Research on Parametric Modeling and Model Transformation of Proton Hospital Based on BIM

Abstract

1. Introduction

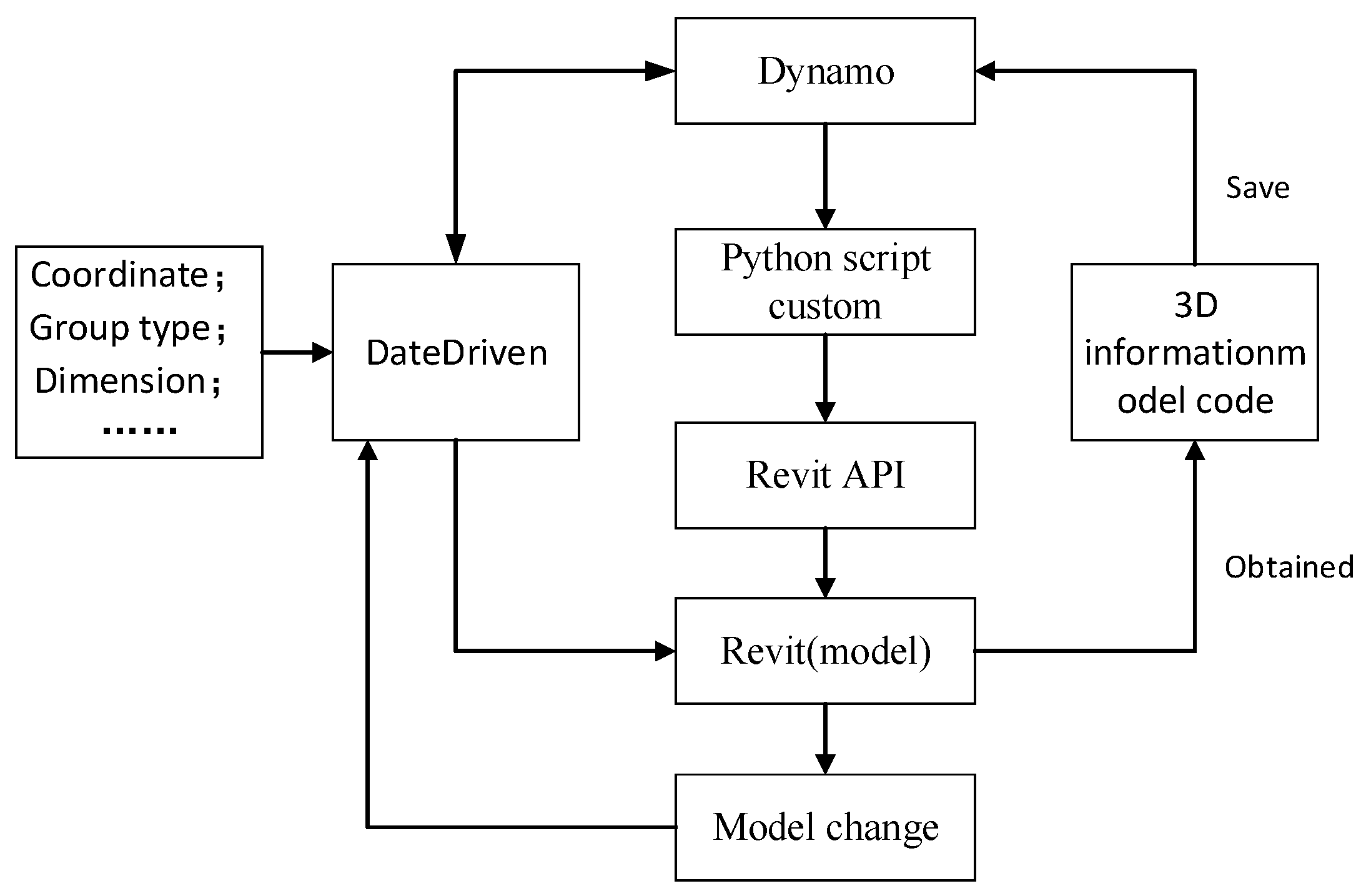

2. Revit Secondary Development

3. Dynamo Visual Programming Modeling Principles

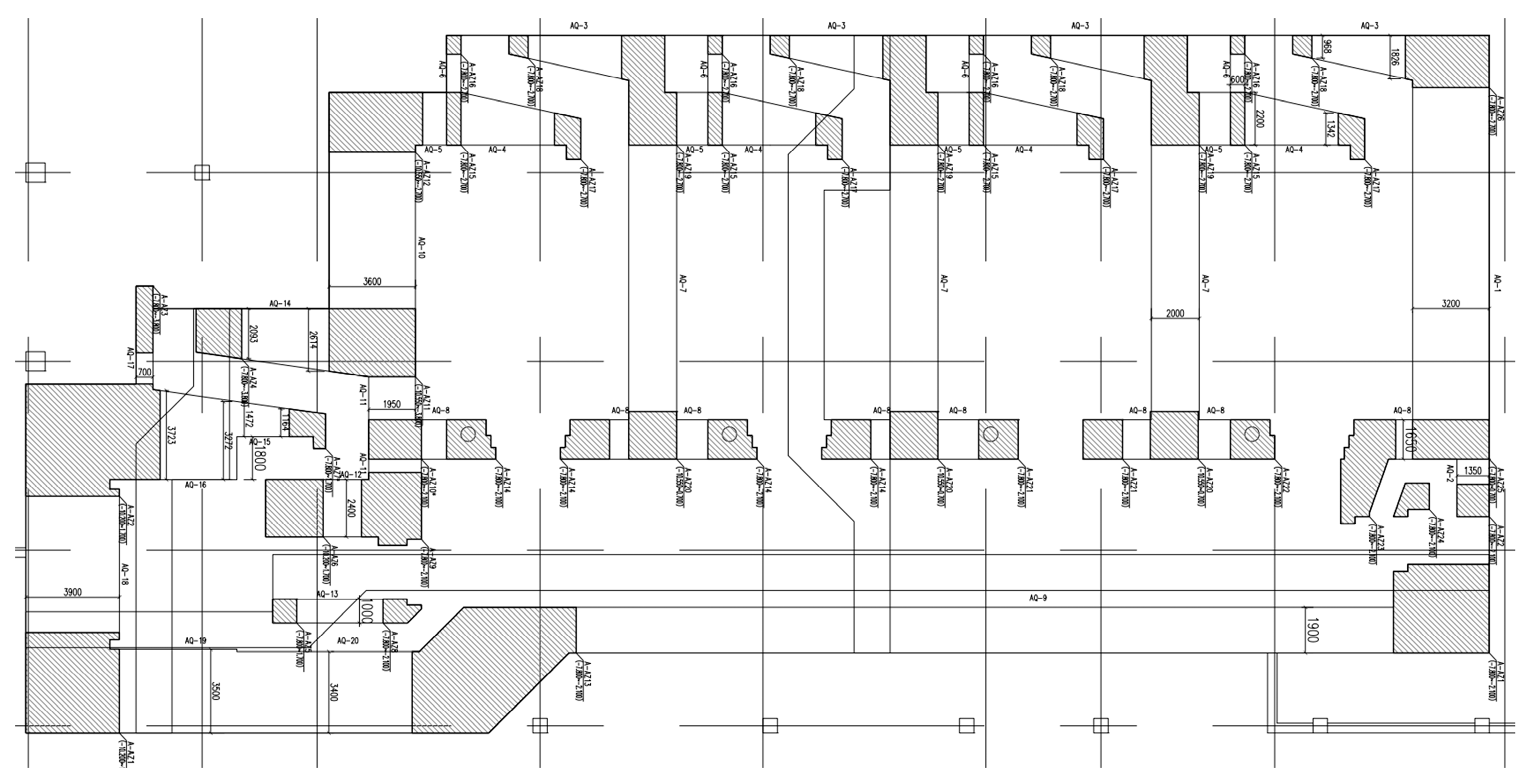

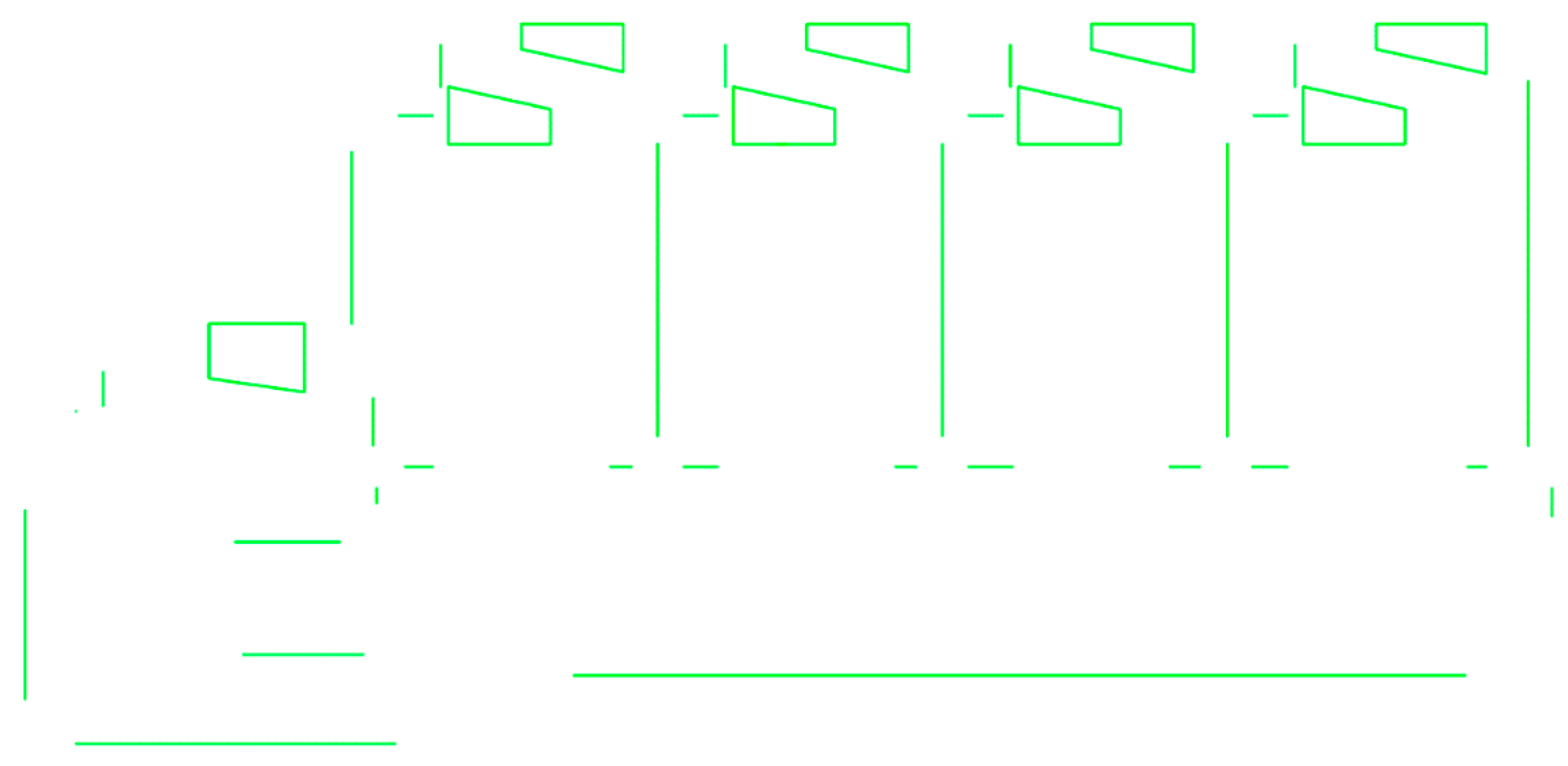

4. Project Overview and Modeling Preparation

4.1. Project Overview

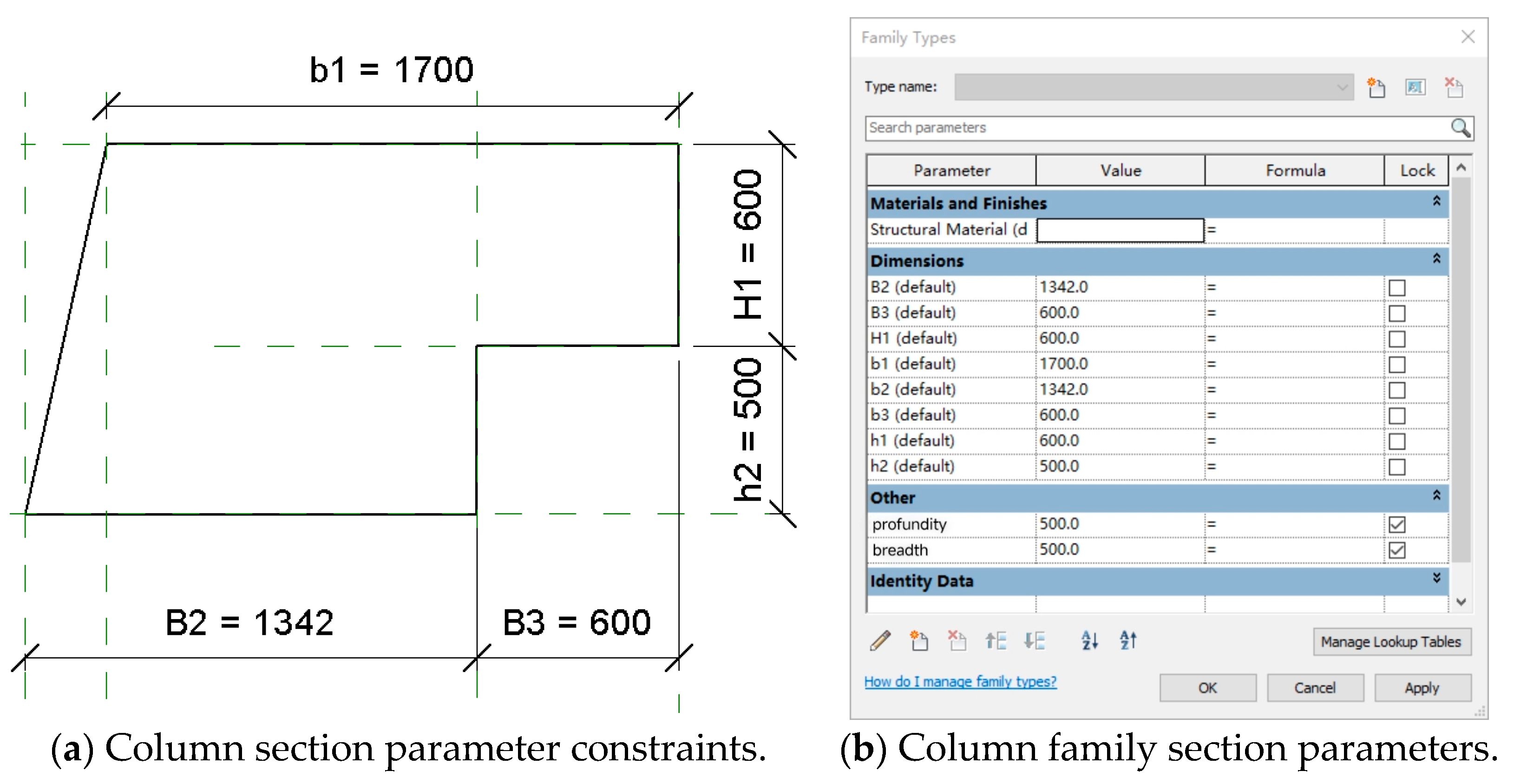

4.2. Create a Parameterized Family of Special-Section Columns

5. Dynamo Proton Hospital Automatic Modeling Logic Code

5.1. Structural Column Modeling Process

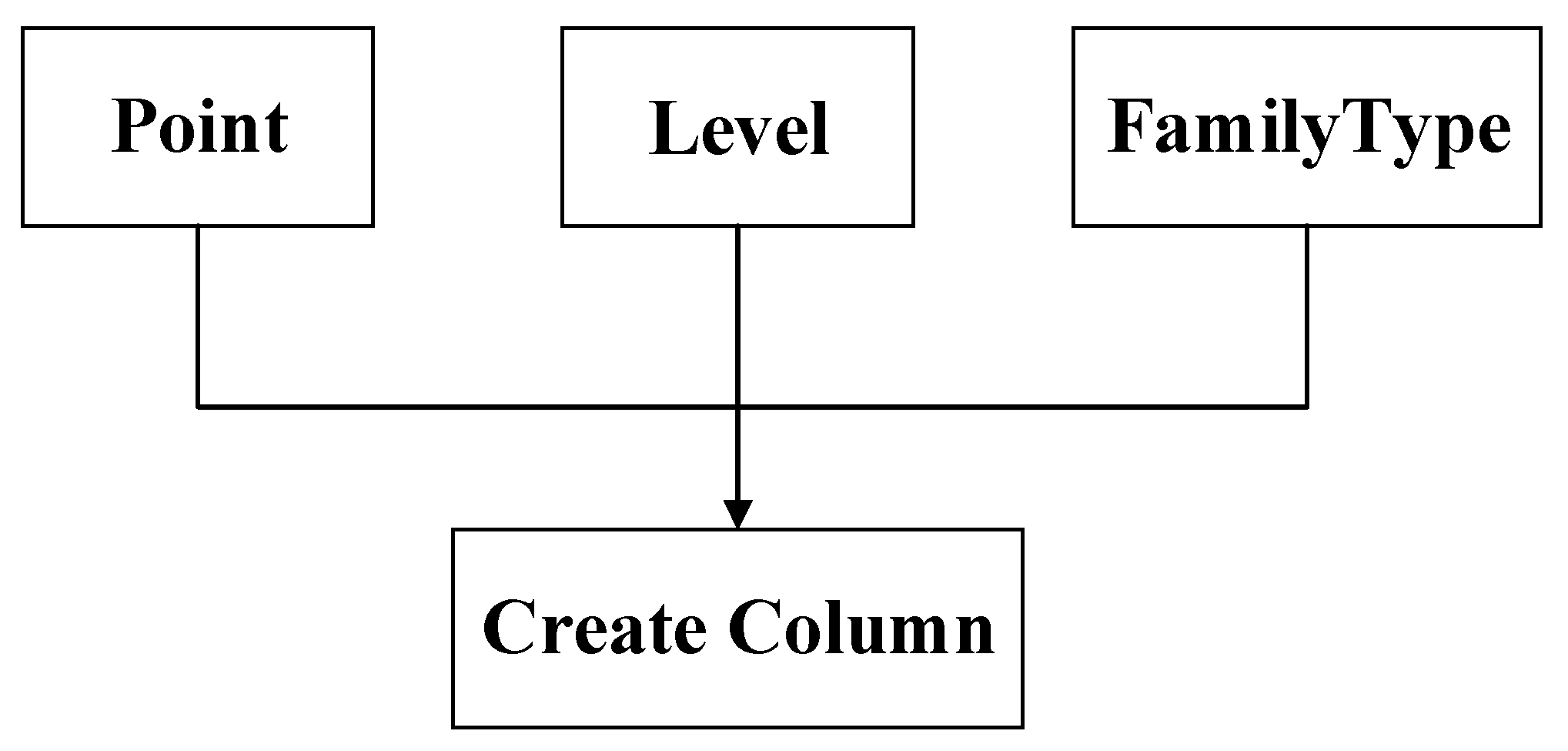

5.1.1. Dynamo Parametric Modeling of Specially Shaped Section Column

- (1)

- Obtain the profile of the specially shaped structural column

- (2)

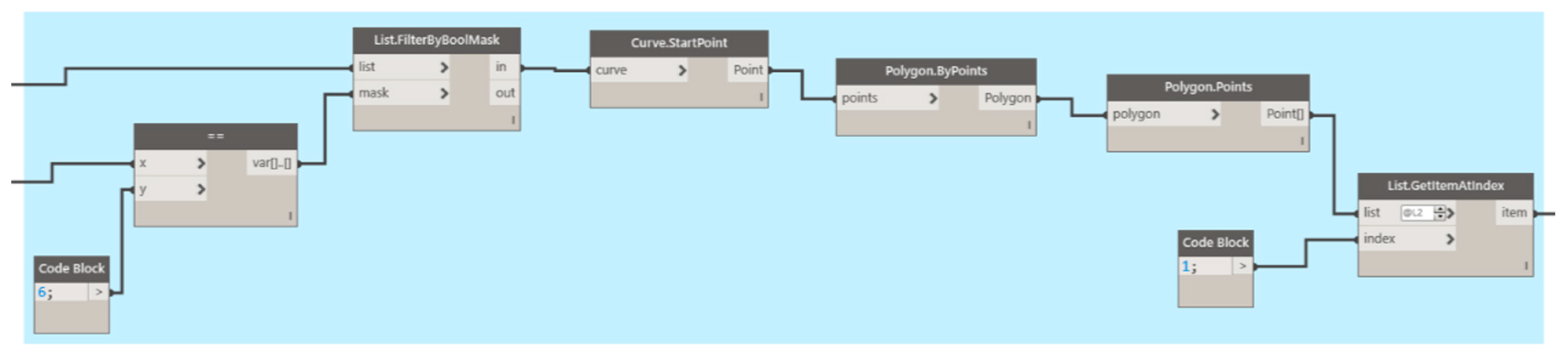

- Calculate the specified corner coordinate data of the profile column section

- (3)

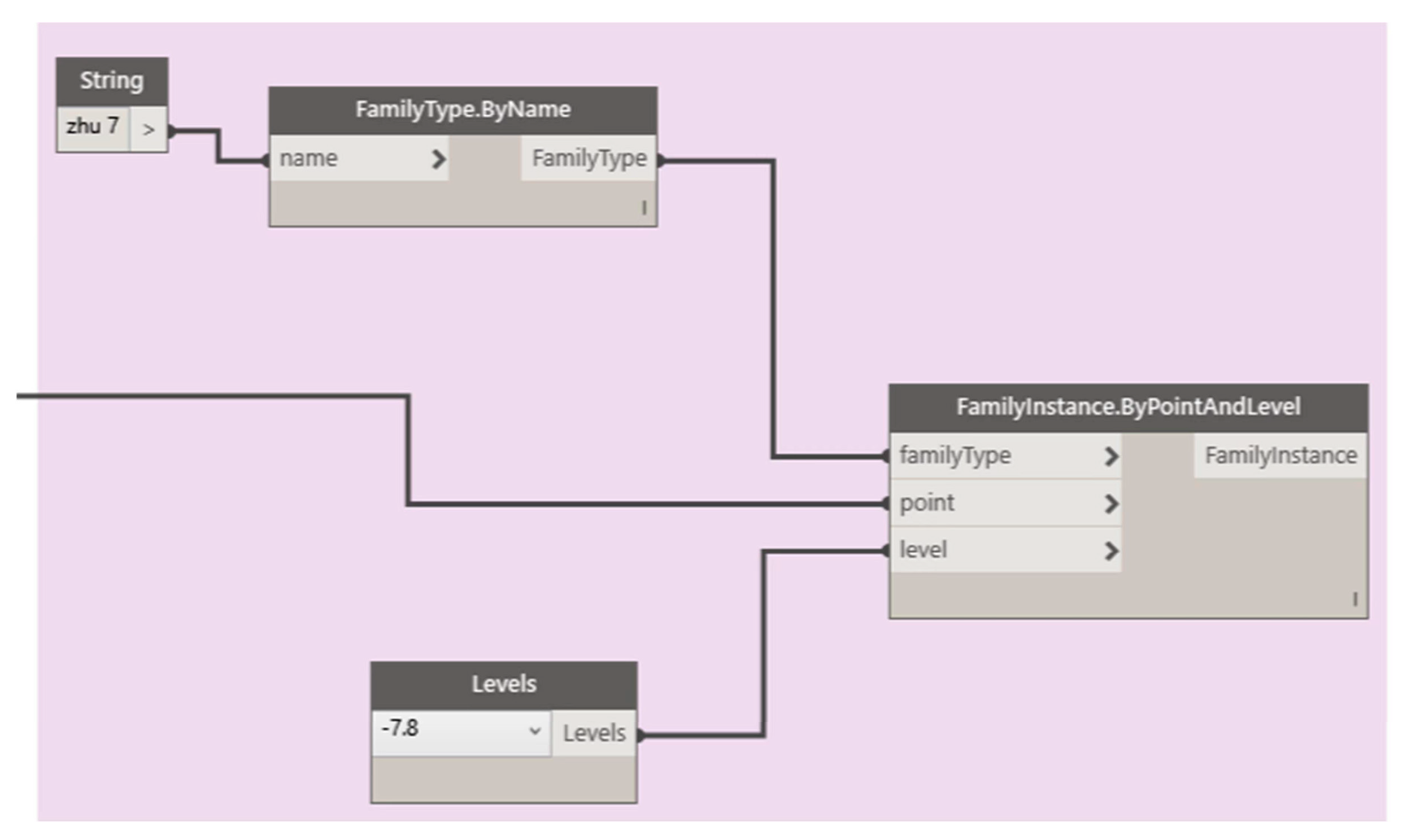

- Generate specially shaped column model

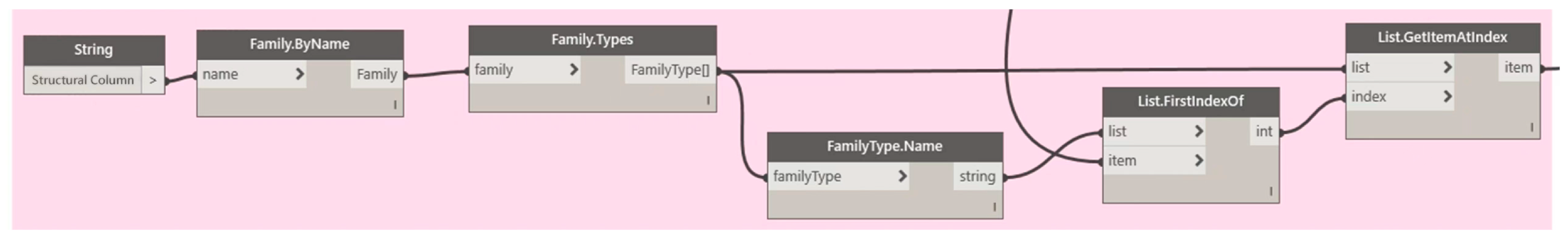

5.1.2. Dynamo Parametric Modeling of Rectangular Section Column

- (1)

- Obtain the outline of the structural column

- (2)

- Calculate the coordinate data of the center point of the section of structural column

- (3)

- Obtain the length and width of the structural column

- (4)

- Size data matching structure column family type

- (5)

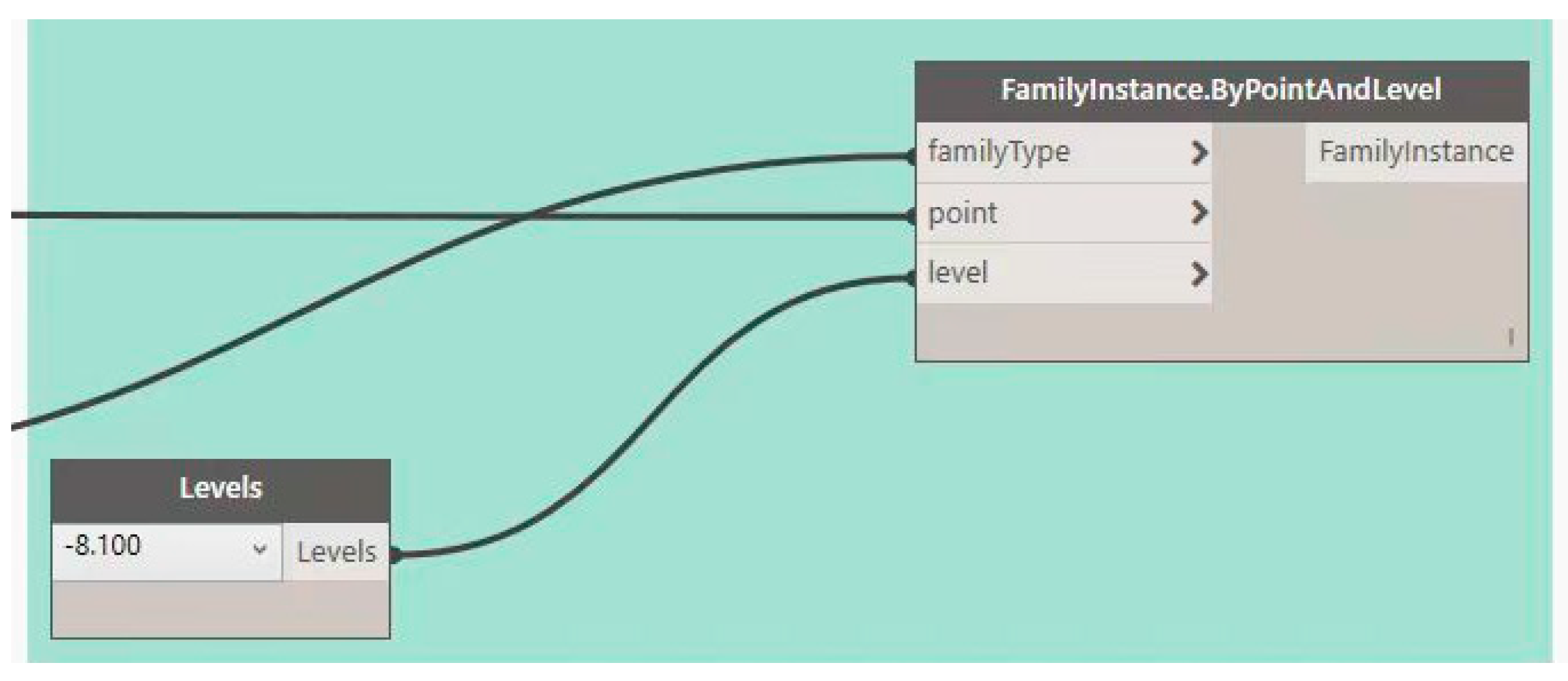

- Generate structural column model

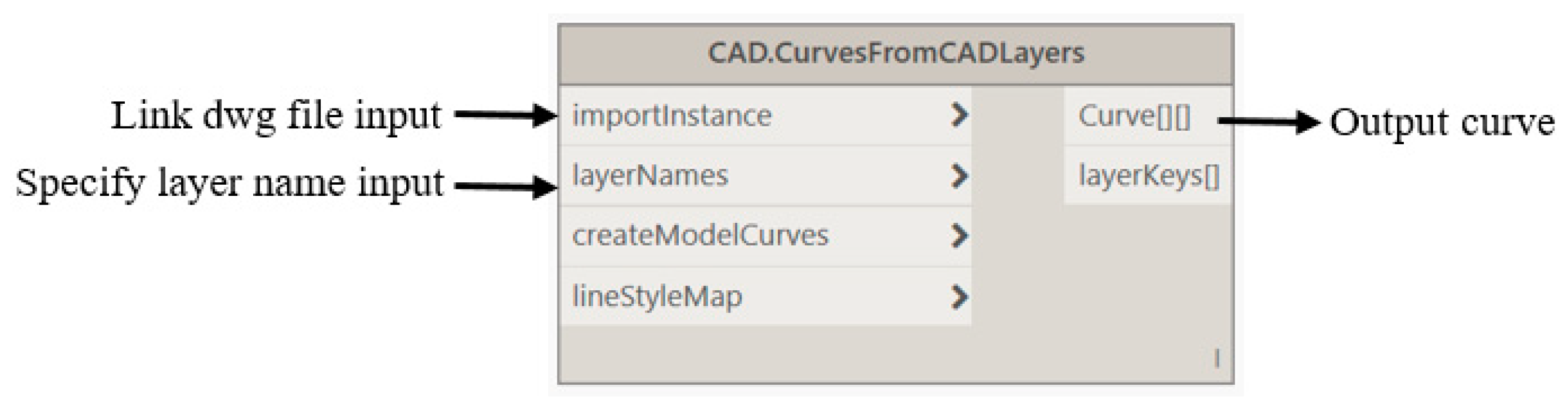

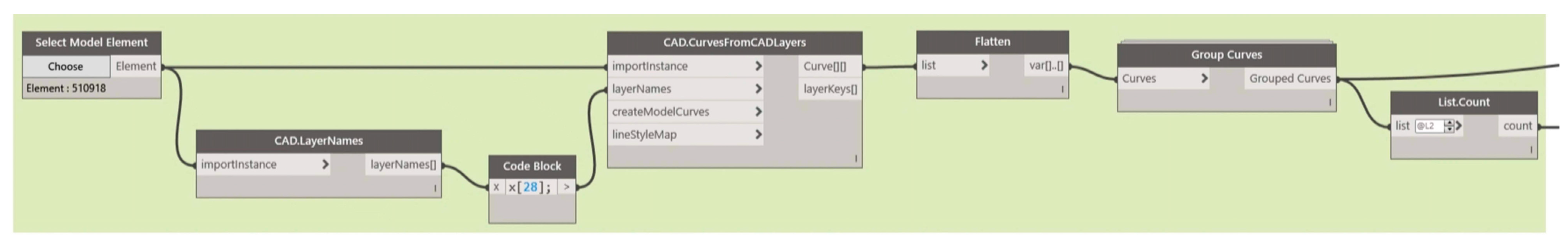

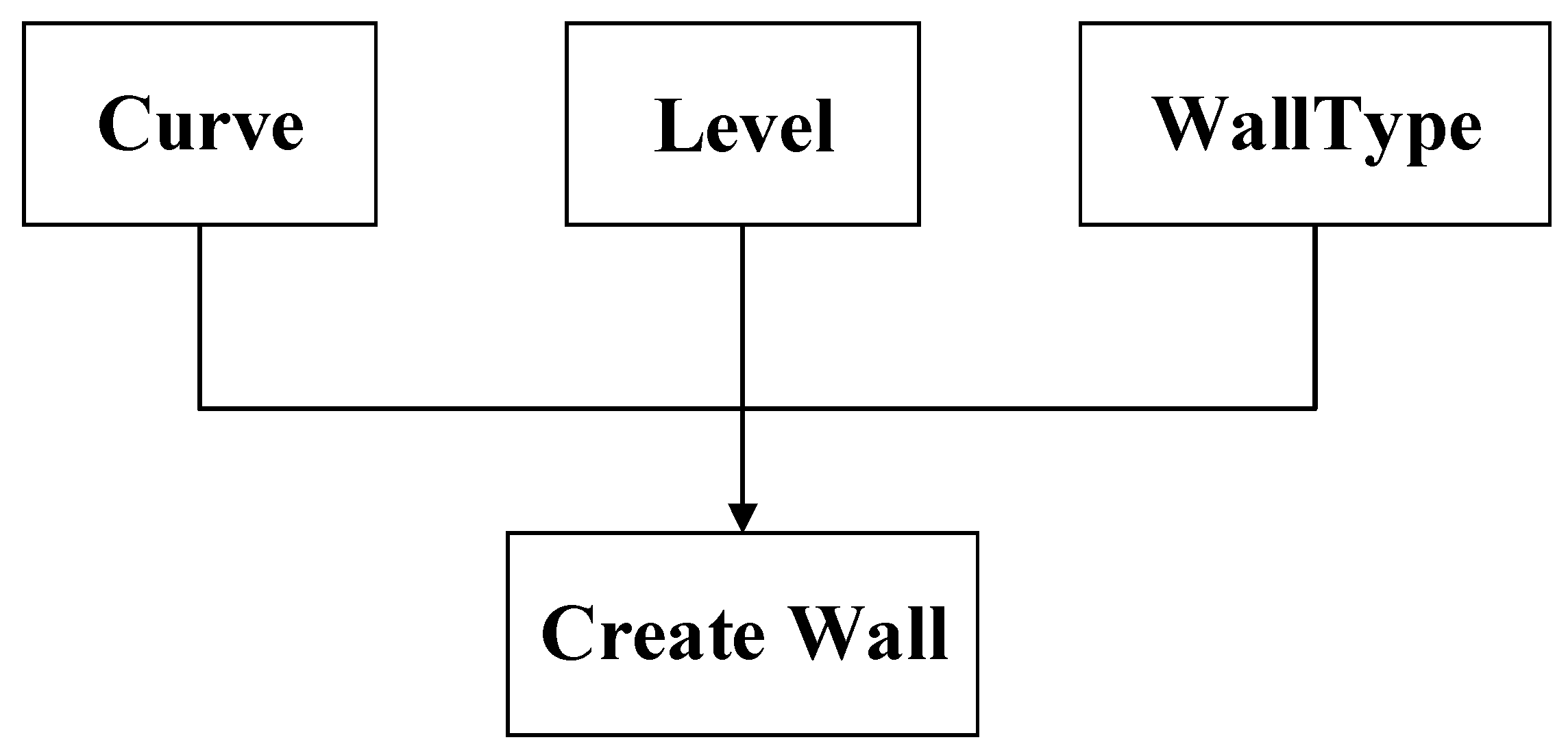

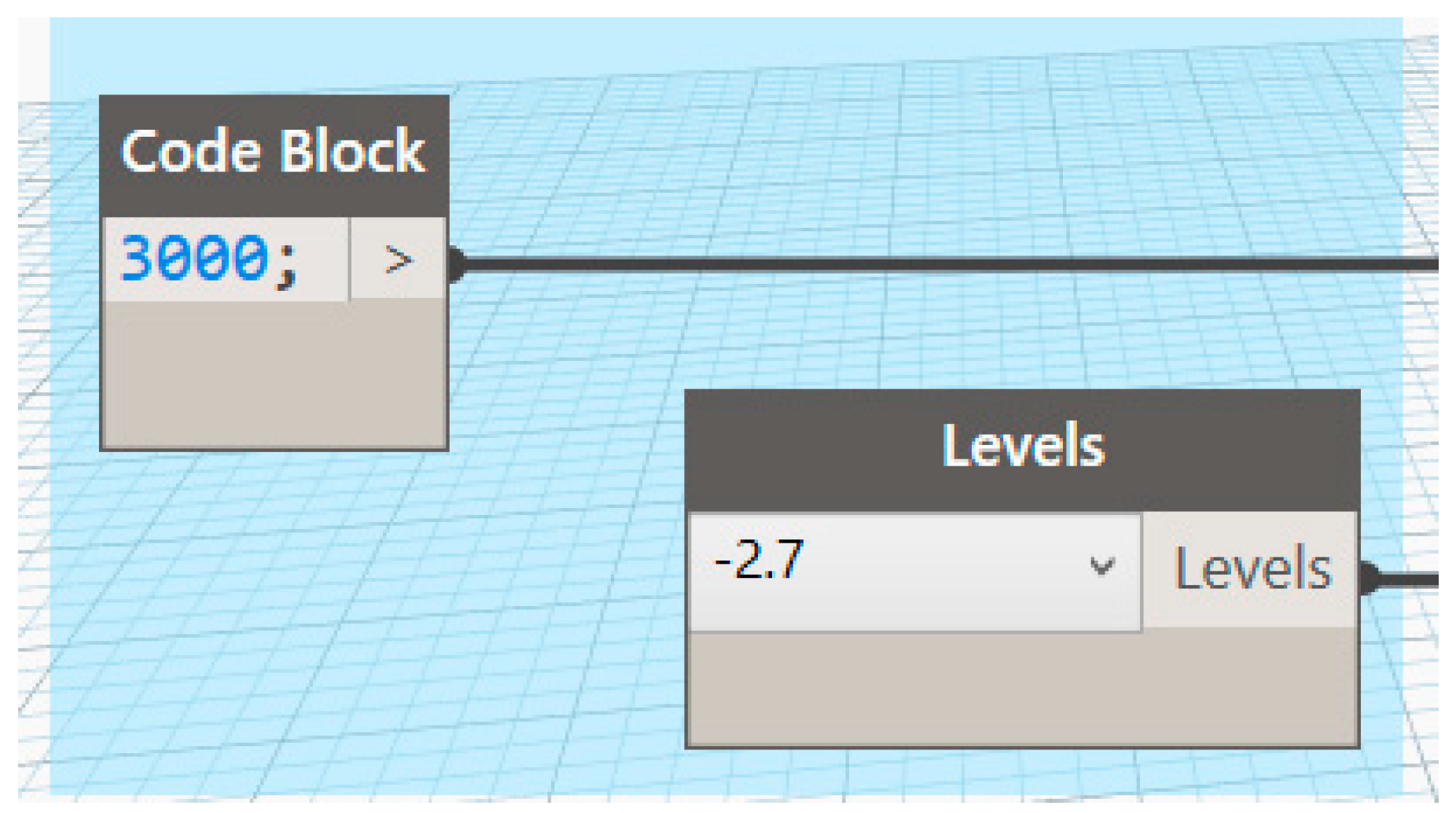

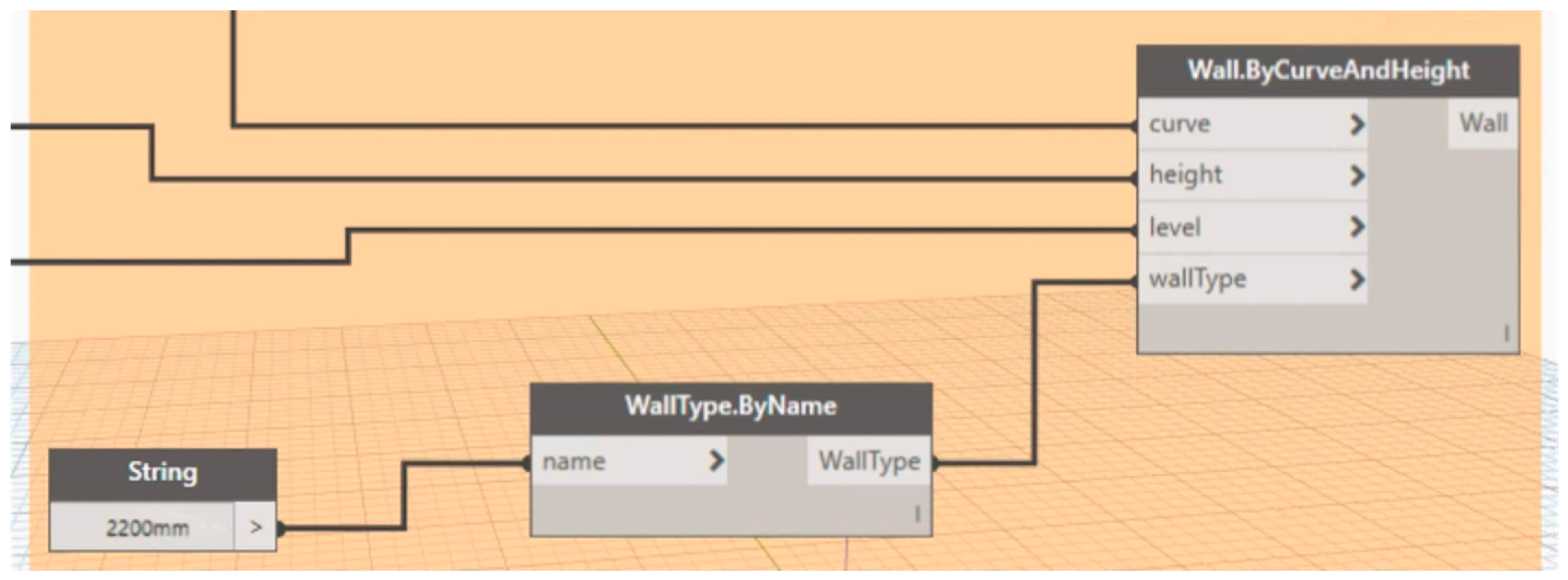

5.2. Structural Wall Modeling Process

- (1)

- Read CAD objects and extract curve elements

- (2)

- Set the height and elevation of the wall

- (3)

- Specify the wall type and generate the structural wall

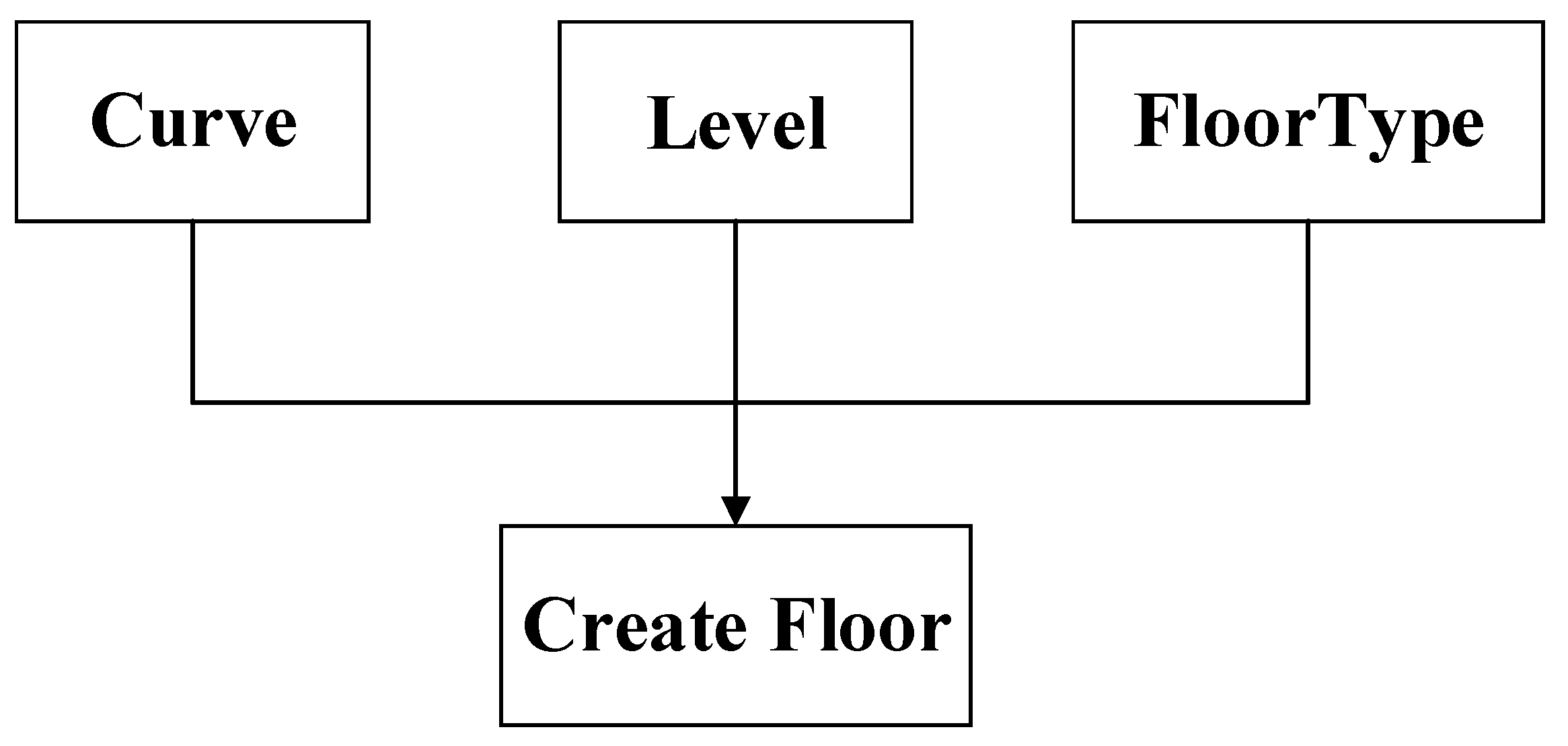

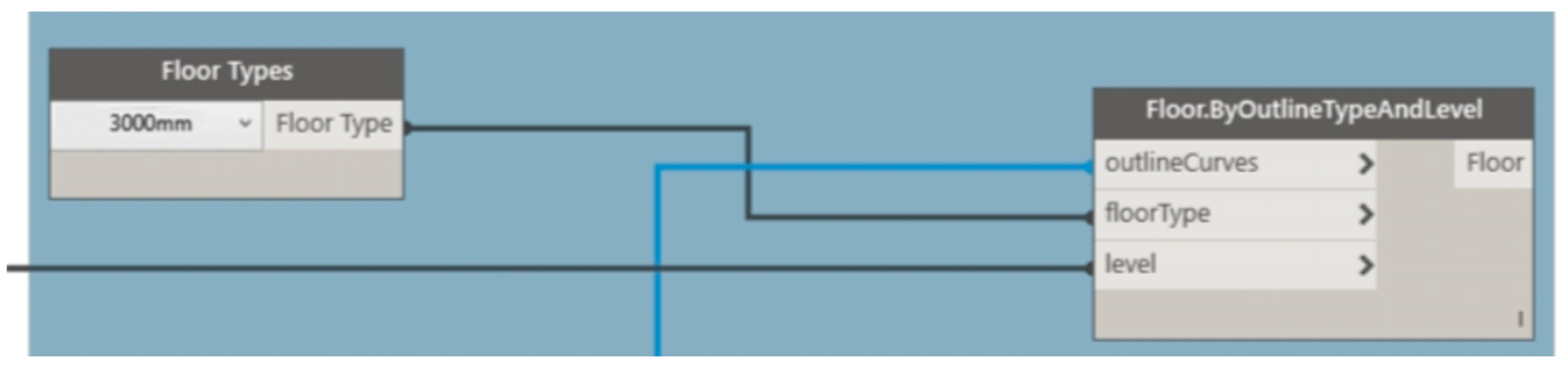

5.3. Structural Floor Modeling Process

- (1)

- Obtain the floor boundary line

- (2)

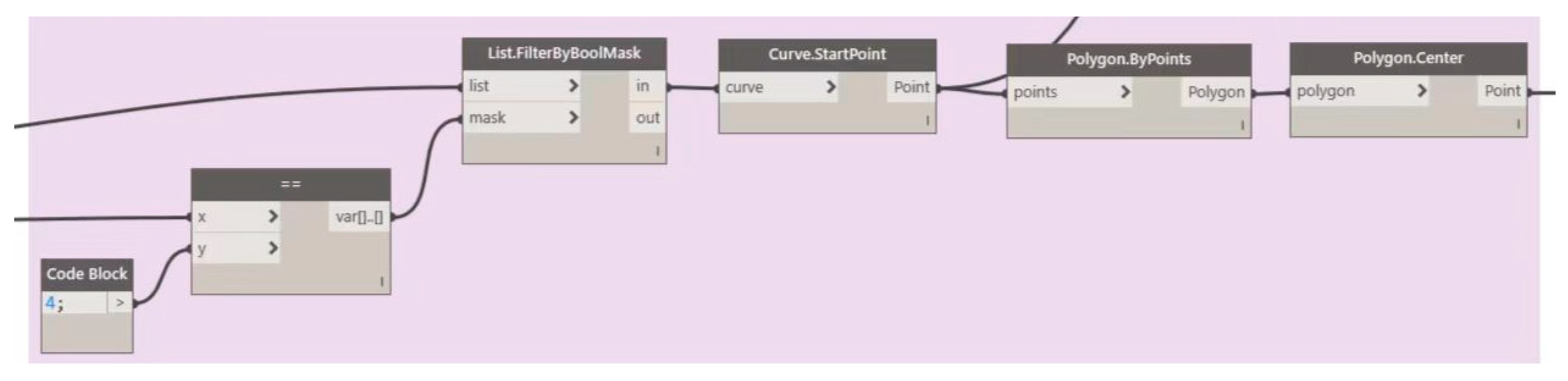

- Filter the outermost contour line

- (3)

- Generate floor model

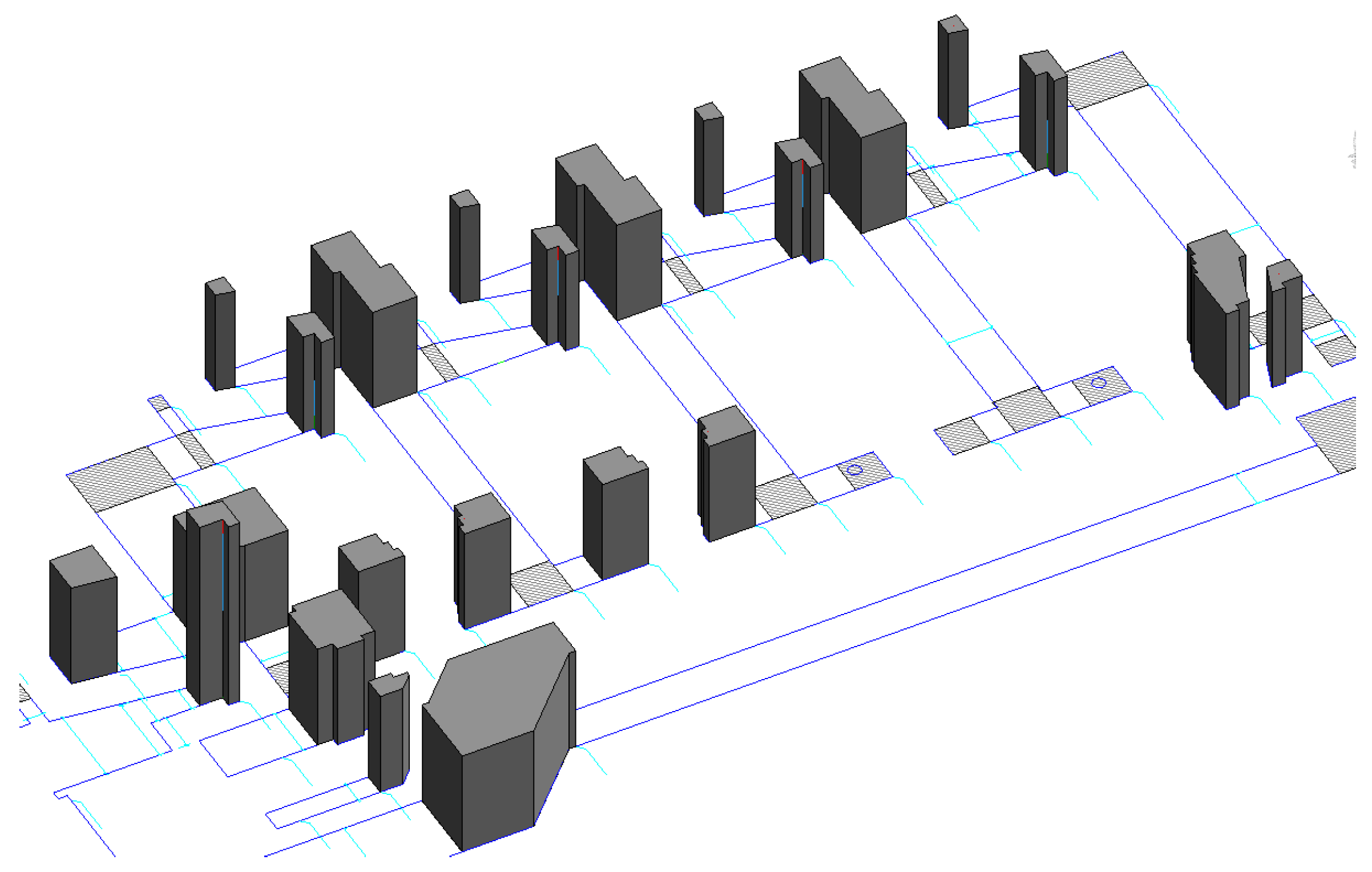

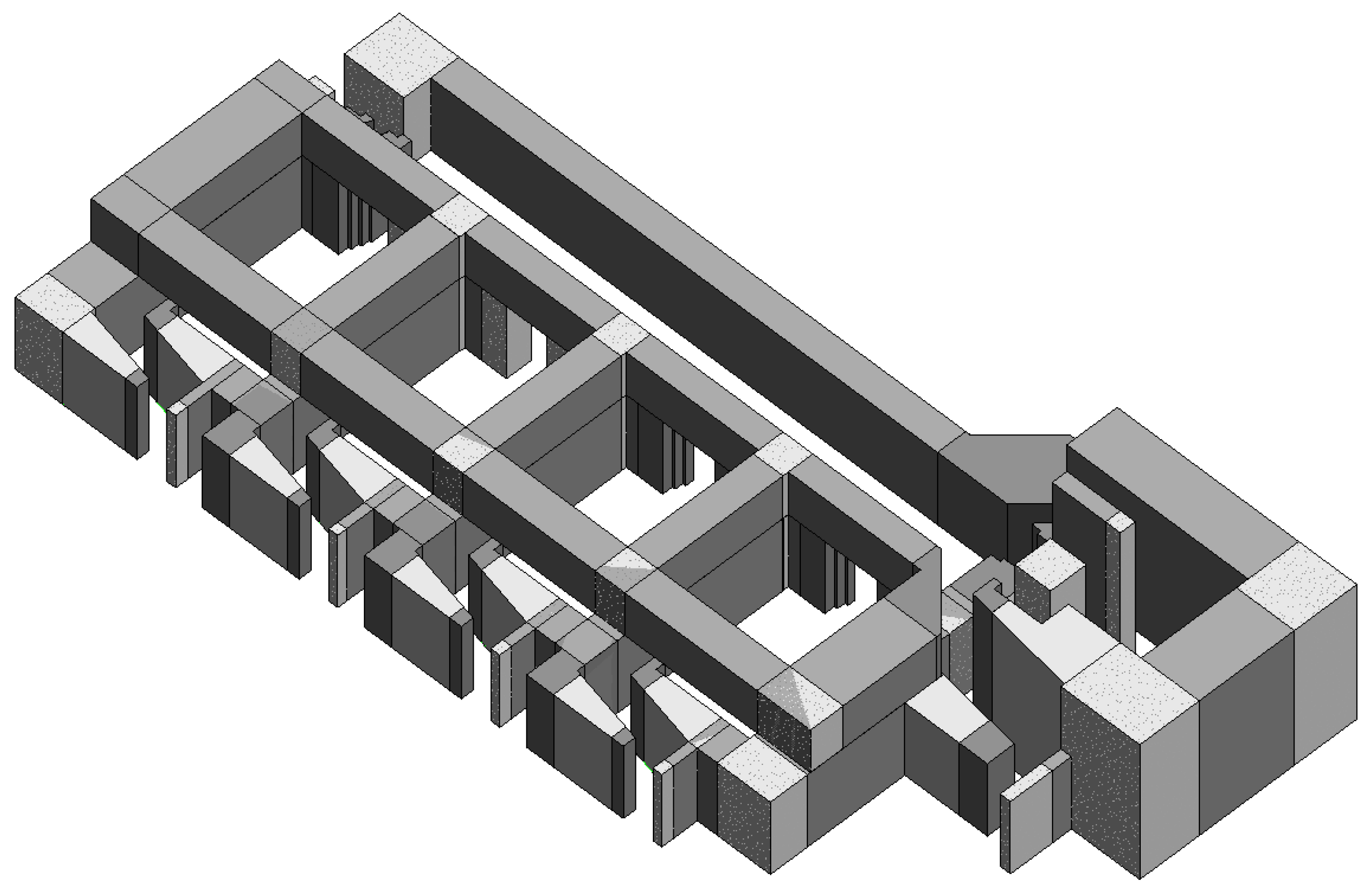

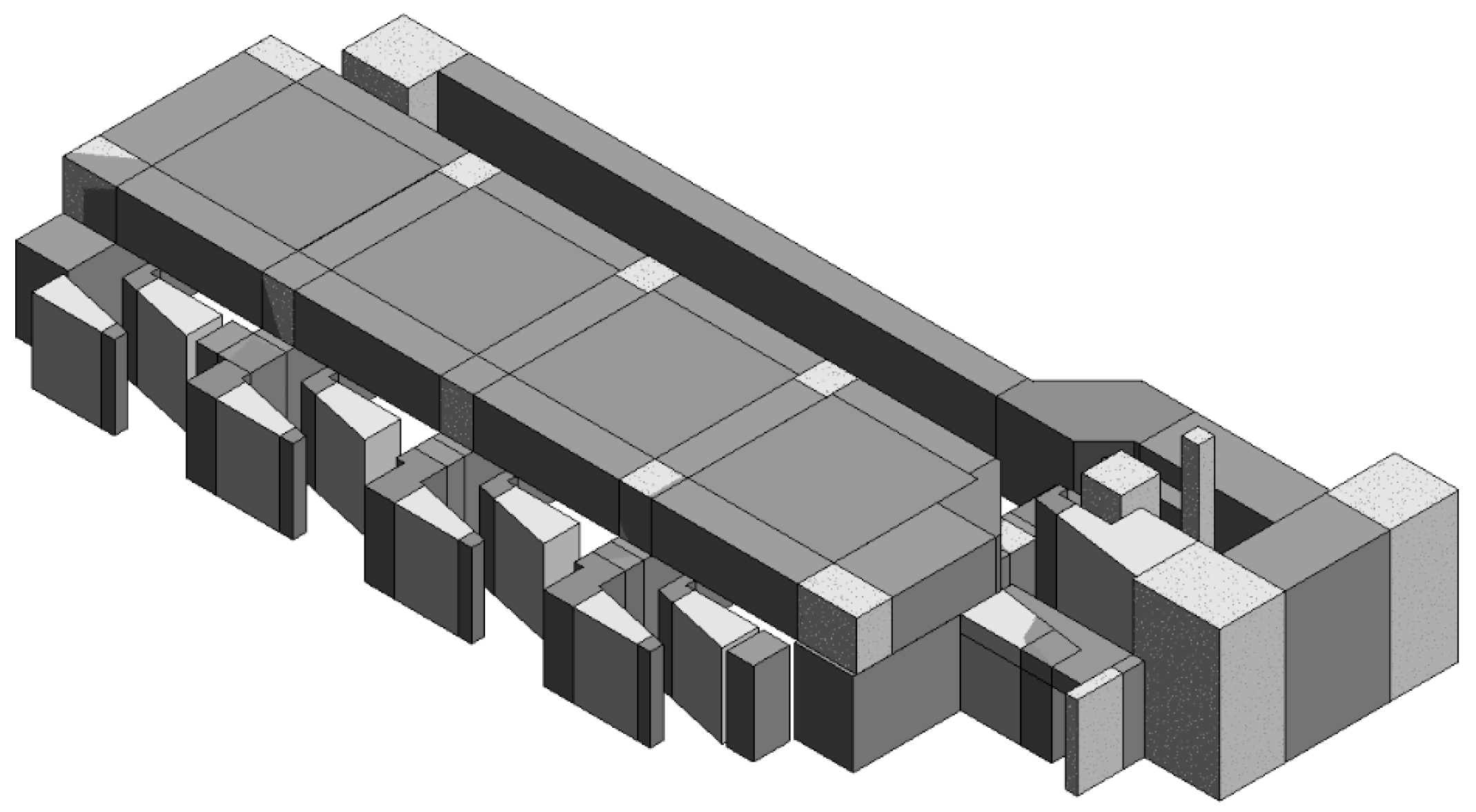

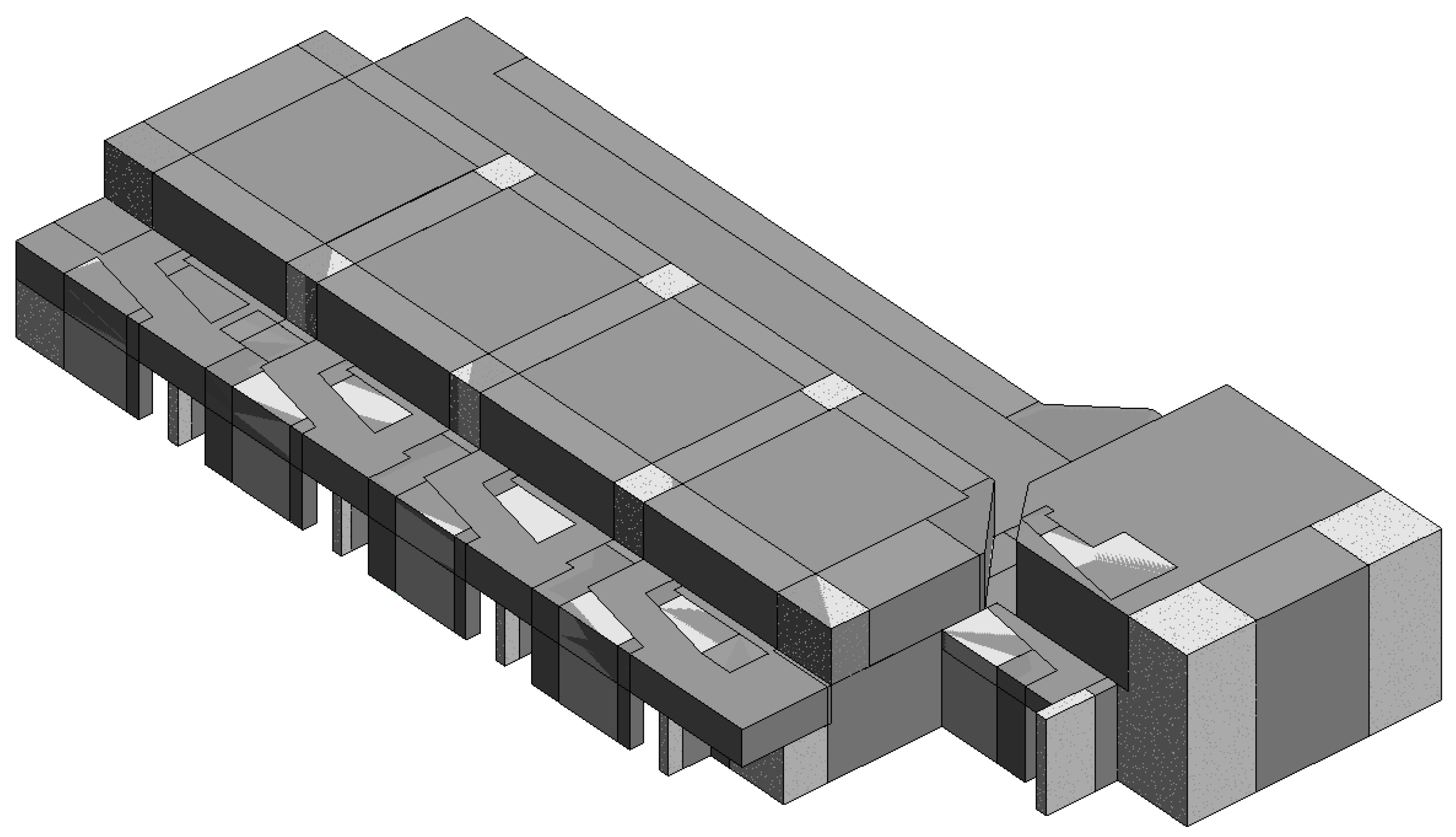

5.4. Generate Proton Hospital Parametric Model

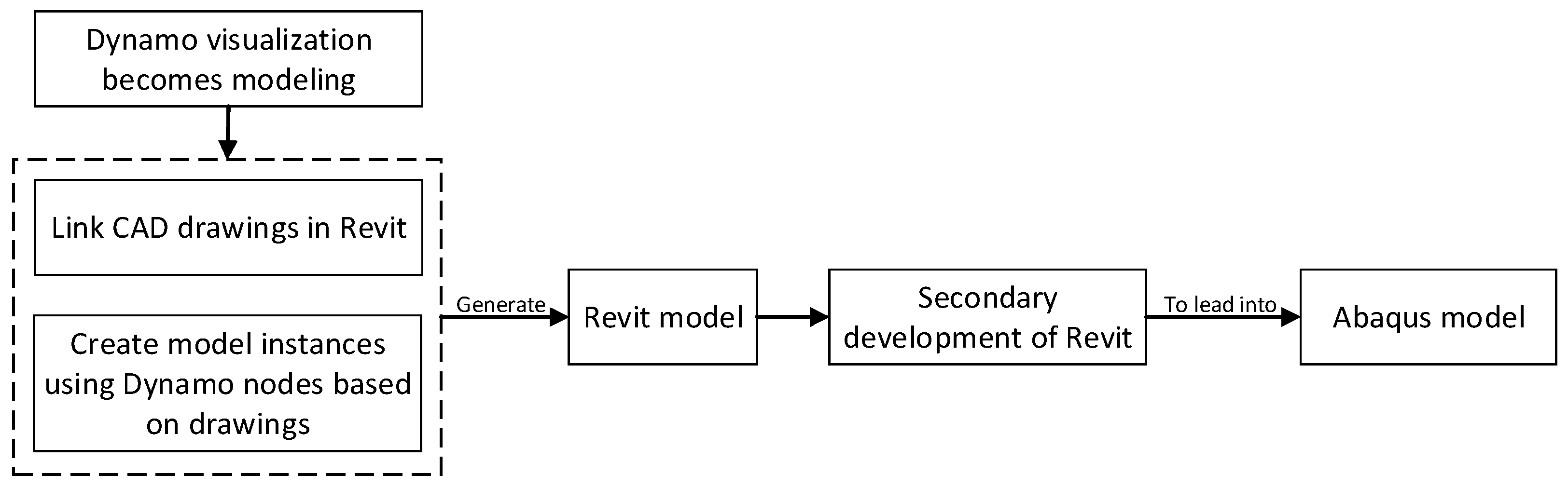

6. Revit–Abaqus Model Conversion Program Development

- (1)

- INP files

- (2)

- Python language script

- (1)

- The location information of the model is lost. Different types of model instances in Revit have different ways of representing positions. After studying Revit model instance data, it is found that the object in the location attribute of the general model is a subclass of LocationPoint, and its location is determined by a reference point coordinate. However, the object type in the location attribute of the structural framework model is LocationCurve, which indicates that the model is positioned by a curve. This approach is not a problem in Revit, but neither the .sat documentation nor the Abaqus program supports it. Therefore, when imported into Abaqus, the structural frame loses the position coordinates and placement of angle information. The conventional model also loses information about the placement angle. In fact, the problem and the naming confusion boil down to the same problem: missing parameter information in the .sat file transfer.

- (2)

- Model export filtering is missing. When you export a .sat file from Revit, the set of exported models is determined by the view. If you do not rely on the program, manual operation needs to manually select the exported model to be isolated into the corresponding view. If the number of models is large, the workload will be relatively large.

- (3)

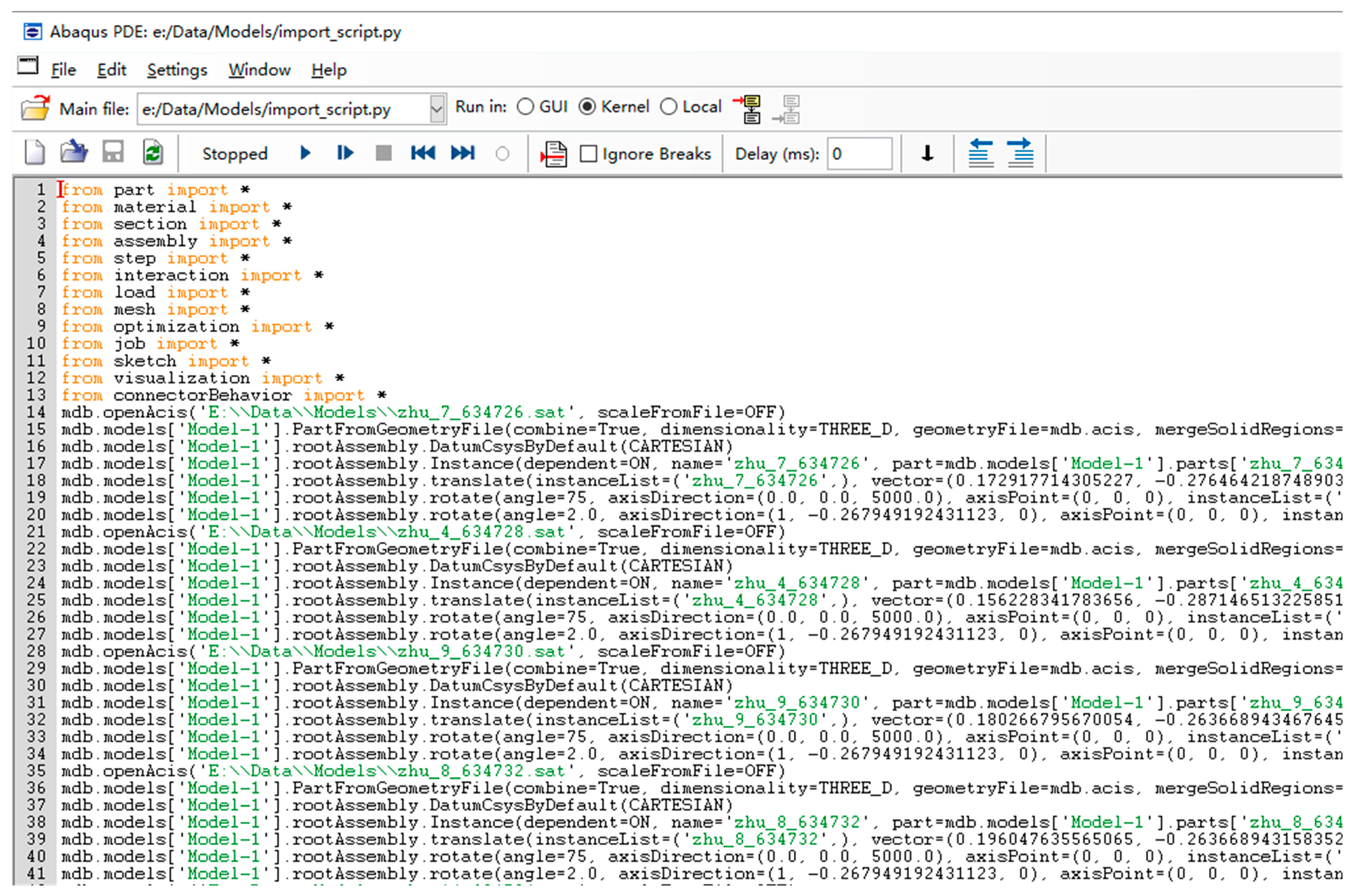

- In general, the two problems of model naming confusion and model location information loss can be summarized as the problem of parameter information loss during model import. In the final analysis, it is difficult to adapt a .sat intermediate file to the data structure of various software. In order to solve these problems, the program developed in this paper manages the interaction of the model and uses Python script to realize the automatic generation of the Abaqus model. The core function of this script is to read .sat files of model components extracted from Revit, including key data such as spatial location and cross-section size. Based on these data, the model parts in Abaqus are created automatically. The orderly import function of the model carries relevant parameters. This provides a new idea for the effective import of Revit model into Abaqus.

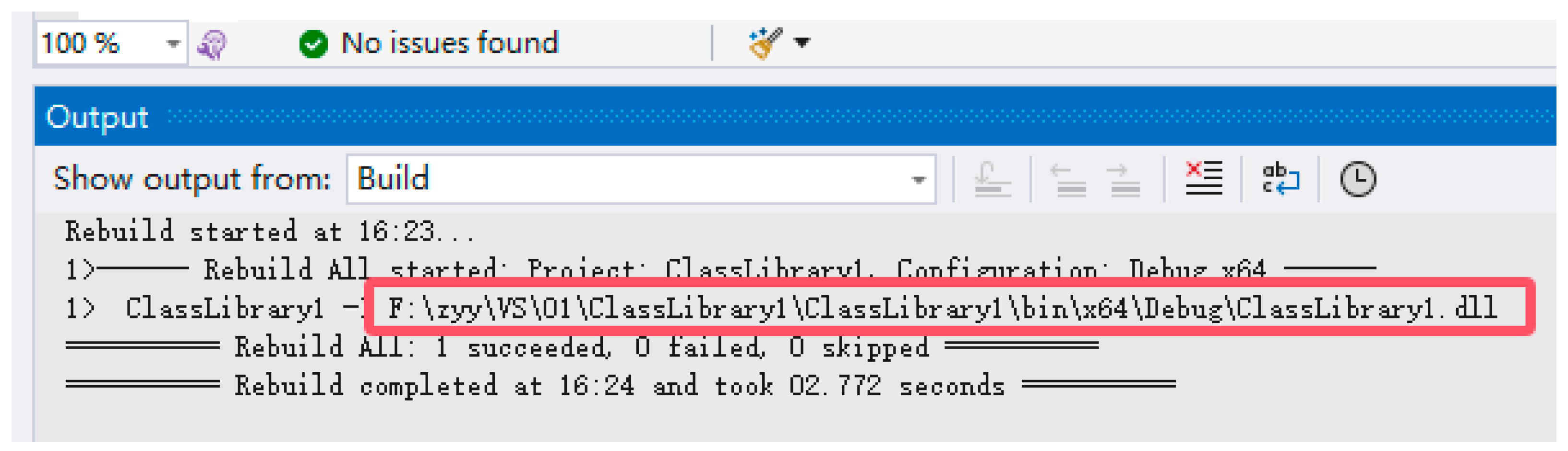

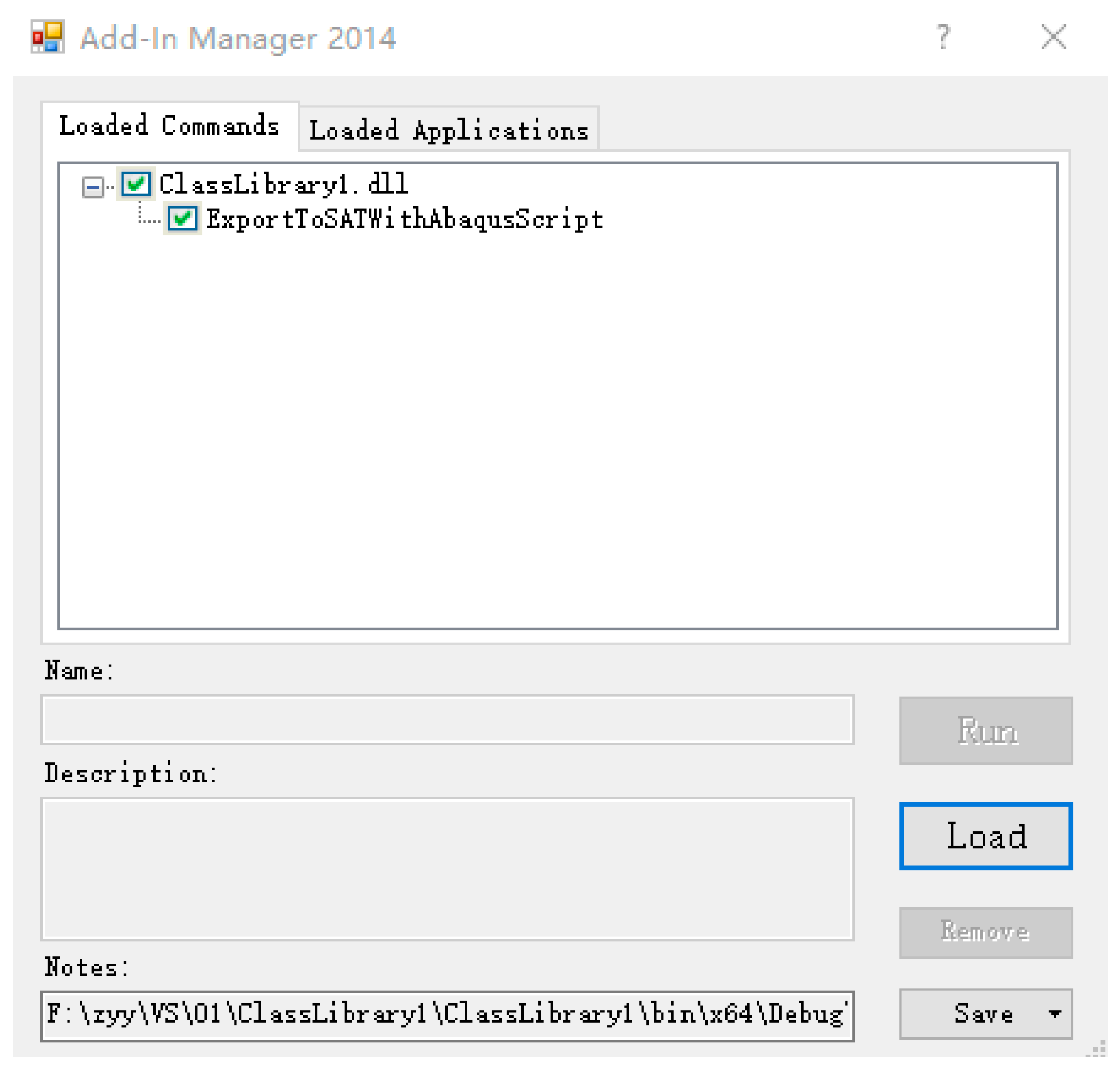

6.1. Development Process of Model Transformation Program

- (1)

- Create a new base in Visual Studio2022 .NET4.7 project, load the class library (. NET framework), and name it.

- (2)

- Add the RevitAPI.dll and RevitAPIUI.dll assemblies in the project reference options and change their properties to False. Add a namespace to the program interface, such as using Autodesk.Revit.

- (3)

- Add the TransactionAttribute transaction attribute to the command class.

- (4)

- Create a new IExternalCommand-derived class and overloaded function Execute() method. Write code.

- (5)

- Generate.dll file after successful compilation, and debug the program in Revit.

- (6)

- After successful debugging, the .sat folder and its corresponding Python script conforming to Abaqus are generated.

- (7)

- Import the generated Python script into Abaqus and run it to verify that it meets the requirements.

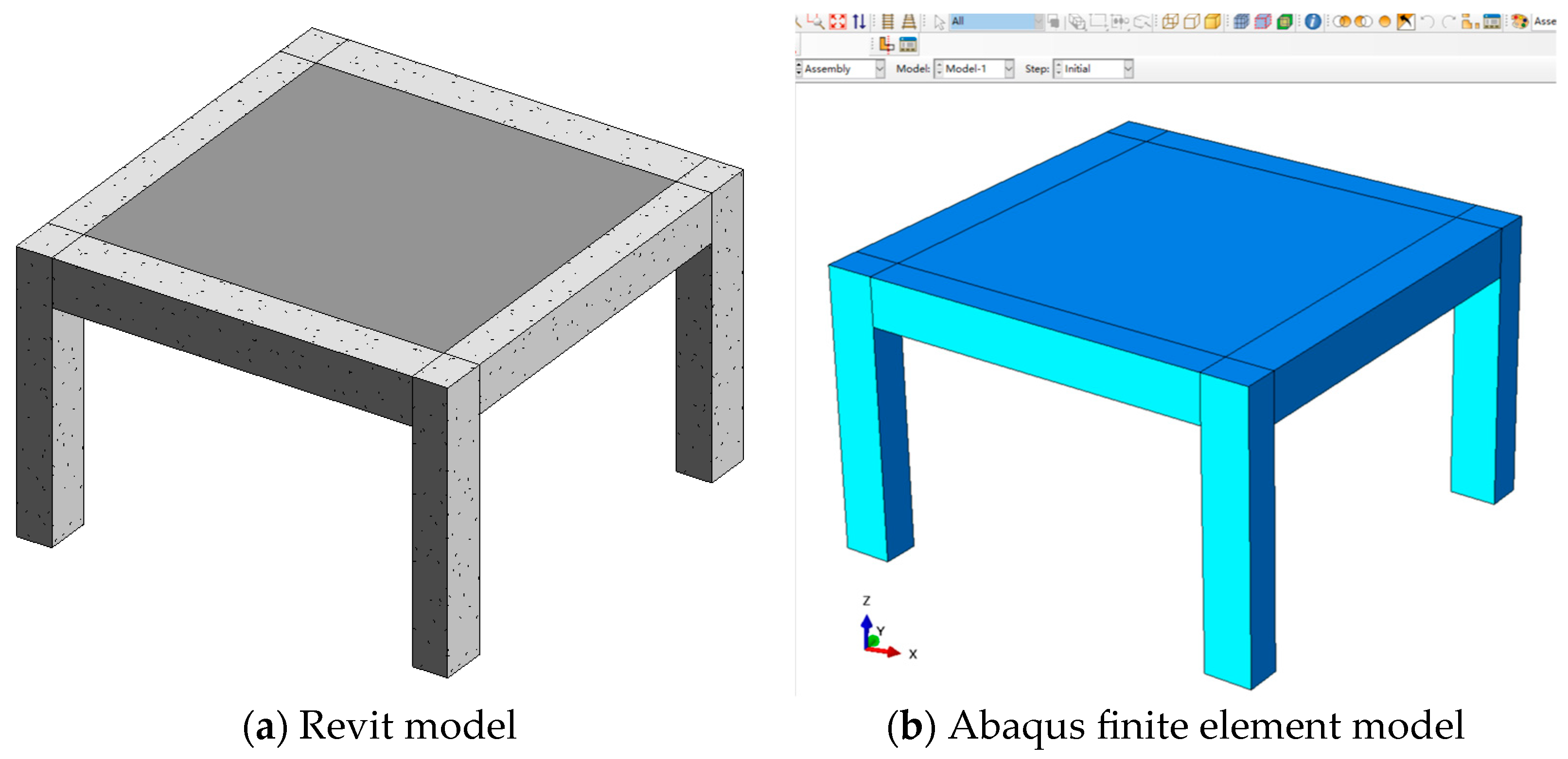

6.2. Verification of Model Transformation Methods

6.2.1. The Main Steps of Interface Development

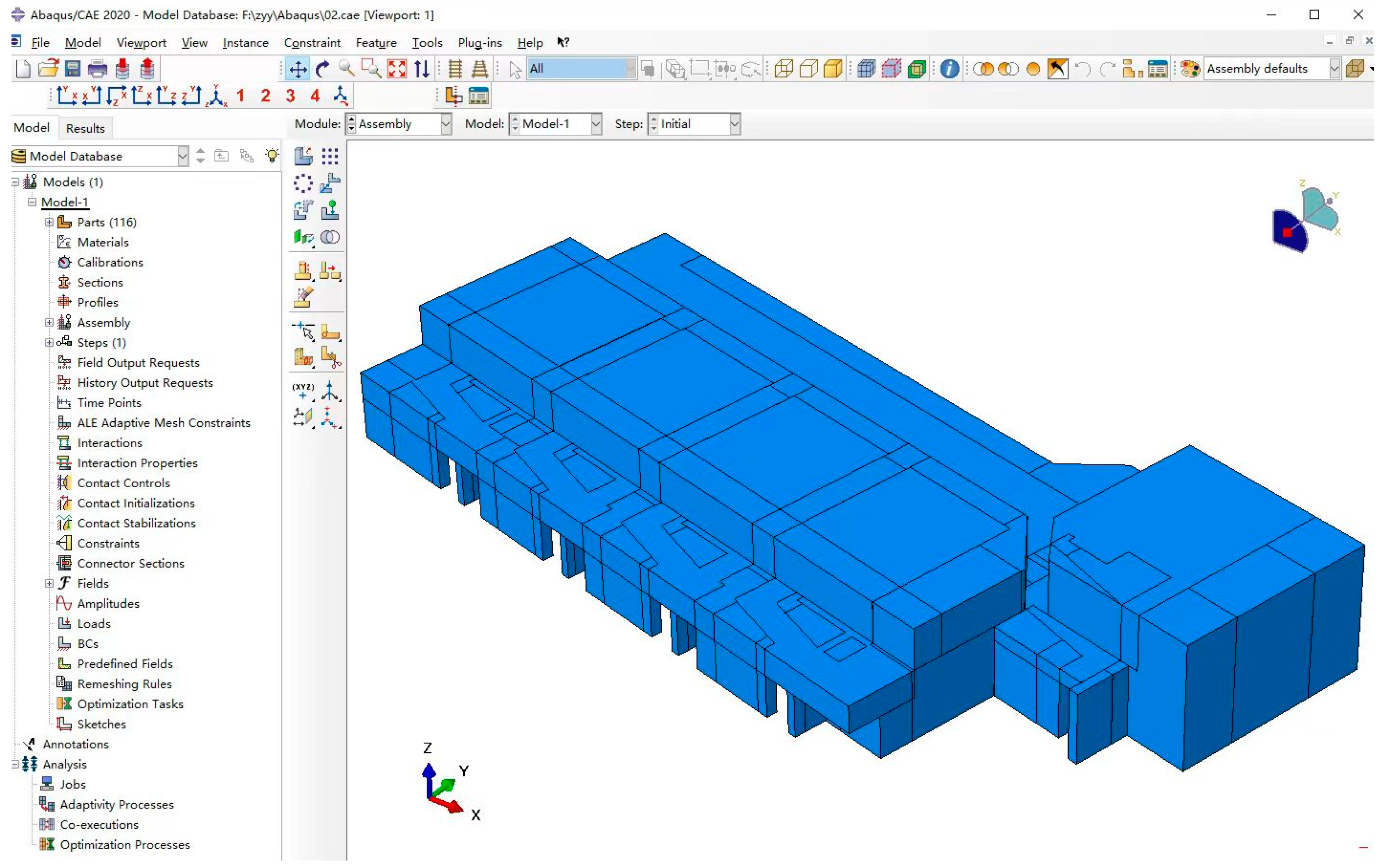

6.2.2. Proton Hospital Model Conversion

7. Conclusions

- (1)

- By integrating Revit and Dynamo technologies, an automated and parameterized proton hospital structural modeling system was built, and Revit’s rapid modeling in proton hospital design was realized. This method significantly improves the conversion efficiency and accuracy from a traditional 2D design to a 3D BIM model, and provides strong technical support for the design and construction of complex engineering projects such as the proton hospital.

- (2)

- A structural model conversion interface between Revit and Abaqus was developed, and the feasibility of the model conversion method and the effectiveness of the model conversion program were verified through their application to the construction of a proton hospital. The method of directly converting the BIM model into the structural analysis model improves the modeling efficiency of the finite element analysis of the building structure and makes up for the shortcomings of BIM technology in the analysis of the building structure.

- (3)

- In the future, the acquisition and transfer methods of data information such as load parameters, boundary conditions, shrinkage, and creep during model conversion will be further improved, and a more efficient and comprehensive BIM-CAE model conversion program will be developed to provide a reference for solving problems such as information fault and repetitive work in the engineering design stage of the proton hospital.

- (4)

- This study systematically addresses the issues of privacy, compliance, equity, and environment in BIM-FEA interoperability by constructing a full-life-cycle ethics governance system.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Rodrigues, F.; Antunes, F.; Matos, R. Safety Plugins for Risks Prevention Through Design Resourcing BIM. Constr. Innov. 2021, 21, 244–258. [Google Scholar] [CrossRef]

- Zeng, Y.; Duan, R.; Huang, S.; Feng, T. Reliability Analysis for Complex Systems Based on Generalized Stochastic Petri Nets and EDA Approach Considering Common Cause Failure. Eng. Comput. 2020, 37, 1513–1530. [Google Scholar] [CrossRef]

- Yavan, F.; Maalek, R.; Toğan, V. Structural Optimization of Trusses in Building Information Modeling (BIM) Projects Using Visual Programming, Evolutionary Algorithms, and Life Cycle Assessment (LCA) Tools. Buildings 2024, 14, 1532. [Google Scholar] [CrossRef]

- Wei, Y.; Choi, H.; Lei, Z. A Generative Design Approach for Modular Construction in Congested Urban Areas. Smart Sustain. Built Environ. 2022, 11, 1163–1181. [Google Scholar] [CrossRef]

- Hamidavi, T.; Abrishami, S.; Ponterosso, P.; Begg, D.; Nanos, N. OSD: A Framework for the Early Stage Parametric Optimisation of the Structural Design in BIM-Based Platform. Constr. Innov. 2020, 20, 149–169. [Google Scholar] [CrossRef]

- Cho, J.; Kim, C.; Song, Y.; Kang, J.; Yeon, J. Lumped Record Management Method Using BIM and Dynamo for Spalling Maintenance. Autom. Constr. 2024, 160, 105324. [Google Scholar] [CrossRef]

- Zhang, Y.; Jiang, G.H.; Tang, S.Y.; Gu, C.L.; Tian, S.F.; Ma, T.X. Forward Intelligent Modeling Method of Aqueduct Based on Revit Secondary Development. Water Resour. Power 2024, 42, 137–141. [Google Scholar] [CrossRef]

- Rocha, G.; Mateus, L. Using Dynamo for Automatic Reconstruction of BIM Elements from Point Clouds. Appl. Sci. 2024, 14, 4078. [Google Scholar] [CrossRef]

- Wang, L.; Shi, H.; Li, Y.; Zhang, P.; Feng, C. Parametric Modeling of Urban Tunnel Foundation Pit Integrated with Revit and Dynamo. Chin. J. Undergr. Space Eng. 2023, 19 (Suppl. 1), 254–262. [Google Scholar]

- Godes, C.R.; Rodriguez, S.A.; Cho, J.; Song, Y.; Yeon, J. Optimizing Evacuation Efficiency in Buildings: A BIM-Based Automated Approach to Sustainable Design. Sustainability 2024, 16, 9240. [Google Scholar] [CrossRef]

- Wen, Z.; Luo, Y.; Wu, Q.; Fan, C.; Zhang, Q. Parametric Design of the Precast Concrete Slab with Truss Rebar Based on Dynamo. Build. Struct. 2022, 52, 128–132. [Google Scholar] [CrossRef]

- Carvalho, J.P.; Bragança, L.; Mateus, R. A Systematic Review of the Role of BIM in Building Sustainability Assessment Methods. Appl. Sci. 2020, 10, 4444. [Google Scholar] [CrossRef]

- Aziz, R.M.; Nasreldin, T.I.; Hashem, O.M. The Role of BIM as a Lean Tool in Design Phase. J. Eng. Appl. Sci. 2024, 71, 23. [Google Scholar] [CrossRef]

- Deng, X.Y.; Chang, T.Y.P.; Liu, X.L. Automatic Generation of Structural Model from IFC-Based Architectural Model. China Civ. Eng. J. 2007, 40, 6–12. [Google Scholar] [CrossRef]

- Liu, Z.Q.; Li, Y.G.; Lu, X.L.; Zhang, H.Y. BIM-Based Integrated Information Framework for Architectural and Structural Design Model. J. Tongji Univ. (Nat. Sci.) 2010, 38, 948–953. [Google Scholar] [CrossRef]

- Tang, F.; Ma, T.; Guan, Y.; Zhang, Z. Parametric Modeling and Structure Verification of Asphalt Pavement Based on BIM-ABAQUS. Autom. Constr. 2020, 111, 103066. [Google Scholar] [CrossRef]

- Jia, J.; Gao, J.; Wang, W.; Ma, L.; Zhang, Z. An Automtic Generation Method of Finite Element Model Based on BIM and Ontology. Buildings 2022, 12, 1949. [Google Scholar] [CrossRef]

- He, X.P.; Wang, H.; Zhang, Y.M.; Wang, F.Q.; Mao, J.X.; Xie, Y.S. Revit-Midas/Civil Model Conversion Approach and Its Application. J. Southeast Univ. (Nat. Sci. Ed.) 2021, 51, 813–818. [Google Scholar] [CrossRef]

- Zou, Y.; Hu, F.; Yang, H.; Cai, J.; Pan, H.; Zhang, Q. Detailed Design of Special-Shaped Steel Structures Based on DfMA: The BIM-FEM Model Conversion Method. Buildings 2024, 14, 1320. [Google Scholar] [CrossRef]

- Wang, X.X.; Huang, Y.L.; Zhao, J.C.; Duan, L.P. Development and Application of Revit-Abaqus Model Exchange Interface. J. Shanghai Jiaotong Univ. 2020, 54, 135–143. [Google Scholar] [CrossRef]

- Wang, J.; Wang, X. Research on Modeling Technology from AUTOCAD to REVIT. J. Eng. Technol. 2015, 7, 111–116. [Google Scholar]

- He, R.X. Research and Program Development of Curve Bridge Design Modeling Technology Based on BIM. Ph.D. Thesis, Chang’an University, Xi’an, China, 2023. [Google Scholar]

| Attribute Class | Attribute Naming | Attribute Meaning |

|---|---|---|

| string | folderPath | Sat file path |

| string | elementName | The name of the import component |

| XYZ | Location | Component placement reference point information |

| Component | Feature |

|---|---|

| Import module | Import the Python module provided by Abaqus |

| Import model | Example Import the .sat file in the specified path to Abaqus |

| Create Part | Create the corresponding Part in the name of the elementName parameter |

| Import Assembly | Import the Part into Assembly |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, S.; Yu, T.; Liu, Y.; Li, Y.; Lei, B.; Qiao, W.; Zhang, Y. Research on Parametric Modeling and Model Transformation of Proton Hospital Based on BIM. Buildings 2025, 15, 1658. https://doi.org/10.3390/buildings15101658

Li S, Yu T, Liu Y, Li Y, Lei B, Qiao W, Zhang Y. Research on Parametric Modeling and Model Transformation of Proton Hospital Based on BIM. Buildings. 2025; 15(10):1658. https://doi.org/10.3390/buildings15101658

Chicago/Turabian StyleLi, Shoufu, Tao Yu, Yang Liu, Yan Li, Bo Lei, Wenjing Qiao, and Yuyan Zhang. 2025. "Research on Parametric Modeling and Model Transformation of Proton Hospital Based on BIM" Buildings 15, no. 10: 1658. https://doi.org/10.3390/buildings15101658

APA StyleLi, S., Yu, T., Liu, Y., Li, Y., Lei, B., Qiao, W., & Zhang, Y. (2025). Research on Parametric Modeling and Model Transformation of Proton Hospital Based on BIM. Buildings, 15(10), 1658. https://doi.org/10.3390/buildings15101658