Comparative Study of Structural and Quality Controls for Grouted Sleeve Connections in Different Standards: Connection Technology, Design, and Mechanical Requirements

Abstract

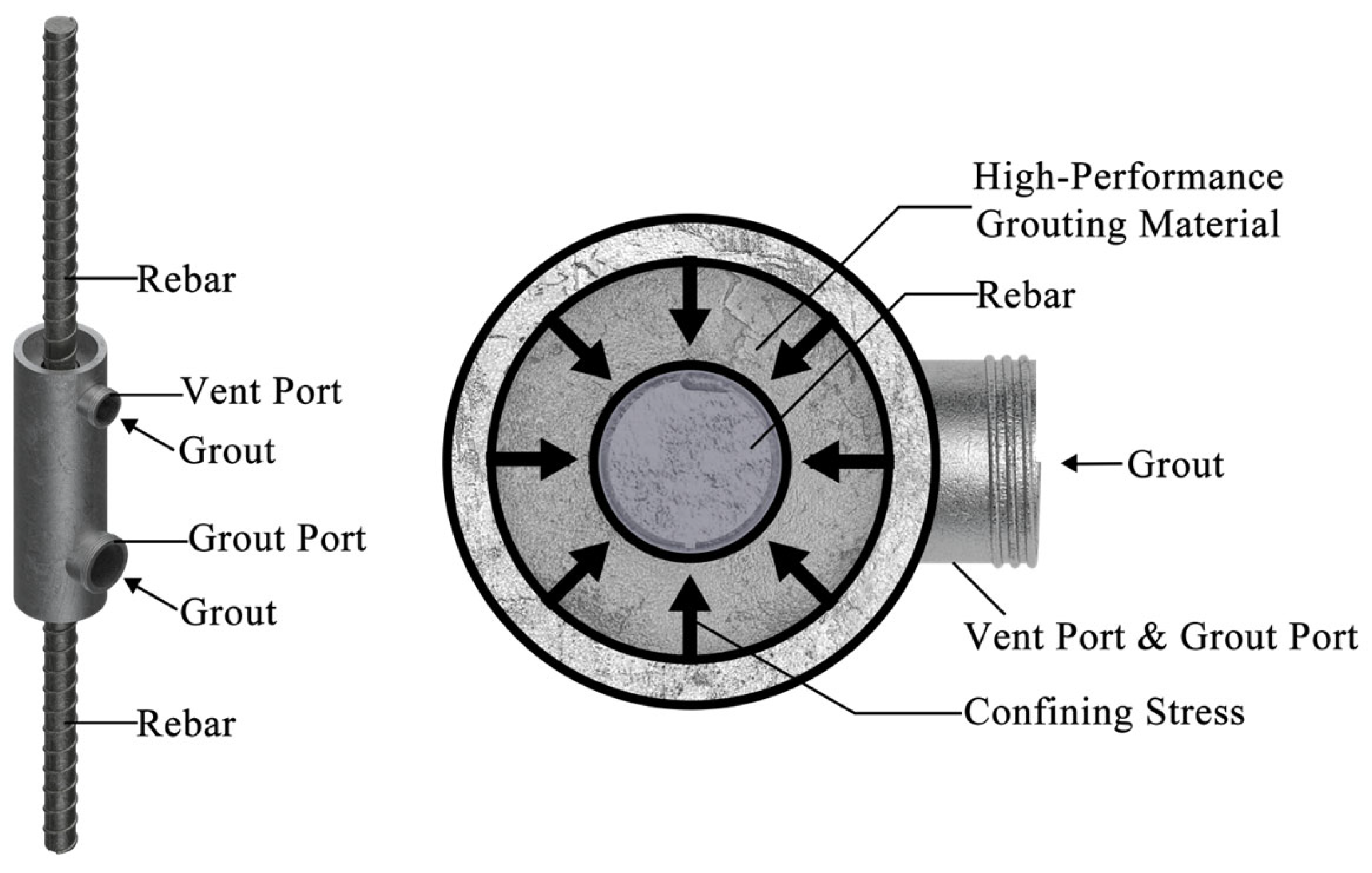

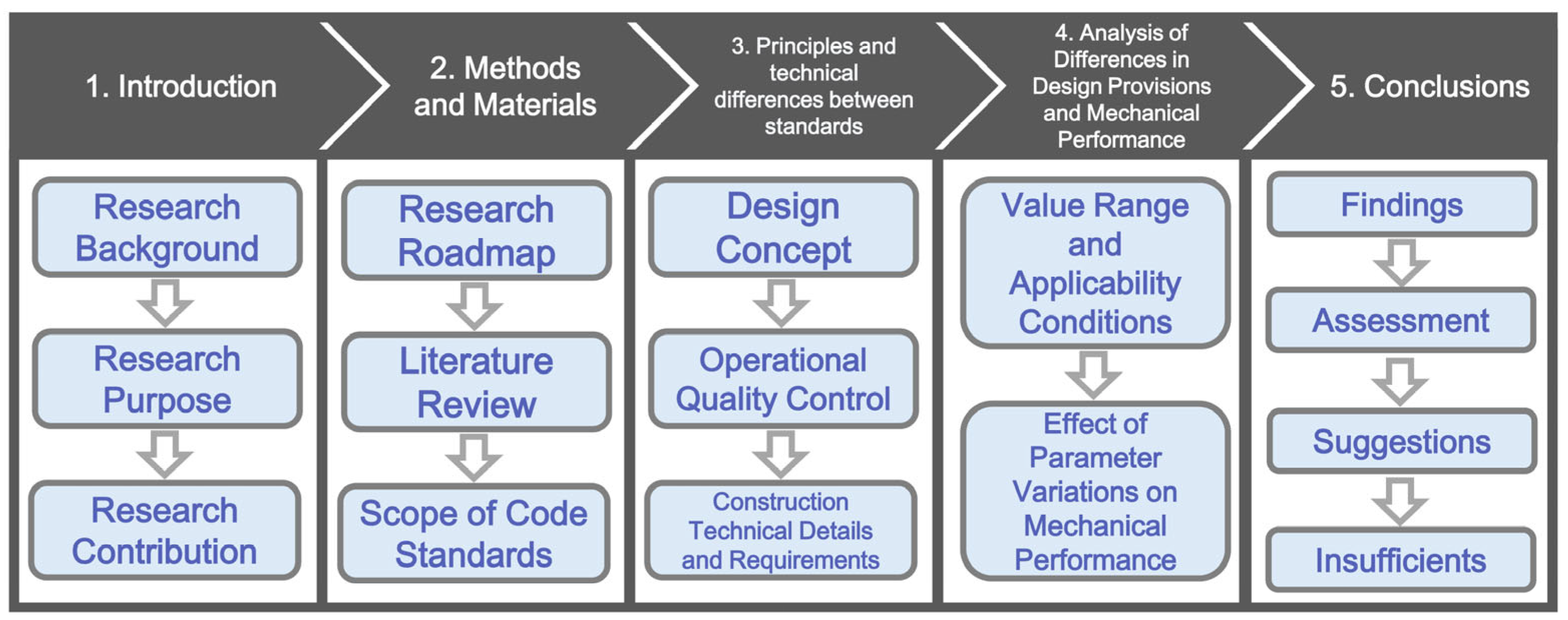

1. Introduction

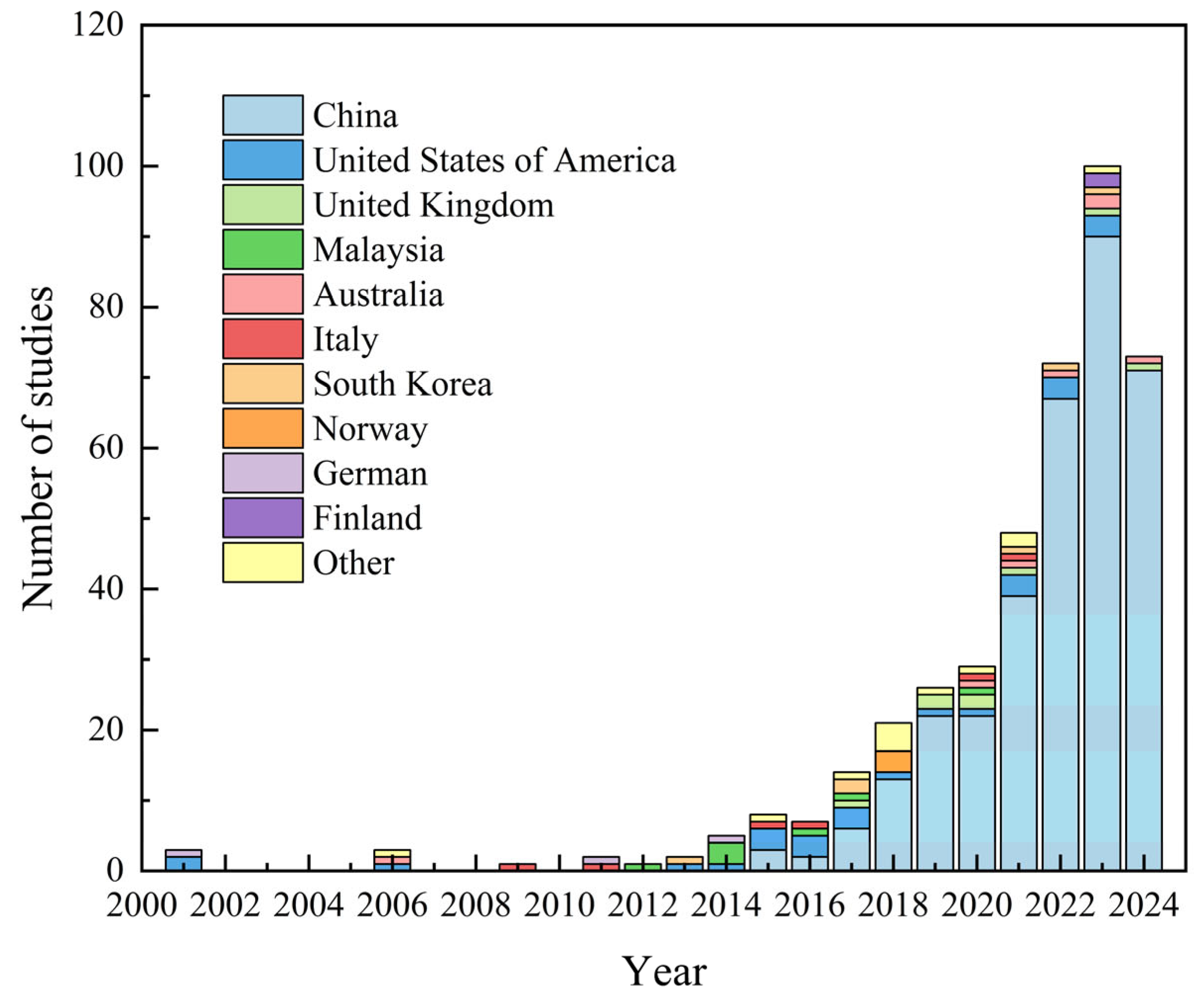

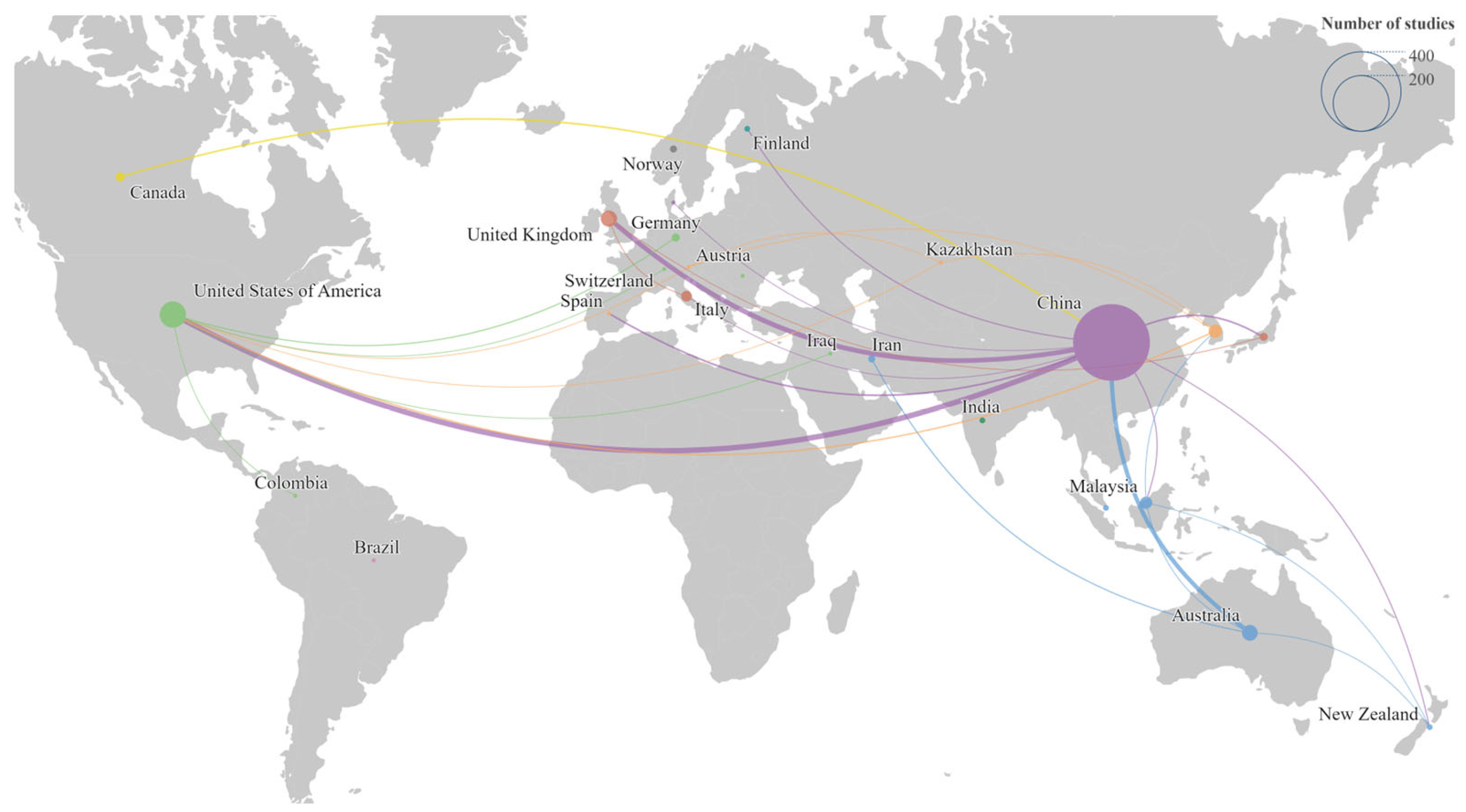

Research Purpose

- (1)

- Identify the most active countries/regions in GS research through bibliometric analysis and compile the full set of standards, codes, or guidelines they currently adopt.

- (2)

- Investigate and compare, for those key countries or regions, the provisions of their standards or guidelines with respect to design basis, applicability limits, material specifications, geometric constraints, construction and inspection procedures, and acceptance criteria.

- (3)

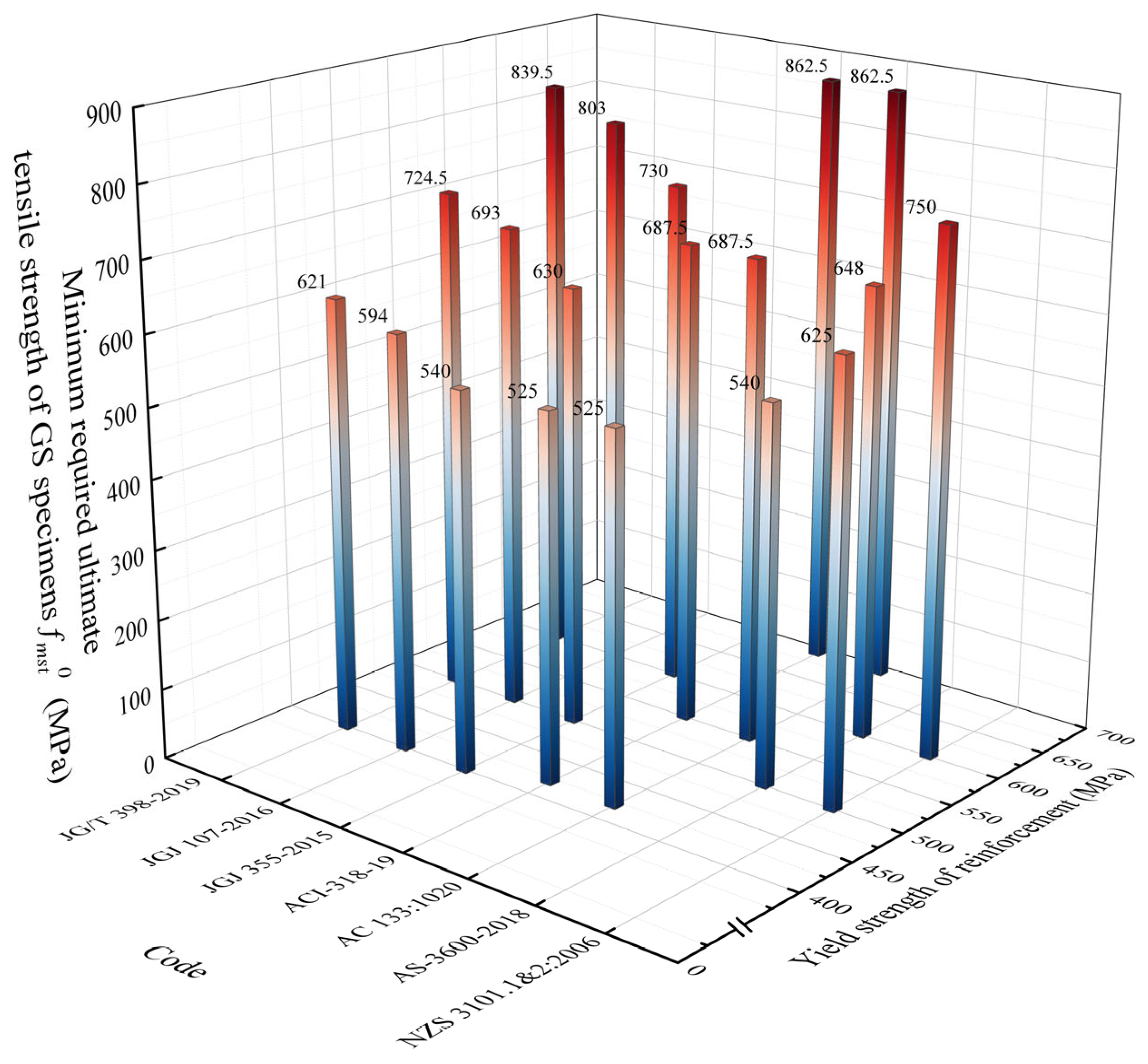

- For representative reinforcing-steel grades, quantitatively evaluate the minimum tensile capacity, ductility, slip limit, and anchorage length required by each standard, and assess how these prescriptions influence structural design outcomes and economy.

- (4)

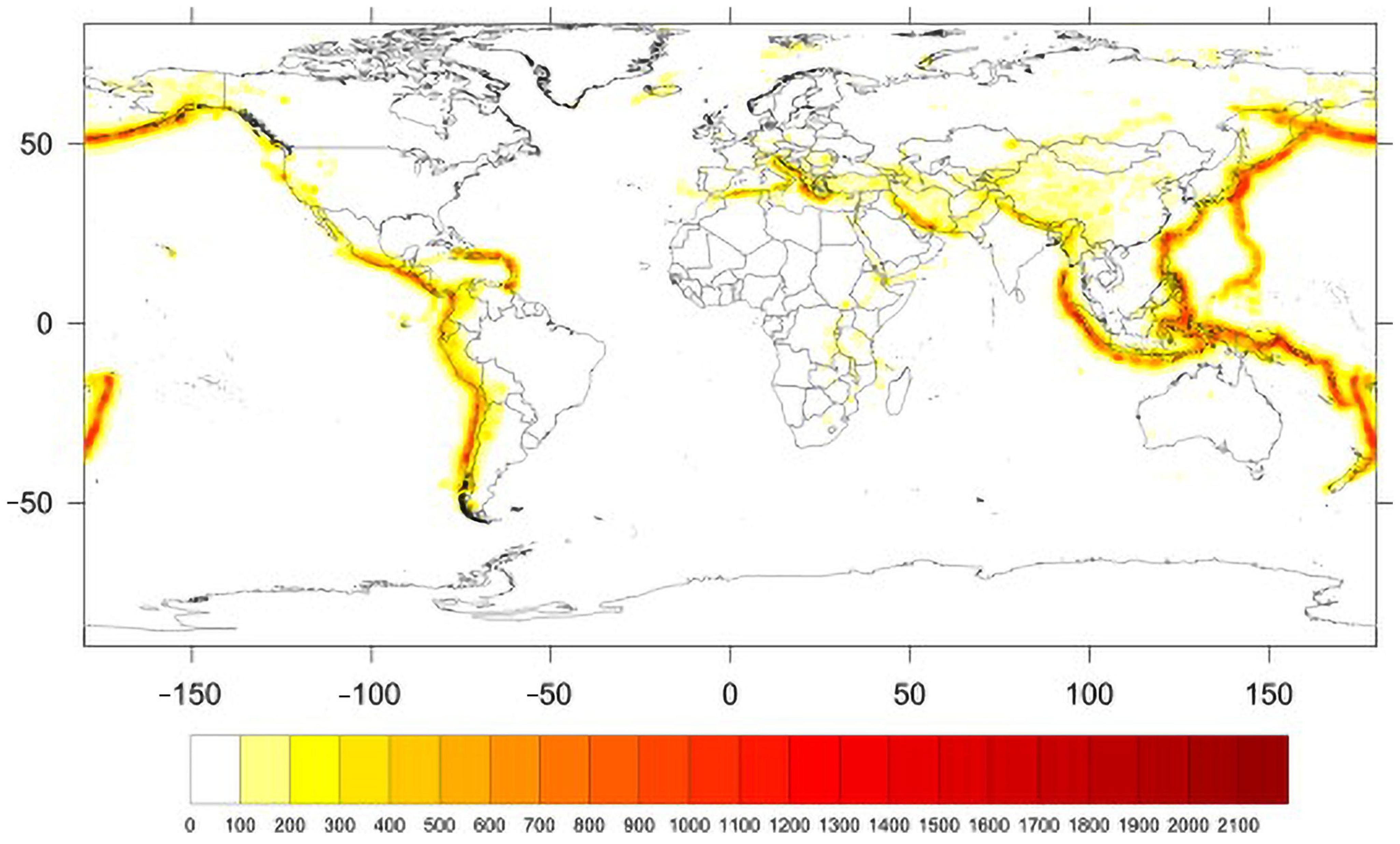

- Link the observed discrepancies to underlying factors such as yield-to-tensile strength ratios, seismic hazard levels, and manufacturing practices, thereby clarifying the technical mechanisms behind different code philosophies.

- (5)

- Propose design recommendations to support future code revisions and promote the safe, economical, and sustainable application of GS connections worldwide.

2. Materials and Methods

3. Principles and Technical Differences Between Standards

3.1. Design Concept

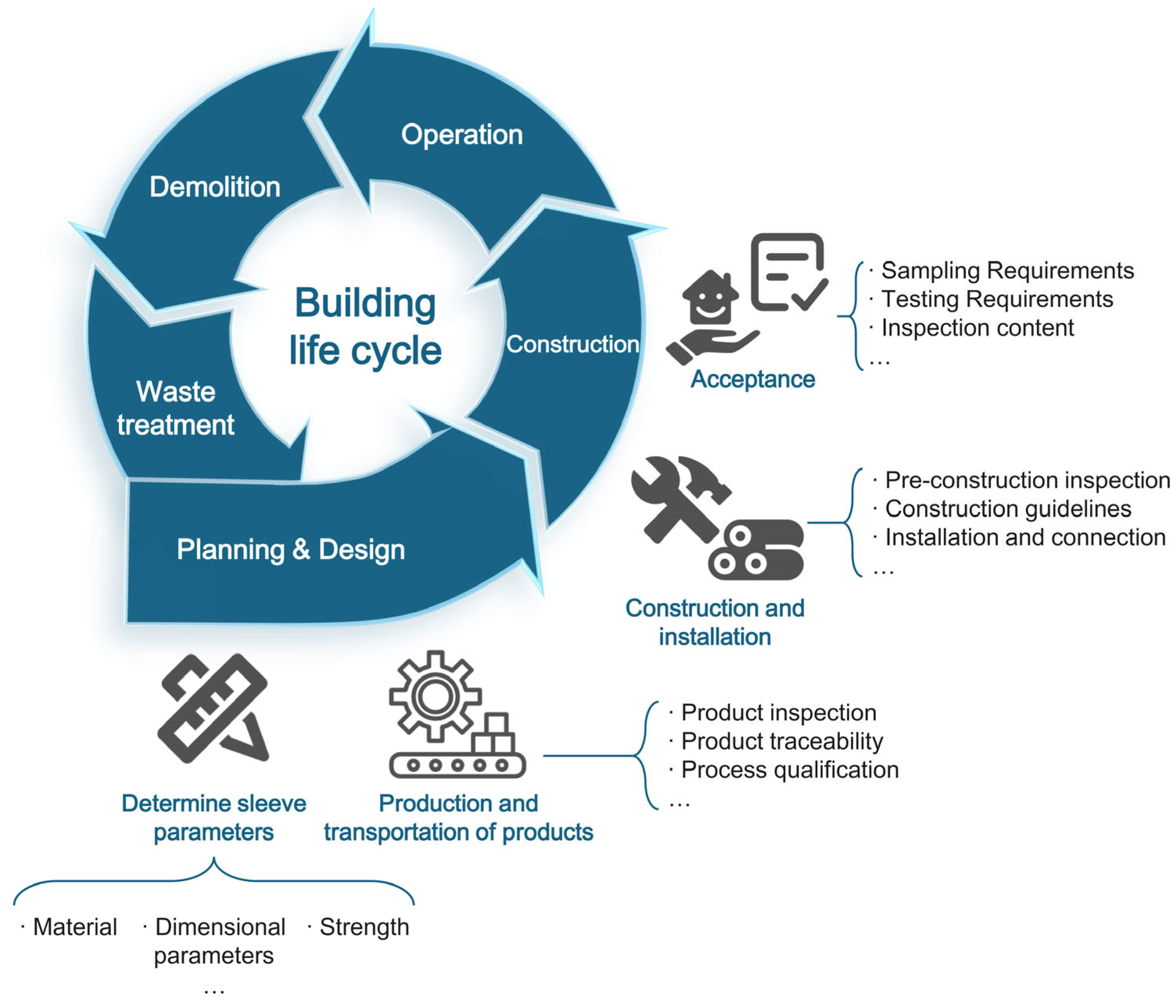

3.2. Operational Quality Control

3.2.1. Incoming Product and Material Quality Control

3.2.2. Installation and Grouting Quality Control

3.2.3. Acceptance Requirements

3.3. Construction Technical Details and Requirements

4. Analysis of Differences in Design Provisions and Mechanical Performance

4.1. Value Range and Applicability Conditions

- (1)

- Stage I: tension upper limit = 2 (where is the strain at yield strength ), compression lower limit = 0.5, total of four cycles, with maximum allowable permanent residual deformation = 0.3 mm.

- (2)

- Stage II: tension upper limit = , compression lower limit = 0.5, total of four cycles, with maximum allowable permanent residual deformation = 0.6 mm.

4.2. Effect of Parameter Variations on Mechanical Performance

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| GS | grouted sleeve |

| QC | quality control |

| PGA | peak ground acceleration |

| LRFD | Load And Resistance Factor Design |

| ULS | Ultimate Limit State |

| SLS | Serviceability Limit State |

References

- Qin, C.; Bai, G.; Xu, Y.; Su, N.; Wu, T. Comparative Study of Seismic Behavior between Monolithic Precast Concrete Structure and Cast-in-Place Structure. Shock. Vib. 2018, 2018, 7029287. [Google Scholar] [CrossRef]

- Murashev, V.I. Crack Resistance, Stiffness and Strength of Reinforced Concrete; Publishing House of the Ministry of Construction of Machine-Building Enterprises: Moscow, Russia, 1950. [Google Scholar]

- Nikolyukin, A.N.; Yarcev, V.P.; Mamontov, S.A.; Kolomnikova, I.I.; Al’ Vard, A.M. Analysis of the stress-strain condition of concrete and reinforcement in the area of their engagement in the ansys software package. Bull. Belgorod State Technol. Univ. Named V. G. Shukhov 2019, 4, 43–52. [Google Scholar] [CrossRef]

- Demartino, C.; Vanzi, I.; Monti, G.; Sulpizio, C. Precast Industrial Buildings in Southern Europe: Loss of Support at Frictional Beam-to-Column Connections under Seismic Actions. Bull. Earthq. Eng. 2018, 16, 259–294. [Google Scholar] [CrossRef]

- AlAjarmeh, O.S.; Manalo, A.C.; Benmokrane, B.; Karunasena, K.; Ferdous, W.; Mendis, P. Hollow Concrete Columns: Review of Structural Behavior and New Designs Using GFRP Reinforcement. Eng. Struct. 2020, 203, 109829. [Google Scholar] [CrossRef]

- Lu, Z.; Huang, J.; Dai, S.; Liu, J.; Zhang, M. Experimental Study on a Precast Beam-Column Joint with Double Grouted Splice Sleeves. Eng. Struct. 2019, 199, 109589. [Google Scholar] [CrossRef]

- Sun, Y. Study of Mechanical Behavior of Grout Sleeve Splicing of Rebars. Front. Phys. 2024, 12, 1397218. [Google Scholar] [CrossRef]

- Zheng, G.; Kuang, Z.; Xiao, J.; Pan, Z. Mechanical Performance for Defective and Repaired Grouted Sleeve Connections under Uniaxial and Cyclic Loadings. Constr. Build. Mater. 2020, 233, 117233. [Google Scholar] [CrossRef]

- Alias, A.; Sapawi, F.; Kusbiantoro, A.; Zubir, M.A.; Rahman, A.B.A. Performance of Grouted Splice Sleeve Connector under Tensile Load. J. Mech. Eng. Sci. 2014, 7, 1094–1102. [Google Scholar] [CrossRef]

- Lu, Z.; Huang, J.; Li, Y.; Dai, S.; Peng, Z.; Liu, X.; Zhang, M. Mechanical Behaviour of Grouted Sleeve Splice under Uniaxial Tensile Loading. Eng. Struct. 2019, 186, 421–435. [Google Scholar] [CrossRef]

- Haber, Z.B.; Mackie, K.R.; Al-Jelawy, H.M. Testing and Analysis of Precast Columns with Grouted Sleeve Connections and Shifted Plastic Hinging. J. Bridge Eng. 2017, 22, 04017078. [Google Scholar] [CrossRef]

- Xiao, S.; Fomin, N.I. Development and Systematic Review of Connection Techniques for RC Precast Structural Elements: Beam and Column Connection. Heliyon 2024, 10, e35886. [Google Scholar] [CrossRef] [PubMed]

- Ferreira, M.A.; Bachega, L.A.; Catoia, B. Monolithic Equivalent Stiffness of Precast Columns with Grouted Splice Sleeve Connections. Rev. IBRACON Estrut. E Mater. 2021, 14, e14115. [Google Scholar] [CrossRef]

- Zhi, Q.; Yuan, Z.; Zheng, Y.; Jia, L.; Guo, Z. Experimental Research on Seismic Performance of Precast Concrete Shear Walls with a Novel Grouted Sleeve Used in the Connection. J. Earthq. Eng. 2024, 28, 1379–1403. [Google Scholar] [CrossRef]

- Jia, L.; Li, Q.; Zhang, Y.; Zhao, W.; Du, M. Experimental Study of the Hysteretic Behavior of Prefabricated Frame-Shear Wall Structures with Grouting Sleeve Connections. J. Build. Eng. 2022, 57, 104704. [Google Scholar] [CrossRef]

- Lei, S.; Liu, L.; Wu, F.; Lin, W.; Peng, K. Experimental Study on Tensile Mechanism of UHPC Grouted Sleeve Splice. Constr. Build. Mater. 2023, 364, 129922. [Google Scholar] [CrossRef]

- Guo, F.; Li, J.; He, S.; Zhou, C. Experimental Study on the Effect of Grouting Defects on Mechanical Properties of the Rebar Connected by Full-Grouted Sleeves. Adv. Civ. Eng. 2022, 2022, 5036505. [Google Scholar] [CrossRef]

- Ling, J.H.; Rahman, A.B.A.; Ibrahim, I.S. Behavior of Grouted Sleeve Wall Connection under Lateral Load. Indones. J. Comput. Eng. Des. 2024, 6, 1–16. [Google Scholar] [CrossRef]

- Zhang, W.; Deng, J.; He, C.; Zhang, J.; Yi, W. Experiment and Analysis on Mechanical Properties of Fully-Grouted Sleeve Connection at Elevated Temperatures. Constr. Build. Mater. 2020, 244, 118314. [Google Scholar] [CrossRef]

- JG/T 398-2019; The Grouting Sleeve for Rebars Splicing. Ministry of Housing and Urban-Rural Development of the People’s Republic of China Standards Press of China: Beijing, China, 2019.

- JG/T 408-2019; Cementitious Grout for Sleeve of Rebar Splicing. Ministry of Housing and Urban-Rural Development of the People’s Republic of China Standards Press of China: Beijing, China, 2019.

- ACI 318-19; Building Code Requirements for Structural Concrete. American Concrete Institute: Farmington Hills, MI, USA, 2019.

- JGJ 355-2015; Technical Specification for Grout Sleeve Splicing of Rebars (2023 Edition). Ministry of Housing and Urban-Rural Development of the People’s Republic of China Standards Press of China: Beijing, China, 2023.

- JGJ 107-2016; Technical Specification for Mechanical Splicing of Steel Reinforcing Bars. Ministry of Housing and Urban-Rural Development of the People’s Republic of China Standards Press of China: Beijing, China, 2016.

- Wu, C.; Xiao, X.; Ma, S.; Yang, C. Mechanical Performance and Failure Mode Judgment Criteria of Grouted Sleeve Connectors Considering Large Deformation and Grouting Compactness. Case Stud. Constr. Mater. 2024, 21, e03997. [Google Scholar] [CrossRef]

- Bing, H.; Yuan, H. Experimental Study on Bond Performance between Rebar and Grout and Confinement Effects of Grouted Sleeve Connections. Constr. Build. Mater. 2022, 354, 129088. [Google Scholar] [CrossRef]

- International Federation of Structural Concrete. Fib Model Code for Concrete Structures (2020); International Federation of Structural Concrete: Lausanne, Switzerland, 2023. [Google Scholar]

- GB 50010-2010; Code for the Design of Concrete Structures. Ministry of Housing and Urban-Rural Development China Architecture & Building Press: Beijing, China, 2010.

- AS 3600:2018; Concrete Structures Code. Council of Standards Australia Standards Australia International: Sydney, Australia, 2018.

- Sharma, L.K.; Abdullah, W.; Niroula, S.; Budhathoki, N.; Ghannoum, W.M. Performance of Mechanical Couplers of High-Strength Reinforcing Bars under Inelastic Strain Demands. ACI Struct. J. 2025, 122, 225–238. [Google Scholar]

- Seifi, P.; Henry, R.S.; Ingham, J.M. Panel Connection Details in Existing New Zealand Precast Concrete Buildings. Bull. New Zealand Soc. Earthq. Eng. 2016, 49, 190–199. [Google Scholar] [CrossRef]

- NZS 3101:2006 A3; Concrete Structures Standard. Standards New Zealand: Wellington, New Zealand, 2017.

- ABNT NBR 9062:2017; Design and Execution of Precast Concrete Structures. Associação Brasileira de Normas Técnicas: Rio de Janeiro, Brazil, 2017.

- Ye, H.; Lu, Y. Rebar-Concrete Bond Behaviour in Grouted Sleeve Connectors. Constr. Build. Mater. 2024, 431, 136487. [Google Scholar] [CrossRef]

- EN 1992; Eurocode 2: Design of Concrete Structures. European Committee for Standardization: Brussels, Belgium, 2004.

- Ghayeb, H.H.; Razak, H.A.; Sulong, N.H.R.; Mo, K.H.; Abutaha, F.; Gordan, M. Performance of Mechanical Steel Bar Splices Using Grouted Couplers under Uniaxial Tension. J. Build. Eng. J. 2021, 34, 101892. [Google Scholar] [CrossRef]

- BS 8110; Structural Use of Concrete. British Standards Institution: London, UK, 1997.

- JGJ 1-2014; Technical Specification for Precast Concrete Structures. Ministry of Housing and Urban-Rural Development of the People’s Republic of China Standards Press of China: Beijing, China, 2014.

- GB 50010-2010(2015); Code for Design of Concrete Structures (2015 Edition). Ministry of Housing and Urban-Rural Development of the People’s Republic of China China Construction Industry Press: Beijing, China, 2010.

- ASTM A1034/A1034M-24; Standard Specification for Mechanical Splices for Steel Reinforcing Bars. American Society for Testing and Materials: West Conshohocken, PA, USA, 2024.

- Structural Engineering Society New Zealand. Precast Concrete—Grouted Connections and Drossbachs—SESOC Guidance; Structural Engineering Society New Zealand: Wellington, New Zealand, 2022. [Google Scholar]

- ABNT NBR 6118:2023; Design of Concrete Structures. Associação Brasileira de Normas Técnicas: Rio de Janeiro, Brazil, 2023.

- ABNT NBR 8548:1984; Barras de Aço Destinadas a Armaduras de Concreto Armado Com Emenda Mecânica Ou Por Solda—Determinação Da Resistência à Tração. Associação Brasileira de Normas Técnicas: Rio de Janeiro, Brazil, 1984.

- ISO 15835-1:2018; International Organization for Standardization. Steels for the Reinforcement of Concrete—Reinforcement Couplers for Mechanical Splices of Bars. International Organization for Standardization: Geneva, Switzerland, 2018.

- AC 133; Mechanical Splice Systems for Steel Reinforcing Bars. International Code Council: Washington, DC, USA, 2020.

- Ordaz, M.G.; Cardona, O.-D.; Salgado-Gálvez, M.A.; Bernal-Granados, G.A.; Singh, S.K.; Zuloaga-Romero, D. Probabilistic Seismic Hazard Assessment at Global Level. Int. J. Disaster Risk Reduct. 2014, 10, 419–427. [Google Scholar] [CrossRef]

- Kwon, D.K.; Kareem, A. Comparative Study of Major International Wind Codes and Standards for Wind Effects on Tall Buildings. Eng. Struct. 2013, 51, 23–35. [Google Scholar] [CrossRef]

- ISO 9000:2015; Quality Management Systems—Fundamentals and Vocabulary. International Organization for Standardization: Geneva, Switzerland, 2015.

- Arditi, D.; Gunaydin, H.M. Total Quality Management in the Construction Process. Int. J. Project Manage. 1997, 15, 235–243. [Google Scholar] [CrossRef]

- Kirkcaldie, D.K.; Lloyd, J.N. Some Concrete Topics Being Addressed in New Zealand Transport Agency Bridge Manual Revisions—Shrinkage and Creep in Concrete: Mechanical Coupling of Reinforcing Steel. In Proceedings of the NZ Concrete Industry Conference 2013, Queenstown, New Zealand, 3–5 October 2013. [Google Scholar]

- Rudkins, N.T.; Modlen, G.F.; Webster, P.J. Residual Stresses in Cold Extrusion and Cold Drawing: A Finite Element and Neutron Diffraction Study. J. Mater. Process. Technol. 1994, 45, 287–292. [Google Scholar] [CrossRef]

- Xie, Q.; Suvarna, M.; Li, J.; Zhu, X.; Cai, J.; Wang, X. Online Prediction of Mechanical Properties of Hot Rolled Steel Plate Using Machine Learning. Mater. Des. 2021, 197, 109201. [Google Scholar] [CrossRef]

- Odusote, J.K.; Shittu, W.; Adeleke, A.A.; Ikubanni, P.P.; Adeyemo, O. Chemical and Mechanical Properties of Reinforcing Steel Bars from Local Steel Plants. J. Fail. Anal. Prev. 2019, 19, 1067–1076. [Google Scholar] [CrossRef]

- Peris Mora, E. Life Cycle, Sustainability and the Transcendent Quality of Building Materials. Build. Environ. 2007, 42, 1329–1334. [Google Scholar] [CrossRef]

- Munaro, M.R.; Tavares, S.F. Materials Passport’s Review: Challenges and Opportunities toward a Circular Economy Building Sector. Built Environ. Proj. Asset Manag. 2021, 11, 767–782. [Google Scholar] [CrossRef]

- Luscuere, L. Materials Passports: Optimising Value Recovery from Materials. Proceedings of the Institution of Civil Engineers–Waste and Resource Management; Thomas Telford Ltd.: London, UK, 2017; Volume 170, pp. 25–28. [Google Scholar]

- Melchers, R.E. Assessment of Existing Structures—Approaches and Research Needs. J. Struct. Eng. 2001, 127, 406–411. [Google Scholar] [CrossRef]

- Hawkins, N.M.; Ghosh, S.K. Acceptance Criteria for Special Precast Concrete Structural Walls Based on Validation Testing. PCI J. 2004, 49, 78–92. [Google Scholar] [CrossRef]

- Straub, D.; Der Kiureghian, A. Reliability Acceptance Criteria for Deteriorating Elements of Structural Systems. J. Struct. Eng. 2011, 137, 1573–1582. [Google Scholar] [CrossRef]

- ASTM C666-97; Standard Test Method for Resistance of Concrete to Rapid Freezing and Thawing. American Society for Testing and Materials: West Conshohocken, PA, USA, 2017.

- ANSI/AISC 360-10; Specification for Structural Steel Buildings. AISC Committee on Specifications: Nicosia, Cyprus, 2005.

- Yang, L.; Xing, Y. Experimental Study on High-Cycle Fatigue Properties of Q420C Steel at Room Temperature. Mater. Res. 2022, 25, e20210589. [Google Scholar] [CrossRef]

- GOST 34028–2016; Rolled Product Reinforcement for Ferroconcrete Structure Reinforcement. Izd-vo Standartov: Moscow, Russia, 2018.

- Tavio; Anggraini, R.; Raka, I.G.P.; Agustiar. Tensile Strength/Yield Strength (TS/YS) Ratios of High-Strength Steel (HSS) Reinforcing Bars. AIP Conf. Proc. 2018, 1964, 020036. [Google Scholar] [CrossRef]

- GB 1499.2-2024; Steel for the Reinforcement of Concrete—Part 2: Hot Rolled Ribbed Bars. China Standards Press: Beijing, China, 2024.

- ASTM A615/A615M-2024; Standard Specification for Deformed and Plain Carbon—Steel Bars for Concrete Reinforcement. American Society for Testing and Materials: West Conshohocken, PA, USA, 2024.

- DIN 1045-1:2023-08; Tragwerke Aus Beton, Stahlbeton Und Spannbeton—Teil 1: Planung, Bemessung Und Konstruktion. DIN Deutsches Institut Für Normung e. V: Berlin, Germany, 2023.

- BS 4449:2005+A3:2016; Steel for the Reinforcement of Concrete—Weldable Reinforcing Steel—Bar, Coil and Decoiled Product—Specification. The British Standards Institution: London, UK, 2016.

- AS/NZS 4671:2019; Steel for the Reinforcement of Concrete. Standards New Zealand: Wellington, New Zealand, 2019.

| Relevant Standard Name | Standard Number | Authorized Institutions | Country/ Region |

|---|---|---|---|

| The Grouting Sleeve for Rebars Splicing [20] | JG/T 398-2019 | Ministry of Housing and Urban–Rural Development of the People’s Republic of China | China |

| Cementitious Grout for Sleeve of Rebar Splicing [21] | JG/T 408-2019 | ||

| Technical Specification for Mechanical Splicing of Steel Reinforcing Bars [24] | JGJ 107-2016 | ||

| Technical Specification of Grout Sleeve Splicing for Rebars (2023 Edition) [23] | JGJ 355-2015 | ||

| Technical Specification for Assembled Concrete Structures [38] | JGJ 1-2014 | ||

| Code For Design of Concrete Structures (2015 Edition) [39] | GB 50010-2010(2015) | ||

| Building Code for Structural Concrete [22] | ACI-318-19 | American Concrete Institute | United States |

| Standard Specification for Mechanical Splices for Steel Reinforcing Bars [40] | ASTM A1034/A1034M-24 | American Society for Testing and Materials | |

| Concrete Structures Code [29] | AS 3600:2018 | Council of Standards Australia | Australia |

| Concrete Structures Standard [32] | NZS 3101.1&2:2006 | Standards New Zealand | New Zeeland |

| Precast Concrete—Grouted Connections and Drossbachs—SESOC Guidance [41] | Structural Engineering Society New Zealand | ||

| Design And Execution of Precast Concrete Structures [33] | ABNT NBR 9062:2017 | Associação Brasileira de Normas Técnicas | Brazil |

| Design of concrete structures [42] | ABNT NBR 6118:2023 | ||

| Steel bars for reinforced concrete with mechanical or welded seams—Determination of tensile strength [43] | ABNT NBR 8548:1984 | ||

| Eurocode 2: Design of concrete structures [35] | EN 1992 | European Committee for Standardization | European Union |

| Steels for the reinforcement of concrete—Reinforcement couplers for mechanical splices of bars [44] | ISO 15835-1:2018 | International Organization for Standardization | Global |

| Mechanical Splice Systems for Steel Reinforcing Bars [45] | AC 133:1020 | International Code Council | |

| Fib Model Code for Concrete Structures 2020 [27] | Fédération Internationale du Béton |

| Standards | Processing Methods | Recommended or Requested Materials |

|---|---|---|

| JG/T 398-2019 [20] | Cast GS | Ductile iron |

| Machined GS | Carbon structural steel; high-strength low-alloy structural steel; alloy structural steel; cold-drawn or cold-rolled precision seamless steel tube; and seamless structural steel tube | |

| ACI-318-19 [22] | No detail | |

| AC 133:1020 [45] | No detail | |

| AS 3600:2018 [29] | No detail | |

| NZS 3101.1&2:2006 [32] | No detail | Mechanical anchors and couplers manufactured from Grade 500/7 spheroidal graphite iron are not to be used; anchors manufactured from cast iron shall not be used |

| ABNT NBR 9062:2017 [33] | No detail | Mechanical anchors must be able to withstand temperatures more than 80 °C and must also prove to be effective both during execution and for the lifetime of the building |

| ABNT NBR 6118:2023 [42] | No detail | |

| EN 1992 [35] | No detail | |

| ISO 15835-1:2018 [44] | No detail | If a material other than steel is used in a coupler, the suitability for use of such material in fire-rated structures as well as any health implications should be evaluated |

| Fib Model Code for Concrete Structures 2020 [27] | No detail | |

| Standards | Raw Materials | Manufacturing | Transportation |

|---|---|---|---|

| JG/T 398-2019 [20] | + (raw material inspection report) | + (product inspection report, product compliance certificate, product quality certificate, and manufacturer and lot identifications) | + (delivery note/outbound document) |

| JGJ 355-2015 [23] | − | + (product inspection report and product quality certificate) | − |

| AC 133:1020 [45] | − | + (acceptance criteria for quality documentation (AC10), test report, and freeze–thaw test report) | − |

| ASTM A1034/A1034M-24 [40] | + (certified mill test report) | + (certified mill test report, low-temperature test report, testing machine calibration certificate, and manufacturer and lot identifications) | − |

| AS 3600:2018 [29] | − | − | − |

| NZS 3101.1&2:2006 [32] | − | + (manufacturer’s or processor’s or supplier’s certificate) | − |

| ABNT NBR 9062:2017 [33] | − | + (inspection record documents for the production phase, test report, and manufacturer and lot identifications) | − |

| EN 1992 [35] | − | − | − |

| ISO 15835-1:2018 [44] | − | + (quality assurance documentation, test report, and manufacturer and lot identifications) | − |

| Fib Model Code for Concrete Structures 2020 [27] | − | − | − |

| Standards | Professional Qualification for Grouting Operations | Grout Record | Compressive Strength (7 Days) (MPa) | Compressive Strength (28 Days) (MPa) | Initial Fluidity (mm) | 30 Minutes Fluidity (mm) | Bleeding Rate | Vertical Expansion Rate (3 h) (%) |

|---|---|---|---|---|---|---|---|---|

| JGJ 355-2015 (2023 Edition) [23] | + (specialized training for construction personnel) | + | ≥60 (Cylinder test strength) | ≥85 (Cylinder test strength) | ≥300 | ≥260 | 0% | 0.02~2 |

| Precast Concrete—Grouted Connections and Drossbachs—SESOC Guidance [41] | + (qualified specialist subcontractor with experience) | + | ≥40 (40 mm × 40 mm × 160 mm prism test strength) | ≥60 (40 mm × 40 mm × 160 mm prism test strength) | − | − | 0% | − |

| Standards | Minimum Number of Specimens Per Test | Monotonous Tensile Test | Cyclic Tensile and Compression Test | Freeze–Thaw Test |

|---|---|---|---|---|

| JG/T 398-2019 [20] | 3 | + | + | − |

| JGJ 107-2016 [24] | 3 | + | + | − |

| JGJ 355-2015 (2023 Edition) [23] | 3 | + | + | − |

| AC 133:1020 [45] | 3 | + | + | + |

| AS 3600:2018 [29] | 2 | + | − | − |

| ABNT NBR 8548:1984 [42] | − | + | − | − |

| ISO 15835-1:2018 [44] | 3 | + | + | − |

| Standards | Minimum Connection’s Tensile Strength | (%) | Permanent Deformation Slip Limit (mm) | Minimum Design Anchor Length Tested or Required |

|---|---|---|---|---|

| JG/T 398-2019 [20] | (at connection failure) | ) ) | ||

| JGJ 107-2016 [24] | (at connection failure) | ) ) | ||

| JGJ 355-2015 (2023 Edition) [23] | (at reinforcement failure) | ) ) | ||

| ACI-318-19 [22] | (at reinforcement failure) | − | − | |

| AC 133:1020 [45] | (at reinforcement failure) | − | − | − |

| AS 3600:2018 [29] | (at reinforcement failure) | − | − | |

| NZS 3101.1&2:2006 [32] | (at reinforcement failure) | − | The specimen is stretched from zero load to , and the total displacement of the connector during loading shall not exceed twice the displacement of the control bar of the same length. | − |

| ABNT NBR 8548:1984 [42] | − | − | − | |

| EN 1992 [35] | − | - | − | [34] |

| ISO 15835-1:2018 [44] | − | |||

| Fib Model Code for Concrete Structures 2020 [27] | − | − | − |

| Reinforcement Grade | Tensile Strength Values Based on 1.25 as a Limit (MPa) | Tensile Strength Values Based on as a Limit (MPa) | Ratio of Tensile Strength Values Based on 1.25 as Limit to Based on as a Limit, λ |

|---|---|---|---|

| A240 | 300 | 380 | 0.79 |

| A400 | 487.5 | 590 | 0.83 |

| A500 | 625 | 600 | 1.04 |

| A600 | 750 | 700 | 1.07 |

| Standards | Country | Steel Grade | Yield Strength (MPa) | Tensile Strength (MPa) |

|---|---|---|---|---|

| GOST 34028-2016 [63] | Russia | A400 | 390 | 590 |

| A500 | 500 | ) | ||

| A600 | 600 | ) | ||

| GB 1499.2-2024 [65] | China | HRB400 | 400 | ) |

| HRB500 | 500 | ) | ||

| HRB600 | 600 | 730 | ||

| ASTM A615/A615M-2024 [66] | United States | Grade 60 | 420 | ) |

| Grade 80 | 550 | ) | ||

| Grade 100 | 690 | ) | ||

| DIN 1045-1-2008 [67] | Germany | 500M | 500 | ) |

| BS 4449:2005 + A3:2016 [68] | United Kingdom | B500A | 500 | ) |

| B500B | 500 | ) | ||

| B500C | 500 | ) | ||

| AS/NZS 4671:2019 [69] | New Zeeland | 500N | 500 | ) |

| Australia | 600N | 600 | ) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiao, S.; Fomin, N.I.; Li, J.; Gu, J. Comparative Study of Structural and Quality Controls for Grouted Sleeve Connections in Different Standards: Connection Technology, Design, and Mechanical Requirements. Buildings 2025, 15, 1768. https://doi.org/10.3390/buildings15111768

Xiao S, Fomin NI, Li J, Gu J. Comparative Study of Structural and Quality Controls for Grouted Sleeve Connections in Different Standards: Connection Technology, Design, and Mechanical Requirements. Buildings. 2025; 15(11):1768. https://doi.org/10.3390/buildings15111768

Chicago/Turabian StyleXiao, Shuoting, Nikita Igorevich Fomin, Jiaxin Li, and Jinhong Gu. 2025. "Comparative Study of Structural and Quality Controls for Grouted Sleeve Connections in Different Standards: Connection Technology, Design, and Mechanical Requirements" Buildings 15, no. 11: 1768. https://doi.org/10.3390/buildings15111768

APA StyleXiao, S., Fomin, N. I., Li, J., & Gu, J. (2025). Comparative Study of Structural and Quality Controls for Grouted Sleeve Connections in Different Standards: Connection Technology, Design, and Mechanical Requirements. Buildings, 15(11), 1768. https://doi.org/10.3390/buildings15111768