Simulation Method for Complex Constraints and the Necessity of Joints in an Early-Age, Large-Volume Concrete Slab—A Case Study of Complex Column Grids and Wall Constraints

Abstract

1. Introduction

2. Methods for Simulating Values in Complex Constraint Situations

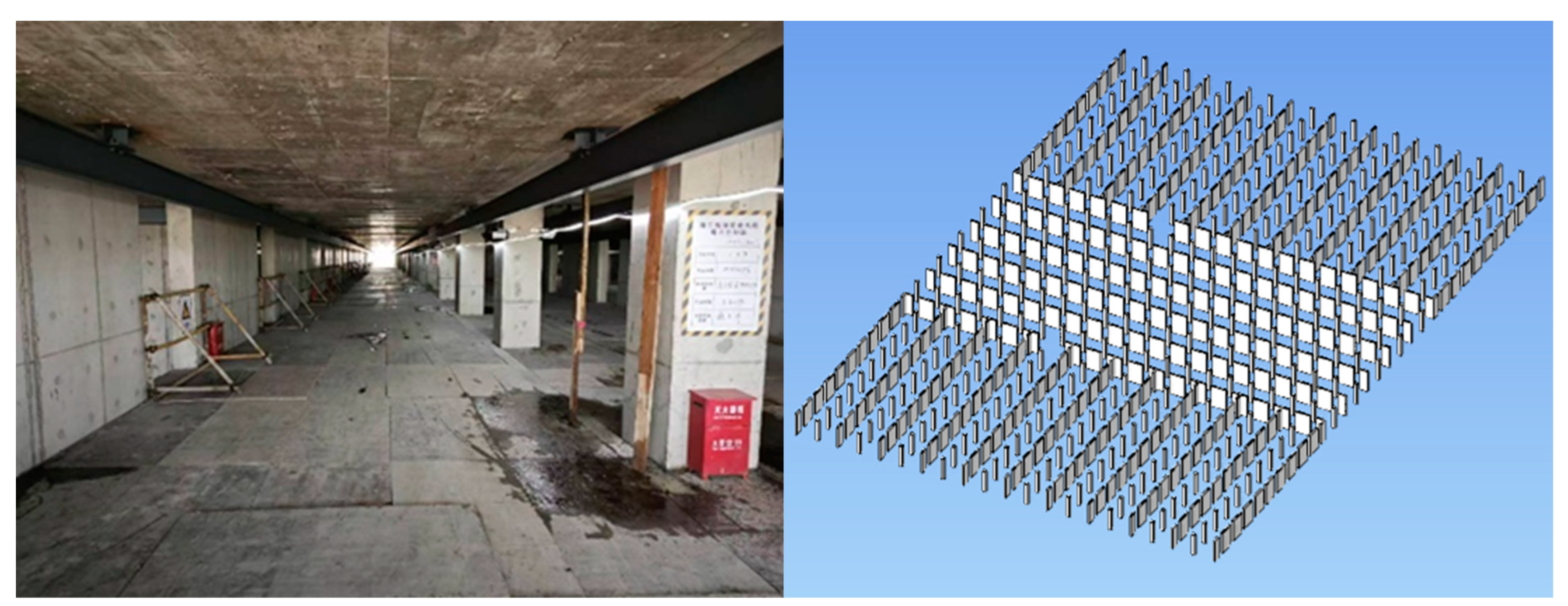

2.1. Complex Constraint Situations

2.2. Theoretical Basis for the Spring Foundation

2.3. Methods for Determining the Spring Constant

2.3.1. X-Direction, Y-Direction Spring Constant

2.3.2. Z-Direction Spring Constant

3. The Impact of Spring Constant Values on Simulation Results

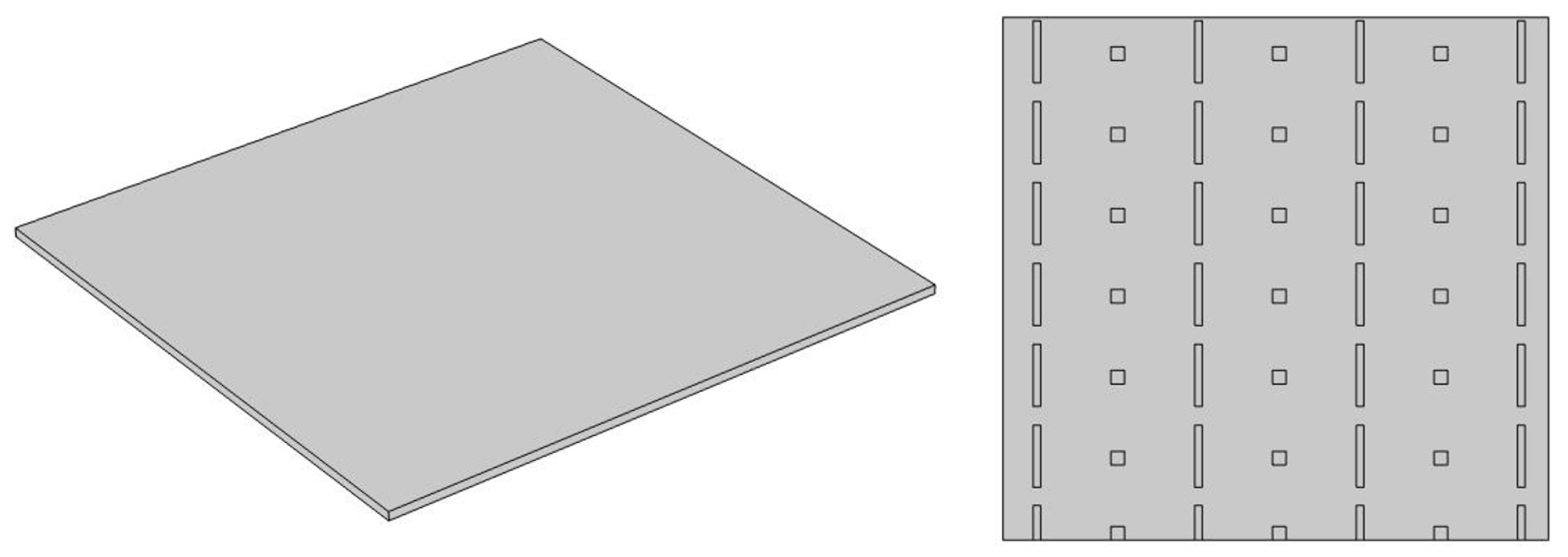

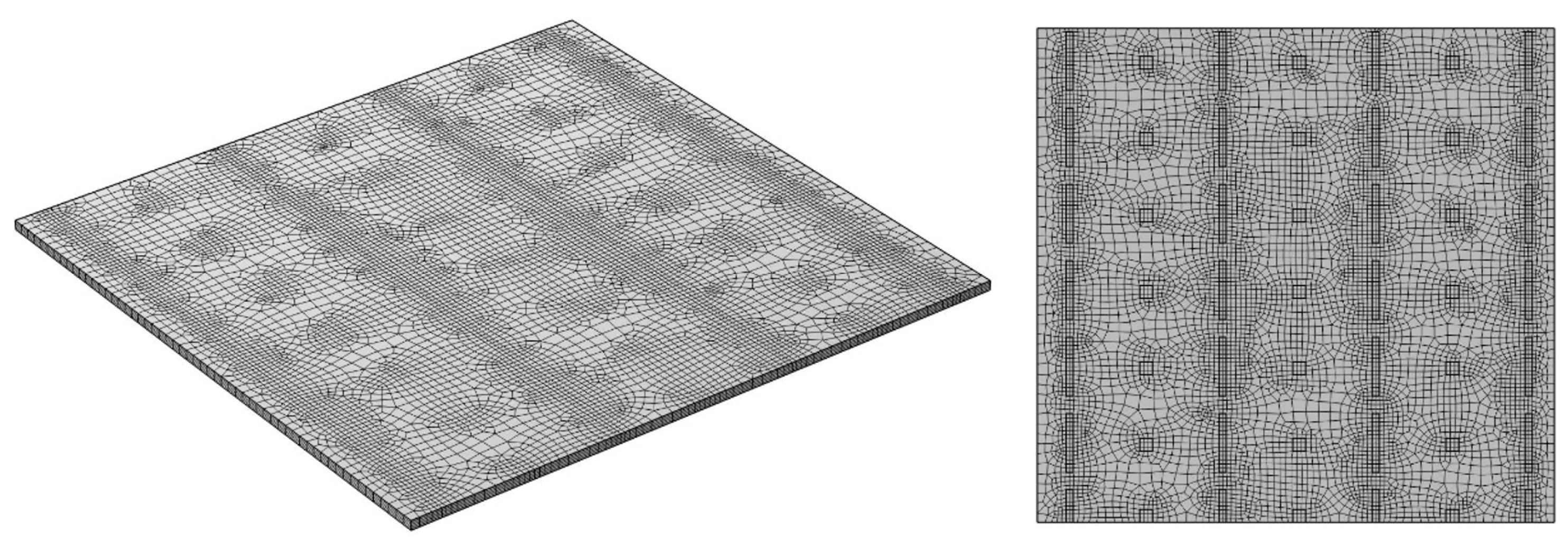

3.1. Geometric Model and Boundary Conditions

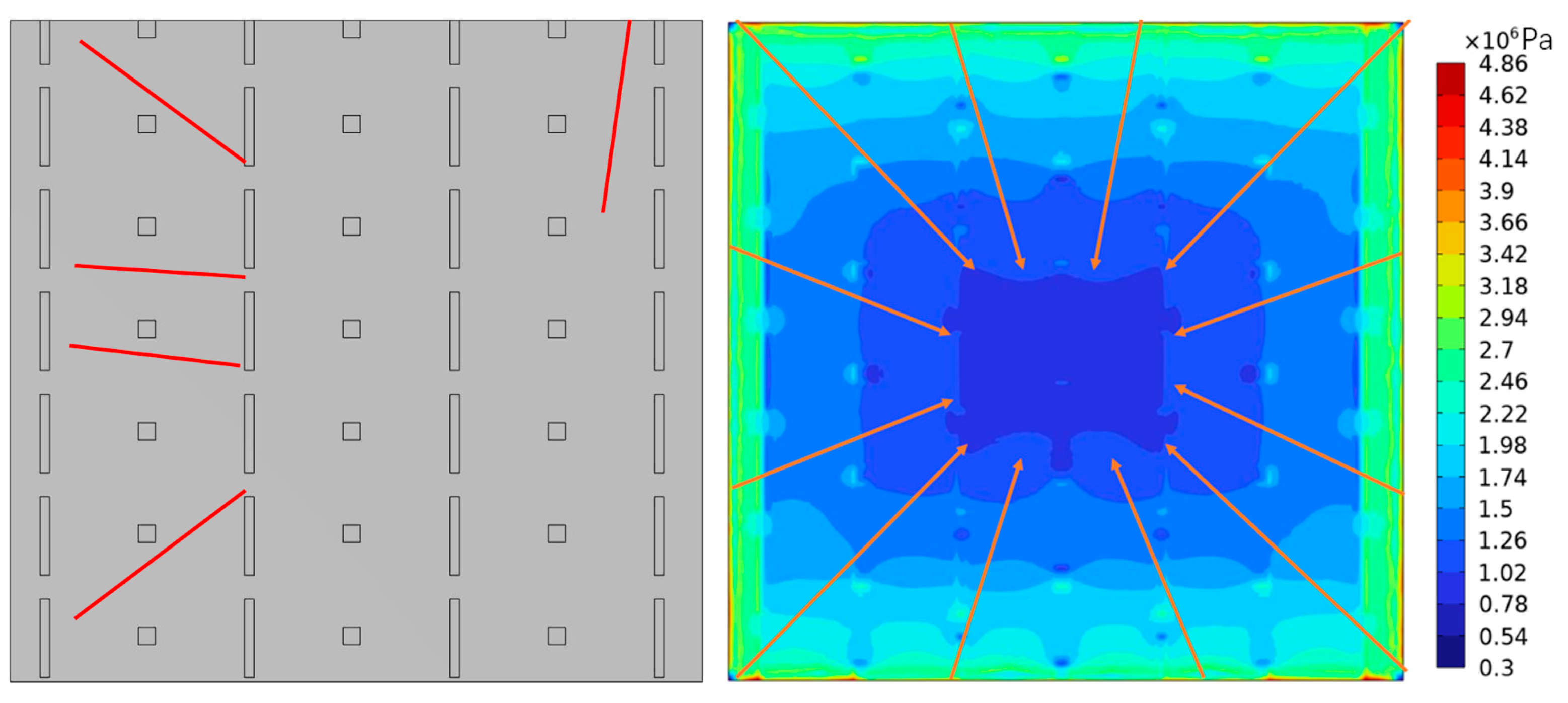

3.2. Stress Conditions During Floor Slab Contraction

3.3. Stress Conditions During Expansion of the Floor Slab

3.4. Summary of the Impact of Spring Constant Magnitude

4. Calculated Results in Actual Engineering and Comparison of Two Scenarios With and Without Floor Joints

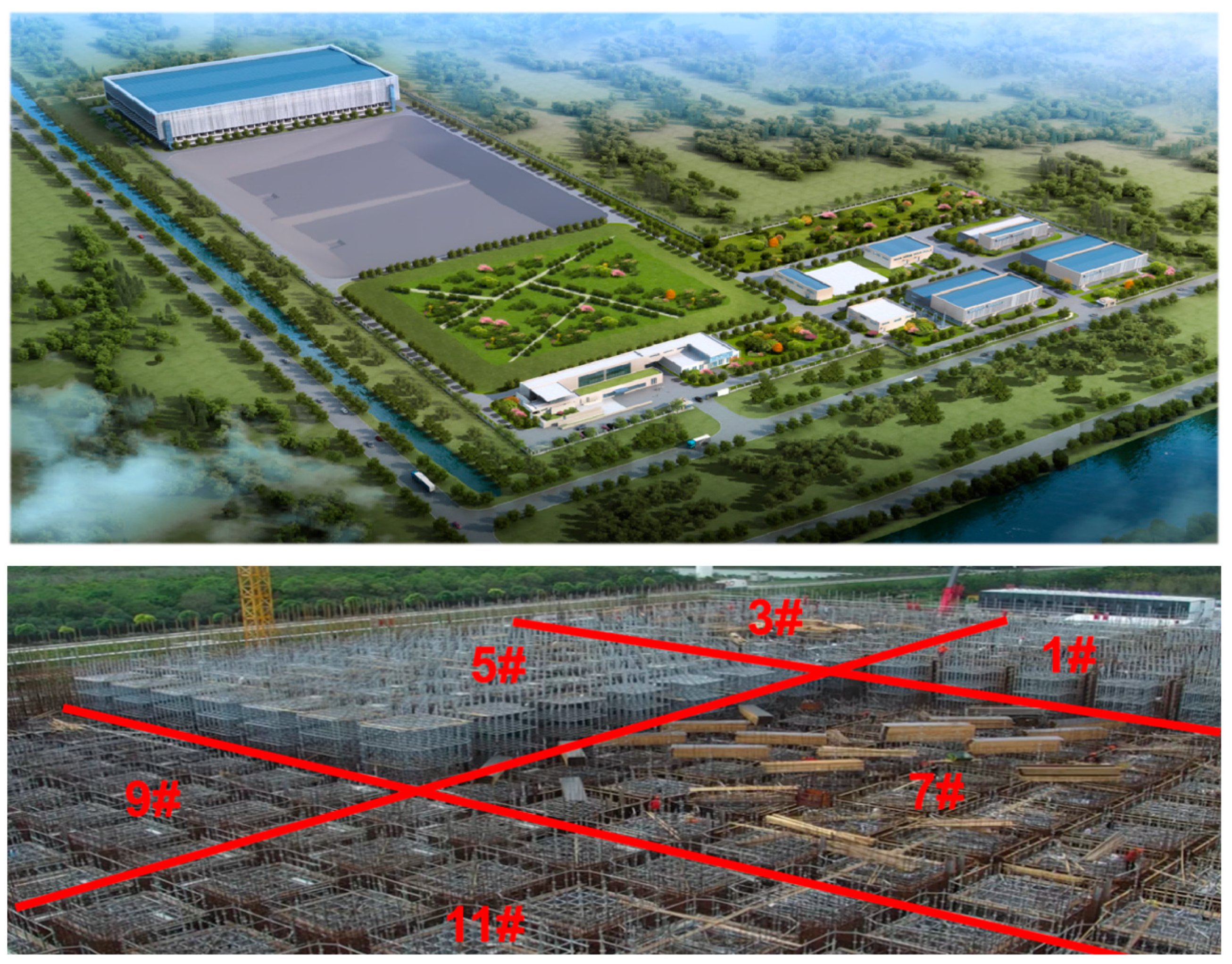

4.1. The Model of the Engineering Project

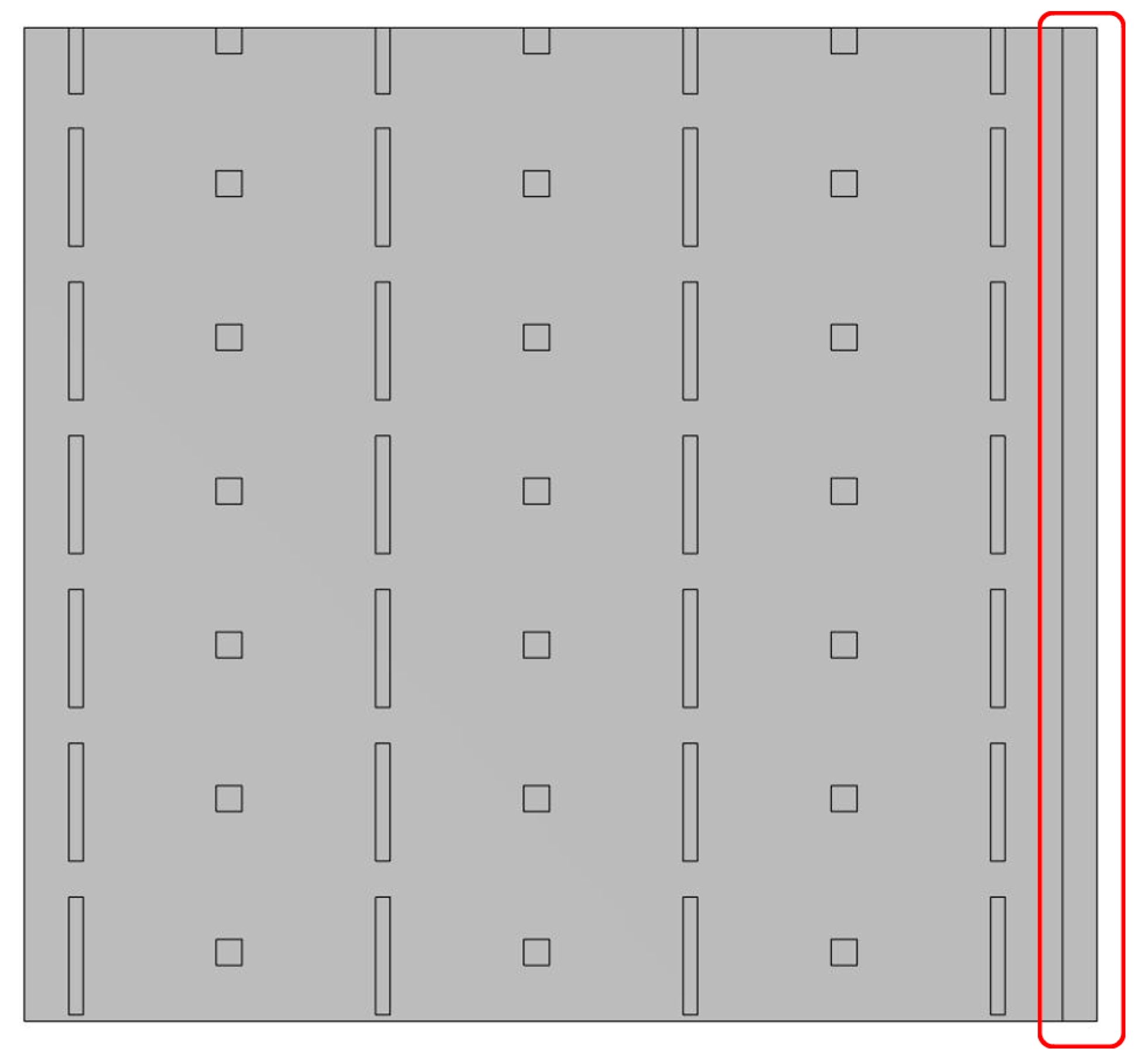

4.1.1. Geometric Model

4.1.2. Constitutive Model

4.1.3. Boundary Conditions

4.1.4. Material Parameters

4.1.5. Model Parameters

4.2. Early-Age Stress Conditions of the Floor Slab Divided by Post-Poured Strips

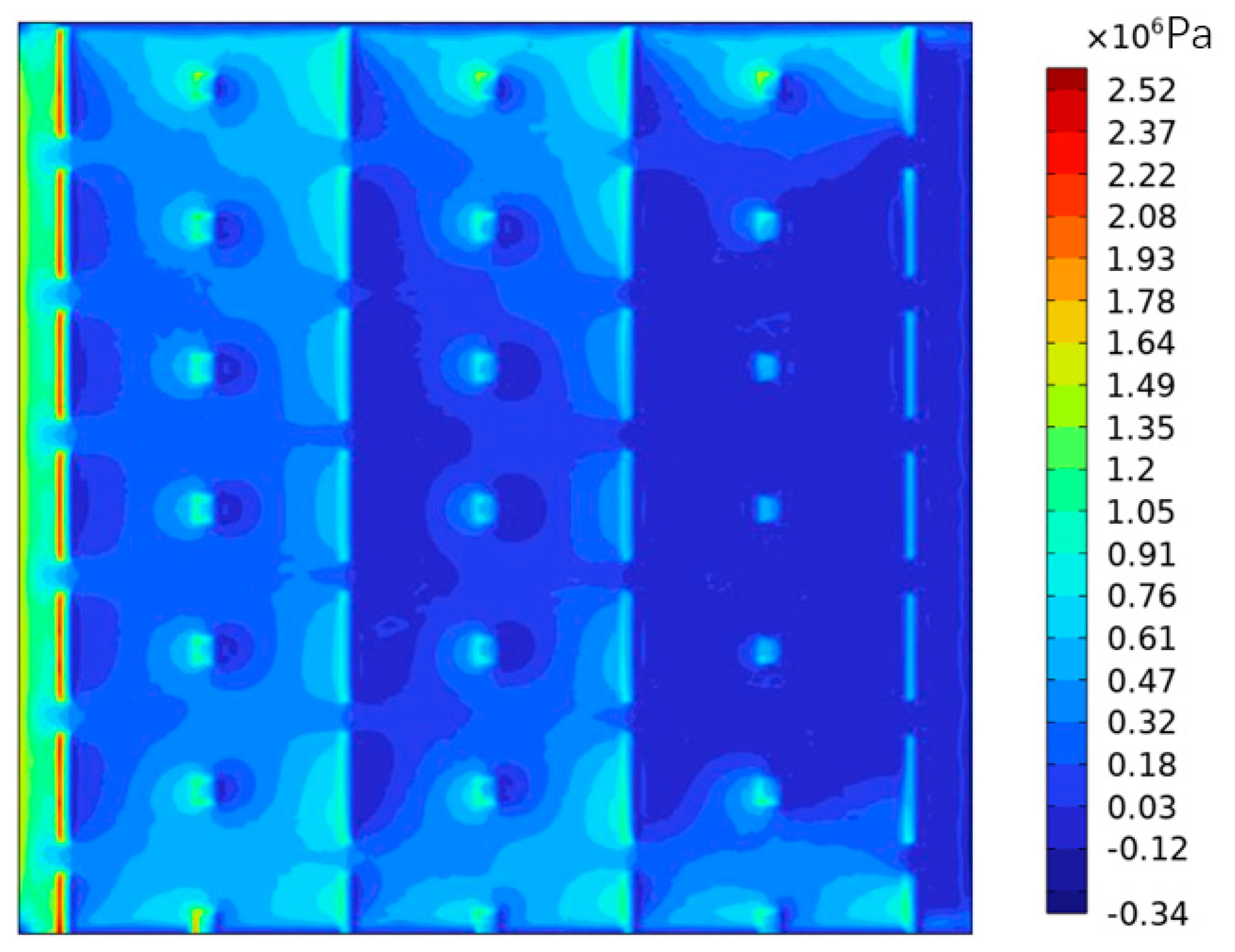

4.3. Early-Age Stress Conditions of the Floor Slab Divided by Reinforcement Strips

5. Conclusions and Discussion

5.1. Conclusions

- Feasibility of spring foundation simulation for complex constraints: This study validates the use of spring foundations to simulate the behavior of the bottom slab under complex constraint conditions. The spring foundation proves to be an effective means of simulating boundary constraints and stress situations, providing accurate numerical simulation for the behavior of the bottom slab under complex constraint conditions;

- Establishment of the spring foundation constraint values method: We have successfully developed a method for determining the spring constant that can be utilized for engineering estimation. This method offers a convenient and viable solution for simulating constraints, providing designers and practitioners with a straightforward approach for accurate constraint assessments in bottom slab design;

- Validation of the feasibility of reinforcement strips as an alternative to post-poured strips: Through the calculations presented in this paper, the use of reinforcement strips as an alternative to post-poured strips proves to be notably feasible in practical engineering scenarios, especially under the complex constraints of intricate column networks and walls. The calculation results conclusively demonstrate that compared to the post-poured strip method, the reinforcement strip approach can reduce the maximum stress value in complexly constrained base slabs by approximately 50%. This solution not only ensures the structural integrity and stability of the base slab, but also effectively shortens the construction period;

- Engineering guidance and widespread application: This conclusion offers reliable guidance for engineering practices and suggests a viable alternative for similar projects. This achievement holds promise for widespread application in practical engineering, enhancing project efficiency, reducing costs, and ensuring the stability and reliability of structures.

5.2. Discussion

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ouyang, J.; Chen, X.; Huangfu, Z.; Lu, C.; Huang, D.; Li, Y. Application of distributed temperature sensing for cracking control of mass concrete. Constr. Build. Mater. 2019, 197, 778–791. [Google Scholar] [CrossRef]

- Lee, C. Assessment of radiological safety of Wolsung site at site boundary considering crack impact. Prog. Nucl. Energ. 2010, 52, 374–378. [Google Scholar] [CrossRef]

- Trávníček, P.; Junga, P.; Kudělka, J.; Kotek, L. Prevention of an atmospheric storage tank bund failure. J. Loss Prevent. Proc. 2021, 70, 104438. [Google Scholar] [CrossRef]

- Jiang, W.; Liu, X.; Yuan, Y.; Wang, S.; Su, Q.; Taerwe, L. Towards early-age performance control in precast concrete immersed tunnels. Struct. Concr. 2015, 16, 558–571. [Google Scholar] [CrossRef]

- Singh, M.P.; Sen, S.; Pathak, H.; Dogra, A.B. Early age cracking relevant to mass concrete dam structures during the construction schedule. Constr. Build. Mater. 2024, 411, 134739. [Google Scholar] [CrossRef]

- Deng, G.; Li, W.; He, Y.; Zhang, K.; Wang, X.; Cui, J.; Li, M.; Zhang, M. Long term properties of Nano-engineered temperature self-controlled concrete served for mass concrete structure. Constr. Build. Mater. 2024, 452, 139034. [Google Scholar] [CrossRef]

- Sun, S.; Zhang, Y.; Lv, Y.; Xu, X.; Wang, Z.; Liu, Z. Research on Temperature Control of Mass Concrete for Multi-Tower Cable-Stayed Bridge Cap during Construction. Buildings 2024, 14, 3112. [Google Scholar] [CrossRef]

- Khan, I.; Yong, G. Role of supplementary cementiteous materials in mitigating heat of hydration in mass concrete elements. Constr. Build. Mater. 2024, 431, 136482. [Google Scholar] [CrossRef]

- Lyu, C.; Xu, M.; Lu, X.; Tian, B.; Chen, B.; Xiong, B.; Cheng, B. Research on thermal- humidity -force coupling characteristics of mass concrete structures under temperature control. Constr. Build. Mater. 2023, 398, 132540. [Google Scholar] [CrossRef]

- Yang, K.; Zhang, W.; Chen, R.; Duan, M.; Shangguan, H. Simulation Analysis of Temperature Field and Stress Field of Mass Concrete Under Different Construction Temperatures. Buildings 2025, 15, 370. [Google Scholar] [CrossRef]

- Zhang, G.; Li, G. Effects of mineral admixtures and additional gypsum on the expansion performance of sulphoaluminate expansive agent at simulation of mass concrete environment. Constr. Build. Mater. 2016, 113, 970–978. [Google Scholar] [CrossRef]

- Raoufi, K. Restrained Shrinkage Cracking of Concrete: The Influence of Damage Localization. Ph.D. Thesis, Purdue University, West Lafayette, IN, USA, 2011. [Google Scholar]

- Boggs, H.L.; Bonikowsky, D.A.; Bradshaw, R.A., Jr.; Cannon, R.W.; Chraibi, A.F.; Cope, J.L.; Diaz, L.H.; Dolen, T.P.; Hammons, M.I.; Hansen, K.D.; et al. Effect of restraint, volume change, and reinforcement on cracking of mass concrete. Aci Man. Concr. Pract. 2002, 87, 271–295. [Google Scholar]

- Yoo, D.; Min, K.; Lee, J.; Yoon, Y.-S. Shrinkage and cracking of restrained ultra-high-performance fiber-reinforced concrete slabs at early age. Constr. Build. Mater. 2014, 73, 357–365. [Google Scholar] [CrossRef]

- Kheder, G.F. A mathematical model for the prediction of volume change cracking in end-restrained concrete members. Mater. Struct. 1997, 30, 174–181. [Google Scholar] [CrossRef]

- Kianoush, M.R.; Acarcan, M.; Ziari, A. Behavior of base restrained reinforced concrete walls under volumetric change. Eng. Struct. 2008, 30, 1526–1534. [Google Scholar] [CrossRef]

- Saeed, M.K.; Rahman, M.; Alfawzan, M.; Basha, S.; Dahish, H.A. Recycling of date kernel powder (DKP) in mass concrete for mitigating heat generation and risk of cracking at an early age. Constr. Build. Mater. 2023, 376, 131033. [Google Scholar] [CrossRef]

- Orozco, C.; Babel, S.; Tangtermsirikul, S.; Sugiyama, T. Comparison of environmental impacts of fly ash and slag as cement replacement materials for mass concrete and the impact of transportation. Sustain. Mater. Technol. 2023, 39, e00796. [Google Scholar] [CrossRef]

- Zhu, J.; Wang, Z. Experimental modeling and quantitative evaluation of mitigating cracks in early-age mass concrete by regulating heat transfer. J. Build. Eng. 2024, 96, 110641. [Google Scholar] [CrossRef]

- GBJ10-89; Code for Design of Concrete Structures. Inspection and Quarantine of the People’s Republic of China: Beijing, China, 1989.

- Wu, J.; Pu, L.; Zhai, C. A Review of Static and Dynamic p-y Curve Models for Pile Foundations. Buildings 2024, 14, 1507. [Google Scholar] [CrossRef]

- Zhao, W.; Yang, Q.; Liu, J.; Wu, W. Influence analysis of the selection of foundation model on fatigue stress evaluation results of cement concrete pavement-based on GPR and FWD. Constr. Build. Mater. 2022, 347, 128586. [Google Scholar] [CrossRef]

- EN 1992-1-1; Eurocode 2: Design of Concrete Structures-Part 1–1: General Rules and Rules for Buildings. British Standard Institution: London, UK, 2005; Volume 668, pp. 659–668.

| Column Side Length/Height | 3 m | 3.5 m | 4 m | 4.5 m | 5 m | 5.5 m | 6 m |

|---|---|---|---|---|---|---|---|

| 500 mm × 500 mm | 6.13 × 107 | 3.95 × 107 | 2.7 × 107 | 1.95 × 107 | 1.46 × 107 | 1.12 × 107 | 8.9 × 106 |

| 700 mm × 700 mm | 1.15 × 108 | 7.39 × 107 | 5.04 × 107 | 3.59 × 107 | 2.66 × 107 | 2.04 × 107 | 1.59 × 107 |

| 900 mm × 900 mm | 1.81 × 108 | 1.16 × 108 | 7.92 × 107 | 5.75 × 107 | 4.24 × 107 | 3.23 × 107 | 2.45 × 107 |

| 1100 mm × 1100 mm | 2.66 × 108 | 1.72 × 108 | 1.17 × 108 | 8.38 × 107 | 6.18 × 107 | 4.74 × 107 | 3.66 × 107 |

| 1300 mm × 1300 mm | 3.59 × 108 | 2.34 × 108 | 1.60 × 108 | 1.14 × 108 | 8.47 × 107 | 6.44 × 107 | 5.01 × 107 |

| 1500 mm × 1500 mm | 4.53 × 108 | 2.97 × 108 | 2.08 × 108 | 1.47 × 108 | 1.09 × 108 | 8.41 × 107 | 6.45 × 107 |

| Z-Axis Spring Constant | XY-Axis Spring Constant | Center of the Top Surface | Center of the Bottom Surface | Maximum Stress Value |

|---|---|---|---|---|

| 109 N/m3 | 2.70 × 106 N/m3 | 5.2 kPa | 6.3 kPa | 25 kPa |

| 2.70 × 107 N/m3 | 52 kPa | 63 kPa | 258 kPa | |

| 2.70 × 108 N/m3 | 511 kPa | 617 kPa | 2.52 MPa | |

| 2.70 × 109 N/m3 | 4.15 MPa | 5.09 MPa | 20.4 MPa | |

| 2.70 × 1010 N/m3 | 14.4 MPa | 19.1 MPa | 71.1 MPa | |

| Fixed Constraint | 21.4 MPa | 28.3 MPa | 142 MPa | |

| 108 N/m3 | 2.70 × 106 N/m3 | 0.29 Pa | 12.9 kPa | 28 kPa |

| 2.70 × 107 N/m3 | 2.98 Pa | 128 kPa | 283 kPa | |

| 2.70 × 108 N/m3 | 28 Pa | 1.24 MPa | 2.736 MPa | |

| 2.70 × 109 N/m3 | 209 Pa | 9.11 MPa | 19.9 MPa | |

| 2.70 × 1010 N/m3 | 534 Pa | 24.7 MPa | 53.7 MPa | |

| Fixed Constraint | 583 Pa | 30.2 MPa | 90.4 MPa | |

| 107 N/m3 | 2.70 × 106 N/m3 | 0.47 Pa | 21 kPa | 30.5 kPa |

| 2.70 × 107 N/m3 | 4.75 Pa | 210 kPa | 304 kPa | |

| 2.70 × 108 N/m3 | 44 Pa | 1.99 MPa | 2.88 MPa | |

| 2.70 × 109 N/m3 | 58 Pa | 11.7 MPa | 14.4 MPa | |

| 2.70 × 1010 N/m3 | 107 Pa | 28.2 MPa | 42.1 MPa | |

| Fixed Constraint | 159 Pa | 31 MPa | 73 MPa |

| Z-Axis Spring Constant | XY-Axis Spring Constant | Center of the Top Surface | Center of the Bottom Surface | Maximum Stress Value |

|---|---|---|---|---|

| 109 N/m3 | 2.70 × 106 N/m3 | −0.16 Pa | −0.96 Pa | 12.4 kPa |

| 2.70 × 107 N/m3 | −1.61 Pa | −9.59 Pa | 124 kPa | |

| 2.70 × 108 N/m3 | −15.9 Pa | −93 Pa | 1.21 MPa | |

| 2.70 × 109 N/m3 | −141 Pa | −776 Pa | 9.7 MPa | |

| 2.70 × 1010 N/m3 | −718 Pa | −2827 Pa | 32.5 MPa | |

| Fixed Constraint | −1426 Pa | −2924 Pa | 123 MPa | |

| 108 N/m3 | 2.70 × 106 N/m3 | 1.3 kPa | −0.87 Pa | 13.1 kPa |

| 2.70 × 107 N/m3 | 13.4 kPa | −8.79 Pa | 130 kPa | |

| 2.70 × 108 N/m3 | 129 kPa | −84 Pa | 1.25 MPa | |

| 2.70 × 109 N/m3 | 949 kPa | −606 Pa | 9.23 MPa | |

| 2.70 × 1010 N/m3 | 2.46 MPa | −1475 Pa | 26.4 MPa | |

| Fixed Constraint | 2.64 MPa | −1059 Pa | 100 MPa | |

| 107 N/m3 | 2.70 × 106 N/m3 | 9.5 kPa | −0.8 Pa | 13 kPa |

| 2.70 × 107 N/m3 | 95 kPa | −7.99 Pa | 13.3 kPa | |

| 2.70 × 108 N/m3 | 903 kPa | −75 Pa | 1.26 MPa | |

| 2.70 × 109 N/m3 | 5.9 MPa | −451 Pa | 8.5 MPa | |

| 2.70 × 1010 N/m3 | 12.7 MPa | −582 Pa | 22.4 MPa | |

| Fixed Constraint | 13.8 MPa | −168 Pa | 96.7 MPa |

| Material Parameters | Values |

|---|---|

| Density | 2400 kg/m3 |

| Constant of Thermal Expansion | 10−6/K |

| Young’s Modulus | 25 GPa |

| Poisson’s Ratio | 0.20 |

| Thermal Conductivity | 1.8 W/(m·K) |

| Specific Heat Capacity | 880 J/(kg·K) |

| Adiabatic Temperature Rise | 50 °C |

| Parameters | Values |

| Concrete Hydration Heat Release Rate | |

| Surface Heat Exchange Constant |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, W.; Jiang, W.; Fu, C.; Li, Z.; Zhang, H. Simulation Method for Complex Constraints and the Necessity of Joints in an Early-Age, Large-Volume Concrete Slab—A Case Study of Complex Column Grids and Wall Constraints. Buildings 2025, 15, 1647. https://doi.org/10.3390/buildings15101647

Li W, Jiang W, Fu C, Li Z, Zhang H. Simulation Method for Complex Constraints and the Necessity of Joints in an Early-Age, Large-Volume Concrete Slab—A Case Study of Complex Column Grids and Wall Constraints. Buildings. 2025; 15(10):1647. https://doi.org/10.3390/buildings15101647

Chicago/Turabian StyleLi, Wenqian, Wei Jiang, Chen Fu, Zhiyi Li, and Hao Zhang. 2025. "Simulation Method for Complex Constraints and the Necessity of Joints in an Early-Age, Large-Volume Concrete Slab—A Case Study of Complex Column Grids and Wall Constraints" Buildings 15, no. 10: 1647. https://doi.org/10.3390/buildings15101647

APA StyleLi, W., Jiang, W., Fu, C., Li, Z., & Zhang, H. (2025). Simulation Method for Complex Constraints and the Necessity of Joints in an Early-Age, Large-Volume Concrete Slab—A Case Study of Complex Column Grids and Wall Constraints. Buildings, 15(10), 1647. https://doi.org/10.3390/buildings15101647