The Comprehensive Energy and Exergy Analysis on Thermal-Catalytic-Type and Thermal-Catalytic–Photovoltaic-Type Trombe Walls

Abstract

1. Introduction

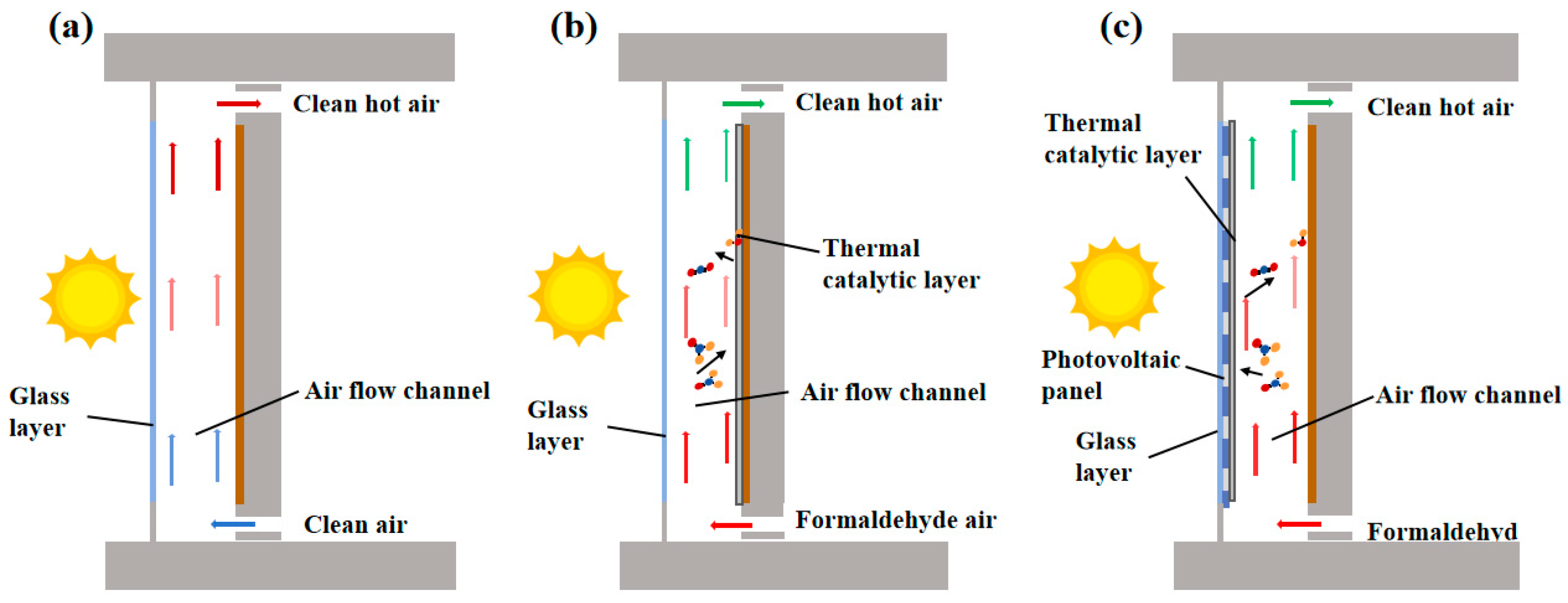

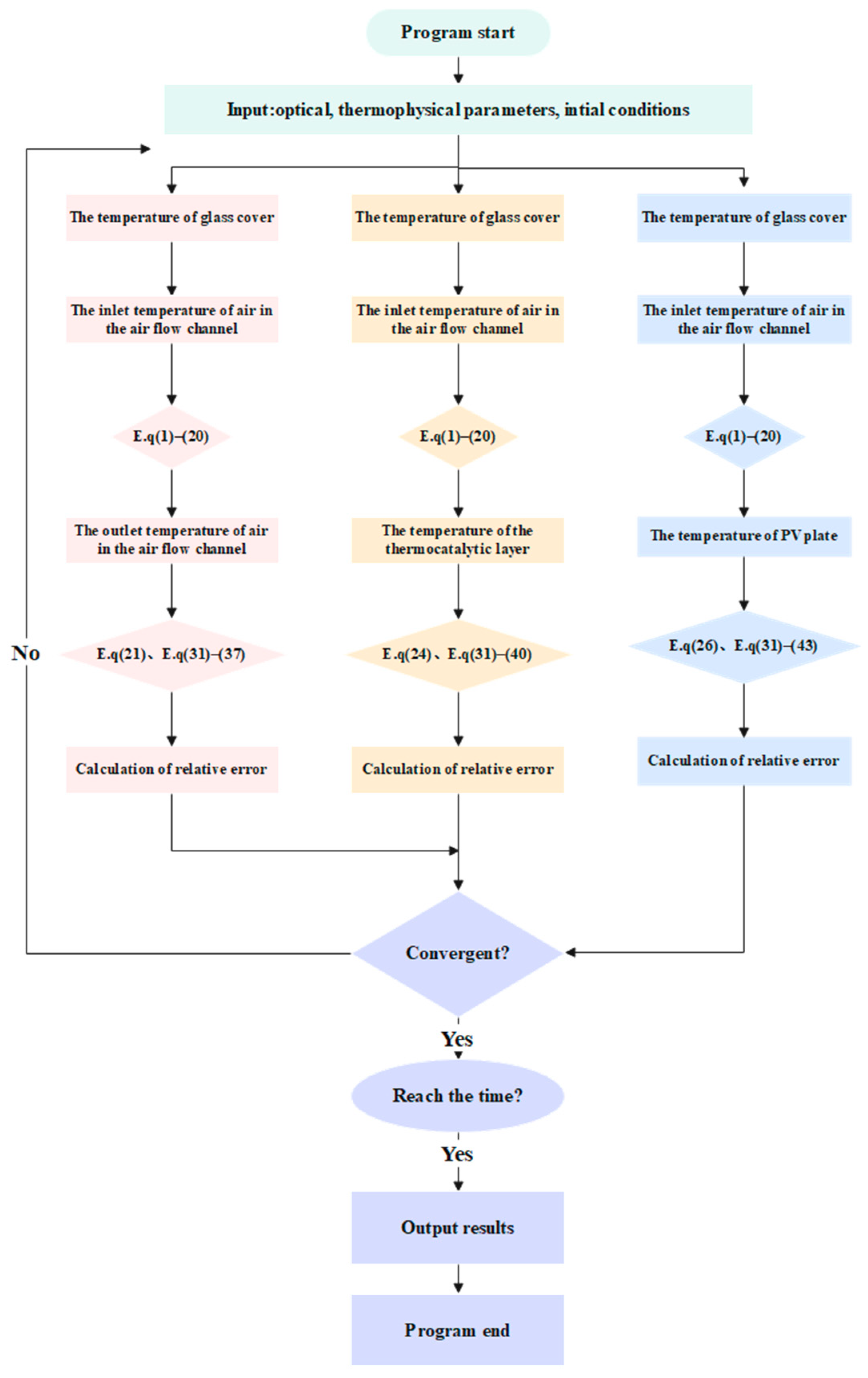

2. The Description of Three Different Types of Trombe Walls

3. Energy Analysis

- (1)

- The system operates under steady-state conditions, assuming the air behaves as an ideal gas and the thermophysical parameters within the system remain constant;

- (2)

- Given the high thermal insulation of the sidewall, heat loss is considered negligible [30];

- (3)

- Given the tightly bonded nature of the glass and the photovoltaic panel, heat transfer due to irradiation intensity between them is neglected;

- (4)

- Given the thinness of the glass and its low heat transfer coefficient, the glass is treated as a single node and heat transfer in both the thickness and height directions is neglected.

4. Exergy Analysis

5. Results and Discussion

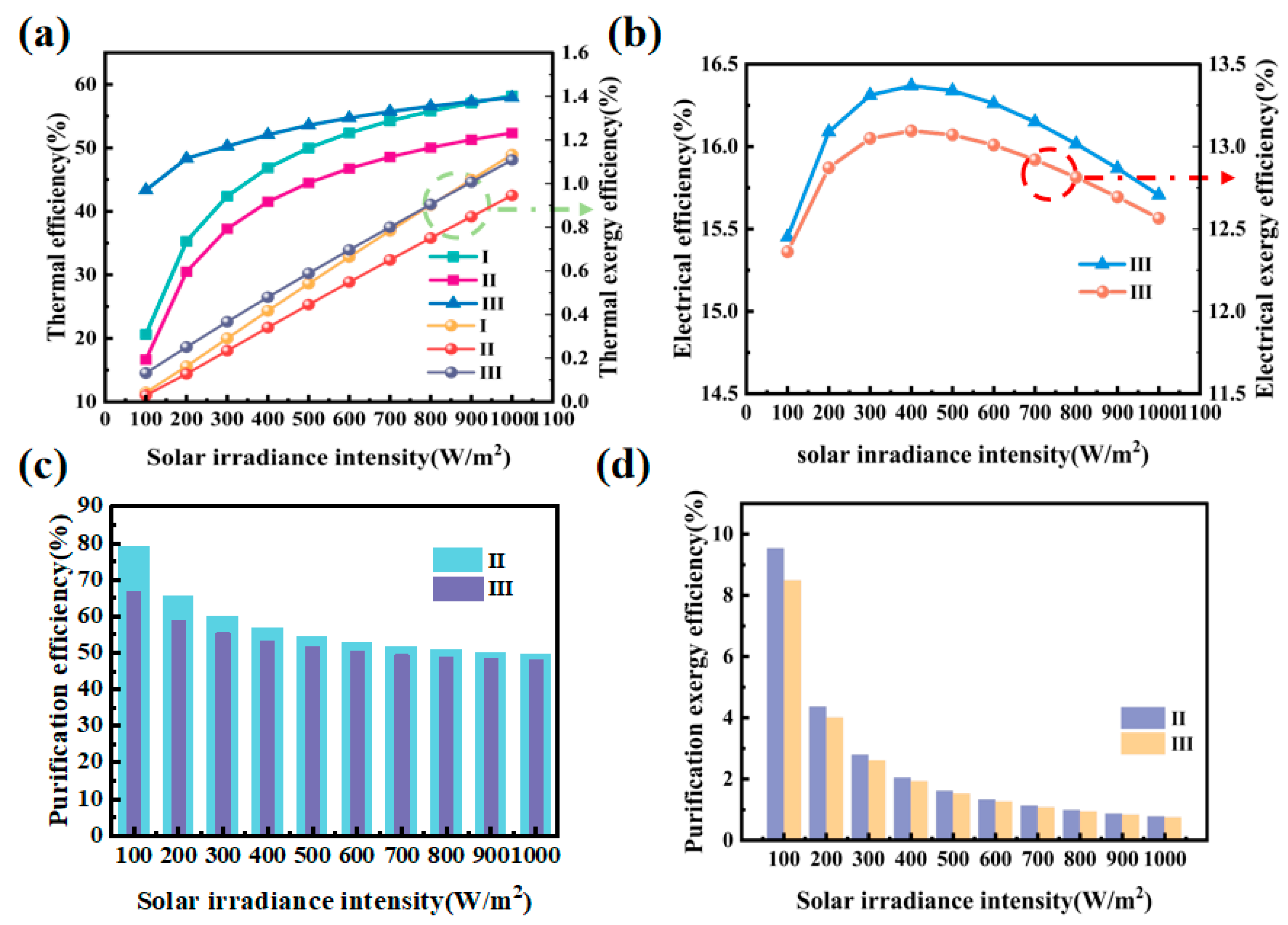

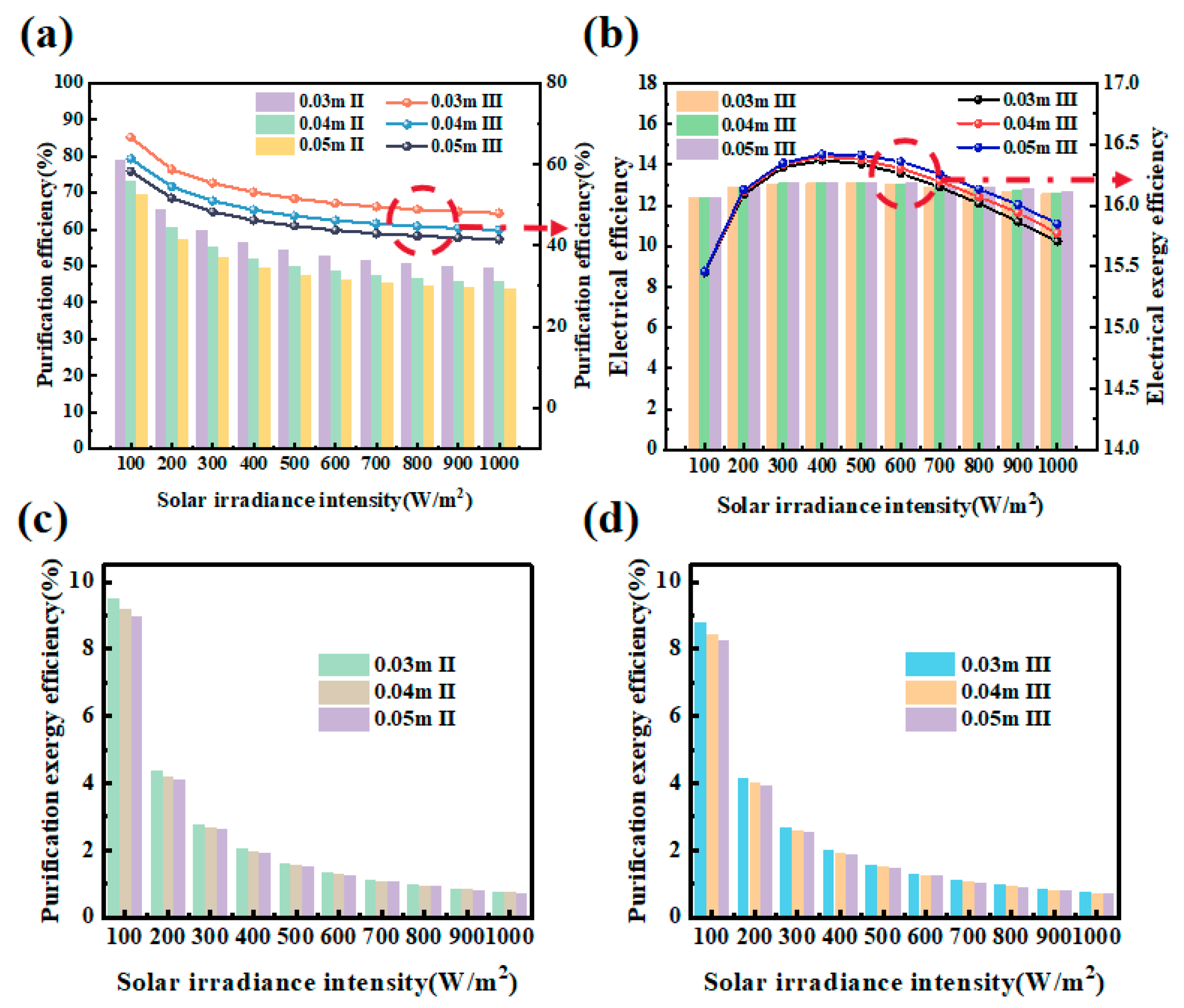

5.1. The Effect of Solar Irradiation Intensity

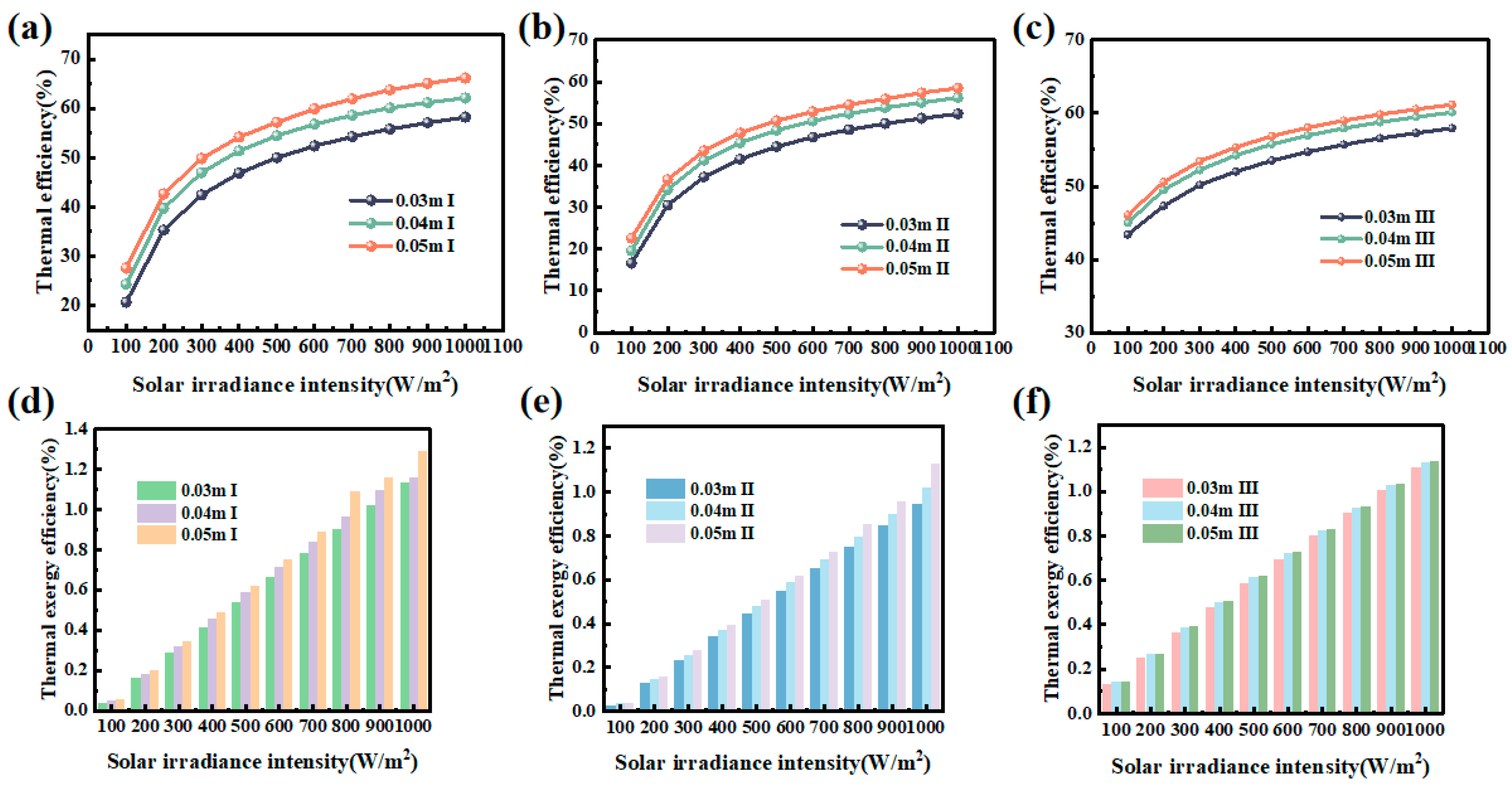

5.2. The Effect of Air Channel Depth

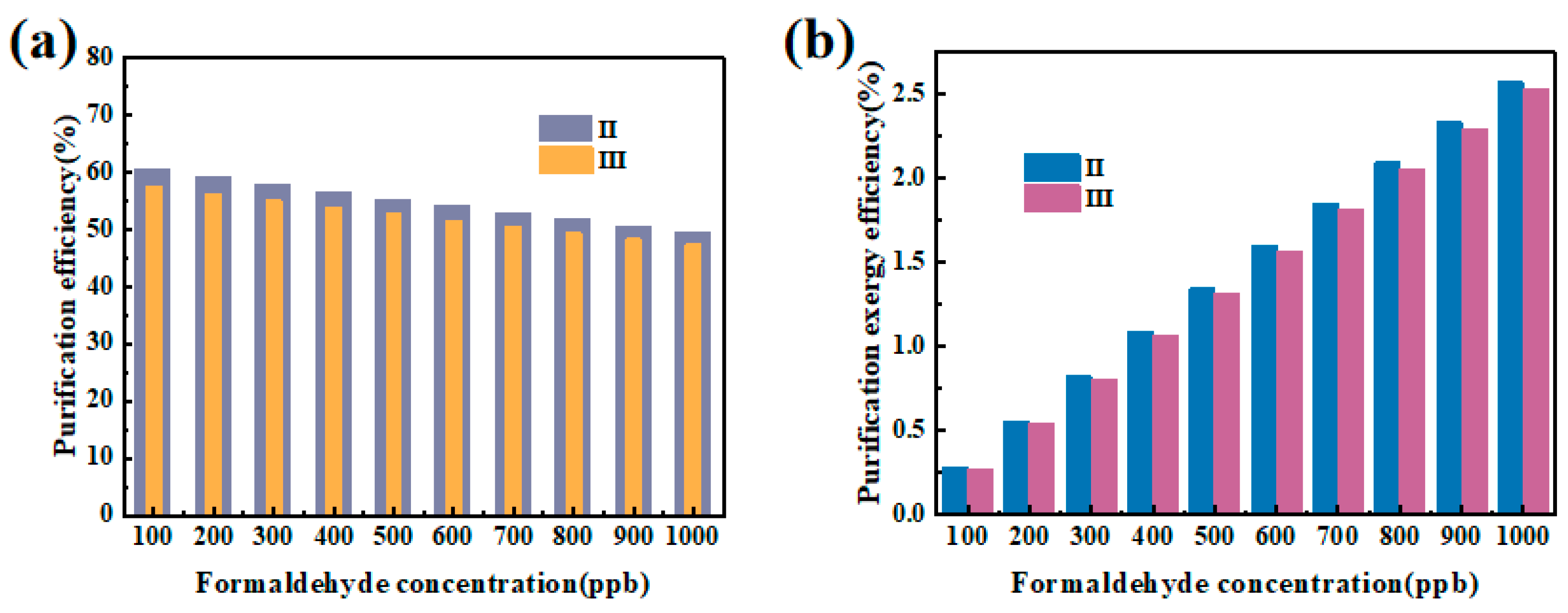

5.3. The Effect of Formaldehyde Concentration

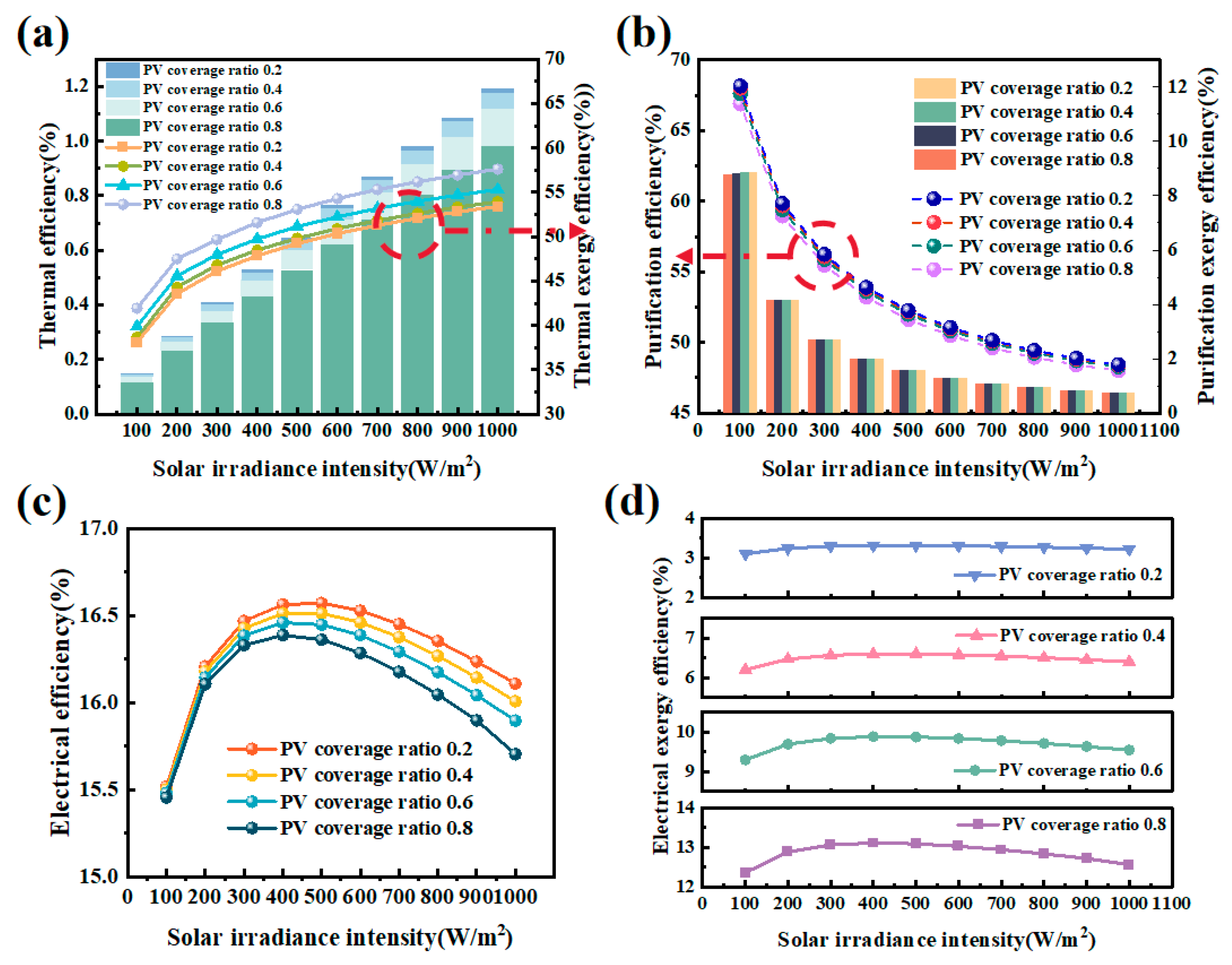

5.4. The Effect of Rate of PV Coverage

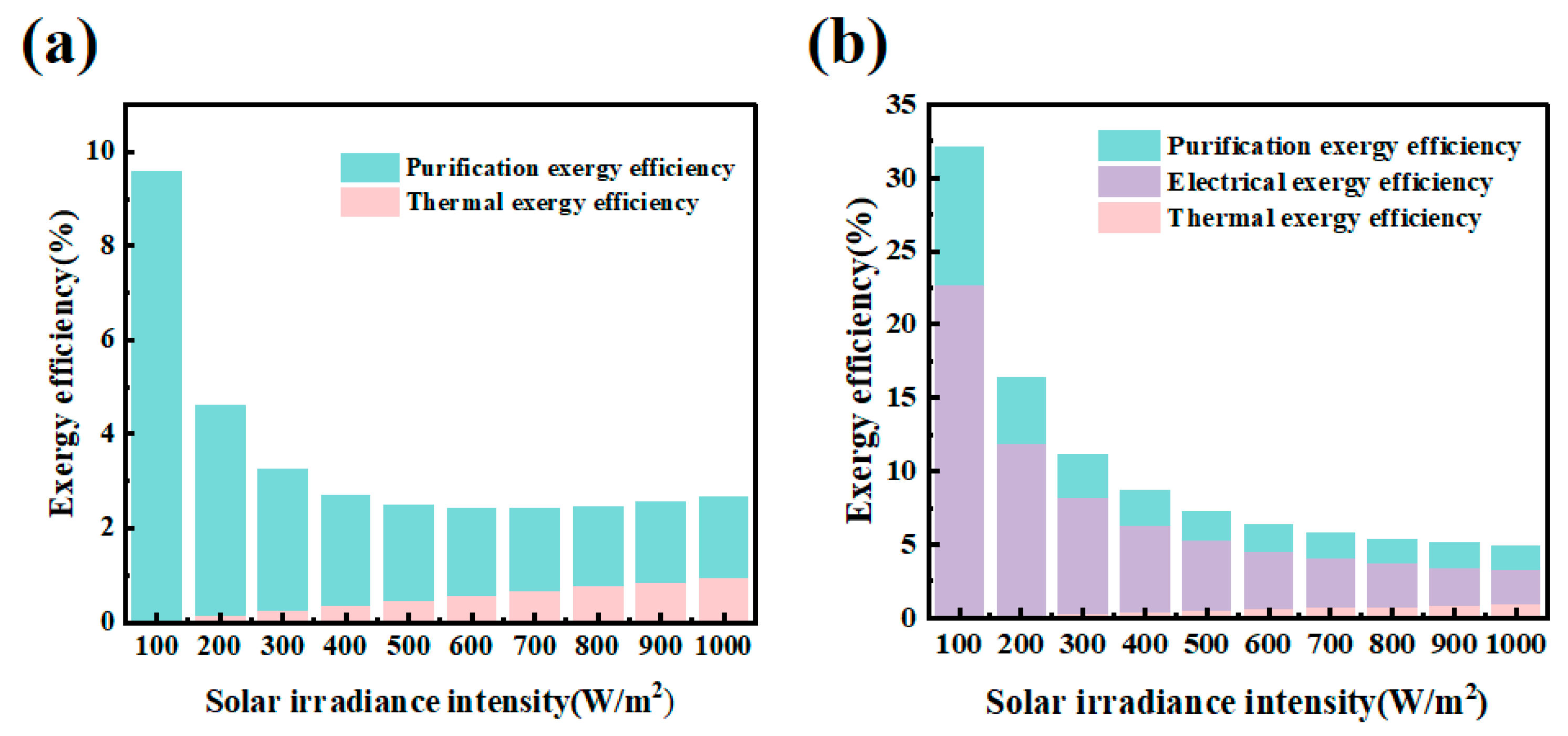

5.5. Gain and Loss of Exergy

6. Conclusions

- (1)

- The energy efficiencies of three Trombe systems were analyzed. The thermal efficiency of a conventional Trombe wall is 47.2%. The thermal efficiency of a TC Trombe wall is 41.9% and the purification efficiency is 57.0%. The thermal efficiency, purification efficiency, and electrical efficiency of a TC-PV Trombe wall are 51.7%, 53.0%, and 16.0%, respectively.

- (2)

- The exergy efficiencies of three Trombe systems were analyzed. The traditional Trombe wall has a thermal exergy efficiency of 0.59%. The TC Trombe wall has thermal and purification exergy efficiencies of 0.49% and 2.53%, respectively. The TC-PV Trombe wall has thermal, purification, and electric exergy efficiencies of 0.63%, 2.42%, and 12.84%, respectively. Purification exergy boosts the efficiency of the TC and TC-PV Trombe walls by 3.6 and 0.24 times, respectively.

- (3)

- Higher solar irradiation and wider air channels boost thermal exergy efficiency but lower purification exergy efficiency. Electrical exergy efficiency peaks at 400 W/m2 solar irradiation and 0.05 m air channel thickness. Purification exergy efficiency rises with formaldehyde concentration and all efficiencies increase with greater PV coverage.

- (4)

- Exergy loss analysis revealed that the catalytic layer is the main source of exergy loss, accounting for 70% of losses in the TC Trombe wall and 73% of losses in TC-PV Trombe wall. To enhance the system’s overall exergy efficiency, it is crucial to develop materials with high absorptivity and high catalytic activity.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| Nomenclature | ε | emissivity | |

| W | width, m | τ | transmittance |

| L | length, m | λ | thermal conductivity (W/m·K) |

| T | temperature, K | η | efficiency |

| I | solar irradiance intensity, W/m2 | Subscripts | |

| h | heat transfer coefficient, W/(m2·K) | gl | glass cover |

| Nu | Nusslet number | air | air |

| d | hydraulic diameter, m | w | heat storage wall |

| V | air velocity, m/s | amb | ambient |

| C | formaldehyde concentration, ppb | ct | catalyst coating |

| Pr | Prandtl number | sky | sky |

| A | area, m2 | th | thermal |

| H | height, m | out | outlet |

| Re | Reynolds number | in | inlet |

| f | resistance factor | income | income |

| ξ | fill factor | disburse | disburse |

| ω | reaction rate | HCHO | formaldehyde |

| c | specific heat capacity, J/(kg·K) | x | thermal storage plate |

| Q | capacity | inair | airflow is directed into the thermal convection channel |

| R | molecular gas constant | outair | air flowing out of the air flow channel |

| h | enthalpy | sun | sun |

| s | entropy | pv | photovoltaic |

| Greeks | pur | purification | |

| δ | thickness, m | i | category |

| exergy efficiency | |||

| ρ | density, kg/m3 | Abbreviation | |

| α | absorptivity | TC Trombe wall | thermal-catalysis Trombe wall |

| σ | Stefan–Boltzmann constant, W/(m2·K4) | TC-PV Trombe wall | thermal-catalysis–photovoltaic Trombe wall |

References

- Vanaga, R.; Blumberga, A.; Freimanis, R.; Mols, T.; Blumberga, D. Solar facade module for nearly zero energy building. Energy 2018, 157, 1025–1034. [Google Scholar] [CrossRef]

- Belaïd, F.; Flambard, V. Boosting buildings energy efficiency: The impact of social norms and motivational feedback. J. Econ. Behav. Organ. 2023, 215, 26–39. [Google Scholar] [CrossRef]

- Wang, D.; Hu, L.; Du, H.; Liu, Y.; Huang, J.; Xu, Y.; Liu, J. Classification, experimental assessment, modeling methods and evaluation metrics of Trombe walls. Renew. Sustain. Energy Rev. 2020, 124, 109772. [Google Scholar] [CrossRef]

- Sergei, K.; Shen, C.; Jiang, Y. A review of the current work potential of a trombe wall. Renew. Sustain. Energy Rev. 2020, 130, 109947. [Google Scholar] [CrossRef]

- Zalewski, L.; Joulin, A.; Lassue, S.; Dutil, Y.; Rousse, D. Experimental study of small-scale solar wall integrating phase change material. Sol. Energy 2012, 86, 208–219. [Google Scholar] [CrossRef]

- Xu, B.; Gan, W.-T.; Wang, Y.-L.; Chen, X.-N.; Fei, Y.; Pei, G. Thermal performance of a novel Trombe wall integrated with direct absorption solar collector based on phase change slurry in winter. Renew. Energy 2023, 213, 246–258. [Google Scholar] [CrossRef]

- Chen, X.-N.; Gan, W.-T.; Shen, Z.-Q.; Xu, B.; Pei, G. Thermal performance analysis of a double-channel phase change slurry Trombe wall with seasonal switching, solar energy storage and utilization. Renew. Energy 2025, 248, 123218. [Google Scholar] [CrossRef]

- Asdaghi, H.; Fayaz, R. The performance of a photovoltaic Trombe wall combined with phase change materials under climate change in Mashhad. Energy 2024, 310, 133250. [Google Scholar] [CrossRef]

- Su, X.; Luo, C.; Chen, X.; Jiang, Q.; Yu, Y.; El Shenawy, E.T.; Li, W.; Zhang, H.; Peng, R. Experimental and theoretical analysis of photovoltaic performance and thermal behavior for bifacial PV-Trombe wall system with reversible louvers in summer. Energy 2024, 312, 133663. [Google Scholar] [CrossRef]

- Hu, Z.; Liu, R.; Li, K.; Wang, Z.; Gu, K.; He, W. Performance analysis and design optimization of a novel Trombe wall system using CFD and response surface method. Energy 2025, 324, 136031. [Google Scholar] [CrossRef]

- Laribi, A.; Bégot, S.; Surdyk, D.; Ait-Oumeziane, Y.; Lepiller, V.; Désévaux, P.; Zein, N.E.; De Carvalho, A.R. Experimental study of the influence of the vents on the thermal performance of a Trombe wall. Energy Build. 2025, 328, 115176. [Google Scholar] [CrossRef]

- Li, Y.; Lei, Y.; Yan, Y.; Song, C. Thermal performance analysis of a Trombe wall with the multi-row channel PCM wallboard. Energy 2024, 313, 133796. [Google Scholar] [CrossRef]

- Dong, X.; Xiao, H.; Liu, M.; Lin, B.; Wang, W. An innovative Trombe wall with a solar concentrating function. Energy Build. 2024, 325, 114942. [Google Scholar] [CrossRef]

- Abdul-Ganiyu, S.; Quansah, D.A.; Ramde, E.W.; Seidu, R.; Adaramola, M.S. Techno-economic analysis of solar photovoltaic (PV) and solar photovoltaic thermal (PVT) systems using exergy analysis. Sustain. Energy Technol. Assess. 2021, 47, 101520. [Google Scholar] [CrossRef]

- Ji, J.; Luo, C.; Sun, W.; Yu, H.; He, W.; Pei, G. An improved approach for the application of Trombe wall system to building construction with selective thermo-insulation façades. Chin. Sci. Bull. 2009, 54, 1949–1956. [Google Scholar] [CrossRef]

- Hu, Z.; Zhu, M.; Li, K.; Yang, C.; Wang, Z.; He, W. Thermal performance of a novel water blind-Trombe wall system: A comparative experimental investigation. Energy Convers. Manag. 2023, 296, 117677. [Google Scholar] [CrossRef]

- Kandilli, C.; Gür, M.; Yilmaz, H.; Öztop, H.F. Experimental and numerical analyses of a model Trombe wall employing the natural zeolite/perlite composite plate as a thermal mass for nearly zero energy buildings. Int. Commun. Heat Mass Transf. 2025, 160, 108386. [Google Scholar] [CrossRef]

- Mokni, A.; Lashin, A.; Ammar, M.; Mhiri, H. Thermal analysis of a Trombe wall in various climatic conditions: An experimental study. Sol. Energy 2022, 243, 247–263. [Google Scholar] [CrossRef]

- Rabani, M.; Kalantar, V.; Dehghan, A.A.; Faghih, A.K. Experimental study of the heating performance of a Trombe wall with a new design. Sol. Energy 2015, 118, 359–374. [Google Scholar] [CrossRef]

- Kanoglu, M.; Dincer, I.; Cengel, Y.A. Exergy for better environment and sustainability. Environ. Dev. Sustain. 2009, 11, 971–988. [Google Scholar] [CrossRef]

- Dincer, I. The role of exergy in energy policy making. Energy Policy 2002, 30, 137–149. [Google Scholar] [CrossRef]

- Dincer, I.; Rosen, M.A. Thermodynamic aspects of renewables and sustainable development. Renew. Sustain. Energy Rev. 2005, 9, 169–189. [Google Scholar] [CrossRef]

- Burghardt, M.D.; Harbach, J.A. Engineering Thermodynamics; HarperCollins College Publishers: New York, NY, USA, 1993. [Google Scholar]

- Cai, G.; Zheng, X.; Gao, W.; Guo, J. Self-extinction characteristics of fire extinguishing induced by nitrogen injection rescue in an enclosed urban utility tunnel. Case Stud. Therm. Eng. 2024, 59, 104478. [Google Scholar] [CrossRef]

- Huang, F.-P.; Qin, W.-J.; Pan, X.-Y.; Yang, K.; Wang, K.; Teng, Q.-H. Visible-Light-Induced Chemodivergent Synthesis of Tetracyclic Quinazolinones and 3-Iminoisoindoliones via the Substrate Control Strategy. J. Org. Chem. 2024, 89, 4395–4405. [Google Scholar] [CrossRef]

- Corasaniti, S.; Manni, L.; Russo, F.; Gori, F. Numerical simulation of modified Trombe-Michel Walls with exergy and energy analysis. Int. Commun. Heat Mass Transf. 2017, 88, 269–276. [Google Scholar] [CrossRef]

- Du, M.; Tang, G.H.; Wang, T.M. Exergy analysis of a hybrid PV/T system based on plasmonic nanofluids and silica aerogel glazing. Sol. Energy 2019, 183, 501–511. [Google Scholar] [CrossRef]

- Du, L.; Ping, L.; Yongming, C. Study and analysis of air flow characteristics in Trombe wall. Renew. Energy 2020, 162, 234–241. [Google Scholar] [CrossRef]

- Duan, X.; Shen, C.; Liu, D.; Wu, Y. The performance analysis of a photo/thermal catalytic Trombe wall with energy generation. Renew. Energy 2023, 218, 119361. [Google Scholar] [CrossRef]

- Duan, S.; Jing, C.; Zhao, Z. Energy and exergy analysis of different Trombe walls. Energy Build. 2016, 126, 517–523. [Google Scholar] [CrossRef]

- Yu, B.; Jiang, Q.; He, W.; Liu, S.; Zhou, F.; Ji, J.; Xu, G.; Chen, H. Performance study on a novel hybrid solar gradient utilization system for combined photocatalytic oxidation technology and photovoltaic/thermal technology. Appl. Energy 2018, 215, 699–716. [Google Scholar] [CrossRef]

- Duffie, J.A.; Beckman, W.A. Solar Engineering of Thermal Processes; Wiley: New York, NY, USA, 1980. [Google Scholar]

- Duffie, J.A.; Beckman, W.A.; Blair, N. Solar Engineering of Thermal Processes, Photovoltaics and Wind; John Wiley & Sons: Hoboken, NJ, USA, 2020. [Google Scholar]

- Guo, C.; Ji, J.; Sun, W.; Ma, J.; He, W.; Wang, Y. Numerical simulation and experimental validation of tri-functional photovoltaic/thermal solar collector. Energy 2015, 87, 470–480. [Google Scholar] [CrossRef]

- Xie, M.; Xu, F.; Wang, Z.; Yin, L.E.; Wu, X.; Xu, M.; Li, X.J.B. Investigating Fire Collapse Early Warning Systems for Portal Frames. Buildings 2025, 15, 296. [Google Scholar] [CrossRef]

- Xu, Q.; Zhang, Y.; Mo, J.; Li, X. Indoor Formaldehyde Removal by Thermal Catalyst: Kinetic Characteristics, Key Parameters, and Temperature Influence. Environ. Sci. Technol. 2011, 45, 5754–5760. [Google Scholar] [CrossRef] [PubMed]

- Verbruggen, S.W.; Lenaerts, S.; Denys, S. Analytic versus CFD approach for kinetic modeling of gas phase photocatalysis. Chem. Eng. J. 2015, 262, 1–8. [Google Scholar] [CrossRef]

- Ziapour, B.M.; Alirezaei, H.; Ghorannevis, S. Energy recovery from the enclosures between the glassing covers in a compact photovoltaic thermal collector. Renew. Energy 2023, 216, 119053. [Google Scholar] [CrossRef]

- Ramdani, H.; Ould-Lahoucine, C. Study on the overall energy and exergy performances of a novel water-based hybrid photovoltaic-thermal solar collector. Energy Convers. Manag. 2020, 222, 113238. [Google Scholar] [CrossRef]

- Li, G.; Liu, Z.; Liu, F.; Yang, B.; Ma, S.; Weng, Y.; Zhang, Y.; Fang, Y.J.E.C. Management. Advanced exergy analysis of ash agglomerating fluidized bed gasification. Energy Convers. Manag. 2019, 199, 111952. [Google Scholar] [CrossRef]

- Baniasadi, E.; Dincer, I.; Naterer, G.F. Exergy and environmental impact assessment of solar photoreactors for catalytic hydrogen production. Chem. Eng. J. 2012, 213, 330–337. [Google Scholar] [CrossRef]

- Howell, J.R.; Pinar Mengüc, M.; Daun, K.; Siegel, R. Thermal Radiation Heat Transfer; CRC Press: Boca Raton, FL, USA, 2020. [Google Scholar]

- Gakkhar, N.; Soni, M.S.; Jakhar, S. Second law thermodynamic study of solar assisted distillation system: A review. Renew. Sustain. Energy Rev. 2016, 56, 519–535. [Google Scholar] [CrossRef]

- Hepbasli, A. A key review on exergetic analysis and assessment of renewable energy resources for a sustainable future. Renew. Sustain. Energy Rev. 2008, 12, 593–661. [Google Scholar] [CrossRef]

- Sato, N. Chemical Energy and Exergy: An Introduction to Chemical Thermodynamics for Engineers; Elsevier: Amsterdam, The Netherlands, 2004. [Google Scholar]

- Garg, H.P.; Agarwal, R.K. Some aspects of a PV/T collector/forced circulation flat plate solar water heater with solar cells. Energy Convers. Manag. 1995, 36, 87–99. [Google Scholar] [CrossRef]

- Hirunlabh, J.; Kongduang, W.; Namprakai, P.; Khedari, J. Study of natural ventilation of houses by a metallic solar wall under tropical climate. Renew. Energy 1999, 18, 109–119. [Google Scholar] [CrossRef]

- Yue, Y.; Feng, B.; Du, C.; Wang, Y.; Wang, S. Study on the Photocatalytic Degradation Rate of Indoor Formaldehyde with Nano-TiO2 Coating. IOP Conf. Ser. Earth Environ. Sci. 2021, 791, 012060. [Google Scholar] [CrossRef]

- Askari, M.; Jahangir, M.H. Evaluation of thermal performance and energy efficiency of a Trombe wall improved with dual phase change materials. Energy 2023, 284, 128587. [Google Scholar] [CrossRef]

- Cao, X.; Wei, W.; Wang, W.; Ji, J.; Yu, B.; Li, N. Energy and exergy analysis of a photocatalytic Trombe wall based on visible-light photocatalytic purification. Renew. Energy 2025, 246, 122942. [Google Scholar] [CrossRef]

- Yu, B.; He, W.; Li, N.; Wang, L.; Cai, J.; Chen, H.; Ji, J.; Xu, G. Experimental and numerical performance analysis of a TC-Trombe wall. Appl. Energy 2017, 206, 70–82. [Google Scholar] [CrossRef]

- Lin, Y.; Ji, J.; Zhou, F.; Ma, Y.; Luo, K.; Lu, X. Experimental and numerical study on the performance of a built-middle PV Trombe wall system. Energy Build. 2019, 200, 47–57. [Google Scholar] [CrossRef]

| Symbol | Explanation | Unit | Value | |

|---|---|---|---|---|

| Glass cover | ρg cg | Density Specific heat capacity Refractive index Extinction coefficient | kg/m3 J/(kg·K) - - | 2500 750 1.5 4 |

| PV panel | ρg cg αg εg | Density Specific heat capacity Absorptivity Emissivity | kg/m3 J/(kg·K) - - | 2300 705 0.9 0.9 |

| Air | ρa ca λa νa ua | Density Specific heat capacity Thermal conductivity Kinematic viscosity Relative humidityua Air flow velocity | kg/m3 J/(kg·K) W/(m·K) m2/s - m/s | 1.18 1005 0.026 1.58 × 10−5 0.6 0.2 |

| Formaldehyde | C0 D | Concentration Diffusion coefficient | ppb m2/s | 600 18.6 × 10−6 m2/s |

| Air channel | Ain Aout La l | Air inlet area Air outlet area Height Length | m2 m2 m m | 0.2 0.2 1 0.6 |

| Thermal catalytic layer | ρg cg αg εg | Density Specific heat capacity Absorptivity Emissivity | kg/m3 J/(kg·K) - - | 2500 700 0.87 0.75 |

| Trombe Wall | I (W/m2) | Exdest1 (W) | Exdset2 (W) | Exdest3 (W) | Exdest4 (W) | Exelse (W) |

|---|---|---|---|---|---|---|

| TC Trombe wall | 100 | 6.40 | 0.26 | 0.52 | 36.6 | 6.1 |

| 200 | 12.77 | 1.66 | 1.29 | 77.4 | 12.6 | |

| 300 | 19.15 | 3.22 | 2.26 | 116.8 | 19.9 | |

| 400 | 25.53 | 4.87 | 3.11 | 155.6 | 27.5 | |

| 500 | 31.91 | 6.49 | 4.71 | 192.4 | 37.0 | |

| 600 | 38.28 | 8.14 | 6.16 | 229.0 | 46.6 | |

| 700 | 44.66 | 9.78 | 7.74 | 264.7 | 56.9 | |

| 800 | 51.04 | 11.41 | 9.45 | 299.7 | 67.8 | |

| 900 | 57.42 | 13.03 | 11.28 | 334.1 | 79.2 | |

| 1000 | 63.79 | 14.63 | 13.24 | 367.8 | 91.3 |

| Trombe Wall | I (W/m2) | Exdest1 (W) | Exdset2 (W) | Exdest3 (W) | Exdest4 (W) | Exelse (W) |

|---|---|---|---|---|---|---|

| TC-PV Trombe wall | 100 | 6.40 | 1.25 | 0.13 | 39.38 | 7.53 |

| 200 | 12.77 | 2.82 | 0.45 | 82.19 | 11.17 | |

| 300 | 19.15 | 4.48 | 0.88 | 123.60 | 15.99 | |

| 400 | 25.53 | 6.17 | 1.41 | 163.88 | 21.82 | |

| 500 | 31.91 | 7.86 | 2.03 | 203.13 | 28.58 | |

| 600 | 38.28 | 9.55 | 2.73 | 241.48 | 36.17 | |

| 700 | 44.66 | 11.22 | 3.51 | 278.98 | 44.55 | |

| 800 | 51.04 | 12.88 | 4.36 | 315.70 | 53.64 | |

| 900 | 57.42 | 14.52 | 5.28 | 351.70 | 63.41 | |

| 1000 | 63.79 | 16.14 | 6.26 | 387.00 | 73.83 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, W.; Li, N.; Wei, W.; Ji, J.; Yu, B. The Comprehensive Energy and Exergy Analysis on Thermal-Catalytic-Type and Thermal-Catalytic–Photovoltaic-Type Trombe Walls. Buildings 2025, 15, 1683. https://doi.org/10.3390/buildings15101683

Wang W, Li N, Wei W, Ji J, Yu B. The Comprehensive Energy and Exergy Analysis on Thermal-Catalytic-Type and Thermal-Catalytic–Photovoltaic-Type Trombe Walls. Buildings. 2025; 15(10):1683. https://doi.org/10.3390/buildings15101683

Chicago/Turabian StyleWang, Weikai, Niansi Li, Wei Wei, Jie Ji, and Bendong Yu. 2025. "The Comprehensive Energy and Exergy Analysis on Thermal-Catalytic-Type and Thermal-Catalytic–Photovoltaic-Type Trombe Walls" Buildings 15, no. 10: 1683. https://doi.org/10.3390/buildings15101683

APA StyleWang, W., Li, N., Wei, W., Ji, J., & Yu, B. (2025). The Comprehensive Energy and Exergy Analysis on Thermal-Catalytic-Type and Thermal-Catalytic–Photovoltaic-Type Trombe Walls. Buildings, 15(10), 1683. https://doi.org/10.3390/buildings15101683