Carbon Emission Analysis of Tunnel Construction of Pumped Storage Power Station with Drilling and Blasting Method Based on Discrete Event Simulation

Abstract

1. Introduction

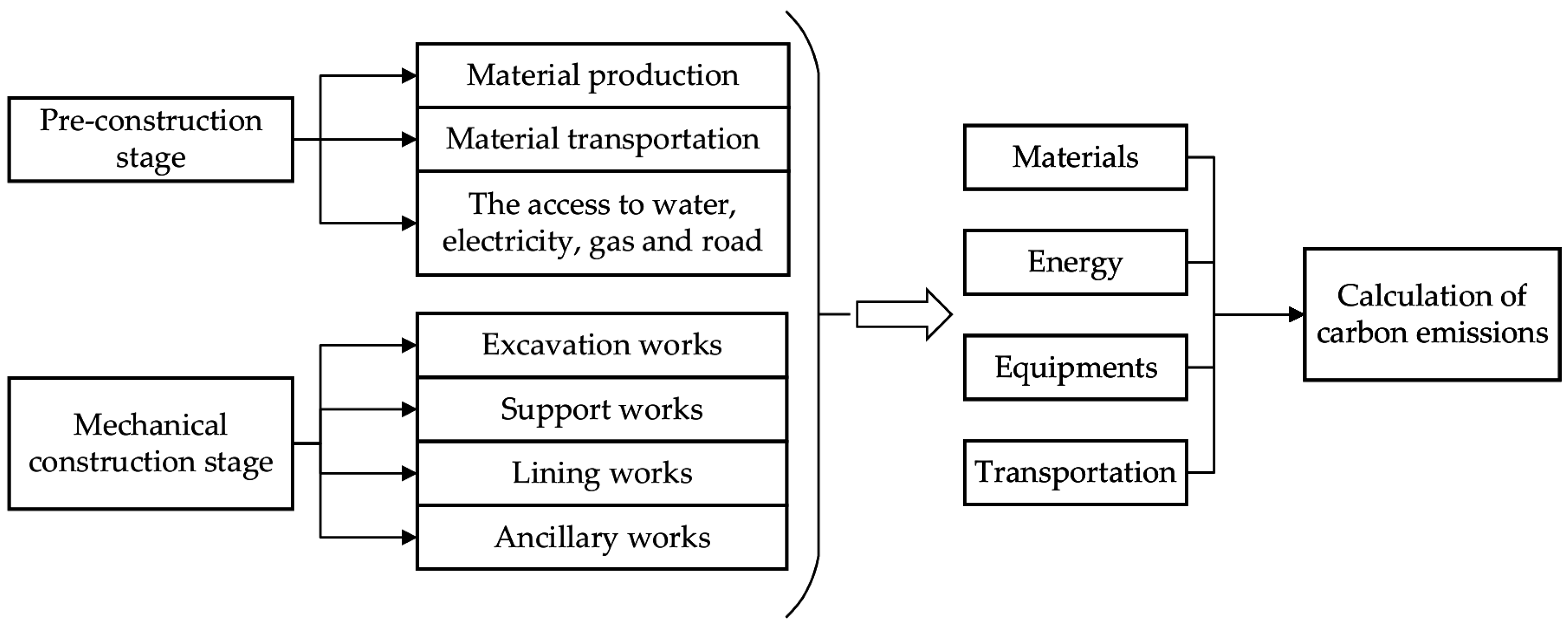

2. Carbon Emission Calculation Model for Tunnel Construction

2.1. General LCA-Based Model for Tunnel Construction

- (1)

- Material production stage: Carbon emissions in this stage are calculated as the sum of emissions from each material type, obtained by multiplying material consumption by its corresponding carbon emission factor. Based on the bill of quantities, emissions for this stage can be determined using Equation (2).where Mi is the consumption of the ith material; βi is the carbon emission factor corresponding to the ith material.

- (2)

- Material transportation stage: Carbon emissions in this stage primarily result from the energy consumed by transport vehicles moving materials from their source to the construction site, including on-site transportation and material handling. Key parameters such as material volume, transport distance, mode of transport, and duration are determined by project scale and construction experience. Using fuel consumption data from the Quota of Hourly Costs for Hydropower Construction Machinery (Trial Version) [35], total fuel usage is multiplied by the corresponding carbon emission factor to calculate emissions for this stage, as expressed in Equation (3).where γj is the carbon emission factor of the jth type of fuel; Mj is the consumption of the jth type of fuel; Mit is the total weight of the ith type of goods; Mc is the load capacity of the vehicle; Li is the transportation distance of the ith type of engineering materials; v is the average transportation speed of the transportation vehicle; αj is the amount of the jth fuel consumed per vehicle shift (8 h).

- (3)

- Mechanical construction stage: Carbon emissions in this stage are calculated using the energy consumption index of construction machinery from the Quota of Hourly Costs for Hydropower Construction Machinery (Trial Version) [35]. The operating time of each machine is determined by analyzing the actual work volume and corresponding equipment productivity. Emissions for this stage are then calculated using Equation (4).where γk is the carbon emission factor of the kth energy source; Mk is the consumption of the kth energy source; Vlt is the total volume of the lth construction task; tr,l is the productivity of the rth type of machinery in the lth construction task; and αr,k is the amount of the kth energy source consumed by the rth type of machinery per shift (8 h).

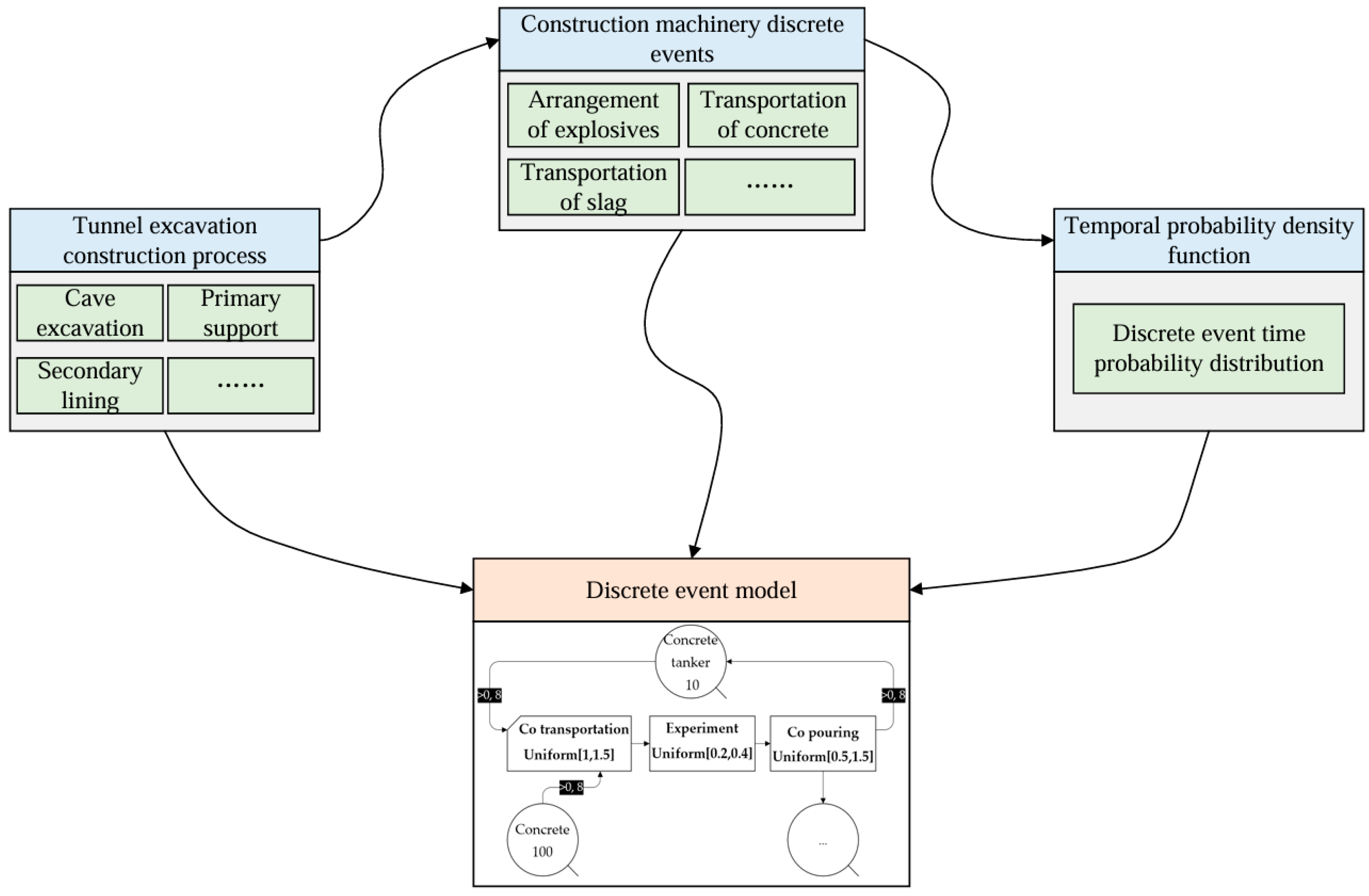

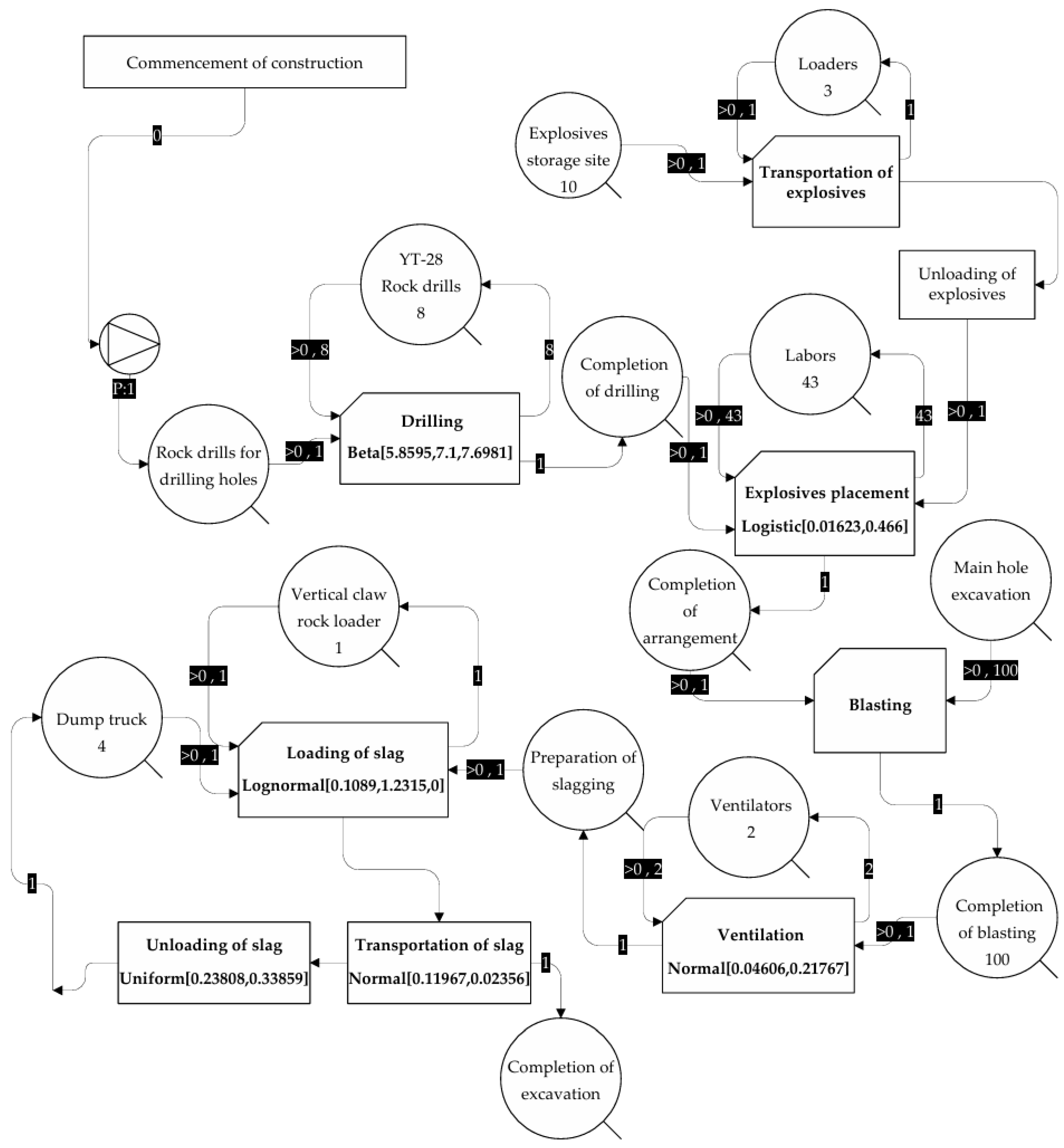

2.2. DES-Based Model for Mechanical Construction Stage

2.2.1. Modeling Process

- (1)

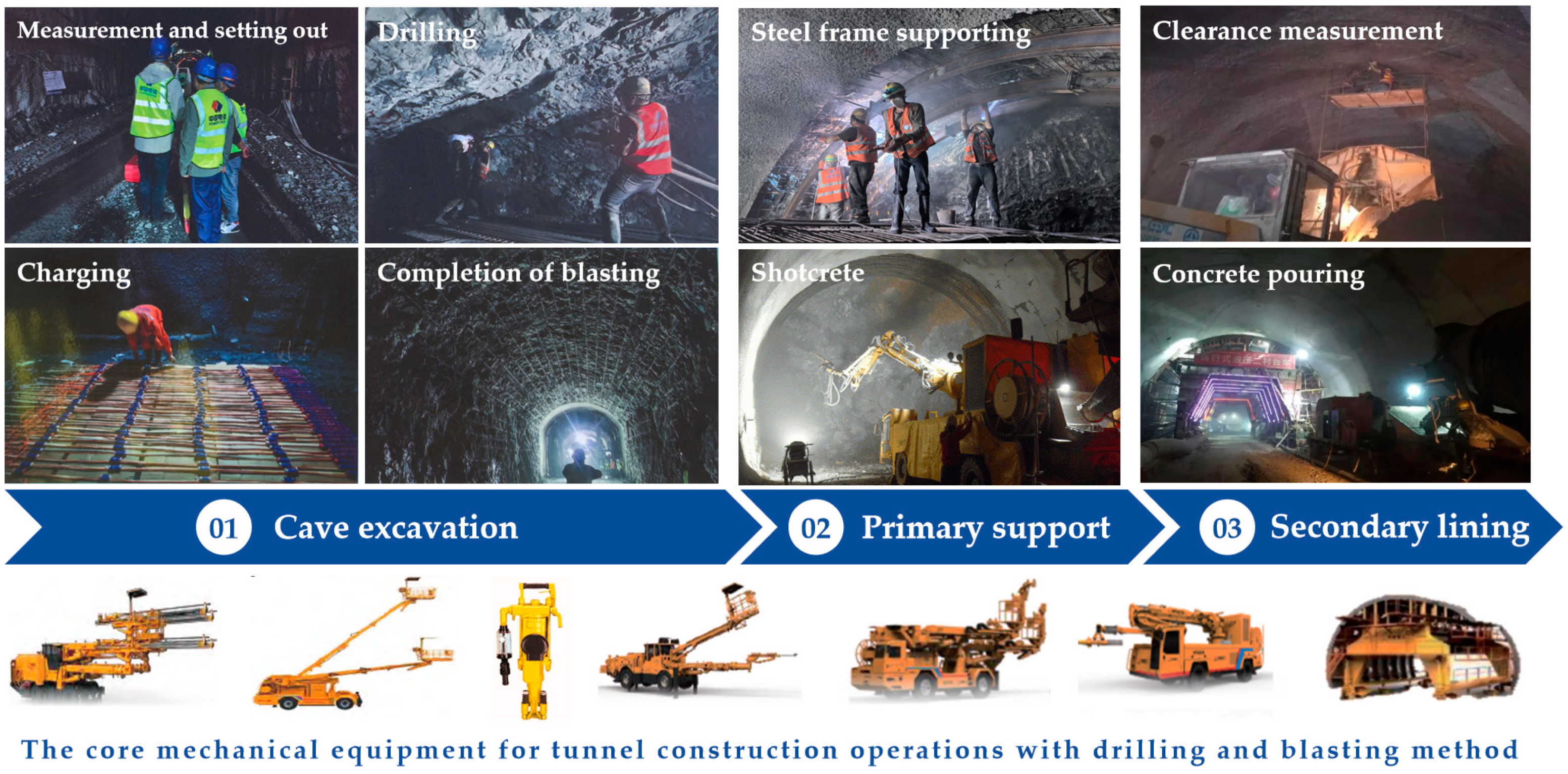

- Defining the tunnel excavation sequence: On-site construction primarily includes tunnel excavation using the drilling and blasting method, primary support, and secondary lining. As construction machinery and resources are discretely distributed across these processes, discrete event modeling by the construction process is necessary.

- (2)

- Separating construction machinery discrete events: After defining the construction sequence, discrete events associated with the machinery required for each stage must be identified. These events are categorized into three types: queuing events, conditional events, and execution events.

- (3)

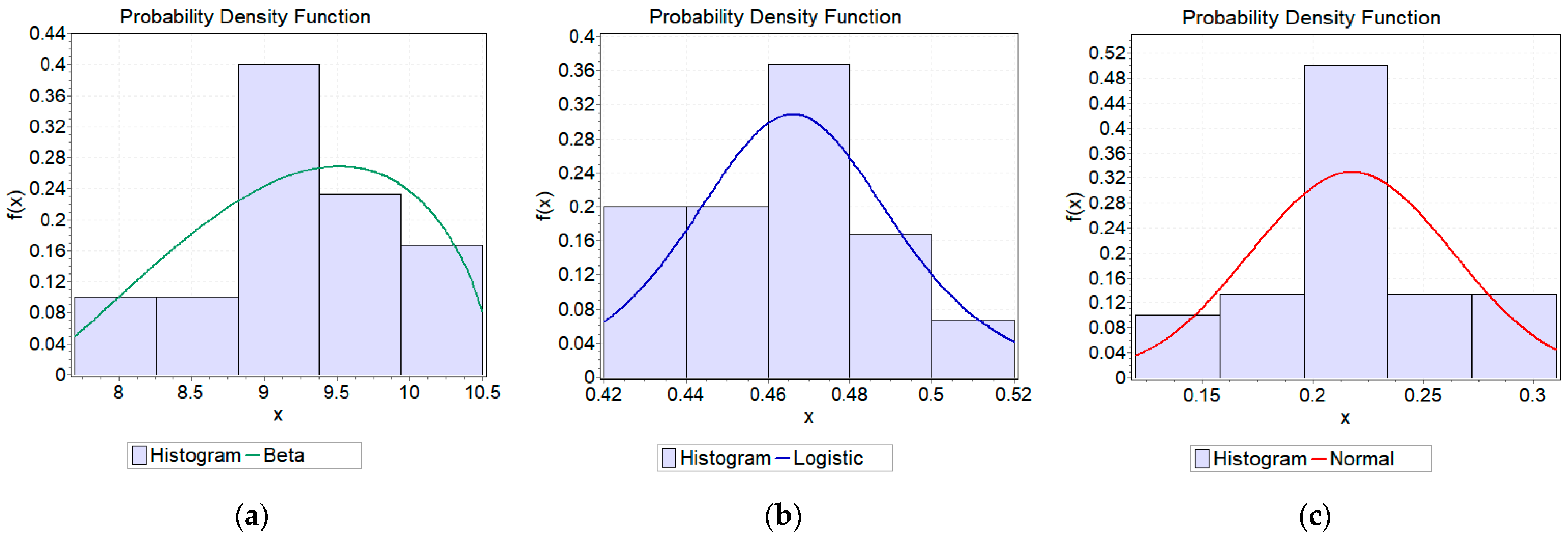

- Determining the probability density functions of time: By collecting construction data and analyzing surveillance footage, the operating and idle times of machinery during each stage are statistically analyzed. These time parameters are then abstracted into probability density distribution functions for use in the model.

2.2.2. Model Formulation

2.2.3. Carbon Emission Factors

3. Case Study on Carbon Emission Assessment of Pumped Storage Tunnel Construction

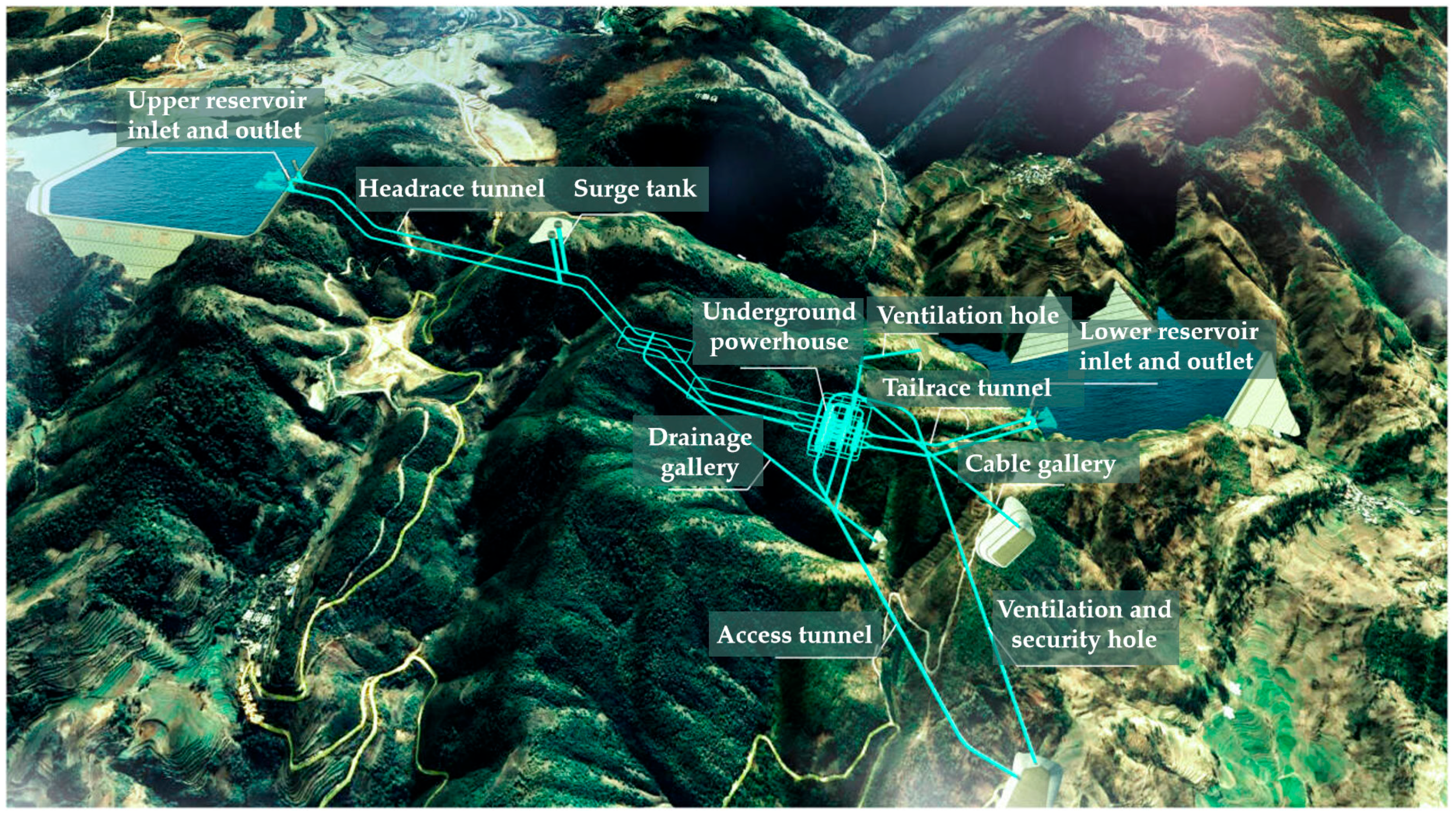

3.1. Project Overview

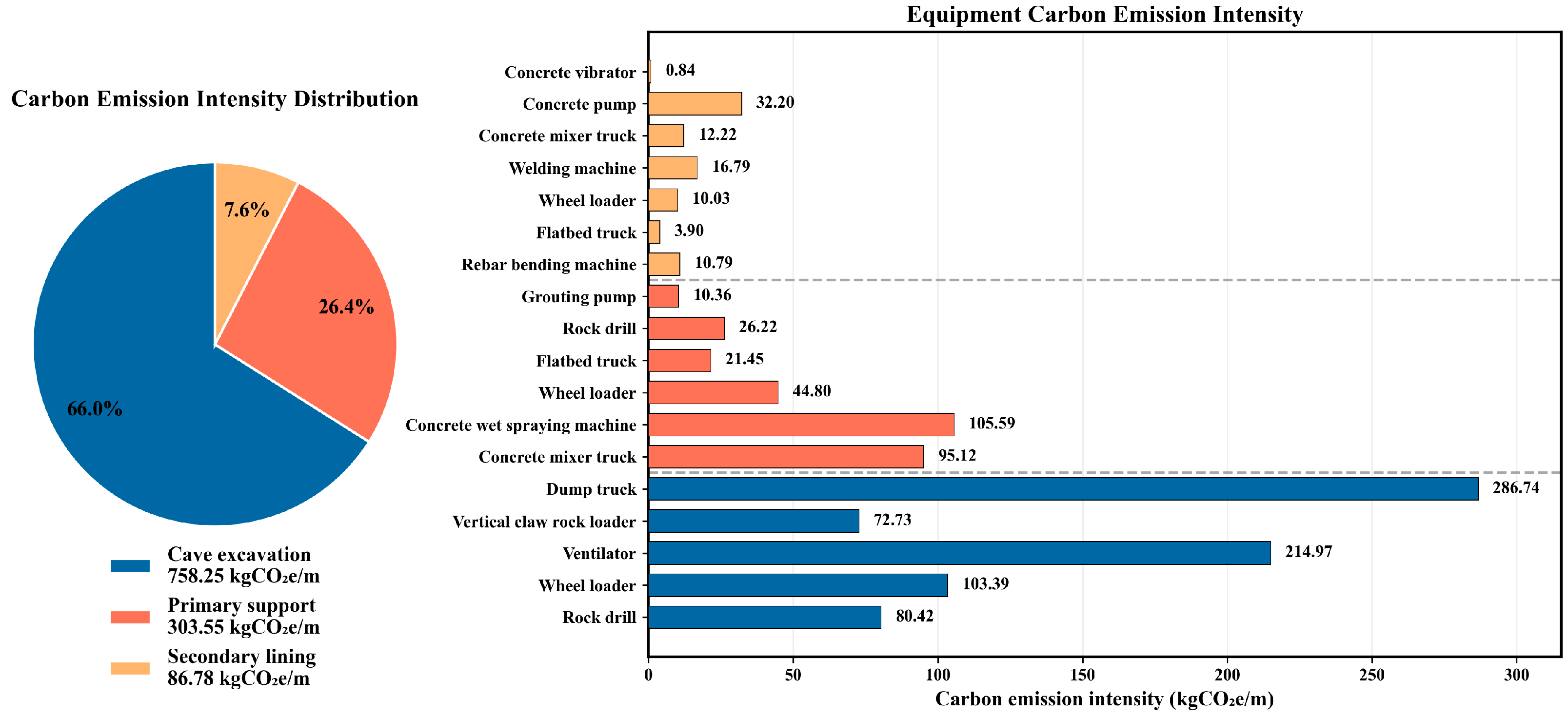

3.2. Carbon Emission Intensity Assessment

3.2.1. LCA-Based Assessment for Pre-Construction Stage

3.2.2. DES-Based Assessment for Mechanical Construction Stage

3.2.3. Summary of Carbon Emission Results

3.3. DES Model and Carbon Emission Results Validation

3.3.1. Model Validation

3.3.2. Carbon Emission Results Validation

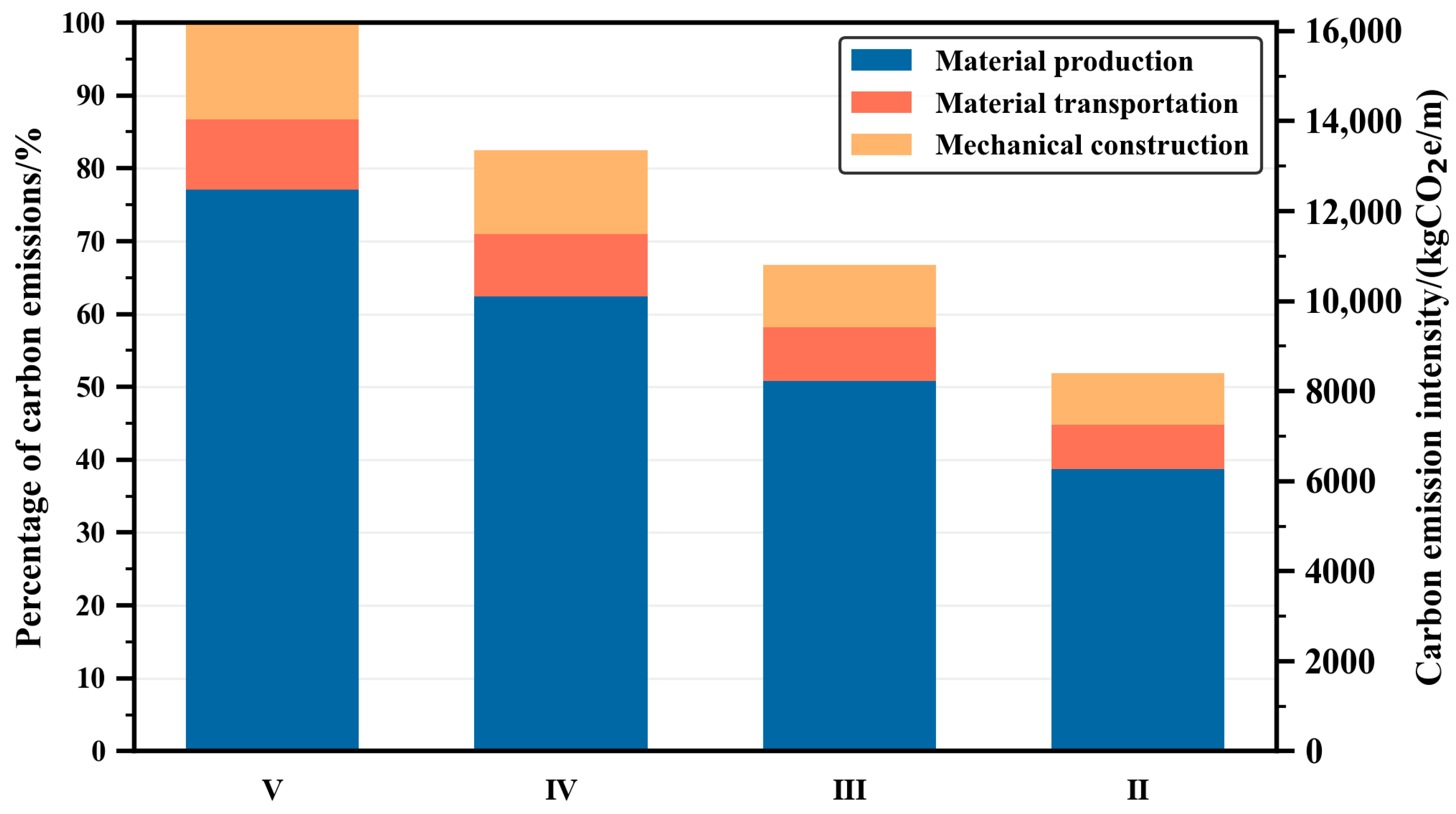

3.4. Carbon Emission Comparison with Different Surrounding Rock Grades

3.5. Total Carbon Emissions of the Water Conveyance Tunnel System

4. Discussion

4.1. Uncertainty Analysis in Carbon Emission Assessment

4.2. Carbon Reduction Strategies in Tunnel Construction

- (1)

- Use of Energy-Efficient Equipment and Regular Maintenance

- (2)

- Optimize excavation zones and construction paths

- (3)

- Incorporating intelligent technologies for real-time carbon monitoring

4.3. Limitations of Calculation Results

5. Conclusions

- (1)

- A hybrid carbon emission calculation model is developed for the construction phase of pumped storage tunnel projects by integrating the carbon emission factor method with a combined LCA-DES model. The proposed method incorporates the dynamic characteristics of construction activities through DES. This integration enables more precise estimation of carbon emissions across varying geological conditions, particularly during the mechanical construction stage.

- (2)

- Based on the Fumin Pumped Storage Power Project, carbon emissions during the construction phase are evaluated under different rock conditions using the DES method. Validation against monitoring data revealed a 1.3% deviation in dump truck operations, while the difference using LCA reached 19.5%, demonstrating the superior accuracy of DES. The results indicate that emission intensity increases as rock quality deteriorates, from 8405.82 kgCO2e/m for Class II to 16,189.30 kgCO2e/m for Class V, primarily due to higher energy and equipment demands. The total carbon emissions for the water conveyance system during the construction phase are 40,019.64 tCO2e.

- (3)

- Carbon emissions from the material production stage contribute approximately 75% of the total emissions during tunnel construction and represent the most influential component in determining overall carbon output. Carbon emission reduction can be achieved through the adoption of energy-efficient equipment, regular maintenance practices, optimized excavation planning and routing, and the integration of smart technologies for real-time carbon monitoring and control.

- (4)

- Admittedly, this study is subject to operational variability and uncertainty in key parameters, which may result in deviations in carbon emission estimates. The generalizability of the findings is also limited. Future research could integrate construction-site big data analytics to establish project-specific equipment energy parameters and localized emission factors, thereby enhancing the precision of carbon emission estimates.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| GHG | Greenhouse gas |

| LCA | Life cycle assessment |

| DES | Discrete event simulation |

| RMR | Rock mass rating |

References

- Guo, Y.L.; Sun, W.H.; Xu, H.W.; He, W.; Chen, Z.; Guo, C. Comparison between Shield Method and Drill and Blast Method Regarding Carbon Emission Intensity in Subway Tunnel Construction. Mod. Tunn. Technol. 2023, 60, 14–23+64. [Google Scholar]

- Zeng, H.R.; Sun, W.H.; He, W.; Guo, Y.L.; Guo, C. Study on the Carbon Emission Prediction Model for Railway Tunnel Construction Based on Machine Learning. Mod. Tunn. Technol. 2023, 60, 29–39. [Google Scholar]

- Evro, S.; Oni, B.A.; Tomomewo, O.S. Global Strategies for a Low-carbon Future: Lessons from the US, China, and EU’s Pursuit of Carbon Neutrality. J. Clean. Prod. 2024, 461, 142635. [Google Scholar] [CrossRef]

- Chen, L.Y.; Gao, X.; Hua, C.X.; Gao, S.T.; Yue, A.B. Evolutionary Process of Promoting Green Building Technologies Adoption in China: A Perspective of Government. J. Clean. Prod. 2021, 279, 123607. [Google Scholar] [CrossRef]

- Zhu, Q.R.; Leibowicz, B.D.; Busby, J.W.; Shidore, S.; Adelman, D.E.; Olmstead, S.M. Enhancing Policy Realism in Energy System Optimization Models: Politically Feasible Decarbonization Pathways for the United States. Energy Policy 2022, 161, 112754. [Google Scholar] [CrossRef]

- Bahn-Walkowiak, B.; Magrini, C.; Berg, H.; Gözet, B.; O’Brien, M.; Arjomandi, T.; Doranova, A.; Gallou, M.T.; Gionfra, S.; Graf, V.; et al. Eco-Innovation and Digitalisation: Case Studies, Environmental and Policy Lessons from EU Member States for the EU Green Deal and the Circular Economy: EIO Biennial Report 2020; European Commission: Brussels, Belgium, 2021; pp. 1–99. [Google Scholar]

- Xi Jinping’s Speech at the General Debate of the Seventy-Fifth United Nations General Assembly. Available online: https://www.xinhuanet.com/politics/leaders/2020-09/22/c_1126527652.htm (accessed on 20 February 2025).

- Şentürk, Z. The Energy Charter Treaty and the European Green Deal: A Critical Analysis Under EU and International Trade Law. In The EU Green Deal and Its Implementation, 1st ed.; Nomos Verlagsgesellschaft: Baden, Germany, 2023; pp. 157–184. [Google Scholar]

- Joseph, V.R.; Mustaffa, N.K. Carbon Emissions Management in Construction Operations: A Systematic Review. Eng. Constr. Archit. Manag. 2023, 30, 1271–1299. [Google Scholar] [CrossRef]

- De La Peña, L.; Guo, R.; Cao, X.J.; Ni, X.J.; Zhang, W. Accelerating the energy transition to achieve carbon neutrality. Resour. Conserv. Recycl. 2022, 177, 105957. [Google Scholar] [CrossRef]

- Amin, A.; Altinoz, B.; Dogan, E. Analyzing the Determinants of Carbon Emissions from Transportation in European Countries: The Role of Renewable Energy and Urbanization. Clean Technol. Environ. Policy 2020, 22, 1725–1734. [Google Scholar] [CrossRef]

- Yang, R.P.; Fan, Z.T. Application and Prospects of Pumped-storage Power Stations in New Power System. Sino-Glob. Energy 2023, 28, 12–17. [Google Scholar]

- China’s Pumped-Storage Hydropower Capacity Ranks First in the World. Available online: https://digitalpaper.stdaily.com/http_www.kjrb.com/kjrb/html/2024-09/10/content_577419.htm (accessed on 20 February 2025).

- Zhang, Y.J.; Jiang, L.; Shi, W. Exploring the Growth-adjusted Energy-emission Efficiency of Transportation Industry in China. Energy Econ. 2020, 90, 104873. [Google Scholar] [CrossRef]

- Li, Y.L.; Xie, P.P.; Yang, Y.; Yang, Y.G.; Lu, Q.Y. Life Cycle Carbon Emission Characteristics of Pumped Storage and New Energy Storage. In Proceedings of the IET Conference Proceedings CP910, Stevenage, UK, 14–15 December 2024. [Google Scholar]

- Rodríguez, R.; Pérez, F. Carbon Foot Print Evaluation in Tunneling Construction Using Conventional Methods. Tunn. Undergr. Space Technol. 2021, 108, 103704. [Google Scholar] [CrossRef]

- Pritchard, J.A.; Preston, J. Understanding the Contribution of Tunnels to the Overall Energy Consumption of and Carbon Emissions from a Railway. Transp. Res. Part D Transp. Environ. 2018, 65, 551–563. [Google Scholar] [CrossRef]

- Jarast, P.; Bakhshi, M. Carbon footprint emissions of different tunneling construction methods. In Expanding Underground-Knowledge and Passion to Make a Positive Impact on the World, 1st ed.; CRC Press: Boca Raton, FL, USA, 2023; pp. 65–73. [Google Scholar]

- Taylor, R.M.; Chanudet, V.; Drommi, J.L.; Aelbrecht, D. Assessing the carbon footprint of pumped storage hydropower—A case study. In Role of Dams and Reservoirs in a Successful Energy Transition, 1st ed.; CRC Press: Boca Raton, FL, USA, 2023; pp. 590–599. [Google Scholar]

- Lee, J.; Shim, J.A.; Kim, K.J. Analysis of Environmental Load by Work Classification for NATM Tunnels. KSCE J. Civ. Environ. Eng. Res. 2016, 36, 307–315. [Google Scholar]

- Xu, J.F.; Guo, C.; Chen, X.F.; Zhang, Z.H.; Yang, L.; Wang, M.N.; Yang, K. Emission Transition of Greenhouse Gases with the Surrounding Rock Weakened—A Case Study of Tunnel Construction. J. Clean. Prod. 2019, 209, 169–179. [Google Scholar] [CrossRef]

- Damián, R.; Zamorano, C.I. Environmental Impact Assessment of High-speed Railway Tunnel Construction: A Case Study for Five Different Rock Mass Rating Classes. Transp. Geotech. 2022, 36, 100817. [Google Scholar] [CrossRef]

- Li, J.H.; Xi, M.X.; Shen, Y.; Lu, A.; Zhu, H.H. Calculation and Composition Assessment of the Carbon Emission in the Construction Phase of Highway Tunnels Based on SimaPro. Mod. Tunn. Technol. 2023, 60, 20–28. [Google Scholar]

- Wu, H.Y.; Zhou, W.W.; Bao, Z.K.; Long, W.J.; Chen, K.Y.; Liu, K. Life Cycle Assessment of Carbon Emissions for Cross-sea Tunnel: A Case Study of Shenzhen-Zhongshan Bridge and Tunnel in China. Case Stud. Constr. Mater. 2024, 21, e03502. [Google Scholar] [CrossRef]

- Huang, Y.Q.; Liu, Y.R.; Xu, W.B.; Li, J.F. Life cycle carbon emissions of water reservoir and hydroelectric projects: A case study of the Quanmutang project. J. Tsinghua Univ. (Sci. Technol.) 2022, 62, 1366–1373. [Google Scholar]

- Xu, S.M.; Zhang, G.; Wang, F.; Pu, L. Carbon Emission Reduction Calculation Method for Pumped Storage Based on CCER Rules. Electr. Power 2024, 57, 175–182. [Google Scholar]

- Li, Z.; Du, H.L.; Xiao, Y.; Guo, J.S. Carbon footprints of two large hydro-projects in China: Life-cycle assessment according to ISO/TS 14067. Renew. Energy 2017, 114, 534–546. [Google Scholar] [CrossRef]

- Yang, T.; Dong, Y.; Tang, B. Developing a dynamic life cycle assessment framework for buildings through integrating building information modeling and building energy modeling program. Sci. Total Environ. 2024, 946, 174284. [Google Scholar] [CrossRef] [PubMed]

- Martinez, J.C. Methodology for Conducting Discrete Event Simulation Studies in Construction Engineering and Management. J. Constr. Eng. Manag. 2010, 136, 3–16. [Google Scholar] [CrossRef]

- AbouRizk, S.M.; Hajjar, D. A Framework for Applying Simulation in Construction. Can. J. Civ. Eng. 1998, 25, 604–617. [Google Scholar] [CrossRef]

- Pena-Mora, F.; Han, S.W.; Lee, S.H.; Park, M. Strategic-Operational Construction Management: Hybrid System Dynamics and Discrete Event Approach. J. Constr. Eng. Manag. 2008, 9, 701–710. [Google Scholar] [CrossRef]

- González, V.; Echaveguren, T. Exploring the Environmental Modeling of Road Construction Operations Using Discrete-event Simulation. Autom. Constr. 2012, 24, 100–110. [Google Scholar] [CrossRef]

- Lewis, P.; Leming, M.; Rasdorf, W. Impact of Engine Idling on Fuel Use and CO2 Emissions of Nonroad Diesel Construction Equipment. J. Manag. Eng. 2011, 28, 31–38. [Google Scholar] [CrossRef]

- Liu, C.N. Research on Evaluating Methods for Carbon Emissions of Concrete Dams Based on Life Cycle Assessment. Master’s Thesis, Tsinghua University, Beijing, China, 2013. [Google Scholar]

- China Renewable Energy Engineering Institute; China Electricity Council. Quota of Hourly Costs for Hydropower Construction Machinery (Trial Version); China Electric Power Press: Beijing, China, 2024. [Google Scholar]

- GB/T 51366–2019; Standard for Calculation of Building Carbon Emission. China Construction Industry Press: Beijing, China, 2019.

- Lai, W.; Qin, J.; Pan, Y.; Zhang, Y. Efficient Online Calculation and Reduction Measures for Metro Foundation Pit Carbon Emission. J. Shanghai Jiao Tong Univ. 2025, 1, 1–21. [Google Scholar]

- Hou, G.Y.; Ma, X.Y.; Yang, Z.H. Calculation and Analysis of Carbon Emissions in the Whole Life Cycle of Pumped Storage Power Stations. J. Environ. Sci. 2023, 43, 326–335. [Google Scholar]

- Miller, L.H. Table of Percentage Points of Kolmogorov Statistics. J. Am. Stat. Assoc. 1956, 51, 111–121. [Google Scholar] [CrossRef]

- Liu, C.; Wu, Q.; Tang, W. Carbon Emission Evaluation of Heavy Equipment on Dam Construction Site Using Discrete Event Simulation. IOP Conf. Ser. Earth Environ. Sci. 2021, 675, 012027. [Google Scholar] [CrossRef]

| Energy Source | Carbon Emission Factor | Unit | Reference |

|---|---|---|---|

| Electricity | 0.80 | kgCO2e/kWh | [36,37] |

| Diesel | 3.59 | kgCO2e/kg | [25,36,38] |

| Gasoline | 3.50 | kgCO2e/kg | [25,36,38] |

| Material | Carbon Emission Factor | Unit | Reference |

|---|---|---|---|

| Plain steel plate | 2.43 | kgCO2e/kg | [1,36] |

| Galvanized steel plate | 2.60 | kgCO2e/kg | [1,36] |

| Small and medium steel products (rebar, steel wire) | 2.31 | kgCO2e/kg | [1,36] |

| Ammonium nitrate explosive | 0.263 | kgCO2e/kg | [36] |

| C20 concrete | 237.32 | kgCO2e/m3 | [1,36] |

| C25 concrete | 266.18 | kgCO2e/m3 | [1,36] |

| C30 concrete | 294.81 | kgCO2e/m3 | [1,36] |

| Cement mortar | 400.94 | kgCO2e/m3 | [1,36] |

| Sand | 6.60 | kgCO2e/t | [1,36] |

| Gravel | 4.40 | kgCO2e/t | [1,36] |

| Substructure Item | Material Consumption per Meter | Material Production | Material Transportation | |||

|---|---|---|---|---|---|---|

| Carbon Emission Factor (kgCO2e/kg or m3) | Carbon Emissions Intensity (kgCO2e/m) | Average Transport Distance (km) | Diesel Consumption (kg) | Carbon Emissions Intensity (kgCO2e/m) | ||

| Ammonium nitrate explosive installation | 14.13 kg | 0.263 | 3.72 | 500.00 | 0.32 | 1.14 |

| Shotcrete support | 6.37 m3 | 237.32 | 1511.73 | 40.00 | 78.07 | 280.28 |

| Rock bolt support | 103.99 kg | 2.31 | 240.21 | 500.00 | 2.35 | 8.42 |

| Steel mesh reinforcement | 169.22 kg | 2.31 | 390.90 | 500.00 | 3.82 | 13.71 |

| Concrete pouring (crown arch) | 9.83 m3 | 266.18 | 2616.55 | 40.00 | 120.48 | 432.52 |

| Steel reinforcement (crown arch) | 3.45 kg | 2.31 | 7.97 | 500.00 | 0.08 | 0.28 |

| Concrete pouring (side wall) | 5.62 m3 | 266.18 | 1495.93 | 40.00 | 68.88 | 247.28 |

| Steel reinforcement (side wall) | 2.76 kg | 2.31 | 6.38 | 500.00 | 0.06 | 0.22 |

| Total | - | - | 6273.39 | - | - | 983.85 |

| Event Activities | Time Distribution | Parameters | K–S |

|---|---|---|---|

| Rock drill drilling | Beta | 5.8598, 7.1, 7.6891 | 0.093 |

| Explosive placement | Logistic | 0.01623, 0.466 | 0.161 |

| Ventilation | Normal | 0.04606, 0.21767 | 0.135 |

| Loading of slag | Lognormal | 0.10889, 1.2315, 0 | 0.193 |

| Transportation of slag | Normal | 0.11967, 0.02356 | 0.148 |

| Unloading of slag | Uniform | 0.23808, 0.33859 | 0.150 |

| Mechanical and Equipment | Energy Consumption per Shift (kg or kWh/8 h) | Quantity of Equipment | Shifts per Unit | Total Diesel Consumption (kg) | Total Electricity Consumption (kWh) | Carbon Emissions (kgCO2e) |

|---|---|---|---|---|---|---|

| Rock drill | 22.65 kWh | 8 | 1.150 | \ | 208.38 | 201.05 |

| Wheel loader | 160 kg | 3 | 0.125 | 60 | \ | 258.48 |

| Ventilator | 528 kWh | 2 | 0.563 | \ | 557.04 | 537.43 |

| Vertical claw rock loader | 50.40 kg/110 kWh | 1 | 0.563 | 28.35 | 61.90 | 181.82 |

| Dump truck | 128 kg | 4 | 0.325 | 166.4 | \ | 716.85 |

| Mechanical and Equipment | Energy Consumption per Shift (kg or kWh/8 h) | Quantity of Equipment | Shifts per Unit | Total Diesel Consumption (kg) | Total Electricity Consumption (kWh) | Carbon Emissions (kgCO2e) |

|---|---|---|---|---|---|---|

| Concrete mixer truck | 96 kg | 2 | 0.288 | 55.20 | \ | 237.80 |

| Concrete wet spraying machine | 243.2 kWh | 2 | 0.563 | \ | 273.60 | 263.97 |

| Wheel loader | 160 kg | 1 | 0.163 | 26.00 | \ | 112.01 |

| Flatbed truck | 99.6 kg | 2 | 0.063 | 12.45 | \ | 53.63 |

| Rock drill | 22.65 kWh | 8 | 0.375 | \ | 67.95 | 65.56 |

| Grouting pump | 143.2 kWh | 1 | 0.188 | \ | 26.85 | 25.90 |

| Mechanical and Equipment | Energy Consumption per Shift (kg or kWh/8 h) | Quantity of Equipment | Shifts per Unit | Total Diesel Consumption (kg) | Total Electricity Consumption (kWh) | Carbon Emissions (kgCO2e) |

|---|---|---|---|---|---|---|

| Rebar bending machine | 48 kWh | 2 | 0.291 | \ | 27.96 | 26.98 |

| Flatbed truck | 99.6 kg | 2 | 0.051 | 10.11 | \ | 9.75 |

| Wheel loader | 160 kg | 1 | 0.163 | \ | 26.00 | 25.08 |

| Welding machine | 85.52 kWh | 1 | 0.509 | \ | 43.51 | 41.98 |

| Concrete mixer truck | 96 kg | 2 | 0.165 | 31.68 | \ | 30.56 |

| Concrete pump | 216 kWh | 1 | 0.386 | \ | 83.43 | 80.49 |

| Concrete vibrator | 16 kWh | 2 | 0.068 | \ | 2.19 | 2.11 |

| Substructure Item | Material Consumption per Meter | Total Carbon Emissions Intensity (kgCO2e/m) | Material Production | Material Transportation | Mechanical Construction | |||

|---|---|---|---|---|---|---|---|---|

| Carbon Emission Intensity (kgCO2e/m) | Proportion (%) | Carbon Emission Intensity (kgCO2e/m) | Proportion (%) | Carbon Emission Intensity (kgCO2e/m) | Proportion (%) | |||

| Ammonium nitrate explosive installation | 14.13 kg | 205.91 | 3.72 | 1.81 | 1.14 | 0.55 | 201.05 | 97.64 |

| Rock excavation | 28.26 m3 | 557.20 | 0.00 | 0.00 | 0.00 | 0.00 | 557.20 | 100.00 |

| Shotcrete support | 6.37 m3 | 1992.72 | 1511.73 | 76.86 | 280.28 | 14.07 | 200.71 | 10.07 |

| Rock bolt support | 103.99 kg | 320.91 | 240.21 | 74.85 | 8.42 | 2.63 | 72.28 | 22.52 |

| Steel mesh reinforcement | 169.22 kg | 435.17 | 390.90 | 89.83 | 13.71 | 3.15 | 30.56 | 7.02 |

| Concrete pouring (crown arch) | 9.83 m3 | 3075.37 | 2616.55 | 85.08 | 432.52 | 14.06 | 26.30 | 0.86 |

| Steel reinforcement (crown arch) | 3.45 kg | 26.95 | 7.97 | 29.57 | 0.28 | 1.04 | 18.70 | 69.39 |

| Concrete pouring (side wall) | 5.62 m3 | 1762.17 | 1495.93 | 84.89 | 247.28 | 14.03 | 18.96 | 1.08 |

| Steel reinforcement (side wall) | 2.76 kg | 29.42 | 6.38 | 21.68 | 0.22 | 0.75 | 22.82 | 77.57 |

| Total | 8405.82 | 6273.39 | 74.63 | 983.85 | 11.71 | 1148.58 | 13.66 | |

| Activities | Monitoring Results (min) | DES Model Results (min) | Differences (%) |

|---|---|---|---|

| Loading | 22.1 | 22.8 | 3.1 |

| Transporting | 53.8 | 55.2 | 2.5 |

| Unloading | 16.9 | 17.4 | 2.9 |

| Returning | 61.4 | 60.6 | 1.3 |

| Idling | 30.5 | 31.2 | 2.2 |

| Method | Carbon Emissions (kgCO2e) | Differences (%) |

|---|---|---|

| Monitoring results | 707.28 | 0 |

| DES model results | 716.85 | 1.3 |

| LCA results | 845.52 | 19.5 |

| RMR Class | Construction Stage | Carbon Emission Intensity (kgCO2e/m) | Proportion (%) |

|---|---|---|---|

| II | Material production | 6273.38 | 74.63 |

| Material transportation | 983.86 | 11.71 | |

| Mechanical construction | 1148.58 | 13.66 | |

| Total | 8405.82 | 100.00 | |

| III | Material production | 8225.10 | 76.16 |

| Material transportation | 1191.56 | 11.04 | |

| Mechanical construction | 1382.48 | 12.80 | |

| Total | 10,799.14 | 100.00 | |

| IV | Material production | 10,107.11 | 75.69 |

| Material transportation | 1388.34 | 10.40 | |

| Mechanical construction | 1857.44 | 13.91 | |

| Total | 13,352.89 | 100.00 | |

| V | Material production | 12,477.06 | 77.07 |

| Material transportation | 1563.24 | 9.66 | |

| Mechanical construction | 2149.00 | 13.27 | |

| Total | 16,189.30 | 100.00 |

| RMR Class | Carbon Intensity (kgCO2e/m) |

|---|---|

| III | 14,301.33 |

| IV | 19,009.03 |

| V | 24,615.59 |

| RMR Class | Length of Drilling and Blasting Section (m) | Carbon Emissions (tCO2e) |

|---|---|---|

| II | 189.55 | 1593.34 |

| III | 1590.54 | 18,566.66 |

| IV | 623.03 | 9251.57 |

| V | 546.88 | 10,608.07 |

| Total | 2950.00 | 40,019.64 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Wu, S.; Cheng, H.; Zeng, T.; Deng, Z.; Lei, J. Carbon Emission Analysis of Tunnel Construction of Pumped Storage Power Station with Drilling and Blasting Method Based on Discrete Event Simulation. Buildings 2025, 15, 1846. https://doi.org/10.3390/buildings15111846

Zhang Y, Wu S, Cheng H, Zeng T, Deng Z, Lei J. Carbon Emission Analysis of Tunnel Construction of Pumped Storage Power Station with Drilling and Blasting Method Based on Discrete Event Simulation. Buildings. 2025; 15(11):1846. https://doi.org/10.3390/buildings15111846

Chicago/Turabian StyleZhang, Yong, Shunchuan Wu, Haiyong Cheng, Tao Zeng, Zhaopeng Deng, and Jinhua Lei. 2025. "Carbon Emission Analysis of Tunnel Construction of Pumped Storage Power Station with Drilling and Blasting Method Based on Discrete Event Simulation" Buildings 15, no. 11: 1846. https://doi.org/10.3390/buildings15111846

APA StyleZhang, Y., Wu, S., Cheng, H., Zeng, T., Deng, Z., & Lei, J. (2025). Carbon Emission Analysis of Tunnel Construction of Pumped Storage Power Station with Drilling and Blasting Method Based on Discrete Event Simulation. Buildings, 15(11), 1846. https://doi.org/10.3390/buildings15111846