Abstract

This study demonstrates the conversion of agricultural and industrial waste into construction materials by developing ultra-high-performance concrete using cold-bonded sesame ash and waste glass aggregates. The primary focus of this study was sustainability and waste valorization in self-curing concrete systems. This study focuses on many aspects of producing cementless concrete with superior short- and long-term properties, incorporating an innovative artificial aggregate premanufactured using sesame ash and waste glass. Prepacking technology of casting was used. A self-curing additive is used to reduce the energy required for curing. In cold-bonded aggregates (CBAs), the aggregate content ranged from 10 to 50% of the total sand volume. Polyethylene glycol was used as an internal curing agent to evaluate the mechanical properties of the concrete, including the compressive strength and tensile strength at different ages. The durability characteristics of the concrete were also analyzed in terms of its resistance to sulfates, chloride ion penetration, and performance at elevated temperatures of 300 and 600 °C. Microscopic analyses were conducted by scanning electron microscopy (SEM), thermogravimetric analysis (TGA), Fourier transform infrared spectroscopy (FTIR), and Differential Scanning Calorimetry (DSC). The results showed a significant improvement in the mechanical and durability performance, especially at 30%, which resulted in the highest compressive strength of 147.2 MPa at 90 days. This is an 11.93% increase compared with that of the reference mix. The tensile strength was also improved by 14.5% at the same replacement ratio. The mix containing 30% manufactured aggregate demonstrated the best thermal resistance, retaining the highest percentage of residual strength at both 300 °C and 600 °C, as well as superior sulfate impact resistance, with a strength reduction factor of 39.5%. When the replacement ratio was increased to 50%, the chloride penetration resistance improved significantly by 41% compared with that of the reference mix. FTIR, TGA, and DSC analyses also demonstrated enhanced silicate polymerization and increased carbonate formation, contributing to the improved chemical stability and density of the concrete matrix.

1. Introduction

Ultrahigh-performance concrete (UHPC) is a cement-based composite material engineered to deliver superior durability and mechanical properties [1]. Concrete remains the cornerstone of the construction sector owing to its high cost efficiency. However, it is inherently constrained by its considerable mass and volumetric demands [2]. These limitations necessitate extensive spatial allocation during construction and involve large-scale components [3]. To overcome these challenges, researchers have focused on optimizing traditional concrete formulations and creating new materials with enhanced performance traits such as increased strength, resilience, and durability through particle packing optimization principles [4]. UHPC exhibits the evolving requirements of modern infrastructure and early research on UHPC manufacturing required strict production protocols, specialized mixing methods, and the exclusive use of refined materials, deliberately excluding coarse aggregates, to achieve optimal performance [5].

Before implementing UHPC in construction projects, rigorous standards should be adhered to, and the best management practices should be applied to ensure quality and reliability [6]. UHPC formulations are adaptable and can be tailored to satisfy diverse functional and structural requirements [7]. Globally, UHPC has been integrated into different applications owing to its advantageous characteristics, including innovative design flexibility, ease of fabrication, ability to form complex shapes, reduced weight, and resilience under extreme environmental and mechanical stresses. UHPC has gained significant traction in demanding projects worldwide and is widely used in constructing vertical structures such as protective overlays, offshore platforms, hydraulic installations, wind turbine foundations, and facilities within the petroleum industry [8]. In addition, they have been extensively employed in structural repair, rehabilitation, bridge construction, and architectural design. Its primary role is in bridge and highway infrastructure projects [9].

A critical challenge in the concrete industry is the implementation of effective curing techniques to enhance performance. Li et al. [10] demonstrated that heat curing notably influences early-age shrinkage when employing dual-phase treatment strategies. Subjecting the concrete to a high temperature of 55 °C with a subjecting time of 70 min substantially improved its quality after curing at 48 °C for 60 min. Steam curing has been identified as an effective curing regime, outperforming conventional curing and autoclave techniques. Furthermore, innovative hybrid curing processes have been introduced to optimize concrete performance [11,12,13]. Although standard curing is the most economical and practical method, it fails to deliver optimal results. According to ACI 308 [14], internal curing can be facilitated by integrating specific additives designed to retain moisture within the concrete matrix without altering the initial water composition. Adequate hydration is critical and typically depends on an external water supply to complete chemical reactions within the cement matrix. In contrast, self-curing methods utilize internal water reservoirs to sustain hydration, thereby improving the durability and mechanical properties of the concrete. However, a notable drawback of this method is the formation of internal voids, which can be mitigated by precisely calibrating the admixture dosage to control the shrinkage. The optimal dosage of liquid curing agents, such as polyethylene glycol (PEG), is generally 1% [15,16,17].

The production of CBAs in concrete has evolved through various methodologies and technological developments aimed at enhancing sustainability and reducing environmental impact [18]. Traditionally, the production of CBAs relies on high-temperature sintering. Although these methods are effective in generating durable materials, they are associated with substantial energy consumption and the release of significant quantities of carbon dioxide (CO2) [19]. Consequently, numerous challenges have been encountered in terms of energy efficiency and environmental impact. To address these challenges, researchers [20,21] have explored cold-bonding granulation techniques as alternatives for producing synthetic aggregates. This process relies on a mixture of raw materials, including recycled resources, and operates at lower temperatures, making it more energy-efficient [22]. Some challenges face the environment owing to agricultural and manufacturing waste.

The rise in global population has increased the demand for agricultural production, resulting in an escalation of agricultural waste [23,24,25]. Assessing agricultural waste is difficult for multiple reasons including its diminished economic value relative to the expenses incurred for collection, transportation, and treatment for productive utilization. Consequently, numerous farmers may incinerate agricultural waste instead of using it for energy production. The annual worldwide sesame production is approximately 5,532,000 metric tons [26]. Sesame has grown in several regions of Egypt. In Egypt, the area dedicated to sesame farming increased from 19,866,000 m2 in 1961 to 65,100,000 m2 in 2010, with increasing productivity from 0.114 kg/m2 in 2005 to 0.125 kg/m2 in 2010 [27]. The global sesame seed consumption amounted to USD 6559.0 million in 2018. [28]. Sesame ash, resulting from burning sesame seed hulls or other biological material from sesame processing waste, has attracted attention for its potential uses in many industries, including construction and materials engineering [29]. Its production typically involves the thermal decomposition of organic materials, resulting in ash with unique chemical and physical properties that make it suitable for incorporation into concrete formulations [29,30]. Sesame ash is characterized by high percentages of silica, calcium oxide, and other reactive compounds, which give it pozzolanic properties that improve mechanical performance and increase the durability of concrete mixtures. TA Sulaiman et al. [30] indicates that concrete mixtures containing sesame ash can improve the compressive strength by up to 58.7% compared to a standard mixture. Furthermore, sesame ash contributes to a denser microstructure, which enhances durability and extends the concrete structure’s life.

In addition to agricultural waste, industrial solid waste can be used in the construction industry, and incorporating waste glass powder (WGP) into the concrete industry is a sustainable and innovative solution to address environmental challenges by reducing the accumulation of glass waste and carbon footprint of Portland cement production [31,32,33,34,35]. Waste glass powder is produced by grinding household or industrial glass waste with high precision. It contains high amorphous silica, which exhibits pozzolanic activity that encourages the construction of calcium silicate hydrate (C-S-H) which, in turn, enhances the compressive, tensile, and flexural strength of concrete. The use of WGP aids in increasing concrete’s durability in regard to sulfur attack as well, reducing permeability, and reducing the alkali–silica reaction (ASR) when appropriately cured [34,36,37,38]. Their use also contributes to achieving sustainability by reducing reliance on energy-intensive cement production and accumulating non-biodegradable glass waste in landfills, thereby providing environmental and economic benefits. However, certain challenges must be carefully addressed to achieve the best performance, such as the possibility of an alkali reaction with silica [39,40,41,42].

Normal or conventional concrete is made by preparing the mix of its constituent parts comprising fine and coarse aggregates, cement, water, and any admixture uniformly and pouring the mix into intended molds [43]. However, concrete can be alternatively prepared by applying prepacking of coarse aggregates into a mold and then injecting cement mortar to fill the spaces between the packed aggregates [44,45]. This two-stage or prepacked-concrete method was first introduced in the 1930s [46]. This method is particularly suitable for constructing structural elements with complex reinforcement or in situations where traditional formwork disrupts the designed frames, such as the presence of pipes or openings [47]. In addition, this approach is suitable for large concrete works, such as bridge piers and piers, as well as underwater concrete works. In addition to the differences in production mechanisms, there are significant differences between traditional and prepackaged concrete [45]. This method effectively addresses coarse aggregate dispersion problems, particularly in heavy aggregate concrete. Furthermore, prepackaged concrete does not require mechanical vibration, compaction, or other compaction methods to achieve a fine dense structure, resulting in lower production costs [46,47,48].

Despite extensive research on improving the performance of UHPC, a gap remains in the use of sustainable waste materials as partial replacements for sand. In particular, This study focuses on many aspects of producing cementless concrete with superior properties and short and long terms in addition to the incorporation of an innovative artificial aggregated premanufactured using sesame ash as agricultural waste and waste glass, which represents solid waste to environmental problems of landfills moreover prepacking technology of casting was used. In addition, a self-curing additive was used to reduce the energy required for curing. Regarding the mechanical properties, mass transport and durability of UHPC have not yet been fully addressed. There is a gap in using environmentally friendly waste materials such as sesame ash and waste glass for sand partial replacement. There is an absence of comprehensive studies of the performance of UHPC with unique artificial aggregates. There is a lack of investigation on the prepacking technique for casting UHPC with waste-derived aggregates. There are limited studies carried on self-curing systems for UHPC using wastes. There is a lack of understanding the combined effects of CBAs with prepacked coarse aggregates and self-curing agents on the properties of UHPC. There is an absence of comprehensive analysis of the microstructure of UHPC with waste-derived CBAs. There has been limited work carried out on the thermal resistance and durability of UHPC with waste-derived aggregates subjected to extreme environments, and there is a lack of information regarding the optimal percentage of sand replacement with waste-derived CBAs in UHPC. This study has made significant advances in improving of extremely UHPC by introducing CBAs manufactured from sesame ash and glass waste powder to enhance the sustainability of building materials. This study combined prepacked coarse aggregates with CBAs and used polyethylene glycol as an internal curing agent, offering an innovative approach for self-curing concrete. By focusing on mechanical strength, heat resistance, and durability under harsh environmental conditions, this study contributes to environmental sustainability and improved material performance. The innovative use of CBAs provides a transformative strategy for improving UHPC, paving the way for more durable and environmentally friendly building practices.

2. Experimental Program

2.1. Materials

This section describes the nature of the raw materials used in this investigation. The experimental study utilized Type I Ordinary Portland Cement (Grade 52.5), which was procured from the Misr Beni Suef Factory for cement in Beni-Suef at Egypt. The cement met the ASTM C150 standards requirements [49]. Silica fume was supplied by Sika Company, having a specific gravity of 2.12 and a specific surface area of 18.1 × 103 m2/kg. The results of X-ray fluorescence of silica fume and cement are listed in Table 1. Crushed dolomite with a maximum nominal size of 10 mm was obtained from Ataqa Mountain in suez, while clean river sand was obtained and used as a replacement for the CBAs. In order to enhance the workability and reduce the water requirement of the UHPC mix, a polycarboxylate superplasticizer, Sika® ViscoCrete®−3425 produced from sika company in Cairo, Egypt, was added. Mixing was carried out using potable water. As a self-curing measure, polyethylene glycol (PEG 400) was used as self curing agent, while the alkaline solutions were sodium silicate and potassium hydroxide.

Table 1.

XRF for binder materials.

Egypt Global Silicates Company was the supplier of the sodium silicate solution (NS) with a pH of 1.526 g/cm3 and a specific gravity of 12.7 a. In addition, the compound’s composition is as follows: water = 55.9%, SiO2 = 29.4%, and Na2O = 14.7% by mass. KOH (potassium hydroxide), grade 98% to 99% purity, was purchased from the EL-Nasr Company for Intermediate Chemicals. This Company is a subsidiary of the National Defense Services industry, Egyptian Armed Forces, 6 October City. Potassium hydroxide (97–98% purity) was added to water and the compound was stirred until a solution with the desired concentration was obtained. Potassium was dissolved in water to make a solution of concentration 12 M.

2.2. CBA Preparation

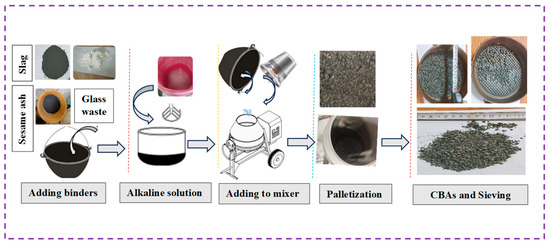

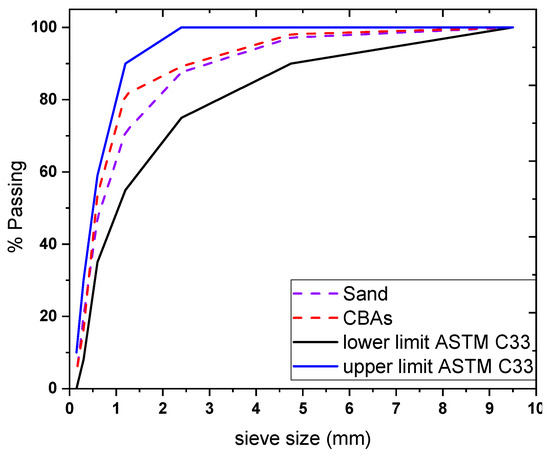

CBAs were produced using cold bonding technology. The preparation began by mixing slag, waste glass, and sesame ash homogeneously in ratios of 70:20:10. The mixture was placed in a disk pelletizer and sprayed evenly with a specified amount of water. This step was repeated until the granules reached a desired size. The preparation of CBAs using slag, potassium hydroxide (KOH), sesame ash, and recycled glass involves several steps. First, the raw materials were collected and prepared. The slag was obtained from industrial processes such as blast furnaces and dried to remove moisture. Sesame ash is produced by burning sesame waste and sifting it to obtain fine particles (less than 75 microns). Similarly, the recycled glass was crushed and screened to ensure a uniform particle size. Subsequently, the materials were mixed together. The dry materials (slag, sesame ash, and recycled glass) were mixed in specific proportions to achieve homogeneity. Next, KOH solution was gradually added to the mixture to ensure uniform wetting of the particles without forming a paste as shown in Figure 1. This mixture formed a base for granulation. The granulation process of producing CBA through disk pelletization is sequentially reproducible and scalable. The literature suggests that parameters like disk angle, rotational speed, pelletization time, and raw material makeup are sufficiently established and can be accurately controlled for consistent pellet properties across different batches. Furthermore, regression analysis performed by Kim et al. [18] confirmed a strong relationship (R2 = 0.9979) between pelletizer disk speed and corresponding size, ensuring that aggregate quality and mechanical performance remain unobstructed during scale-up from lab to pilot-scale production. This has been validated in pilot studies using pelletizers with diameters between 40 cm and 160 cm, confirming not only the repeatability of the process but also the industrial applicability of the developed method. Laboratory tests confirmed the ability of this process to produce aggregates with homogeneous bulk density, strength, and particle size distribution which confirms the reliability of the process [20]. The industrial pan granulator is utilized in this process, which is also employed by other industries including fertilizer granulation, iron ore agglomeration, and waste remediation for contaminant solidification. Such success in these industries demonstrates that the granulation process is indeed suitable for production scale levels without degrading performance or product quality. Granulated ion was performed using a rotary or a disc granulator. The mixture was fed into the granulator, and water or an additional KOH solution was sprayed to improve cohesion. The spinning process was continued until spherical pellets of desired size were formed, usually between 15 µm and 5 mm. Granulator parameters such as the angle and rotation speed were adjusted to control the size and quality of the pellets [20]. The newly formed pellets underwent pretreatment and were left to air dry for 24–48 h to obtain initial strength and stability. Subsequently, hardening occurs under natural environmental conditions. The solidification process allows for optimal chemical reactions, particularly the pozzolanic activity of sesame ash and glass with slag. After hardening, quality tests were performed on the aggregates. The compressive or endurance strength was measured to ensure mechanical durability, and the density and porosity were measured to evaluate its suitability. The particles were characterized, and the results revealed that the bulk density was 1695 kg/m3. The fineness coefficient was 2.98, which was placed in Zone II based on particle size distribution. To maintain the same properties of CBAs for all batches, a production method was established. The proportions of the ingredients (70% slag, 20% waste glass, 10% sesame ash) were kept on precision balances, and the moisture content was regulated during granulation. Granulation was carried out with the same disc pelletizer for all the active processes (disc angle, rotation speed, water spray rate) that were set in stone. Once the pellets were formed, all batches were air-dried for the same period of time (24–48 h) and in the same conditions. Aggregate batches were tested for bulk density, fineness modulus, and particle size distribution prior to usage. The accepted aggregate batches were those that met the stipulated tolerance limits defined with reference to ASTM C136/C136M [50] for sieve analysis and ASTM C29/C29M [51] for unit weight before being subjected to concrete production. The particle size distribution curves of the fine particles were also analyzed, as shown in Figure 2.

Figure 1.

Preparation of CBAs.

Figure 2.

Sieve analysis for fine aggregate.

2.3. Concrete Mix Design

The mix ratios used to develop the UHPC mixtures, determined through several trials, are listed in Table 2, based on the weight of the components until the best mix performance was obtained [37,41]. Table 2 outlines the components of the various mixes. A fixed water-to-binder ratio (w/b) of 0.18, 15% silica fume [38], and consistent dolomite were added to the pre-packed technique. Several trial mixtures were used to determine the target strength of the UHPC. Table 2 provides the details of the mix specifications. The chosen replacement ratios of 10%, 20%, 30%, 40%, and 50% were based on the previous literature alongside internal preliminary trial mixes. Previous studies indicated that replacing a portion of natural sand within this range with artificial or recycled aggregates could significantly improve mechanical performance while maintaining workability, and durability [52,53,54]. These preliminary tests carried out prior to the main experimental programs also supported these findings, suggesting that these replacement levels up to 50% would still maintain mix stability with the target strength parameters.

Table 2.

Mix proportions in kg/m3.

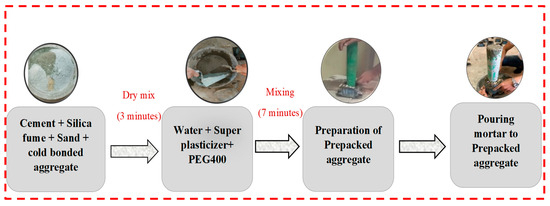

2.4. Mixing Procedures

The mixing procedures used in this study are as follows: The mixing process began with the binder components, cement, and silica fume, which were mixed for 2 min to achieve a homogeneous distribution of materials. Subsequently, 50% of the total water content was mixed with the self-curing agent. Simultaneously, a superplasticizer was introduced into the half-water mixture. The mixing sequence used to prepare UHPC is shown in Figure 2. The mix design ratios for the UHPC formulations derived from extensive experimental trials are presented in Table 2 and estimated with respect to the weight of the cement to achieve optimal performance outcomes [37,41]. Table 2 lists the proportion of each mixture. A consistent water-to-binder ratio (w/b) of 0.18 was maintained, incorporating 15% silica fume and uniformly blended CB. Various experimental combinations were evaluated to achieve the targeted UHPC strength; the corresponding mix ratios are listed in Table 2.

2.5. Casting

A 10-litre concrete mixer was used for mixing. The ratios of the slurry components comprising binders of cement, silica fume, sand, and coal bottom ash were measured before mixing to achieve a uniform mixture. Water was included in the dry constituents of the mixer drum by combining a superplasticizer and water in a separate vessel. The ingredients were meticulously blended to attain the consistency required for casting. The distinct elements of each mixture necessitated varying the blending durations. Aggregate was introduced into the molds, followed by the simultaneous pouring of the prepared mortar into a cylindrical tube using a dynamic vibrator for compaction and void reduction, as shown in Figure 3. Cylindrical specimens 100 mm in diameter and 200 mm in height and cubic specimens with a side length of 100 mm were produced for each concrete mixture. The concrete poured into the molds was gently vibrated. The prepacking casting method was selected in this study because of its merits in producing homogeneous dense concrete structures, especially when considering the use of CBAs with high porosity. This method reduces the need for mechanical vibration, minimizes segregation, and enhances bonding between aggregate and paste in addition to decreasing energy consumption. Even though no direct comparison with conventional casting was performed, the rationale stems from the literature [41,42,43,44,45] that validates the claims regarding the shortcomings of conventional approaches and the advantages of using prepacked concrete with recycled or lightweight aggregates.

Figure 3.

Mixing procedures of UHPC.

2.6. Testing

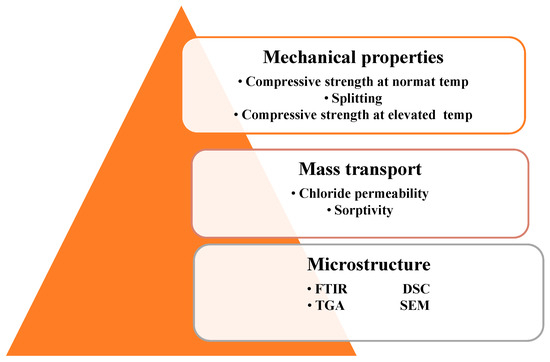

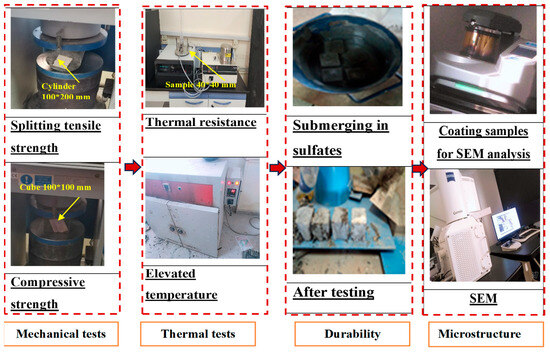

Standard testing procedures were used to assess the compressive strength of the concrete, which was tested according to ASTM C109 criteria [55]. For each concrete mix, three cube specimens of 10 × 10 × 10 cm3 were fabricated and evaluated for compressive strength at curing intervals of 7, 28, and 90 days. The experiments were conducted employing an ELE compression testing apparatus of 3000 KN loading capacity. The splitting tensile strength was measured in accordance with ASTM C496 [56] employing cylindrical specimens of 10 cm × 20 cm. The average of three specimens was calculated to ensure accuracy and consistency in the outcome. Concrete durability testing in this study was conducted in accordance with specific procedures of relevant standards. The evaluation of sulfate resistance was carried out by soaking the specimens in a 5% sodium sulfate (Na2SO4) solution followed by the determination of compressive strength based on ASTM C109/C109 M-21 [55]. Chloride penetration resistance was evaluated through immersion in a 3.5% sodium chloride (NaCl) solution, and subsequent compressive strength testing was carried out using an immersion-based method rather than electrical conductivity methods. Thermal resistance was evaluated by subjecting specimens to 300 °C and 600 °C for 2 h in a furnace under controlled conditions simulating fire exposure as cited in previous studies involving concrete exposed to high temperatures. All of these methods met the concrete’s required chemical and thermal stressors for durability assessment. Sorptivity tests were tested to assess the endurance of the concrete following ASTM [57], using cylindrical specimens with dimensions of 10 cm × 5 cm. Before testing, the materials were dried in an oven at 105 °C and separated from the external sources. The penetration of chloride ions was measured after 28 days by submerging the specimens in a 3.5% sodium chloride (NaCl) solution, while the sulfate resistance was examined by exposing the samples to a 5% sodium sulfate (Na2SO3) solution to observe the strength degradation. Moreover, the thermal resistance of the concrete was measured by subjecting the specimens to elevated temperatures of 350 °C and 700 °C to study the impact of extreme heat on the material performance. A microstructural analysis was conducted using scanning electron microscopy (SEM) to investigate the internal morphology of the concrete. Thin slices, approximately 1 × 1 cm in size, were extracted from the cores of the crushed cube specimens for this analysis. SEM observations were performed using a Philips XL 30 microscope to examine the distribution and characteristics of the hydration products and to detect potential microstructural flaws. DSC, TGA, and FTIR analyses were conducted for microstructural analysis. Figure 4 summarizes the testing. Figure 5 illustrates the test procedure.

Figure 4.

Mechanical, mass transport, and microstructure tested performed on UHPC.

Figure 5.

Testing procedures.

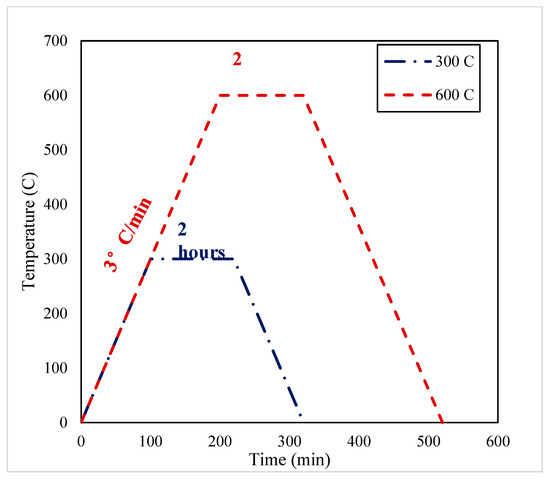

2.7. Furnace and Heating Rate

The temperature was pre-raised and constant heating was performed at 3 °C in a closed electronic oven. The separation was approximately 20 and was not delayed. For example, experiments on concrete construction and target temperatures of 300 and 600 °C were chosen. The samples were maintained at the target temperature for 2 h to achieve a homogeneous thermal condition. Figure 6 illustrates the relationship between temperature and exposure time over different periods. The oven was turned off after each heating cycle to reduce the effect of the temperature gradient. The samples were left to cool gradually, and the door was closed. The next steps of the analysis were prepped following the achievement of room temperature with the samples.

Figure 6.

Furnace and heating procedure.

3. Results and Discussion

3.1. Mechanical Properties

The comparative analysis of the behavior of the manufactured UHPC mixtures was conducted during the curing periods of 7, 28, and 90 days. The choice of these periods was not arbitrary; rather, it aligns with the ASTM standards for testing compressive (ASTM C109/C109M-21 [55]) and splitting tensile strengths (ASTM C496/C496M-17 [56]) and cemented cross-cut field volumes. The 7-day curing period reflects the composites’ early-age strength development, 28 days is regarded as the standard mark for design strength, and beyond 90 days is widely accepted as the period where the long-term pozzolanic and alkali–silica reactions are assumed to fully develop [58], especially when artificial aggregates like the CBAs are incorporated. Therefore, these curing durations provide a comprehensive evaluation of the strength development over time. Moreover, all specimen count and sample sizes were in compliance with the mentioned standards to ensure their repeatability and reliability. Compressive strength tests were performed under normal conditions, elevated temperatures of 300 °C and 600 °C, and severe conditions when subjected to sulfate and chloride solutions.

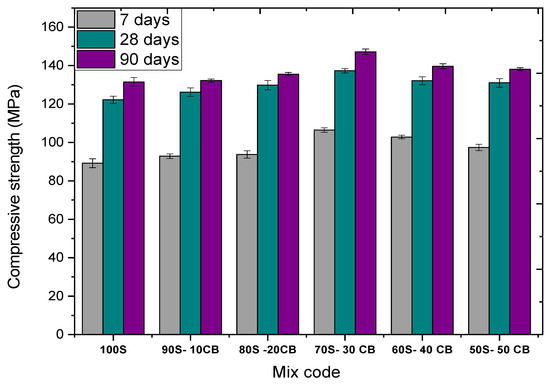

3.1.1. Compressive Strength for Mixes with CBAs at Normal Conditions

The results in Figure 7 demonstrate the compressive strength of UHPC containing CBAs prepared using sesame ash and glass waste as sand substitutes, with replacement ratios ranging from 10% to 50%. The standard deviation was calculated to be approximately ±2 MPa for all ages. The compressive strength was measured at curing periods of 7, 28, and 90 days for various mixtures, including the standard mixture (100S) and mixtures with varying replacement ratios (90S-10CB, 80S-20CB, 70S-30CB, 60S-40CB, and 50S-50CB). At 7 d of age, the standard mixture (100S) recorded a compressive strength of 89.18 MPa. At the replacement ratio of 10% (90S-10CB), the strength increased to 92.82 MPa, representing an improvement of 4.08%. With a replacement ratio of 20% (80S-20CB), the strength reached 93.73 MPa, an improvement of 5.10%. At a replacement ratio of 30% (70S-30CB), the highest compressive strength was recorded, amounting to 106.44 MPa, which represents an improvement of 19.34% as a result of the optimal production of the C-S-H compound from pozzolanic reactions. When the replacement ratios were increased to 40% and 50%, the strength decreased slightly to 102.83 MPa (60S-40CB, 15.27% improvement) and 97.37 MPa (50S-50CB, 9.18% improvement). These results indicate the positive effect of chemical reactions at low substitution ratios, with a decreased benefit at higher ratios.

Figure 7.

Compressive strength for UHPC contains CBAs.

At 28 d, the reference mix recorded a compressive strength of 122.19 MPa. At the replacement ratio of 10% (90S-10CB), the strength increased to 126.16 MPa, representing an improvement of 3.25%. With a replacement ratio of 20% (80S-20CB), the strength increased to 129.83 MPa, an improvement of 6.25%. At a replacement ratio of 30% (70S-30CB), the strength reached 137.28 MPa, representing an improvement of 12.34% owing to the continued hydration and pozzolanic reactions. 132.1 MPa (8.10% improvement) and 131.03 MPa (7.24% improvement) at 40% and 50% replacement ratios, respectively. A reduction in compressive strength with an increasing replacement ratio indicates that although the pozzolanic and alkali–silica interactions are effective, high ratios of pre-packed aggregates may disrupt the matrix structure [47].

At 90 d of age, the compressive strength continued to improve for all mixtures owing to the longer curing period, which enhanced the hydration and pozzolanic reactions. The standard mixture exhibited a compressive strength of 131.5 MPa. With a replacement ratio of 10% (90S-10CB), the strength increased to 132.2 MPa (0.53% improvement), and with a replacement ratio of 20% (80S-20CB), the strength reached 135.5 MPa (3.04% improvement). For the replacement rate of 30% (70S-30CB), the highest strength was recorded at 147.2 MPa (11.93% improvement), 139.6 MPa (6.16% improvement), and 138.1 MPa (5.01% improvement), respectively, with 40% and 50% replacement ratios. These results indicate the effectiveness of sesame ash and glass waste in improving the long-term strength of concrete, primarily through the continued production of C-S-H and potassium silicate (K2SiO3) compounds that enhance bonding and increase the matrix density. These results indicate that using CBAs prepared from sesame ash and glass waste as partial sand substitutes significantly enhances the compressive strength of UHPC through chemical reactions, particularly at an optimal replacement rate of 30%. These reactions involve the reaction of silica with calcium hydroxide to form a C-S-H compound, which increases the binder content and improves the concrete matrix [59]. In addition, the alkali–silica reaction between glass waste and potassium hydroxide produces a potassium silicate compound (K2SiO3), contributing to filling voids and increasing density [17]. At replacement ratios exceeding 30%, the compressive strength decreases slightly because of the high content of CBAs, which may disrupt the matrix structure. However, even at higher replacement ratios (40–50%), the compressive strength remained competitive with that of the standard mixture, indicating the sustainability and efficiency of using sesame ash and glass waste in producing high-performance concrete [32,60].

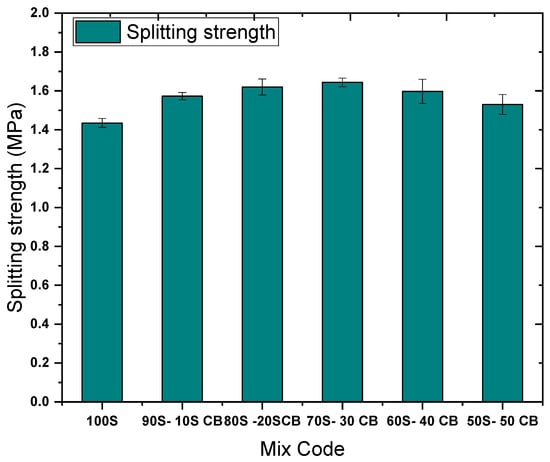

3.1.2. Split Tensile Strength

The results in Figure 8 demonstrate the split tensile strength of UHPC containing CBAs as sand substitutes, with replacement ratios ranging from 10% to 50%. The splitting tensile strength was measured for the standard mixture 100S (no replacement) and partial replacement mixtures 90S-10SCB, 80S-20SCB, 70S-30CB, 60S-40CB, and 50S-50CB.

Figure 8.

Splitting strength for UHPC contains CBAs.

The standard mixture (100S) recorded a splitting tensile strength of 1.4352 MPa. With the addition of 10% CBAs (90S-10SCB), the tensile strength increased to 1.5729 MPa, reflecting an improvement of approximately 9.6%. At a 20% replacement (80S-20SCB), the strength increased to 1.61998 MPa, which is an improvement of 12.9% compared to the standard mixture. The standard deviation was found to be ±0.04 MPa. The highest splitting tensile strength was observed at a 30% replacement ratio (70S-30CB), reaching 1.64352 MPa, representing a 14.5% improvement over that of the standard mixture. As the replacement ratio increased beyond 30%, a slight decrease in splitting tensile strength was observed. At a 40% replacement (60S-40CB), the strength decreased to 1.59751 MPa, which is still an 11.3% improvement over the standard mixture. At a 50% replacement ratio (50S-50CB), the strength decreased to 1.53 MPa, representing a 6.6% improvement over the standard mixture, but lower than mixtures with 10–40% replacement ratios. These results indicate that the use of sesame ash and glass waste as partial sand substitutes enhances the splitting tensile strength of UHPC [60,61], particularly at an optimal replacement ratio of 30%. This improvement is due to enhanced bonding between the matrix and aggregate resulting from pozzolanic and alkali–silica reactions, which produce hydrated calcium silicates (C-S-H) and potassium silicates (K2SiO3). These interactions contribute to the densification and strengthening of the internal structure of concrete [62,63,64]. However, when the replacement ratio exceeds 30%, the decrease in tensile strength may be due to the excess content of CBAs, which may disrupt matrix continuity, thus reducing mechanical performance.

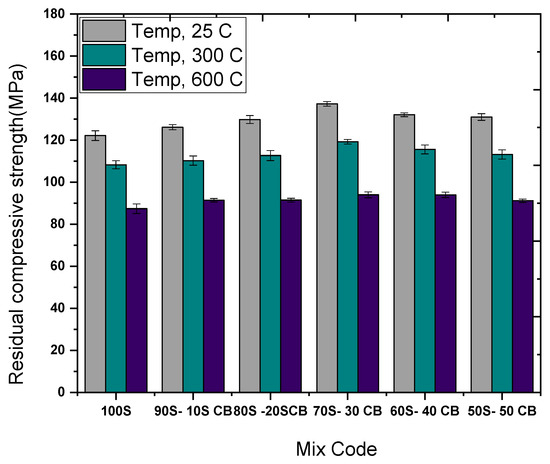

3.1.3. Compressive Strength When Concrete Is Subjected to Elevated Temperature

The results in Figure 9 show the compressive strength of UHPC containing CBAs as sand substitutes at different temperatures (25, 300, and 600 °C). Six different mixtures were analyzed: 100S (standard mixture without replacement), 90S-10SCB, 80S-20SCB, 70S-30CB, 60S-40CB, and 50S-50CB. At room temperature (25 °C), the standard mixture (100S) exhibited a compressive strength of 122.19 MPa, which increased with CBAs. At a replacement ratio of 10% (90S-10SCB), the compressive strength increased to 126.16 MPa, an improvement of 3.2%. With a replacement ratio of 20% (80S-20SCB), the strength increased to 129.83 MPa, an improvement of 6.3%. The highest compressive strength was observed at a 30% replacement ratio (70S-30CB), reaching 137.28 MPa, representing a 12.3% improvement over that of the standard mixture. At the replacement ratios of 40% and 50% (60S-40CB and 50S-50CB), the compressive strengths reached 132.10 MPa (8.1% improvement) and 131.02 MPa (7.2% improvement), respectively. After being subjected to a temperature of 300 °C, all mixtures lost compressive strength relative to that at room temperature because of the thermal deterioration of the concrete matrix [65]. The strength of the standard mixture decreased to 108.28 MPa, representing an 11.4% decrease compared to its value at room temperature. The standard deviation was calculated to be ±2 MPa. Likewise, at 10% and 20% replacement ratios (90S-10SCB and 80S-20SCB), the strength decreased to 110.28 MPa and 112.71 MPa, representing a decrease of 12.6% and 13.2%, respectively, compared to their values at room temperature.

Figure 9.

Residual compressive strength for UHPC contains CBAs.

The mixture with a 30% replacement ratio (70S-30CB) exhibited the highest thermal resistance, retaining a strength of 119.24 MPa, with a reduction of only 13.1%. At 40% and 50% replacement ratios (60S-40CB and 50S-50CB), the compressive strengths decreased to 115.59 MPa and 113.20 MPa, representing a 12.5% and 13.6% decrease, respectively. At 300 °C, all mixtures showed a moderate compressive strength reduction compared to room temperature owing to several main processes. Free water began to evaporate from the capillary pores at temperatures between 100 °C and 150 °C, which increased the porosity of the concrete matrix and weakened its structure. In addition, the dewatering process of C-S-H, the primary binder in concrete, begins, resulting in associated chemical water loss and a decrease in bond strength. The differences in thermal expansion that occur between the aggregate and the cement paste give rise to the internal stress which in turn creates micro cracks [66]. Together, these effects explain the decrease in the compressive strength of all mixtures at 300 °C. The strength of the standard mixture (100S) decreased from 122.19 MPa at 25 °C to 108.28 MPa at 300 °C, while the mixture with a 30% replacement ratio (70S-30CB) retained the highest thermal resistance, as its strength decreased from 137.28 MPa to 119.24 MPa. Pascal showed better stability than other mixtures because of the formation of stable compounds such as potassium silicate (K2SiO3) and a denser microstructure [67,68,69].

At 600 °C, the compressive strength decreased for all mixtures owing to the significant thermal damage to the concrete structure. The standard deviation was found to be ±1 MPa. The strength of the standard mixture (100S) decreased to 87.41 MPa, representing a 28.5% decrease from its value at room temperature. At 10% and 20% replacement ratios (90S-10SCB and 80S-20SCB), the compressive strengths decreased to 91.42 MPa and 91.46 MPa. This represents decreases of 27.5% and 29.6%, respectively. Again, the mixture with a 30% replacement ratio (70S-30CB) exhibited superior performance, retaining a strength of 94 MPa, representing a 31.5% reduction. At 40% and 50% replacement ratios (60S-40CB and 50S-50CB), the compressive strengths were 93.98 MPa and 91.2 MPa, representing a decrease of 28.8% and 30.4%, respectively. At 600 °C, the compressive strength of all mixtures decreased significantly owing to severe thermal deterioration. The dewatering of the C-S-H compound continued, causing its structure to collapse, and Ca(OH)2 decomposed into calcium oxide (CaO) and water, creating voids and further weakening the matrix. Thermal damage also extended to the bond between the aggregate and matrix, which weakened owing to chemical degradation and increased microcracks. This explains the significant drop in strength, as the strength of the standard mixture decreased from 122.19 MPa at 25 °C to 87.41 MPa at 600 °C, while the 30% replacement mixture (70S-30CB) retained a relatively higher strength of 94 MPa. These results highlight the superior thermal performance of the mixture with 30% replacement, likely owing to the influence of pozzolanic and alkali–silica interactions that contributed to the formation of thermally stable compounds [70,71,72].

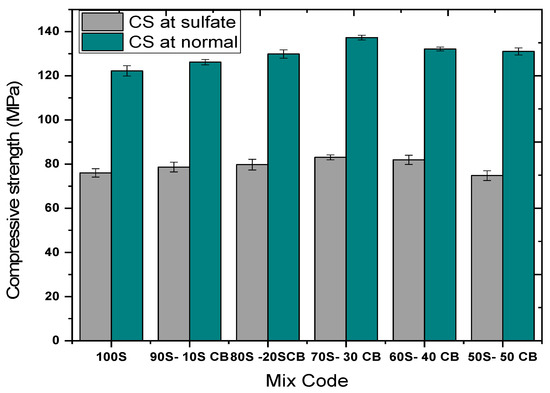

3.1.4. Compressive Strength After Submerging to Sulfates

The experimental results in Figure 10 illustrate the compressive strength performance of the UHPC containing CBA as a partial replacement for sand. The measurements were taken after 28 days under standard curing conditions and following exposure to a 3.5% sodium sulfate solution. The study included six mixed designs: 100S, 90S-10SCB, 80S-20SCB, 70S-30CB, 60S-40CB, and 50S-50CB. Under normal conditions, the compressive strength ranged between 122.18 MPa for the 100S mix (reference mix) and 137.28 MPa for the 70S-30CB mix with a standard deviation of ±1.5 MPa, demonstrating enhancement in strength up to a 30% replacement level. Thereafter, a minor decrease in strength was noted when the 50S-50CB mixture attained a compressive strength of 131.03 MPa. Under sulfate exposure conditions, the compressive strength of all mixtures was reduced because of the adverse effects of sodium sulfate on matrix integrity. The residual strength ranged between 74.80 MPa for the 50S-50CB mixture and 83.05 MPa for the 70S-30CB mixture with a small standard deviation of ±2 MPa, highlighting the superior performance of the latter in maintaining strength under aggressive environments. The results show that replacing sand by up to 30% with CBA improves the sulfate resistance and mechanical properties of high-performance concrete. The results highlight the effect of the CBA replacement levels on the compressive strength (CS) of UHPC under normal and sulfate exposure conditions. The reduction factor, which represents the relative decrease in compressive strength owing to sulfate attack [73,74,75,76], ranged from 37.8% for the reference mix (100S) to 42.9% for the mix with the highest CBA content (50S-50CB). A consistent trend was observed, with the decline factor increasing as the CBA substitution levels increased. At low substitution levels (100S to 70S-30CB), the sulfate resistance was relatively high, likely because of the high matrix density and low porosity, which limited the penetration of sulfate ions. The mixture 70S-30CB showed the best performance, with a reduction factor of 39.5%. However, sulfate resistance decreased at high replacement levels (60S-40CB and 50S-50CB). This can be attributed to the increased porosity and weak CB in the matrix resulting from the high percentage of CBAs [18,77], which allows sulfate ions to penetrate more quickly and cause more significant damage [78]. These reactions include the formation of ettringite and gypsum, which decalcifies C-S-H, resulting in a decrease in the compressive strength. These results highlight the need to balance sustainability goals with durability considerations when designing UHPC mixtures.

Figure 10.

Residual compressive strength for UHPC contains CBA after a sulfate attack.

3.2. Durability and Mass Transport

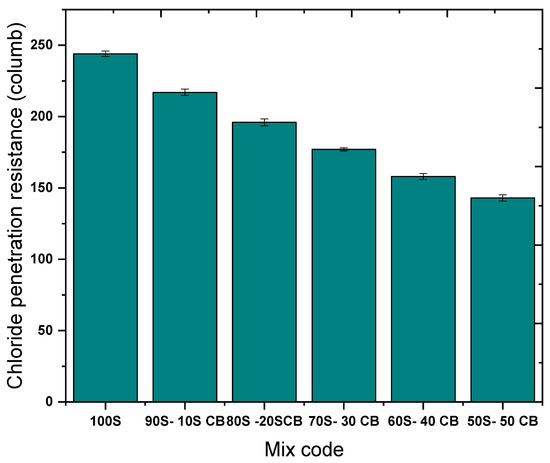

3.2.1. Chloride Penetration

The results in Figure 11 show an improvement in the chloride penetration resistance in UHPC with an increasing proportion of CBA, indicating an improved performance with gradual replacement of the conventional aggregate. The reference mixture (100S) exhibited the largest chloride penetration depth (244 coulombs), whereas increasing the proportion of CBAs gradually reduced the penetration depth: 10% CB (217 coulombs, ~11% improvement), 20% CB (196 coulombs, ~20% improvement), 30% CB (177 coulombs, ~20% improvement) 27%), 40% CB (158 coulombs, ~35% improvement), and 50% CB (143 coulombs, ~35% improvement ~41%). The standard deviation was found to be 2. This improvement was attributed to the properties of CBAs made from sesame ash and waste glass, which may contribute to reduced permeability through improved microscopic density and increased pozzolanic interaction between the aggregate and matrix [79]. These results indicate that high performance can be achieved with higher substitution levels (30–50%), with further improvement possible by optimizing the manufacturing process and using additives to enhance chemical reactions within the matrix.

Figure 11.

Chloride penetration resistance for UHPC contains CBAs.

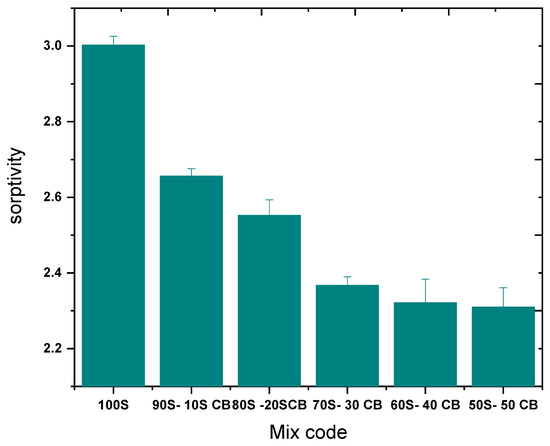

3.2.2. Sorptivity

The results shown in Figure 12 explain a significant reduction in sorptivity as the proportion of CBA used as a replacement for natural sand increased. This trend indicates the enhanced durability of UHPC when CBA is incorporated under self-curing conditions with a pre-packed aggregate system. The absorption improvement rate, which was calculated for the 100S mixture, provides additional insight into the efficiency of CB use. For the 90S-10CB mixture, the absorption rate decreased by approximately 11.55% compared to that of 100S. The 80S-20CB mixture achieved a reduction of 14.98%, whereas the 70S-30CB mixture exhibited a greater improvement of 21.2%. This trend continued with the 60S-40CB and 50S-50CB mixtures, which achieved reductions of 22.7% and 23.1%, respectively. These results highlight a decreasing rate of improvement as the CB content increases beyond 30%, indicating that the density and remobilization effects resulting from replacing sand with CB begin to stabilize. This behavior indicates that while replacing sand with CB enhances the matrix density and reduces capillary porosity [80], there is an optimal replacement level, perhaps around 30–40%—where the benefits of reducing the absorption rate are most apparent. After this point, the effect of adding CB to reduce the absorption rate becomes marginal [45].

Figure 12.

Sorptivity for UHPC contains CBAs.

3.3. Microstructural Assessments

3.3.1. FTIR

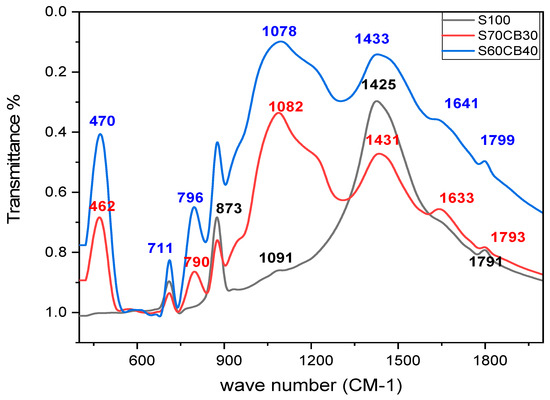

Figure 13 shows the FTIR spectra, indicating the transmittance of UHPC containing CB prepared using sesame ash and waste glass in different proportions, denoted as S100, S70CB30, and S60CB40. Representing S100, distinctive peaks were observed at 796.56, 1076.21, 1433.02, 1641.32, and 1799.48 cm−1. This was due to the bending vibrations of the Si–O–Si bond, stretching of the Si–O bond, and carbonate groups. The addition of sesame ash and waste glass to samples S70CB30 and S60CB40 led to noticeable changes in the locations and intensities of these peaks of 482.88, 711.69, 1082.00, 1431.09, 1633.61, 1793.49 at S70CB30, and 473.70, 790.76, 1091.64, 1425.31, 1631.61, and 1791.76 cm−1. The peaks appeared especially at 1082.00 cm−1 and 1425.31 cm−1, reflecting enhanced silicate polymerization and increased formation of carbonate compounds as a result of the pozzolanic activity of sesame ash and the high content of amorphous silica in waste glass [81]. The peaks in the range 790–800 cm−1 and 1633–1793 cm−1 indicate the formation of C-S-H and calcium carbonate, which indicates improved hydration reactions and increased carbonation in high-performance concrete with a higher proportion of CBAs. Adding sesame ash and waste glass to CBA improves the microstructure of concrete and enhances its chemical stability, density, and durability.

Figure 13.

FTIR for UHPC contains CBAs.

3.3.2. Thermogravimetric Analysis (TGA)

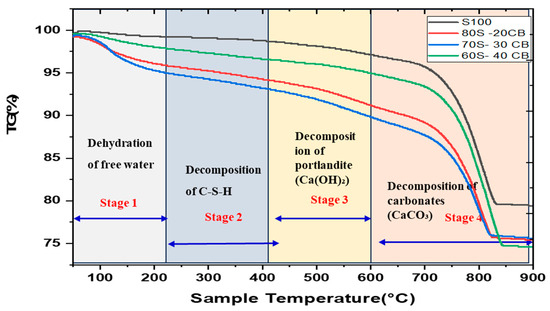

Figure 14 shows the TGA results for UHPC containing varying proportions of CBAs as sand substitutes, indicating a clear relationship between the aggregated aggregate content and thermal stability. The control sample (S100) containing 100% sand exhibited the highest thermal stability with minimal weight loss across the temperature range. In contrast, samples with increasing aggregate content (80S-20CB, 70S-30CB, and 60S-40CB) showed progressively greater mass loss, indicating decreased thermal stability [82]. In the first stage, absorbed water is physically lost at low temperatures. All mixtures showed a weight reduction, but mixtures containing CB in higher proportions, such as 70S-30CB and 60S-40CB, lost less water, indicating the effect of CB in reducing free water absorption.

Figure 14.

TGA for UHPC contains CBAs.

In the second stage, the decomposition of the C-S-H compound, Sample S100, showed less weight loss, indicating that it contained the lowest proportion of hydrated compounds. Conversely, as the CB content increased, the weight loss increased, indicating that CB promoted the formation of C-S-H or affected the hydration process.

In the third stage, portlandite (Ca(OH)2) decomposes, releasing water vapor. S100 exhibited the highest weight loss at this stage, indicating that it contained more portlandite. As the CB ratio increased, the weight loss decreased, indicating a reduction in the Ca(OH)2 formation in the cement system.

Finally, in the fourth stage, calcium carbonate (CaCO3) decomposes at the highest temperatures, turning into calcium oxide (CaO) and releasing carbon dioxide (CO2). The curve shows that S100 lost the most significant mass during this stage, whereas increasing CB led to a lower weight loss ratio, indicating reduced CaCO3 formation in mixtures containing CB. Comparing the behavior of the different mixtures, it is obvious that S100 (pure sample) shows the highest weight loss in all stages, indicating that it contains the highest percentage of hydrated cementitious compounds and carbonates. In contrast, as the percentage of CB, such as 80S-20CB, 70S-30CB, and 60S-40CB, increased, the weight loss gradually decreased at each stage, indicating less formation of cementitious products such as C-S-H, portlandite, and carbonate. In general, the addition of CB affects the stability of refractory compounds. It modifies the degradation behavior, which may improve the heat resistance of materials and reduce the effect of conventional cementitious reactions during hydration.

In conclusion, all samples experienced a slight weight loss below 200 °C owing to the evaporation of free water, gradual dissolution of hydration products such as hydrated CSH and CH between 200 °C and 600 °C [38], and a sharp mass decline between 700 °C and 800 °C, primarily due to the breakdown of calcium carbonate into calcium oxide and carbon dioxide. The largest mass loss was recorded in the 60S-40CB sample, indicating that increasing the aggregate content introduces more thermally unstable phases and may increase porosity, accelerating the decomposition process [83].

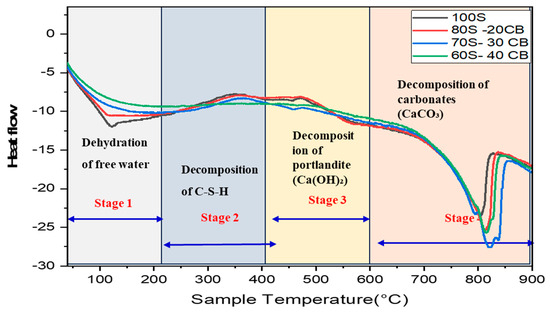

3.3.3. Differential Scanning Calorimetry (DSC)

Figure 15 shows that the DSC analysis of UHPC with different percentages of CB as a surrogate for sanding provides important insights into its behavior and evolutionary transformations. The temperature–flow curves for the ductile (100S) and modified extracts (80S-20CB, 70S-30CB, and 60S-40CB) modalities remained similar, with noticeable printing pipette peaks. An initial decrease in the heat flux was observed below 200 °C in all the samples, this is primarily a result of the evaporation of unbound waters as well as water from the hydration shells figuring around the solid. An endothermic peak between 400 and 600 °C was observed which marks the transition from CH to CaO and is also the release of steam.

Figure 15.

DSC for UHPC contains CBAs.

The prominent endothermic peak near 600–900 °C is attributed to the dissociation of calcium carbonate (CaCO3) into calcium oxide and carbon dioxide. It is worth noting that the intensity of these endothermic reactions increased with increasing CBA content, especially in the 60S-40CB sample, indicating greater thermal activity and increased phase transformations. This behavior suggests that increasing the content of CBAs introduces thermally sensitive phases or increases the porosity, facilitating decomposition reactions. However, the overall thermal response remained similar across all mixtures.

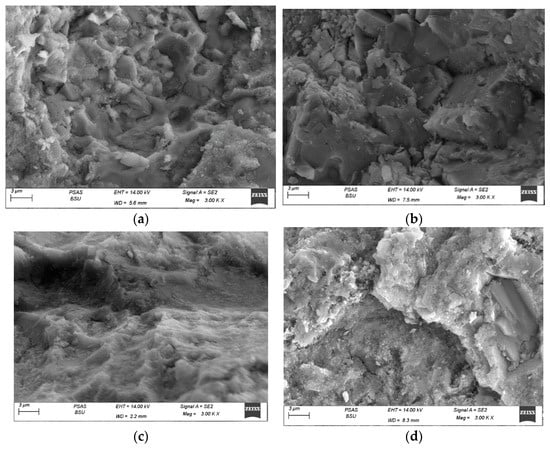

3.3.4. Scanning Electron Microscope at Normal Condition

Figure 16 shows SEM images of the sample (100S) (100% sand control mixture), which illustrate considerable growth in porosity as well as the formation of microcracks. From the SEM image, it can be noticed that the interfacial transition zones (ITZs) between the aggregated aggregate and cement paste become more evident, which may constitute weak points within the structure. The CSH gel also appeared less cohesive and the matrix showed increased structural variation. The SEM image shows a slightly less dense structure than the control sample in the (80S-20CB) sample, where CBAs replaced 20% of the sand. Small gaps and microcracks begin to appear, most likely because of the introduction of aggregates, which can create areas with weaker bonds. However, the overall structure remained relatively compact with a good distribution of C-S-H gels throughout the matrix. The (70S-30CB), with 30% sand replaced by aggregate, showed a dense, cohesive microstructure with very low porosity. The hydration products appear well-developed, with tightly packed C-S-H phases and an almost complete absence of microcracks or interstices. This dense structure contributes to the high mechanical strength and thermal stability of the control mixture. The absence of weak transition zones or loose bonds reflects the homogeneity of concrete. The SEM image reveals a noticeably porous and heterogeneous structure in the sample (60S-40CB), with 40% of the sand replaced by aggregates. Large gaps and areas with weak bonds are visible, along with increased microcracks [53]. The CSH gel appeared more friable and less homogeneously distributed [84], indicating that a high proportion of aggregated aggregates significantly weakened the matrix cohesion [85]. The interfacial transition zones also became more pronounced, reflecting the weakening of the bonds between the aggregate and the cement paste.

Figure 16.

SEM for UHPC contains with and without CBAs. (a) SEM micrograph for control mix (100S). (b) SEM micrograph for 80S-20CB. (c) SEM micrograph for 70S-30CB. (d) SEM micrograph for 60S-40CB.

4. Discussion

The enhancement of compressive strength may be interpreted by the principles involving the core chemical processes taking place in the concrete matrix owing to the use of sesame ash and glass waste. One of the main reactions is the pozzolanic reaction of silica (SiO2) in sesame ash and glass waste with CH, which is a byproduct of the cement hydration reaction [29]. This reaction produces C-S-H, which is the primary compound responsible for the strength of concrete. In addition, an alkali–silica reaction happens between the silica in glass waste and potassium hydroxide (KOH) in cement paste, leading to the formation of potassium silicate (K2SiO3) and water [86]. These interactions contribute to the production of additional binders that reduce voids and increase the density of the concrete matrix, leading to an improved compressive strength. A compressive strength of 147.2 MPa was recorded as the average of three specimens tested at 90 days, with a low standard deviation, confirming the repeatability of this value under consistent mixing, casting, and curing conditions. Multiple batches were tested and yielded similar results, attributed to precise control over the mix design, as well as the use of the prepacking method, which minimized internal voids and enhanced the paste-to-aggregate bond. When compared to commercial UHPC, which typically exhibits compressive strengths in the range of 120–150 MPa [7,9,38,87,88,89], the achieved value falls within or even slightly exceeds this range. This highlights the effectiveness of the developed system, particularly since the mix did not rely on high volumes of steel fibers or advanced thermal curing methods, offering a high-performance solution with favorable cost and processing considerations. At high temperatures. The strength of the standard mixture (100S) decreased from 122.19 MPa at 25 °C to 108.28 MPa at 300 °C, while the mixture with a 30% replacement ratio (70S-30CB) retained the highest thermal resistance, as its strength decreased from 137.28 MPa to 119.24 MPa. Pascal showed better stability than other mixtures due to the formation of stable compounds such as potassium silicate (K2SiO3) and a denser microstructure [67,68,69]. At 600 °C, although all mixtures showed a decrease in strength at elevated temperatures, the mixture with a 30% replacement ratio showed the best resistance to thermal damage, supporting its feasibility for applications requiring high thermal resistance. Furthermore, the cold bonding process may have contributed to the improvement in the granular distribution within the mixture, reducing the chloride penetration depth. After sulfates, the mixture 70S-30CB showed the best performance, with a reduction factor of 39.5%. However, sulfate resistance decreased at high replacement levels (60S-40CB and 50S-50CB). This can be attributed to the increased porosity and weak CB in the matrix resulting from the high percentage of CBAs [18,77].

Various instruments such as SEM using Zessis devise sourced from Oberkochen, Gemany, FTIR using Bruker sourced from Rheinstetten, Germany, TGA, and DSC device NETZSCH sourced from Selb, Germany were used to complete a comprehensive analysis that established the correlation between microstructure and mechanical properties. Microscopic examination of CBAs 30% mixtures (70S-30CB) showed the SEM-70S-30CB having the best microstructure with low levels of microcracking, high levels of interfacial bonding, and dense structure. This observation matched the predicted outcomes of compressive and tensile strength, meaning it was the highest value estimation. FTIR was able to detect higher levels of silicate polymerization, enabling more carbonates to form at this level of replacement suggesting greater intensity of pozzolanic as well as alkali–silica reactions, and therefore better continuity and strength of the matrix. Lowered portlandite levels leading to improved decomposition temperatures supported the finding of enhanced thermal stability, enabling better durability of the material as demonstrated in TGA and DSC. Optimized microstructural development in CBA-containing mixes drove the superior performance in mechanical and durability resulting from improved structural performance withstanding stress CBA blends.

Finally, in conclusion, the optimal level of the 30% replacement ratio was chosen to be the most favorable based on mechanical, durability, and microstructural assessment synergies. Of all mixtures tested, the 70S-30CB mixture had the highest compressive strength 147.2 MPa at 90 days), which was an 11.93% increase over the control. It also had the highest splitting tensile strength, the best thermal stability at 300 °C and 600 °C, and the best sulfate resistance with the lowest strength reduction factor (39.5%). Chloride penetration and sorptivity results corroborated a reduction in permeability at this level. Additionally, SEM images showed a dense and well-bonded microstructure. FTIR and TGA results showed greater amounts of silicate formation and lower amounts of portlandite. There was a decrease in strength and an increase in porosity with higher replacement ratios of 40% and 50%, but performance remained acceptable. Therefore, the best balance between strength, durability, and microstructural integrity was found to be a 30% replacement of CBA, making it the optimal proportion in the study.

5. Mechanism

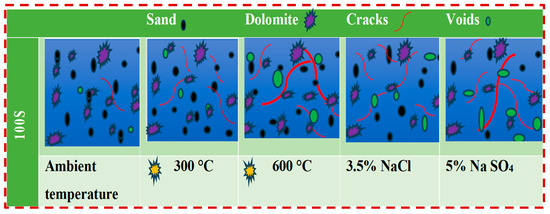

Figure 17 shows the UHPC mechanism without CBAs. The 100S mix presents challenges under various conditions. At ambient temperature (25 °C), it has a high compressive strength owing to the high density and bond strength between the components; however, problems begin to appear when exposed to high temperatures (300 °C and 600 °C). At 300 °C, the strength decreased owing to the loss of internal moisture and the thermal expansion of the aggregate. Although concrete retains some strength, 600 °C causes a significant loss of strength owing to the thermal decomposition of hydraulic products and microcracks due to sand expansion, which weakens the internal cohesion in terms of chloride resistance. The mixture showed good durability owing to its high density and low porosity; however, it was still susceptible to the long-term absorption of chloride ions. In contrast, when exposed to sulfate, the mixture shows significant weakening owing to chemical reactions between sulfate and cement products, leading to the formation of ettringite and gypsum and causing crack expansion and erosion of the cement matrix, affecting durability over time.

Figure 17.

Mechanism for UHPC without CBAs.

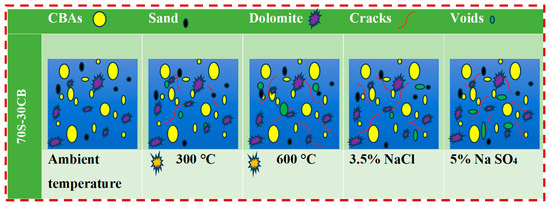

Figure 18 shows that the mechanism for concrete reactions occurs because of the substitution of CBAs as sand replacements. The results indicate that using CBAs prepared from sesame ash and glass waste as partial sand substitutes significantly enhances the compressive strength of high-performance concrete through chemical reactions, particularly at an optimal replacement ratio of 30%. These reactions involve the reaction of silica with calcium hydroxide to form a C-S-H compound, which increases the binder content and improves the concrete matrix [59]. In addition, the alkali–silica reaction between glass waste and potassium hydroxide produces a potassium silicate compound (K2SiO3), which fills voids and increases density [17]. At 300 °C, all mixtures showed a moderate compressive strength reduction compared to room temperature, owing to several main processes. Free water began to evaporate from the capillary pores at temperatures between 100 and 150 °C, which increased the porosity of the concrete matrix and weakened its structure. In addition, the dewatering process of C-S-H, the primary binder in concrete, begins, resulting in an associated chemical water loss and a decrease in bond strength. The internal stresses that lead to microcracks are caused by the differential thermal expansion between the aggregate and cement paste [66]. At 600 °C, all mixtures’ compressive strength decreased significantly due to severe thermal deterioration. The dewatering of the C-S-H compound continued, causing its structure to collapse, and Ca(OH)2 decomposed into calcium oxide (CaO) and water, creating voids and further weakening the matrix. Thermal damage also extended to the bond between the aggregate and matrix, which became weaker due to chemical degradation and increased microcracks. Sulfate resistance allows sulfate ions to penetrate more easily and cause greater damage [78]. These reactions include the formation of ettringite and gypsum, which decalcifies C-S-H, resulting in an observed decrease in compressive strength. These results highlight the need to balance sustainability goals with durability considerations when designing UHPC mixtures. Curing is essential in the development of strength, durability, and microstructural integrity in UHPC. These include external water curing, steam curing, and membrane curing. Each approach offers a specific merit or drawback in UHPC systems. For example, steam curing greatly accelerates the hydration and early-age strength development of UHPC, but it also requires specialized equipment and incurs high energy costs. Additionally, rapid thermal gradients might cause microcracking. Although external water curing is quite popular with conventional concrete, it may be less effective in UHPC due to the material’s low permeability and dense microstructure that impede external moisture penetration. While membrane curing is more efficient in dry or windy conditions, its lack of moisture addition makes it less efficient in low water-to-binder ratio systems. On the other hand, self-curing through internal curing agents like PEG may be better suited for UHPC, especially in field applications where external curing poses logistical challenges [13]. PEG-based self-curing maintains internal relative humidity by releasing vaporized water, which supports continued hydration and mitigates autogenous shrinkage. The results of this study showed that the use of 1% PEG 400 as an internal curing agent increased durability and compressive strength without the addition of external water [15,16,90,91]. This is consistent with other research that states internal curing is particularly beneficial for high-strength and low w/b ratio high-performance concretes. This means that self-curing is a simple and effective method for enhancing the field performance of UHPC over time. The 70S-30CB mix featured 70% sand and 30%CBA prepared from sesame ash and waste glass in the presence of potassium hydroxide and slag, significantly improving the performance compared with 100S. At ambient temperature (25 °C), this mixture provides a similar compressive strength but with improved internal bonding owing to the pozzolanic reaction between the slag and potassium, which increases the density and durability. When exposed to high temperatures (300 and 600 °C), 70S-30CB performed better than 100S. At 300 °C, the slag and potassium hydroxide reduced the strength loss by improving the stability of the hydration products. In contrast, at 600 °C, the presence of waste glass and ash enhanced the heat resistance by forming a more stable structure, reducing thermal expansion and microcracks. In the chloride resistance test, this mixture showed improvement owing to the pozzolanic reaction between the slag and ash, which led to the formation of denser and less permeable cement products, thus reducing the penetration of chloride ions further than 100S. Regarding exposure to sulfates, the performance of 70S-30CB is better than that of 100S because the slag contributes to the formation of a matrix that is more resistant to sulfate reactions. This reduced the formation of ettringite and gypsum, thus reducing the structural deterioration of the concrete compared with the 100S mix. Although the 100S mixture suffers from a loss of strength at high temperatures and is highly susceptible to sulfates, the 70S-30CB mixture shows a clear improvement under these conditions because of the effect of slag and potassium hydroxide in improving the stability of cement products, as well as increased resistance to chlorides and reduced susceptibility to sulfates, making it a more durable option.

Figure 18.

Mechanism for UHPC contains CBAs.

6. Conclusions

- This research focused on the behavior of UHPC made with pre-packed coarse aggregate as well as varying sand substitutes with CBAs between 10% and 50%. The concrete’s mechanical properties, including compressive strength along with splitting tensile strength, were measured at different ages. Along with microstructure investigation, soudanaite and calcium sulfate durability, chloride porosity, and high-temperature performance were assessed. The conclusions are as follows:

- The optimal replacement ratio of CBAs was found to be 30%, which showed the highest compressive strength (147.2 MPa at 90 days, representing an improvement of 11.93% compared to the control mixture.

- The 30% CBAs replacement ratio also exhibited the highest split tensile strength, reaching 1.64352 MPa, an improvement of 14.5% over the control mixture.

- While all mixtures showed decreased strength at high temperatures, the 30% CBA replacement mixture demonstrated the best thermal resistance, retaining a higher strength than the other mixtures at 300 °C and 600 °C.

- The 30% CBA replacement mixture exhibited superior performance in maintaining strength under sulfate exposure, with a reduction factor of 39.5% compared to the control mix (100S).

- Increasing the proportion of CBAs improved the chloride penetration resistance, with the 50% CBA mixture showing a 41% improvement compared with the control.

- The SEM images revealed that the 30% CBA mixture had a dense cohesive microstructure with very low porosity, contributing to its high mechanical strength and thermal stability compared to the control mix without CBAs.

- FTIR peaks in the range 790–800 cm−1 and 1633–1793 cm−1 in the case of 30% CBAs indicate the formation of C-S-H and calcium carbonate, which indicates improved hydration reactions.

- DSC showed that endothermic reactions increased with a higher CBA content, indicating greater thermal activity and increased phase transformations.

- TGA demonstrated that as the CBA content increased, the weight loss increased, indicating that CBAs facilitated the formation of C-S-H or affected the hydration process.

There are several limitations to this study that should be noted while interpreting the results. First, the experimental program considered only laboratory-scale specimens and controlled curing conditions, which might not capture the true field performance influenced by external factors like humidity, temperature changes, or mechanical loading, while thorough assessments were made of the mechanical and durability performance, there was no investigation into long-term durability under realistic cyclic conditions (e.g., freeze–thaw cycles, carbonation) which are present in real-world scenarios. Future work should explore field validation of these findings, investigate alternative self-curing methods, and study the long-term aging impacts of CBA-based UHPC in extreme environments.

Author Contributions

Conceptualization, A.R., A.H.A., M.A. and S.A.M.; Methodology, A.R. and S.A.M.; Investigation, A.R., A.H.A., M.A. and S.A.M.; Resources, A.H.A.; Data curation, M.A.; Writing—original draft, A.R., A.H.A., M.A. and S.A.M.; Writing—review & editing, A.H.A., M.A. and S.A.M.; Supervision, S.A.M.; Funding acquisition, A.R. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported and funded by the Deanship of Scientific Research at Imam Mohammad Ibn Saud Islamic University (IMSIU) (grant number IMSIU-DDRSP2502).

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding author.

Conflicts of Interest

The author declares no conflict of interest.

References

- Salahaddin, S.D.; Haido, J.H.; Wardeh, G. The behavior of UHPC containing recycled glass waste in place of cementitious materials: A comprehensive review. Case Stud. Constr. Mater. 2022, 17, e01494. [Google Scholar] [CrossRef]

- Ramezani, M.; Ozbulut, O.E.; Sherif, M. Mechanical characterization of high-strength and ultra-high-performance engineered cementitious composites reinforced with polyvinyl alcohol and polyethylene fibers subjected to monotonic and cyclic loading. Cem. Concr. Compos. 2024, 148, 105472. [Google Scholar] [CrossRef]

- de-Prado-Gil, J.; Martínez-García, R.; Jagadesh, P.; Juan-Valdés, A.; Gónzalez-Alonso, M.-I.; Palencia, C. To determine the compressive strength of self-compacting recycled aggregate concrete using artificial neural network (ANN). Ain Shams Eng. J. 2024, 15, 102548. [Google Scholar] [CrossRef]

- Hosseinzadeh, H.; Salehi, A.M.; Mehraein, M.; Asadollahfardi, G. The effects of steel, polypropylene, and high-performance macro polypropylene fibers on mechanical properties and durability of high-strength concrete. Constr. Build. Mater. 2023, 386, 131589. [Google Scholar] [CrossRef]

- Ahmed, T.; Elchalakani, M.; Karrech, A.; Mohamed Ali, M.S.; Guo, L. Development of ECO-UHPC with very-low-C3A cement and ground granulated blast-furnace slag. Constr. Build. Mater. 2021, 284, 122787. [Google Scholar] [CrossRef]

- Zhong, R.; Wille, K.; Viegas, R. Material efficiency in the design of UHPC paste from a life cycle point of view. Constr. Build. Mater. 2018, 160, 505–513. [Google Scholar] [CrossRef]

- Randl, N.; Steiner, T.; Ofner, S.; Baumgartner, E.; Mészöly, T. Development of UHPC mixtures from an ecological point of view. Constr. Build. Mater. 2014, 67, 373–378. [Google Scholar] [CrossRef]

- Azmee, N.M.; Shafiq, N. Ultra-high performance concrete: From fundamental to applications. Case Stud. Constr. Mater. 2018, 9, e00197. [Google Scholar] [CrossRef]

- Arora, A.; Yao, Y.; Mobasher, B.; Neithalath, N. Fundamental insights into the compressive and flexural response of binder- and aggregate-optimized ultra-high performance concrete (UHPC). Cem. Concr. Compos. 2019, 98, 1–13. [Google Scholar] [CrossRef]

- Li, W.; Huang, Z.; Hu, G.; Hui Duan, W.; Shah, S.P. Early-age shrinkage development of ultra-high-performance concrete under heat curing treatment. Constr. Build. Mater. 2017, 131, 767–774. [Google Scholar] [CrossRef]

- Vijayan, D.S.; Arvindan, S.; Parthiban, D.; Kumar, R.S.; Saravanan, B.; Robert, Y. An experimental study on mechanical and durable properties of self-curing concrete by adding admixture. Mater. Today Proc. 2020, 33, 496–501. [Google Scholar] [CrossRef]

- Shen, P.; Lu, L.; He, Y.; Wang, F.; Hu, S. The effect of curing regimes on the mechanical properties, nano-mechanical properties and microstructure of ultra-high performance concrete. Cem. Concr. Res. 2019, 118, 1–13. [Google Scholar] [CrossRef]

- Sun, Y.; Alqurashi, M.; Mostafa, S.A. Exploring the impact of seashell powder and nano-silica on ultra-high-performance self-curing concrete: Insights into mechanical strength, durability, and high-temperature resilience. Rev. Adv. Mater. Sci. 2024, 63, 20240080. [Google Scholar] [CrossRef]

- ACi, H. 308R-Guide to Curing Concrete; American Concrete Institute International: Farmington Hills, MI, USA, 2001. [Google Scholar]

- Pourchet, S.; Liautaud, S.; Rinaldi, D.; Pochard, I. Effect of the repartition of the PEG side chains on the adsorption and dispersion behaviors of PCP in presence of sulfate. Cem. Concr. Res. 2012, 42, 431–439. [Google Scholar] [CrossRef]

- Singh, K. Mechanical properties of self curing concrete studied using polyethylene glycol-400: A-review. Mater. Today Proc. 2020, 37, 2864–2871. [Google Scholar] [CrossRef]

- Yuan, X.; Xu, W.; AlAteah, A.H.; Mostafa, S. Evaluation of the performance of high-strength geopolymer concrete prepared with recycled coarse aggregate containing eggshell powder and rice husk ash cured at different curing regimes. Constr. Build. Mater. 2024, 434, 136722. [Google Scholar] [CrossRef]

- Kim, D.; Cho, S.; Pyo, S.; Bae, Y.; Oh, J.E. New cold-bonded artificial aggregate using a Ba(OH)2-activated cementless binder for cement-free concrete production. Constr. Build. Mater. 2024, 428, 136333. [Google Scholar] [CrossRef]

- Das, P.; Kashem, A.; Islam, M.; Ahmed, A.; Haque, M.A.; Khan, M. Alkali-activated binder concrete strength prediction using hybrid-deep learning along with shapely additive explanations and uncertainty analysis. Constr. Build. Mater. 2024, 435, 136711. [Google Scholar] [CrossRef]

- Tajra, F.; Elrahman, M.A.; Stephan, D. The production and properties of cold-bonded aggregate and its applications in concrete: A review. Constr. Build. Mater. 2019, 225, 29–43. [Google Scholar] [CrossRef]

- Thomas, J.; Harilal, B. Mechanical properties of cold bonded quarry dust aggregate concrete subjected to elevated temperature. Constr. Build. Mater. 2016, 125, 724–730. [Google Scholar] [CrossRef]

- Wyrzykowski, M.; Toropovs, N.; Winnefeld, F.; Lura, P. Cold-bonded biochar-rich lightweight aggregates for net-zero concrete. J. Clean. Prod. 2024, 434, 140008. [Google Scholar] [CrossRef]

- Seddik Hassan, A.M.; Abdeen, A.; Mohamed, A.S.; Elboshy, B. Thermal performance analysis of clay brick mixed with sludge and agriculture waste. Constr. Build. Mater. 2022, 344, 128267. [Google Scholar] [CrossRef]

- Ahmed, S.; Ali, M. Use of agriculture waste as short discrete fibers and glass-fiber-reinforced-polymer rebars in concrete walls for enhancing impact resistance. J. Clean. Prod. 2020, 268, 122211. [Google Scholar] [CrossRef]

- Du, B.; Xu, F.; AlAteah, A.H.; Mostafa, S.A. Sustainable development of ultra high-performance concrete using basil plant waste: Investigation at normal and extreme conditions. J. Build. Eng. 2023, 80, 107997. [Google Scholar] [CrossRef]

- Myint, D.; Gilani, S.A.; Kawase, M.; Watanabe, K.N. Sustainable sesame (Sesamum indicum L.) production through improved technology: An overview of production, challenges, and opportunities in Myanmar. Sustainability 2020, 12, 3515. [Google Scholar] [CrossRef]

- Kamel, S.; Blal, A.; Mahfouz, H.; Said, M.J.A. The most common insect pollinator species on sesame crop (Sesamum indicum L.) in Ismailia Governorate, Egypt. Arthropods 2013, 2, 66. [Google Scholar]

- Morris, J.B. Food, industrial, nutraceutical, and pharmaceutical uses of sesame genetic resources. In Trends in New Crops and New Uses; ASHS Press: Alexandria, VA, USA, 2002; pp. 153–156. [Google Scholar]

- Hakeem, I.Y.; Amin, M.; Zeyad, A.M.; Tayeh, B.A.; Maglad, A.M.; Agwa, I.S. Effects of nano sized sesame stalk and rice straw ashes on high-strength concrete properties. J. Clean. Prod. 2022, 370, 133542. [Google Scholar] [CrossRef]

- Sulaiman, T.A.; Garba, I.; Yau, Y.; Isah, A.L.; Mohammed, A.; Aliyu, I.; Aliyu, S.I. Assessment of the Characteristics and Durability of Sesame Husk Ash Concrete. J. Environ. Spectr. 2024, 4, 14–21. [Google Scholar]

- Salahaddin, S.D.; Haido, J.H.; Wardeh, G.J. Rheological and mechanical characteristics of basalt fiber UHPC incorporating waste glass powder in lieu of cement. Ain Shams Eng. J. 2024, 15, 102515. [Google Scholar] [CrossRef]

- Zheng, D.; AlAteah, A.H.; Alsubeai, A.; Mostafa, S.A. Integrating micro-and nanowaste glass with waste foundry sand in ultra-high-performance concrete to enhance material performance and sustainability. Rev. Adv. Mater. Sci. 2024, 63, 20240012. [Google Scholar] [CrossRef]

- Maglad, A.M.; Mydin, M.A.O.; Majeed, S.S.; Tayeh, B.A.; Mostafa, S.A. Development of eco-friendly foamed concrete with waste glass sheet powder for mechanical, thermal, and durability properties enhancement. J. Build. Eng. 2023, 80, 107974. [Google Scholar] [CrossRef]

- Xiao, R.; Polaczyk, P.; Zhang, M.; Jiang, X.; Zhang, Y.; Huang, B.; Hu, W. Evaluation of Glass Powder-Based Geopolymer Stabilized Road Bases Containing Recycled Waste Glass Aggregate. Transp. Res. Rec. J. Transp. Res. Board 2020, 2674, 22–32. [Google Scholar] [CrossRef]

- Essam, A.; Mostafa, S.A.; Khan, M.; Tahwia, A.M. Modified particle packing approach for optimizing waste marble powder as a cement substitute in high-performance concrete. Constr. Build. Mater. 2023, 409, 133845. [Google Scholar] [CrossRef]

- Mostafa, S.A.; El-Deeb, M.M.; Farghali, A.A.; Faried, A.S. Evaluation of the nano silica and nano waste materials on the corrosion protection of high strength steel embedded in ultra-high performance concrete. Sci. Rep. 2021, 11, 2617. [Google Scholar] [CrossRef] [PubMed]