A Case Study of Pavement Construction Materials for Wet-Freeze Regions: The Application of Waste Glass Aggregate and High-Content Rubber Modified Asphalt

Abstract

1. Introduction

2. Materials and Methods

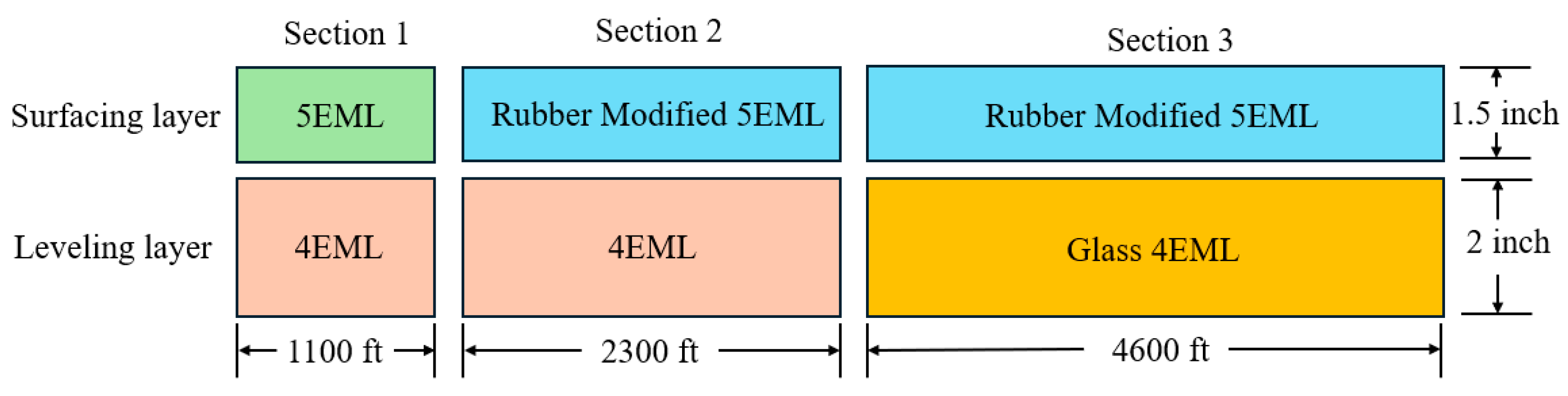

2.1. Mixture Designs and Materials

2.2. Plant Production

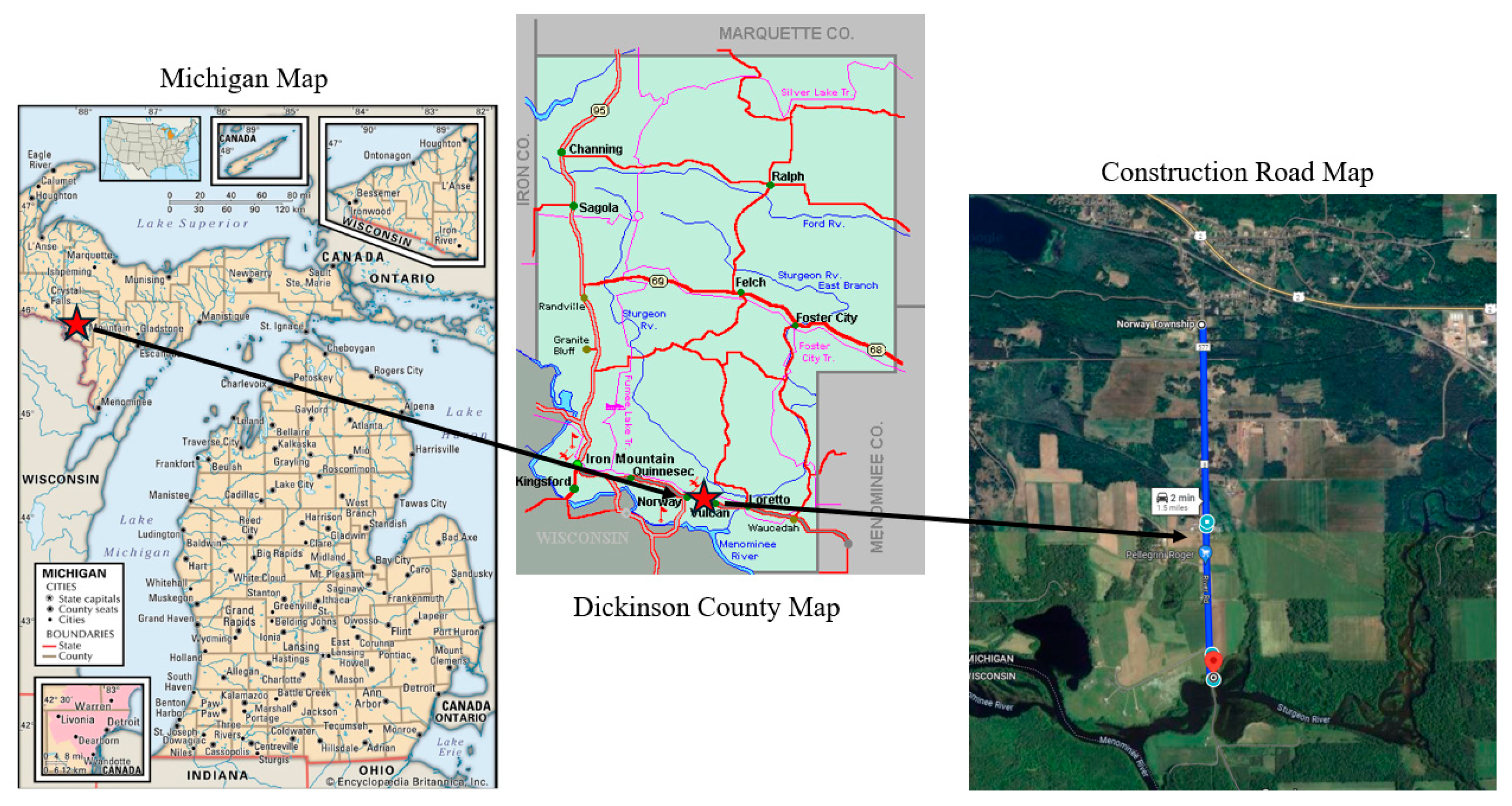

2.3. Construction and Field Implementation

2.4. Laboratory Testing

2.5. Noise Measurement

3. Results and Discussion

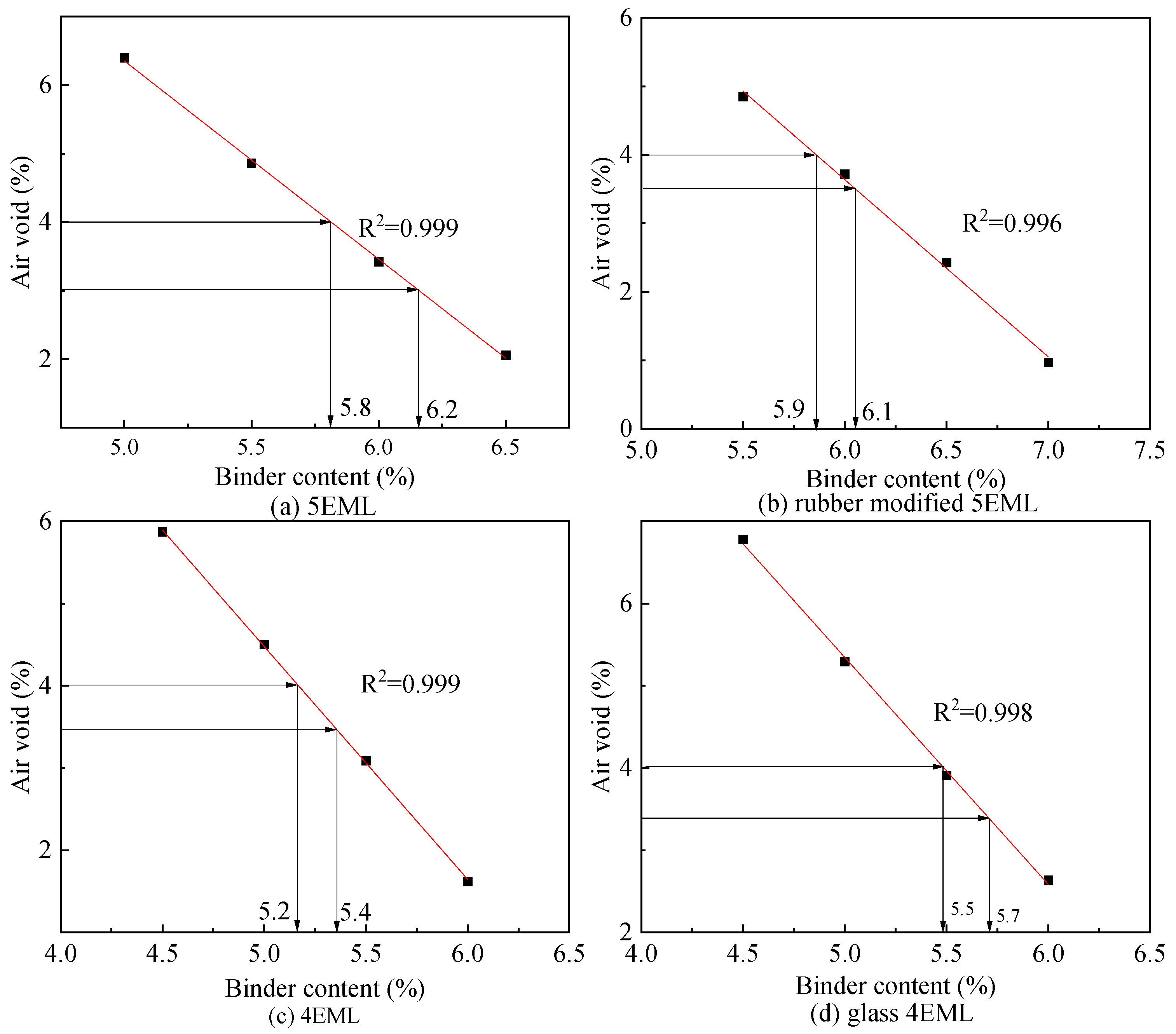

3.1. Mix Design Results

3.2. Field-Mixed and Laboratory-Compacted Sample Performance

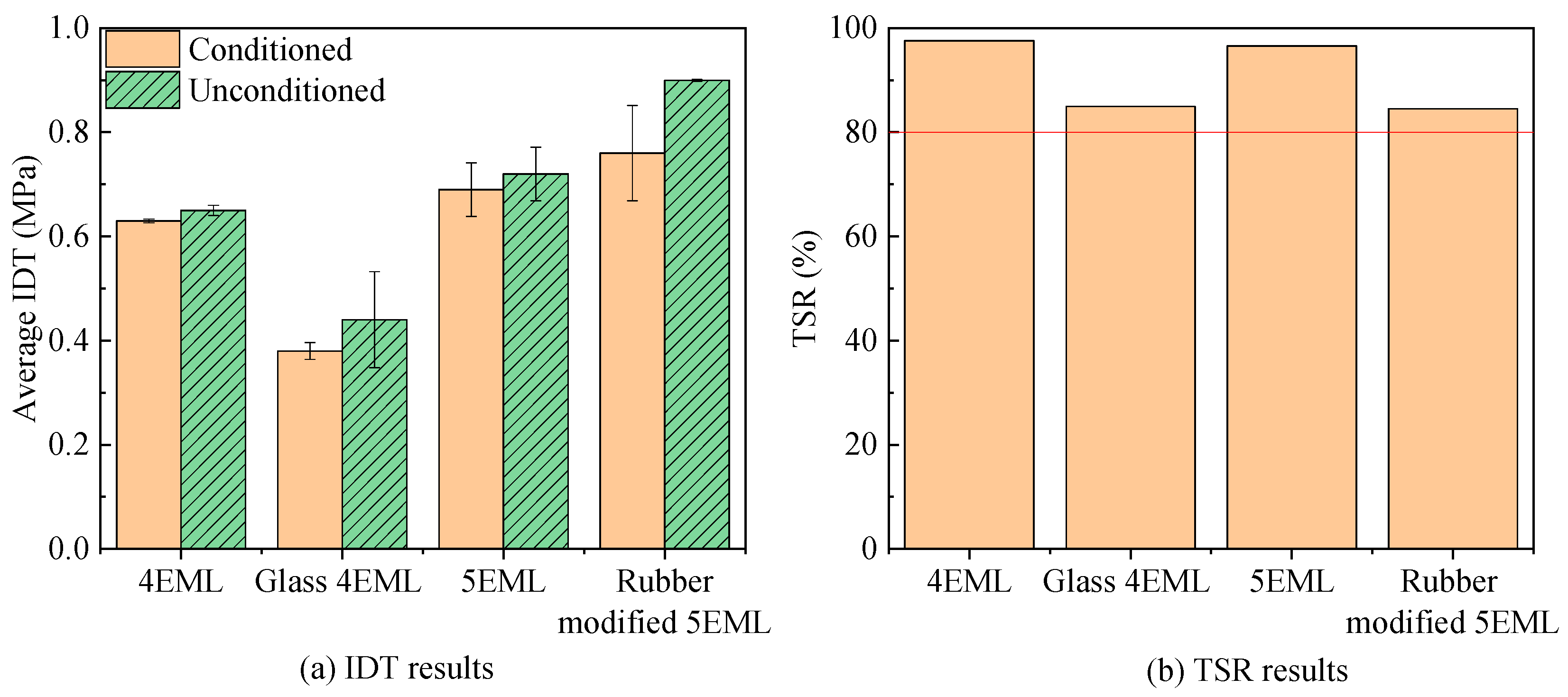

3.2.1. IDT and TSR

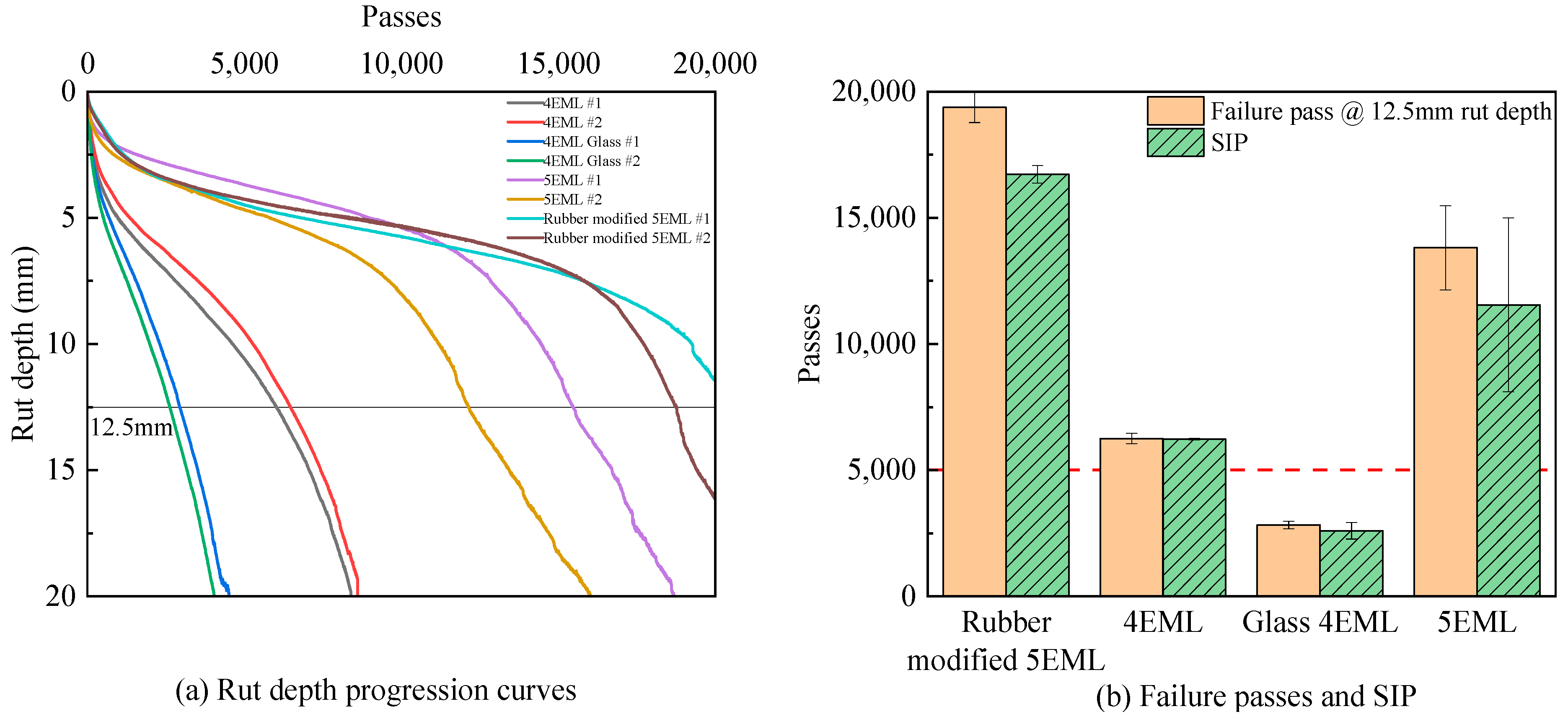

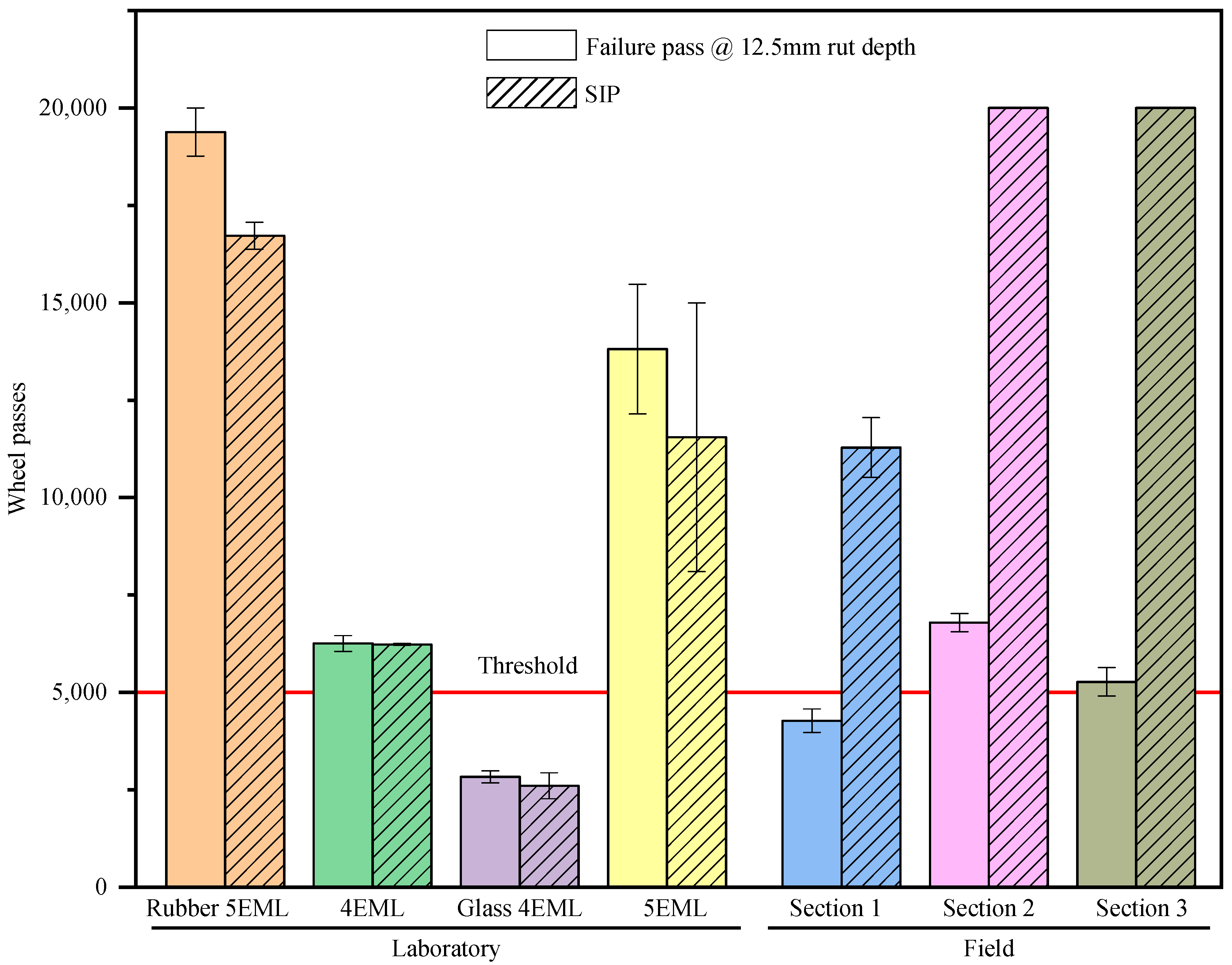

3.2.2. HWTT

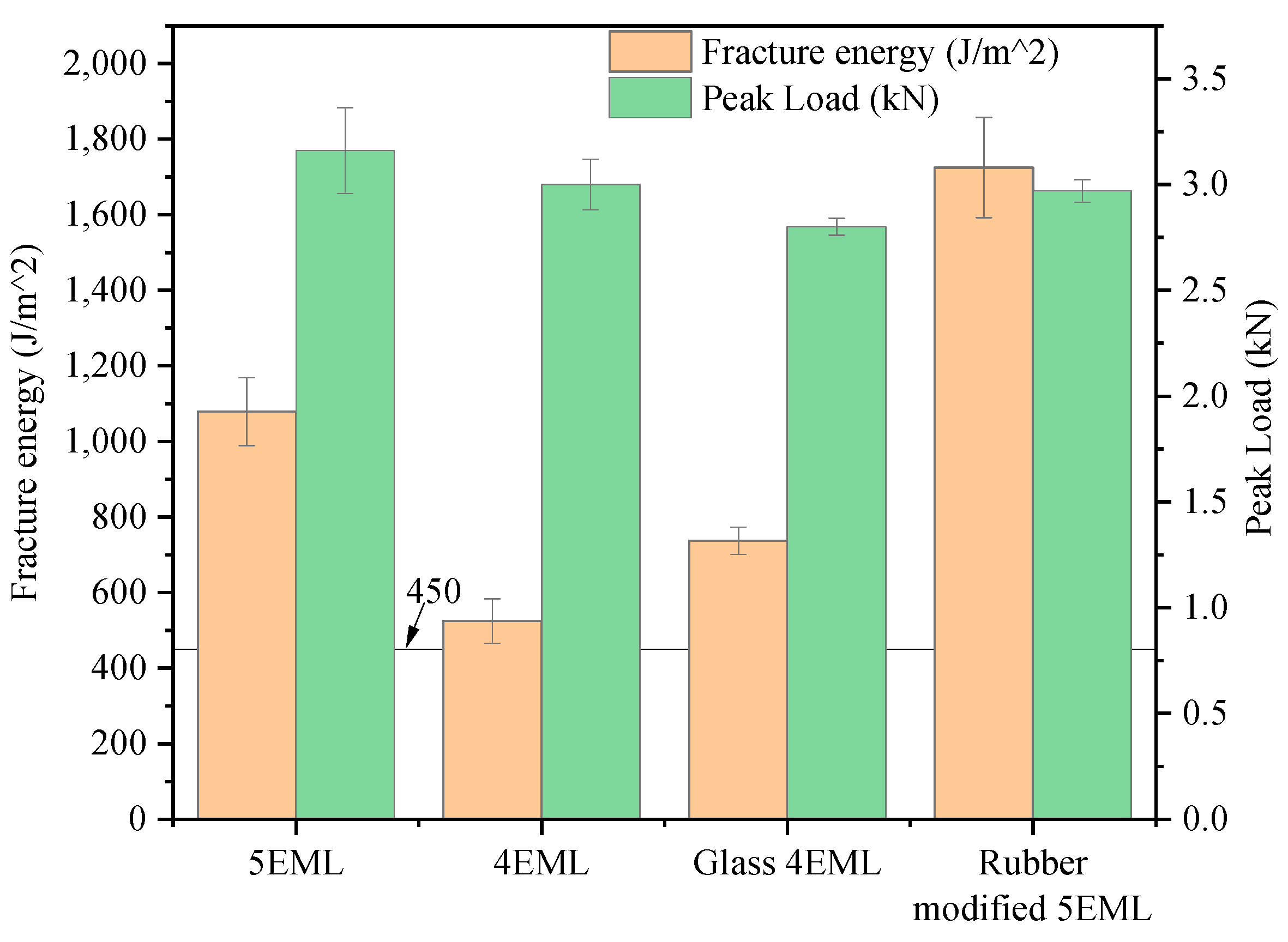

3.2.3. DCT

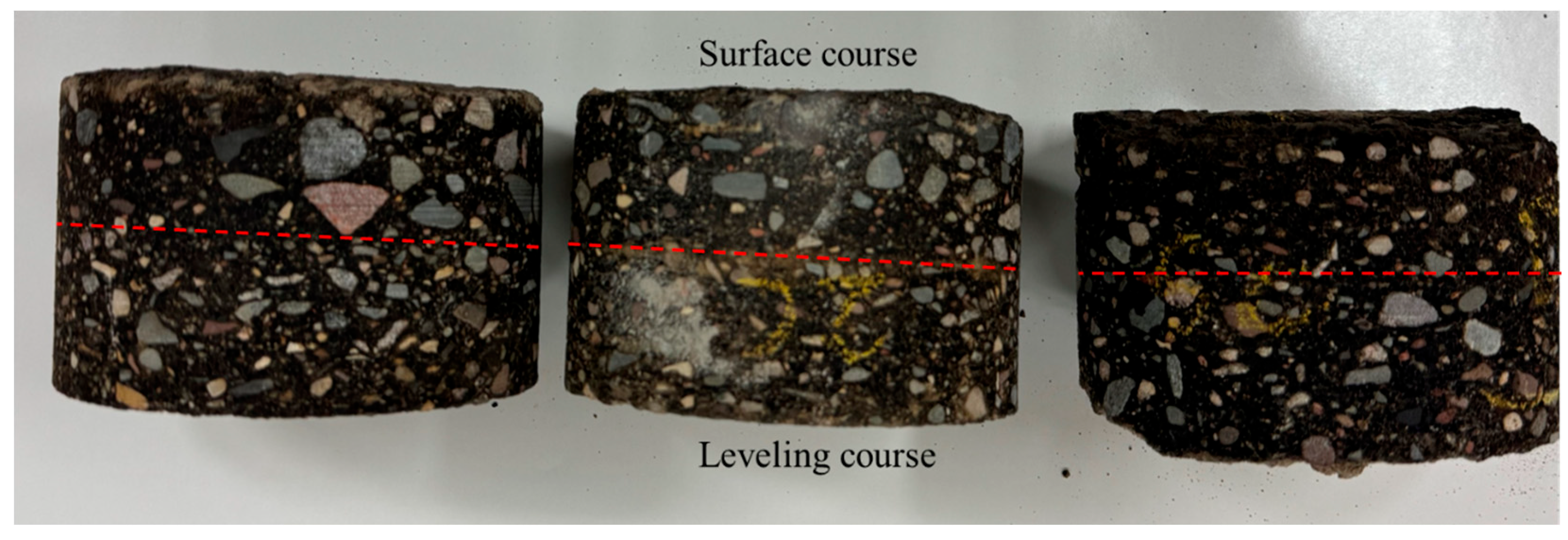

3.3. Field Cores Performance

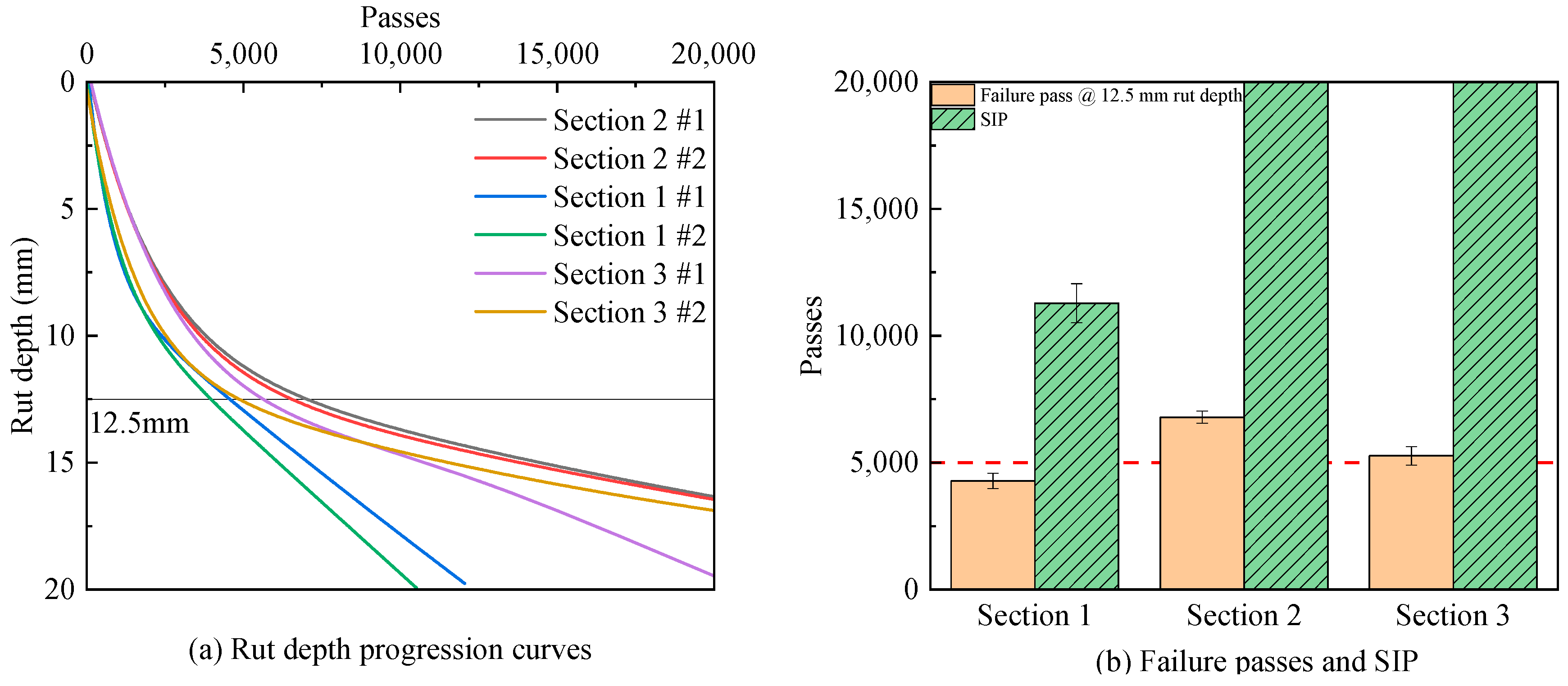

3.3.1. Field Cores HWTT

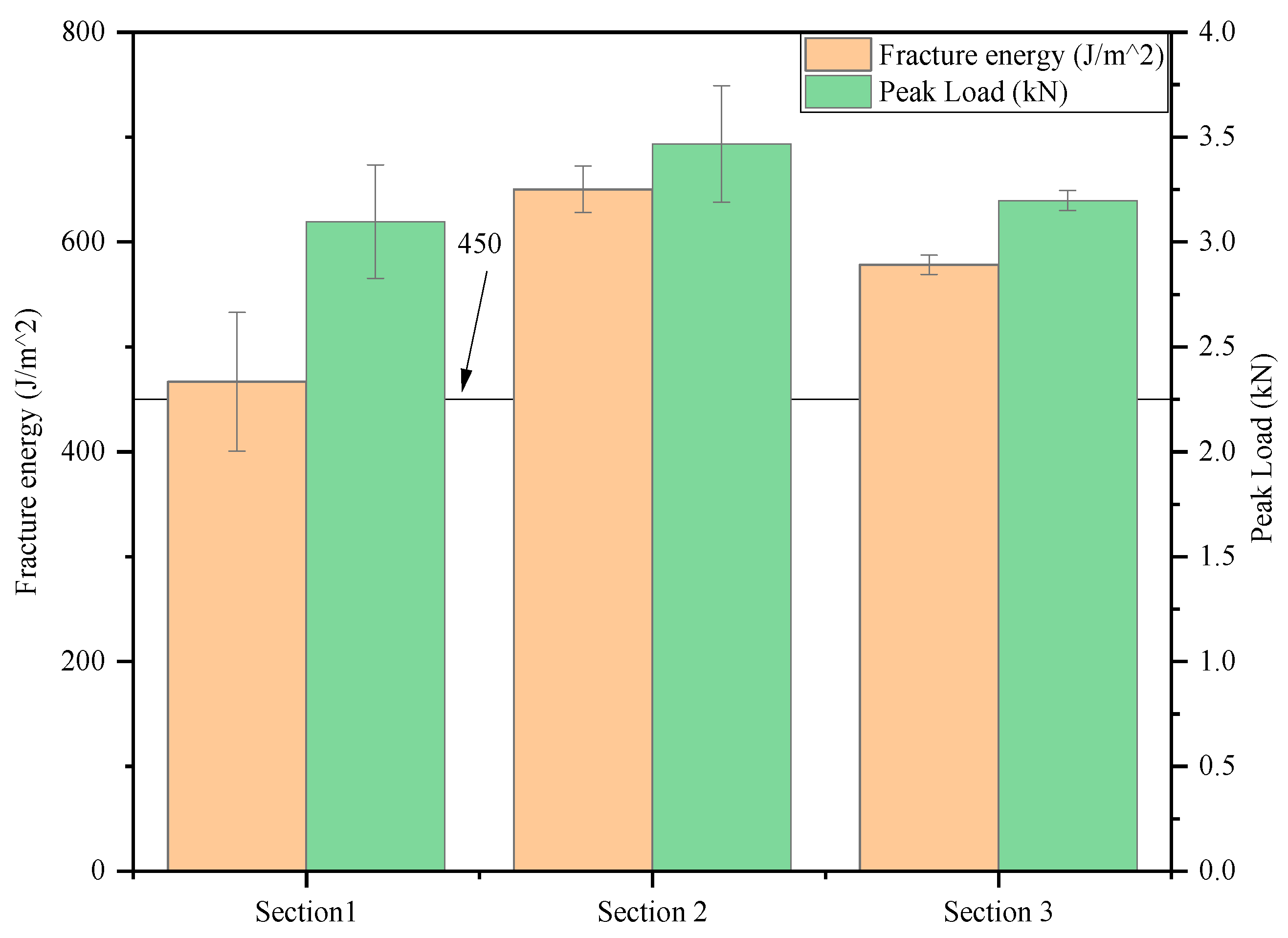

3.3.2. Field Cores DCT

3.4. Comparison of Field-Mixed and Laboratory-Compacted Samples with Field Core Samples

3.4.1. Field and Laboratory HWTT Comparison

3.4.2. Field and Laboratory DCT Comparison

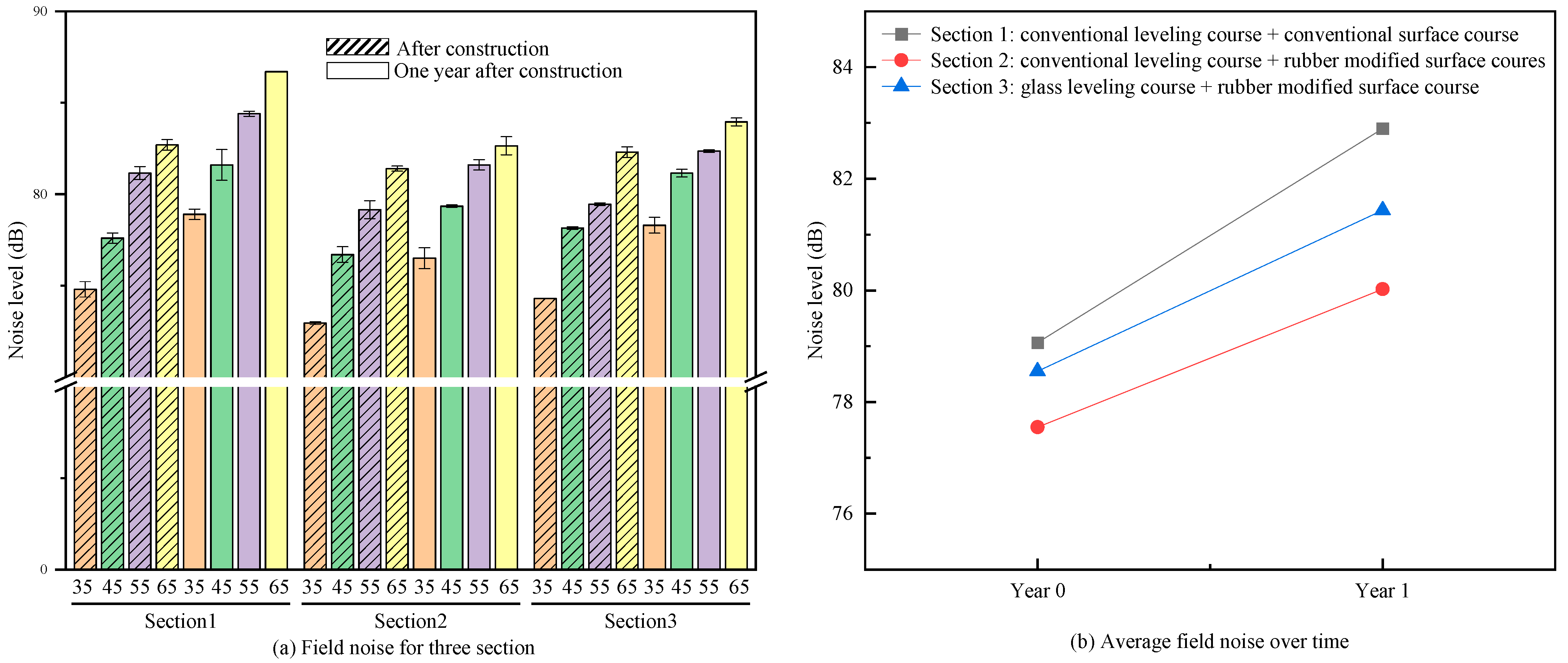

3.5. Field Noise Measurement

3.6. Brief Discussion of Life Cycle Assessment and Cost-Benefits

4. Conclusions

- (1)

- Laboratory tests revealed that targeting lower air voids (3.0–3.5%) and increasing binder content improved low-temperature cracking resistance.

- (2)

- The rubber-modified 5EML mixture exhibited a significant increase in fracture energy compared to conventional 5EML, while the glass 4EML mixture also showed notable improvement over conventional 4EML. Although the glass mixture had a lower IDT, all mixtures exceeded the 80% TSR threshold, confirming adequate moisture resistance.

- (3)

- Field performance demonstrates that sections with rubber-modified surface courses achieved superior rutting resistance, exceeding MnDOT’s minimum threshold.

- (4)

- Field core DCT tests showed that composite systems improved fracture energy compared to the control, despite the complexity of two-layer systems.

- (5)

- Field noise measurements confirmed that rubber-modified sections maintained lower noise levels over time, highlighting the acoustic benefits of crumb rubber.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| DCT | Disk-shaped compact tension |

| HWTT | Hamburg wheel-tracking test |

| IDT | Indirect tensile strength |

| TSR | Tensile strength ratio |

| MDOT | Michigan Department of Transportation |

| ESALs | Equivalent single-axle loads |

| VMA | Voids in mineral aggregate |

| VFA | Voids filled with asphalt |

| HMA | Hot-mix asphalt |

| SIP | Stripping inflection point |

| LCA | Life cycle assessment |

| LCCA | Life cycle cost analysis |

References

- Huang, Y.; Bird, R.N.; Heidrich, O. A review of the use of recycled solid waste materials in asphalt pavements. Resour. Conserv. Recycl. 2007, 52, 58–73. [Google Scholar] [CrossRef]

- You, L.; Jin, D.; Guo, S.; Wang, J.; Dai, Q.; You, Z. Leaching evaluation and performance assessments of asphalt mixtures with recycled cathode ray tube glass: A preliminary study. J. Clean. Prod. 2021, 279, 123716. [Google Scholar] [CrossRef]

- West, R.C.; Page, G.C.; Murphy, K.H. Evaluation of crushed glass in asphalt paving mixtures. ASTM Spec. Tech. Publ. 1993, 1193, 117. [Google Scholar]

- Maupin, G. Glasphalt Test Sections in Virginia; Virginia Transportation Research Council (VTRC): Charlottesville, VA, USA, 1997. [Google Scholar]

- Arabani, M. Effect of glass cullet on the improvement of the dynamic behaviour of asphalt concrete. Constr. Build. Mater. 2011, 25, 1181–1185. [Google Scholar] [CrossRef]

- Maupin, G. Effect of Glass Concentration on Stripping of Glasphalt (No. VTRC-98-R30); Virginia Transportation Research Council: Charlottesville, DC, USA, 1998. [Google Scholar]

- Su, N.; Chen, J. Engineering properties of asphalt concrete made with recycled glass. Resour. Conserv. Recycl. 2002, 35, 259–274. [Google Scholar] [CrossRef]

- Nicholls, J.; Lay, J. Crashed glass in macadam for binder course and roadbase layers. In Performance of Bituminous and Hydraulic Materials in Pavements; Routledge: London, UK, 2017; pp. 197–211. [Google Scholar]

- Arabani, M.; Mirabdolazimi, S.; Ferdowsi, B. Modeling the fatigue behaviors of glasphalt mixtures. Sci. Iran. 2012, 19, 341–345. [Google Scholar] [CrossRef]

- Androjić, I.; Dimter, S. Properties of hot mix asphalt with substituted waste glass. Mater. Struct. 2016, 49, 249–259. [Google Scholar] [CrossRef]

- Xu, O.; Xiao, F.; Han, S.; Amirkhanian, S.N.; Wang, Z. High temperature rheological properties of crumb rubber modified asphalt binders with various modifiers. Constr. Build. Mater. 2016, 112, 49–58. [Google Scholar] [CrossRef]

- Xu, G.; Kong, P.; Yu, Y.; Yang, J.; Zhu, M.; Chen, X. Rheological properties of rubber modified asphalt as function of waste tire rubber reclaiming degree. J. Clean. Prod. 2022, 332, 130113. [Google Scholar] [CrossRef]

- Gui, W.; Liang, L.; Wang, L.; Gao, X.; Zhang, F. Performance evaluation of warm-mixed crumb rubber modified asphalt based on rheological characteristics. Constr. Build. Mater. 2021, 285, 122881. [Google Scholar] [CrossRef]

- Ameri, M.; Afshin, A.; Shiraz, M.E.; Yazdipanah, F. Effect of wax-based warm mix additives on fatigue and rutting performance of crumb rubber modified asphalt. Constr. Build. Mater. 2020, 262, 120882. [Google Scholar] [CrossRef]

- Kocak, S.; Kutay, M.E. Effect of devulcanized rubber modification on the performance grade, fatigue cracking resistance, and rutting resistance of asphalt binders. J. Mater. Civ. Eng. 2021, 33, 04021248. [Google Scholar] [CrossRef]

- Luan, Y.; Ma, Y.; Ma, T.; Wang, C.; Xia, F. Research on the effects of asphalt performance on rutting resistance and its correlation with rutting performance indicators. Constr. Build. Mater. 2023, 400, 132773. [Google Scholar] [CrossRef]

- Chen, Z.; Wang, T.; Pei, J.; Amirkhanian, S.; Xiao, F.; Ye, Q.; Fan, Z. Low temperature and fatigue characteristics of treated crumb rubber modified asphalt after a long term aging procedure. J. Clean. Prod. 2019, 234, 1262–1274. [Google Scholar] [CrossRef]

- Rath, P.; Gettu, N.; Chen, S.; Buttlar, W.G. Investigation of cracking mechanisms in rubber-modified asphalt through fracture testing of mastic specimens. Road Mater. Pavement Des. 2022, 23, 1544–1563. [Google Scholar] [CrossRef]

- Chen, X.; Solaimanian, M. Evaluating fracture properties of crumb rubber modified asphalt mixes. Int. J. Pavement Res. Technol. 2019, 12, 407–415. [Google Scholar] [CrossRef]

- Zhang, H.; Xu, G.; Chen, X.; Wang, R.; Shen, K. Effect of long-term laboratory aging on rheological properties and cracking resistance of polymer-modified asphalt binders at intermediate and low temperature range. Constr. Build. Mater. 2019, 226, 767–777. [Google Scholar] [CrossRef]

- Yin, D.; Wang, L.; Wang, Z.; Yin, L.; Liu, S.; Li, L. Enhancing shear resistance in pavement structures with crumb rubber modified asphalt gravel as a bonding layer. Constr. Build. Mater. 2024, 426, 136184. [Google Scholar] [CrossRef]

- Arabani, M.; Tahami, S.A.; Hamedi, G.H. Performance evaluation of dry process crumb rubber-modified asphalt mixtures with nanomaterial. Road Mater. Pavement Des. 2018, 19, 1241–1258. [Google Scholar] [CrossRef]

- Ma, J.; Sun, G.; Sun, D.; Zhang, Y.; Falchetto, A.C.; Lu, T.; Hu, M.; Yuan, Y. Rubber asphalt modified with waste cooking oil residue: Optimized preparation, rheological property, storage stability and aging characteristic. Constr. Build. Mater. 2020, 258, 120372. [Google Scholar] [CrossRef]

- Michigan Department of Transportation, Standard Specifications for Construction. 2020. Available online: https://www.michigan.gov/mdot/-/media/Project/Websites/MDOT/Business/Construction/Standard-Specifications-Construction/2020-Standard-Specifications-Construction.pdf (accessed on 7 May 2025).

- ASTM D7313-20; Standard Test Method for Determining Fracture Energy of Asphalt Mixtures Using the Disk-Shaped Compact Tension Geometry. American Society for Testing and Materials: West Conshohocken, PA, USA, 2020.

- AASHTO T 324-23; Standard Method of Test for Hamburg Wheel-Track Testing of Compacted Asphalt Mixtures. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2023.

- AASHTO T 283; Standard Method of Test for Resistance of Compacted Asphalt Mixtures to Moisture-Induced Damage. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2019.

- Zhang, W.; Shen, S.; Wu, S.; Chen, X.; Xue, J.; Mohammad, L.N. Effects of in-place volumetric properties on field rutting and cracking performance of asphalt pavement. J. Mater. Civ. Eng. 2019, 31, 04019150. [Google Scholar] [CrossRef]

- Harvey, J.T.; Deacon, J.A.; Tsai, B.W.; Monismith, C.L. Fatigue Performance of Asphalt Concrete Mixes and Its Relationship to Asphalt Concrete Pavement Performance in California. 1995. Available online: https://escholarship.org/uc/item/80c7d0rc (accessed on 7 May 2025).

- Chen, S.; Ge, D.; Jin, D.; Zhou, X.; Liu, C.; Lv, S.; You, Z. Investigation of hot mixture asphalt with high ground tire rubber content. J. Clean. Prod. 2020, 277, 124037. [Google Scholar] [CrossRef]

- Jin, D.; Ge, D.; Zhou, X.; You, Z. Asphalt mixture with scrap tire rubber and nylon fiber from waste tires: Laboratory performance and preliminary ME design analysis. Buildings 2022, 12, 160. [Google Scholar] [CrossRef]

- Navarro, F.M.; Gámez, M.C.R. Influence of crumb rubber on the indirect tensile strength and stiffness modulus of hot bituminous mixes. J. Mater. Civ. Eng. 2012, 24, 715–724. [Google Scholar] [CrossRef]

- Peng, Y.; Yu, Z.; Long, Y.; Li, Y. Experimental investigation on the effects of a new anti-stripping additive on performance properties of asphalt and its mixtures. Constr. Build. Mater. 2022, 353, 129173. [Google Scholar] [CrossRef]

- Kim, Y.-R.; Pinto, I.; Park, S.-W. Experimental evaluation of anti-stripping additives in bituminous mixtures through multiple scale laboratory test results. Constr. Build. Mater. 2012, 29, 386–393. [Google Scholar] [CrossRef]

- Hesami, E.; Mehdizadeh, G. Study of the amine-based liquid anti-stripping agents by simulating hot mix asphalt plant production process. Constr. Build. Mater. 2017, 157, 1011–1017. [Google Scholar] [CrossRef]

- Zhu, C.; Tang, J.; Zhang, H.; Duan, H. Effect of liquid anti-stripping agents on moisture sensitivity of crumb rubber modified asphalt binders and mixtures. Constr. Build. Mater. 2019, 225, 112–119. [Google Scholar] [CrossRef]

- Sanij, H.K.; Meybodi, P.A.; Hormozaky, M.A.; Hosseini, S.H.; Olazar, M. Evaluation of performance and moisture sensitivity of glass-containing warm mix asphalt modified with zycothermTM as an anti-stripping additive. Constr. Build. Mater. 2019, 197, 185–194. [Google Scholar] [CrossRef]

- Hughes, C.S. Feasibility of Using Recycled Glass in Asphalt; Virginia Transportation Research Council (VTRC): Charlottesville, VA, USA, 1990. [Google Scholar]

- Kalampokis, S.; Kalama, D.; Kesikidou, F.; Stefanidou, M.; Manthos, E. Assessment of waste glass incorporation in asphalt concrete for surface layer construction. Materials 2023, 16, 4938. [Google Scholar] [CrossRef]

- Newcomb, D.; Zhou, F. Balanced Design of Asphalt Mixtures; Minnesota Department of Transportation Research Services & Library: Saint Paul, MN, USA, 2018. [Google Scholar]

- Xiao, F.; Amirkhanian, S.; Juang, C.H. Rutting resistance of rubberized asphalt concrete pavements containing reclaimed asphalt pavement mixtures. J. Mater. Civ. Eng. 2007, 19, 475–483. [Google Scholar] [CrossRef]

- Zhao, Z.; Xu, L.; Guan, X.; Li, X.; Xiao, F. Rutting and strain characteristics of rubberized asphalt pavement based on accelerated pavement tester. J. Clean. Prod. 2022, 376, 134219. [Google Scholar] [CrossRef]

- Fontes, L.P.; Trichês, G.; Pais, J.C.; Pereira, P.A. Evaluating permanent deformation in asphalt rubber mixtures. Constr. Build. Mater. 2010, 24, 1193–1200. [Google Scholar] [CrossRef]

- Hajikarimi, P.; Rahi, M.; Nejad, F.M. Comparing different rutting specification parameters using high temperature characteristics of rubber-modified asphalt binders. Road Mater. Pavement Des. 2015, 16, 751–766. [Google Scholar] [CrossRef]

- Cheng, M.; Chen, M.; Wu, S.; Yang, T.; Zhang, J.; Zhao, Y. Effect of waste glass aggregate on performance of asphalt micro-surfacing. Constr. Build. Mater. 2021, 307, 125133. [Google Scholar] [CrossRef]

- Airey, G.D.; Collop, A.C.; Thom, N.H. Mechanical performance of asphalt mixtures incorporating slag and glass secondary aggregates. In Proceedings of the 8th Conference on Asphalt Pavements for Southern Africa (CAPSA’04), Sun City, South Africa, 12–16 September 2004. [Google Scholar]

- Shafabakhsh, G.; Sajed, Y. Investigation of dynamic behavior of hot mix asphalt containing waste materials; case study: Glass cullet. Case Stud. Constr. Mater. 2014, 1, 96–103. [Google Scholar] [CrossRef]

- Ding, X.; Huang, F.; Rath, P.; Ye, Z.; Buttlar, W.G.; Ma, T. Comparative fracture resistance assessment of rubber-modified asphalt mortar based on meso-and macro-mechanical analysis. Int. J. Pavement Eng. 2023, 24, 2265032. [Google Scholar] [CrossRef]

- Jin, D.; Xin, K.; Yin, L.; Mohammadi, S.; Cetin, B.; You, Z. Performance of rubber modified asphalt mixture with tire-derived aggregate subgrade. Constr. Build. Mater. 2024, 449, 138261. [Google Scholar] [CrossRef]

- Wang, H.; You, Z.; Mills-Beale, J.; Hao, P. Laboratory evaluation on high temperature viscosity and low temperature stiffness of asphalt binder with high percent scrap tire rubber. Constr. Build. Mater. 2012, 26, 583–590. [Google Scholar] [CrossRef]

- Min, Z.; Zhou, L.; Wang, Q.; Zhang, Y. Performance evaluation of epoxy-asphalt mixture blended with glass aggregate. J. Mater. Civ. Eng. 2019, 31, 04019083. [Google Scholar] [CrossRef]

- Zhou, B.; Zhang, J.; Pei, J.; Li, R.; Zhang, Z. Design and evaluation of high–luminance porous asphalt mixtures based on wasted glass for sponge city. Constr. Build. Mater. 2021, 273, 121696. [Google Scholar] [CrossRef]

- Lachance-Tremblay, É.; Vaillancourt, M.; Perraton, D. Evaluation of the impact of recycled glass on asphalt mixture performances. Road Mater. Pavement Des. 2016, 17, 600–618. [Google Scholar] [CrossRef]

- Feng, C.; Zhang, H.; Jia, W.; Lai, F. The effects of hollow glass microsphere modification on the road performances and thermal performance of asphalt binder and mixture. Constr. Build. Mater. 2019, 220, 64–75. [Google Scholar] [CrossRef]

- Kadhim, M.A.; Al-Busaltan, S.; Nemaa, Z.K.; Abo Almaali, Y.; Saghafi, B.; Al-Kafaji, M.; Al-Jawad, O.; Al-Yasari, R. Evaluating the cracking performance indices of half-warm mix asphalt comprising waste glass. Int. J. Pavement Res. Technol. 2022, 15, 1262–1276. [Google Scholar] [CrossRef]

- Barraj, F.; Mahfouz, S.; Kassem, H.; Khatib, J.; Goulias, D.; Elkordi, A. Investigation of using crushed glass waste as filler replacement in hot asphalt mixtures. Sustainability 2023, 15, 2241. [Google Scholar] [CrossRef]

- Mandal, T.; Hanz, A.J.; Bahia, H.U. Challenges in using the Disc-Shaped Compact Tension (DCT) test to determine role of asphalt mix design variables in cracking resistance at low temperatures. Int. J. Pavement Eng. 2019, 20, 1275–1284. [Google Scholar] [CrossRef]

- Xu, L.; Ni, H.; Zhang, Y.; Sun, D.; Zheng, Y.; Hu, M. Porous asphalt mixture use asphalt rubber binders: Preparation and noise reduction evaluation. J. Clean. Prod. 2022, 376, 134119. [Google Scholar] [CrossRef]

- Xu, L.; Zhang, Y.; Zhang, Z.; Ni, H.; Hu, M.; Sun, D. Optimization design of rubberized porous asphalt mixture based on noise reduction and pavement performance. Constr. Build. Mater. 2023, 389, 131551. [Google Scholar] [CrossRef]

- Knabben, R.M.; Trichês, G.; Gerges, S.N.; Vergara, E.F. Evaluation of sound absorption capacity of asphalt mixtures. Appl. Acoust. 2016, 114, 266–274. [Google Scholar] [CrossRef]

- Sandberg, U. Low noise road surfaces-a state-of-the-art review. J. Acoust. Soc. Jpn. (E) 1999, 20, 1–17. [Google Scholar] [CrossRef]

- Xin, K.; Jin, D.; Handler, R.M.; You, Z. Life Cycle Assessment of Rubber Modified Asphalt Pavement in Michigan: A Case Study. In International Symposium on Pavement, Roadway, and Bridge Life Cycle Assessment; Springer: Berlin/Heidelberg, Germany, 2024. [Google Scholar]

| Design Criteria | Surface Course | Leveling Course | ||

|---|---|---|---|---|

| 5EML | Rubber Modified 5EML | 4EML | Glass 4EML | |

| Air void | 3% | 3.5% | 3.5% | 3.5% |

| Optimum binder content | 6.2% | 6.1% | 5.4% | 5.7% |

| VMA min % at Ndesign (based on Gsb) | 15.9 | 16.0 | 14.5 | 15.2 |

| VFA at Ndesign (%) | 81.1 | 78.1 | 75.9 | 77.0 |

| Dust proportion (PNo200/Pbe) | 0.88 | 0.92 | 1.01 | 0.79 |

| Additives | N/A * | 0.08% anti-stripping agent | N/A | N/A |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xin, K.; Wu, M.; Jin, D.; You, Z. A Case Study of Pavement Construction Materials for Wet-Freeze Regions: The Application of Waste Glass Aggregate and High-Content Rubber Modified Asphalt. Buildings 2025, 15, 1637. https://doi.org/10.3390/buildings15101637

Xin K, Wu M, Jin D, You Z. A Case Study of Pavement Construction Materials for Wet-Freeze Regions: The Application of Waste Glass Aggregate and High-Content Rubber Modified Asphalt. Buildings. 2025; 15(10):1637. https://doi.org/10.3390/buildings15101637

Chicago/Turabian StyleXin, Kai, Meng Wu, Dongzhao Jin, and Zhanping You. 2025. "A Case Study of Pavement Construction Materials for Wet-Freeze Regions: The Application of Waste Glass Aggregate and High-Content Rubber Modified Asphalt" Buildings 15, no. 10: 1637. https://doi.org/10.3390/buildings15101637

APA StyleXin, K., Wu, M., Jin, D., & You, Z. (2025). A Case Study of Pavement Construction Materials for Wet-Freeze Regions: The Application of Waste Glass Aggregate and High-Content Rubber Modified Asphalt. Buildings, 15(10), 1637. https://doi.org/10.3390/buildings15101637