Dynamic Response and Computational Modeling of Truss-Reinforced Phosphogypsum-Concrete Composite Slabs Subjected to Impact Loading: A Parametric Finite Element Analysis

Abstract

1. Introduction

2. Test Overview

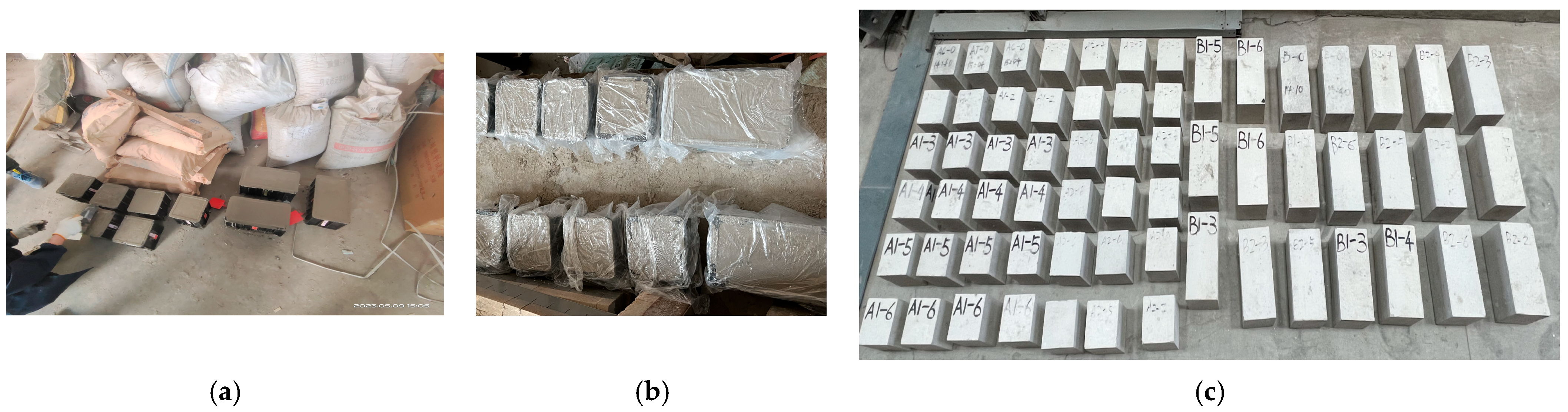

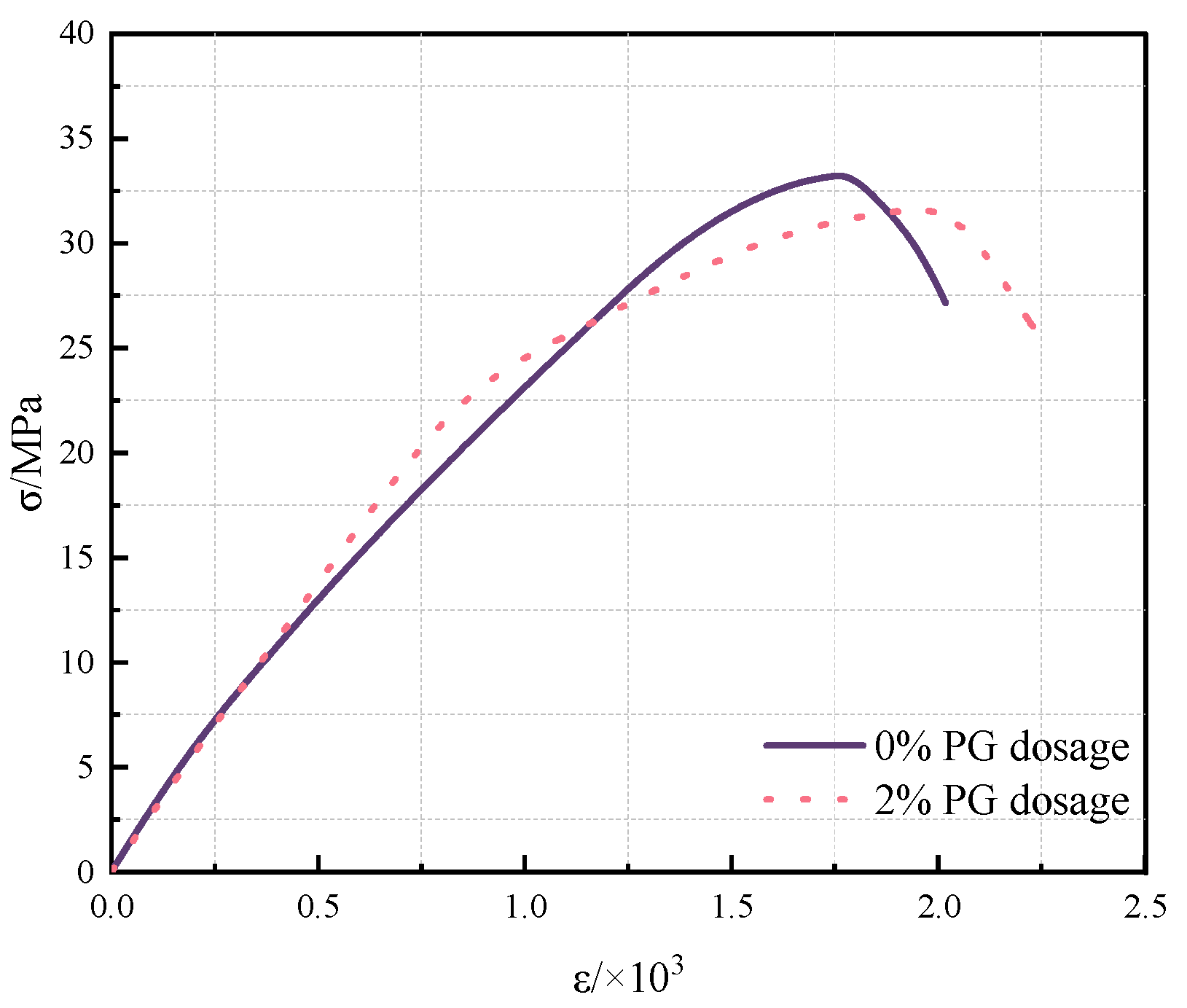

2.1. Material Properties

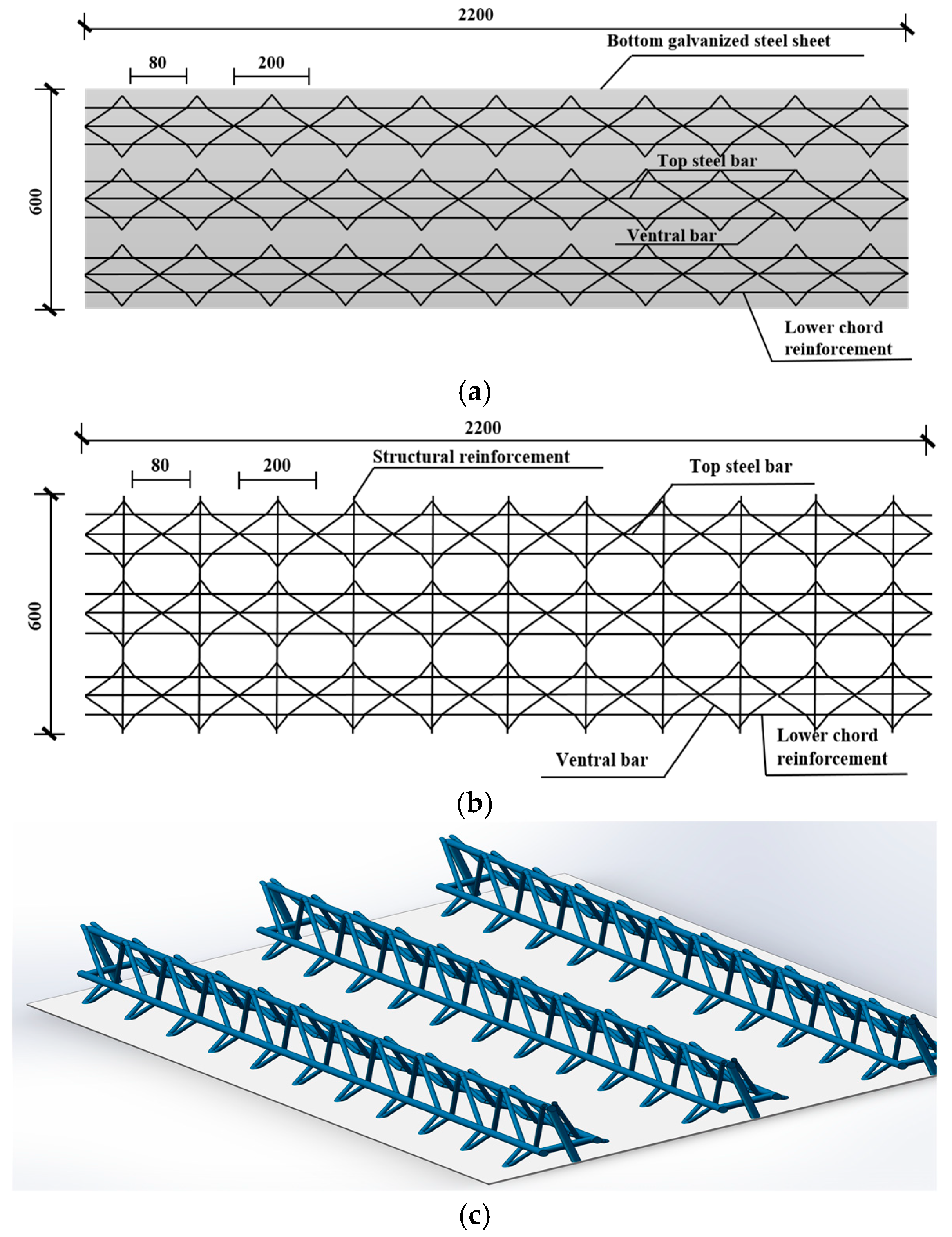

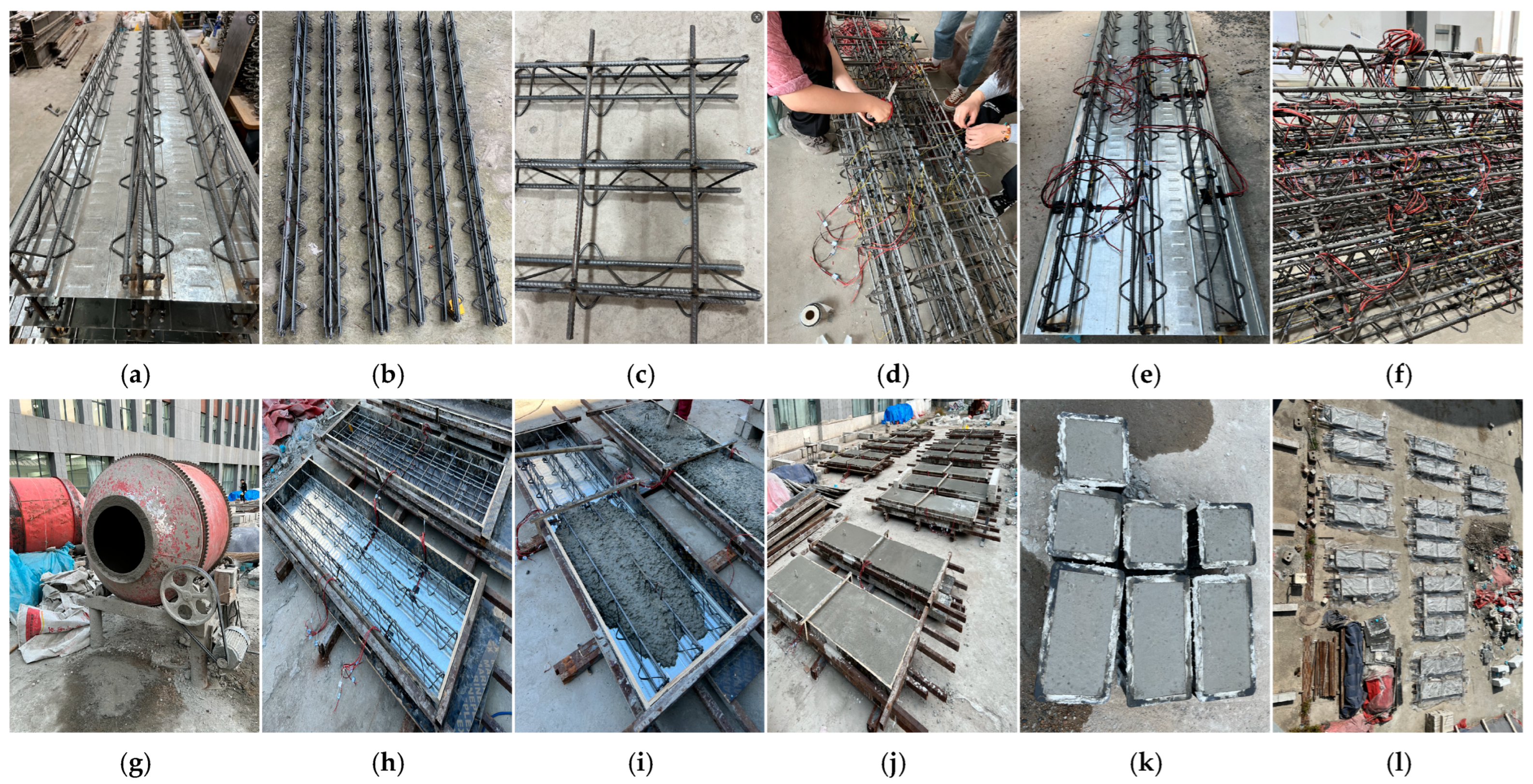

2.2. Test Piece Design and Fabrication

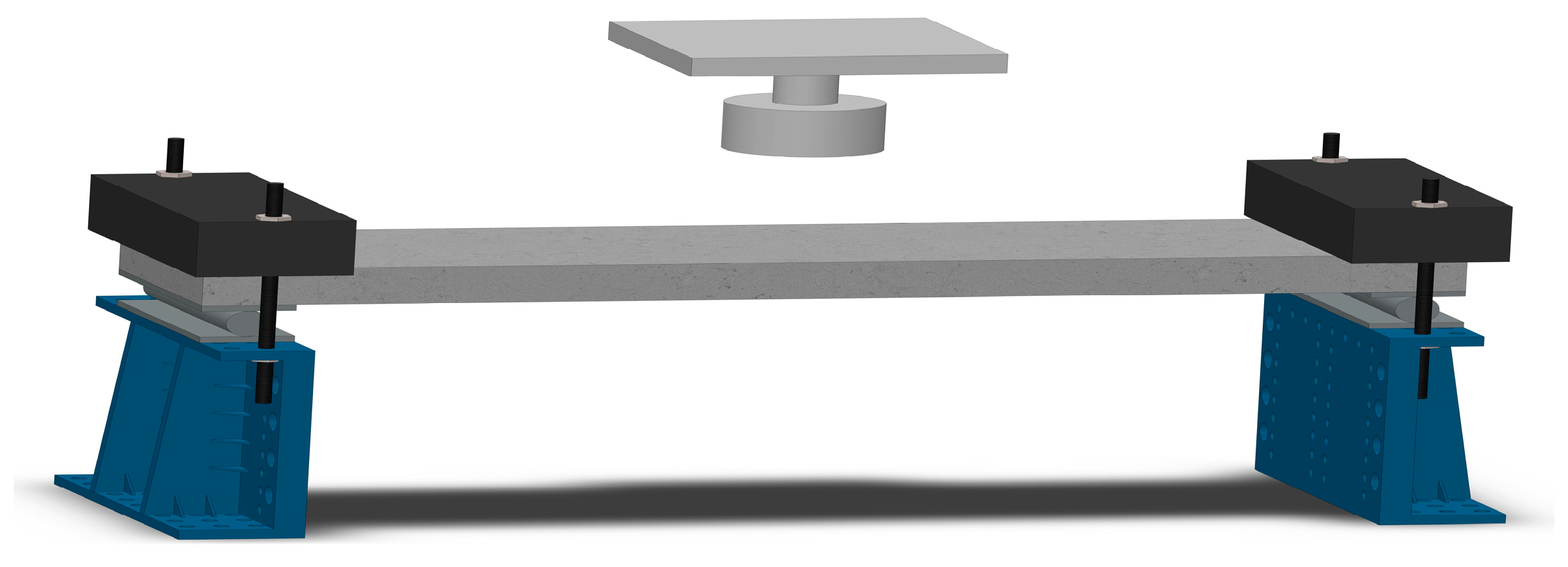

2.3. Loading Program Design

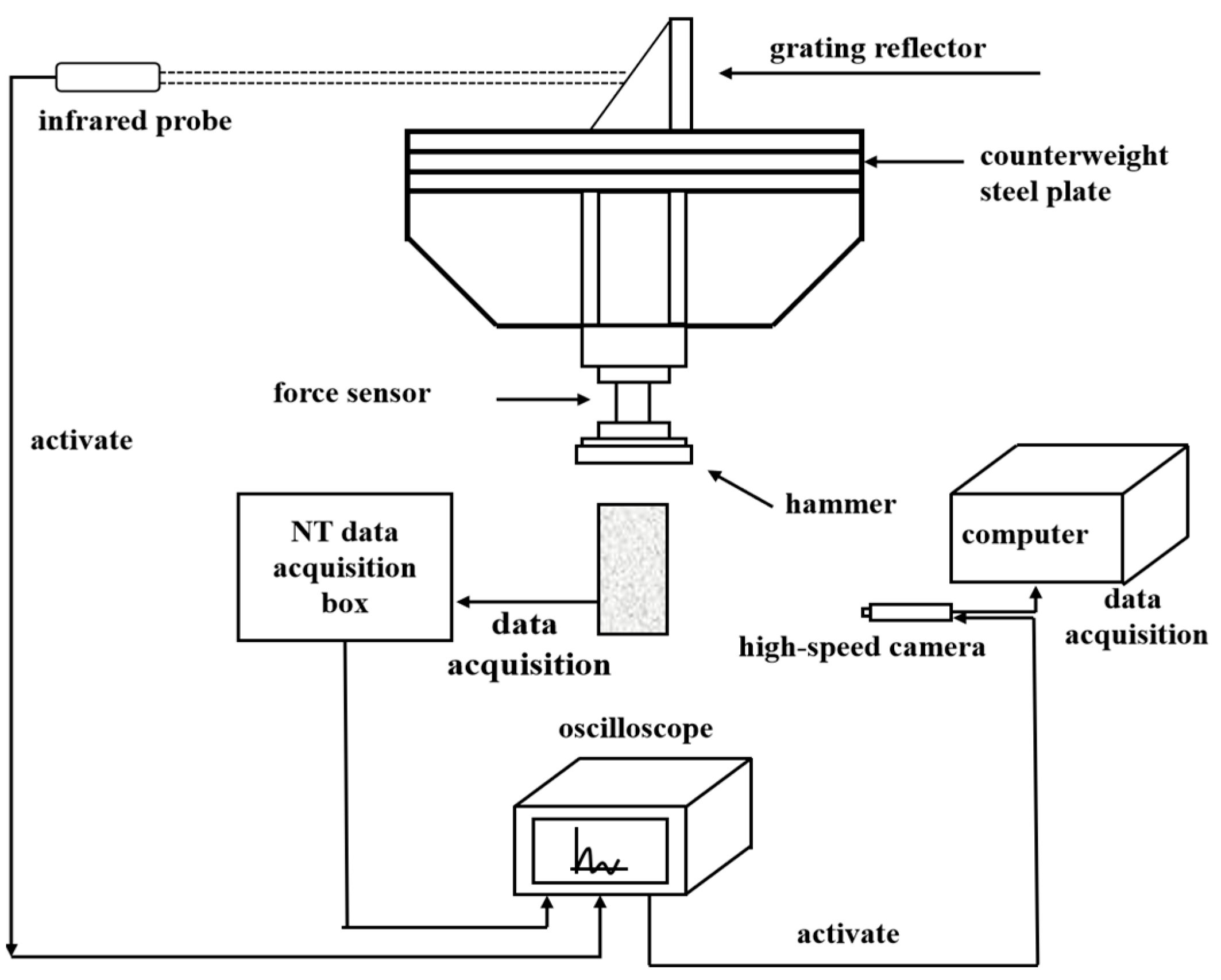

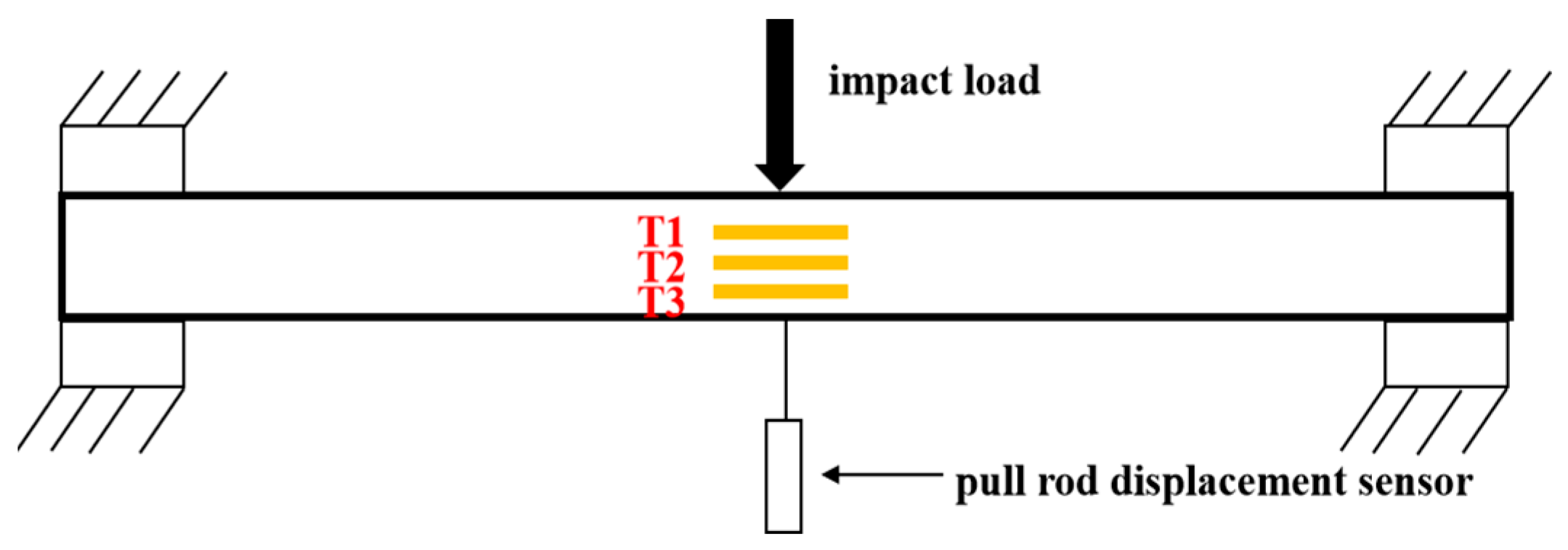

2.4. Design of the Experimental Observation Program

3. Test Results and Analysis

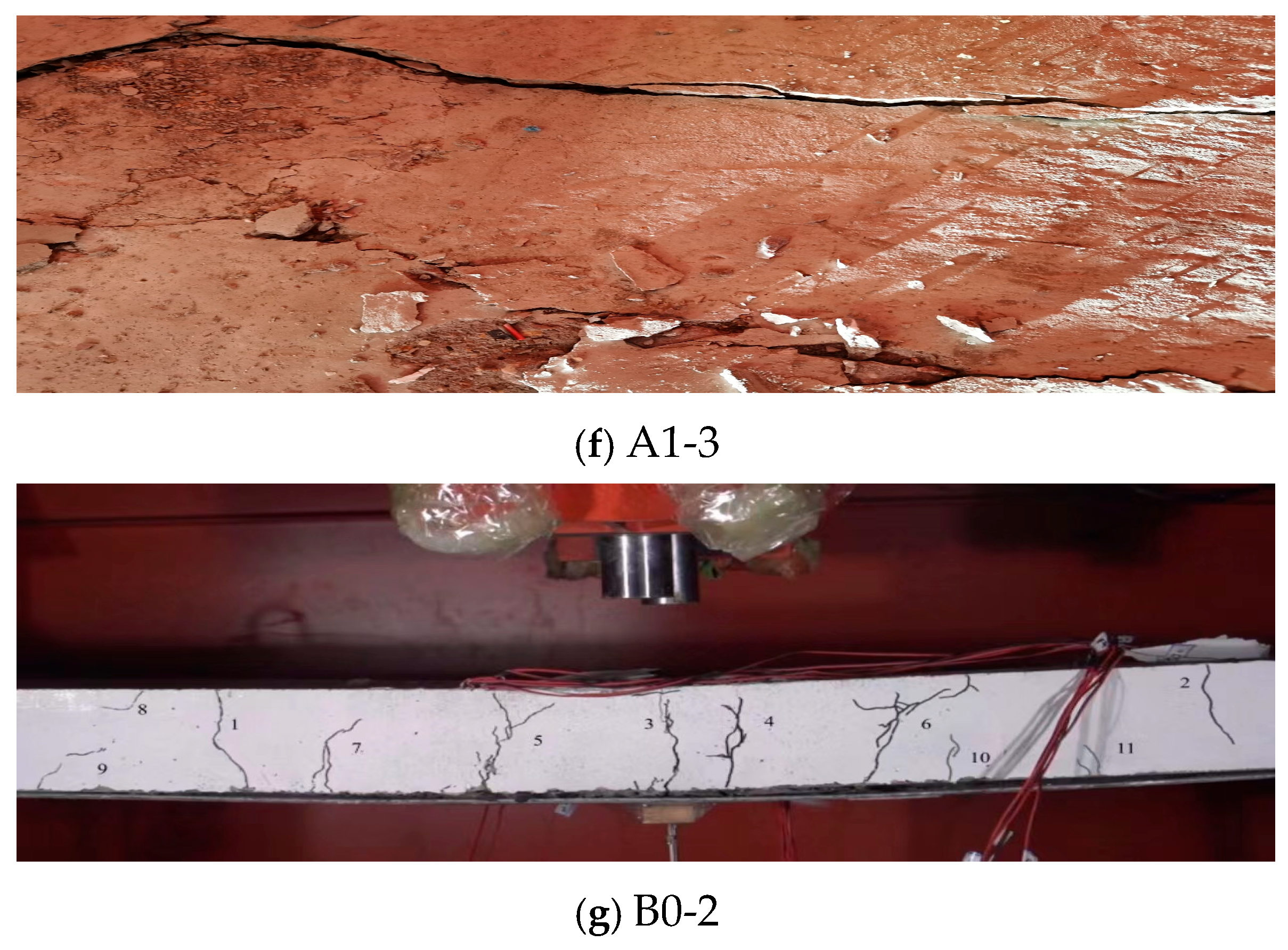

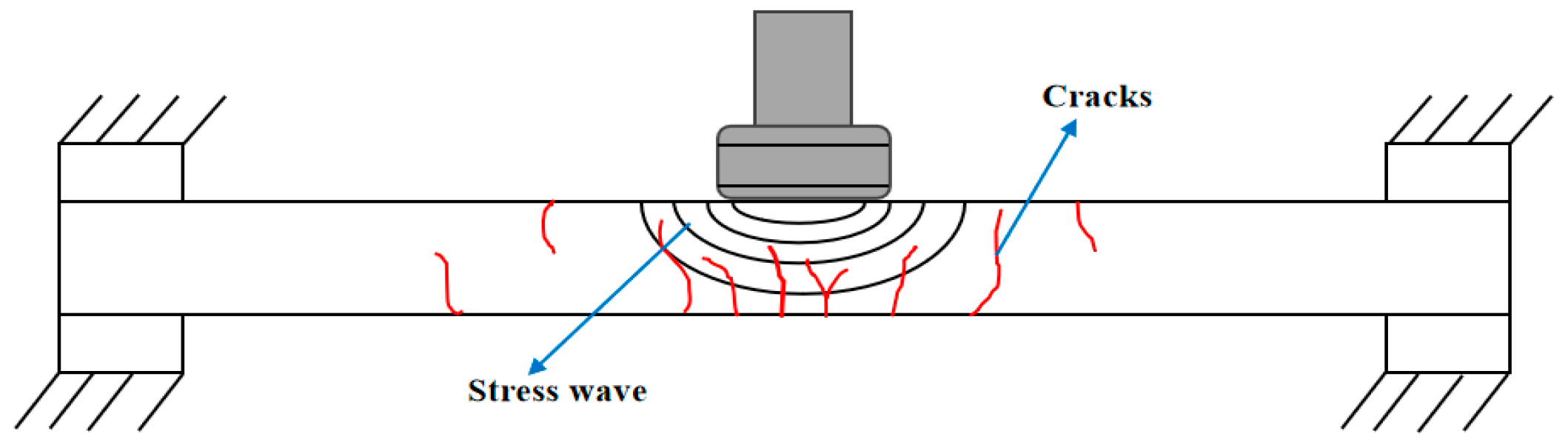

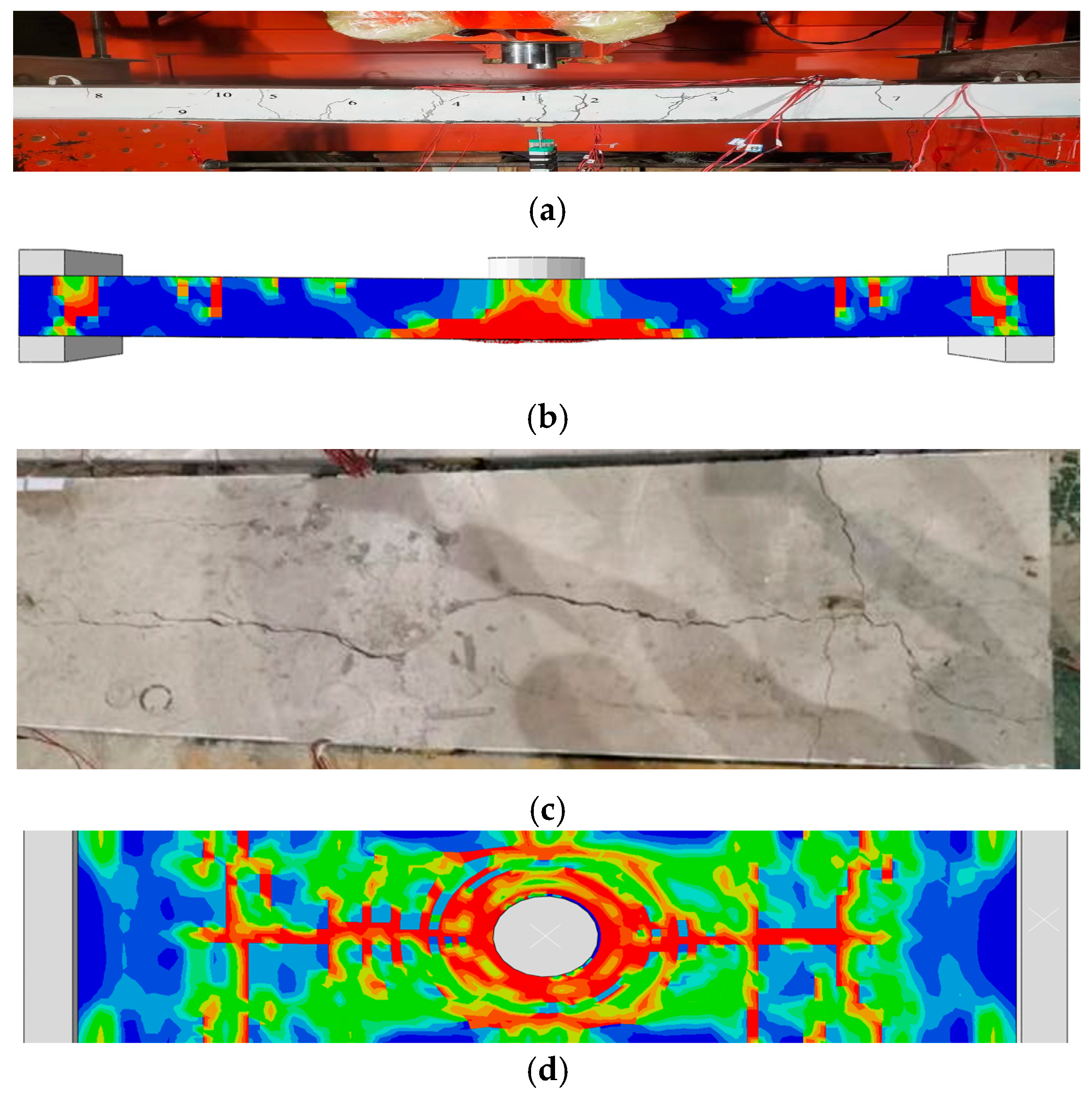

3.1. Failure Pattern of PGC Unidirectional Floor of Steel Truss

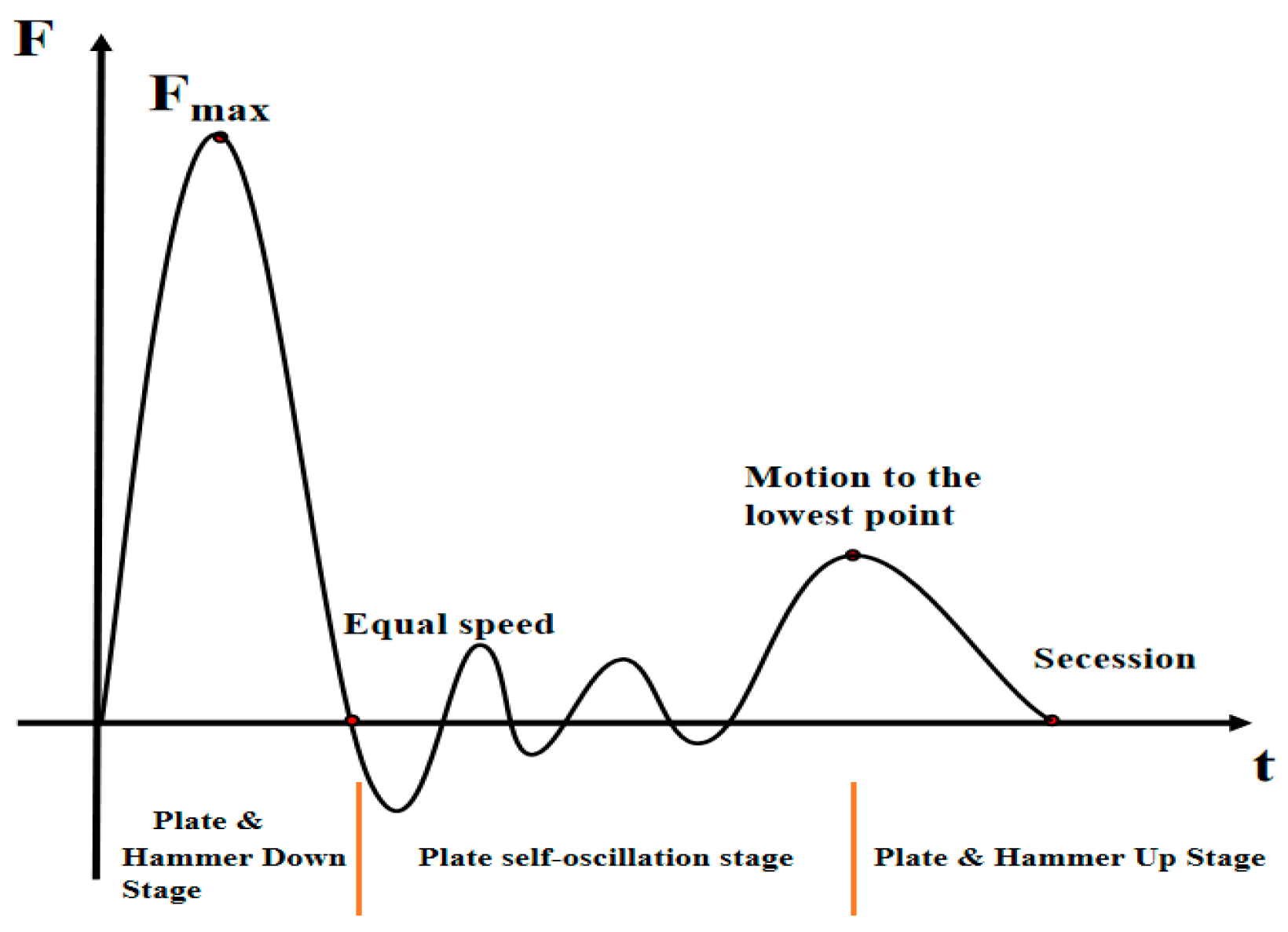

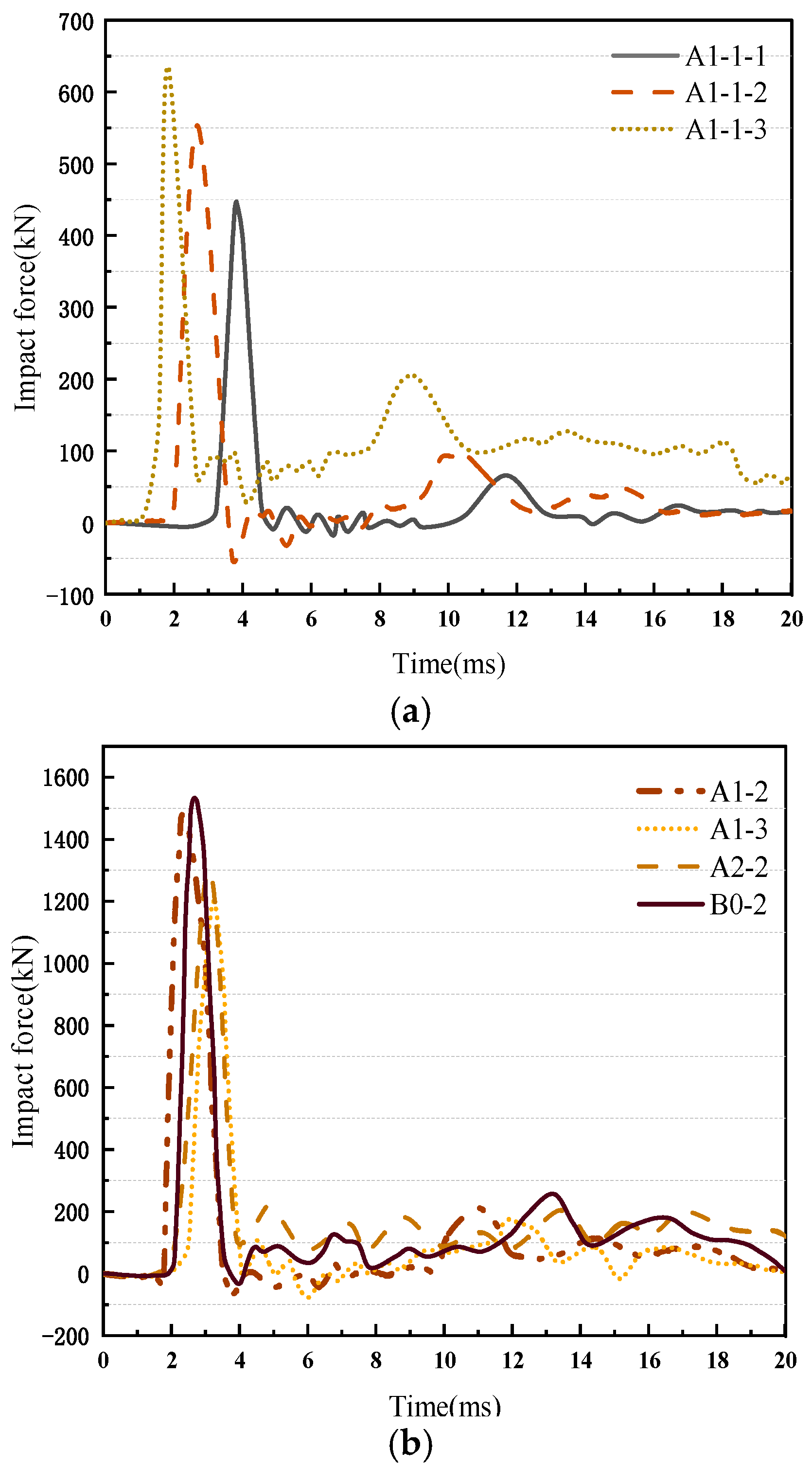

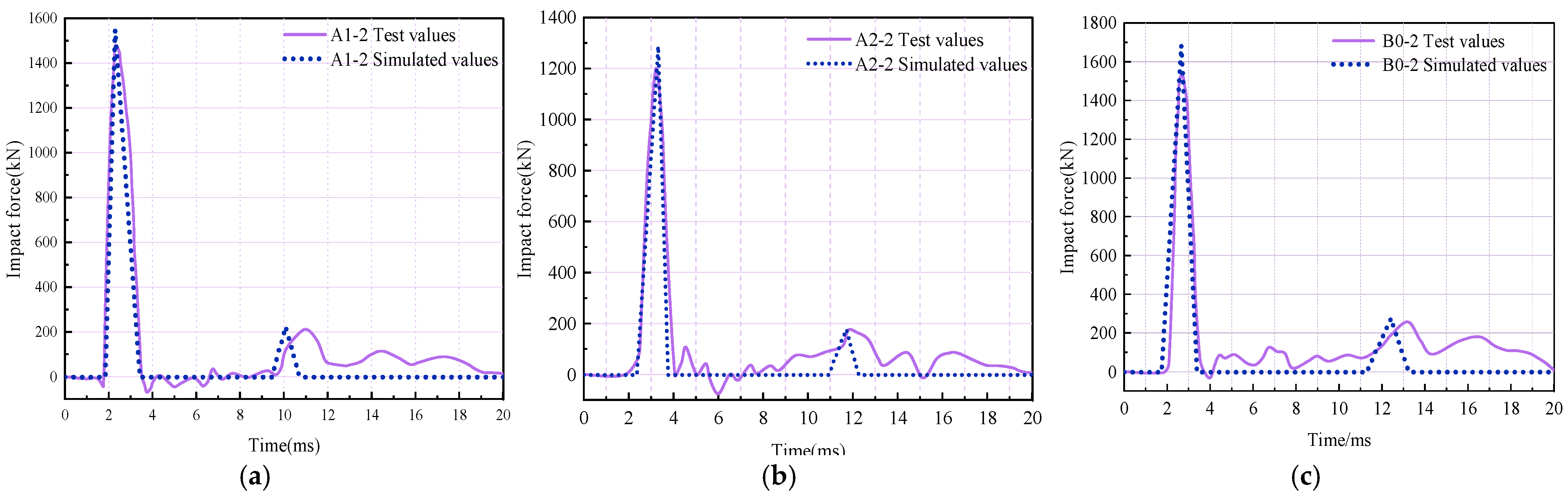

3.2. Impact Force Time Course Curve

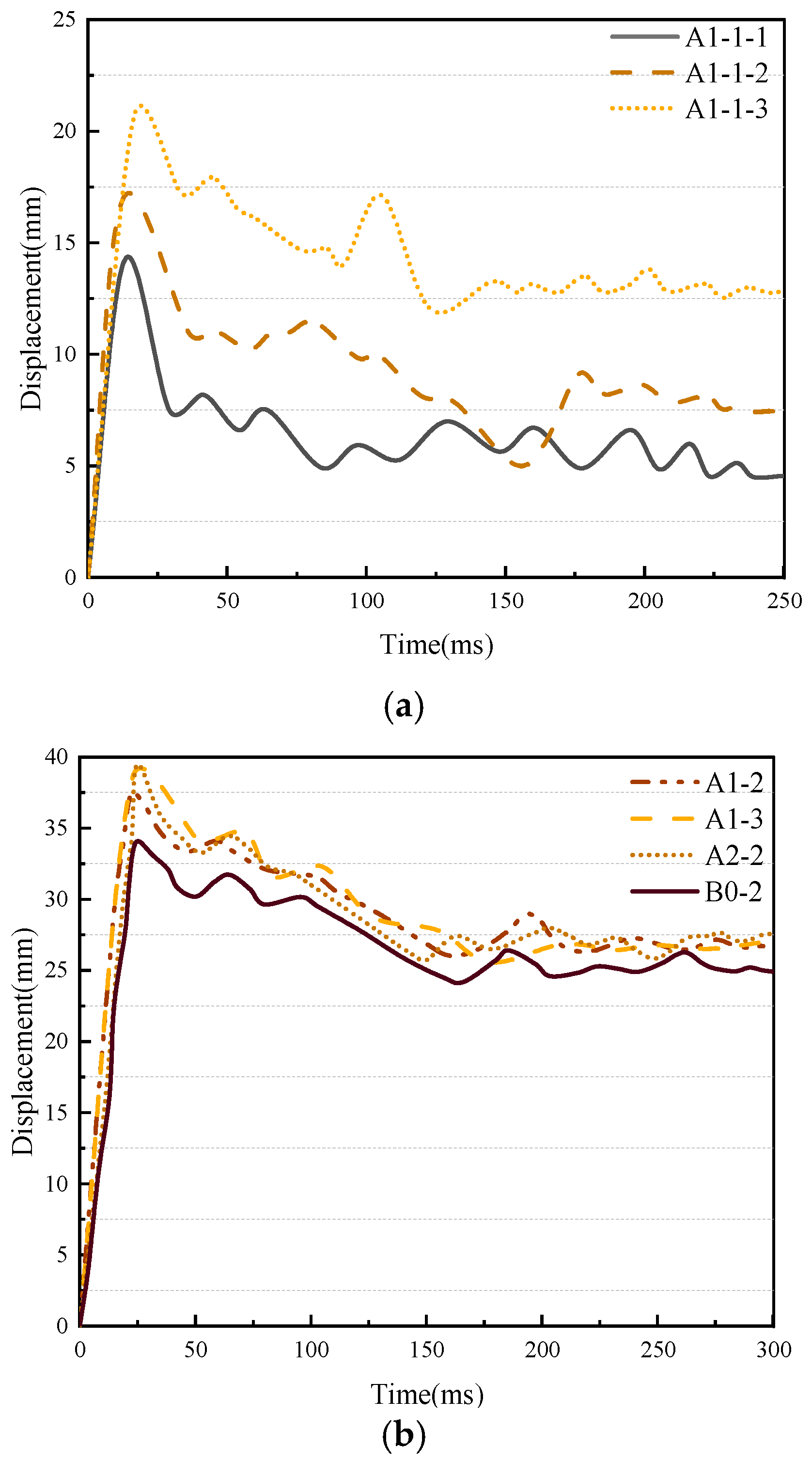

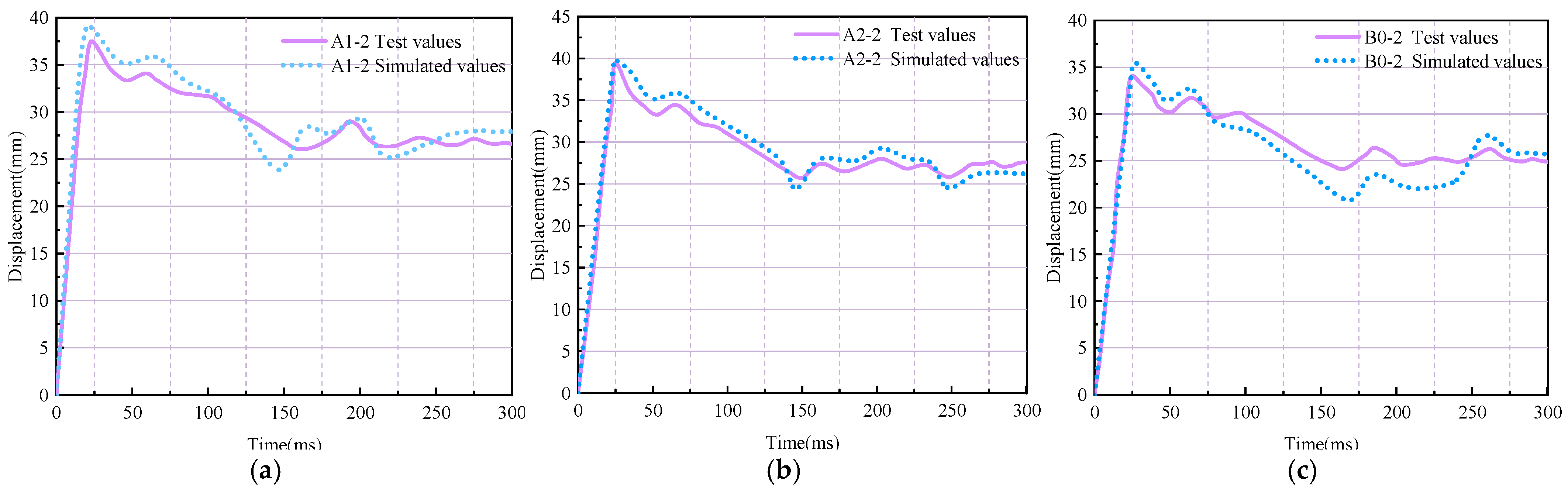

3.3. Displacement Time History Curve

3.4. Analysis of Floor Residual Energy Absorption Capacity

4. Numerical Simulation

4.1. Basic Assumptions of Numerical Simulation

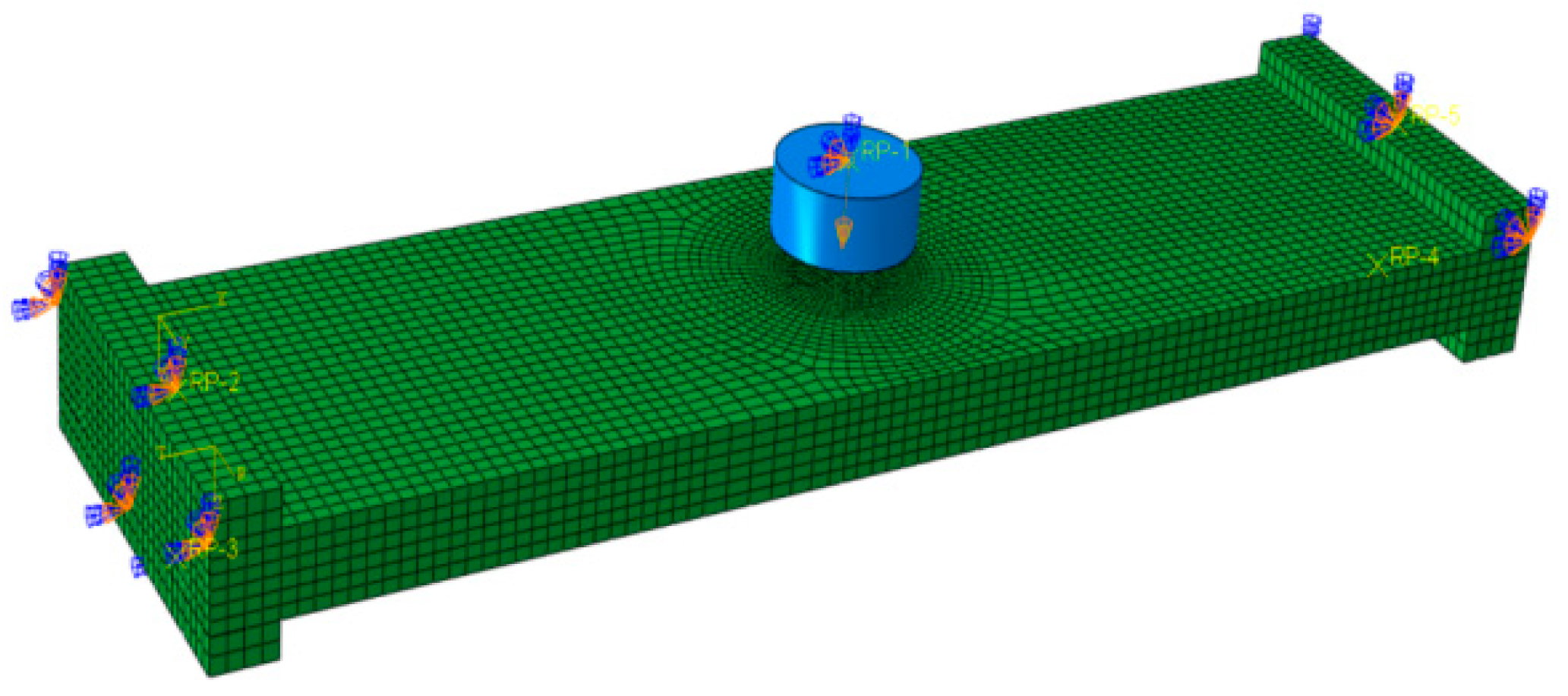

4.2. Establishment of Finite Element Model

4.3. Comparison of Results

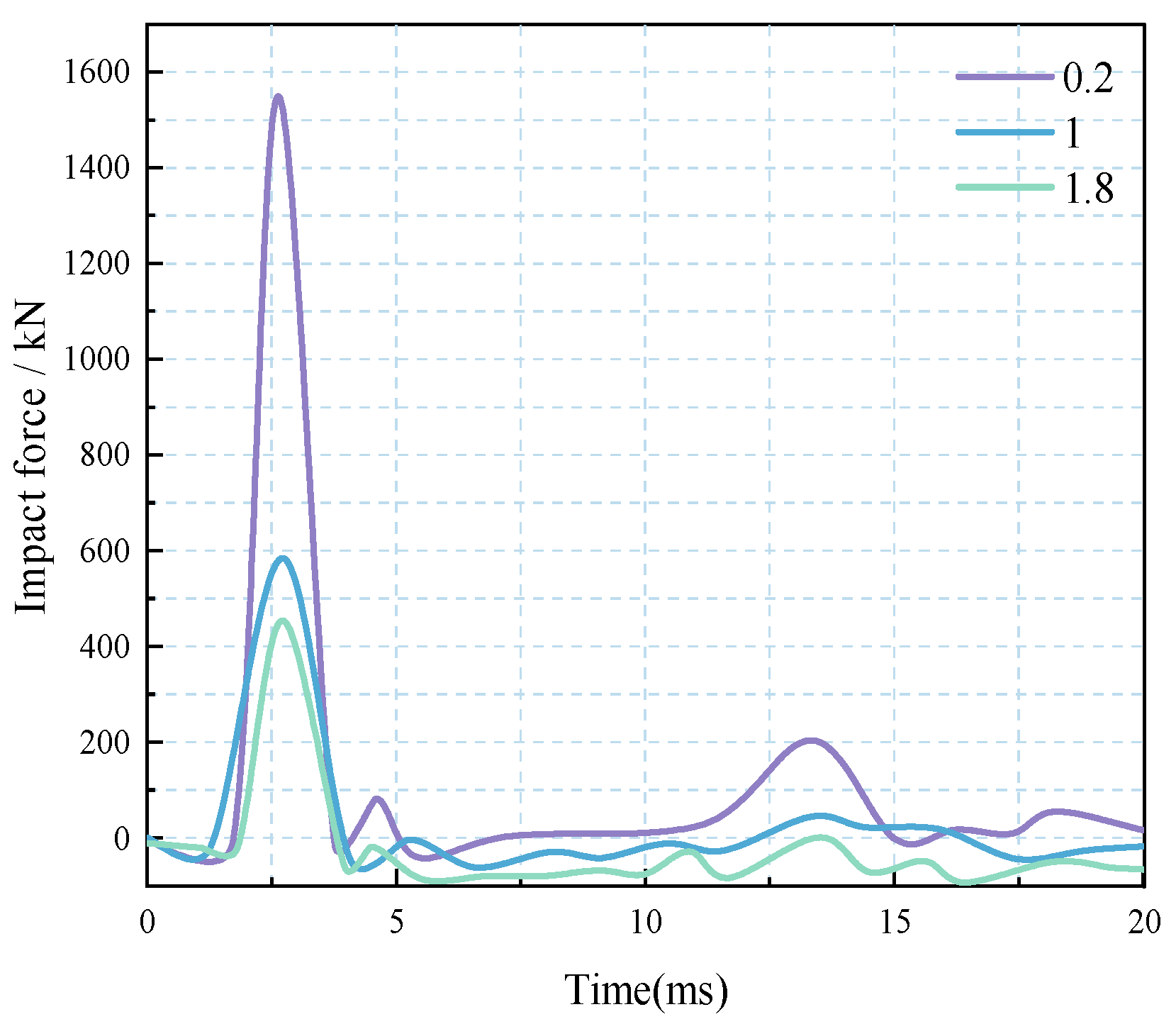

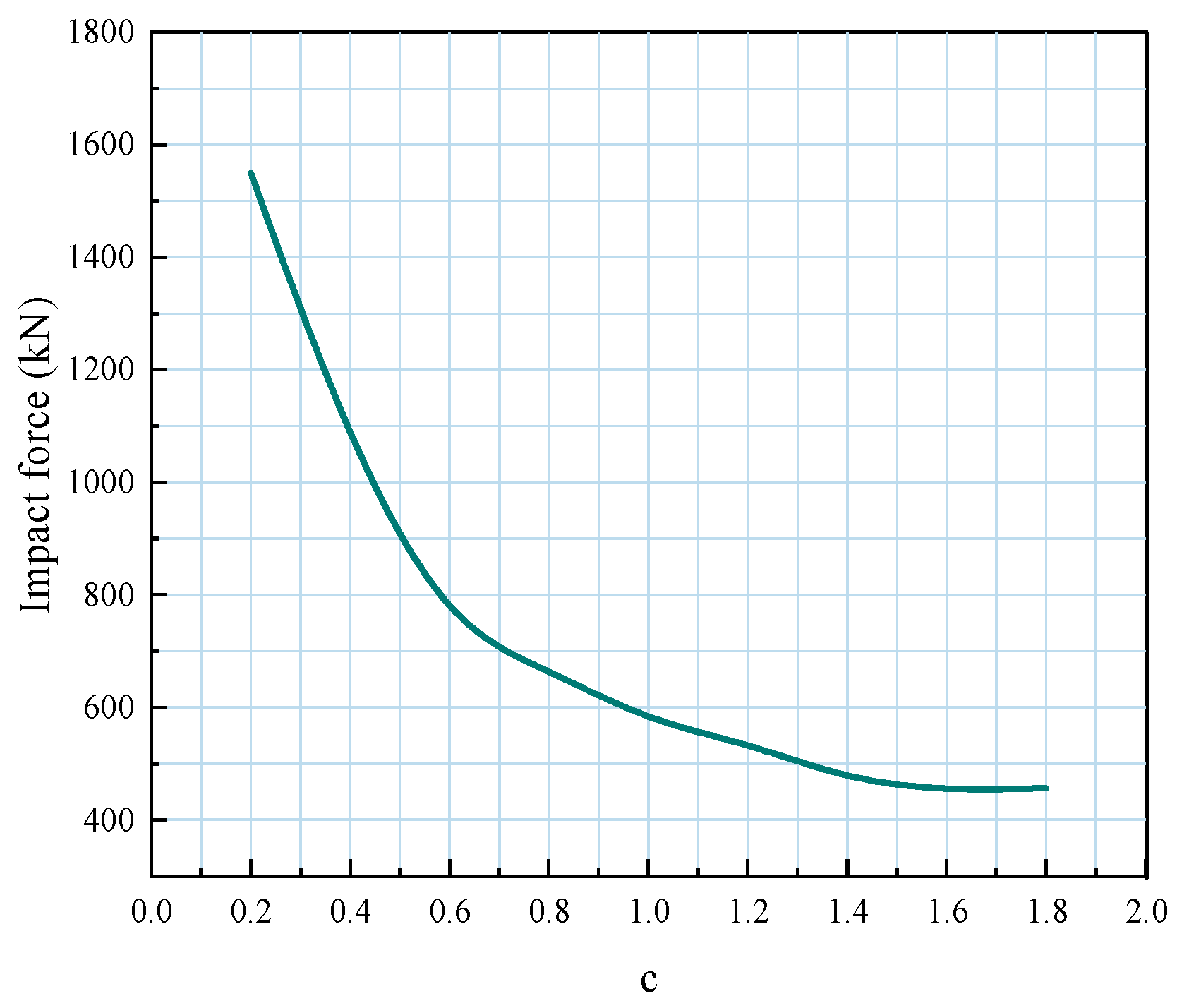

4.4. The Impact of Aspect Ratio on Impact Force

5. Conclusions

- (1)

- Under low-velocity impact, steel-truss-reinforced PGC slabs predominantly exhibited flexural failure mechanisms. Continuous longitudinal cracks propagating from the impact epicenter to slab peripheries were observed in the tensile zone, demonstrating characteristic through-thickness fracture patterns. For equivalent PG dosage, 120 mm-thick specimens demonstrated localized concrete spalling at the impact zone while maintaining structural integrity. This cohesive fracture morphology with controlled crack propagation (width < 0.3 mm) achieved complete energy dissipation, validating that increased slab thickness and steel plate integration effectively constrain crack initiation (35% reduction) and width development (42% decrease), thereby enhancing crack resistance and minimizing impact-induced damage.

- (2)

- Progressive PG dosage escalation (0–2%) under constant impact height revealed congruent mid-span displacement time-history profiles. Notably, both maximum and residual mid-span displacements exhibited 2 mm increments. PG-modified concrete demonstrated enhanced free-water viscous effects, augmenting structural compactness, energy dissipation capacity, and ductility. This modification preserved deformation resistance parity with conventional concrete, while concurrently reducing environmental contamination potential from PG utilization.

- (3)

- Under identical total impact energy conditions, the mid-span displacement of the slab subjected to a single impact load is reduced, and the ejection of concrete debris from the slab’s top surface is minimal. This suggests that multiple impacts pose a greater risk compared to a single impact of equivalent total energy.

- (4)

- Variations in PG content (0–2%) exhibited statistical invariance in both secondary impact force peaks and temporal characteristics under identical impact energy conditions, demonstrating statistically insignificant influence (p > 0.05) within the studied parameter space.

- (5)

- The ABAQUS finite element analysis (FEA) platform was employed to simulate impact scenarios, yielding time-history responses of impact forces and displacements that exhibited strong correlation (R2 ≥ 0.92) with experimental data, with discrepancies confined within 10%. This validation confirms the model’s predictive capability in capturing critical impact mechanics parameters.

- (6)

- Experimental results demonstrate that the incorporation of 2% PG composite admixture enables efficient utilization of industrial solid waste (8.5 tons per 100 m3 of concrete) while maintaining compliance with mechanical performance criteria (compressive strength and durability). This formulation provides a feasible solution for environmentally sound disposal of industrial by-products. Through synergistic optimization of the waste-cementitious matrix system, the design achieves balanced functional performance and ecological benefits, aligning with the sustainable development objectives of green concrete technology.

- (7)

- Numerical analysis of drop hammer geometry effects on rockfall impact loading reveals three critical parametric relationships: (1) impact load magnitude demonstrates inverse proportionality to contact width; (2) impactor thickness exhibits negative correlation with peak contact force; (3) decreasing width-to-height ratio induces accelerated growth in impact intensity, following an inverse proportional function with progressive rate enhancement. These findings provide quantitative references for post-impact structural monitoring system optimization and targeted reinforcement strategy formulation, thereby improving operational precision in disaster-affected infrastructure maintenance.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Tayibi, H.; Choura, M.; López, F.A.; Alguacil, F.J.; López-Delgado, A. Environmental impact and management of phosphogypsum. J. Environ. Manag. 2009, 90, 2377–2386. [Google Scholar] [CrossRef] [PubMed]

- Jalali, J.; Gaudin, P.; Capiaux, H.; Ammar, E.; Lebeau, T. Fate and transport of metal trace elements from phosphogypsum piles in Tunisia and their impact on soil bacteria and wild plants. Ecotoxicol. Environ. Saf. 2019, 174, 12–25. [Google Scholar] [CrossRef] [PubMed]

- Yang, J.; Liu, W.; Zhang, L.; Xiao, B. Preparation Of Load-bearing Building Materials From Autoclaved Phosphogypsum. Constr. Build. Mater. 2009, 23, 687–693. [Google Scholar] [CrossRef]

- Zhang, D.; Luo, H.; Zheng, L.; Wang, K.; Li, H.; Wang, Y.; Feng, H. Utilization of waste phosphogypsum to prepare hydroxyapatite nanoparticles and its application towards removal of fluoride from aqueous solution. J. Hazard. Mater. 2012, 241–242, 418–426. [Google Scholar] [CrossRef]

- Murali, G.; Azab, M. Recent research in utilization of phosphogypsum as building materials: Review. J. Mater. Res. Technol. 2023, 25, 960–987. [Google Scholar] [CrossRef]

- Liu, D.-S.; Wang, C.-Q.; Mei, X.-D.; Zhang, C. An effective treatment method for phosphogypsum. Environ. Sci. Pollut. Res. 2019, 26, 30533–30539. [Google Scholar] [CrossRef]

- Wang, Y.; Huo, H.; Chen, B.; Cui, Q. Development and optimization of phosphogypsum-based geopolymer cement. Constr. Build. Mater. 2023, 369, 130577. [Google Scholar] [CrossRef]

- Islam, G.S.; Chowdhury, F.H.; Raihan, M.T.; Amit, S.K.S.; Islam, M.R. Effect of phosphogypsum on the properties of Portland cement. Procedia Eng. 2017, 171, 744–751. [Google Scholar] [CrossRef]

- Muthukumar, P.; Shewale, M.; Asalkar, S.; Shinde, N.; Korke, P.; Anitha, M.; Gobinath, R.; Anuradha, R. Experimental study on light weight panel using phosphogypsum. Mater. Today Proc. 2022, 49, 1852–1856. [Google Scholar] [CrossRef]

- Chen, S.; Kong, D.; Wang, L.; Cheng, X.; Fu, R.; Lv, F. Experimental Investigation on Dynamic Compressive Properties of Phosphogypsum-Based Concretes. J. Mater. Civ. Eng. 2023, 35, 04023477. [Google Scholar] [CrossRef]

- Yin, C.; Zhou, L.; Zou, Q.; Xu, Y. Effect of filling phosphogypsum on the axial compression behavior of cold-formed thin-walled steel walls. Buildings 2022, 12, 1325. [Google Scholar] [CrossRef]

- Rehman, S.; Iqbal, S.; Ali, A. Combined influence of glass powder and granular steel slag on fresh and mechanical properties of self-compacting concrete. Constr. Build. Mater. 2018, 178, 153–160. [Google Scholar] [CrossRef]

- Kezmane, A.; Chiaia, B.; Kumpyak, O.; Maksimov, V.; Placidi, L. 3D modelling of reinforced concrete slab with yielding supports subject to impact load. Eur. J. Environ. Civ. Eng. 2017, 21, 988–1025. [Google Scholar] [CrossRef]

- Asakura, T.; Mizunuma, H.; Kasai, Y.; Tanaka, M.; Hiramitsu, A. Prediction of low-frequency floor impact vibration of CLT structures using a single-layer FE model. J. Build. Eng. 2024, 98, 111336. [Google Scholar] [CrossRef]

- Yasunori, M.; Natsuki, I. Behavior of thin reinforced concrete slabs and effect of reinforcement bars subjected low-velocity impact. Structures 2022, 38, 832–847. [Google Scholar] [CrossRef]

- Sadraie, H.; Khaloo, A.; Soltani, H. Dynamic performance of concrete slabs reinforced with steel and GFRP bars under impact loading. Eng. Struct. 2019, 191, 62–81. [Google Scholar] [CrossRef]

- Peng, F.; Gu, S.; Li, T.; Kong, C.; Huang, Y.; Li, J. Experimental and Theoretical Study of Rockfall Impacts on Concrete Slab under Low-velocity Impact. KSCE J. Civ. Eng. 2022, 26, 4653–4663. [Google Scholar] [CrossRef]

- Beppu, M.; Kataoka, S.; Mori, K.; Ichino, H. Local damage characteristics of reinforced concrete slabs subjected to hard/deformable projectile impact. Adv. Struct. Eng. 2022, 7, 1505–1518. [Google Scholar] [CrossRef]

- Senthil, K.; Sharma, R. Evaluation of Compressive and Tensile Stress–Strain Parameters of Concrete Damage Plasticity Model for Concrete Slabs Under Impact load. J. Vib. Eng. Technol. 2023, 11, 2733–2754. [Google Scholar] [CrossRef]

- Chen, C.; Zhang, X.; Hao, H. Investigation on the impact resistance of reinforced geopolymer concrete slab. J. Clean. Prod. 2023, 406, 137144. [Google Scholar] [CrossRef]

- Zhang, J.; Yan, Y.; Hu, Z. Preparation and characterization of foamed concrete with Ti-extracted residues and red gypsum. Constr. Build. Mater. 2018, 171, 109–119. [Google Scholar] [CrossRef]

- GB/T 5081-2019; Test Methods for Building Slabs Under Impact Loading. China Standards Press: Beijing, China, 2019.

- GB 50010-2010; Code for Design of Concrete Structures. Architecture & Building Press: Beijing, China, 2010.

- GB/T 50743-2012; Technical Code for Recycling of Construction and Demolition Waste. China Architecture & Building Press: Beijing, China, 2012.

- JGJ 55-2011; Specification for Mix Proportion Design of Ordinary Concrete. China Architecture & Building Press: Beijing, China, 2011.

- GB/T 14685-2022; Pebble and Crushed Stone for Construction. China Standards Press: Beijing, China, 2022.

- GB/T 14684-2022; Sand for Construction. China Standards Press: Beijing, China, 2022.

- GB 8076-2008; Concrete Admixtures. China Standards Press: Beijing, China, 2008.

- GB/T 1346-2011; Test Methods for Water Requirement of Normal Consistency, Setting Time and Soundness of Cement. China Standards Press: Beijing, China, 2011.

- Wei, H.; Wen, Z.; Ba, L.; Gao, Q. Study on strength test and hydration mechanism of phosphogypsum based cemented backfill. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2021; Volume 768, p. 012100. [Google Scholar] [CrossRef]

- Zhang, J.-L.; Liu, B.-D.; Liu, R. Behavior of sinusoidal-corrugated-steel-plate–concrete composite slabs: Experimental investigation and theoretical model development. J. Constr. Steel Res. 2021, 187, 106958. [Google Scholar] [CrossRef]

- Lian, M.; Luo, Z.; Su, M.; Zhang, H.; Shen, H. Composite floor slab effect on seismic performance of steel-framed-tube structures with shear links. Soil Dyn. Earthq. Eng. 2024, 183, 108800. [Google Scholar] [CrossRef]

- Huang, Z.; Zhao, X.; Guo, Y.; Liu, X. Residual Flexural Performance of Double-Layer Steel–RLHDC Composite Panels after Impact. Buildings 2023, 13, 2916. [Google Scholar] [CrossRef]

- Chernysh, Y.; Plyatsuk, L. Environmentally friendly concept of phosphogypsum recycling on the basis of the biotechnological approach. In International Business, Trade and Institutional Sustainability; Springer: Cham, Switzerland, 2020; pp. 167–182. [Google Scholar]

- Chen, Y.; May, I.M. Reinforced concrete members under drop-weight impacts. Proc. Inst. Civ. Eng.-Struct. Build. 2009, 162, 45–56. [Google Scholar] [CrossRef]

| PG Dosage | Dissociation | Clinker | Coal Ash | Mineral Powder | PG | Crushed or Broken Rock | Alumina | Water Reducing Agent | Water |

|---|---|---|---|---|---|---|---|---|---|

| 0% | C35 | 235.39 | 33.63 | 67.25 | 0.0 | 1114.43 | 774.74 | 4.04 | 157.03 |

| 2% | C35 | 230.68 | 33.63 | 67.25 | 4.71 | 1114.43 | 774.74 | 4.04 | 157.03 |

| Group | Test Block Size | PG Blending Ratio | Production Quantity |

|---|---|---|---|

| AC | 150 mm × 150 mm × 150 mm | 0% | 6 |

| A1 | 150 mm × 150 mm × 150 mm | 2% | 6 |

| B0 | 150 mm × 150 mm × 300 mm | 0% | 4 |

| B1 | 150 mm × 150 mm × 300 mm | 2% | 4 |

| Specimen Number | Grade of Concrete | Plate Size L*b*h (mm) | Bottom Plate or Not | PG Content | Loading Mode |

|---|---|---|---|---|---|

| A1-1 | C40 | 2200 × 600 × 120 | yes | 2% | Repeatedlly |

| A1-2 | C40 | 2200 × 600 × 120 | yes | 2% | Single |

| A1-3 | C40 | 2200 × 600 × 120 | no | 2% | Single |

| A2-2 | C40 | 2200 × 600 × 100 | yes | 2% | Single |

| B0-2 | C40 | 2200 × 600 × 120 | yes | 0% | Single |

| Specimen Number | PG Dosage | Weight of a Hammer/kg | Impact Height/m | Impact Energy/J |

|---|---|---|---|---|

| A1-1 | 2% | 239 | 1 | 2323 |

| 1.25 | 2903 | |||

| 1.5 | 3484 | |||

| A1-2 | 2% | 239 | 3.75 | 8198 |

| A1-3 | 2% | 239 | 3.75 | 8198 |

| A2-2 | 2% | 239 | 3.75 | 8198 |

| B0-2 | 0% | 239 | 3.75 | 8198 |

| Specimen Number | Impact Maximum (kN) | Second Peak of Impact (kN) | Ratio of Second Peak to Maximum Impact Force |

|---|---|---|---|

| A1-1-1 | 447 | 65 | 15% |

| A1-1-2 | 553 | 99 | 18% |

| A1-1-3 | 636 | 206 | 32% |

| A1-2 | 1476 | 217 | 15% |

| A1-3 | 1302 | 205 | 15% |

| A2-2 | 1195 | 165 | 14% |

| B0-2 | 1534 | 257 | 17% |

| Parameters | Plain Concrete | PG Concrete | Steel Reinforcing Bar | Plate | Hammer Head |

|---|---|---|---|---|---|

| Poisson’s ratio | 0.19 | 0.19 | 0.3 | 0.3 | 0.3 |

| Densities (kg/m3) | 2500 | 2500 | 7850 | 7850 | 7850 |

| Modulus of elasticity (GPa) | 32.7 | 32.6 | 210 | 210 | 210 |

| yield strength (MPa) | — | — | 425.08 (8 mm) 427.15 (10 mm) | 400 | 1000 |

| Specimen Number | ||||||

|---|---|---|---|---|---|---|

| A1-2 | 1450 | 1548 | 6.8 | 37 | 40 | 8.1 |

| A2-2 | 1195 | 1288 | 7.8 | 39 | 40 | 2.6 |

| B0-2 | 1533 | 1643 | 7.2 | 34 | 37 | 8.8 |

| Serial Number | c | Impact Force/kN |

|---|---|---|

| 1 | 0.2 | 1549.4 |

| 2 | 0.4 | 1089.7 |

| 3 | 0.6 | 781.1 |

| 4 | 0.8 | 663.5 |

| 5 | 1 | 584.1 |

| 6 | 1.2 | 532.1 |

| 7 | 1.4 | 479.2 |

| 8 | 1.6 | 455.7 |

| 9 | 1.8 | 453.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sha, L.; Han, Y.; Zhang, L. Dynamic Response and Computational Modeling of Truss-Reinforced Phosphogypsum-Concrete Composite Slabs Subjected to Impact Loading: A Parametric Finite Element Analysis. Buildings 2025, 15, 1948. https://doi.org/10.3390/buildings15111948

Sha L, Han Y, Zhang L. Dynamic Response and Computational Modeling of Truss-Reinforced Phosphogypsum-Concrete Composite Slabs Subjected to Impact Loading: A Parametric Finite Element Analysis. Buildings. 2025; 15(11):1948. https://doi.org/10.3390/buildings15111948

Chicago/Turabian StyleSha, Lirong, Yan Han, and Lijie Zhang. 2025. "Dynamic Response and Computational Modeling of Truss-Reinforced Phosphogypsum-Concrete Composite Slabs Subjected to Impact Loading: A Parametric Finite Element Analysis" Buildings 15, no. 11: 1948. https://doi.org/10.3390/buildings15111948

APA StyleSha, L., Han, Y., & Zhang, L. (2025). Dynamic Response and Computational Modeling of Truss-Reinforced Phosphogypsum-Concrete Composite Slabs Subjected to Impact Loading: A Parametric Finite Element Analysis. Buildings, 15(11), 1948. https://doi.org/10.3390/buildings15111948