Non-Conventional and Sustainable Retrofitting of Fire-Exposed Reinforced Concrete Columns Using Basalt Fiber–Engineered Geopolymer Composites

Abstract

1. Introduction

1.1. General

1.2. Research Significance

2. Experimental Program

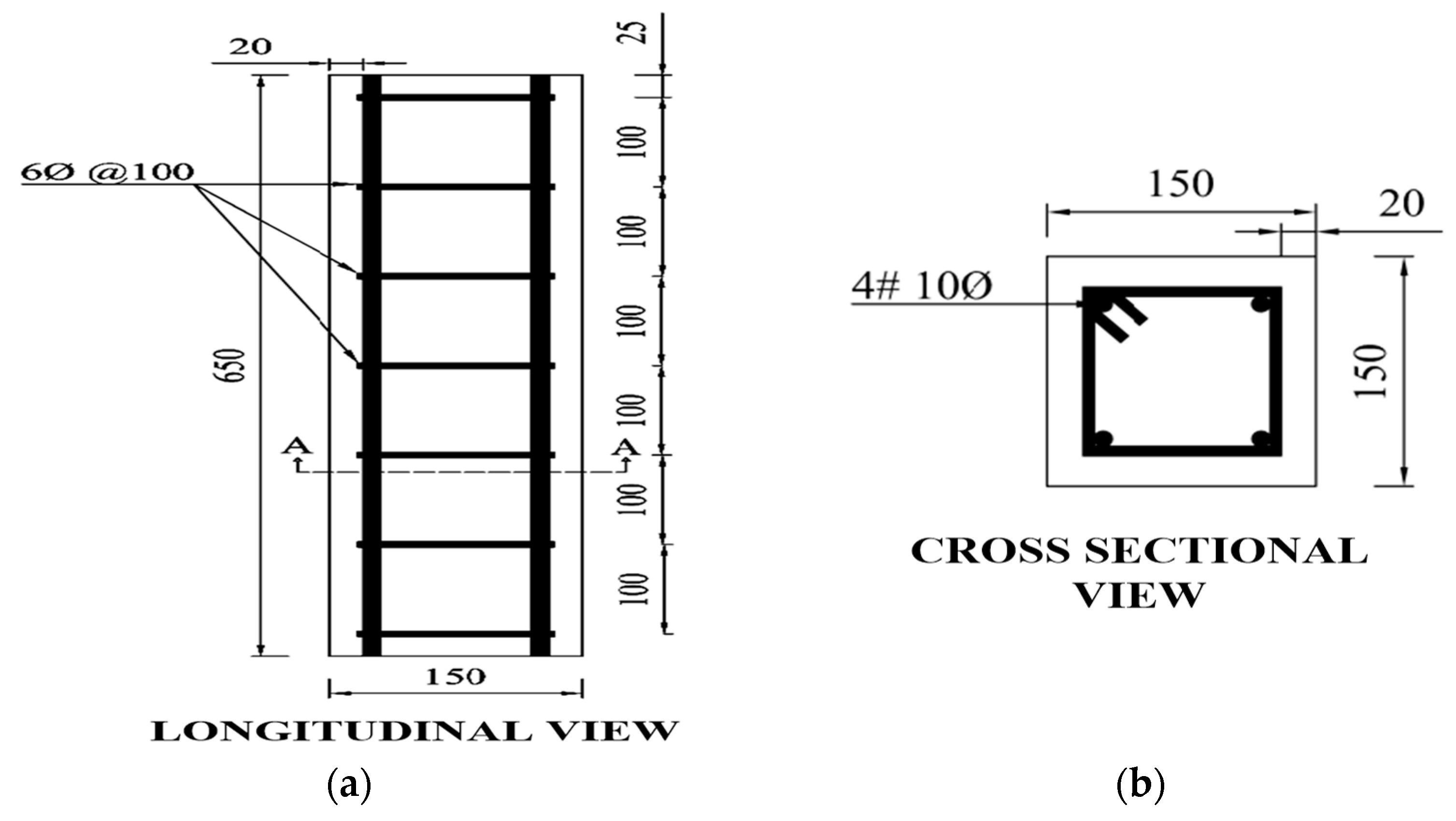

2.1. Description of the Specimens

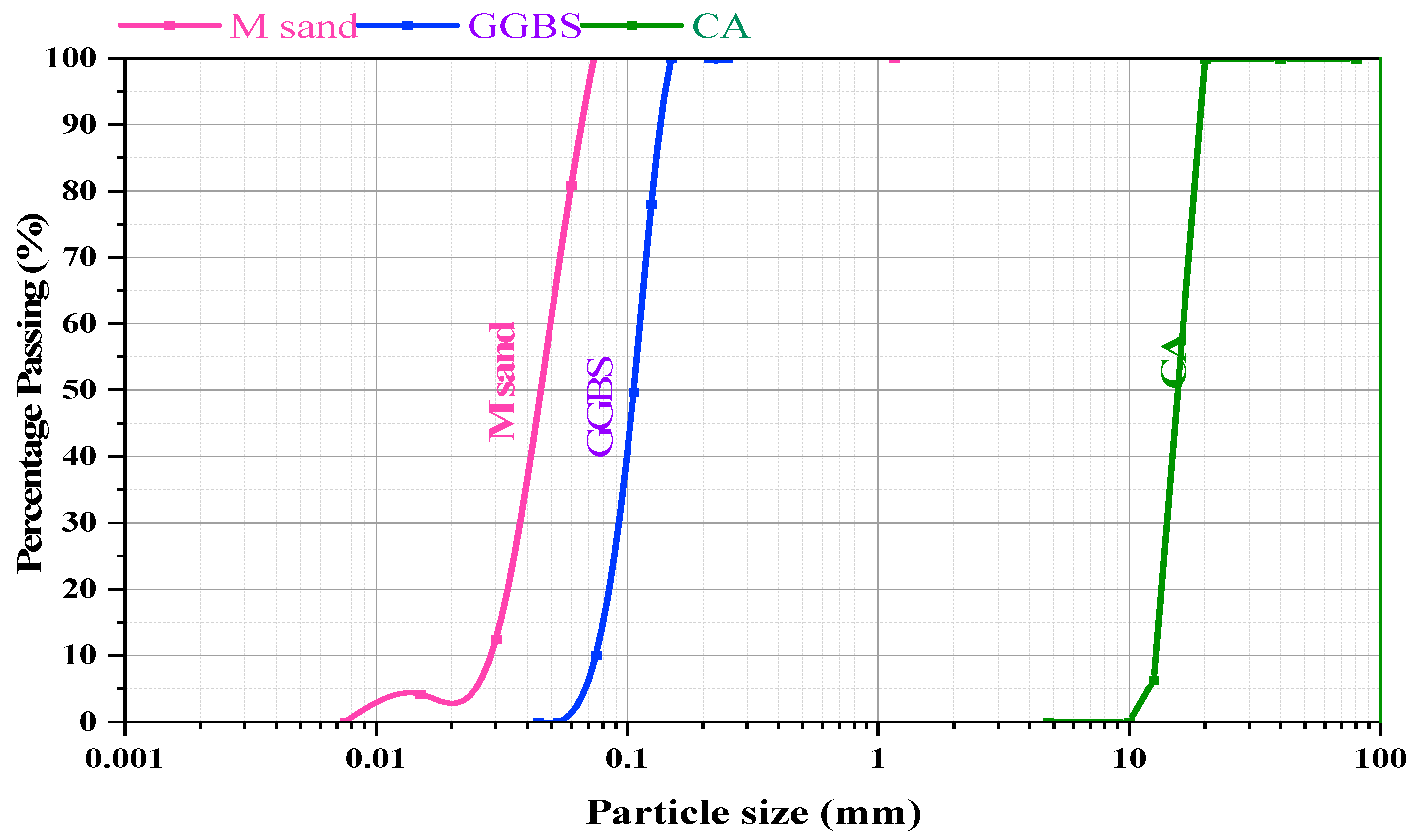

2.2. Materials

Casting of Column Specimens

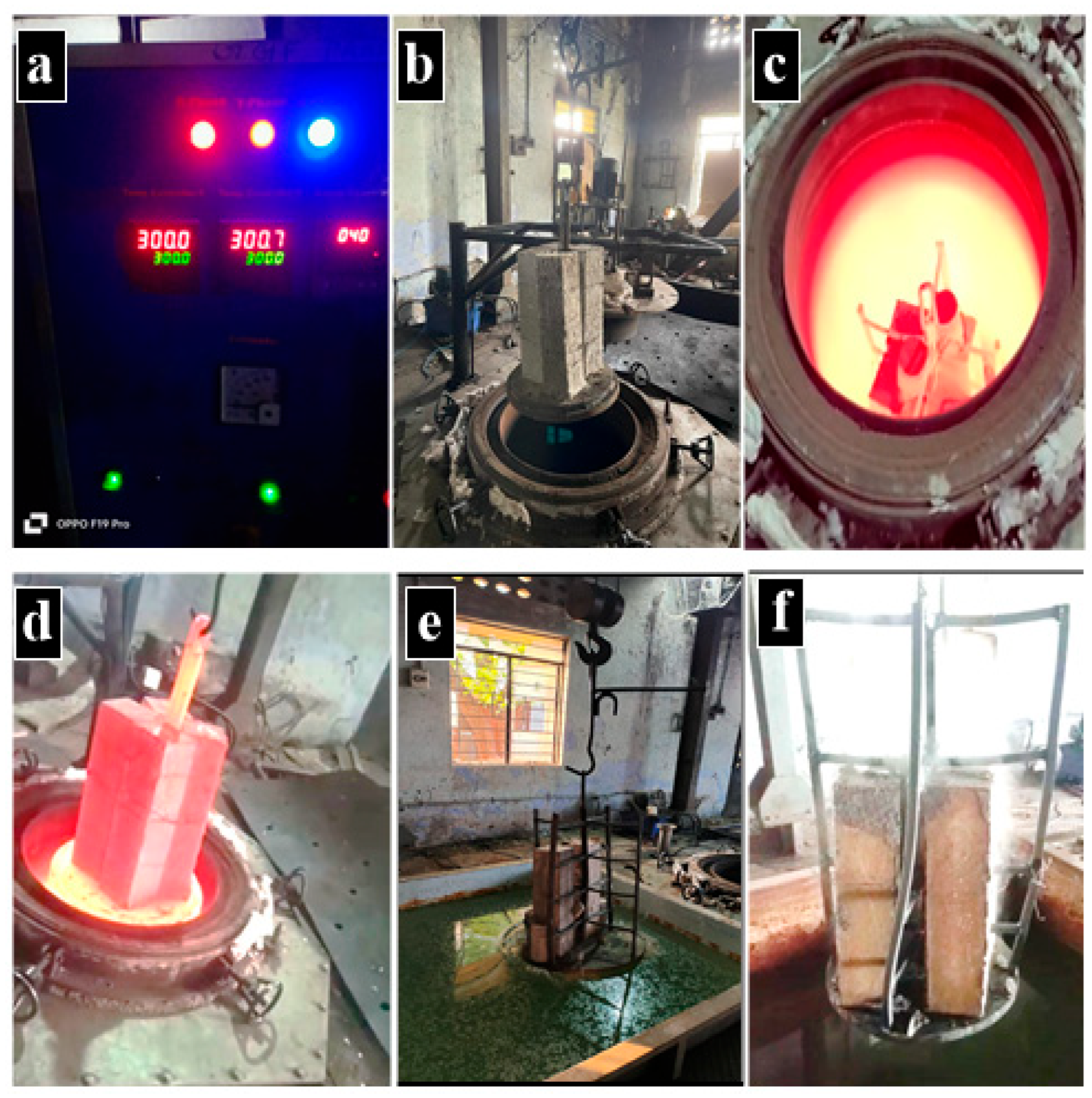

2.3. Columns Under Elevated Temperature

2.4. Strengthening of Damaged Columns

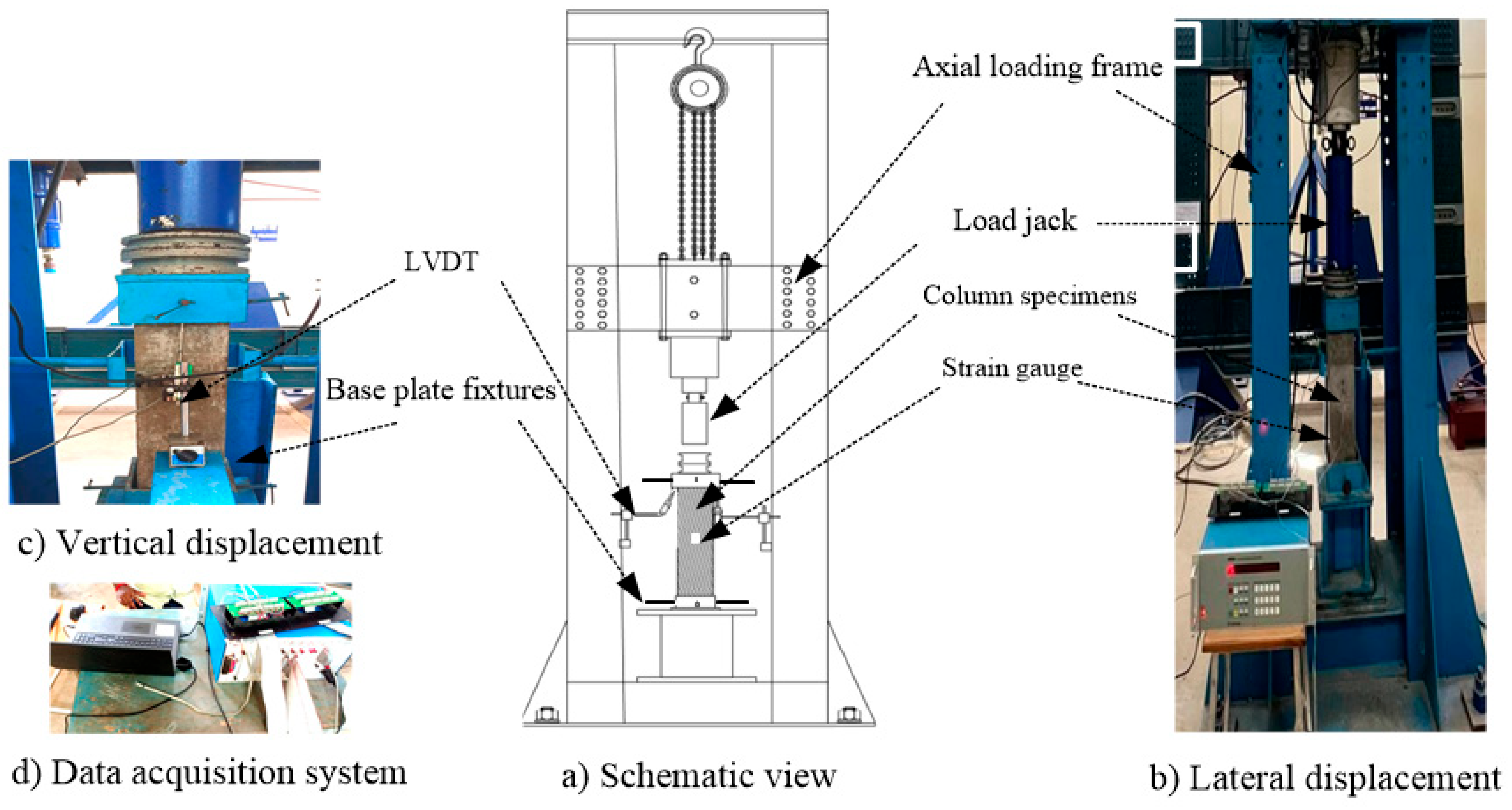

2.5. Experimental Setup

3. Results and Discussion

3.1. Observation During Fire Loading of Columns

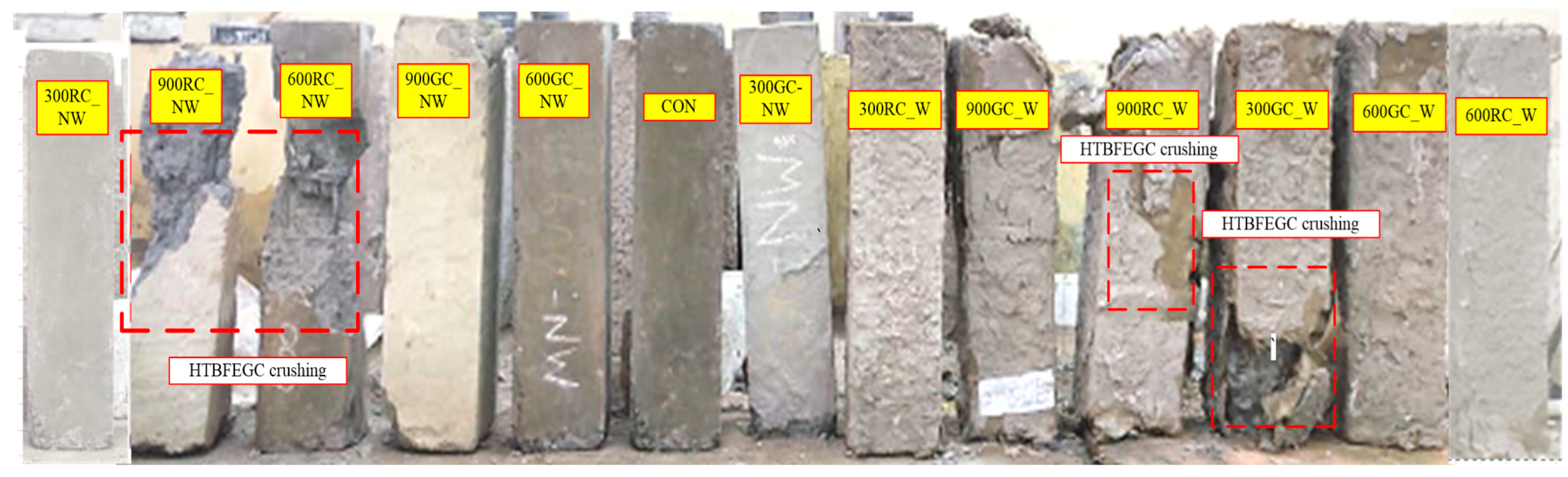

3.2. Failure Pattern of the Fired Column Under Axial Loading

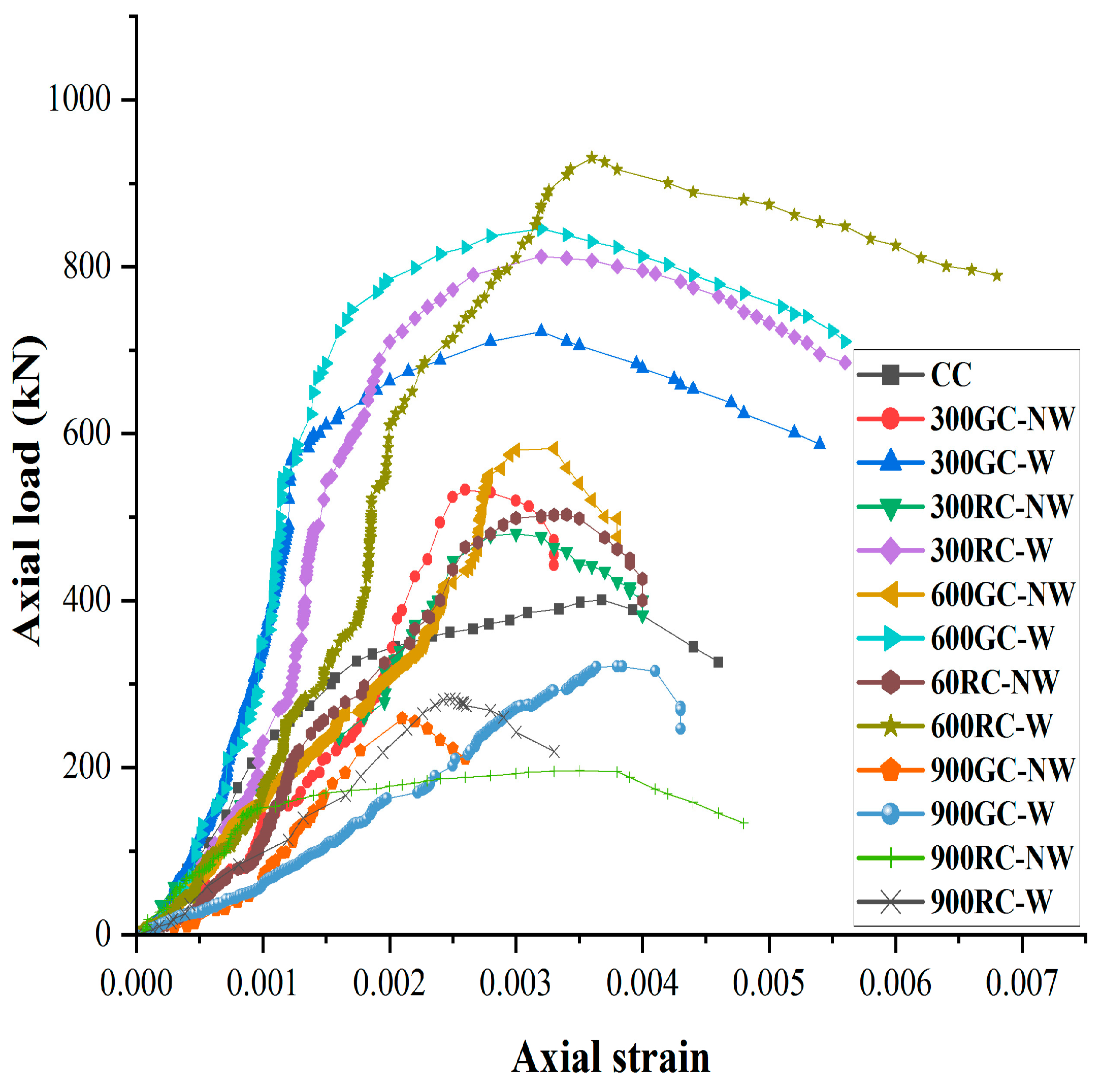

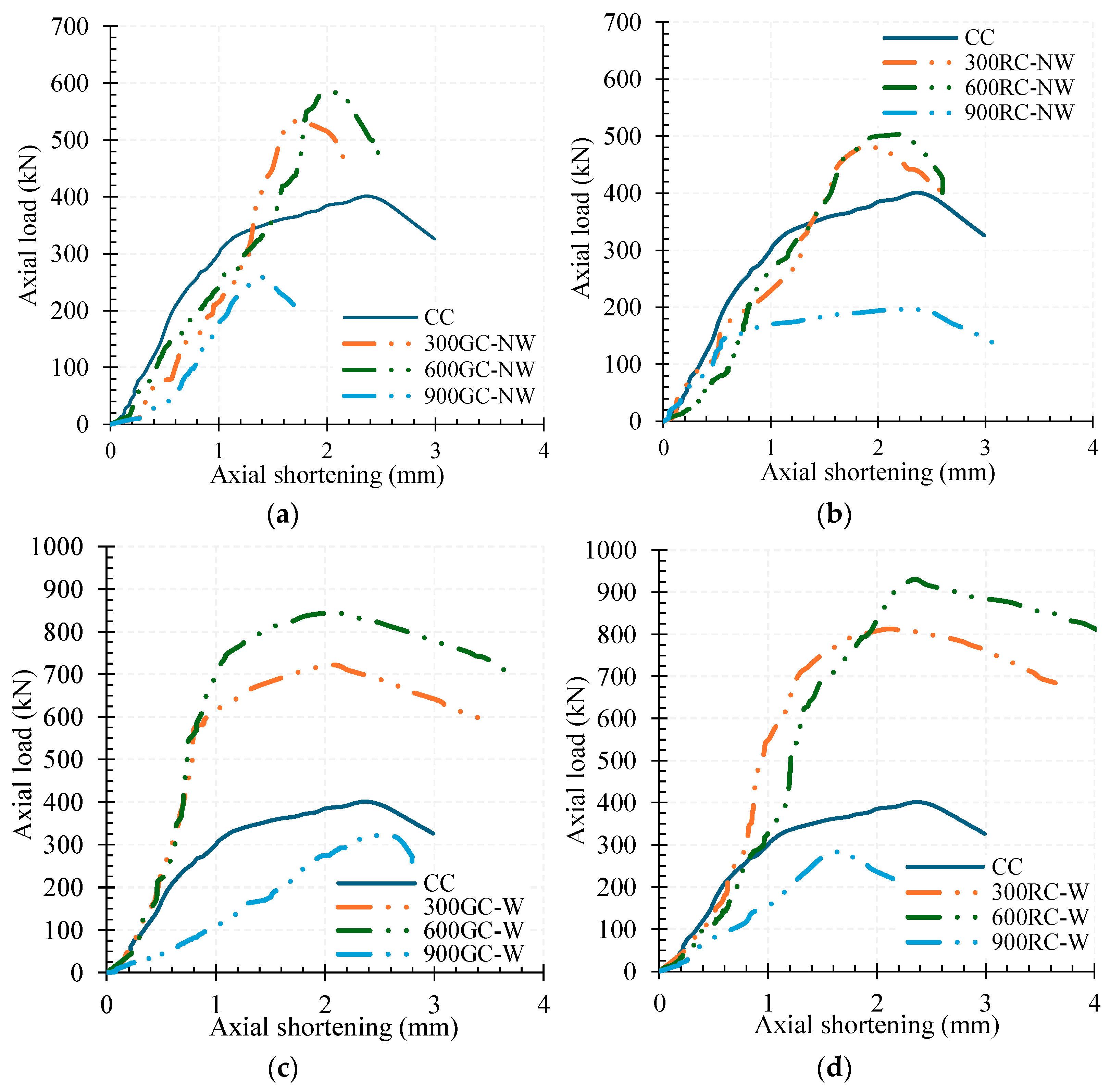

3.3. Axial Load-Axial Strain Behavior of RC Columns

3.4. Displacement Ductility of Column Specimens

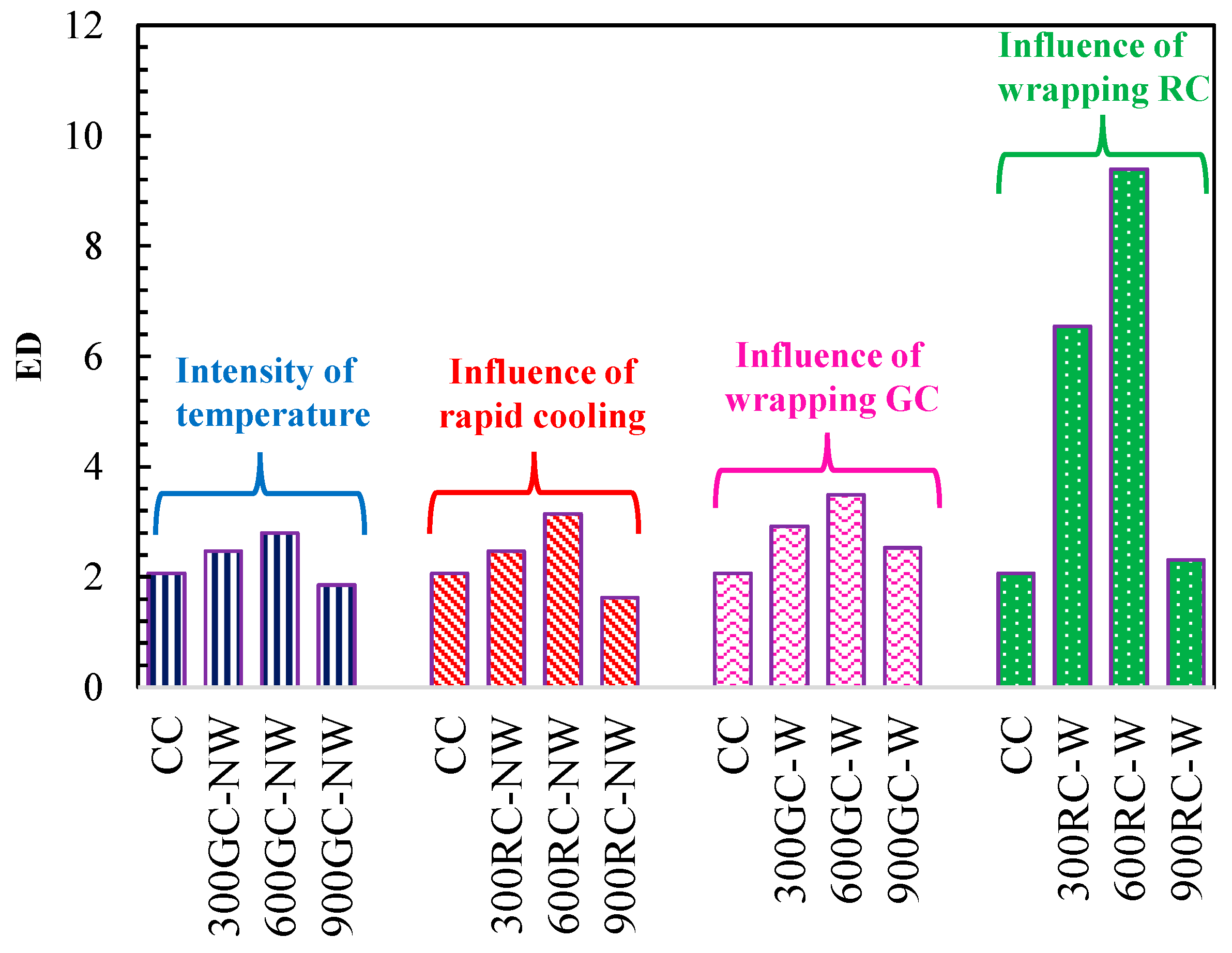

3.5. Energy Ductility of Column Specimens

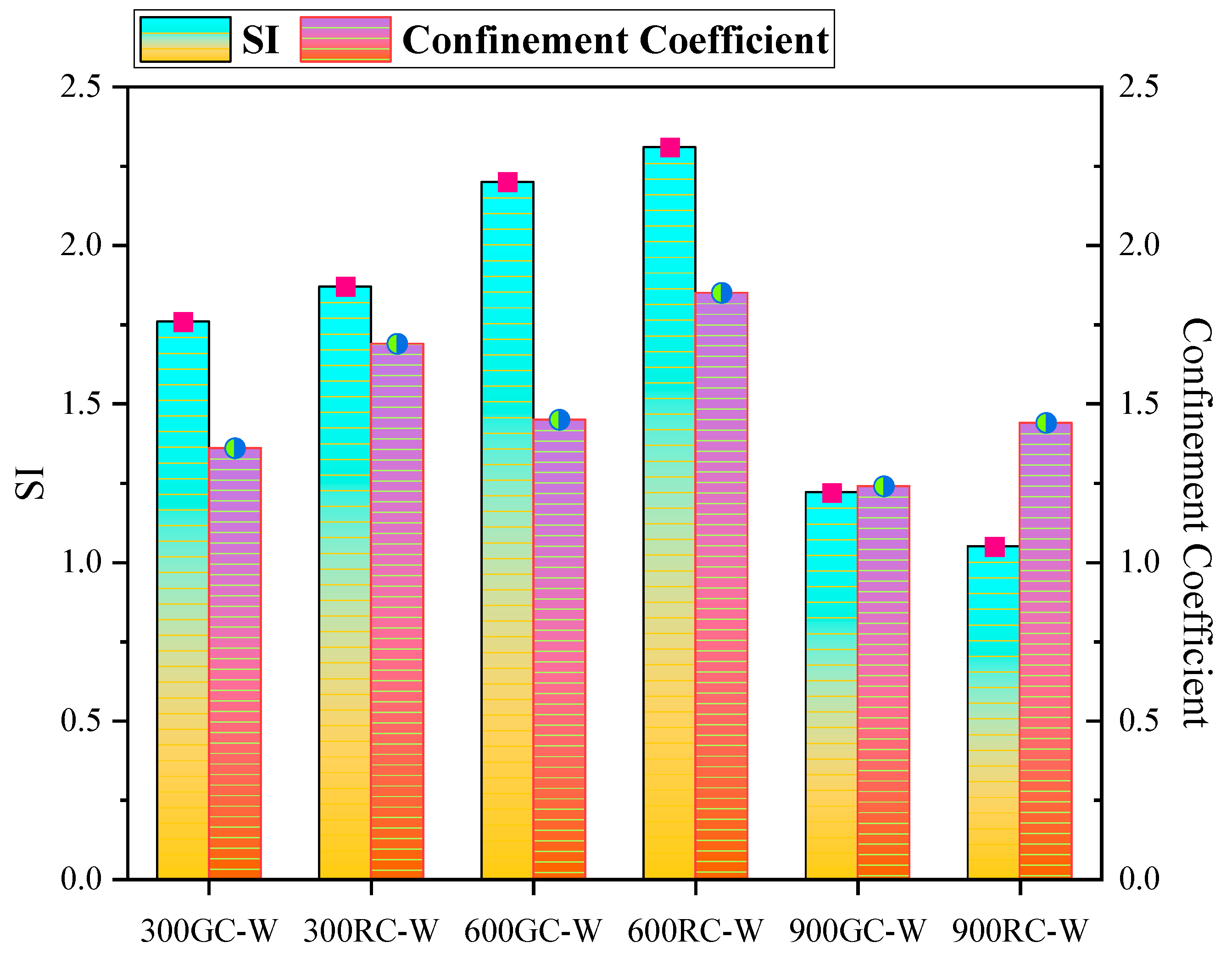

3.6. Confinement Effect of Basalt Sheet

3.7. Confinement Coefficient

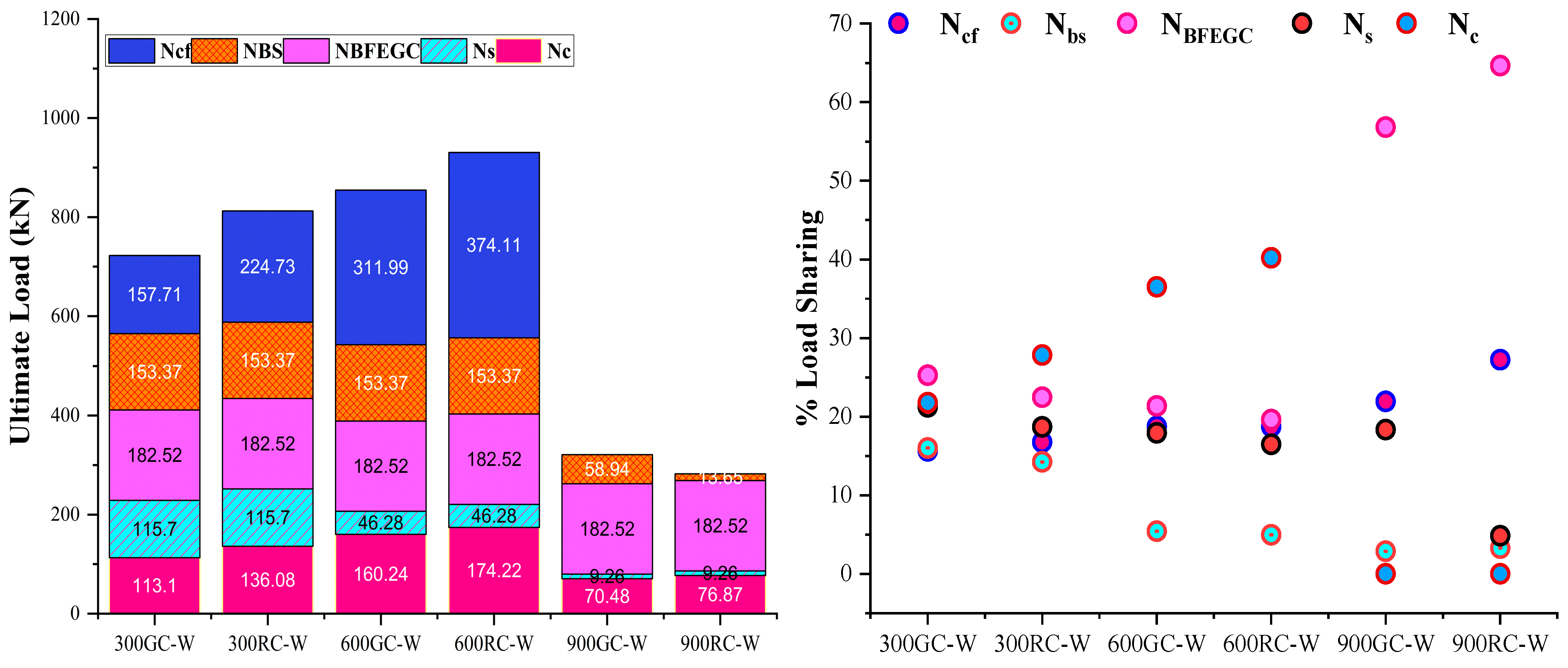

3.8. Contribution of Basalt Sheet on Column Axial Capacity

4. Microstructural Analysis

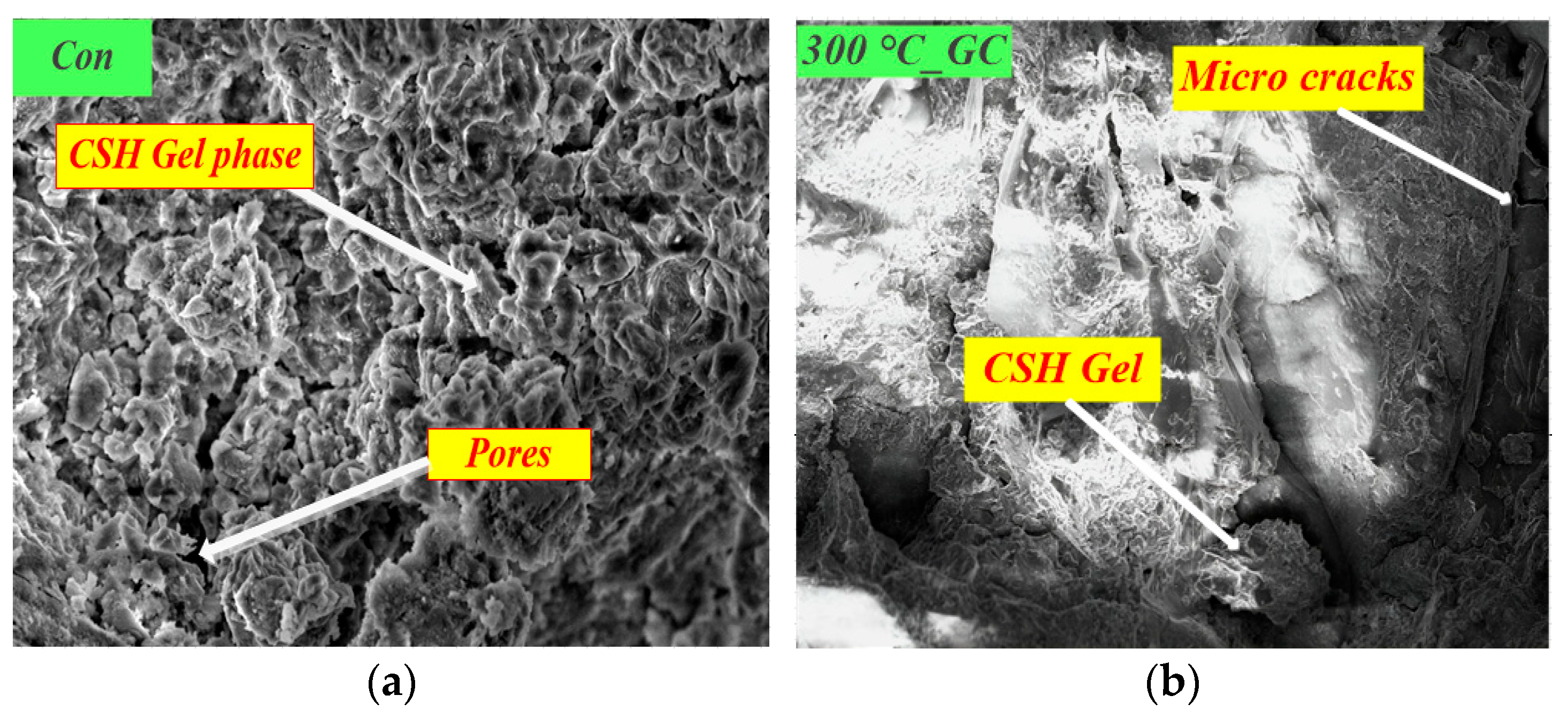

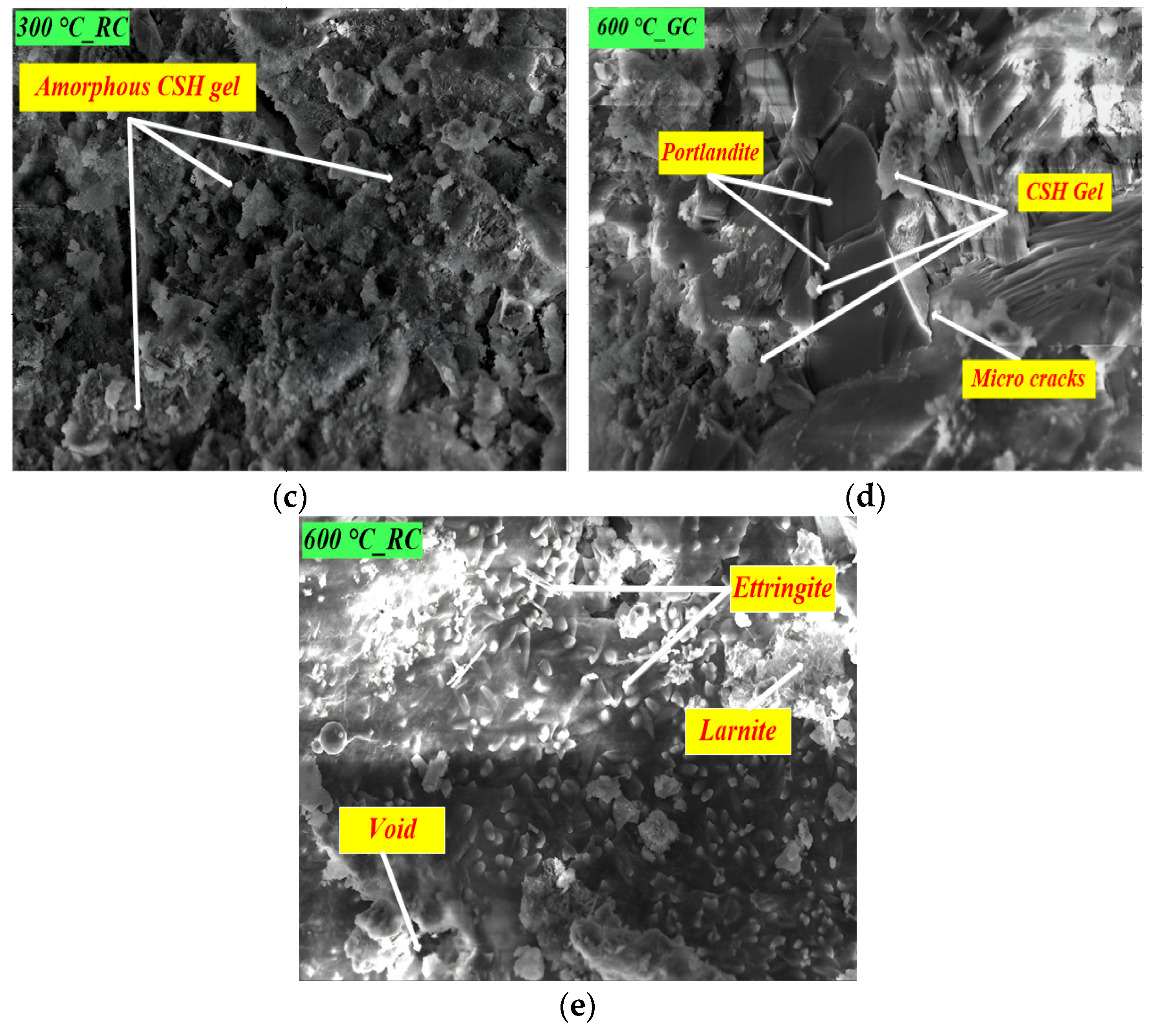

4.1. Scanning Electron Microscopy

4.2. X-Ray Diffraction

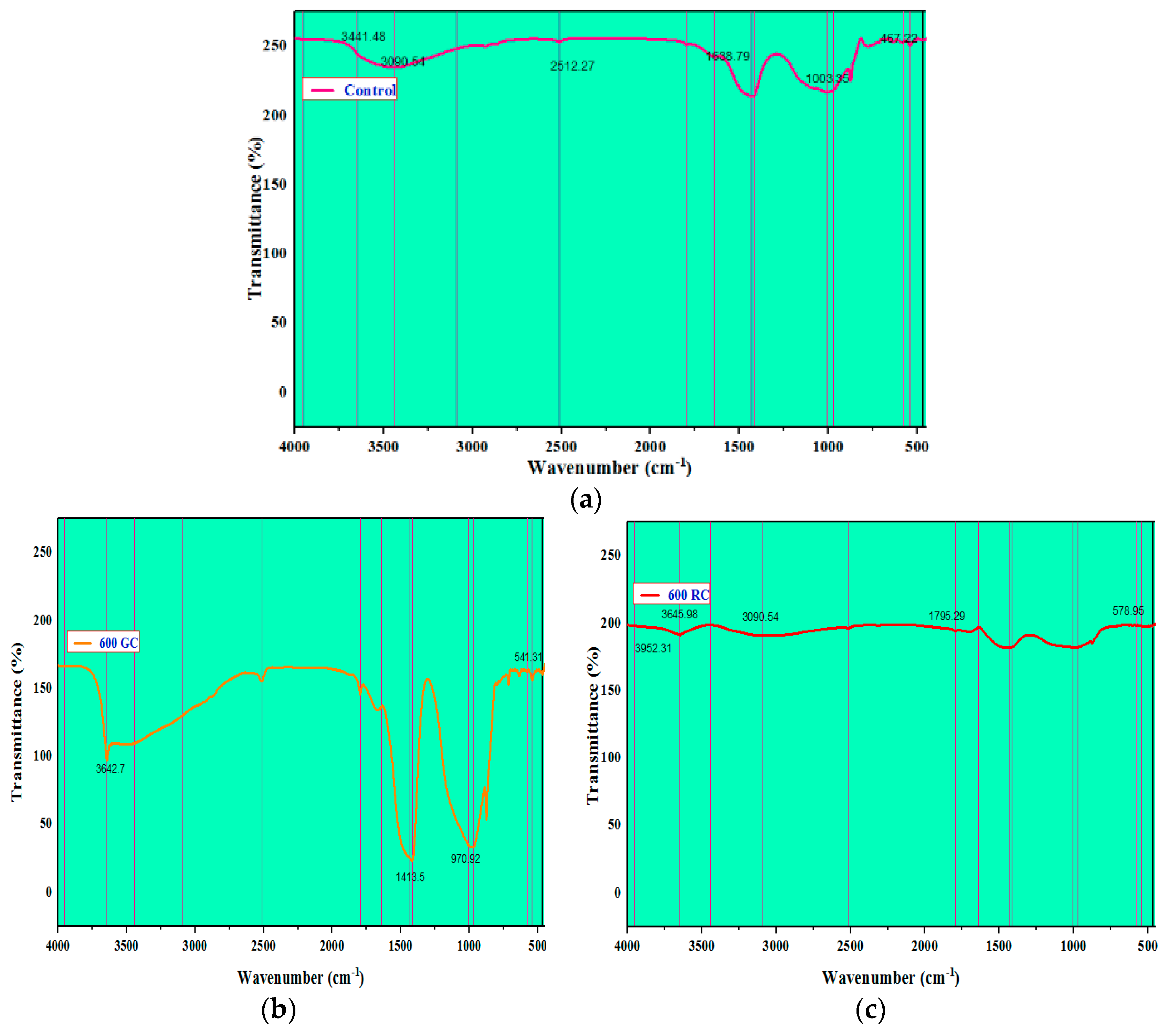

4.3. FTIR Spectroscopy

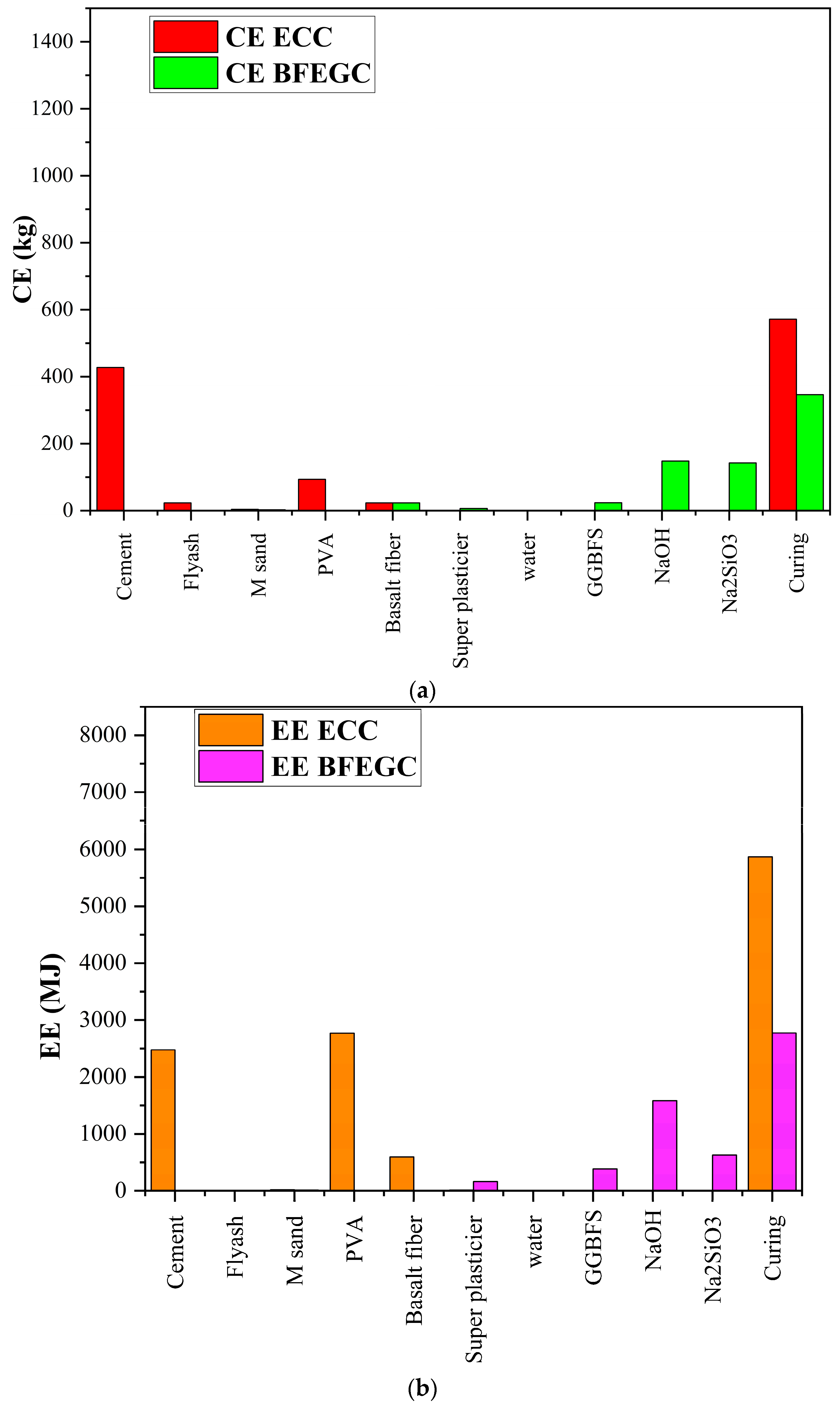

5. Sustainability of BFEGC Binders

6. Conclusions

- Using an inorganic binder made from basalt fiber-based geopolymer composites has proven compatible with the underlying concrete, avoiding any issues with impregnation.

- Rapid cooling mimics the practical scenario of extinguishing fires in buildings. Parametric analysis indicates that the effectiveness of wrapping was more significant in specimens that underwent rapid cooling after being subjected to a moderate temperature of 600 °C.

- Compared to unwrapped columns (600RC-NW), the wrapped columns (600RC-W) demonstrated enhancements by 1.85 times for ultimate load, 1.56 times for displacement ductility, and 2.99 times for energy ductility.

- The strength index and confinement coefficient for the 600RC-W columns showed improvements, with a value of 2.31 and a 40.2% increase, respectively.

- The microstructure of the 600RC-W columns revealed the formation of new compounds due to the hydration of unreacted materials in the concrete when exposed to higher temperatures followed by rapid cooling, resulting in a denser matrix.

- The performance of columns damaged by high-intensity fires and rapid cooling could be further enhanced by adopting improved repair techniques before applying the basalt fiber-based BFEGC layers.

- The sustainable BFEGC binder demonstrated a reduction in carbon emissions and embodied energy significantly, compared to the ECC binder used in fiber-reinforced polymer systems.

Limitation and Future Scope

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Brunesi, E.; Nascimbene, R.; Casagrande, L. Seismic analysis of high-rise mega-braced frame-core buildings. Eng. Struct. 2016, 115, 1–17. [Google Scholar] [CrossRef]

- Xie, J.; Irwin, P.A. Wind-induced response of a twin-tower structure. Wind. Struct. 2001, 4, 495–504. [Google Scholar] [CrossRef]

- Qin, D.; Gao, P.; Aslam, F.; Sufian, M.; Alabduljabbar, H. A comprehensive review on fire damage assessment of reinforced concrete structures. Case Stud. Constr. Mater. 2022, 16, e00843. [Google Scholar] [CrossRef]

- Palanivelu, R.; Panchanatham, B.; Eszter, L.E. Strengthening of axially loaded RC Columns using FRP with inorganic binder: A Review on Engineered Geopolymer Composites (EGC). Case Stud. Constr. Mater. 2025, 22, e04590. [Google Scholar] [CrossRef]

- Castro, J.M.; Araújo, M.; D’Aniello, M.; Landolfo, R. Strengthening of RC buildings with steel elements. In Strengthening and Retrofitting of Existing Structures; Costa, A., Arêde, A., Varum, H., Eds.; Springer: Singapore, 2018; pp. 139–162. [Google Scholar] [CrossRef]

- Choi, S.W.; Kim, Y.; Park, H.S. Multi-objective seismic retrofit method for using FRP jackets in shear-critical reinforced concrete frames. Compos. Part B 2014, 56, 207–216. [Google Scholar] [CrossRef]

- De Caso y Basalo, F.J.; Matta, F.; Nanni, A. Fiber reinforced cement-based composite system for concrete confinement. Constr. Build. Mater. 2012, 32, 55–65. [Google Scholar] [CrossRef]

- Imjai, T.; Setkit, M.; Garcia, R.; Figueiredo, F.P. Strengthening of damaged low strength concrete beams using PTMS or NSM techniques. Case Stud. Constr. Mater. 2020, 13, e00403. [Google Scholar] [CrossRef]

- Maheswaran, J.; Chellapandian, M.; Arunachelam, N. Retrofitting of severely damaged reinforced concrete members using fiber reinforced polymers: A comprehensive review. Structures 2022, 38, 1257–1276. [Google Scholar] [CrossRef]

- Belarbi, A.; Acun, B. FRP Systems in Shear Strengthening of Reinforced Concrete Structures. Procedia Eng. 2013, 57, 2–8. [Google Scholar] [CrossRef]

- Ekenel, M.; Rizzo, A.; Myers, J.J.; Nanni, A. Flexural fatigue behavior of reinforced concrete beams strengthened with FRP fabric and precured laminate systems. J. Compos. Constr. 2006, 10, 433–442. [Google Scholar] [CrossRef]

- Koutas, L.; Triantafillou, T.C. Use of anchors in shear strengthening of reinforced concrete T-beams with FRP. J. Compos. Constr. 2013, 17, 101–107. [Google Scholar] [CrossRef]

- Gudonis, E.; Timinskas, E.; Gribniak, V.; Kaklauskas, G.; Arnautov, A.K.; Tamulėnas, V. FRP reinforcement for concrete structures: State-of-the-art review of application and design. Eng. Struct. Technol. 2014, 5, 147–158. [Google Scholar] [CrossRef]

- Koutas, L.N.; Tetta, Z.; Bournas, D.A.; Triantafillou, T.C. Strengthening of Concrete Structures with Textile Reinforced Mortars: State-of-the-Art Review. J. Compos. Constr. 2019, 23, 1–20. [Google Scholar] [CrossRef]

- Abdulrahman, A.S.; Kadir, M.R.A. Behavior and flexural strength of fire damaged high strength reinforced rectangular concrete beams after strengthening with CFRP laminates. Ain Shams Eng. J. 2022, 13, 101767. [Google Scholar] [CrossRef]

- Ni, S.; Gernay, T. Predicting residual deformations in a reinforced concrete building structure after a fire event. Eng. Struct. 2020, 202, 109853. [Google Scholar] [CrossRef]

- Mamdouh, H.; Zenhom, N.; Essam, A. Strengthening of concrete columns using core reinforced bars and steel fibers. Case Stud. Constr. Mater. 2023, 19, e02415. [Google Scholar] [CrossRef]

- Euro Code 2 (ENV2001); Design of Concrete Structures, Part 1–2 Structural Fire Design. CEN: Brussels, Belgium, 2001.

- Soe, K.T.; Zhang, Y.X.; Zhang, L.C. Material properties of a new hybrid fibre-reinforced engineered cementitious composite. Constr. Build. Mater. 2013, 43, 399–407. [Google Scholar] [CrossRef]

- Lamanna, A.J.; Bank, L.C.; Scott, D.W. Flexural strengthening of reinforced concrete beams by mechanically attaching fiber-reinforced polymer strips. J. Compos. Constr. 2004, 8, 203–210. [Google Scholar] [CrossRef]

- Awani, O.; El-Maaddawy, T.; Ismail, N. Fabric-reinforced cementitious matrix: A promising strengthening technique for concrete structures. Constr. Build. Mater. 2017, 132, 94–111. [Google Scholar] [CrossRef]

- Elmesalami, N.; Celik, K. A critical review of engineered geopolymer composite: A low-carbon ultra-high-performance concrete. Constr. Build. Mater. 2022, 346, 128491. [Google Scholar] [CrossRef]

- Palanivelu, R.; Panchanatham, B. Study on the Mechanical Properties of Retrofitted Concrete Damaged under Fire and Rapid Cooling. J. Struct. Des. Constr. Pract. 2024, 30, 04024105. [Google Scholar] [CrossRef]

- Shoji, D.; He, Z.; Zhang, D.; Li, V.C. The greening of engineered cementitious composites (ECC): A review. Constr. Build. Mater. 2022, 327, 126701. [Google Scholar] [CrossRef]

- Li, S.; Ma, W.; Lu, Y.; He, B.; Liu, Z. Axial behavior of concrete cylinders retrofitted with a hybrid system of CFRP textile grid and engineered geopolymer composite. J. Build. Eng. 2024, 91, 109536. [Google Scholar] [CrossRef]

- Tang, W.; Liu, Z.; Lu, Y.; Li, S. Hybrid confinement mechanism of large-small rupture strain FRP on concrete cylinder. J. Build. Eng. 2022, 51, 104335. [Google Scholar] [CrossRef]

- Chen, Y.H.; Chang, Y.F.; Yao, G.C.; Sheu, M.S. Experimental research on post-fire behaviour of reinforced concrete columns. Fire Saf. J. 2009, 44, 741–748. [Google Scholar] [CrossRef]

- IS 10262-2009; Indian Standard Code of Practice for Recommended Guidelines for Concrete Mix Design. Bureau of Indian Standards: New Delhi, India, 2009.

- IS 516-1959; Methods of Tests for Strength of Concrete. Bureau of Indian Standards: New Delhi, India, 1959.

- ASTM D3039-M08; Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials. ASTM: West Conshohocken, PA, USA, 2008.

- ISO-834-1:1999; Fire Resistance Tests-Elements of Building Construction—Part I: General Requirements. ISO: Geneva, Switzerland, 1999.

- BS EN ISO 527-5 (2009); Plastics—Determination of Tensile Properties Part 5: Test Conditions for Unidirectional Fibre-Reinforced Plastic Composites. ISO: Geneva, Switzerland, 2009.

- IS 4031-2013; Ordinary Portland Cement-53 Grade-Specification. Bureau of Indian Standards: New Delhi, India, 2013.

- IS 383-1970; Coarse and Fine Aggregates from Natural Sources for Concrete. Bureau of Indian Standards: New Delhi, India, 1970.

- ASTM C 1437–07; Standard Test Method for Flow of Hydraulic Cement Mortar1. ASTM: West Conshohocken, PA, USA, 2007.

- IS 456-2000; Plain and Reinforced Concrete-Code of Practice. Bureau of Indian Standards: New Delhi, India, 2000.

- SP 16–1980; Design Aids for Reinforced Concrete to IS 456:1978. Bureau of Indian Standards: New Delhi, India, 1980.

- Rickard, W.D.; Riessen, A.V.; Walls, P. Thermal character of geopolymers synthesized from class F fly ash containing high concentrations of iron and α-quartz. Int. J. Appl. Ceram. Technol. 2010, 7, 81–88. [Google Scholar] [CrossRef]

- Trapko, T. Fibre Reinforced Cementitious Matrix confined concrete elements. Mater. Des. 2013, 44, 382–391. [Google Scholar] [CrossRef]

- Tao, Z.; Wang, X.Q.; Uy, B. Stress-strain curves of structural and reinforcing steels after exposure to elevated temperatures. J. Mater. Civil Eng. 2013, 25, 1306–1316. [Google Scholar] [CrossRef]

- Marthong, C.; Sutnga, D.; Kharshandi, O.; Khryiemmujat, I.J.; Shangpliang, A. Mechanical Strength of Galvanized Steel Wire Mesh (GSWM) as a Strengthening Material of Short RC Column. IOP Conf. Ser. Mater. Sci. Eng. 2019, 491, 012014. [Google Scholar] [CrossRef]

- Yan, Y.; Liang, H.; Lu, Y.; Huang, Y. Behaviour of concrete-filled steel-tube columns strengthened with high-strength CFRP textile grid-reinforced high-ductility engineered cementitious composites. Constr. Build. Mater. 2021, 9, 121283. [Google Scholar] [CrossRef]

- ACI 549.4R-13; Guide to Design and Construction of Externally Bonded Fabric-Reinforced Cementitious Matrix (FRCM) Systems for Repair and Strengthening Concrete and Masonry Structures. American Concrete Institute: Farmington Hills, MI, USA, 2013.

- Ombres, L.; Mazzuca, S. Confined Concrete Elements with Cement-Based Composites: Confinement Effectiveness and Prediction Models. J. Compos. Constr. 2017, 21, 04016103. [Google Scholar] [CrossRef]

- Yang, X.; Tang, C.; Chen, Y.; Qiao, T.Y. Compressive behavior of steel-reinforced concrete-filled square steel tubular stub columns after exposure to elevated temperature. Eng. Struct. 2020, 204, 110048. [Google Scholar] [CrossRef]

- Colajanni, P.; De Domenico, F.; Recupero, A.; Spinella, N. Concrete columns confined with fiber reinforced cementitious mortars: Experimentation and modelling. Constr. Build. Mater. 2014, 52, 375–384. [Google Scholar] [CrossRef]

- Georgali, B.; Tsakiridis, P.E. Microstructure of fire-damaged concrete. A case study. Cem. Concr. Compos. B 2005, 27, 255–259. [Google Scholar] [CrossRef]

- Lindgård, J.; Andiç-Çakır, O.; Fernandes, I.; Rønning, T.F.; Thomas, M.D. Alkali–silica reactions (ASR): Literature review on parameters influencing laboratory performance testing. Cem. Concr. Res. 2012, 42, 223–243. [Google Scholar] [CrossRef]

- Lim, S.; Mondal, P. Micro- and nano-scale characterization to study the thermal degradation of cement-based materials. Mater. Charact. 2014, 92, 15–25. [Google Scholar] [CrossRef]

- Jo, B.W.; Sikandar, M.A.; Chakraborty, S.; Baloch, Z. Strength and durability assessment of Portland cement mortars formulated from hydrogen-rich water. Adv. Mater. Sci. Eng. 2017, 2017, 526130. [Google Scholar] [CrossRef]

- Zhang, R.; Matsumoto, K.; Hirata, T.; Ishizeki, Y.; Niwa, J. Shear behavior of polypropylene fiber reinforced ECC beams with varying shear reinforcement ratios. J. JSCE 2014, 2, 39–53. [Google Scholar] [CrossRef]

- Yan, Y.; Lu, Y.; Li, S.; Lin, C. Eccentrically Loaded Square Concrete-Filled Steel Tubes Strengthened with CFRP Grid-Reinforced Engineered Cementitious Composite. J. Compos. Constr. 2024, 28, 04024011. [Google Scholar] [CrossRef]

- Alsalman, A.; Assi, L.N.; Kareem, R.S.; Carter, K.; Ziehl, P. Energy and CO2 emission assessments of alkali-activated concrete and Ordinary Portland Cement concrete: A comparative analysis of different grades of concrete. Clean. Environ. Syst. 2021, 3, 100047. [Google Scholar] [CrossRef]

- Hammond, G.; Jones, C.; Lowrie, F.; Tse, P.; Building Services Research and Information Association; University of Bath. Embodied Carbon: The Inventory of Carbon and Energy (ICE); BSRIA: Bracknell, UK, 2011. [Google Scholar]

- Zhu, X.; Zhang, Y.; Liu, Z.; Qiao, H.; Ye, F.; Lei, Z. Research on carbon emission reduction of manufactured sand concrete based on compressive strength. Constr. Build. Mater. 2023, 403, 1–23. [Google Scholar] [CrossRef]

- Zhang, D.; Yu, J.; Wu, H.; Jaworska, B.; Ellis, B.R.; Li, V.C. Discontinuous micro-fibers as intrinsic reinforcement for ductile Engineered Cementitious Composites (ECC). Compos. Part B 2020, 184, 107741. [Google Scholar] [CrossRef]

- Huang, X.; Ranade, R.; Li, V.C. Feasibility study of developing green ECC using iron ore tailings powder as cement replacement. J. Mater. Civ. Eng. 2013, 25, 923–931. [Google Scholar] [CrossRef]

- Yang, E.H.; Yang, Y.; Li, V.C. Use of high volumes of fly ash to improve ECC mechanical properties and material greenness. ACI Mater. J. 2007, 104, 620. [Google Scholar]

- Eurochlor. An Eco-Profile and Environmental Product Declaration of the European Chlor-Alkali Industry; Eurochlor: Brussels, Belgium, 2013; pp. 1–36. [Google Scholar]

- Fawer, M.; Concannon, M.; Rieber, W. Life Cycle Inventories for the Production of Sodium Silicates. Int. J. LCA 1999, 4, 207–212. [Google Scholar] [CrossRef]

- EFCA—European Federation of Concrete Admixtures Assoc’s. Available online: http://www.efca.info/ (accessed on 14 June 2020).

| Oxides | SiO2 | Al2O3 | CaO | Fe2O3 | SO3 | MgO | TiO2 | LOI * |

|---|---|---|---|---|---|---|---|---|

| Value (%) | 36.6 | 12.5 | 37.6 | 0.6 | 182 | 9.58 | 0.52 | 0.73 |

| Properties | Ultimate Tensile Strength (MPa) | Fiber Modulus (GPa) | Ultimate Tensile Elongation (%) | Fiber Thickness (mm) | Fiber Density (g/cm3) | Fiber Weight (g/m2) |

|---|---|---|---|---|---|---|

| Values | 4900 | 230 | 2.1 | 0.227 | 1.76 | 400 |

| Materials | Cement | Fine Aggregate | Coarse Aggregate | Water | Chemical Admixtures |

|---|---|---|---|---|---|

| Quantity | 360 | 584 | 1223 | 186 | 3.61 |

| ID | Strengthening Type | Number of Specimens | Intensity of Temperature | Duration (Minutes) | Cooling Regime |

|---|---|---|---|---|---|

| CC | - | 2 | - | - | - |

| NS300GC_W | Retrofit | 1 | 300 °C | 30 | Gradual |

| NS300RC_W | Retrofit | 1 | 300 °C | 30 | Rapid |

| NS300GC_NW | - | 1 | 300 °C | 30 | Gradual |

| NS300RC_NW | - | 1 | 300 °C | 30 | Rapid |

| NS600GC_W | Retrofit | 1 | 600 °C | 20 | Gradual |

| NS600RC_W | Retrofit | 1 | 600 °C | 20 | Rapid |

| NS600GC_NW | - | 1 | 600 °C | 20 | Gradual |

| NS600RC_NW | - | 1 | 600 °C | 20 | Rapid |

| NS900GC_W | Retrofit | 1 | 900 °C | 15 | Gradual |

| NS900RC_W | Retrofit | 1 | 900 °C | 15 | Rapid |

| NS900GC_NW | - | 1 | 900 °C | 15 | Gradual |

| NS900RC_NW | - | 1 | 900 °C | 15 | Rapid |

| Specimen | Pu (kN) | EΔy (kJ) | EΔf (kJ) | E (kJ) | SI | |||

|---|---|---|---|---|---|---|---|---|

| CC | 401 | 264.71 | 546.18 | 810.89 | 2.06 | 1.197 | - | |

| 300GC-NW | 532.5 | 165.32 | 407.67 | 572.99 | 2.47 | 1.27 | ||

| 300GC-W | 722.4 | 459.62 | 1342.5 | 1802.12 | 2.92 | 1.63 | 1.76 | 1.36 |

| 300RC-NW | 480 | 213.31 | 526.65 | 739.96 | 2.47 | 1.3 | ||

| 300RC-W | 812.4 | 373.21 | 1661.3 | 2034.51 | 6.55 | 1.69 | 1.87 | 1.69 |

| 600GC-NW | 582.1 | 201.61 | 565.18 | 766.79 | 2.80 | 1.15 | ||

| 600GC-W | 845.4 | 492.63 | 1720.96 | 2213.59 | 3.49 | 1.72 | 2.2 | 1.45 |

| 600RC-NW | 503 | 176.21 | 554.76 | 730.97 | 3.14 | 1.18 | ||

| 600RC-W | 930.5 | 305.03 | 2865.2 | 3170.23 | 9.39 | 1.83 | 2.31 | 1.85 |

| 900GC-NW | 258.7 | 58.3 | 131 | 189.3 | 2.25 | 1.19 | ||

| 900GC-W | 321.2 | 128.12 | 325.1 | 453.22 | 2.53 | 1.13 | 1.22 | 1.24 |

| 900RC-NW | 196.1 | 158.65 | 258.05 | 416.7 | 1.63 | 1.2 | ||

| 900RC-W | 282.3 | 87.47 | 201.8 | 289.27 | 2.31 | 1.21 | 1.05 | 1.44 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Palanivelu, R.; Panchanatham, B.; Zapris, A.G.; Kytinou, V.K. Non-Conventional and Sustainable Retrofitting of Fire-Exposed Reinforced Concrete Columns Using Basalt Fiber–Engineered Geopolymer Composites. Buildings 2025, 15, 1962. https://doi.org/10.3390/buildings15121962

Palanivelu R, Panchanatham B, Zapris AG, Kytinou VK. Non-Conventional and Sustainable Retrofitting of Fire-Exposed Reinforced Concrete Columns Using Basalt Fiber–Engineered Geopolymer Composites. Buildings. 2025; 15(12):1962. https://doi.org/10.3390/buildings15121962

Chicago/Turabian StylePalanivelu, Ruba, Bhuvaneshwari Panchanatham, Adamantis G. Zapris, and Violetta K. Kytinou. 2025. "Non-Conventional and Sustainable Retrofitting of Fire-Exposed Reinforced Concrete Columns Using Basalt Fiber–Engineered Geopolymer Composites" Buildings 15, no. 12: 1962. https://doi.org/10.3390/buildings15121962

APA StylePalanivelu, R., Panchanatham, B., Zapris, A. G., & Kytinou, V. K. (2025). Non-Conventional and Sustainable Retrofitting of Fire-Exposed Reinforced Concrete Columns Using Basalt Fiber–Engineered Geopolymer Composites. Buildings, 15(12), 1962. https://doi.org/10.3390/buildings15121962