1. Introduction

Reinforced concrete (RC) structures are inevitably affected by long-term loading and continuous environmental degradation during their service life, which can impair their mechanical properties. To ensure the overall safety of building structures, strengthening RC structures is crucial. Fiber-reinforced polymer (FRP) is a high-performance composite material composed of fiber reinforcement and a synthetic resin matrix. It possesses characteristics such as high strength, light weight, corrosion resistance, and ease of construction, making it widely used in the construction, retrofitting, and repair of civil engineering structures [

1,

2,

3]. Studies have shown that lateral pressure can effectively constrain the circumferential expansion deformation of concrete. FRP-confined concrete cylinders utilize the high strength and high elastic modulus of FRP materials to subject the concrete to triaxial compression, thereby improving both the strength and ductility of the concrete [

4]. Extensive experimental and theoretical research [

5,

6,

7] has confirmed that FRP-confined concrete technology (including FRP wrapping and FRP tube confinement for concrete enhancement) can effectively improve the durability, safety, and mechanical performance of structures, and extend their service life. This technology has demonstrated excellent potential for structural reinforcement and other applications involving FRP-confined concrete.

The ultimate condition under compression typically refers to the state corresponding to the maximum axial compressive load that a concrete component can withstand. It reflects the bearing capacity and the changes in the mechanical behavior of the concrete component before failure. Researchers commonly use two core parameters, namely the ultimate compressive strength and the ultimate compressive strain, to describe the ultimate condition under compression of concrete components. However, due to the significant increase in strength and ultimate strain resulting from the confinement reinforcement provided by FRP materials, the mechanical behavior and ultimate condition under compression of FRP-confined concrete undergo significant changes under loading, and the ductility of FRP-confined concrete shows a significant improvement [

8]. Zeng et al. [

8] conducted an experimental study on the stress–strain behavior of polyethylene terephthalate (PET) fiber-reinforced polymer (FRP)-confined normal-strength, high-strength, and ultra-high-strength concrete. The results demonstrated that high- and ultra-high-strength concrete confined with PET FRP exhibited strain hardening–softening–hardening behavior. Lim and Ozbakkaloglu [

9] found that concrete age has a minimal effect on the compressive strength and strain of FRP-confined concrete, with slight reductions observed as concrete ages beyond 28 days. Liao et al. [

10] investigated the compressive behavior of ultra-high-performance concrete (UHPC) confined with FRP. Their study found that the addition of steel fibers significantly enhanced the first peak stress and ultimate strain, improving confinement efficiency and ductility. The research also highlighted the importance of FRP thickness, specimen size, and steel fiber content in determining the stress–strain response of FRP-confined UHPC. In addition, the mechanical behavior of FRP-confined concrete columns with different shapes varies. Zeng et al. [

11] investigated the axial compression behavior of PET FRP-confined concrete in square stub columns by considering the effects of confinement thickness, corner radius, and specimen size. Their results showed that increasing the corner radius improves the uniformity of the confinement pressure, enhancing the concrete’s ultimate strength. Ye et al. [

12] conducted a review of FRP-confined steel-reinforced concrete (FCSRC) structural members, with a focus on the effects of FRP tube shape. The results showed that square and rectangular FRP tubes are less efficient in confining concrete compared to circular tubes, particularly at the flat sides, which reduces their confinement effectiveness in practical applications. However, existing models struggle to accurately capture the stress reduction phenomenon [

13]. To ensure structural safety and the rationality of design, it is necessary to specifically predict the behavior of FRP-confined concrete.

The main issue in the research on FRP-confined concrete cylinders is how to improve the overall mechanical performance of concrete cylinders, specifically, how to accurately predict their compressive strength and ultimate strain. To accurately predict their compressive strength and ultimate strain, many different stress–strain models have been developed. Early studies on FRP-confined concrete stress–strain models typically used steel-confined concrete models to analyze the mechanical behavior of FRP-confined concrete cylinders under axial loads. However, due to the differences in the mechanical properties between steel and FRP materials, this model could not accurately reflect the stress–strain characteristic [

14,

15,

16]. Subsequently, researchers proposed calculation formulas for the ultimate compressive strength, ultimate strain at concrete failure, and stress–strain curves of FRP-confined concrete cylinders, based on studies of GFRP (glass fiber-reinforced polymer) and CFRP (carbon fiber-reinforced polymer). They established stress–strain models for FRP-confined concrete cylinders and identified the main factors affecting the mechanical properties of FRP-confined concrete cylinders, including the circumferential fracture strain of FRP materials, FRP material parameters, the ultimate stress of the core concrete, and the geometric parameters of the cross-section [

17]. Furthermore, some studies have proposed calculation formulas for the peak stress, peak strain, ultimate stress, and ultimate strain of FRP-confined concrete cylinders with softening segments, along with corresponding models [

18].

FRP-confined concrete stress–strain models are generally divided into three categories: empirical models obtained through regression analysis of experimental data, theoretical models derived from mechanical principles, and design-oriented models. Many existing models are empirical models established through regression analysis, fitting, and the simplification of experimental data. The initial compressive strength model is similar to the empirical model for the compressive strength of FRP-confined concrete proposed by Richart [

19] in 1929. Although subsequent models differ in form, their mathematical essence is similar, and the calculation results are relatively stable. However, these models are all based on the fitting of experimental data, and their results represent point estimates for specific parameters, which may have some degree of deviation from the actual ultimate condition under compression. Therefore, the accuracy and completeness of the experimental data play a critical role in the establishment of the model. Additionally, in axial compression tests of FRP-confined concrete cylinders, due to variations in FRP materials, measurement errors, estimation errors, and changes in environmental conditions, it is impossible to precisely predict the ultimate condition under compression of FRP-confined concrete cylinders, and the prediction results exhibit significant uncertainty. These uncertainties are propagated through the model parameter identification process, leading to uncertain model predictions. Consequently, it is necessary to consider these uncertainties through identification of probabilistic parameters. For example, prior probability distributions can be assigned to measurement errors and model parameters, and their posterior probability distributions can be identified through Bayesian inference to quantify the uncertainty in model predictions.

Currently, many researchers have proposed various stress–strain models for FRP-confined concrete cylinders from different perspectives, achieving varying degrees of progress in prediction accuracy. Researchers have conducted experimental studies by controlling different variables and proposed new predictive models for forecasting the compressive strength and ultimate strain of FRP-confined concrete cylinders. However, comprehensive integration and unification of existing data are rarely performed, which limits the applicability of the current models. Furthermore, most existing models are data-driven. While they offer better prediction accuracy compared to traditional models, they are still based on a limited set of experimental data. These models often involve complex or uncertain information, with some parameters needing to be derived from empirical data, making them difficult to obtain through simplified calculation methods. These models are typically expressed in complex or undefined forms, and certain parameters require intricate computational methods, which are not easily obtained through experimentation. Both traditional models and data-driven models are deterministic models, where the predicted compressive strength and ultimate strain of FRP-confined concrete cylinders are given as single values. This overlooks the uncertain relationship between the model inputs and outputs under various unforeseen conditions and fails to reasonably quantify the uncertainty of the prediction results, which does not align with the practical application in engineering.

Bayesian inference has been proven to effectively quantify uncertainty by calculating the posterior distribution. Most of the existing predictive models are empirical formulas developed based on experimental data. These empirical formulas often fail to account for the influence of objective parameters, such as specimen size and fiber type, resulting in limited applicability. This study applies Bayesian inference to calibrate existing models, thereby improving their applicability and prediction accuracy. The results show that the Bayesian method cleverly combines prior information (subjective information) and test data (objective information) to infer the posterior distribution of model parameters. Probability density functions are used to represent parameter estimates, yielding statistical quantities such as mean, variance, and confidence intervals, which better predict the structural performance under load [

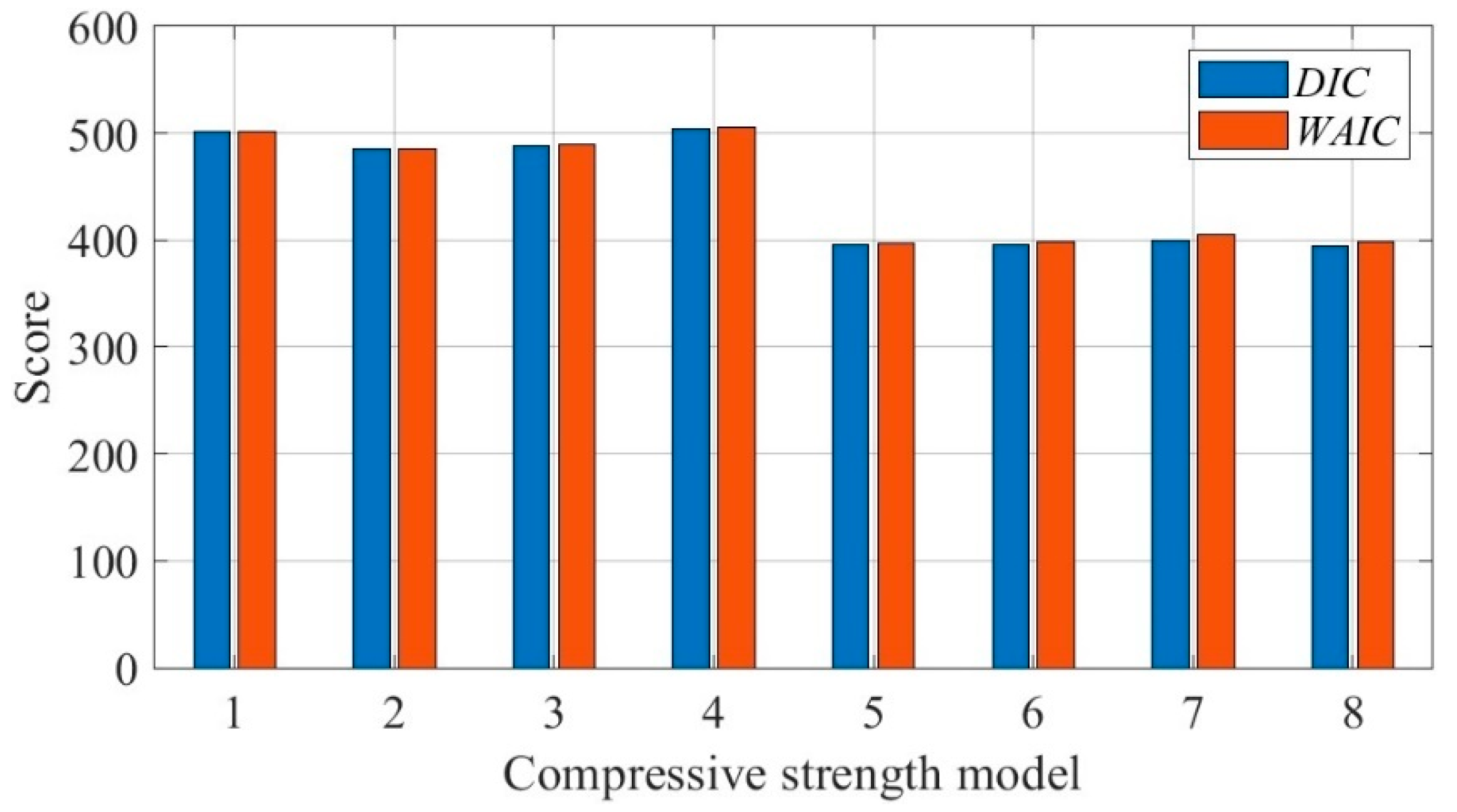

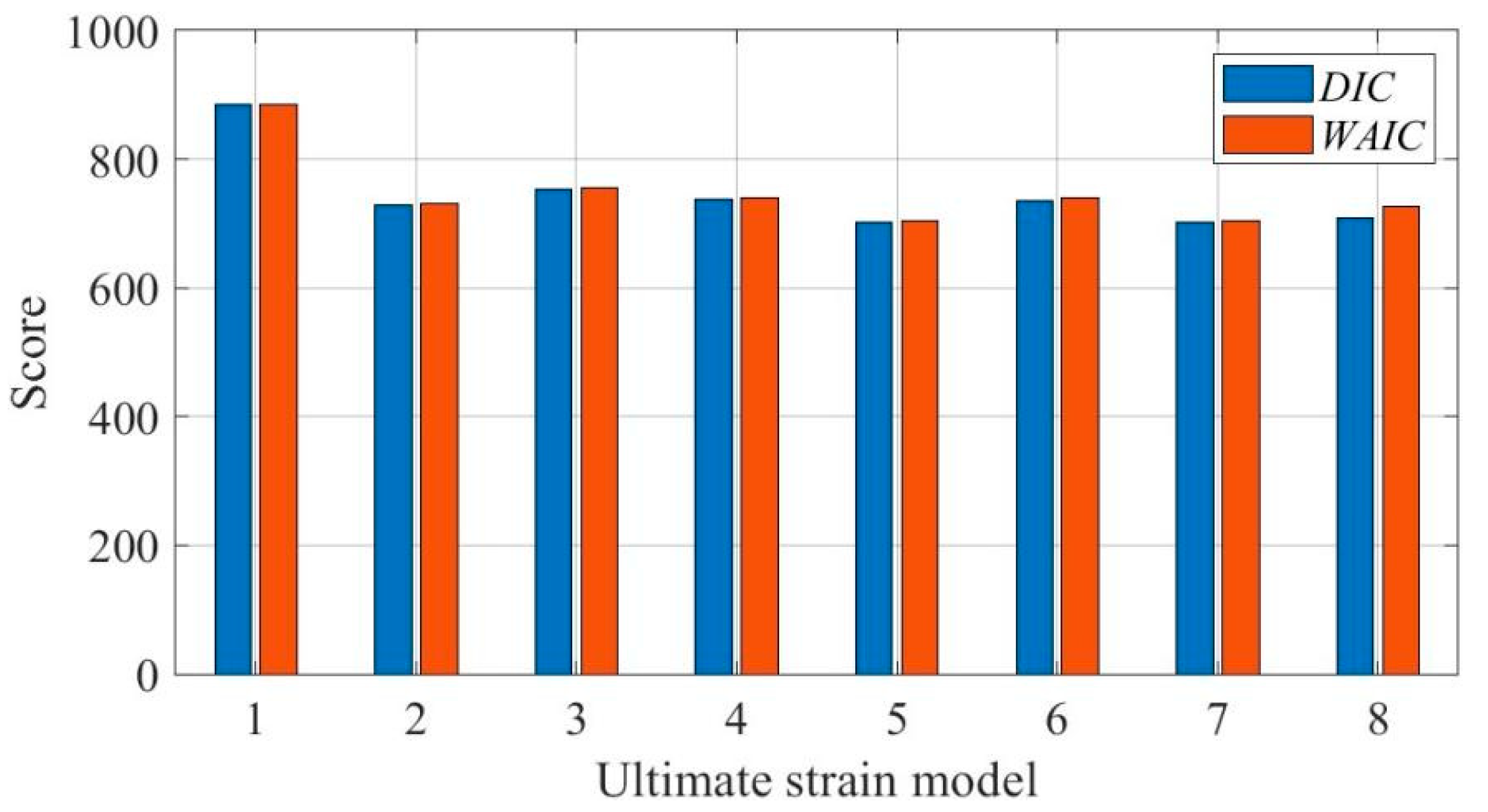

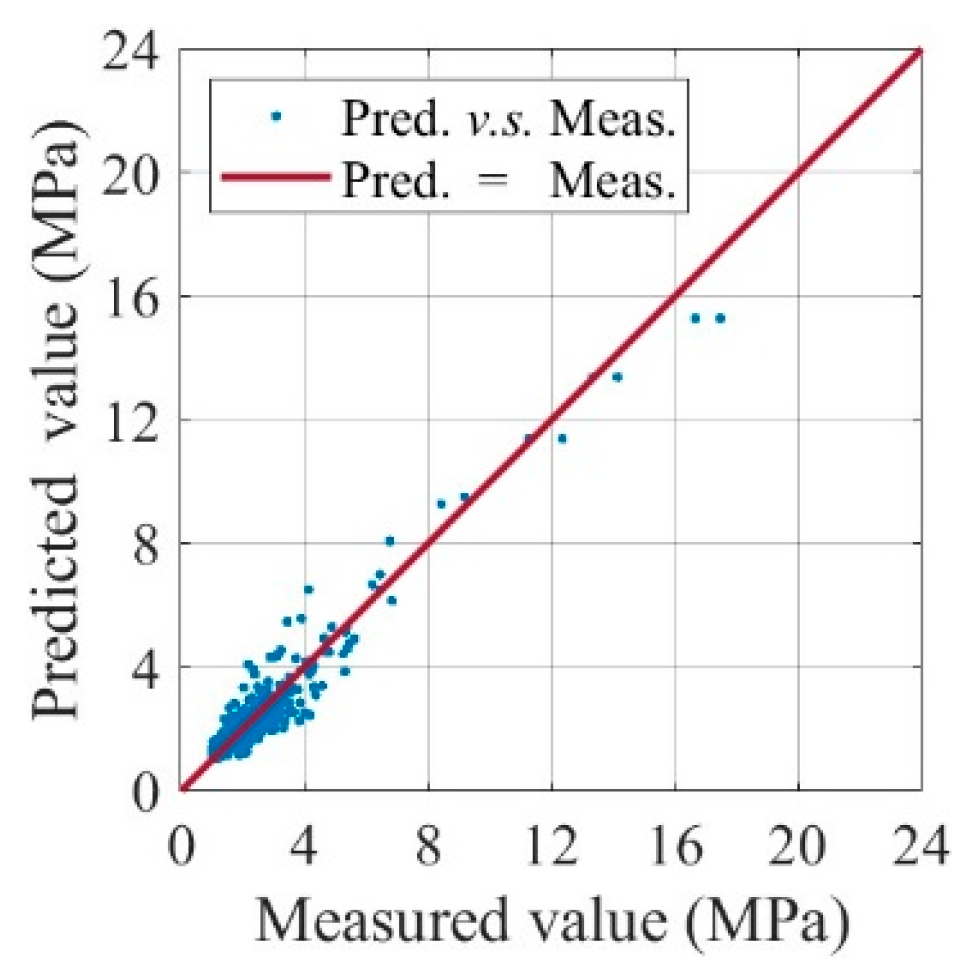

13]. Moreover, the research results demonstrate that the probability model corrected through Bayesian inference significantly improves the prediction accuracy. It enhances the prediction accuracy of the compressive ultimate condition and the rationality of design decisions for FRP-confined concrete cylinders. The findings can provide a useful reference for engineering applications and future research.

2. Collection of Experimental Data

Many studies have conducted uniaxial compression tests on FRP-confined circular concrete cylinders. This study extensively surveys the existing literature and collects 1016 sets of experimental samples on the ultimate condition under compression of FRP-confined circular concrete cylinders [

9,

15,

20,

21,

22,

23,

24,

25,

26,

27,

28,

29,

30,

31,

32,

33,

34,

35,

36,

37,

38,

39,

40,

41,

42,

43,

44,

45,

46,

47,

48,

49,

50,

51,

52,

53,

54,

55,

56,

57,

58,

59,

60,

61,

62,

63,

64,

65,

66,

67,

68,

69,

70,

71,

72,

73,

74,

75,

76,

77,

78,

79,

80,

81,

82,

83,

84,

85,

86,

87,

88,

89,

90,

91]. Each data set includes the following information: the diameter of the concrete cylinder

; the axial compressive strength of the unconfined concrete cylinder

; the axial compressive strength of the FRP-confined concrete cylinder

; the axial strain of the unconfined concrete cylinder

; the ultimate strain of the FRP-confined circular concrete cylinder

; the total thickness of the FRP material

; the elastic modulus of the FRP material

; and the circumferential fracture strain of the FRP material

. Furthermore, the collected experimental samples encompass various types of FRP materials, including CFRP, AFRP, BFRP, and GFRP.

The database in this study includes only unreinforced concrete specimens, excluding those with internal transverse or longitudinal reinforcement and those using fully wrapped FRP materials. Specimens with a length-to-diameter ratio greater than three were also excluded. The compressive strength of the unconfined concrete in the specimen ranges from 6.2 to 188.2 MPa, covering some high-strength concrete data. All specimens failed due to the rupture of the FRP material, and specimens that failed prematurely due to other reasons (such as loss of adhesion of the FRP material or excessive eccentricity) were excluded. The loading form applied was concentric axial load, excluding specimens subjected to eccentric or lateral loads. Specimens that failed to accurately record experimental results due to equipment, instrument errors, or insufficient material geometric properties were also excluded.

Table 1 presents the statistical information of the experimental database collected in this study.

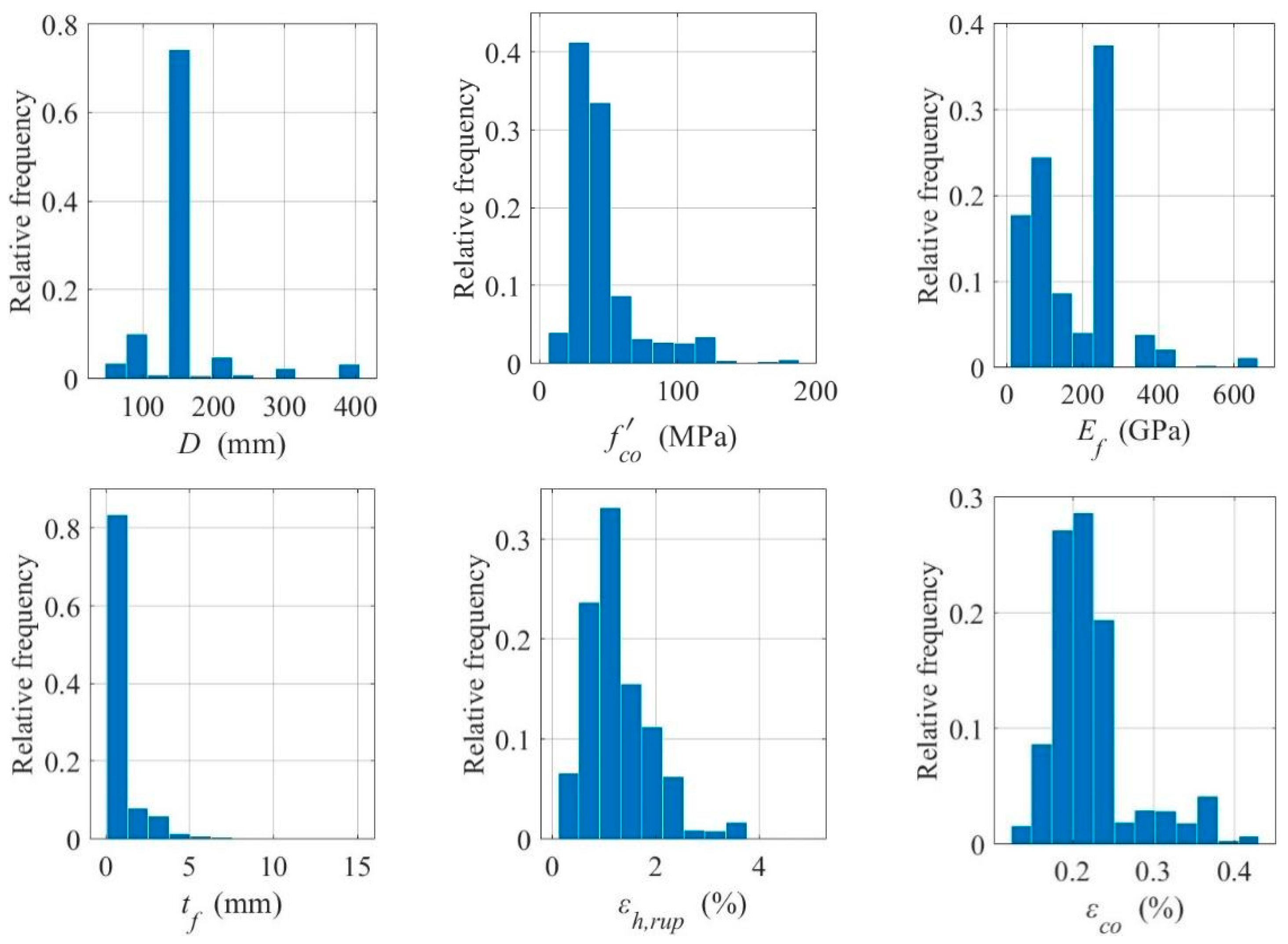

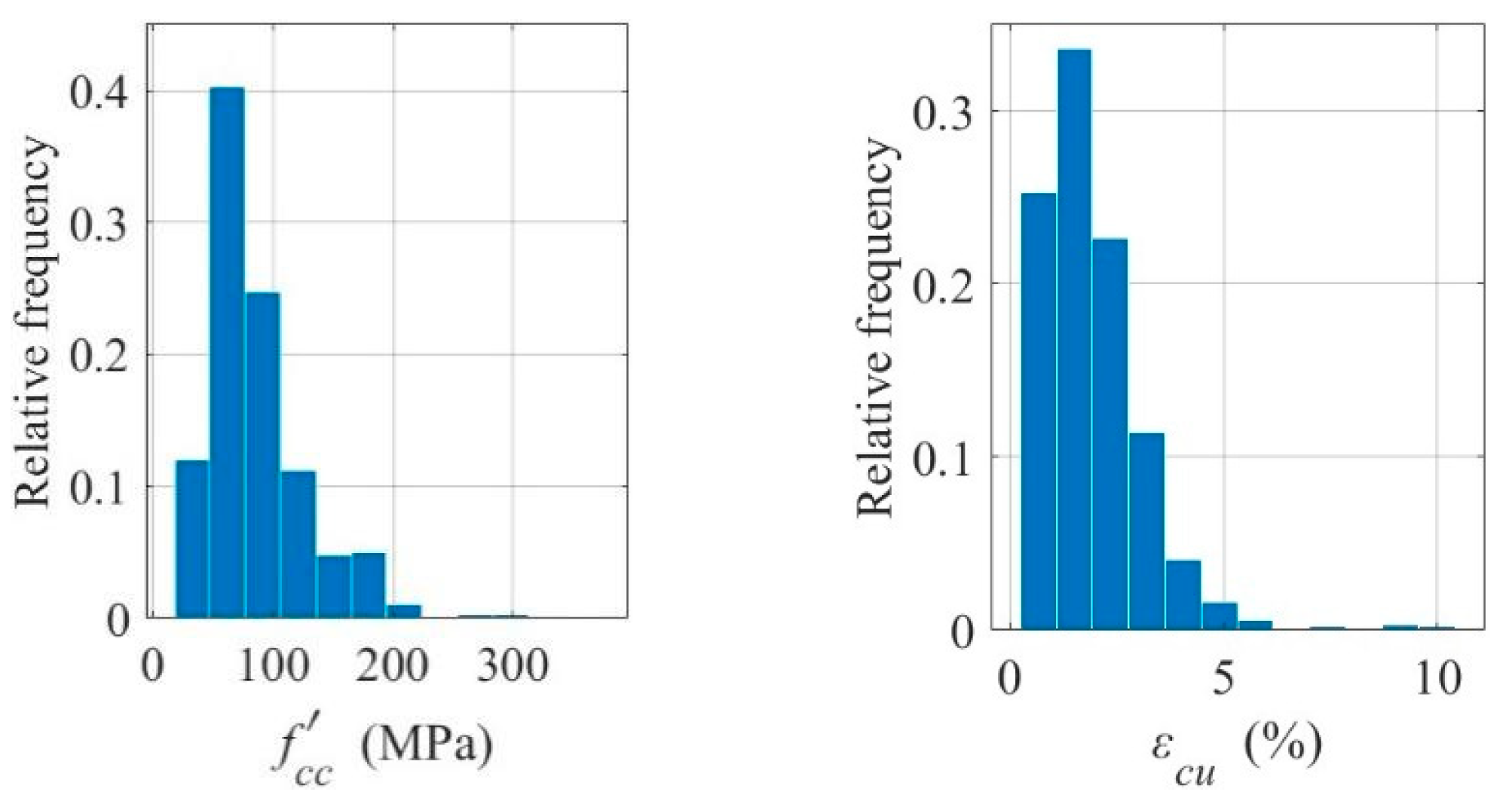

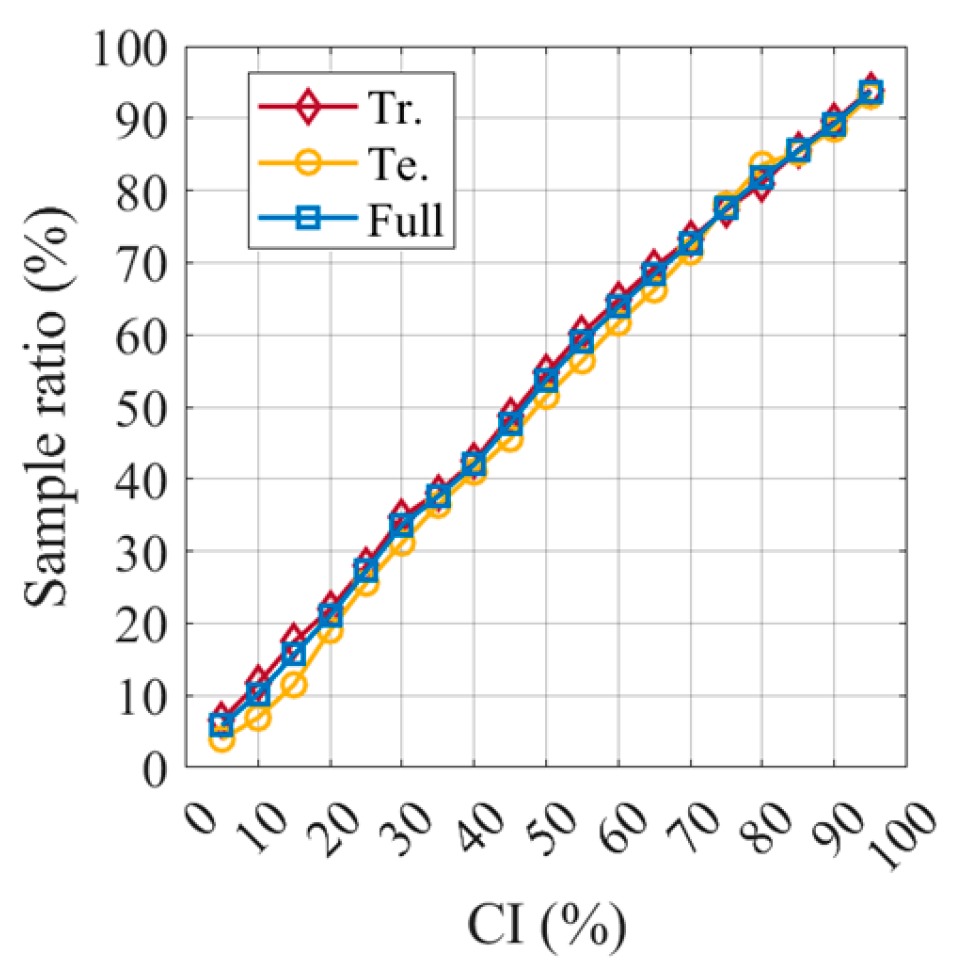

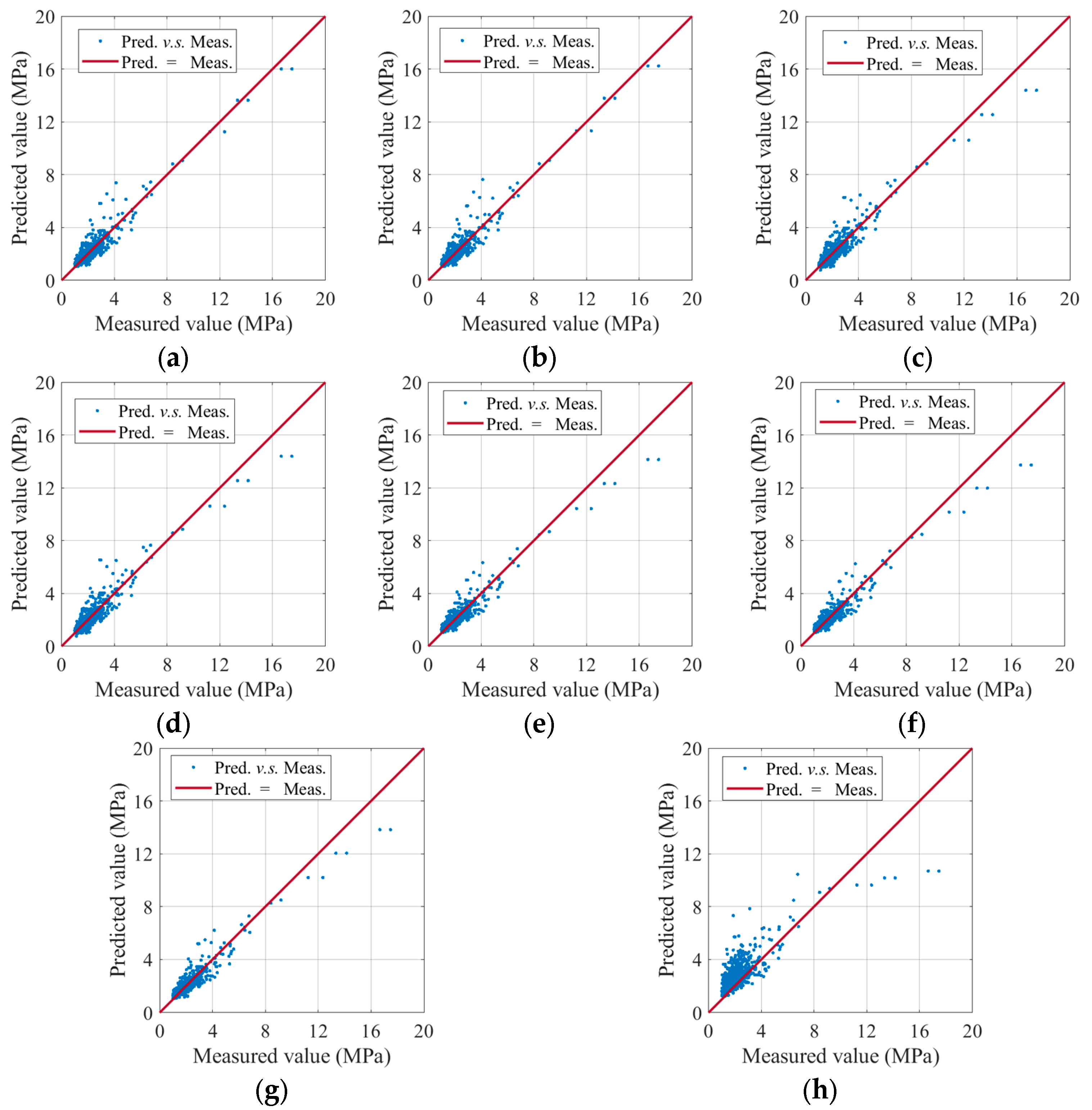

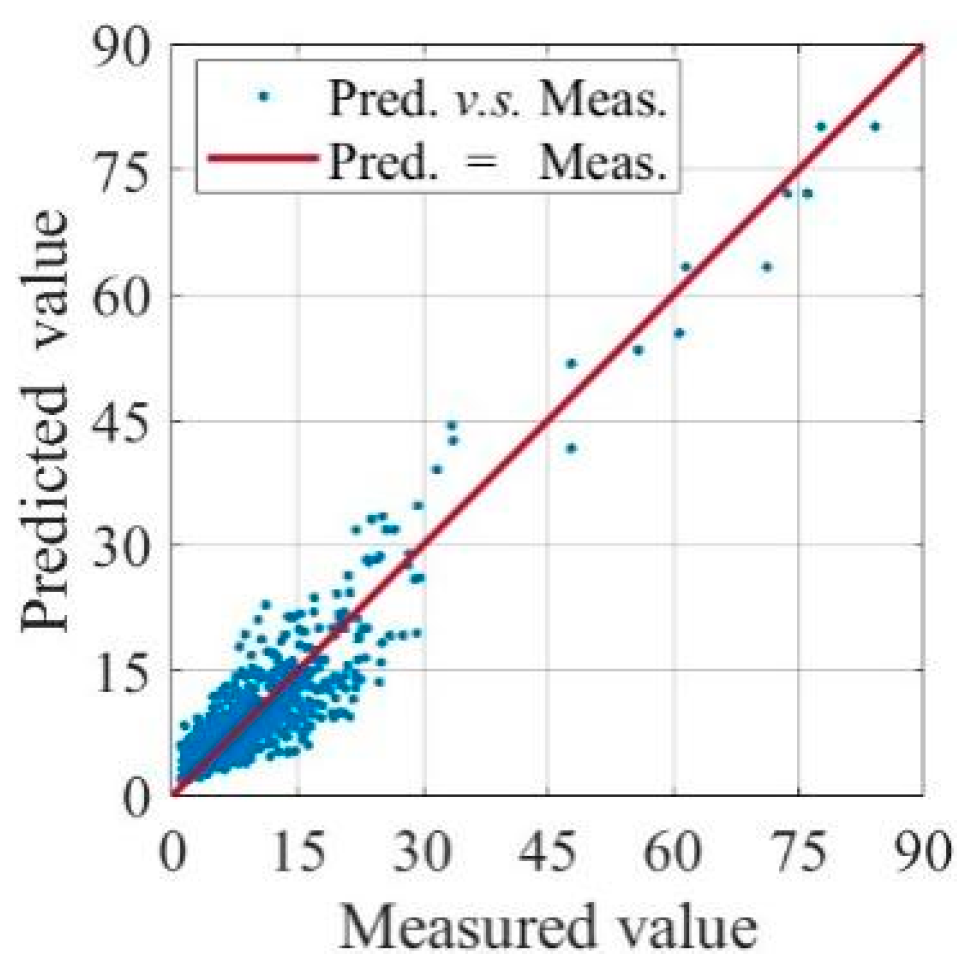

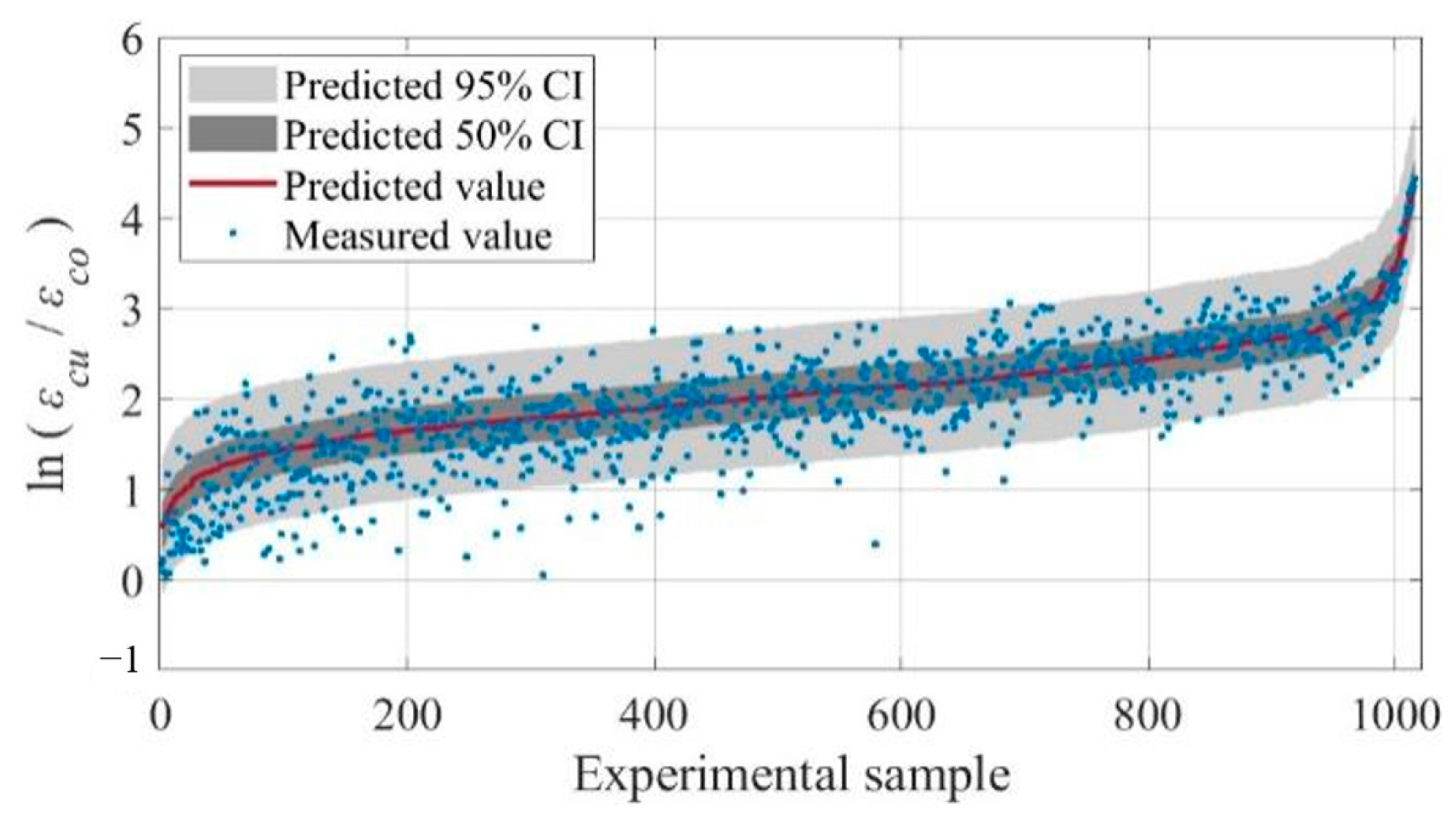

Figure 1 and

Figure 2 show the frequency distribution histograms of the relevant design variables and test variables. As seen from

Table 1 and

Figure 1 and

Figure 2, the design variables included in the current database (such as geometric dimensions and mechanical properties) cover a wide range, indicating its substantial representativeness. In terms of geometric dimensions, the cylinder diameter ranges from 47 to 406.4 mm, and the thickness of the FRP material ranges from 0.06 to 15 mm. Regarding mechanical properties, the elastic modulus of the FRP material ranges from 10.3 to 663 GPa, the compressive strength of unconfined concrete cylinders ranges from 6.21 to 188.2 MPa, and the ultimate strain of unconfined concrete cylinders ranges from 0.12% to 0.43%. Therefore, evaluating compressive strength and ultimate strain based on this database is appropriate, and this database can also be used for probabilistic calibration of models and uncertainty quantification studies.

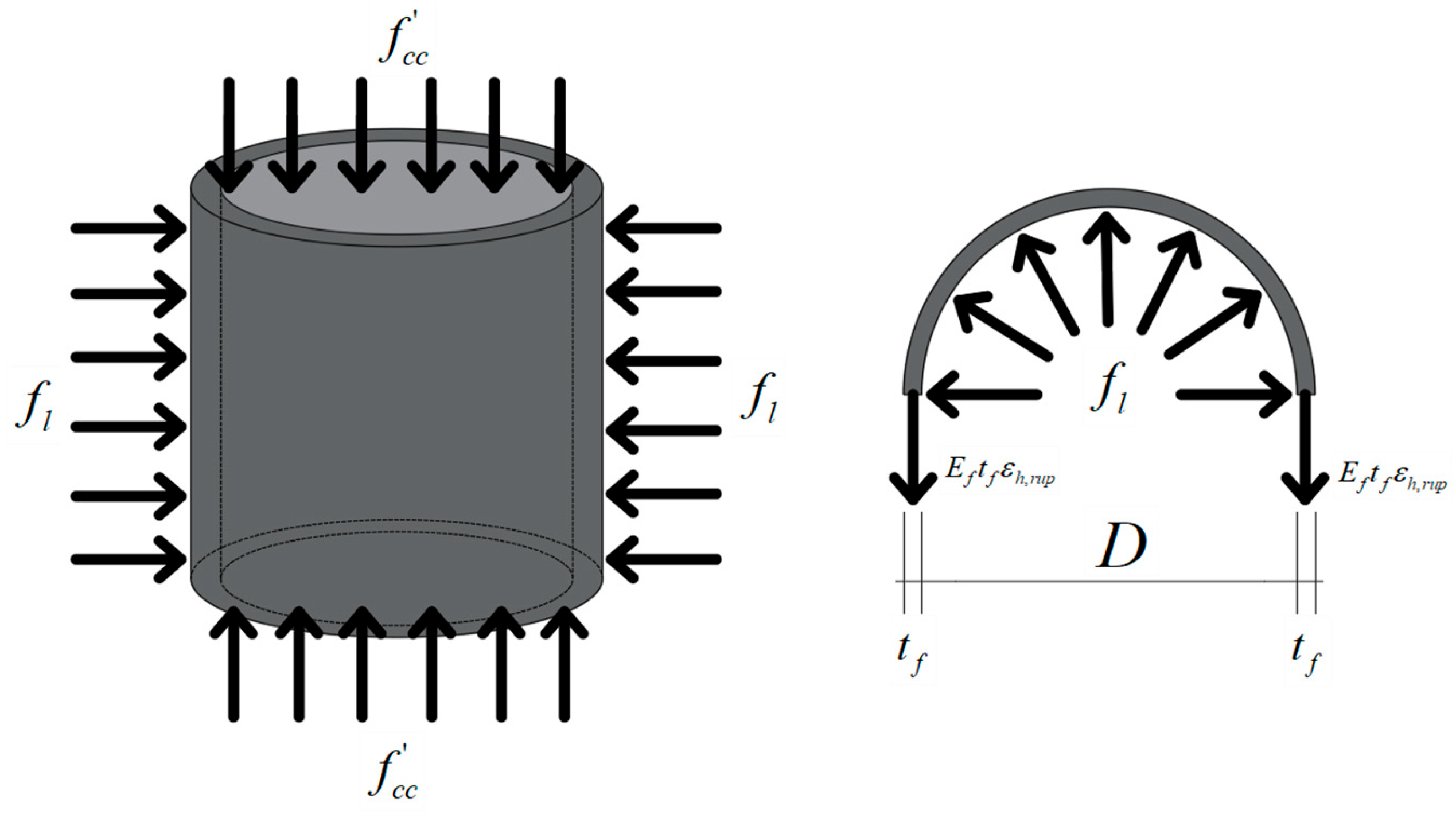

FRP-confined concrete cylinders provide confinement to the internal concrete through the circumferential load applied by the external FRP material, thereby enhancing the overall mechanical performance of the concrete cylinder.

Figure 3 illustrates the confinement mechanism of FRP-confined concrete. Scholars around the world have proposed numerous studies on the compressive strength-bearing models for FRP-confined circular concrete cylinders. Existing strength models define several commonly used parameters, including the maximum confinement stress

, confinement stiffness ratio

, and ratio of strain

, where

represents the stiffness of the FRP material relative to the core concrete, and

is a measure of the strain capacity of the FRP material. These two parameters were introduced by Teng et al. [

92]. Additionally, Keshtegar [

93] introduced the lateral stiffness

and area ratio

.

Table 2 lists the expressions for these commonly used parameters, where

is the diameter of the circular concrete cylinder,

is the axial compressive strength of the unconfined concrete cylinder,

is the axial compressive strength of the FRP-confined circular concrete cylinder,

is the axial strain of the unconfined concrete cylinder,

is the ultimate strain of the FRP-confined circular concrete cylinder,

is the total thickness of the FRP material,

is the elastic modulus of the FRP material, and

is the circumferential fracture strain of the FRP material.

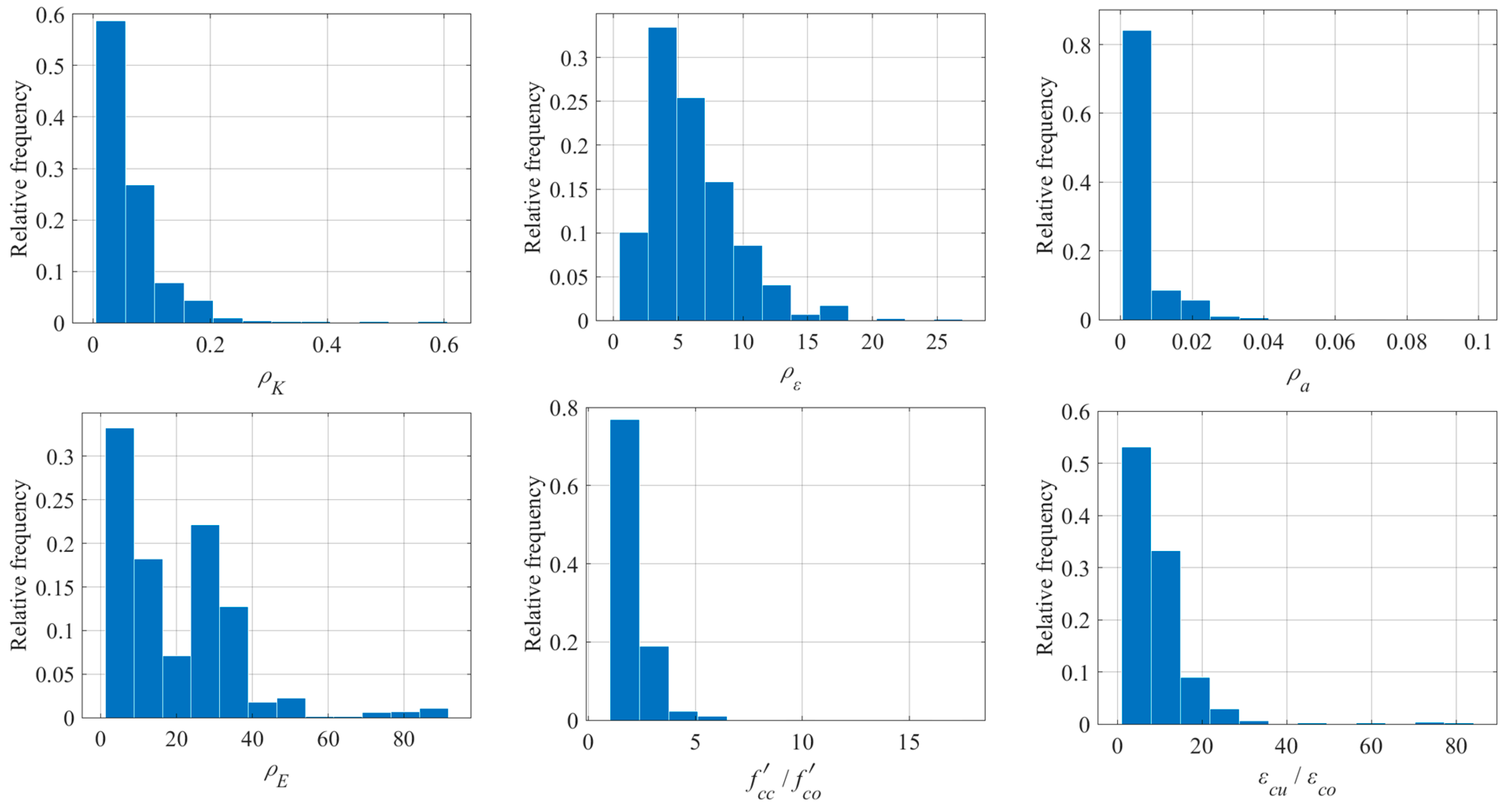

As shown in the expressions listed in

Table 2, the commonly used composite variables in these models are typically formed by a combination of the mechanical properties of the FRP material and the confined concrete, along with the diameter of the concrete. Therefore, these composite variables can also be statistically analyzed using the combination of existing data to determine whether the collected data can be used to evaluate the current ultimate condition prediction models. The confinement ratio

/

is a commonly used parameter in existing compressive strength models and is equal to the product of the confinement stiffness ratio

and the ratio of strain

. According to the study by Teng et al. [

92], the approximate value of 0.002 should not be used to calculate the confinement ratio. Instead, it should be calculated using the following formula (where

is in MPa):

The statistical information of the commonly used composite parameters in the model is listed in

Table 3. The table shows that the range of composite design variables in the database is wide, including the confinement stiffness ratio, ratio of strain, area ratio, and confinement stiffness, with ranges of 0.005 to 0.605, 0.464 to 26.946, 0.0006 to 0.099, and 1.190 to 91.689, respectively. The output variables, strength enhancement ratio and strain enhancement ratio, have ranges of 100.58% to 1746.8% and 105.5% to 8415.6%, respectively. It is evident that, after reinforcement with FRP materials, both the strength and ultimate strain of the concrete cylinders have increased to varying extents, indicating that FRP confinement can effectively improve the mechanical properties of the core concrete cylinders.

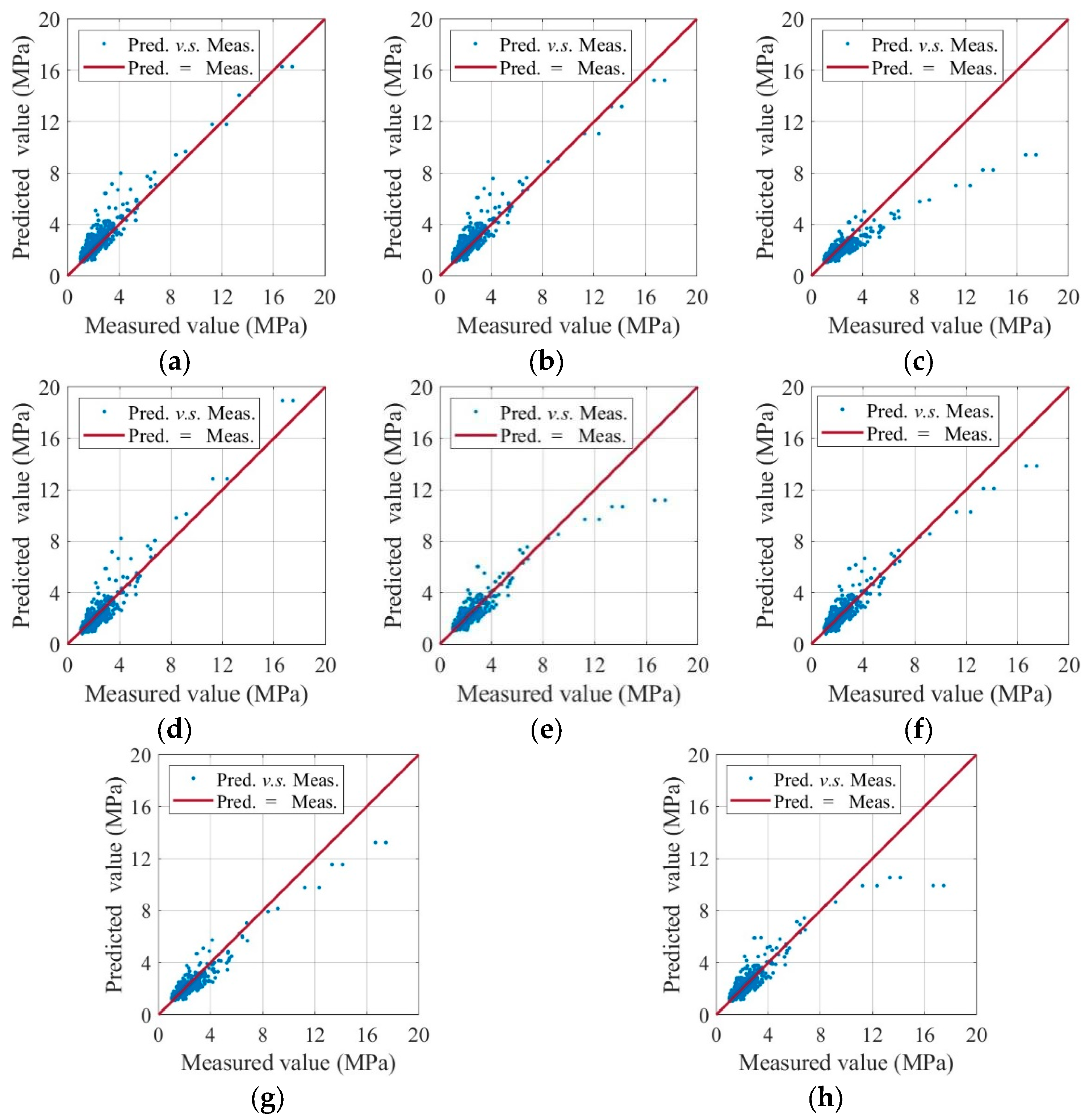

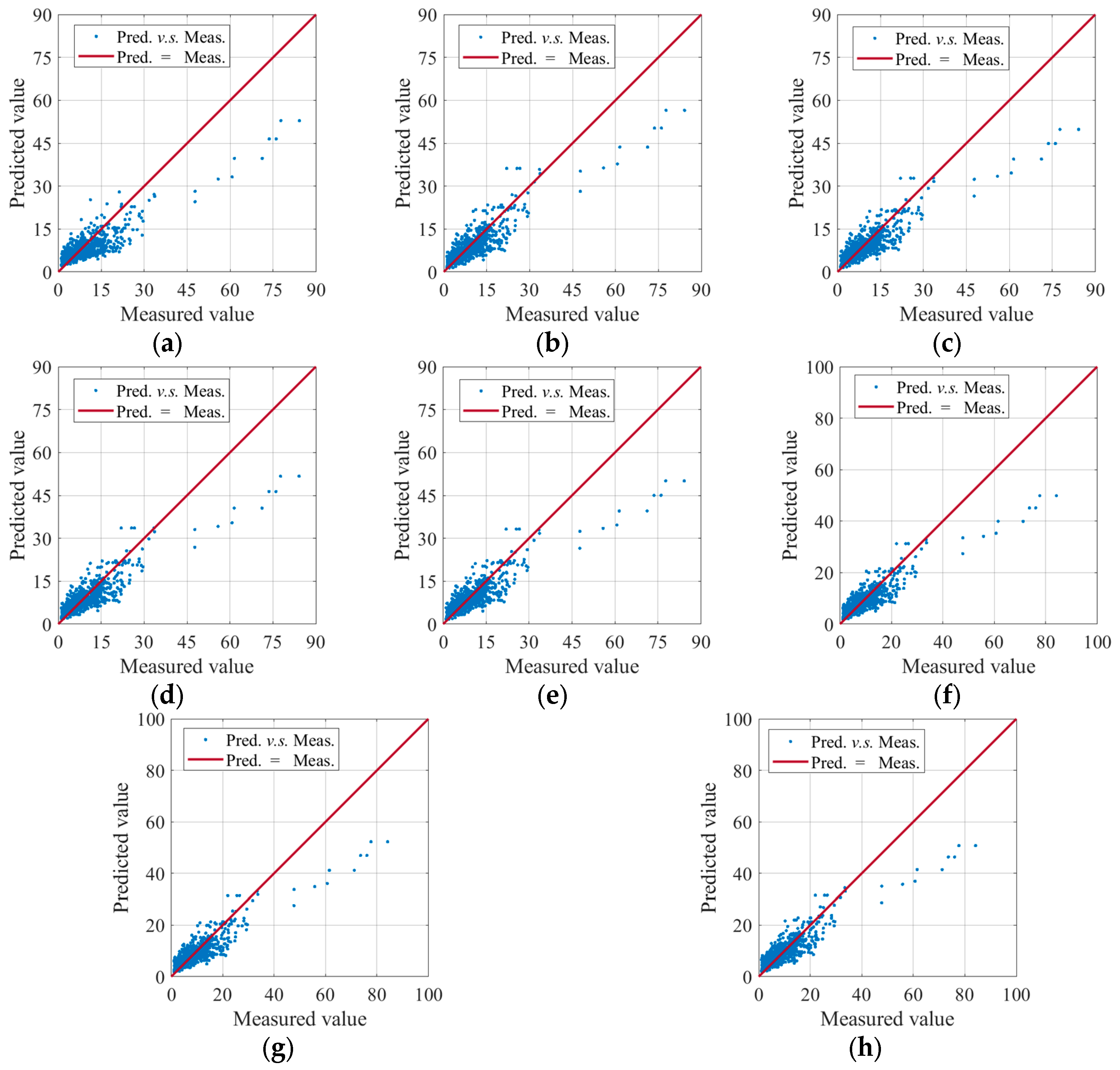

Figure 4 presents the frequency distribution of each composite design variable.