, 31.0%, and 36.3%, respectively. The trend in energy absorption at the 35 mm support length was similar to that at 40 mm, but the results show that the standard deviation of the energy values obtained at the 35 mm support length was much larger, indicating greater dispersion in the results. This may be due to the fact that at 40 mm, the cement paste is primarily fractured by bending, leading to less dispersion and more focused results, while at the 35 mm support length, the fracture is a combination of bending and shear, leading to higher dispersion and greater energy absorption.

As analyzed, the energy absorption capacity of SBR latex-modified cement paste increases with higher polymer content, with the optimal ratio being P/W 10%. These results are consistent with the findings of Ohama et al. [

29] and Nguyen, Tri NM. et al. [

14]. A key highlight of this study is the discovery of the impact of support length on the Charpy impact energy results, which had not been addressed in previous studies. Specifically, this study shows that the cement paste sample size of 10 × 10 × 55 mm is suitable for a 40 mm support distance in the Charpy test.

3.3. Fracture Energy and Its Correlation with Charpy Impact Energy in SBR Latex-Modified Cement Paste

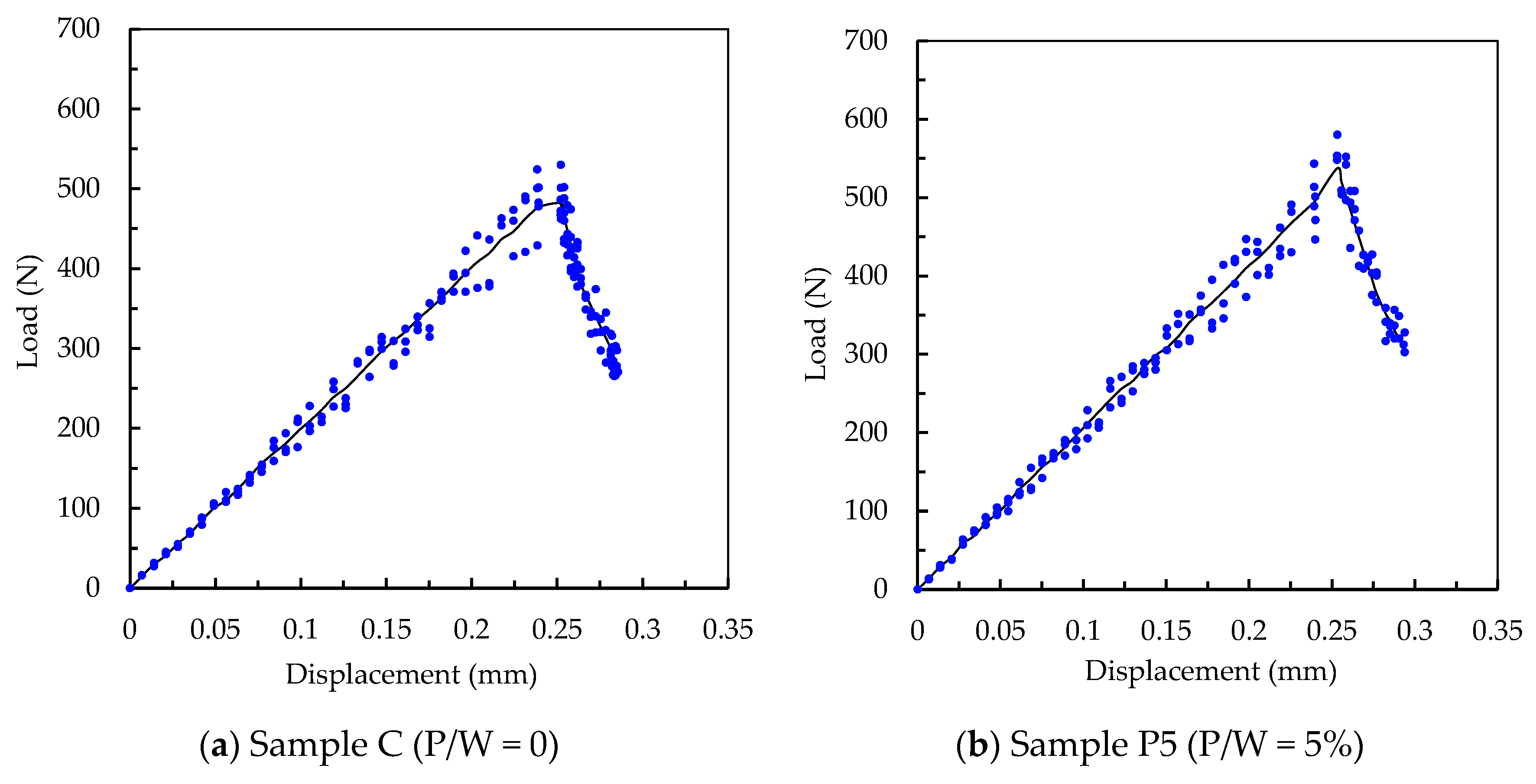

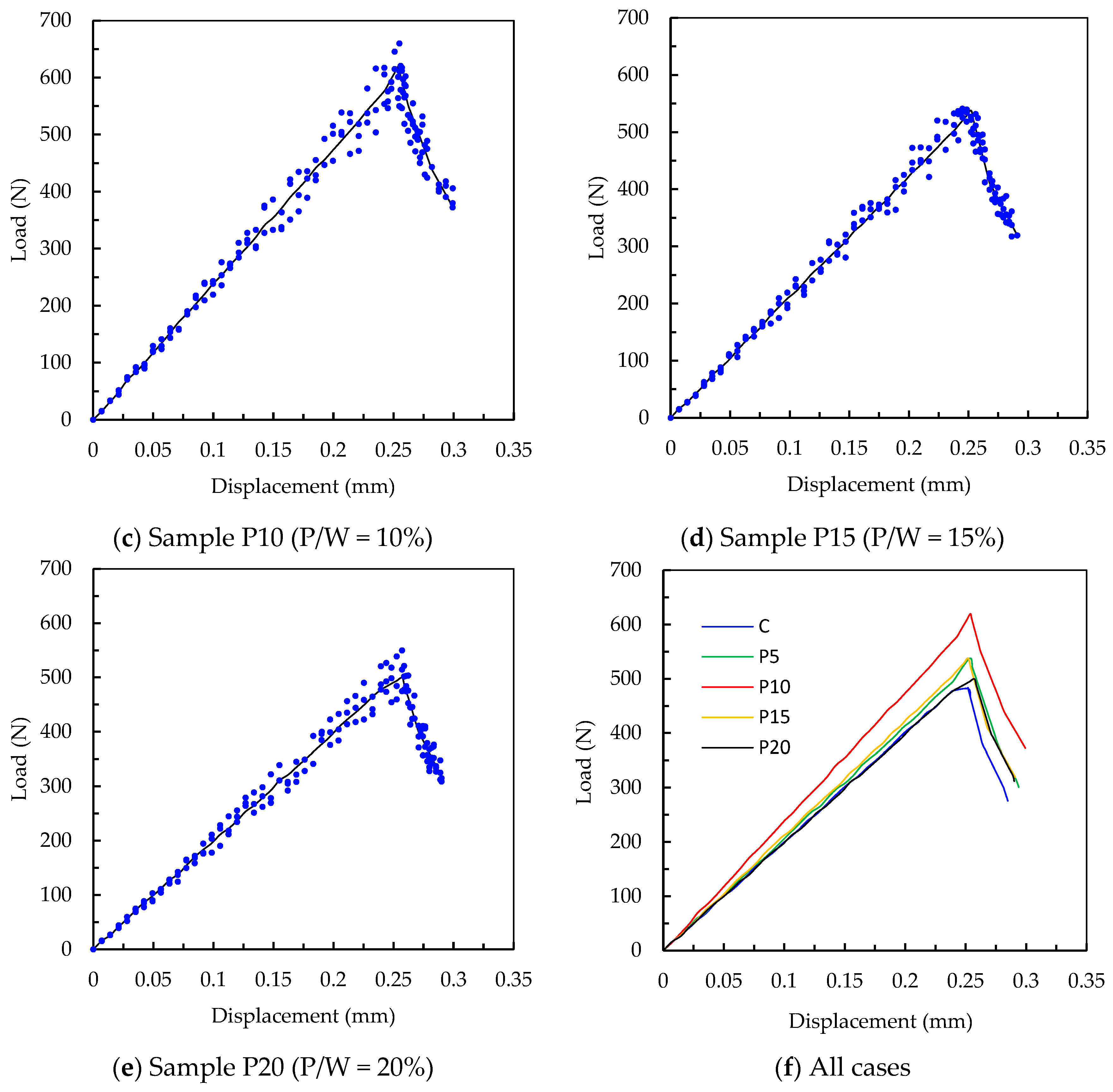

The three-point bending test was conducted on U-notched cement paste beams after 28 days of curing. The experimental data are presented through load–displacement curves in

Figure 5, reflecting the variation in load corresponding to different polymer-to-water (P/W) ratios, ranging from 0% to 20%. Each graph illustrates the relationship between the applied load and displacement throughout the entire bending test.

Based on the average curves obtained from three specimens, the typical brittle behavior of cement paste can be clearly observed. In the initial phase, the load increased almost linearly with displacement, indicating the elastic response of the material. Minor fluctuations during this stage may be associated with micro-elastic deformation and the formation of microcracks as the load increases. Upon reaching the peak load, the specimens failed abruptly, resulting in a sudden load drop.

A notable contrast can be seen when comparing these results with those reported by Pavel et al. [

30]. While the specimens in this study demonstrated clear brittle failure characterized by a sharp drop immediately after the peak, the load–displacement curves in Pavel’s study exhibited an extended post-peak tail approaching near-zero load—a behavior not typically observed in plain cement paste. In repeated trials conducted in this study, such behavior was never encountered; once the peak was surpassed, failure occurred instantaneously, with no substantial residual load capacity.

This difference may stem from variations in specimen geometry and test setup. Specifically, Pavel and colleagues used small beam specimens (20 × 20 × 100 mm) with U-notches 7–11 mm deep and a support span of 80 mm—conditions that can significantly alter stress distribution and influence crack propagation. Therefore, the prolonged post-peak response observed in their study may reflect the influence of testing configuration rather than the intrinsic mechanical behavior of unreinforced cement paste. In contrast, the results of this study—supported by consistent repetition—indicate that plain cement paste typically exhibits brittle failure, characterized by a steep decline in load immediately after the peak, which is consistent with the nature of brittle materials.

Furthermore, a study by De Domenico et al. [

26] on concrete beams reinforced with polybenzoxazole (PBO) mesh at the tension face, incorporated into an FRCM system with two surrounding mortar layers, demonstrated a similar initial trend: load and displacement increased linearly, reflecting elastic behavior. Once cracking occurred in the tension zone of the concrete, a sharp load drop was observed. However, due to the contribution of the PBO mesh, displacement continued to increase while the load decreased gradually, illustrating the mesh’s capacity for tensile resistance and stress redistribution post-cracking. These observations further reinforce the characterization of cementitious materials as inherently brittle when unreinforced.

To improve the reliability of the calculated fracture energy values, the correlation between fracture energy (GF) and Charpy impact energy is also examined in this study.

Figure 5a through 5e present the individual test results for each specific polymer-to-water ratio (0%, 5%, 10%, 15%, and 20%). In these figures, the data points represent the measured experimental results (F, δ) from three specimens per ratio, while the solid lines show the corresponding trend curves for each polymer-to-water ratio.

The composite

Figure 5f provides an overall view of the load–displacement behavior for all the P/W ratios. This chart highlights the differences in material behavior at different P/W ratios, clearly identifying the optimal ratio for improving fracture energy. The 10% P/W ratio shows the highest fracture energy, suggesting that this polymer ratio optimizes the mechanical properties and load-bearing capacity of the SBR latex-modified cement paste. On the other hand, higher P/W ratios (15% and 20%) show a slight decrease in fracture energy, likely due to the changes in the microstructure of the material as the polymer content increases, which makes the material less flexible.

These charts provide an important overview of the relationship between the P/W ratio and the load-bearing capacity of the SBR latex-modified cement paste, helping to determine the optimal P/W ratio to achieve the best crack resistance.

The fracture energy (G

F) results for SBR latex-modified cement paste at different P/W ratios show a distinct change in energy absorption as the P/W ratio increases. Initially, the control cement paste (P/W = 0) had a fracture energy of 97.19 J/m

2 (

Table 3). As the P/W ratio increases, G

F also increases significantly, especially at the 10% P/W ratio, where G

F reaches its highest value of 125.93 J/m

2, corresponding to a 29.6% increase compared to the initial cement paste.

The growth in fracture energy continues to decrease as the P/W ratio increases to 15% and 20%, with GF values of 106.85 J/m2 and 101.6 J/m2, respectively. Specifically, the increases compared to the original cement paste are 9.9% and 4.5%, respectively.

These results suggest that the addition of SBR latex to the cement paste improves fracture energy absorption, but only up to an optimal ratio of 10% P/W. After this, continuing to increase the P/W ratio leads to a slight reduction in fracture energy, which could be due to changes in the cement matrix structure or the effects of too high a polymer ratio. Overall, the P/W = 10% ratio shows the optimal improvement in fracture energy for SBR latex-modified cement paste.

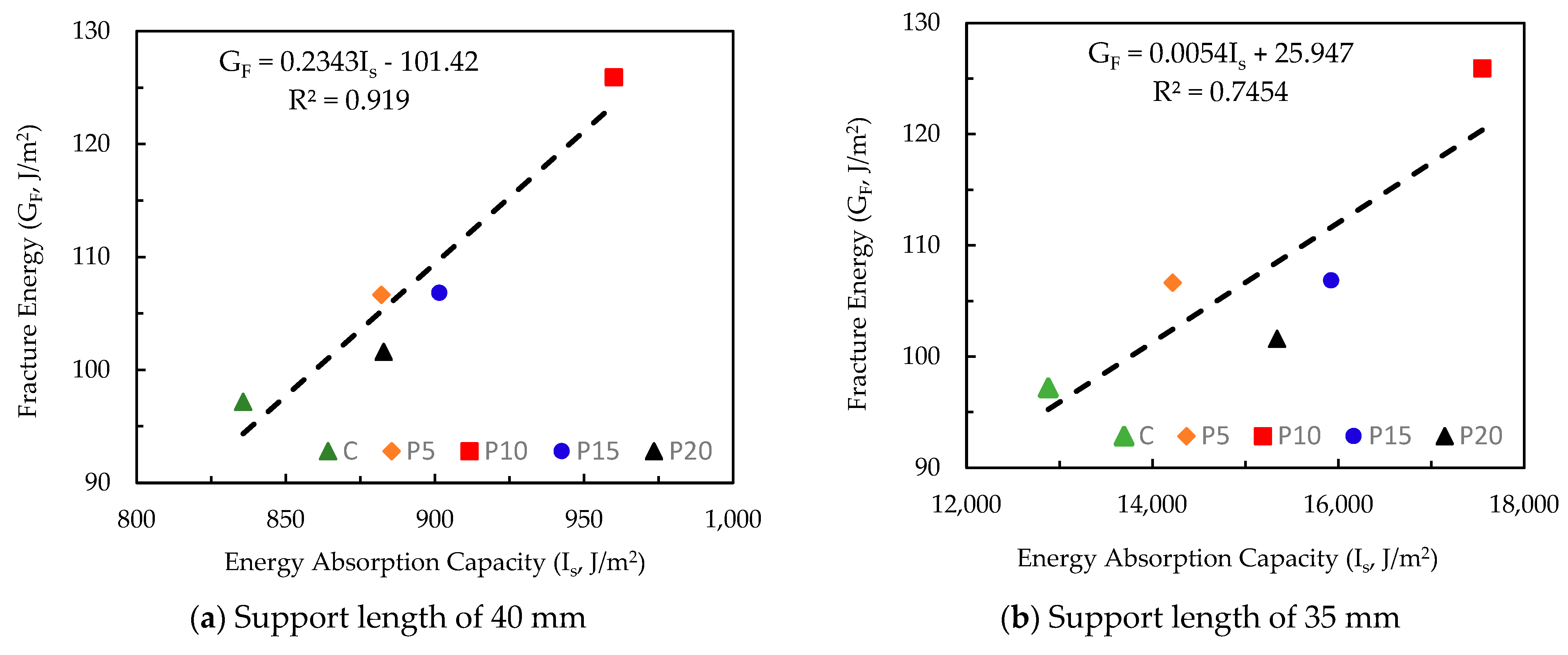

Figure 6 shows the correlation between fracture energy (G

F) and Charpy impact energy (I

s) in SBR latex-modified cement paste, with results categorized by the polymer-to-water ratio (P/W).

Figure 6a (support length of 40 mm) shows a stronger correlation with a high R

2 value of 0.919, indicating a clear relationship between fracture energy and Charpy impact energy. Specifically, at a P/W ratio of 10%, the fracture energy is highest, and its correlation with Charpy impact energy is also stronger.

Figure 6b (support length of 35 mm) shows a lower correlation (R

2 = 0.7454), indicating that the fracture energy reflects changes in Charpy impact energy less clearly than the 40 mm support length.

In conclusion, while the compressive strength of SBR latex-modified cement paste shows a slight decrease, the mechanical properties of the modified cement paste, such as tensile strength, energy absorption capacity, and fracture energy, all exhibit a similar trend of improvement. The optimal polymer-to-water ratio is 10%, suggesting that the modified cement paste is suitable for impact-resistant applications.

4. Conclusions

This study evaluates the effects of using SBR latex emulsion to modify cement paste on the material’s mechanical properties and energy absorption capacity. The experiments conducted included compressive strength, tensile strength, Charpy impact energy, and fracture energy (GF) measured through the three-point bending method. The cement paste samples were prepared with polymer-to-water (P/W) ratios ranging from 0% to 20% in order to determine the optimal ratio for improving mechanical performance and impact load resistance.

The key conclusions drawn from this study are as follows:

A polymer-to-water (P/W) ratio of 10% is optimal for improving the tensile strength, fracture energy, and impact energy of the modified cement paste.

Compressive strength decreases slightly as the P/W ratio increases, while tensile strength increases significantly, especially at the P/W ratio of 10%, with an increase of up to 42.1%. However, beyond this ratio, tensile strength slightly decreases, indicating that the effect of SBR latex polymer on ductility and bonding has limits.

Charpy impact energy increases with curing time (7, 14, and 28 days) as well as with increasing P/W ratios (from 0% to 20%), reaching its optimal value at P/W = 10%. The energy absorption capacity increases by 14.9% and 36.3% at the optimal P/W ratio of 10% with support lengths of 40 mm and 35 mm, respectively.

Fracture energy (GF), determined from the three-point bending test, confirms that ductility increases at all P/W ratios, with the greatest increase of 29.6% at the P/W ratio of 10%. This trend is similar to the energy absorption capacity, reflecting the ductile properties of the SBR latex-modified cement paste.

A strong correlation (R2 = 0.919) was found between fracture energy and Charpy impact energy at a support length of 40 mm, confirming that this support length is more suitable for assessing the material’s toughness. This clarifies the argument that the dominant failure mode is flexural, with minimal error at a 40 mm support length.

The findings of this study support the application of SBR latex-modified cement paste in sustainable construction, particularly in harsh environments that demand materials with high durability and impact load resistance.