Unfired Bricks from Wastes: A Review of Stabiliser Technologies, Performance Metrics, and Circular Economy Pathways

Abstract

1. Introduction

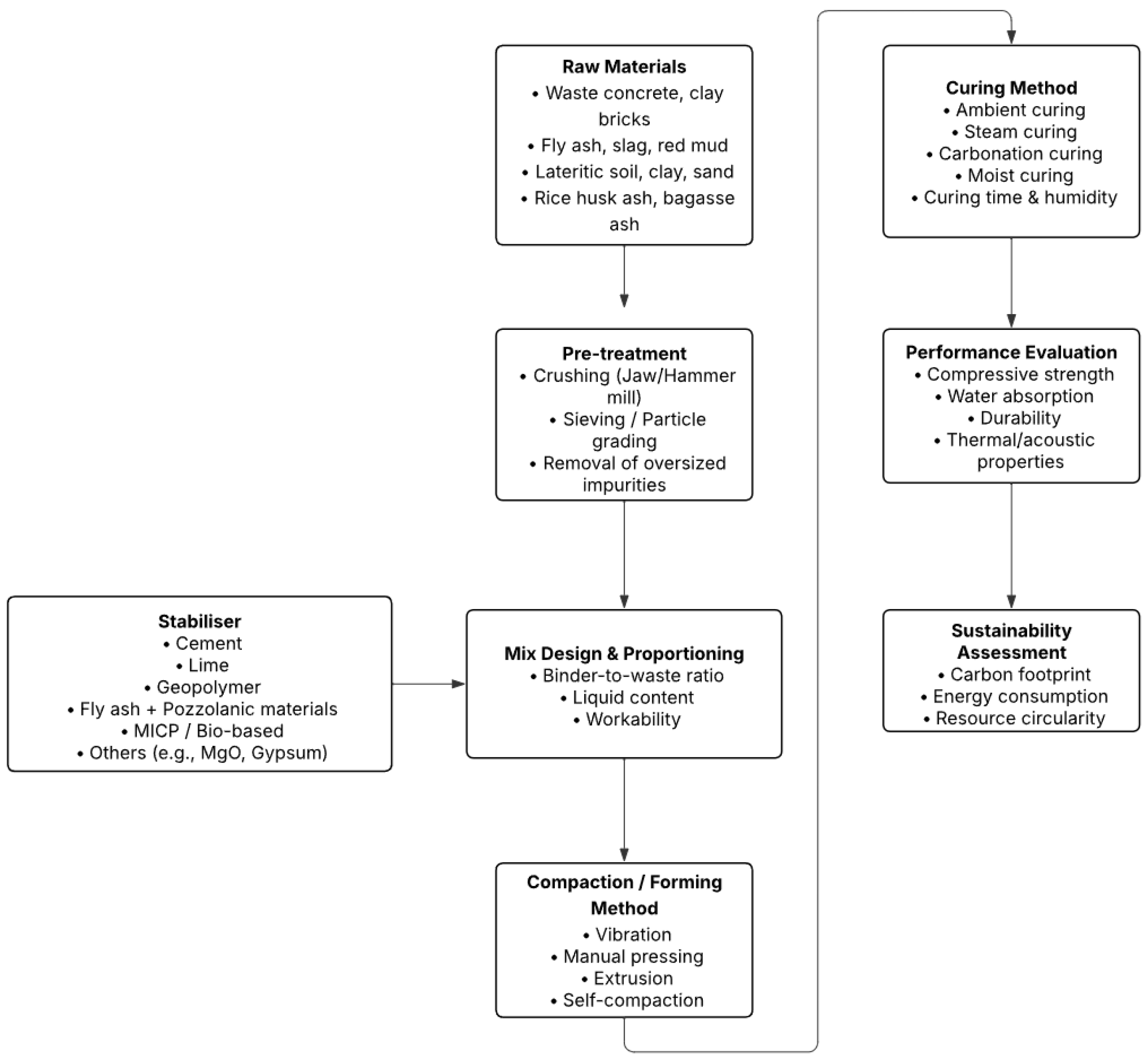

Review Scope and Methodology

2. Comparison of Fired and Unfired Brick Technologies

2.1. Raw Materials

2.2. Manufacturing Process

2.3. Energy Consumption and Emissions

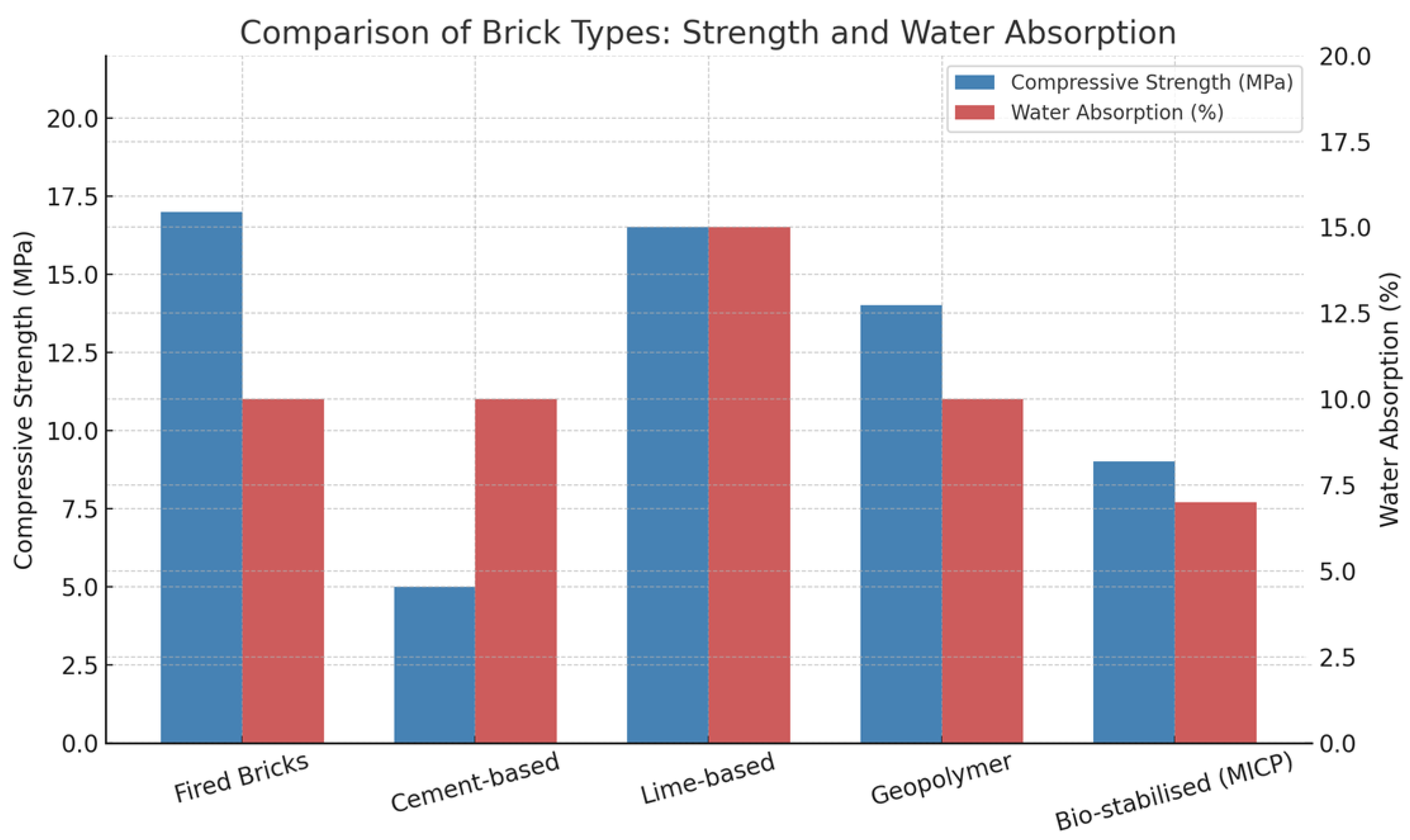

2.4. Strength and Application

3. Use of Stabiliser in Unfired Brick Production

3.1. Cement

3.2. Lime

3.3. Fly Ash and Pozzolanic Stabiliser

3.4. Geopolymers

3.5. MICP and Bio-Stabilisers

3.6. Others

4. Engineering Properties of Unfired Bricks

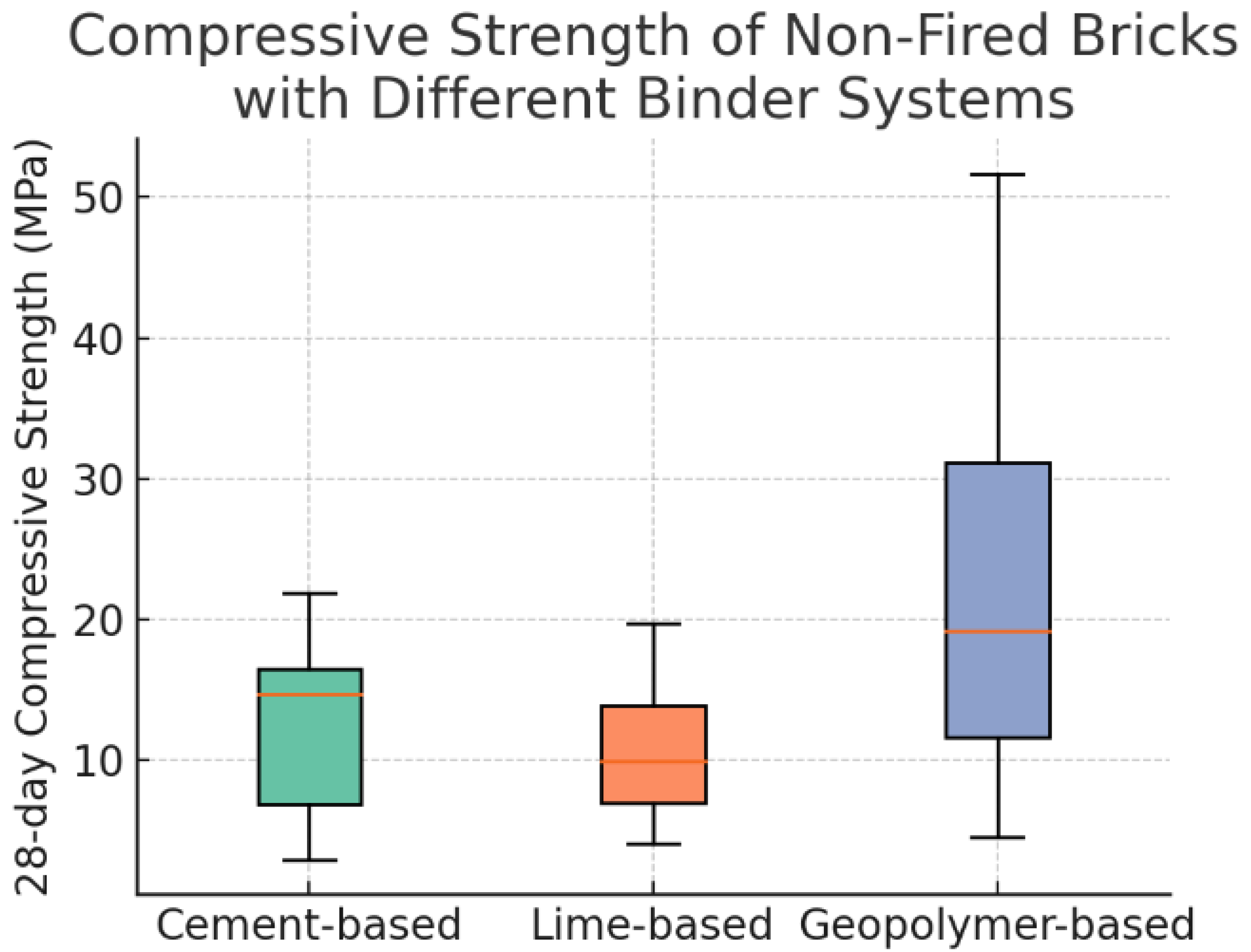

4.1. Compressive Strength

4.2. Water Absorption

4.3. Drying Shrinkage and Dimensional Stability

4.4. Thermal and Acoustic Properties

4.4.1. Thermal Conductivity

4.4.2. Acoustic Properties

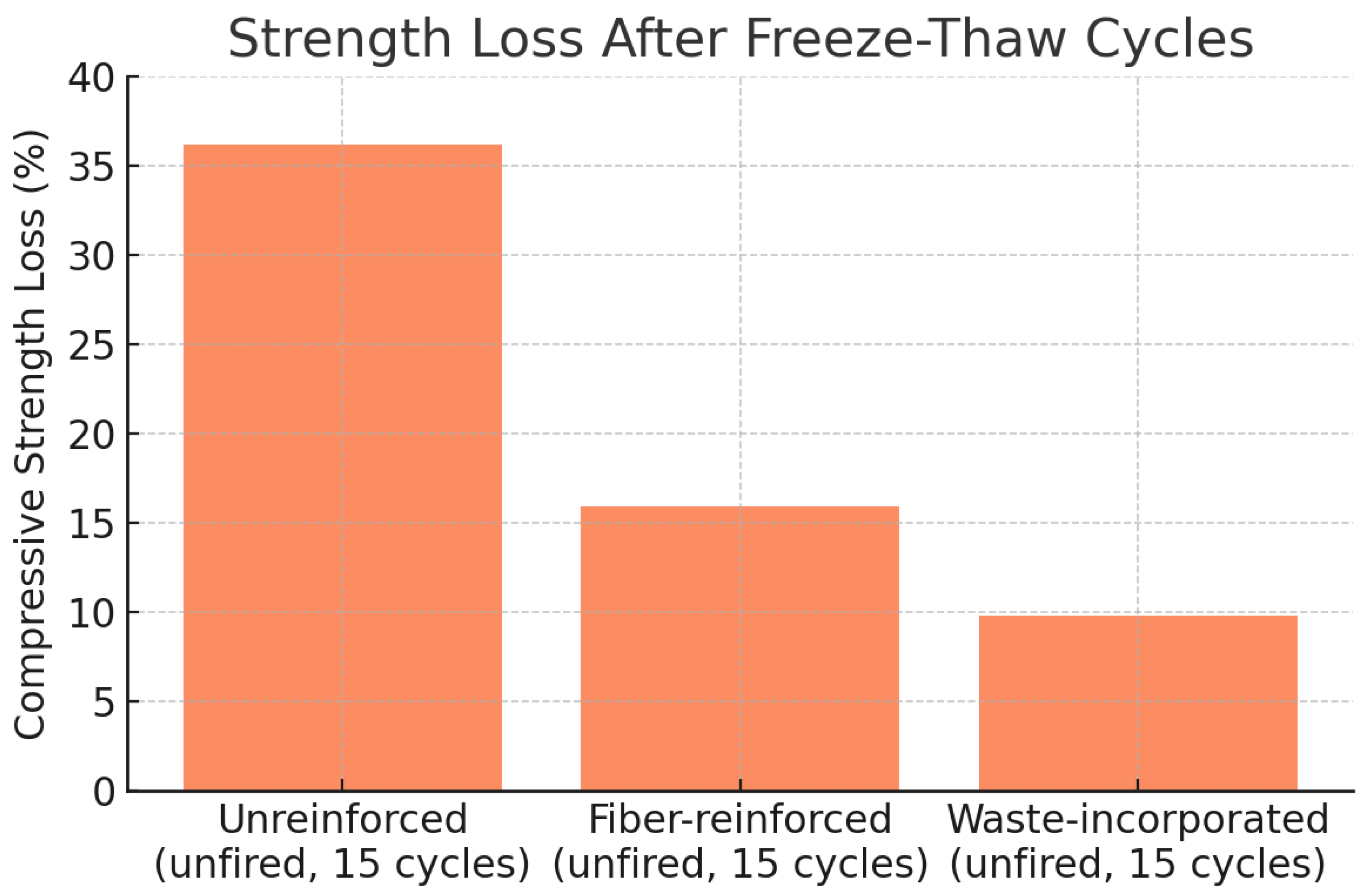

4.5. Durability: Freeze–Thaw and Wet–Dry Resistance

5. Sustainability and Circular Economy Potential

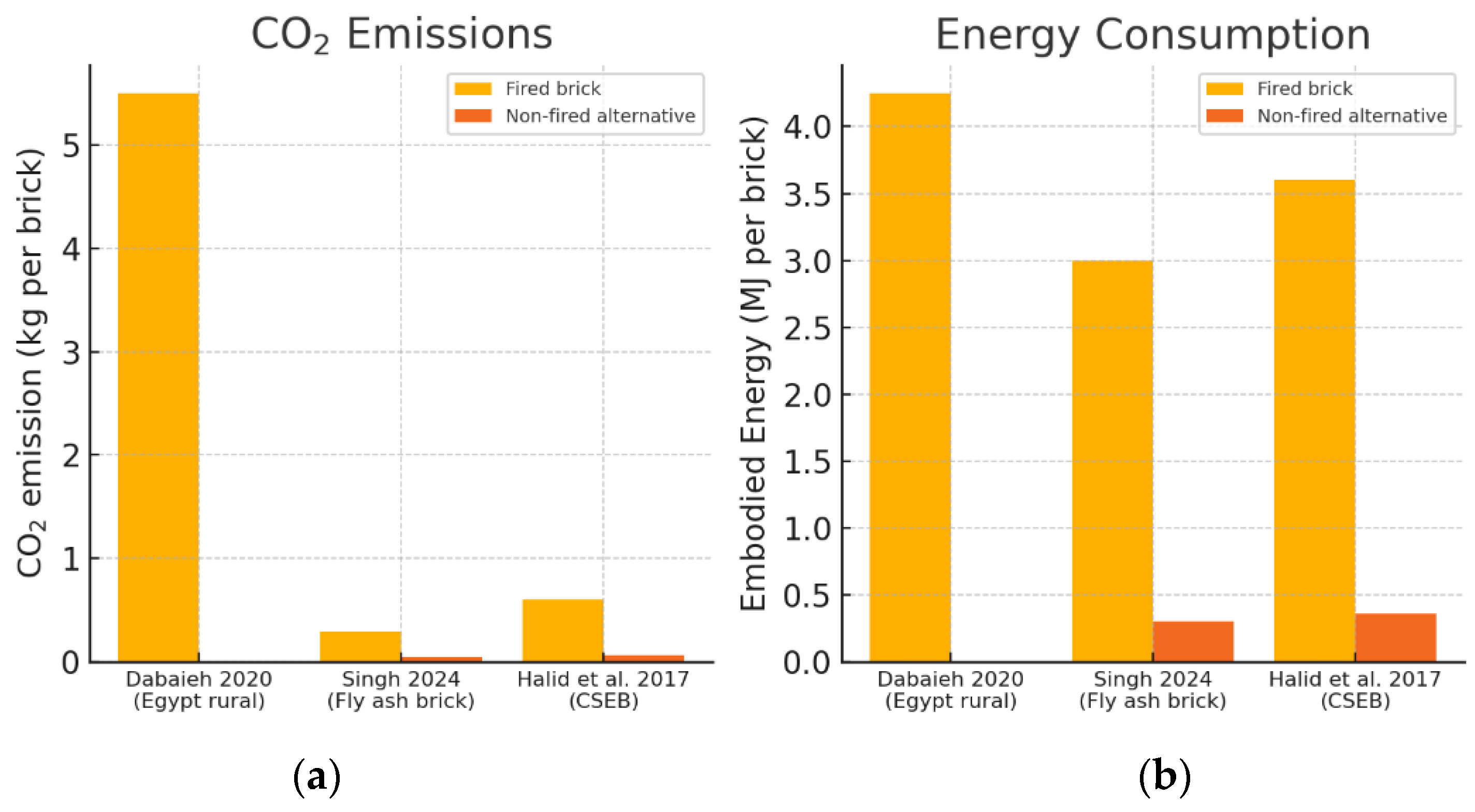

5.1. CO2 Emission Reduction

5.2. Energy Savings

5.3. Waste Utilization Efficiency

6. Discussion

7. Conclusions

- Up to 90% reductions in energy consumption and carbon emissions

- Effective waste valorisation, with up to 80–90% waste incorporation

- Comparable mechanical performance, especially when stabilised with cement, lime, or geopolymer stabilisers

- Enhanced insulation and moisture buffering properties, suited for both rural and urban construction

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kaza, S.; Yao, L.; Bhada-Tata, P.; Van Woerden, F. What a Waste 2.0: A Global Snapshot of Solid Waste Management to 2050; World Bank Publications: Herndon, VA, USA, 2018. [Google Scholar]

- Kabirifar, K.; Mojtahedi, M.; Wang, C.; Tam, V.W.Y. Construction and Demolition Waste Management Contributing Factors Coupled with Reduce, Reuse, and Recycle Strategies for Effective Waste Management: A Review. J. Clean. Prod. 2020, 263, 121265. [Google Scholar] [CrossRef]

- Yao, Z.T.; Ji, X.S.; Sarker, P.K.; Tang, J.H.; Ge, L.Q.; Xia, M.S.; Xi, Y.Q. A Comprehensive Review on the Applications of Coal Fly Ash. Earth-Sci. Rev. 2015, 141, 105–121. [Google Scholar] [CrossRef]

- Guo, J.; Bao, Y.; Wang, M. Steel Slag in China: Treatment, Recycling, and Management. Waste Manag. 2018, 78, 318–330. [Google Scholar] [CrossRef]

- Joseph, A.; Snellings, R.; Van Den Heede, P.; Matthys, S.; De Belie, N. The Use of Municipal Solid Waste Incineration Ash in Various Building Materials: A Belgian Point of View. Materials 2018, 11, 141. [Google Scholar] [CrossRef]

- Vergara, S.E.; Tchobanoglous, G. Municipal Solid Waste and the Environment: A Global Perspective. Annu. Rev. Environ. Resour. 2012, 37, 277–309. [Google Scholar] [CrossRef]

- Sun, R.; Gao, Y.; Yang, Y. Leaching of Heavy Metals from Lead-Zinc Mine Tailings and the Subsequent Migration and Transformation Characteristics in Paddy Soil. Chemosphere 2022, 291, 132792. [Google Scholar] [CrossRef]

- Silva, R.V.; De Brito, J.; Dhir, R.K. Properties and Composition of Recycled Aggregates from Construction and Demolition Waste Suitable for Concrete Production. Constr. Build. Mater. 2014, 65, 201–217. [Google Scholar] [CrossRef]

- Ghisellini, P.; Cialani, C.; Ulgiati, S. A Review on Circular Economy: The Expected Transition to a Balanced Interplay of Environmental and Economic Systems. J. Clean. Prod. 2016, 114, 11–32. [Google Scholar] [CrossRef]

- Gupta, V.; Chai, H.K.; Lu, Y.; Chaudhary, S. A State of the Art Review to Enhance the Industrial Scale Waste Utilization in Sustainable Unfired Bricks. Constr. Build. Mater. 2020, 254, 119220. [Google Scholar] [CrossRef]

- European Commission A New Circular Economy Action Plan: For a Cleaner and More Competitive Europe; European Commission: Brussels, Belgium, 2020.

- Lachheb, M.; Youssef, N.; Younsi, Z. A Comprehensive Review of the Improvement of the Thermal and Mechanical Properties of Unfired Clay Bricks by Incorporating Waste Materials. Buildings 2023, 13, 2314. [Google Scholar] [CrossRef]

- Miqueleiz, L.; Ramirez, F.; Oti, J.E.; Seco, A.; Kinuthia, J.M.; Oreja, I.; Urmeneta, P. Alumina Filler Waste as Clay Replacement Material for Unfired Brick Production. Eng. Geol. 2013, 163, 68–74. [Google Scholar] [CrossRef]

- Ikponmwosa, E.; Ehikhuenmen, S. The effect of ceramic waste as coarse aggregate on strength properties of concrete. Niger. J. Technol. 2017, 36, 691–696. [Google Scholar] [CrossRef]

- Asif, M.; Saleem, S.; Tariq, A.; Usman, M.; Haq, R.A.U. Pollutant Emissions from Brick Kilns and Their Effects on Climate Change and Agriculture. ASEAN J. Sci. Eng. 2021, 1, 135–140. [Google Scholar] [CrossRef]

- Liu, J.; Wang, Y.; Li, Y.; Tian, J.; You, X.; Mao, Y.; Hu, X.; Shi, C. Carbonated Concrete Brick Capturing Carbon Dioxide from Cement Kiln Exhaust Gas. Case Stud. Constr. Mater. 2022, 17, e01474. [Google Scholar] [CrossRef]

- Singh, S.; Maiti, S.; Bisht, R.S.; Panigrahi, S.K.; Yadav, S. Large CO2 Reduction and Enhanced Thermal Performance of Agro-Forestry, Construction and Demolition Waste Based Fly Ash Bricks for Sustainable Construction. Sci. Rep. 2024, 14, 8368. [Google Scholar] [CrossRef] [PubMed]

- Dabaieh, M.; Heinonen, J.; El-Mahdy, D.; Hassan, D.M. A Comparative Study of Life Cycle Carbon Emissions and Embodied Energy between Sun-Dried Bricks and Fired Clay Bricks. J. Clean. Prod. 2020, 275, 122998. [Google Scholar] [CrossRef]

- C15 Committee ASTM International. Standard Specification for Building Brick (Solid Masonry Units Made From Clay or Shale); ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar] [CrossRef]

- Bruno, A.W.; Gallipoli, D.; Perlot, C.; Kallel, H. Thermal Performance of Fired and Unfired Earth Bricks Walls. J. Build. Eng. 2020, 28, 101017. [Google Scholar] [CrossRef]

- Abdullah, A.H.; Nagapan, S.; Antonyova, A.; Rasiah, K.; Yunus, R.; Sohu, S. Strength and Absorption Rate of Compressed Stabilized Earth Bricks (CSEBs) Due to Different Mixture Ratios and Degree of Compaction. MATEC Web Conf. 2017, 103, 01028. [Google Scholar] [CrossRef]

- Islam, M.S.; Elahi, T.E.; Shahriar, A.R.; Mumtaz, N. Effectiveness of Fly Ash and Cement for Compressed Stabilized Earth Block Construction. Constr. Build. Mater. 2020, 255, 119392. [Google Scholar] [CrossRef]

- Guettala, A.; Abibsi, A.; Houari, H. Durability Study of Stabilized Earth Concrete under Both Laboratory and Climatic Conditions Exposure. Constr. Build. Mater. 2006, 20, 119–127. [Google Scholar] [CrossRef]

- Preethi, R.K.; Venkatarama Reddy, B.V. Characteristics of Geopolymer Stabilised Compressed Earth Bricks. Structures 2024, 61, 106007. [Google Scholar] [CrossRef]

- Bernardi, D.; DeJong, J.T.; Montoya, B.M.; Martinez, B.C. Bio-Bricks: Biologically Cemented Sandstone Bricks. Constr. Build. Mater. 2014, 55, 462–469. [Google Scholar] [CrossRef]

- Ma, S.; Akca, A.H.; Esposito, D.; Kawashima, S. Influence of Aqueous Carbonate Species on Hydration and Carbonation of Reactive MgO Cement. J. CO2 Util. 2020, 41, 101260. [Google Scholar] [CrossRef]

- Elahi, T.E.; Shahriar, A.R.; Islam, M.S. Engineering Characteristics of Compressed Earth Blocks Stabilized with Cement and Fly Ash. Constr. Build. Mater. 2021, 277, 122367. [Google Scholar] [CrossRef]

- Thennarasan Latha, A.; Murugesan, B.; Thomas, B.S. Compressed Stabilized Earth Block Incorporating Municipal Solid Waste Incinerator Bottom Ash as a Partial Replacement for Fine Aggregates. Buildings 2023, 13, 1114. [Google Scholar] [CrossRef]

- Bradley, R.A.; Gohnert, M.; Fitchett, A. Guidelines to Mitigate Cracking in Compressed Stabilized Earth Brick Shells. J. Perform. Constr. Facil. 2018, 32, 04018018. [Google Scholar] [CrossRef]

- Shihata, S.A.; Baghdadi, Z.A. Simplified Method to Assess Freeze-Thaw Durability of Soil Cement. J. Mater. Civ. Eng. 2001, 13, 243–247. [Google Scholar] [CrossRef]

- Erunkulu, I.O.; Malumbela, G.; Oladijo, O.P. Performance Evaluation of Fly Ash–Copper Slag-Based Geopolymer Bricks. Low-Carbon. Mater. Green. Constr. 2024, 2, 14. [Google Scholar] [CrossRef]

- Kejkar, R.; Wanjari, S. Development and Optimisation of Curing Temperature of Energy-Efficient Geopolymer Bricks. Građevinar 2020, 72, 411–420. [Google Scholar] [CrossRef]

- Degirmenci, F.N. Freeze-thaw and fire resistance of geopolymer mortar based on natural and waste pozzolans. Ceram. -Silik. 2017, 62, 41–49. [Google Scholar] [CrossRef]

- Malkanthi, S.N.; Balthazaar, N.; Perera, A.A.D.A.J. Lime Stabilization for Compressed Stabilized Earth Blocks with Reduced Clay and Silt. Case Stud. Constr. Mater. 2020, 12, e00326. [Google Scholar] [CrossRef]

- Ndjeumi, C.C.; Djomou, D.P.N.; Nkeng, G.E.; Souaibou, F.A.; Anong, S. Assessment of Cement-Lime as Stabilizer on Mud Bricks. MSCE 2024, 12, 229. [Google Scholar] [CrossRef]

- Zhang, K.; Tang, C.-S.; Jiang, N.-J.; Pan, X.-H.; Liu, B.; Wang, Y.-J.; Shi, B. Microbial-induced Carbonate Precipitation (MICP) Technology: A Review on the Fundamentals and Engineering Applications. Environ. Earth Sci. 2023, 82, 229. [Google Scholar] [CrossRef] [PubMed]

- Manzur, T.; Shams Huq, R.; Hasan Efaz, I.; Afroz, S.; Rahman, F.; Hossain, K. Performance Enhancement of Brick Aggregate Concrete Using Microbiologically Induced Calcite Precipitation. Case Stud. Constr. Mater. 2019, 11, e00248. [Google Scholar] [CrossRef]

- Liu, S.; Wen, K.; Armwood, C.; Bu, C.; Li, C.; Amini, F.; Li, L. Enhancement of MICP-Treated Sandy Soils against Environmental Deterioration. J. Mater. Civ. Eng. 2019, 31, 04019294. [Google Scholar] [CrossRef]

- Raoof, S.M.; Hameed, A.M. Compressive Strength of Geopolymer Mortar Produced from Fire Brick and Ceramic Waste 2025; Preprints.org: Basel, Switzerland, 2025. [Google Scholar]

- C15 Committee ASTM International. Standard Test Methods for Sampling and Testing Brick and Structural Clay Tile; ASTM International: West Conshohocken, PA, USA, 2023. [Google Scholar] [CrossRef]

- IS 3495-1 to 4 (1992): Methods of Tests of Burnt Clay Building Bricks: Part 1 Determination of Compressive Strength Part 2 Determination of Water Absorption Part 3 Determination of Efflorescence, Part 4: Determination of Warpage. Available online: https://standardsbis.bsbedge.com/BIS_SearchStandard.aspx?Standard_Number=IS+3495&id=0 (accessed on 2 May 2025).

- BSI British Standards. Methods of Test for Masonry Units; BSI British Standards: Milton Keynes, UK, 2019. [Google Scholar] [CrossRef]

- Verma, N.K.; Rao, M.C.; Kumar, S. Effect of Curing Regime on Compressive Strength of Geopolymer Concrete. IOP Conf. Ser.: Earth Environ. Sci. 2022, 982, 012031. [Google Scholar] [CrossRef]

- Tian, X.; Xu, W.; Song, S.; Rao, F.; Xia, L. Effects of Curing Temperature on the Compressive Strength and Microstructure of Copper Tailing-Based Geopolymers. Chemosphere 2020, 253, 126754. [Google Scholar] [CrossRef]

- Abdel Gelil Mohamed, N.; Moustafa, A.; Darwish, E.A. Structural, Acoustical, and Thermal Evaluation of an Experimental House Built with Reinforced/Hollow Interlocking Compressed Stabilized Earth Brick-Masonry. J. Build. Eng. 2024, 86, 108790. [Google Scholar] [CrossRef]

- Ni, H.; Wu, W.; Lv, S.; Wang, X.; Tang, W. Formulation of Non-Fired Bricks Made from Secondary Aluminum Ash. Coatings 2021, 12, 2. [Google Scholar] [CrossRef]

- Liu, D.; Guo, Y.; Zhang, Y.; Zhu, Z.; Xu, P.; Zhang, S.; Ren, Y. Mechanism of Strength Formation of Unfired Bricks Composed of Aeolian Sand–Loess Composite. Materials 2024, 17, 1184. [Google Scholar] [CrossRef]

- Pitroda, D.J.; Mistry, S.; Zala, L.B.; Patel, S.; Bhavsar, J.J.; Umrigar, F.S. Fly ash bricks masonry: An experimental study. In Proceedings of the National Conference on Recent Trends in Engineering & Technology, Gujarat, India, 13 May 2011; pp. 1–6. [Google Scholar]

- Lavanya, B.; Kuriya, P.D.; Suganesh, S.; Indrajith, R.; Chokkalingam, R.B. Properties of Geopolymer Bricks Made with Flyash and GGBS. IOP Conf. Ser. Mater. Sci. Eng. 2020, 872, 012141. [Google Scholar] [CrossRef]

- Ige, O.; Danso, H. Experimental Characterization of Adobe Bricks Stabilized with Rice Husk and Lime for Sustainable Construction. J. Mater. Civ. Eng. 2022, 34, 04021420. [Google Scholar] [CrossRef]

- Walker, P.; Stace, T. Properties of Some Cement Stabilised Compressed Earth Blocks and Mortars. Mat. Struct. 1997, 30, 545–551. [Google Scholar] [CrossRef]

- Sujatha, E.R.; Mahalakshmi, S.; Kannan, G. Potential of Fibre Reinforced and Cement Stabilized Fibre Reinforced Soil Blocks as Sustainable Building Units. J. Build. Eng. 2023, 78, 107733. [Google Scholar] [CrossRef]

- Woyciechowski, P.; Narloch, P.L.; Cichocki, D. Shrinkage Characteristics of Cement Stabilized Rammed Earth. MATEC Web Conf. 2017, 117, 00178. [Google Scholar] [CrossRef]

- Bailly, G.C.; El Mendili, Y.; Konin, A.; Khoury, E. Advancing Earth-Based Construction: A Comprehensive Review of Stabilization and Reinforcement Techniques for Adobe and Compressed Earth Blocks. Eng 2024, 5, 750–783. [Google Scholar] [CrossRef]

- Wang, L.; Yu, Z.; Liu, B.; Zhao, F.; Tang, S.; Jin, M. Effects of Fly Ash Dosage on Shrinkage, Crack Resistance and Fractal Characteristics of Face Slab Concrete. Fractal Fract. 2022, 6, 335. [Google Scholar] [CrossRef]

- Bui, Q.-B.; Nguyen, T.-P.; Schwede, D. Manually Compressed Soil Blocks Stabilised by Fly Ash Based Geopolymer: A Promising Approach for Sustainable Buildings. Sci. Rep. 2023, 13, 22905. [Google Scholar] [CrossRef]

- Ashour, T.; Korjenic, A.; Abdelfattah, A.; Sesto, E.; Wu, W. Shrinkage Behavior of Stabilized Earth Bricks Reinforced with Wheat and Barley Straw. Sustainability 2023, 15, 16254. [Google Scholar] [CrossRef]

- Nshimiyimana, P.; Messan, A.; Courard, L. Physico-Mechanical and Hygro-Thermal Properties of Compressed Earth Blocks Stabilized with Industrial and Agro By-Product Stabilisers. Materials 2020, 13, 3769. [Google Scholar] [CrossRef]

- Ahmed, M.M.; El-Naggar, K.A.M.; Tarek, D.; Ragab, A.; Sameh, H.; Zeyad, A.M.; Tayeh, B.A.; Maafa, I.M.; Yousef, A. Fabrication of Thermal Insulation Geopolymer Bricks Using Ferrosilicon Slag and Alumina Waste. Case Stud. Constr. Mater. 2021, 15, e00737. [Google Scholar] [CrossRef]

- Rickard, W.D.A.; Van Riessen, A. Performance of Solid and Cellular Structured Fly Ash Geopolymers Exposed to a Simulated Fire. Cem. Concr. Compos. 2014, 48, 75–82. [Google Scholar] [CrossRef]

- Adam, E.A.; Jones, P.J. Thermophysical Properties of Stabilised Soil Building Blocks. Build. Environ. 1995, 30, 245–253. [Google Scholar] [CrossRef]

- Nikvar-Hassani, A.; Hodges, R.; Zhang, L. Production of Green Bricks from Low-Reactive Copper Mine Tailings: Durability and Environmental Aspects. Constr. Build. Mater. 2022, 337, 127571. [Google Scholar] [CrossRef]

- Paul, S.; Islam, M.S.; Elahi, T.E. Potential of Waste Rice Husk Ash and Cement in Making Compressed Stabilized Earth Blocks: Strength, Durability and Life Cycle Assessment. J. Build. Eng. 2023, 73, 106727. [Google Scholar] [CrossRef]

- Pang, Z.; Zhang, T.; Zheng, C.; Liu, S.; Xu, H. Preparation of Water-Based Drilling Cuttings Derived Non-Fired Bricks and Insights into Heavy Metal Fixation Mechanisms. Energy Sources Part A Recovery Util. Environ. Eff. 2025, 47, 8744–8757. [Google Scholar] [CrossRef]

- Gomes, K.C.; Carvalho, M.; Diniz, D.D.P.; Abrantes, R.D.C.C.; Branco, M.A.; Carvalho Junior, P.R.O.D. Carbon Emissions Associated with Two Types of Foundations: CP-II Portland Cement-Based Composite vs. Geopolymer Concrete. Matéria 2019, 24, e12525. [Google Scholar] [CrossRef]

- Talaat, A.; Emad, A.; Kohail, M. Environmental Impact Assessment for Performance-Oriented Geopolymer Concrete Research. J. Mater. Civ. Eng. 2023, 35, 04022370. [Google Scholar] [CrossRef]

- Cheng, L.; Kobayashi, T.; Shahin, M.A. Microbially Induced Calcite Precipitation for Production of “Bio-Bricks” Treated at Partial Saturation Condition. Constr. Build. Mater. 2020, 231, 117095. [Google Scholar] [CrossRef]

- Le, H.A.; Oanh, N.T.K. Integrated Assessment of Brick Kiln Emission Impacts on Air Quality. Env. Monit. Assess. 2010, 171, 381–394. [Google Scholar] [CrossRef]

- Muheise-Araalia, D.; Pavia, S. Properties of Unfired, Illitic-Clay Bricks for Sustainable Construction. Constr. Build. Mater. 2021, 268, 121118. [Google Scholar] [CrossRef]

- Mahmood, A.; Noman, M.T.; Pechočiaková, M.; Amor, N.; Petrů, M.; Abdelkader, M.; Militký, J.; Sozcu, S.; Hassan, S.Z.U. Geopolymers and Fiber-Reinforced Concrete Composites in Civil Engineering. Polymers 2021, 13, 2099. [Google Scholar] [CrossRef] [PubMed]

- Zami, M.S.; Lee, A. Economic Benefits of Contemporary Earth Construction in Low-Cost Urban Housing—State-of-the-Art Review. J. Build. Apprais. 2010, 5, 259–271. [Google Scholar] [CrossRef]

- Wong, P.Y.; Mal, J.; Sandak, A.; Luo, L.; Jian, J.; Pradhan, N. Advances in Microbial Self-Healing Concrete: A Critical Review of Mechanisms, Developments, and Future Directions. Sci. Total Environ. 2024, 947, 174553. [Google Scholar] [CrossRef]

- Guimarães, J.S.; Peixoto, M.S.; Sales, A.S.B. Biological Concrete, a Viable Alternative in Modern Civil Construction: Review. Inter. J. Sci. Manag. Tour. 2024, 10, e1233. [Google Scholar] [CrossRef]

- Ojha, A.; Kumar, A.; Das, D.; Bandyopadhyay, T.K. Bio-Concrete and Its Self-Healing Capacity to Next-Generation Sustainable Architecture: A Comprehensive Review. Exon 2025, 2, 1–5. [Google Scholar] [CrossRef]

- Keyvanfar, A.; Talaiekhozani, A.; Kamyab, H.; Ismail, M.; Ponraj, M.; Zaimi, M.; Mohamad, R. Bioconcrete Strength Durability Permeability Recycling and Effects on Human Health A Review. In Proceedings of the Third International Conference on Advances in Civil, Structural and Mechanical Engineering CSM 2015, Birmingham, UK, 27 May 2015; Institute of Research Engineers and Doctors: Birmingham, UK, 2015; pp. 1–9. [Google Scholar]

- Bhina, M.R.; Wibowo, A.H.; Liu, K.Y.; Khan, W.; Salim, M. An Overview on Bioconcrete and the Utilization of Microbes in Civil Engineering; Preprints.org: Basel, Switzerland, 2021. [Google Scholar]

- Kilani, A.; Fapohunda, C.; Adeleke, O.; Metiboba, C. Evaluating the Effects of Agricultural Wastes on Concrete and Composite Mechanical Properties: A Review. Res. Eng. Struct. Mat. 2022, 8, 307–336. [Google Scholar] [CrossRef]

- Solahuddin, B.A. A Comprehensive Review on Waste Paper Concrete. Results Eng. 2022, 16, 100740. [Google Scholar] [CrossRef]

- Fapohunda, C.; Akinbile, B.; Oyelade, A. A Review of the Properties, Structural Characteristics and Application Potentials of Concrete Containing Wood Waste as Partial Replacement of One of Its Constituent Material. YBL J. Built Environ. 2018, 6, 63–85. [Google Scholar] [CrossRef]

- Mo, K.H.; Thomas, B.S.; Yap, S.P.; Abutaha, F.; Tan, C.G. Viability of Agricultural Wastes as Substitute of Natural Aggregate in Concrete: A Review on the Durability-Related Properties. J. Clean. Prod. 2020, 275, 123062. [Google Scholar] [CrossRef]

| Stabiliser System | Compressive Strength (MPa) | Flexural Strength (MPa) | Water Absorption (%) | Thermal Conductivity (W/m·K) | Drying Shrinkage (%) | Freeze–Thaw Strength Loss (%) | References |

|---|---|---|---|---|---|---|---|

| Cement-based | ~2.5–7.4 MPa (with 4–10% cement)–higher with more cement | ~1.2 MPa (with 10% cement) | ~10% (low if well-compacted) | 0.40–1.20 W/m·K (range for CSEBs) | ~0.1% (typical allowable limit) | ~6% mass loss after standard F-T cycles (significantly lower than unstabilized soil) | [27,28,29,30] |

| Geopolymer-based | ~14 MPa (fly ash geopolymer brick, ambient cured) | ~3.4 MPa (for ~18 MPa compressive brick) | ~8–12% (generally low) | 0.42–0.46 W/m·K (typical range) | –n/a (no notable drying shrinkage reported) | ~30% strength loss after 150 F-T cycles (excellent durability vs. OPC concrete) | [31,32,33] |

| Lime-based | ~16.5 MPa (28-day, 10% lime stabilization) | ~0.5–1.0 MPa (lower than cement-stabilized) | ~12–18% (higher porosity than cement) | ~0.5–0.8 W/m·K (estimated, slightly lower than cement) | ~0.2% (reduces raw clay shrinkage markedly) | Moderately durable; e.g., mass loss ~7.7% (lime) vs. 5.6% (cement) after drying; less freeze–thaw resistance than OPC-stabilized | [34,35] |

| Bio-stabiliser/MICP | ~9 MPa (partially saturated microbial CaCO3 curing) | –n/a (brittle, not typically reported) | ~5–10% (MICP reduces pore absorption) | –n/a (assumed similar to base soil) | –n/a (minimal drying shrinkage) | –n/a | [36,37,38] |

| Ceramic waste-based | ~25 MPa (alkali-activated ceramic waste stabiliser) | –n/a | ~10% (comparable to clay brick) | ~0.45 W/m·K (comparable to geopolymer brick) | –n/a | High durability | [32,39] |

| Brick Type/Mix | 7-Day Shrinkage (%) | 28-Day Shrinkage (%) | 90-Day Shrinkage (%) | 180-Day Shrinkage (%) | References |

|---|---|---|---|---|---|

| 100% Cement (~10%) | 0.2 | 0.3 | 0.35 | 0.4 | [53,54] |

| 50% cement + 50% Fly Ash | 0.18 | 0.25 | 0.3 | 0.32 | [55] |

| Lime-based (~10% Lime) | 0.25 | 0.4 | 0.45 | 0.5 | [35] |

| Geopolymer-based | 0.15 | 0.22 | 0.25 | 0.27 | [56] |

| 1% Areca fiber +2.5% Cement | 0.02 | 0.1 | 0.1 | 0.1 | [52] |

| Parameter | Fired Clay Brick | Unfired Brick | Improvement (Using Unfired) | Reference |

|---|---|---|---|---|

| CO2 Emissions (production of 1000 bricks) | ~5907 kg CO2e | ~0 kg CO2e (no kiln firing) | ~5907 kg reduction (nearly 100% cut in production emissions) | [18] |

| Life-cycle CO2 Footprint (per brick) | 290 g CO2e/brick | 43.3 g CO2e/brick | 85% lower net carbon footprint per brick | [17] |

| Embodied Energy (manufacturing 1000 bricks) | ~5305 MJ | ~0 MJ (sun-dried; no fossil fuel) | ~5305 MJ saved (essentially eliminated firing energy) | [18] |

| SO2 Emissions (kg/1000 bricks) | 0.5–5.9 kg SO2 | ~0 kg SO2 | 100% elimination of SO2 emissions | [68] |

| Particulate (PM) Emissions (kg/1000 bricks) | 0.64–1.4 kg PM | ~0 kg PM | 100% elimination of PM2.5 and dust emissions | [68] |

| Waste Material Utilization | Mainly virgin clay (natural soil); typically <15% waste additives | Can incorporate ≥60% industrial wastes (fly ash, slag, etc.) | Much higher reuse of waste resources (diverts waste from landfill) | [46] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Abuel-Naga, H. Unfired Bricks from Wastes: A Review of Stabiliser Technologies, Performance Metrics, and Circular Economy Pathways. Buildings 2025, 15, 1861. https://doi.org/10.3390/buildings15111861

Wang Y, Abuel-Naga H. Unfired Bricks from Wastes: A Review of Stabiliser Technologies, Performance Metrics, and Circular Economy Pathways. Buildings. 2025; 15(11):1861. https://doi.org/10.3390/buildings15111861

Chicago/Turabian StyleWang, Yuxin (Justin), and Hossam Abuel-Naga. 2025. "Unfired Bricks from Wastes: A Review of Stabiliser Technologies, Performance Metrics, and Circular Economy Pathways" Buildings 15, no. 11: 1861. https://doi.org/10.3390/buildings15111861

APA StyleWang, Y., & Abuel-Naga, H. (2025). Unfired Bricks from Wastes: A Review of Stabiliser Technologies, Performance Metrics, and Circular Economy Pathways. Buildings, 15(11), 1861. https://doi.org/10.3390/buildings15111861