1. Introduction

With the widespread use of cement-based materials in infrastructure such as roads, bridges, and airport runways, these materials must resist not only static loads but also cyclic impact loads from vehicles and aircraft. Repeated impacts can cause internal damage and cracking, reducing performance, shortening service life, and posing safety hazards. Thus, improving the impact toughness of cement-based materials under dynamic loads has become a key research focus [

1]. Conventional approaches often emphasize compressive strength enhancement, but this typically leads to increased brittleness and insufficient improvement in impact resistance. Studies show that fiber incorporation can enhance toughness and crack resistance, making it one of the most effective and economical strategies [

2,

3,

4,

5].

Aramid fiber (AF), a high-performance synthetic fiber, offers excellent tensile strength, toughness, and impact resistance [

6,

7]. While AFs are widely used for concrete reinforcement, the direct inclusion of short-cut AFs into cement matrices has received limited attention. Acebedo et al. [

8] reported increased fracture energy in mortar with AFs, and Walton et al. [

9] identified 1.9% as the optimal AF volume fraction for impact resistance.

Calcium sulfate whiskers (CSWs), sub-nanometer mineral fibers with high strength, modulus, and durability, have shown positive effects on concrete performance and longevity [

10,

11,

12,

13,

14,

15]. For instance, Wan [

16] found that 5% CSWs improved mortar flexural and compressive strengths by 28.3% and 8.5%, respectively. This conclusion is supported by Guoqiang Liu et al. [

17], who demonstrated CSWs’ efficacy in mortar reinforcement.

Basalt fiber (BF), derived from molten basalt, exhibits high tensile strength, modulus, and excellent resistance to heat and corrosion [

18]. Its incorporation has been shown to improve the mechanical properties and impact resistance of concrete [

19]. Moreover, both the length and content of basalt fibers significantly influence the performance of cementitious mortars [

20]. Appropriately selected fiber lengths contribute to effective crack-bridging mechanisms, thereby restraining microcrack propagation, while optimized fiber content enhances mechanical strength without inducing fiber agglomeration or adversely affecting workability. Therefore, careful control of fiber dimensions and dosage is essential to maximize the reinforcing efficiency in cement-based materials.

Recent research has turned toward hybrid fiber systems, which combine fibers with complementary properties to achieve superior mechanical and durability performance compared to single-fiber systems [

4,

21,

22,

23]. Li et al. [

24] reported that a 1:1 mix of AF and carbon fiber yielded optimal compressive and tensile strengths. Other studies also confirm the efficacy of hybrid combinations, such as aramid–steel [

25,

26], aramid–polypropylene, and steel–PVA fibers [

27], in improving tensile and impact performance.

This study explores cement-based composites with a low water-to-binder ratio (w/b = 0.20), positioned between conventional mortar (w/b = 0.4–0.6) and ultra-high-performance concrete (UHPC, w/b < 0.25) [

28]. While fiber-reinforced UHPC has been widely investigated, few studies address the hybrid use of AFs, CSWs, and BFs in low w/b mortars to enhance impact resistance. To fill this gap, this work systematically evaluates the effects of hybrid AF–CSW–BF reinforcement on the mechanical and impact resistance properties of low w/b cement-based composites. Fiber contents were selected based on literature-reported optimal ranges, emphasizing the complementary roles of the fibers and practical considerations for large-scale mixing and testing. Final compositions were determined through combined macro-mechanical tests, microstructural SEM analysis, and statistical optimization.

The novelty of this study lies in the first systematic investigation of the synergistic toughening effects of aramid fibers (AFs), basalt fibers (BFs), and calcium sulfate whiskers (CSWs) in cementitious composites with a low water-to-binder ratio. A cooperative toughening mechanism—characterized by microcrack filling, crack inhibition, and energy dissipation—is proposed to elucidate how the three types of fibers interact to improve the impact toughness and reliability of the material under dynamic loading conditions. Furthermore, the impact resistance data are analyzed using Weibull statistical modeling to reveal the variability in performance. The results provide both theoretical insights and technical guidance for the design of impact-resistant infrastructure such as airport runways, highways, and industrial flooring systems.

3. Results and Discussion

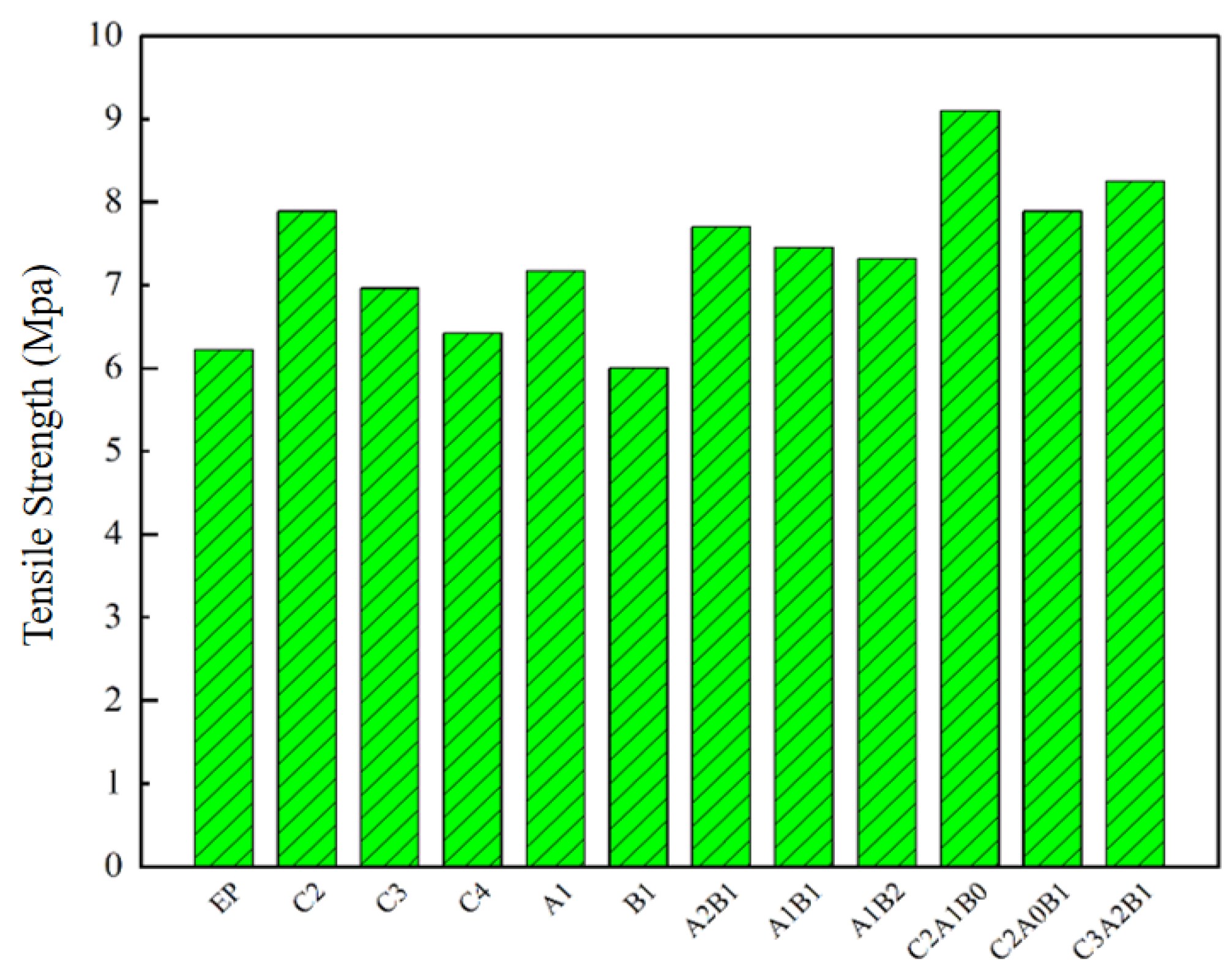

3.1. Splitting Tensile Strength of Hybrid Fiber-Reinforced High-Performance Cement-Based Composites

The tensile strength of cement-based materials is significantly lower than their compressive strength, typically ranging from 5% to 12% of the compressive strength. As a critical factor influencing crack resistance, tensile strength plays a vital role in the cracking behavior of cement-based materials. The splitting tensile test, an indirect method for measuring tensile strength, is widely adopted due to its simplicity, reproducibility, and reliability. Tensile strength is not only an essential parameter for assessing the overall mechanical performance of cement-based materials but also serves as a key reference for crack-resistance design and performance optimization in practical engineering applications.

As shown in

Figure 4, the splitting tensile strength of fiber-reinforced mortars exhibited a fluctuating trend with increasing CSW content. Among the tested mixtures, the mortar incorporating 2% CSW (C2) achieved the highest splitting tensile strength, showing a 32.8% increase compared to the EP control group. This was followed by the 4% CSW mortar (C4), which demonstrated a 17.4% improvement, while the 3% CSW mortar (C3) showed a relatively modest increase of 12.0%. The mortar with only AF incorporation (A1) exhibited a slight improvement of 2.62% over the control group. In contrast, the BF-only mortar (B1) displayed a reduction in splitting tensile strength by 8.3% compared to the control group, representing the only case among the single-fiber series where a decrease was observed. The reduction in tensile strength observed in the B1 group can be attributed to several factors. First, basalt fibers (BFs) are relatively long and rigid, making them prone to agglomeration, which leads to non-uniform dispersion and the formation of weak interfacial zones, thereby compromising mechanical performance. Second, the smooth surface of BFs results in poor interfacial bonding with the cement matrix, limiting their ability to effectively transfer stress. Additionally, the BF content used in this study was 0.1%, which may not have reached the optimal dosage for reinforcement, and in some cases, may have provided negligible enhancement or even disrupted the matrix structure. These findings indicate that, within the low water-to-binder ratio mortar system investigated, the use of BFs alone is insufficient to achieve effective reinforcement. Therefore, combining BFs with other fibers or applying surface modifications may be necessary to improve their reinforcing performance.

All hybrid fiber-reinforced mortars (A2B1 to A1B2) exhibited higher splitting tensile strength than those reinforced with single fibers (AFs or BFs) and the EP control group. However, as the BF content increased, the splitting tensile strength of the hybrid mortars showed a gradual decline, indicating that aramid fiber (AF) played the dominant role in tensile strength enhancement. Notably, the mortar incorporating 0.067% AF and 0.033% BF (A2B1) showed a 31.4% improvement over the control, suggesting an effective synergistic interaction between AF and BF at this ratio. AFs, characterized by their high tensile strength and aspect ratio, played a leading role in bridging cracks and inhibiting crack propagation. Meanwhile, appropriately dosed BFs contributed to energy dissipation; however, due to their greater stiffness and relatively weak interfacial bonding with the cement matrix, excessive BF incorporation tended to result in poor dispersion or fiber agglomeration, thereby diminishing the reinforcing effect. Therefore, a 2:1 ratio of AF to BF achieved a well-balanced reinforcement mechanism. However, in the dual-fiber system, as the basalt fiber (BF) content increases, the tensile strength of A1B2 decreases by 6.8% compared to A1B1. This is mainly attributed to the high stiffness and brittleness of BF, which hinders its synergistic interaction with the more ductile aramid fiber (AF). The mismatch in deformability tends to cause stress concentration, while the high rigidity of BF also makes it more prone to agglomeration or breakage during mixing and casting, leading to reduced effective length and interfacial bonding performance, thereby weakening its reinforcing effect. In addition, the splitting tensile strength of the AF–CSW hybrid mortar (C2A1B0) exceeded that of the single-AF mortar (A1) and the EP control group, while the CSW–BF hybrid mortar (C2A0B1) outperformed the single-BF mortar (B1) and the control. Compared to the control, the splitting tensile strength increased by 50.7% in the mortar containing 2% CSW and 0.1% AF (C2A1B0), and by 26.6% in the mortar with 2% CSW and 0.1% BF (C2A0B1). These results further confirm the advantages of fiber hybridization in enhancing the tensile properties of mortar and highlight that the reinforcing effectiveness depends on a well-designed fiber ratio and uniform dispersion of each component.

The ternary fiber combination of CSWs, AFs, and BFs demonstrated superior reinforcement performance compared to binary fiber systems. Notably, the mixture containing 3% CSW, 0.067% AF, and 0.033% BF (C3A2B1) exhibited a 46.9% increase in splitting tensile strength relative to the EP control group, significantly outperforming the AF–BF binary fiber blend. This result indicates that the synergistic interaction of multi-scale fibers in the ternary system effectively enhances the overall strength of the mortar.

Among all tested specimens, the mortar incorporating 2% CSW and 0.1% AF (C2A1B0) achieved the highest splitting tensile strength. This highlights the presence of a positive hybrid effect in the binary fiber system, where the synergistic action of the two fibers at both the micro and macro scales significantly improves the tensile performance of the mortar. In contrast, although CSWs, AFs, and BFs individually contribute to crack control at different scales in the ternary system, their interactions may introduce a negative hybrid effect, thereby compromising the overall reinforcing efficiency. Consequently, the combination of 2% CSW and 0.1% AF was identified as the optimal fiber dosage, yielding the best tensile strength enhancement among all tested groups.

Further analysis suggests that nano-scale CSW fibers enhance matrix compactness by filling micropores and limiting the initiation and propagation of microcracks. Meanwhile, the millimeter-scale AFs and BFs primarily act to bridge and control larger cracks. The multi-scale reinforcement mechanism provided by CSWs, AFs, and BFs collectively improves the matrix integrity and crack resistance, thereby enhancing the mortar’s splitting tensile performance.

3.2. Tensile Strength of Hybrid Fiber-Reinforced High-Performance Cement-Based Composites

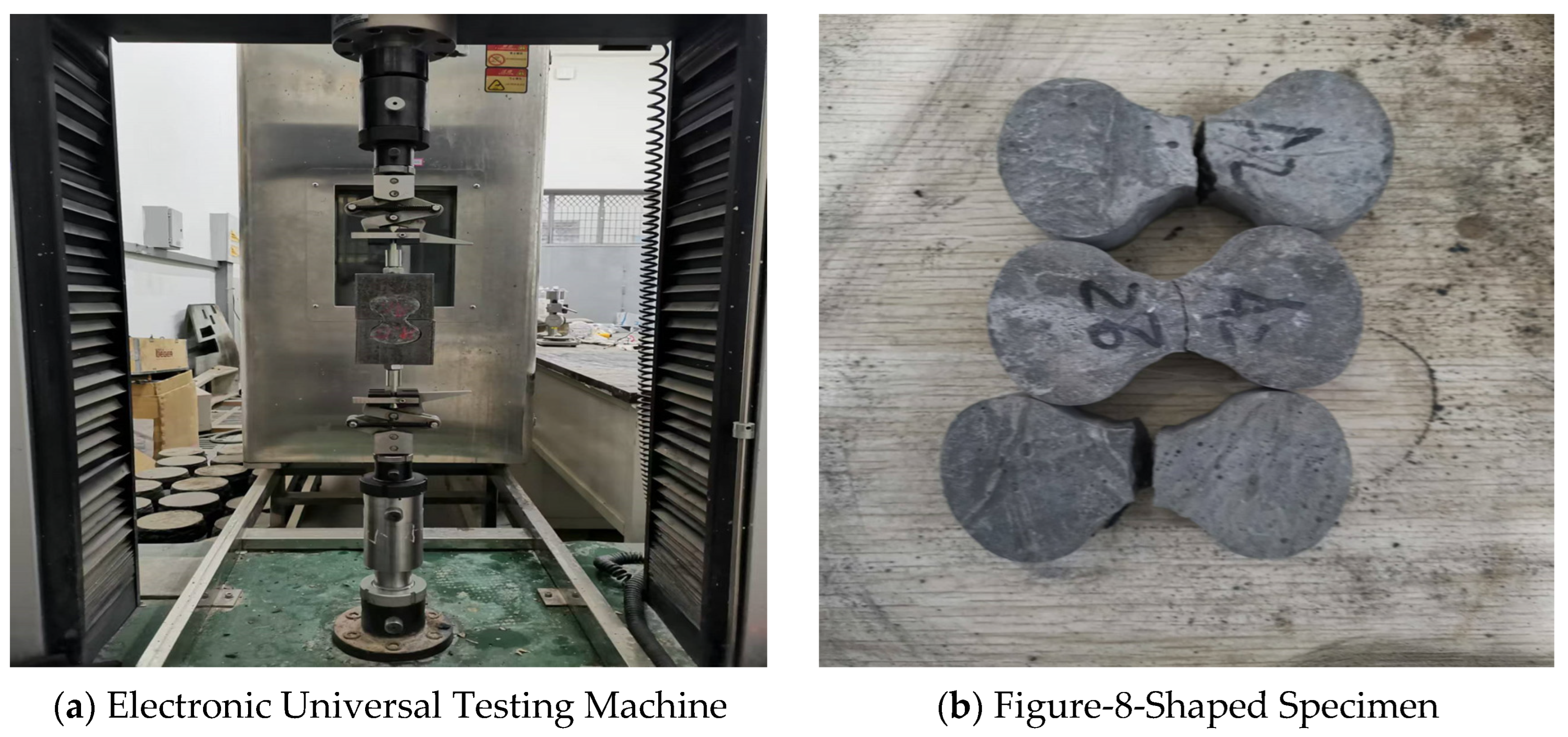

The uniaxial tensile test is a direct tensile testing method that provides a more accurate representation of the tensile strength of cement-based materials.

As shown in

Figure 5, the tensile strength of the mortar initially increases and then decreases as the CSW content increases. The tensile strength of mortars with 2% CSW (C2), 3% CSW (C3), and 4% CSW (C4) is 26.8%, 11.9%, and 3.2% higher than that of the EP control group, respectively, with the 2% CSW mortar (C2) exhibiting the best performance. The tensile strength of mortar with only AFs (A1) is 15.3% higher than that of the CAB0 control group, whereas the tensile strength of mortar with only BFs (B1) is slightly lower than the control group, decreasing by 3.5%. This indicates that AFs are more effective than BFs in enhancing tensile strength. Among the single-fiber mortars, the 2% CSW mortar (C2) demonstrated the highest tensile strength.

Among the single-fiber-reinforced mortars, the specimen incorporating 2% calcium sulfate whiskers (CSWs) (C2) exhibited the highest tensile performance. Binary fiber-reinforced mortars combining aramid fibers (AFs) and basalt fibers (BFs) (A2B1 to A1B2) demonstrated superior tensile strength compared to specimens with single AFs (A1), single BFs (B1), and the plain control (EP), indicating an effective stress distribution capability and interfacial synergy under static loading. Specifically, AFs contributed significantly to tensile reinforcement due to their high tensile strength and aspect ratio, while BFs provided auxiliary bridging effects through frictional resistance and mechanical interlocking. However, with increasing BF content, the tensile strength of the binary systems gradually declined, suggesting that under the current interfacial bonding conditions, BFs’ reinforcing contribution was limited, and AFs played a more dominant role in strength enhancement. Notably, the mortar with 0.067% AF and 0.033% BF (ABC7) exhibited a remarkable increase in tensile strength, 23.8% higher than that of the EP control. The specimen incorporating 2% CSW and 0.1% AF (C2A1B0) showed a 46.3% improvement, while the specimen with 2% CSW and 0.1% BF (C2A0B1) exhibited a 26.8% increase compared to the EP control, outperforming the single-fiber AF (A1) and BF (B1) specimens, respectively. These findings confirm a pronounced synergistic enhancement effect under static loading that is attributable to the pore structure densification induced by CSW and the bridging and interfacial contributions of the hybrid fiber system.

Furthermore, the ternary fiber-reinforced mortar (C3A2B1), composed of 3% CSW, 0.067% AF, and 0.033% BF, achieved a 32.6% increase in tensile strength compared to the EP group, exceeding that of the binary AF-BF combination (A2B1), and demonstrating a positive synergistic effect among the three fibers.

Among all tested groups, the C2A1B0 specimen exhibited the highest tensile strength, which is consistent with the trend observed in splitting tensile strength. This further validates the effectiveness of the CSW–AF hybrid system in achieving optimal reinforcement under static loading, through synergistic improvements in pore structure, interfacial bonding, and stress distribution. However, the ternary system did not exhibit additional positive hybrid effects under the current mix proportions, and a partial reduction in performance was observed.

3.3. Enhancement of Compressive Strength in HPCC Using Hybrid Fibers

Figure 6 shows the compressive strength of hybrid fiber-reinforced high-performance cementitious composites at 28 days.

As shown in

Figure 6, a moderate addition of calcium sulfate whiskers (CSWs) significantly enhances the compressive strength of high-performance cementitious composites (HPCCs) reinforced with hybrid aramid (AFs) and basalt fibers (BFs), outperforming the fiber-free control. However, excessive CSW content leads to strength reduction due to agglomeration, uneven dispersion, and overlapping weak interfaces in the dense matrix, which induce internal defects.

In the AF–BF (2:1) system, compressive strength increased by 14.6%, −0.5%, and 6.7% with 2%, 3%, and 4% CSW, respectively, compared to the same fiber system without CSWs. Relative to the control, the increases were 33.6%, 15.9%, and 24.4%. These results suggest that CSWs interact more effectively with AFs, and their contribution decreases with higher BF content.

Overall, 2% CSW combined with AF yields the most significant strength gain, indicating a positive hybrid effect. In contrast, the ternary system shows limited fiber synergy and potential interference, resulting in reduced compressive performance.

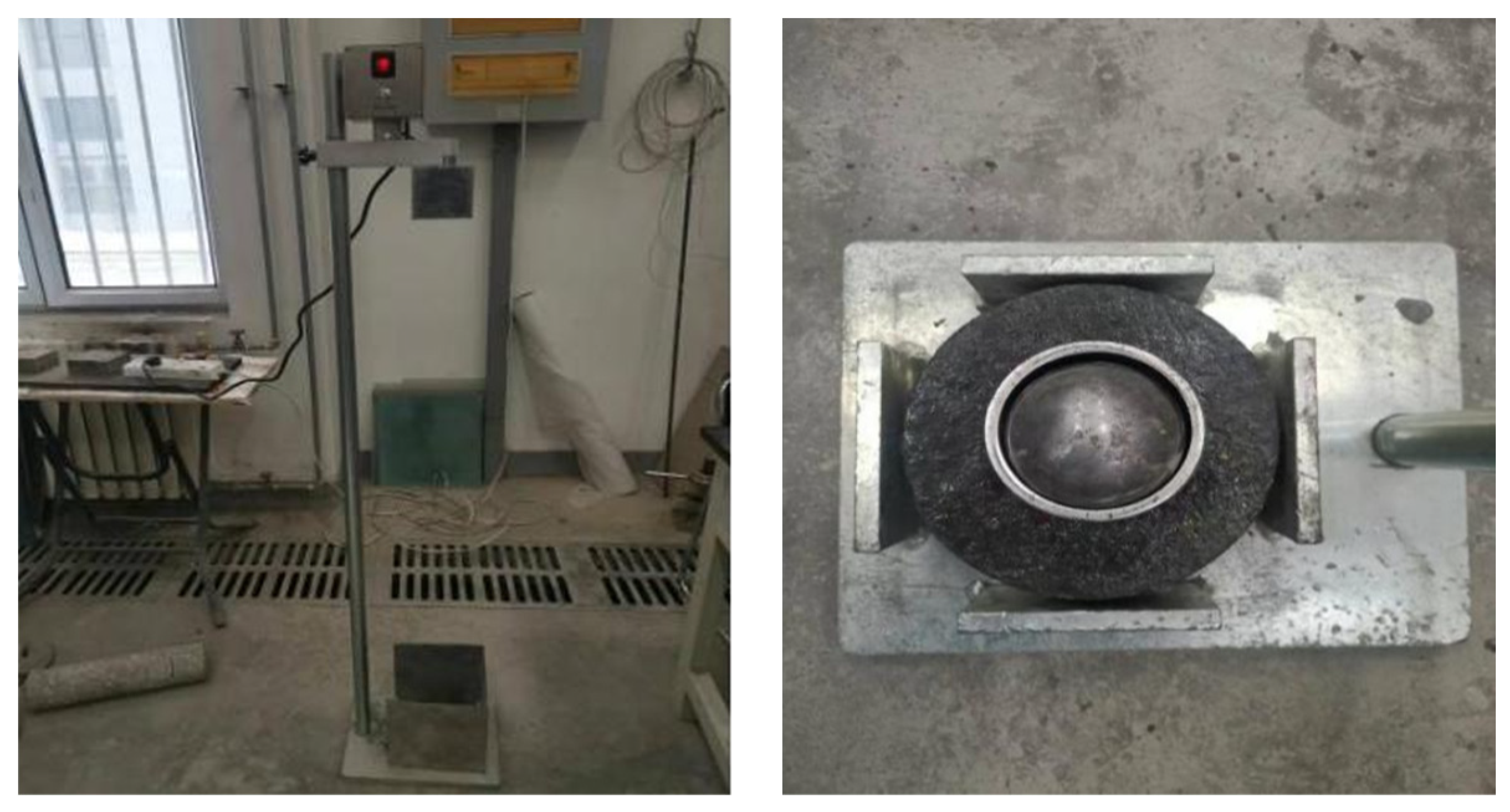

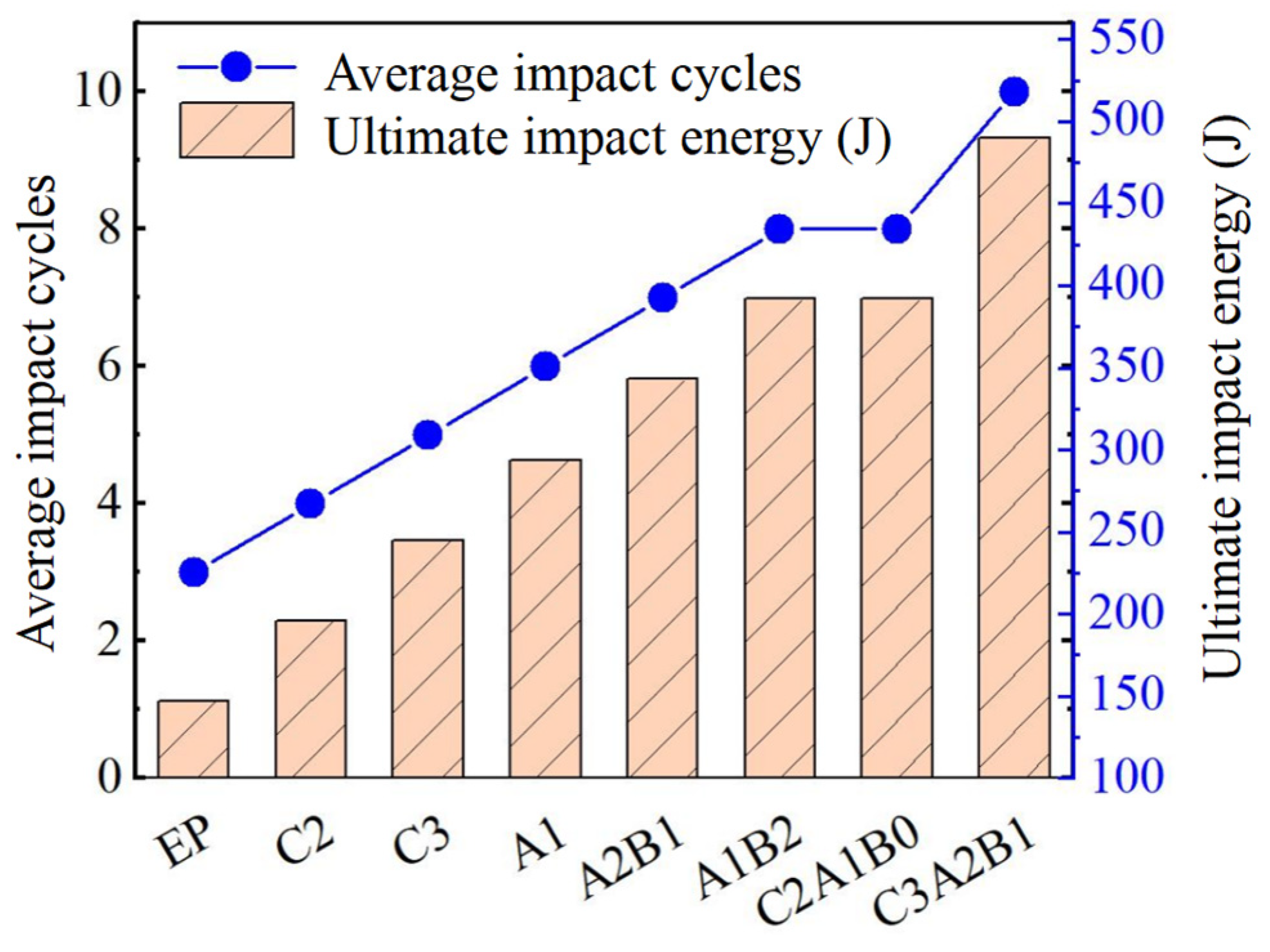

3.4. Impact Resistance Test

As shown in

Figure 7, the failure impact energy of the mortar progressively increases with rising CSW content. The fracture impact energy of mortars with 2% CSW (C2) and 3% CSW (C3) was 33.3% and 66.7% higher, respectively, than that of the EP control group. The fracture impact energy and final crack impact toughness ratio of mortar reinforced solely with AFs increased by 100%, establishing AFs as the best performer in impact resistance among all single-fiber specimens. This finding suggests that the relatively long aramid fibers are more effective in restraining the development of macrocracks within the mortar, thereby significantly enhancing its impact resistance.

The impact resistance of dual-fiber mortars containing AFs and BFs (A2B1 and A1B2) showed further improvement, with fracture impact energy increasing by 133.3% and 166.7%, respectively. As the proportion of BFs increased, the impact resistance of the dual-fiber mortar continued to improve, indicating that the combination of longer BFs and AFs significantly optimized the impact resistance of the mortar.

For the dual-fiber combination of CSWs and AFs (C2A1B0), both fracture impact energy and impact toughness ratio surpassed those of the single-fiber CSW and AF mortars, showing a 166.7% improvement over the EP control group. Furthermore, the three-fiber combination (C3A2B1) exhibited the highest impact resistance, with fracture impact energy increasing by 233.3% compared to the control group.

In summary, the hybrid fiber system significantly enhances the impact resistance of high-performance cementitious composites under dynamic loading through mechanisms such as fiber pull-out energy dissipation, synergistic stiff–soft reinforcement, and delayed crack propagation. Specifically, calcium sulfate whiskers (CSWs) primarily suppress microcracks, aramid fibers (AFs) control macrocrack development, and basalt fibers (BFs) enhance structural integrity. The combined action of these three fibers forms a multi-scale crack-resistance network, delivering the highest levels of toughness and energy absorption among all tested specimens.

3.5. Impact Failure Modes

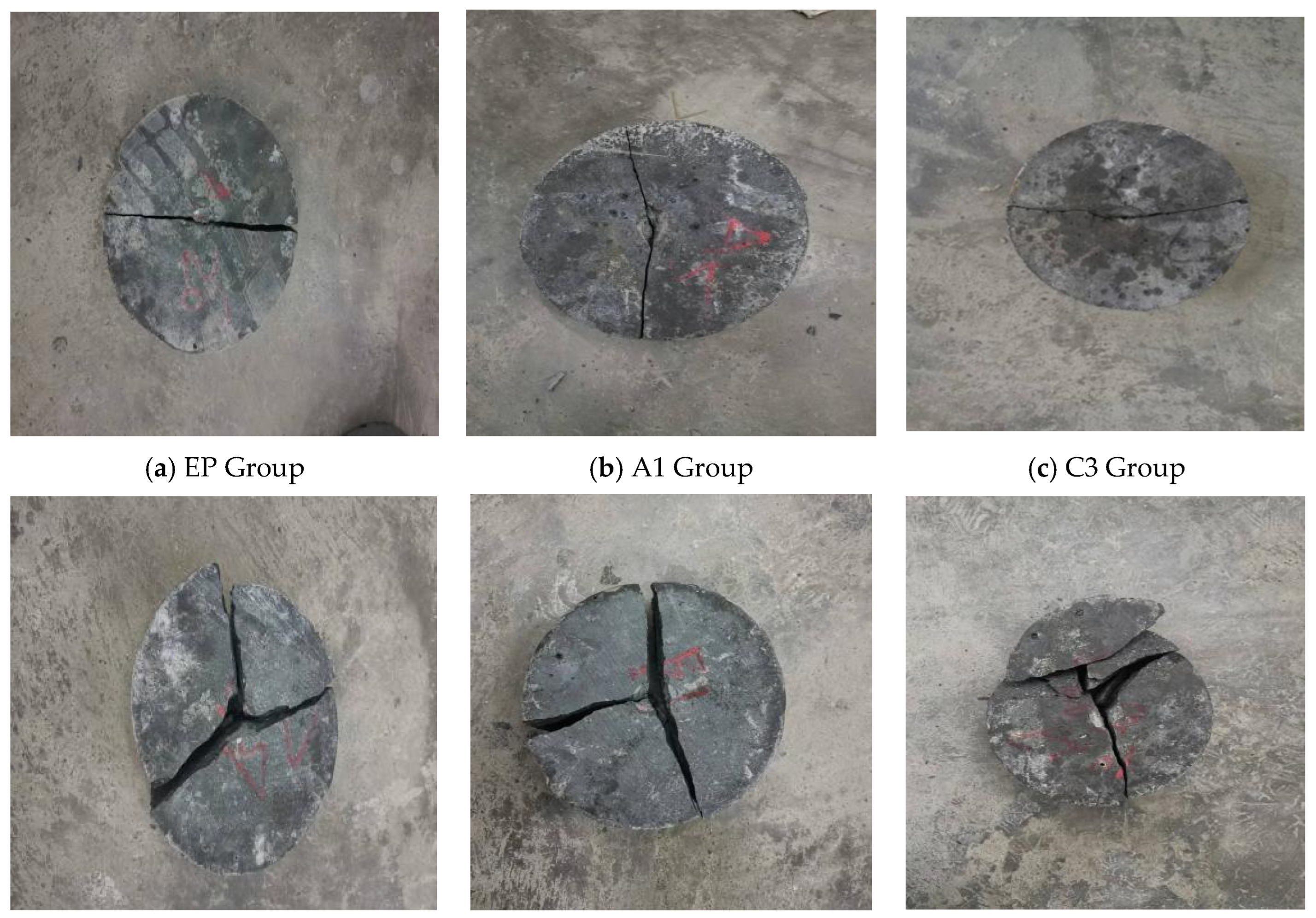

As shown in

Figure 8, different fiber combinations had a significant impact on the fracture patterns of the mortar. The control group without fibers exhibited a single, straight-line crack. Mortars containing only AF or 3% CSW (A3) displayed crescent-shaped cracks. In contrast, dual-fiber mortars with AFs and BFs (A2B1 to A1B2) and the three-fiber mortar (C3A2B1) exhibited T-shaped or Y-shaped crack patterns, accompanied by multiple secondary cracks, indicating distinct toughening fracture characteristics.

This variation in crack morphology can be attributed to the high-energy impact from the 1110 mm drop height used in the test. The finer and shorter calcium sulfate whiskers (CSWs) and aramid fibers (AFs) are less effective at resisting the propagation of macrocracks, whereas the longer and coarser basalt fibers (BFs) more effectively inhibit macrocrack development.

Therefore, the failure modes of the dual-fiber combination of AFs and BFs, as well as the three-fiber combination of CSWs, AFs, and BFs (C3A2B1), indicate that these mixtures require higher impact energy to induce failure. This not only delays the formation of the primary crack but also results in multiple secondary cracks, reflecting enhanced toughness and an improved capacity of the fiber-reinforced mortar to resist crack propagation.

3.6. Statistical Analysis of Impact Resistance Test Results for Hybrid Fiber-Reinforced High-Performance Cement-Based Composites

Cement-based materials consist of cementitious materials, aggregates, and water. Due to their multi-phase composition and the inherent presence of pores and cracks, results from drop hammer impact tests often exhibit considerable variability. To better characterize this variability, effective tools such as statistical methods are used [

31]. Among these, the normal distribution and the Weibull distribution are commonly applied statistical models. Initially developed for analyzing the fatigue life of metals, these models have, in recent years, been widely used in research on the fatigue life of concrete.

However, studies have shown that drop hammer impact test data for fiber-reinforced concrete do not follow a normal distribution [

32,

33], indicating that the normal distribution is unsuitable for this type of analysis. In contrast, the Weibull distribution has proven to be more accurate in analyzing the impact resistance of fiber-reinforced concrete, providing a better fit to experimental data. Consequently, this study employs Weibull distribution theory to analyze the impact resistance of hybrid high-performance cement-based composites. This approach not only allows for a more precise characterization of variability in material performance but also offers valuable insights into the design and optimization of future high-performance composite materials.

3.7. Weibull Distribution Fitting Analysis for Impact Resistance Test Results of Hybrid Fiber-Reinforced High-Performance Cement-Based Composites

The probability density function of the Weibull distribution for impact fatigue life is expressed as follows:

where

N0 is the minimum life parameter;

Na is the characteristic life parameter;

b is the Weibull shape parameter, with Na and b both greater than 0.

When N

0 = 0, Equation (6) simplifies to a two-parameter Weibull distribution:

If the cumulative failure probability function of the impact failure cycles N for a specimen is represented by P(N), then

By taking the natural logarithm twice on both sides of Equation (8) and simplifying it, we obtain

If we let

,

,

, and

, then Equation (9) becomes

In cases with a small sample size (n < 20, where n is the total number of impact test samples, and in this experiment, n = 6), to improve the accuracy of the test results, the impact test results of each group are arranged in ascending order. The expected estimate is calculated using the mean rank method, and the cumulative failure probability function is expressed as follows:

In this formula,

is the rank of a specific test result in ascending order, where i = 1, 2, 3, …, n;

n is the total number of samples in this test group, which is six in this study.

If a strong linear relationship exists between the final crack impact cycles

and

, this indicates that the final crack impact cycles N follow a Weibull distribution. Based on Equations (9)–(11), we can calculate and plot the fitted curve by taking y as the vertical axis and x as the horizontal axis, applying the least squares method for linear fitting.

Table 8 presents the fitting analysis results for the final crack impact cycles, providing the linear regression fitting parameters α, β, and the correlation coefficient R

2 for the failure impact cycles of different fiber-reinforced mortars.

As shown in

Table 8 and

Figure 9, the linear fit between x and y suggests that the failure impact cycles of hybrid fiber HPCCs can be effectively described using a Weibull distribution. Furthermore,

Table 8 indicates that the correlation coefficient R

2 for the final crack impact cycles ranges from 0.907 to 0.978. According to Rahmani et al. [

34], an R

2 value of 0.7 or higher is adequate to satisfy the reliability model. Therefore, it can be concluded that the final crack impact cycles of hybrid fiber mortar can be analyzed using a two-parameter Weibull distribution.

3.8. Final Fracture Impact Cycles of Hybrid Fiber-Reinforced High-Performance Cement-Based Composites Under Different Failure Probabilities

By selecting failure probabilities of 15%, 35%, and 55%, the final crack impact cycles N for hybrid fiber mortar at these respective failure probabilities can be calculated using Equation (12).

In the formula, α and β represent the Weibull distribution fitting regression parameters, which can be found in the table.

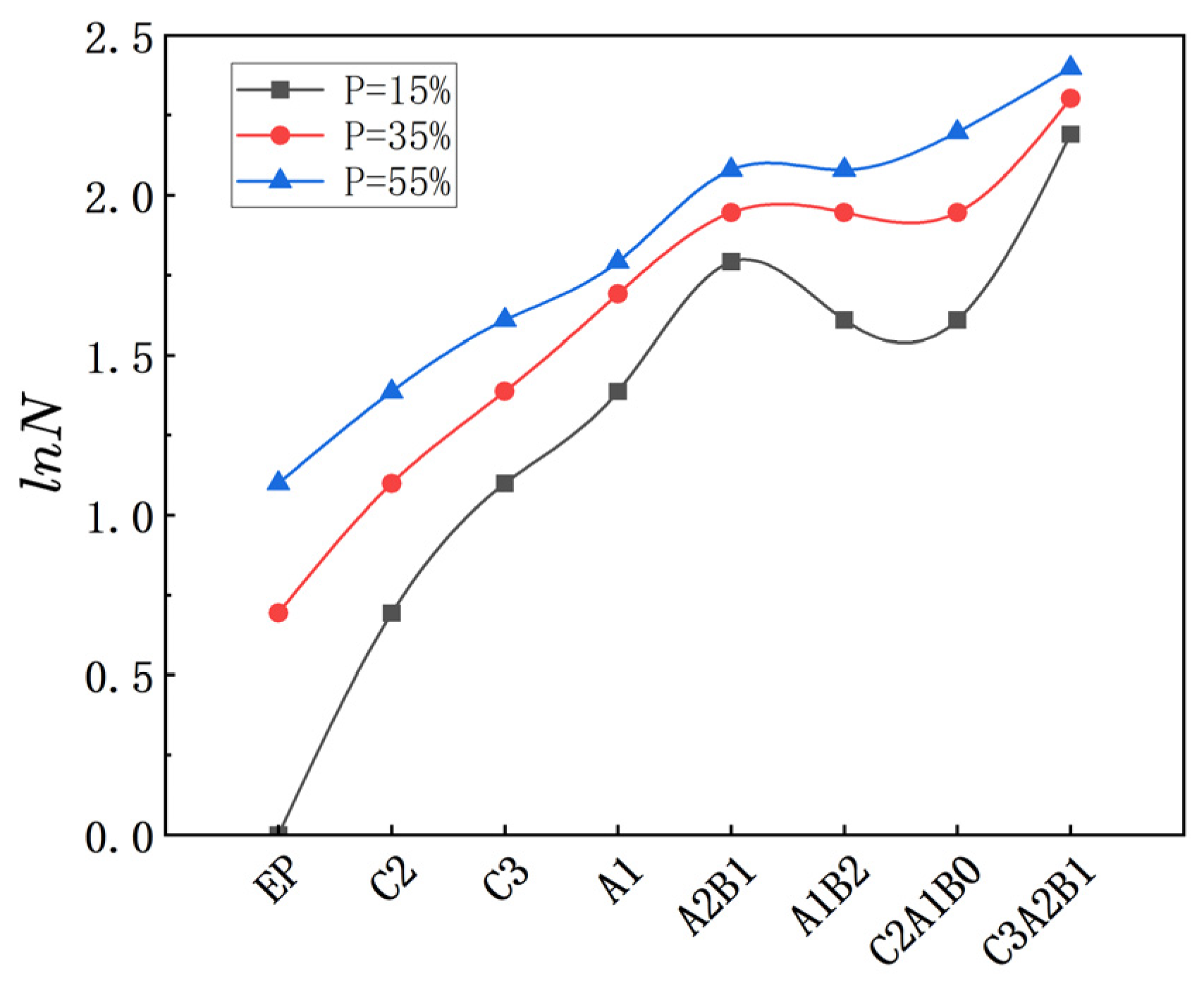

As shown in

Figure 7, the combination of CSWs, AFs, and BFs increases the final crack failure cycles of the mortar. When the failure probability is 15%, the final crack cycles for the mortar containing 3% CSW, 0.067% AF, and 0.033% BF (three-fiber blend) reach nine. This value is higher than that of single-fiber AF mortar (A1), 3% CSW mortar (C3), and dual-fiber AF and BF mortars (A2B1 to A1B2), and significantly higher than the control group. These results indicate that the addition of 3% CSW, 0.067% AF, and 0.033% BF substantially enhances the impact resistance of the mortar.

At varying failure probabilities, the mortar containing 3% CSW, 0.067% AF, and 0.033% BF consistently exhibits the highest final crack impact cycles among all impact-resistant specimen groups, aligning with the impact resistance test results.

Figure 10 shows the ln(N) curves of impact failure cycles for hybrid fiber-reinforced HPCCs under different failure probabilities.

3.9. Microscopic Morphology Analysis

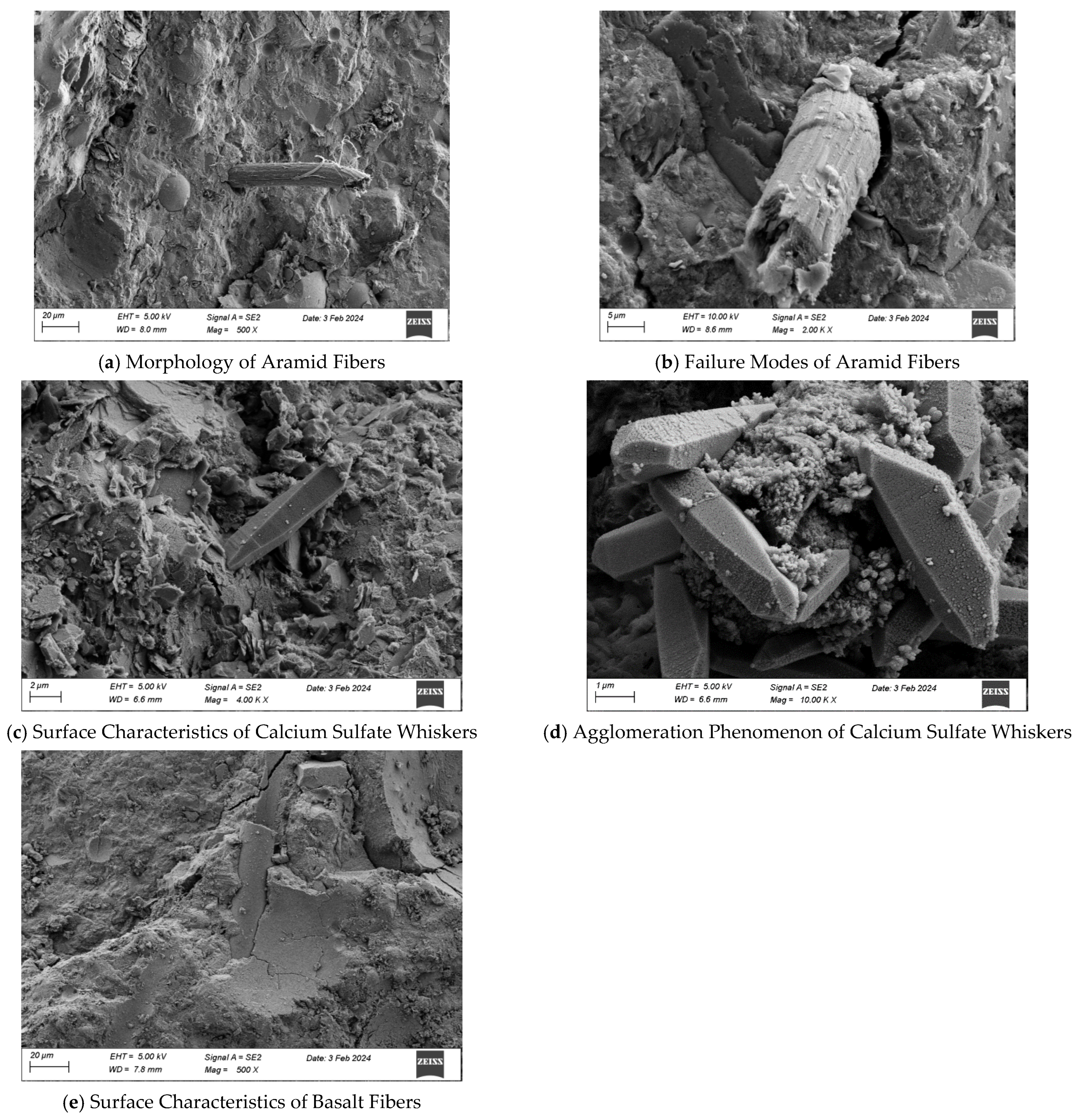

The microstructure and surface morphology of fibers on the fracture surface of mortar samples were observed using scanning electron microscopy (SEM). The results showed that the aramid fibers, basalt fibers, and calcium sulfate whiskers were all present as single filaments within the mortar.

As shown in

Figure 11a,b, after fracture, AFs left pull-out pits in the matrix, indicating a failure mode involving both rupture and pull-out. Additionally, hydration product particles adhered to the AF fiber surface, demonstrating good bonding with the matrix. The flocculent structures observed on the AF surface may represent scratch marks caused by sliding friction with the mortar matrix.

Figure 11c,d illustrate that one end of the CSW fiber was pulled out, suggesting a pull-out failure mode. Although CSW fibers exhibit good bonding with the matrix, an excessive CSW content can lead to fiber agglomeration.

Figure 11e shows that BFs primarily failed through pull-out, with small amounts of hydration product adhering to the surface, indicating relatively strong bonding with the matrix. When hybrid fiber-reinforced mortar is subjected to impact, microcracks develop within the matrix as the impact cycles increase. Through synergistic and complementary effects, the hybrid fibers effectively alter the direction of crack propagation and bridge the cracks, limiting their growth. As stress continues to increase, the fibers are ultimately pulled out or broken, dissipating a significant amount of impact energy and thereby enhancing the impact resistance of the mortar.

However, an excessive addition of calcium sulfate whiskers (CSWs) may lead to agglomeration, increasing the number of weak interfaces within the mortar. These interfaces are susceptible to crack formation during impact, ultimately reducing the material’s impact resistance.

3.10. Pore Structure Analysis

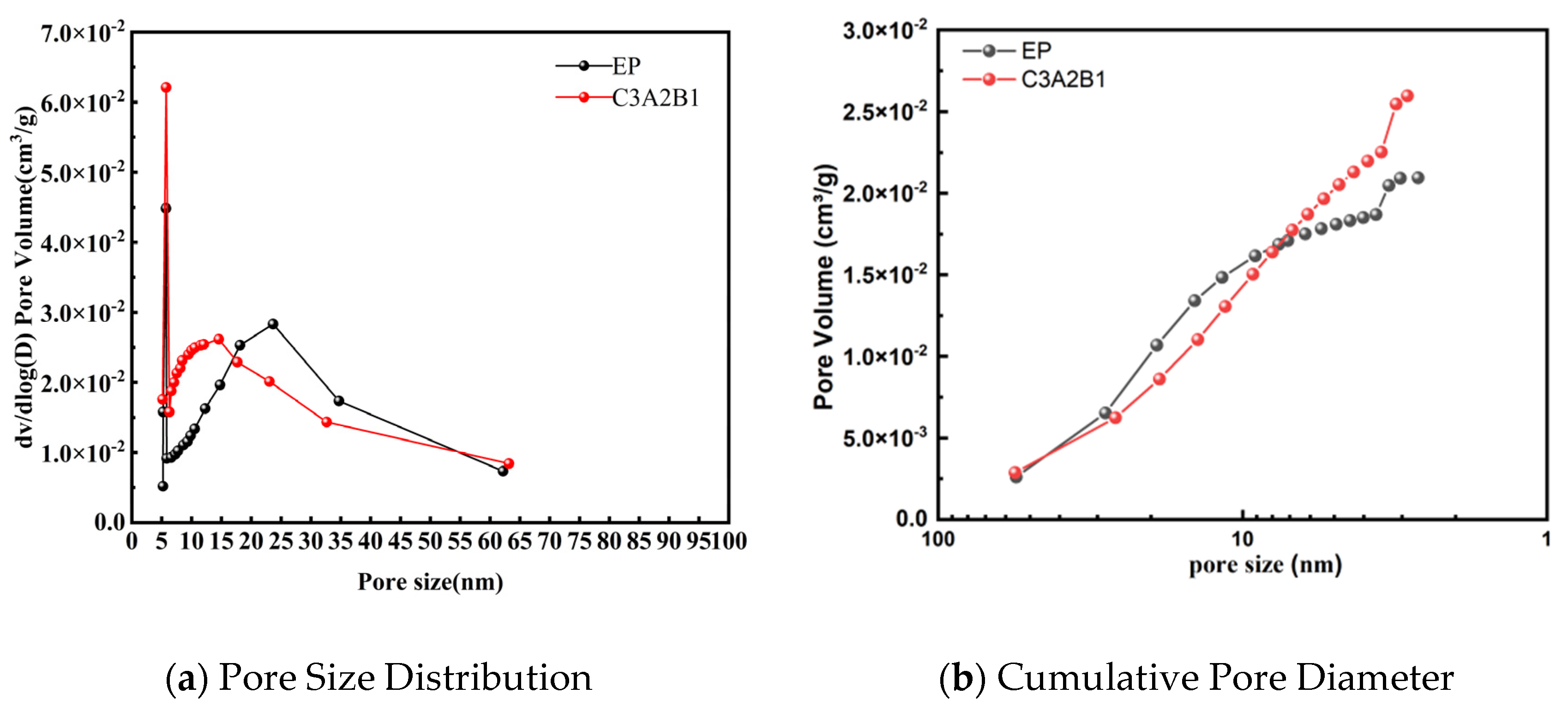

The pore structure of mortars significantly influences their macroscopic properties. According to Wu Zhongwei [

35], pores in cement-based materials can be classified into four types: pores sized 0–20 nm are considered harmless, 20–50 nm as slightly harmful, 50–200 nm as harmful, and those larger than 200 nm as highly harmful. In this study, nitrogen adsorption was employed to analyze the pore structure of the C3A2B1 group, which demonstrated excellent impact resistance.

As shown in

Figure 12a,b, the mortar containing 3% CSW + 0.067% AF + 0.033% BF (denoted as C3A2B1) exhibited the most probable pore diameter still within the gel pore range compared to the control group EP. However, the overall pore content increased significantly. Specifically, the most probable pore volume of C3A2B1 was 0.06032 mL/g, markedly higher than the control group EP’s 0.0419 mL/g, representing an approximate increase of 44%. This finding indicates that this fiber combination effectively increases the total pore content while maintaining the same pore distribution range.

As shown in

Figure 12, the C3A2B1 group exhibited a slight increase in harmful pore volume (50–200 nm), from 0.00261 to 0.00288 mL/g, while harmless (0–20 nm) and less harmful (20–50 nm) pore volumes decreased slightly. More notably, the average pore diameter dropped significantly from 11.29 nm to 8.23 nm, indicating that the fiber–CSW combination effectively refined the pore structure. The marginal rise in harmful pores may result from local CSW agglomeration, which enhances pore connectivity. Nevertheless, the overall reduction in average pore size and increase in gel pores suggest a significant pore-refining effect.

In summary, the hybrid system optimizes the microstructure by reducing pore size, increasing dominant pore volume, and lowering less harmful pore content. These improvements enhance matrix densification and uniformity, contributing to superior mechanical performance and durability.

3.11. Mechanism of Impact Resistance in Hybrid Fiber-Reinforced Mortars

Concrete is a composite material in which aggregates are bonded into a cohesive structure by cementitious materials. However, inherent weak zones, such as cracks and pores, are naturally present within its matrix. Under continuous impact loading, these weak areas experience stress concentrations, leading to rapid crack propagation until catastrophic failure occurs. To address this issue, incorporating fibers into concrete can fill voids within the matrix, enhancing its tensile strength and crack resistance, thereby improving the impact resistance of the concrete [

36,

37].

In this context, three types of fibers (CSWs, AFs, and BFs) are uniformly distributed in a three-dimensional random pattern throughout the concrete. These fibers function at different structural levels and stages of failure. Specifically, during the initial phase of impact loading, the material remains in the elastic stage, with the fibers and matrix jointly bearing external forces and undergoing deformation. As the number of impacts increases, microcracks begin to develop within the matrix. At this stage, the small size and high quantity of CSW fibers allow them to effectively control microcrack formation, reduce stress concentrations at crack tips, and prevent crack propagation.

When cracks grow to the millimeter scale, CSW fibers gradually become ineffective, and stress is transferred to the AFs. With a high elastic modulus, minimal deformation under load, and strong adhesion to the hardened matrix, AFs effectively inhibit further crack growth. As the crack width exceeds 6 mm, AFs start to fail, transferring stress to the BFs. The longer, coarser BFs, with their larger contact area with the matrix, can bridge both sides of the crack and penetrate deeper into the matrix, absorbing more impact energy and thus prolonging the period of crack restraint at this stage. Additionally, when fibers undergo actions such as fracture, pull-out, slip, or debonding within the matrix, a substantial amount of impact energy is absorbed, further enhancing the material’s impact resistance. It is important to note that the crack-inhibiting effect of the fibers does not occur in isolation. When one type of fiber improves matrix performance, it also enhances the effectiveness of other fibers, creating a synergistic effect.

In summary, the hybridization of CSWs, AFs, and BFs enables these fibers to work synergistically at various stages of impact loading, fully exerting their crack-inhibiting and reinforcing effects and significantly enhancing the specimen’s impact resistance. Compared to non-fiber-reinforced, single-fiber, or dual-fiber concrete, the three-fiber combination demonstrates a more favorable positive hybrid effect, resulting in superior impact resistance performance.