Enhancing Facility Management with a BIM and IoT Integration Tool and Framework in an Open Standard Environment

Abstract

1. Introduction

- How can IFC-based BIM data be structured using open standards (JSON) for effective real-time integration with IoT sensor data in IEQ monitoring for FM?

- What low-code integration methods enable FM personnel to effectively use BIM–IoT solutions without advanced BIM or programming expertise?

- How does BIM–IoT integration enhance operational decision-making and predictive maintenance compared to traditional FM practices?

- How can we effectively address the primary interoperability and cybersecurity challenges associated with integrating BIM and IoT in cloud-based platforms?

- Enhanced data interoperability: IFC-to-JSON conversion ensures efficient cloud-based integration, facilitating the unified management of diverse datasets;

- Real-time IEQ monitoring: Node-RED’s low-code integration of live IoT sensor streams with BIM components enables real-time spatially contextualized visualization, significantly enhancing operational decisions;

- Improved usability and cross-disciplinary collaboration: an intuitive web-based dashboard facilitates seamless collaboration among BIM specialists, IT developers, and FM professionals;

- Open standards and vendor neutrality: utilizing open standards (IFC, JSON) and accessible low-code tools minimizes reliance on proprietary software, reducing costs and improving scalability.

2. Literature Review

2.1. Technological Barriers

2.2. Usability

2.3. Organizational and Workflow Challenges

2.4. Advancements in Digital Twin Technology

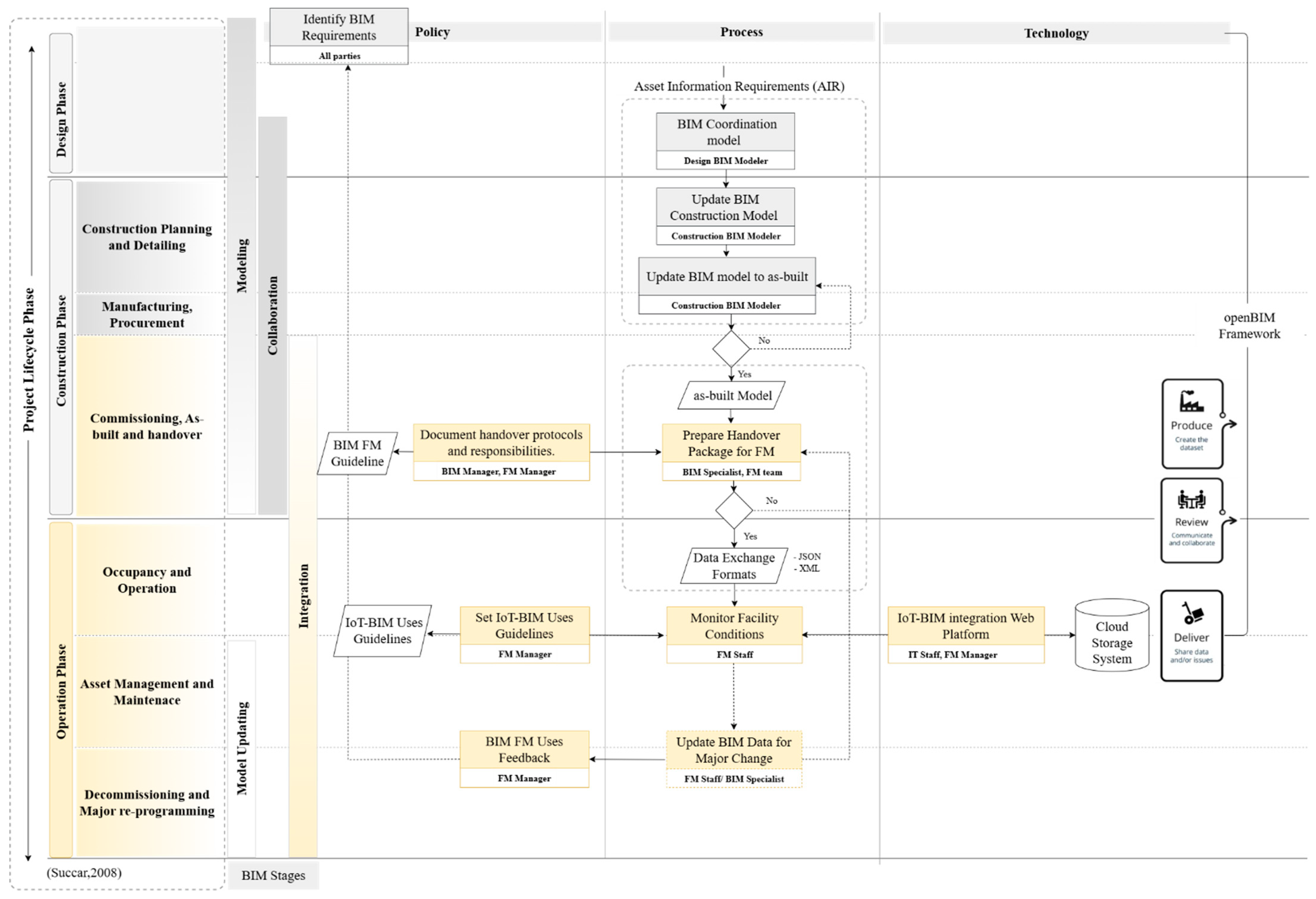

3. Research Method

4. Proposed Approach

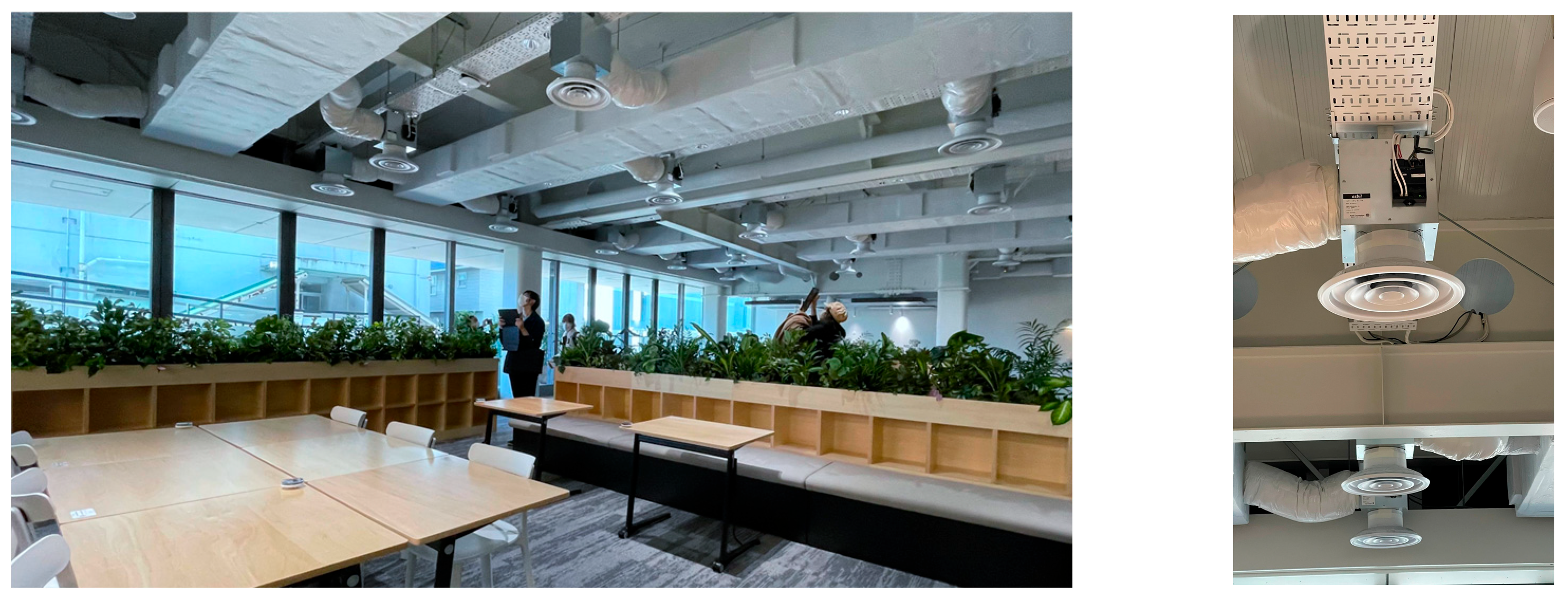

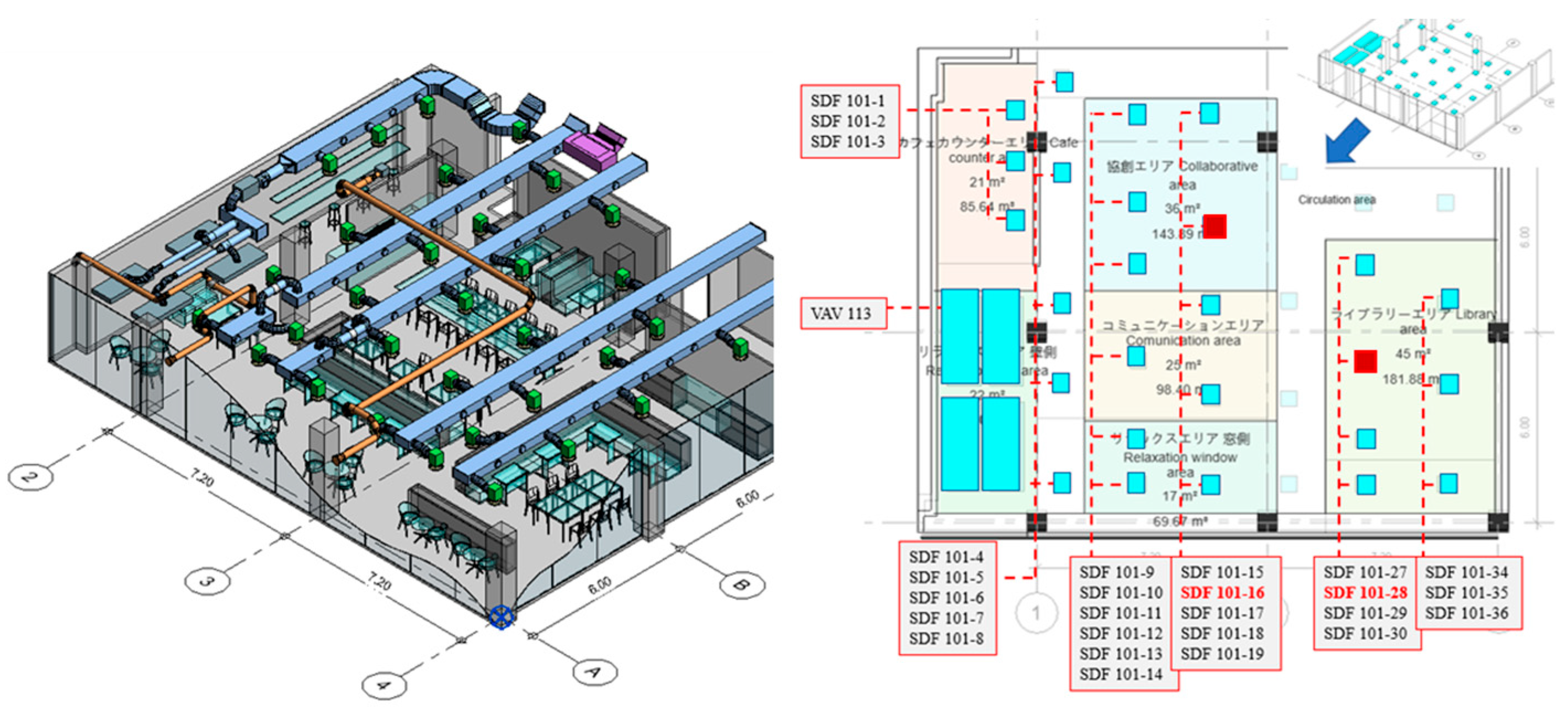

4.1. Case Study: Office Building in Kanagawa, Japan

4.2. Data Source and Collection

4.3. IFC-to-JSON Data Conversion

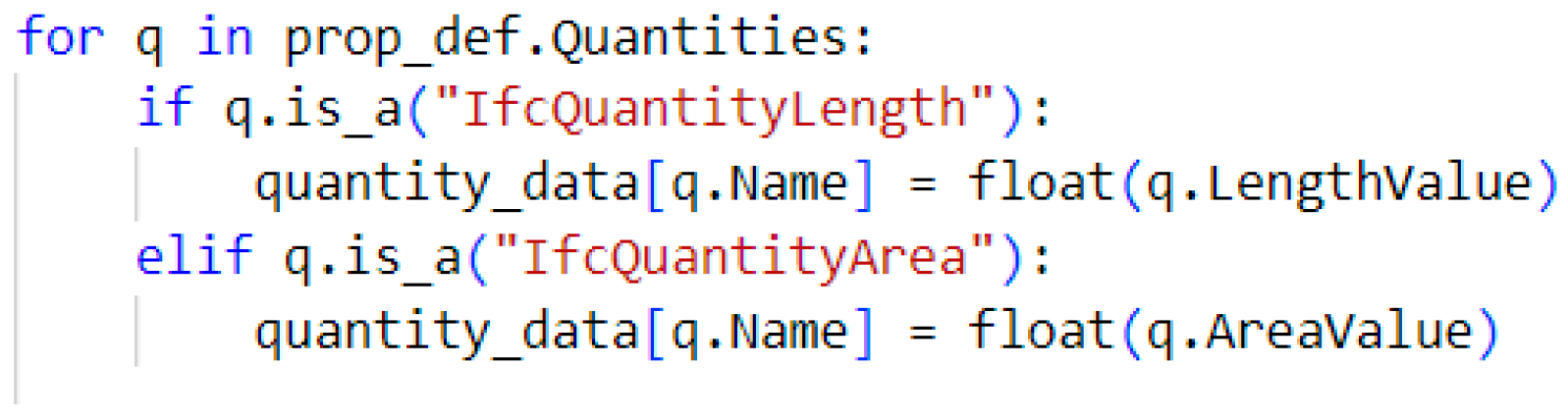

- Asset information (metadata and quantities): Asset metadata was collected from each IfcProduct entity using .get_info(), selectively retaining properties relevant to FM (e.g., Name, GlobalId, PredefinedType, and Tag). We extracted quantitative data embedded within IfcElementQuantity sets, such as area, volume, and length, using the following dedicated Python function (Figure 7).

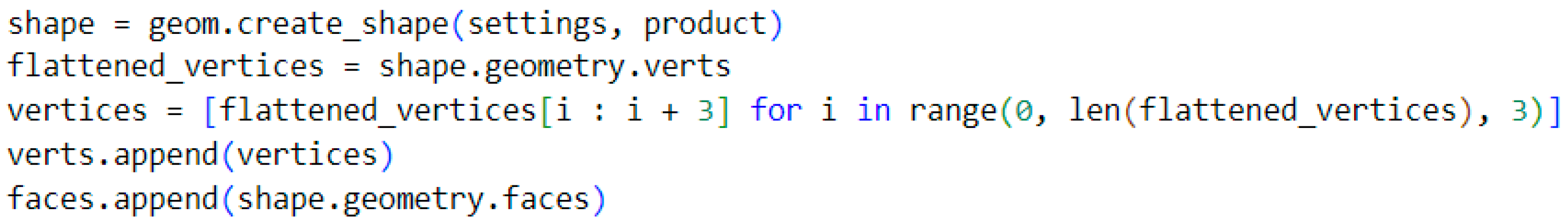

- Spatial information (geometric representation): To preserve the spatial context of each asset, the script utilizes the geom.create_shape() method from IfcOpenShell’s geometry module. This method converts the 3D representation of each IfcProduct into a list of vertices and indexed triangle faces. We processed the geometry using world coordinates to ensure consistency across all elements (Figure 8).

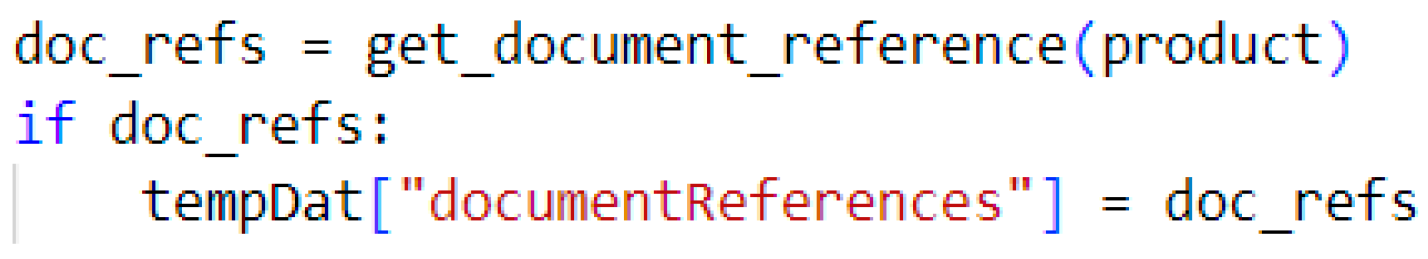

- External system integration (documentation and IoT interfaces): The conversion pipeline also extracted references to external documents and systems by traversing IFC relationships (IfcRelAssociatesDocument). We captured URLs or file paths using a tailored Python function, as follows (Figure 9).

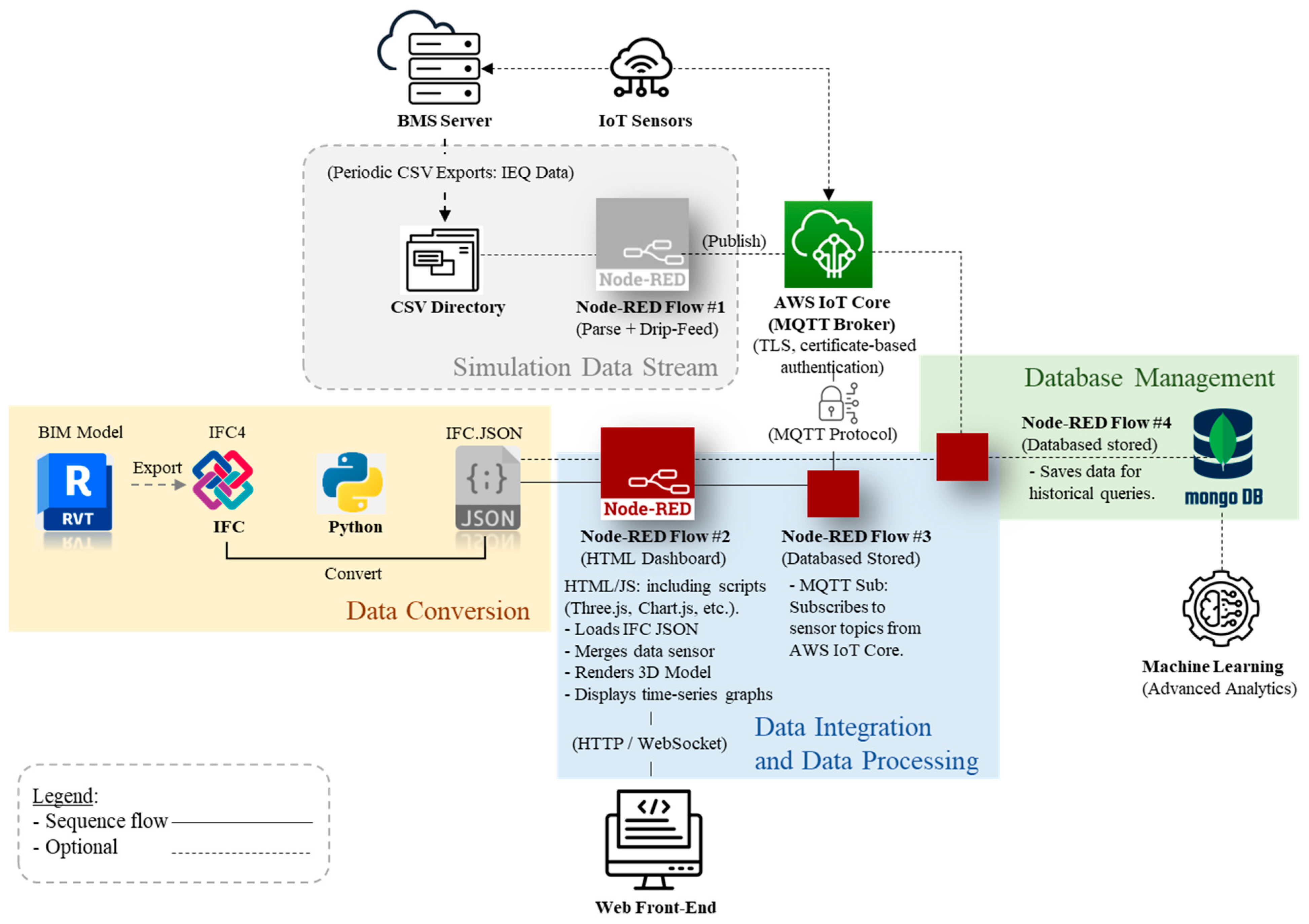

4.4. Node-RED Workflow for Data Integration

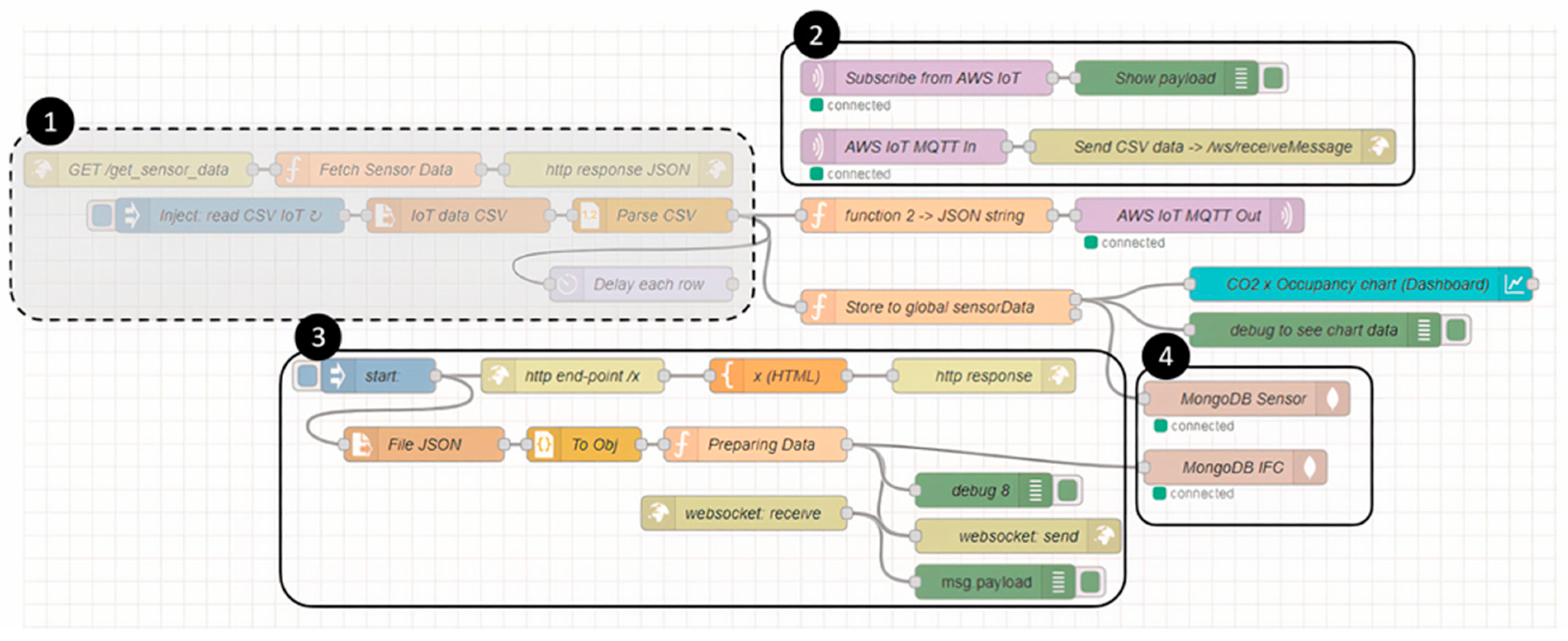

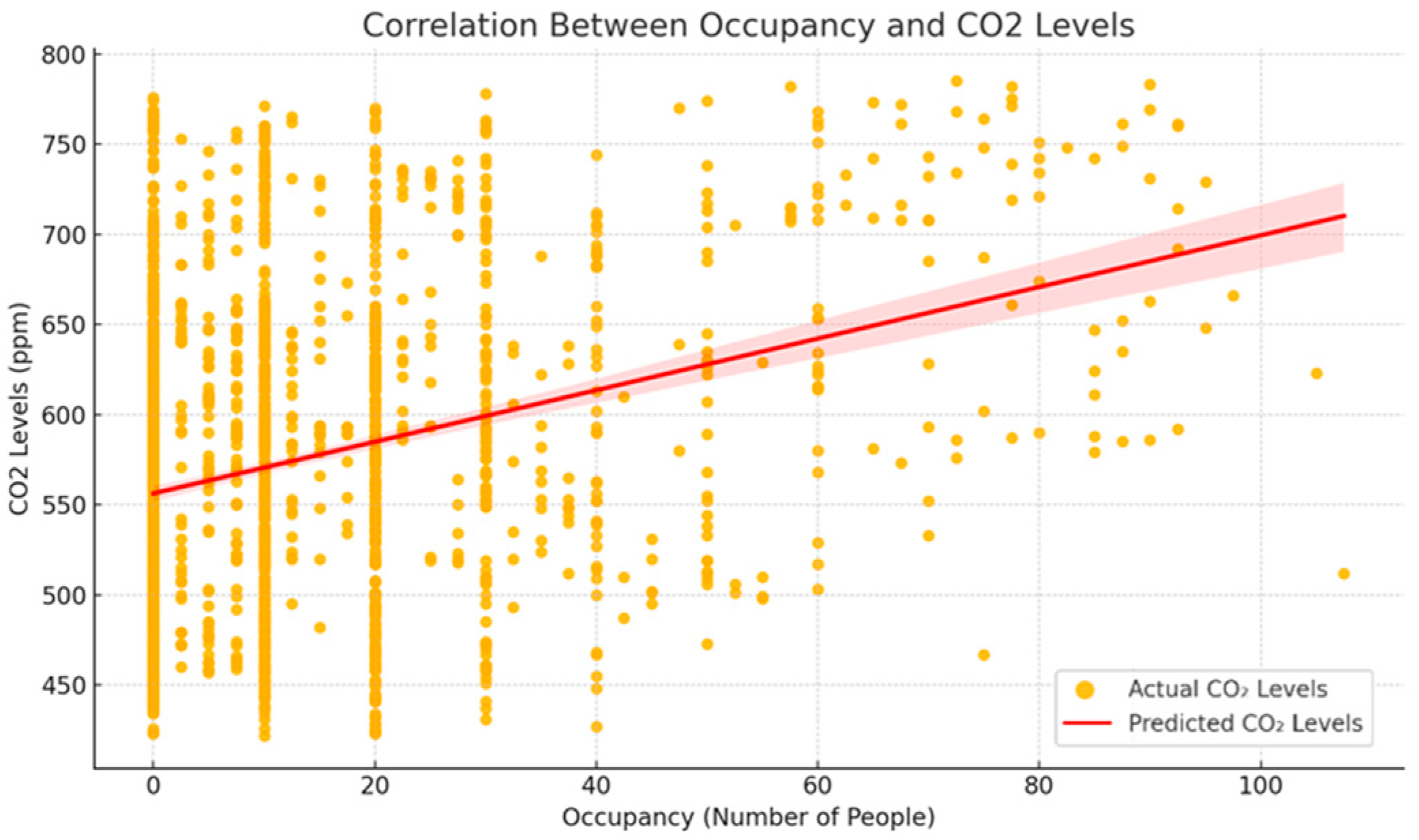

- Sensor Data Retrieval and Real-Time Simulation. (1) The implementation of a practical data simulation method was necessary due to cybersecurity constraints that prevented direct real-time data streaming from the BMS. Node-RED workflows continuously retrieve periodic CSV exports from the BMS containing IEQ parameters such as CO2 levels, occupancy, temperature, and humidity. Each CSV file is systematically parsed, converting each row into structured JSON objects, including sensor identifiers, timestamps, and measurement values. This approach effectively emulates real-time data streams, thereby enabling realistic system testing and validation without compromising data security;

- Real-Time Data Streaming. (2) The parsed sensor data is securely transmitted real-time using the MQTT protocol through AWS IoT Core, an IoT broker providing robust security features such as transport layer security (TLS) encryption and certificate-based authentication. MQTT subscription nodes (AWS IoT MQTT In) ensure secure and continuous sensor data streaming, subsequently relaying these data points to the dashboard for instantaneous visualization. This robust security architecture guarantees reliable and secure data flow between the BMS and the visualization components;

- HTTP Endpoint. (3) The HTTP endpoint (/x) within Node-RED acts as the primary data gateway for interactive client–server communication. Upon receiving a client request, structured JSON files derived from IFC-based BIM models are loaded, parsed, and processed into JavaScript objects for seamless integration. Advanced web technologies, such as Three.js and Chart.js, power sophisticated client-side visualizations that combine these data with real-time IoT sensor streams. WebSocket nodes enable real-time, bidirectional data transmission between server and client interfaces, ensuring responsive and dynamic visualization updates;

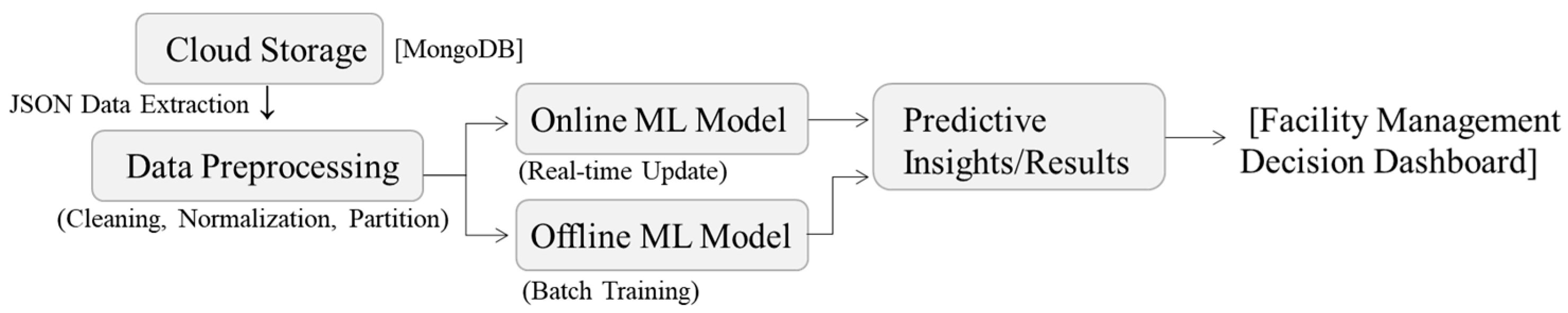

- Database Management for Historical Analytics. (4) Node-RED integrates MongoDB to handle long-term data storage and management. Two dedicated MongoDB nodes (MongoDB Sensor and MongoDB IFC) separately store sensor data and BIM-related metadata, respectively. This structured storage allows comprehensive historical analyses, enabling advanced analytics and machine-learning-based predictive maintenance. Consequently, facility managers benefit from actionable insights derived from historical data, significantly enhancing predictive operational capabilities.

4.5. Web-Based BIM–IoT Integration

5. Validation of the Proposed Framework

5.1. Interoperability and Dashboard Functionality

5.2. Advanced Data Integration

5.3. Cybersecurity and Data Integrity

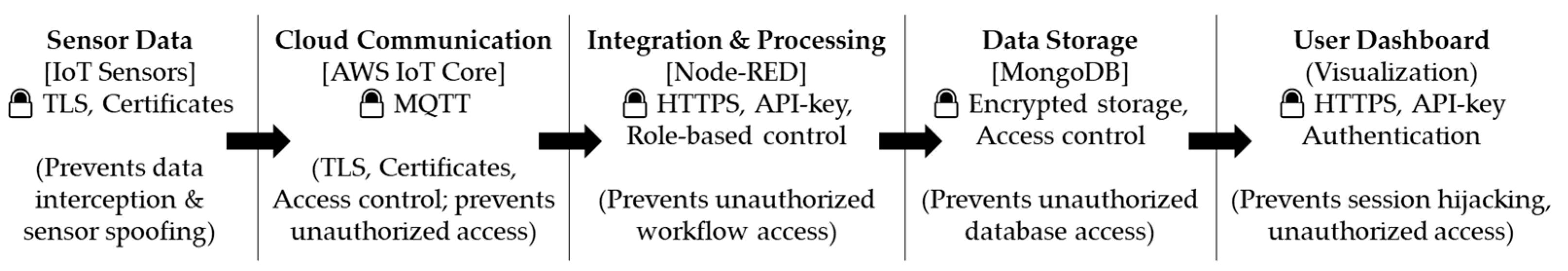

- Layer 1 (sensor data): IoT sensors are secured with TLS encryption and certificate-based authentication to prevent data interception and sensor spoofing;

- Layer 2 (cloud communication): AWS IoT Core secured through MQTT with TLS encryption, certificate-based authentication, and access controls to protect against unauthorized data access;

- Layer 3 (integration and processing): Node-RED secured via HTTPS, API-key authentication, and role-based access control to prevent unauthorized access to workflows;

- Layer 4 (data storage): MongoDB uses encryption-at-rest and implements strict access controls to prevent data theft and unauthorized access to the database.

- Layer 5 (user dashboard): web interfaces secured with HTTPS and API-key authentication to protect against session hijacking and unauthorized access.

5.4. Comparative Validation

6. Discussion

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AECO | Architecture, engineering, construction, and operations |

| API | Application programming interface |

| ASHRAE | American Society of Heating, Refrigerating, and Air-Conditioning Engineers |

| AWS | Amazon Web Services |

| BEP | BIM execution plan |

| BIM | Building information modeling |

| BMS | Building management systems |

| CDE | Common data environment |

| CMMS | Computerized maintenance management system |

| CO2 | Carbon dioxide |

| CSV | Comma-separated values |

| EIR | Employer’s information requirements |

| FM | Facility management |

| GUID | Globally unique identifier |

| HTML | Hypertext markup language |

| HTTPS | Hypertext transfer protocol secure |

| HVAC | Heating, ventilation, and air conditioning |

| IAQ | Indoor air quality |

| IEQ | Indoor environmental quality |

| IFC | Industry foundation class |

| IoT | Internet of things |

| ISO | International Organization for Standardization |

| IT | Information technology |

| JSON | JavaScript object notation |

| ML | Machine learning |

| MQTT | Message queuing telemetry transport |

| NIST | National Institute of Standards and Technology |

| PAS | Publicly available specification |

| PM2.5 | Particulate matter (2.5 microns in diameter or smaller) |

| ROI | Return on investment |

| TLS | Transport layer security |

| URL | Uniform resource locator |

| XML | Extensible markup language |

References

- Cespedes-Cubides, A.S.; Jradi, M. A review of building digital twins to improve energy efficiency in the building operational stage. Energy Inform. 2024, 7, 11. [Google Scholar] [CrossRef]

- Deng, M.; Menassa, C.C.; Kamat, V.R. From BIM to digital twins: A systematic review of the evolution of intelligent building representations in the AEC-FM industry. J. Inf. Technol. Constr. 2021, 26, 58–83. [Google Scholar] [CrossRef]

- Altohami, A.B.A.; Haron, N.A.; Ales@Alias, A.H.; Law, T.H. Investigating approaches of integrating BIM, IoT, and facility management for renovating existing buildings: A review. Sustainability 2021, 13, 3930. [Google Scholar] [CrossRef]

- Tang, S.; Shelden, D.R.; Eastman, C.M.; Pishdad-Bozorgi, P.; Gao, X. A review of building information modeling (BIM) and the internet of things (IoT) devices integration: Present status and future trends. Autom. Constr. 2019, 101, 127–139. [Google Scholar] [CrossRef]

- Hakimi, O.; Liu, H.; Abudayyeh, O. Digital twin-enabled smart facility management: A bibliometric review. Front. Eng. Manag. 2023, 11, 32–49. [Google Scholar] [CrossRef]

- Chamari, L.; Petrova, E.; Pauwels, P. A web-based approach to BMS, BIM and IoT integration: A case study. In Proceedings of the 14th REHVA HVAC World Congress, CLIMA 2022, Rotterdam, The Netherlands, 22–25 May 2022. [Google Scholar] [CrossRef]

- Arsiwala, A.; Elghaish, F.; Zoher, M. Digital twin with Machine learning for predictive monitoring of CO2 equivalent from existing buildings. Energy Build. 2023, 284, 112851. [Google Scholar] [CrossRef]

- Venkateswarlu, N.; Sathiyamoorthy, M. Sustainable innovations in digital twin technology: A systematic review about energy efficiency and indoor environment quality in built environment. Front. Built Environ. 2025, 11, 1523464. [Google Scholar] [CrossRef]

- Kučera, A.; Pitner, T. Semantic BMS: Allowing usage of building automation data in facility benchmarking. Adv. Eng. Inform. 2018, 35, 69–84. [Google Scholar] [CrossRef]

- Tibaut, A.; Rebolj, D.; Perc, M.N. Interoperability requirements for automated manufacturing systems in construction. J. Intell. Manuf. 2014, 27, 251–262. [Google Scholar] [CrossRef]

- Tsay, G.S.; Staub-French, S.; Poirier, É. BIM for Facilities Management: An Investigation into the Asset Information Delivery Process and the Associated Challenges. Appl. Sci. 2022, 12, 9542. [Google Scholar] [CrossRef]

- Mannino, A.; Dejaco, M.C.; Re Cecconi, F. Building information modelling and internet of things integration for facility management—Literature review and future needs. Appl. Sci. 2021, 11, 3062. [Google Scholar] [CrossRef]

- Gordo-Gregorio, P.; Alavi, H.; Forcada, N. Decoding BIM Challenges in Facility Management Areas: A Stakeholders’ Perspective. Buildings 2025, 15, 811. [Google Scholar] [CrossRef]

- Dixit, M.K.; Venkatraj, V.; Ostadalimakhmalbaf, M.; Pariafsai, F.; Lavy, S. Integration of facility management and building information modeling (BIM): A review of key issues and challenges. Facilities 2019, 37, 455–483. [Google Scholar] [CrossRef]

- Enshassi, M.A.; Al Hallaq, K.A.; Tayeh, B.A. Limitation Factors of Building Information Modeling (BIM) Implementation. Open Constr. Build. Technol. J. 2019, 13, 189–196. [Google Scholar] [CrossRef]

- Pavón, R.M.; Alvarez, A.A.A.; Alberti, M.G. Possibilities of BIM-FM for the management of COVID in public buildings. Sustainability 2020, 12, 9974. [Google Scholar] [CrossRef]

- Pinti, L.; Codinhoto, R.; Bonelli, S. A Review of Building Information Modelling (BIM) for Facility Management (FM): Implementation in Public Organisations. Appl. Sci. 2022, 12, 1540. [Google Scholar] [CrossRef]

- Liu, S.; Xie, B.; Tivendal, L.; Liu, C. Critical Barriers to BIM Implementation in the AEC Industry. Int. J. Mark. Stud. 2015, 7, 162. [Google Scholar] [CrossRef]

- Beach, T.H.; Rana, O.F.; Rezgui, Y.; Parashar, M. Cloud computing for the architecture, engineering & construction sector: Requirements, prototype & experience. J. Cloud Comput. 2013, 2, 8. [Google Scholar] [CrossRef]

- Matarneh, R.T.; Hamed, S.A. Exploring the Adoption of Building Information Modeling (BIM) in the Jordanian Construction Industry. J. Archit. Eng. Technol. 2017, 6, 1–7. [Google Scholar] [CrossRef]

- Afsari, K.; Eastman, C.M.; Castro-Lacouture, D. JavaScript Object Notation (JSON) data serialization for IFC schema in web-based BIM data exchange. Autom. Constr. 2017, 77, 24–51. [Google Scholar] [CrossRef]

- Liu, H.; Abudayyeh, O.; Liou, W. BIM-Based Smart Facility Management: A Review of Present Research Status, Challenges, and Future Needs. In Proceedings of the Construction Research Congress 2020: Computer Applications—Selected Papers from the Construction Research Congress 2020, Tempe, Arizona, 8–10 March 2020; pp. 1087–1095. [Google Scholar] [CrossRef]

- Shelden, D.; Brouwer, J.; Pauwels, P.; Saha, N.; Sparks, D.; McGinley, T. IFC.JSON—Overview. 2020. Available online: https://research.tue.nl/files/189895365/IFC.JSON_Overview.pdf (accessed on 14 May 2025).

- Huang, X.; Liu, Y.; Huang, L.; Onstein, E.; Merschbrock, C. BIM and IoT data fusion: The data process model perspective. Autom. Constr. 2023, 149, 104792. [Google Scholar] [CrossRef]

- Aguilar, A.J.; de la Hoz-Torres, M.L.; Ruiz, D.P.; Martínez-Aires, M.D. Monitoring and Assessment of Indoor Environmental Conditions in Educational Building Using Building Information Modelling Methodology. Int. J. Environ. Res. Public Health 2022, 19, 13756. [Google Scholar] [CrossRef]

- Hu, X.; Assaad, R.H. A BIM-enabled digital twin framework for real-time indoor environment monitoring and visualization by integrating autonomous robotics, LiDAR-based 3D mobile mapping, IoT sensing, and indoor positioning technologies. J. Build. Eng. 2024, 86, 108901. [Google Scholar] [CrossRef]

- Settimo, G.; Yu, Y.; Gola, M.; Buffoli, M.; Capolongo, S. Challenges in IAQ for Indoor Spaces: A Comparison of the Reference Guideline Values of Indoor Air Pollutants from the Governments and International Institutions. Atmosphere 2023, 14, 633. [Google Scholar] [CrossRef]

- Siddique, A.; Al-Shamlan, M.Y.M.; Al-Romaihi, H.E.; Khwaja, H.A. Beyond the outdoors: Indoor air quality guidelines and standards—Challenges, inequalities, and the path forward. Rev. Environ. Health 2023, 40, 21–35. [Google Scholar] [CrossRef]

- Khalid, M.U.; Bashir, M.K.; Newport, D. Development of a building information modelling (BIM)-based real-time data integration system using a building management system (BMS). In Building Information Modelling, Building Performance, Design and Smart Construction; Springer: Cham, Switzerland, 2017; pp. 93–104. [Google Scholar] [CrossRef]

- buildingSMART International. IFC Formats. Available online: https://technical.buildingsmart.org/standards/ifc/ifc-formats/ (accessed on 9 May 2025).

- Chatsuwan, M.; Manajitt, B.; Ichinose, M.; Alkhalaf, H. A Review of BIM Maturity in Standards and Guidelines Across Asia. In Proceedings of the 41st International Conference of CIB W78, Marrakech, Morocco, 2–3 October 2024; Available online: https://itc.scix.net/paper/w78-2024-48 (accessed on 22 May 2025), ISSN 2706-6568.

- ISO 19650-1:2018; Organization and Digitization of Information About Buildings and Civil Engineering Works, Including Building Information Modelling (BIM)—Information Management Using Building Information Modelling. ISO: Geneva, Switzerland, 2018.

- buildingSMART. Industry Foundation Classes (IFC) Overview. Available online: https://www.buildingsmart.org/ (accessed on 1 November 2024).

- Kang, K.; Lin, J.; Zhang, J. BIM- and IoT-based monitoring framework for building performance management. J. Struct. Integr. Maint. 2018, 3, 254–261. [Google Scholar] [CrossRef]

- Eneyew, D.D.; Capretz, M.A.M.; Bitsuamlak, G.T. Toward Smart-Building Digital Twins: BIM and IoT Data Integration. IEEE Access 2022, 10, 130487–130506. [Google Scholar] [CrossRef]

- Chang, K.-M.; Dzeng, R.-J.; Wu, Y.-J. An automated IoT visualization BIM platform for decision support in facilities management. Appl. Sci. 2018, 8, 1086. [Google Scholar] [CrossRef]

- Desogus, G.; Quaquero, E.; Rubiu, G.; Gatto, G.; Perra, C. BIM and IoT sensors integration: A framework for consumption and indoor conditions data monitoring of existing buildings. Sustainability 2021, 13, 4496. [Google Scholar] [CrossRef]

- Dave, B.; Buda, A.; Nurminen, A.; Främling, K. A framework for integrating BIM and IoT through open standards. Autom. Constr. 2018, 95, 35–45. [Google Scholar] [CrossRef]

- Fialho, B.C.; Codinhoto, R.; Fabricio, M.M.; Estrella, J.C.; Ribeiro, C.M.N.; Bueno, J.M.d.S.; Torrezan, J.P.D. Development of a BIM and IoT-Based Smart Lighting Maintenance System Prototype for Universities’ FM Sector. Buildings 2022, 12, 99. [Google Scholar] [CrossRef]

- Dai, C.; Cheng, K.; Liang, B.; Zhang, X.; Liu, Q.; Kuang, Z. Digital twin modeling method based on IFC standards for building construction processes. Front. Energy Res. 2024, 12, 1334192. [Google Scholar] [CrossRef]

- Giel, B.; Issa, R.R.A. Framework for Evaluating the BIM Competencies of Facility Owners. J. Manag. Eng. 2016, 32, 04015024. [Google Scholar] [CrossRef]

- Munteanu, A.; Mehedintu, G. The Importance of Facility Management in the Life Cycle Costing Calculation. Rev. Gen. Manag. 2016, 23, 65–77. [Google Scholar]

- Sabri, M.; Sekak, A.; Junus, Y.M. Issues and Challenges of Building Information Modelling (BIM) Implementation in Facilities Management. Built Environ. J. 2024, 21, 1–11. [Google Scholar]

- Abdelalim, A.M.; Essawy, A.; Alnaser, A.A.; Shibeika, A.; Sherif, A. Digital Trio: Integration of BIM–EIR–IoT for Facilities Management of Mega Construction Projects. Sustainability 2024, 16, 6348. [Google Scholar] [CrossRef]

- Becerik-Gerber, B.; Jazizadeh, F.; Li, N.; Calis, G. Application Areas and Data Requirements for BIM-Enabled Facilities Management. J. Constr. Eng. Manag. 2012, 138, 431–442. [Google Scholar] [CrossRef]

- Kassem, M.; Kelly, G.; Dawood, N.; Serginson, M.; Lockley, S. BIM in facilities management applications: A case study of a large university complex. Built Environ. Proj. Asset Manag. 2015, 5, 261–277. [Google Scholar] [CrossRef]

- Gao, X.; Pishdad-Bozorgi, P. BIM-enabled facilities operation and maintenance: A review. Adv. Eng. Inform. 2019, 39, 227–247. [Google Scholar] [CrossRef]

- Ozturk, G.B. Interoperability in building information modeling for AECO/FM industry. Autom. Constr. 2020, 113, 103122. [Google Scholar] [CrossRef]

- Jupp, J.; Awad, R. BIM-FM and Information Requirements Management: Missing Links in the AEC and FM Interface. In Product Lifecycle Management and the Industry of the Future, Proceedings of the 4th IFIP WG 5.1 International Conference, PLM 2017, Seville, Spain, 10–12 July 2017; Springer: Cham, Switzerland, 2017; Volume 9, pp. 311–323. [Google Scholar] [CrossRef]

- Lovell, L.J.; Davies, R.J.; Hunt, D.V.L. Building Information Modelling Facility Management (BIM-FM). Appl. Sci. 2024, 14, 3977. [Google Scholar] [CrossRef]

- Wijeratne, P.U.; Gunarathna, C.; Yang, R.J.; Wu, P.; Hampson, K.; Shemery, A. BIM enabler for facilities management: A review of 33 cases. Int. J. Constr. Manag. 2023, 24, 251–260. [Google Scholar] [CrossRef]

- Motawa, I.; Almarshad, A. A knowledge-based BIM system for building maintenance. Autom. Constr. 2013, 29, 173–182. [Google Scholar] [CrossRef]

- Chen, W.; Chen, K.; Cheng, J.C.; Wang, Q.; Gan, V.J. BIM-based framework for automatic scheduling of facility maintenance work orders. Autom. Constr. 2018, 91, 15–30. [Google Scholar] [CrossRef]

- Kazado, D.; Kavgic, M.; Eskicioglu, R. Integrating Building Information Modeling (BIM) and Sensor Technology for Facility Management. J. Inf. Technol. Constr. 2019, 24, 441. [Google Scholar]

- Quinn, C.; Shabestari, A.Z.; Misic, T.; Gilani, S.; Litoiu, M.; McArthur, J. Building automation system—BIM integration using a linked data structure. Autom. Constr. 2020, 118, 103257. [Google Scholar] [CrossRef]

- Panteli, C.; Kylili, A.; Fokaides, P.A. Building information modelling applications in smart buildings: From design to commissioning and beyond A critical review. J. Clean. Prod. 2020, 265, 121766. [Google Scholar] [CrossRef]

- Heaton, J.; Parlikad, A.K.; Schooling, J. Design and development of BIM models to support operations and maintenance. Comput. Ind. 2019, 111, 172–186. [Google Scholar] [CrossRef]

- Edirisinghe, R.; London, K.A.; Kalutara, P.; Aranda-Mena, G. Building information modelling for facility management: Are we there yet? Eng. Constr. Arch. Manag. 2017, 24, 1119–1154. [Google Scholar] [CrossRef]

- Gartoumi, K.I.; Zaki, S.; Aboussaleh, M. Building information modelling (BIM) interoperability for architecture and engineering (AE) of the structural project: A case study. Mater. Today Proc. 2023, in press. [Google Scholar] [CrossRef]

- Kim, S.; Poirier, E.A.; Staub-French, S. Information commissioning: Bridging the gap between digital and physical built assets. J. Facil. Manag. 2020, 18, 231–245. [Google Scholar] [CrossRef]

- Patacas, J.; Dawood, N.; Kassem, M. BIM for facilities management: A framework and a common data environment using open standards. Autom. Constr. 2020, 120, 103366. [Google Scholar] [CrossRef]

- Jamriska, M.; Morawska, L.; Clark, B.A. Effect of Ventilation and Filtration on Submicrometer Particles in an Indoor Environment. Indoor Air 2000, 10, 19–26. [Google Scholar] [CrossRef] [PubMed]

- Hänninen, O.O.; Tuomisto, J.T.; Jantunen, M.J.; Lebret, E. Characterization of Model Error in a Simulation of Fine Particulate Matter Exposure Distributions of the Working Age Population in Helsinki, Finland. J. Air Waste Manag. Assoc. 2005, 55, 446–457. [Google Scholar] [CrossRef]

- Montgomery, J.F.; Reynolds, C.C.; Rogak, S.N.; Green, S.I. Financial implications of modifications to building filtration systems. Build. Environ. 2015, 85, 17–28. [Google Scholar] [CrossRef]

- Liang, W.; Qiang, G.; Fan, L.; Zhang, H.; Ye, Z.; Tang, S. Automatic Indoor Thermal Comfort Monitoring Based on BIM and IoT Technology. Buildings 2024, 14, 3361. [Google Scholar] [CrossRef]

- Kanna, K.; Lachguer, K.A.; Yaagoubi, R. MyComfort: An integration of BIM-IoT-machine learning for optimizing indoor thermal comfort based on user experience. Energy Build. 2022, 277, 112547. [Google Scholar] [CrossRef]

| Barrier Dimension | Identified Challenges | Proposed Solutions | References |

|---|---|---|---|

| Technological | Interoperability, legacy systems, and data formats | Open standards (IFC, JSON) and low-code integration (Node-RED) | [11,13,22,24,44] |

| Usability | Steep learning curves and inadequate BIM expertise among FM staff | Intuitive, web-based dashboard interfaces; targeted user training programs | [12,13,14,15,16] |

| Organizational and workflow | Insufficient managerial support, unclear roles, and ROI uncertainty | Structured integration frameworks, clear governance, and standardized workflows | [11,17,18,19,20] |

| Advancements in digital twin | Limited implementation examples and persistent interoperability issues | Vendor-neutral, scalable implementations using open standards and accessible tools | [1,7,8] |

| Data Category | Description | Preferred Location | Remarks | References |

|---|---|---|---|---|

| Asset information | Equipment details and specifications | BIM + FM system | Core data embedded in BIM; lifecycle data externally maintained | [11,17,45,46,47,48,49,50] |

| Maintenance records | Work orders and maintenance logs | External system | Stored and updated in CMMS; BIM serves as access gateway or index | [17,49,50,51,52,53] |

| Performance and sensor data | Real-time sensor data | External system | IoT/BMS capture data; BIM visualizes without storing raw data | [17,38,50,54,55,56] |

| Spatial information | Building geometry and floor plans | BIM | Provides authoritative spatial context | [17,49,50,57,58,59] |

| Documentation | Manuals, warranties, and checklists | Linked externally | Managed in EDMS/FM systems, referenced via BIM hyperlinks | [17,48,49,60,61] |

| GlobalId (IFC) | Element Name | Sensor ID | Sensor or Zone Name |

|---|---|---|---|

| 0eyMYa5qz2eeRNRT2UhxQ | 1st floor collaborative creation area | 1.00903.204 | Occupancy rates |

| 059mVaylX87vpmyegNh8ad | 1st floor library area | 1.00903.205 | Occupancy rates |

| Research Aspect | Previous Studies | This Research | |

|---|---|---|---|

| Software dependency | [36,37,39,65,66] | Previous methods relied on commercial software, causing high recurring costs and vendor dependency | Employs open standards (IFC, JSON) and open-source tools (Node-RED), reducing vendor dependency and operational costs |

| Expertise requirements | [36,37,39,65,66] | Most existing methods required personnel with combined high-level expertise in both BIM modeling and programming, limiting practical usability and implementation | Clearly defines and separates roles (BIM modeling, data integration, facility management), reducing combined skillset requirements |

| Value beyond visualization | [6,34,35,36,37,65] | Limited to real-time visualization | Demonstrates benefits of integrating real-time IoT data with BIM for advanced maintenance analytics |

| Cybersecurity considerations | [6,34,35,36,37,38,39] | Rarely addressed cybersecurity explicitly, potentially increasing risks of data breaches or system vulnerabilities | Concern, employs security protocols (TLS encryption, certificate-based authentication) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chatsuwan, M.; Ichinose, M.; Alkhalaf, H. Enhancing Facility Management with a BIM and IoT Integration Tool and Framework in an Open Standard Environment. Buildings 2025, 15, 1928. https://doi.org/10.3390/buildings15111928

Chatsuwan M, Ichinose M, Alkhalaf H. Enhancing Facility Management with a BIM and IoT Integration Tool and Framework in an Open Standard Environment. Buildings. 2025; 15(11):1928. https://doi.org/10.3390/buildings15111928

Chicago/Turabian StyleChatsuwan, Mayurachat, Masayuki Ichinose, and Haitham Alkhalaf. 2025. "Enhancing Facility Management with a BIM and IoT Integration Tool and Framework in an Open Standard Environment" Buildings 15, no. 11: 1928. https://doi.org/10.3390/buildings15111928

APA StyleChatsuwan, M., Ichinose, M., & Alkhalaf, H. (2025). Enhancing Facility Management with a BIM and IoT Integration Tool and Framework in an Open Standard Environment. Buildings, 15(11), 1928. https://doi.org/10.3390/buildings15111928