Abstract

Alongside technological advancement, there is a growing need for materials that are easier to obtain and process and that offer multiple uses, thereby reducing environmental impact. Such materials are generally subject to mechanical, resistance and fatigue studies, often without considering their thermal properties, which could potentially expand the range of applications for the studied compound. The current study aims to analyze possible fluctuations and deviations from linearity in temperature flow curves, as well as their impact on the conductivity coefficient. These studies are conducted on a new type of panel made of fiberglass, a low-cost material with significant recycling potential, using foam elements recycled from packaging insulations and a cement biding mixture. This study considers the time variation of the different thermal coefficients and the temperature curves obtained from the experimental measurements. These data are analyzed and used to simulate heat variation in order to observe the heat flux fluctuations within the plate. The results suggest that the proposed composite plate can serve as an alternative to classical insulating panels.

1. Introduction

In recent years, the main focus of the building industry has been the development and use of new materials that can improve building comfort levels and lower energy costs. Technological advancement is driven by the technical and visual requirements of manufacturers. Therefore, there is a growing need to build composite structures with reinforced fibers that have a high resistance module. The building sector has significantly changed since 1953, as composite materials became a viable alternative to conventional ones. These new materials offered desirable properties such as light weight, high resistance, and good thermal properties. Despite the initial challenges of high costs and longer production times associated with these materials, they have proven to exhibit better long-term performance due to their lower transfer rate. Fiber reinforced composites are characterized by their lightweight nature, resistance, and durability, characteristics that play a crucial role in the building sector by satisfying many requirements related to energy waste reduction [1,2,3,4,5,6].

These properties contribute to the reduction in energy consumption, enhance sustainability, and have a lower impact on the environment. These facts may lead to the development of reinforced composites that utilize both natural and synthetic fibers, paving the way for a more sustainable future. Compared to metallic components, composite structures exhibit superior properties such as resistance and stiffness, in addition to their reduced mass, making them suitable for various industrial applications beyond just the building industry. For example, composites might be used not only for exterior element design but also for interior ones. The used polymers for interiors in the building industry offer excellent processing properties, mechanical resistance, and heat transfer properties [7,8,9,10,11].

An important aspect that needs to be studied is the thermal conductivity of composite materials, as heat insulation properties can vary depending on the designed panel structure. Therefore, we need to consider this property, in addition to the mechanical ones. Composites have a different structure compared to conventional material, leading to several elements that one needs to take into account when planning to use them. Consequently, the measurement of thermal conductivity for these materials is a crucial step. The preferred technology when it comes to composites involves using fiber-based materials. Fiberglass is usually manufactured and delivered in different forms, such as bulk, blankets, blocks, encapsulated fibers, panels, or pre-pregs. Fiber insulation has several advantages over other forms of composites, including reduced costs, flexibility, low mass, and thermal resistance, providing superior properties at low prices [12,13,14,15,16].

In the building industry, continuous research is of high importance because technology advances rapidly, especially concerning components that need to have a reduced mass to lead to lower structural weight and fuel consumption when heating. Nowadays, the aim is to create multi-functional components to increase production efficiency and decrease waste and energy consumption [17,18]. To maintain our way of life with existing facilities that ease our lives, we need to reduce the pollution generated by the building sector. Therefore, there is a need to improve performance not only in pollution-free extraction technologies but also in the components used on site by utilizing composites with recycled elements [19].

Several studies have been conducted on the performances of composites in the building industry. The need for lightweight structures and recycled materials has opened new paths of research.

Several researchers have studied the problem of thermal flow in construction panels and different building structures, aiming to reduce waste heat with their innovative materials. Iranian et al. [20] conducted a study regarding the influence of radiation and thermal conductivity on a semi-infinite perpendicular plate, taking into account the friction of a fluid. They showed that thermal conductivity influences the heat transfer parameters and the overall temperature distribution on the plate, describing the evolution of temperature over time and also considering the flow effect.

Wu D. et al. [21] considered developing a model that allowed simulating the process of temperature distribution in composite materials used for manufacturing insulating parts. They took into consideration the need for a temperature equilibrium state to validate the model, using the two-plate method, similar to the method we used in this study.

Janumala et al. [22] studied the growing demand for energy and its environmental impact, conducting research based on solar energy storage and the technology used in this context. They studied the latent heat of the used composites, determining the thermal conductivity coefficient in different change phase states. This study showed that energy consumption can be lowered by using the presented storage technology for capturing solar radiation, especially in cold climates.

Mirkovi et al. [23] focused on determining the energy balance analysis of composite samples made of mineral wool by using the plate method and obtaining the thermal conductivity coefficient in a steady flow state.

Dia M. et al. [24] conducted heat transfer measurements without considering the influence of the environment. They based their measurements on an analytical model they developed and compared them with measurements where they took into account the convection around the apparatus. The study was conducted on several samples and validated with a numerical model, resulting in a relative error of less than 4%.

Indra et al. [25] aimed to study panels made of natural fibers manufactured by pressing. They reported that an increased particle size increases the thermal conductivity coefficient but lowers water resistance, density, and strength.

These studies indicate an increasing interest in developing new materials and technologies that lead to low energy consumption.

A crucial factor in analyzing potential insulators is the thermal conductivity coefficient, which helps us classify materials into insulating classes. Cekon et al. [26] focused their studies on lowering energy consumption by using panels made of polycarbonate with air cavities to enhance thermal proprieties. They employed a rotating plate method to determine the conductivity coefficient, creating a model that helps analyze and develop high-performance thermal systems; their model presented errors of under 1.8%. This research highlights the importance of controlled thermal conductivity coefficient within air cavities when considering the fabrication of insulating panels. Liu et al. [27] studied the thermal and acoustic proprieties of prefabricated composites, developing a heat transfer coefficient model to utilize thermal conductivity equivalence methods that were applied in the deduction of thermodynamic parameters. Antypas et al. [28] suggested a method of using plastic waste and polyester resin for creating thermal insulation panels. Their study focused on different types of panels with varying compositions of recycled plastic materials and the impact of this composition on the conductivity coefficient. Paramasivam, C. et al. [1] focused on the blend proportion for composite panels used in the building industry. They highlighted the importance of finding new materials, such as fiber-reinforced panels that possess high mechanical and thermal proprieties. The studied blends were made using basaltic fiber and fiberglass. Research showed that the properties were also influenced by the manufacturing process, with curing time and applied pressure during production having a significant impact. Berardi, U. et al. [29] studied the importance of the thermal environment when computing the thermal conductivity coefficient and the need for more than one value for each material. They argued that the commonly used average value may not fully represent the material’s behavior under thermal stress. Their study focused on a region in Italy to evaluate the environment impact on insulating panels, highlighting the importance of studying the thermal coefficient variations in composite materials made of rockwool and fiberglass. Modarresifar F. et al. [13] reviewed the international standards for measuring thermal conductivity of refractory glass fibers. They demonstrated that temperature changes alter the internal structure of the material, thus affecting the conductivity coefficient in the case of repetitive measurements. Another significant factor influencing this coefficient was the production method of the tested samples, with the manufacturing process having a considerable impact on the results.

Thermal conductivity can be enhanced by adding plastic elements, according to the studies mentioned above. Therefore, by adding such elements to concrete plates, the properties of the final product can be improved, also lowering the impact on the environment. For example, Ali, K. et al. [30] studied the use of plastic waste as aggregates in concrete. They developed seven samples including different percentages of plastic concrete aggregates. The research focused on the properties of the studied materials, such as density, workability, compressive strength, splitting tensile strength, stress–strain response, Poisson’s ratio, and thermal proprieties. The results showed that including the plastic elements increased the workability of the concrete but had an impact on its density and mechanical proprieties. Adding silica fume managed to solve the problem, showing the capability of the product to be used in eco-friendly concrete production. This study emphasizes the importance of using recycled plastic elements in concrete production and their capability to increase the thermal proprieties of such compounds. Hassan, A. et al. [31] also focused their research on substituting traditional aggregates in concrete with used materials, in their case, electronic plastic waste. The main objective was to reduce waste production by giving a second life to plastic materials. They managed to enhance the mechanical proprieties of the compound by adding nano iron oxide particles and sisal fiber reinforcements in various percentages. This proved that reinforcing concrete by adding fibers and recycled plastic particles can significantly lead to improvements in the proprieties of the compound.

In conclusion, more research groups have focused on finding environmentally friendly solutions, not only by using plant-based materials but by incorporating recycled ones, giving a new life to used elements in order to reduce pollution and energy waste. Aiming to replace conventional materials with reusable, eco-friendly ones, Lakreb, N. et al. [32] analyzed the thermal conductivity of cork-based sandwich panels. They studied several constructive solutions, adding layers and employing three measurement methods. Their findings indicate a growing necessity to include recycled and natural materials in the development of efficient insulating panels.

As one of the main polluters is plastic, we created for this study a panel that incorporates recycled plastic foam elements to serve as air-pockets that can increase the insulating properties of the plate. This panel also incorporates recycled fiberglass consolidated by using epoxy resin. This study is focused on presenting an experimental approach used to determine the conductivity coefficient and heat variation inside the experimental panel.

2. Materials and Methods

The thermal conductivity coefficient is influenced by the type of layered materials used in a composite panel and, therefore, depends on the nature and properties of the studied material. One factor that influences thermal conductivity is moisture. The tests were made in a controlled environment with low moisture content and constant temperature.

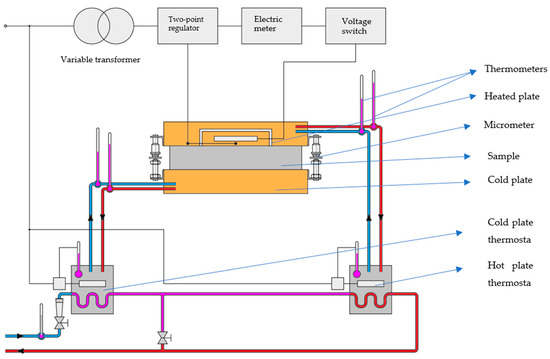

The experimental plates were subjected to thermal conductivity coefficient (λ) measurements using the hot plate technique according to ISO 8301:1991 [33] and DIN EN 12667:2001 [34]. The HFM436 Lambda apparatus (Netzsch, Selb, Germany) was used for the test (Figure 1). The method is based on the determination of the heat that passes from the hot plate to the cold plate through the tested material or structure. The temperatures of the two plates and the thermal conductivity coefficient, which is calculated based on Fourier’s law, are automatically recorded by the software of the apparatus.

Figure 1.

Experimental setup.

The installation used for determining the coefficient of thermal conductivity for the composite panel is presented in the figure. It consists of a bench on which a control panel is mounted and a system of metal plates. Between the two plates, hot and cold, the specimens are mounted for testing. The installation for determining the coefficient of thermal conductivity is connected to the electricity and the water network.

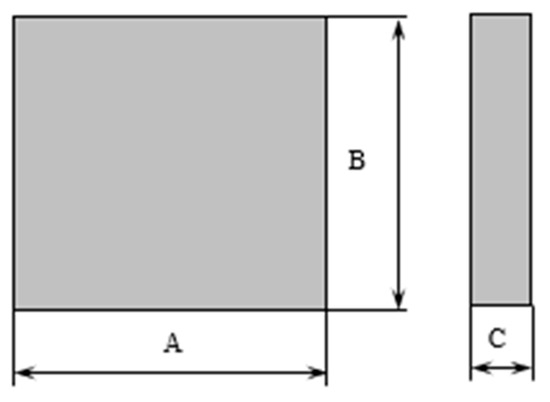

The determination of the thermal conductivity coefficient is based on the heating plate method, with a single sample body having the following dimensions for the surface: A and B, which vary between 200 and 250 mm, and C, the sample thickness, which can have different values with a maximum of 70 mm (Figure 2).

Figure 2.

Sample sizing.

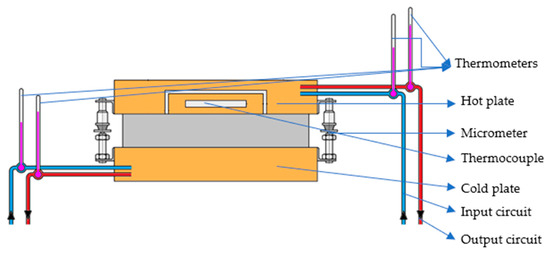

The composite sample is placed between the two metallic plates: the upper one, called the heater, having a higher constant temperature and equipped with an electrical resistance; and the lower one, the cold plate, in which a constant flow of water is provided. The readings are taken with thermometers positioned on both plates at the entry points of the plates, as well as the exit points (Figure 3).

Figure 3.

Sample positioning inside the measuring device.

The heating plate is covered by another protective plate to prevent heat loss from the heating plate. The metal plates are surrounded during the measurements by a protective box, which has the role of reducing heat loss to the outside by convection.

In order to obtain the optimum values for the temperatures, the machine has to enter a stationary heat regime; the fluctuations in the upper and lower plate temperatures have to be almost constant. The determinations were made at different time intervals by reading the electric consumption meter, the temperatures of the plates, the room temperature, the cooling water temperature, and also the thickness of the sample.

Before conducting the measurements for the selected composite panels, the device was calibrated using a standardized reference plate for which the conductivity coefficient is known [32]. In Table 1, we present the measured values for the reference plate as follows.

Table 1.

Reference plate conductivity measurements.

After performing the computations for the reference plate, we obtained a value of 0.109722 W/mK and an error in the thermal conductivity coefficient of 2.034% by comparing with the known value of the reference plate.

2.1. Thermal Conductivity Coefficient Method

The thermal conductivity coefficient was computed using Equation (1), which uses the measured heat flow in each time frame and temperature drop across a composite plate [33,34,35]:

where:

is the thermal conductivity coefficient (W/m·K);

q is the heat flow rate (W/m2), which is measured;

is the average thickness of the plate (m), which is measured;

is the average drop of temperature in the plate (°C), which is measured;

is the hot plate testing device constant, ra = 0.001118 m2K/W.

The constant for the testing device, ra, is based on the all-thermal resistances considered at the passing of the heat flow between the thermostatic fluids and the contact surface of the material sample.

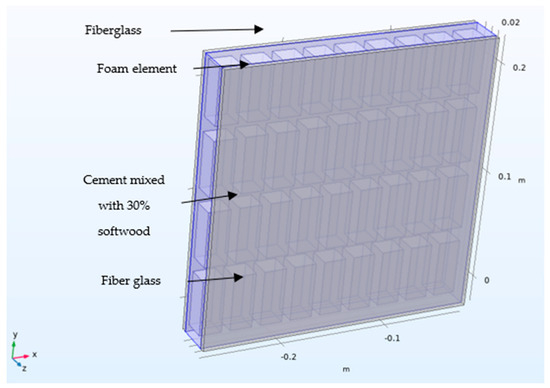

2.2. Cement Plate with Foam Insertions

The fiberglass cement plate (Figure 4) was made using second-hand foam elements to induce air pockets that will improve the thermal insulating properties of the plate. The use of second-hand elements is important, as it is a significant step toward a cleaner environment and waste reduction. The plate’s surface area is 0.2 × 0.2 m2.

Figure 4.

Composite plate with foam insertions, 3D views.

We used 3 layers of MAT fiberglass with a specific mass of 450g on each side of the panel. An important factor that we had to consider was the variation in the panel’s thickness. The median variation could not surpass 2% of its median value to ensure uniform surface contact on the plates of the testing device.

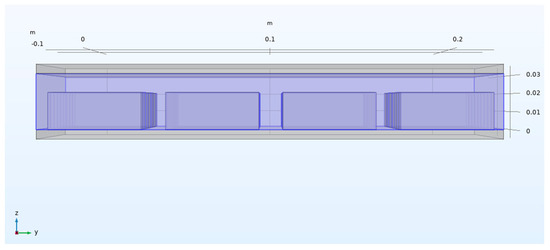

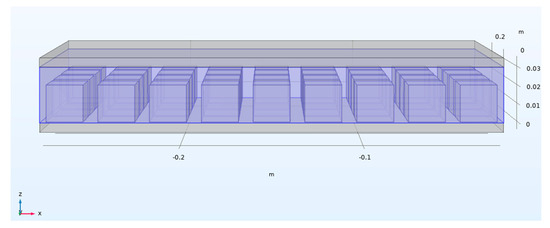

The foam elements (50 × 20 × 20 mm) are made of recycled material used in packing in the delivery industry. Before selection, the elements were thoroughly inspected, the selected ones maintaining their geometry even after the first use. Due to the foam’s elasticity, most of the elements were usable, therefore, having a high reusage percentage. The total number of foam elements was 36 per plate (Figure 5 and Figure 6).

Figure 5.

Side view of the foam elements inside the plate.

Figure 6.

Front view of the foam element distribution inside the plate.

For the inner panel, instead of polymer resin, we used cement mixed with 30% sawdust from softwood as a binding agent. The sawdust was collected from a wood processing facility and categorized as waste from the wood cutting process. The reason for using wood was to increase the thermal insulation properties of the plate.

3. Heat Transfer Measurements

After performing and recording the measurements, the data were organized in the tables presented below. The measurements were taken after the installation reached a thermal steady state, meaning that the temperatures between the two plates reached their maximum/minimum values without significant variations. Readings for temperature were taken with 0.01 °C precision. The obtained values are presented in Table 2.

Table 2.

Recorded values for the composite panel.

The values were computed to determine the conductivity coefficient variation. For each temperature reading, corrections were applied to both plates. We needed to input these corrections to obtain an accurate value for the median temperature for each state. The fluctuations in temperature occur because the cooling plate has a significant influence on the thermal state. The computed values are presented in Table 3.

Table 3.

Computed values for the hot and cold plate temperatures using corrections for the composite panel.

To compute the unitary heat flow (q), we needed to establish the value for the energy consumption between each reading and to take into account the apparatus constant regarding the power level. The apparatus constant depends on the ratio between the electric power consumed by the hot plate and the total electric power drawn from the rheostat; the corresponding electric energy is measured with the electric meter.

The temperature drop (Δt) is considered for each measurement; therefore, we obtain the conductivity coefficient for all the recorded steps.

The measurements were made using micrometers on each side of the plate. Changes in the thickness of the plate can occur due to the influence of the temperatures that arise at the surface or inside the sample. The average thickness of the material sample (δm), used in Equation (1), is calculated using the corrected values of the plate’s thickness, recorded before and after the measurements (Table 4).

Table 4.

Sample thickness. Measured and corrected values.

4. Experimental Results

After processing the data from the experimental measurements, we obtained the following values (presented in Table 5) for the unitary heat flow and for the thermal conductivity coefficient.

Table 5.

Thermal conductivity for the composite panel.

The values for the conductivity coefficient decrease as the thermal flow crossing the material sample from the upper surface to the lower one lessens. This is due to the heating plate transferring heat to the cooling plate, thus increasing its temperature. Consequently, the energy consumption increases to maintain the selected hot plate temperature. Both samples have a conductivity coefficient within the range of values for insulating materials, making them suitable for use in construction panels.

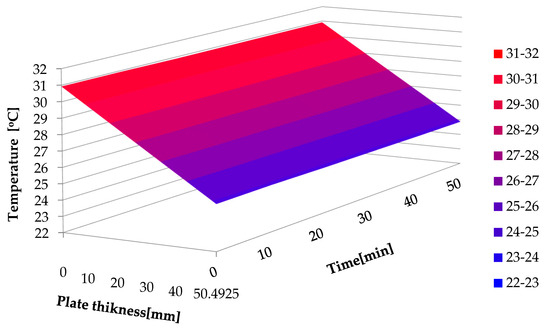

Figure 7 illustrates the temperature variation between the two plates over the time frame in which the measurements were taken, considering the plate thickness.

Figure 7.

Variation in the temperature in the composite panel.

The heating plate must maintain a constant temperature to ensure accurate measurements. Before the experimental installation reaches a steady state, the cooling plate exerts a significant influence on the sample. The heat flow becomes more constant over time as heat transfers to the cooling plate, and, because of this, the thermostat must maintain a specific value for the upper plate. The recycled foam elements may have different geometries due to their previous uses. This imperfection could affect the symmetry between the layers of the panel and therefore influence the heat transfer.

The fluctuation of the heat in the hot plate is caused, on the one hand, by the constant temperature maintained by the thermostat and, on the other hand, by the almost linear temperature distribution on the cold plate, which is ensured by the cold-water cooling agent. The cold plate temperature rises gradually as the hot plate transfers its heat through the sample.

The heat flow is transmitted in the normal direction to the surfaces of the panel. The composite panels gain heat over time, causing the flow curve to linearize as the heated plate maintains its selected value with the help of the thermostat.

5. Thermal Conductivity Coefficient Resulted by Simulation

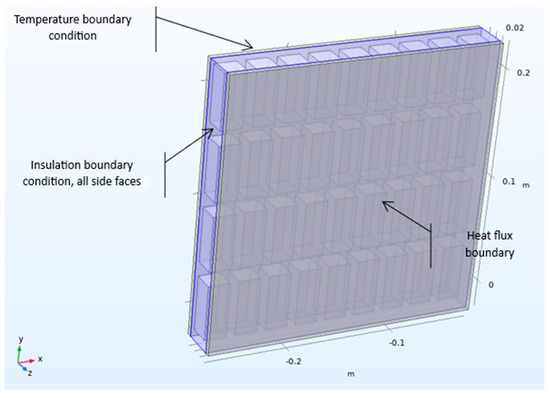

From the proposed composite panel, we selected the model definition presented in Figure 8 for simulation. The panel dimensions are 250 × 250 × 50 mm, featuring a 3D array of 36 foam elements (50 × 20 × 20 mm) in its inner layout, encapsulated within the cement mixture mass.

Figure 8.

Model geometry definition of all the boundaries and domain conditions.

The thermal boundary conditions are also shown in Figure 8. The physics for the thermal field are solved using finite element modeling discretization using COMSOL Multiphysics 3.5a software. The global definitions of thermophysical property values are assigned using the material database.

The mesh was generated using the extremely fine option, resulting in 311,204 tetrahedral elements, 74,394 triangular elements, 6673 edge elements, and 600 vertex elements. The average element quality is 0.6563, which is considered a good value for mesh.

The simulation results are presented in the Table 6. The values for heat flow rate and temperature gradient are averaged over the normal surface area.

Table 6.

Resulting values from simulation for the composite panel.

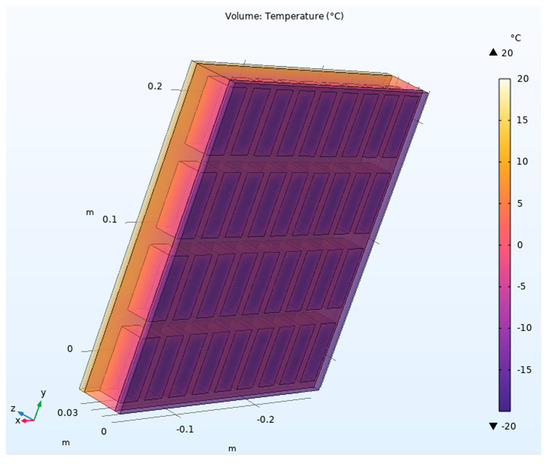

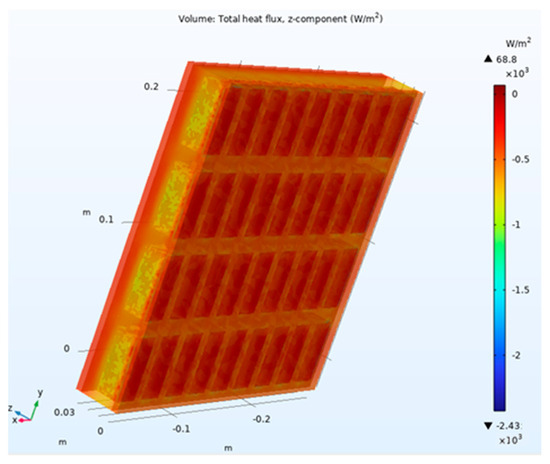

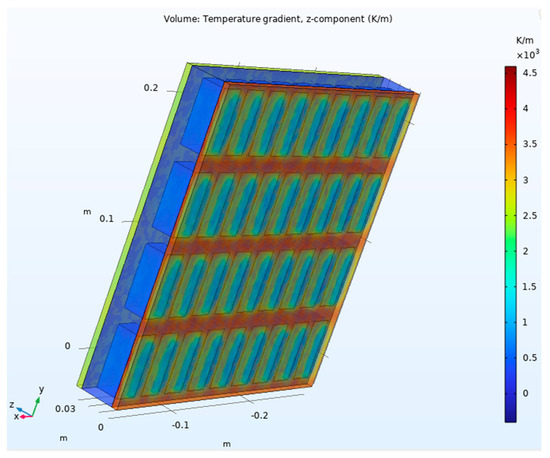

Thus, the resulting temperature field on the experimental panel for temperature conditions ranging from −20 °C on the cold side to +20 °C on the warm side is presented in Figure 9. Under the same temperature conditions, the total heat flux in the z direction is presented in Figure 10 and the temperature gradient in Figure 11.

Figure 9.

Temperature field distribution on the panel.

Figure 10.

Total heat flux distribution on the panel.

Figure 11.

Temperature gradient on the panel.

As Figure 10 shows, the heat flow variation within the inner foam elements can be determined. These elements play an important role in increasing the thermal properties of the panel, acting similarly to air pockets within the panel structure. In the presented simulation, we considered a wider range of temperatures applied to the surfaces of the panel, starting from negative 20 to positive 20 °C. By analyzing the temperature scale and the heat flux variation on the mentioned elements, the inner foam elements act as insulation, as shown in Figure 10, when the outer face of the panel is subjected to −20 °C.

The effective thermal conductivity calculated using Fourier’s law is λ = 0.1299 W/m·K for the proposed panel geometry. Simulation 6 was performed to compare the effective thermal conductivity value with the experimental obtained value. The simulated value is λ = 0.130 W/m·K, while the measured experimental value is λ = 0.133567 W/m·K, resulting in a relative error of 2.67%.

6. Discussions and Conclusions

The proposed composite panel was studied to highlight the possibility of using a different arrangement of foam within a building wall structure to achieve increased thermal resistance, decreasing the effective thermal conductivity of the panel by 10 times compared with the thermal conductivity of the concrete, which is about 1.33 W/(mK). The 2.67% relative error between simulated and experimental thermal conductivity values may stem from the difference in concrete thermal conductivity. The simulation used the properties for dry concrete from the material library, while the experimental plate was under ambient laboratory conditions. Future work will explore the effect of wall and ambient humidity.

The foam we used for this study has a defined shape, but one can use any type of foam insertions as a solution to prevent waste and give another life to already produced materials. Our study shows that the proposed foam insertion panel has a similar average conductivity to thermo-insulating bricks and, as an advantage, a lower mass per panel.

The heat stored by the panel remains relatively constant over time, thus exhibiting superior thermal properties compared to the conventional metallic materials used for panels and simple cement samples used in the building industry. This creates opportunities for multiple uses of the proposed fiberglass panels and foam insertion core panels with cement.

This research points out the influence of thermal behavior on samples made of composite materials. It highlights the possibilities that new types of materials bring to the development of a future in which conventional, single-use materials are cast aside. Another important aspect is that studying the thermal behavior of layered materials will lead to further research for their unique aspects that were not encountered in classic materials due to the need for a binding agent.

A further study direction that will be considered is the investigation of mechanical properties of the proposed panel, since the thermal insulation of the panel has been analyzed and demonstrated as a valuable solution.

Author Contributions

Conceptualization, E.C., V.G., I.C. and L.C.; methodology, E.C. and V.G.; software, L.C. and I.C.; validation, E.C. and L.C.; formal analysis, V.G. and I.C.; investigation, E.C. and I.C.; resources, E.C. and V.G; data curation, V.G., I.C. and L.C.; writing—original draft preparation, E.C., I.C. and L.C.; writing—review and editing, E.C. and I.C.; visualization, V.G.; supervision, E.C. and L.C.; project administration, E.C. and I.C.; funding acquisition, V.G. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding authors.

Acknowledgments

We are very grateful to Transilvania University of Brasov for the given support and for helping us with the APC.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Paramasivam, C.; Venugopal, R. Design and development of glass/basalt fiber reinforced composite material for automobile applications. J. Ind. Text. 2022, 51 (Suppl. S1), 1668S–1681S. [Google Scholar] [CrossRef]

- Yea, K.; Dasari, A.; Hooper, T.J.N. Structural characterization and fire performance of geopolymer-glass fiber composite panels. Constr. Build. Mater. 2023, 400, 132633. [Google Scholar] [CrossRef]

- Hosseini-Toudeshky, H.; Sadighi, M.; Vojdani, A. Effects of curing thermal residual stresses on fatigue crack propagation of aluminum plates repaired by FML patches. Compos. Struct. 2013, 100, 154–162. [Google Scholar] [CrossRef]

- Pavlović, A.; Sintoni, D.; Minak, G.; Fragassa, C. On the modal behaviour of ultralight composite sandwich automotive panels. Compos. Struct. 2020, 248, 112523. [Google Scholar] [CrossRef]

- Olhan, S.; Antil, B.; Khatkar, V.; Behera, B.K. Mechanical, thermal, and viscoelastic behavior of sisal fibre-based structural composites for automotive applications: Experimental and FEM analysis. Compos. Struct. 2023, 322, 117427. [Google Scholar] [CrossRef]

- Rajabi, M.; Aboutalebi, M.R.; Seyedein, S.H.; Ataie, S.A. Simulation of residual stress in thick thermal barrier coating (TTBC) during thermal shock: A response surface-finite element modeling. Ceram. Int. 2022, 48, 5299–5311. [Google Scholar] [CrossRef]

- Olhan, S.; Behera, B.K. Mechanical, thermogravimetric, and dynamic mechanical behavior of high-performance textile structural composite panels for automotive applications. J. Manuf. Process. 2023, 102, 608–621. [Google Scholar] [CrossRef]

- Mountasir, A.; Hoffmann, G.; Cherif, C.; Löser, M.; Großmann, K. Competitive manufacturing of 3D thermoplastic composite panels based on multi-layered woven structures for lightweight engineering. Compos. Struct. 2015, 133, 415–424. [Google Scholar] [CrossRef]

- Min, J.G.; Lim, W.B.; Lee, J.H.; Bae, J.H.; Huh, P.H. The Effect of NCO Content in Polyurethane Foam for Automotive Instrument Panel. Int. J. Precis. Eng. Manuf. 2023, 24, 1435–1441. [Google Scholar] [CrossRef]

- Ayrilmis, N.; Jarusombuti, S.; Fueangvivat, V.; Bauchongkol, P.; White, R.H. Coir Fiber Reinforced Polypropylene Composite Panel for Automotive Interior Applications. Fibers Polym. 2011, 12, 919–926. [Google Scholar] [CrossRef]

- Mali, M.; Hussain, A.K.; Hassan, M.B.; Mahmud, J. Analysis of Hard Point Mechanical Behaviour Due to Variations of Potting Agent Volume on a Composite Sandwich Panel. Mater. Sci. 2022, 28, 467–473. [Google Scholar] [CrossRef]

- Peng, C.; Kim, Y.J.; Zhang, J. Thermal and energy characteristics of composite structural insulated panels consisting of glass fiber reinforced polymer and cementitious materials. J. Build. Eng. 2021, 43, 102483. [Google Scholar] [CrossRef]

- Modarresifar, F.; Bingham, P.A.; Jubb, G.A. Thermal conductivity of refractory glass fibres. A study of materials, standards and test methods. J. Therm. Anal. Calorim. 2016, 125, 35–44. [Google Scholar] [CrossRef]

- Wazeer, A.; Das, A.; Abeykoon, C.; Sinha, A.; Karmakar, A. Composites for electric vehicles and automotive sector: A review. Green Energy Intell. Transp. 2023, 2, 100043. [Google Scholar] [CrossRef]

- Venkata Ramana, M.; Rao, G.V.; Shankar Rao, B.; Shiva Prasad, B. Design & development of durable low cost housing from glass fiber composites. Mater. Today Proc. 2021, 38, 3205–3212. [Google Scholar]

- Samyal, R.; Singh, S.; Bagha, A.K. Modal Analysis of Composite Panel at different Fiber Orientations. Mater. Today Proc. 2019, 16, 477–480. [Google Scholar] [CrossRef]

- Zhao, W.; Yan, W.; Zhang, Z.; Gao, H.; Zeng, Q.; Du, G.; Fan, M. Development and performance evaluation of wood-pulp/glass fibre hybrid composites as core materials for vacuum insulation panels. J. Clean. Prod. 2022, 357, 131957. [Google Scholar] [CrossRef]

- Virgillito, E.; Sisca, L.; Carello, M. Influence of Freeze-Thaw Aging on the Impact Performance of Damped Carbon Fiber Reinforced Plastics for Automotive Applications. Appl. Sci. 2022, 12, 4020. [Google Scholar] [CrossRef]

- Di, X.; Gaoa, Y.; Baoa, C.; Maa, S. Thermal insulation property and service life of vacuum insulation panels with glass fiber chopped strand as core materials. Energy Build. 2014, 73, 176–183. [Google Scholar] [CrossRef]

- Iranian, D.; Sudarmozhi, K.; Karthik, S.; Manigandan, J.; Chamkha, A.J. Finite difference analysis on radiative flow on a perpendicular plate using the influence of thermal conductivity. Forces Mech. 2023, 12, 100217. [Google Scholar] [CrossRef]

- Wu, D.; Sugio, K.; Sasaki, G. Estimation of Effective Thermal Conductivity of Copper-Plated Carbon Fibers Reinforced Iron-Based Composites by 2D Image Analysis. Mater. Trans. 2023, 64, 974–982. [Google Scholar] [CrossRef]

- Janumala, E.; Govindarajan, M.; Bomma Reddi, V.R.; Chinnasamy, S. Investigations on phase change materials for enhancement of thermal conductivity. Therm. Sci. 2022, 26, 955–961. [Google Scholar] [CrossRef]

- Mirkovic Marjanovic, M.R.; Kijanovic, A.I.; Ilic, S.B.; Jankovic, K.S.; Zakic, D.M. Verification and validation of an advanced guarded hot plate for determination of thermal conductivity. Therm. Sci. 2022, 26, 4735–4747. [Google Scholar] [CrossRef]

- Dia, M.; Faye, M.; Diallo, M.S.; Sambou, V. Measurement of the thermal properties of materials by the hot plate method considering the convection coefficient around the device. Mater. Res. Express 2023, 10, 065502. [Google Scholar] [CrossRef]

- Indra, M.; Sri, A.; Muhammad, F.; Ikramullah; Samsul, R. An investigation of thermal conductivity and sound absorption from binderless panels made of oil palm wood as bio-insulation materials. Results Eng. 2022, 13, 100319. [Google Scholar]

- Čekon, M.; Šikula, O. Experimental and numerical study on the thermal performance of polycarbonate panels. J. Build. Eng. 2020, 32, 101715. [Google Scholar] [CrossRef]

- Liu, P.; Luo, X.; Chen, Y.; Yu, Z.; Yu, D. Thermodynamic and acoustic behaviors of prefabricated composite wall panel. Struct. 2020, 28, 1301–1313. [Google Scholar]

- Antypas, I.R.; Savostina, T.P. Use of Panels Made from Plastic Waste in Thermal Insulation. Mater. Plast. 2023, 60, 112–120. [Google Scholar] [CrossRef]

- Berardi, U.; Tronchin, L.; Manfren, M.; Nastasi, B. On the Effects of Variation of Thermal Conductivity in Buildings in the Italian Construction Sector. Energies 2018, 11, 872. [Google Scholar] [CrossRef]

- Ali, K.; Saingam, P.; Qureshi, M.I.; Saleem, S.; Nawaz, A.; Mehmood, T.; Maqsoom, A.; Malik, M.W.; Suparp, S. Influence of Recycled Plastic Incorporation as Coarse Aggregates on Concrete Properties. Sustainability 2023, 15, 5937. [Google Scholar] [CrossRef]

- Hassan, A.; Farhan, A.; Muhammad, I.Q. Enhanced mechanical and durability resilience of plastic aggregate concrete modified with nano-iron oxide and sisal fiber reinforcement. Constr. Build. Mater. 2023, 401, 132911. [Google Scholar] [CrossRef]

- Lakreb, N.; Şen, U.; Toussaint, E.; Amziane, S.; Djakab, E.; Pereira, H. Physical properties and thermal conductivity of cork-based sandwich panels for building insulation. Constr. Build. Mater. 2023, 368, 130420. [Google Scholar] [CrossRef]

- ISO 8301; Thermal Insulation–Determination of Steady-State Thermal Resistance and Related Properties–Heat Flow Meter Apparatus. International Organization for Standardization: Geneva, Switzerland, 1991.

- DIN EN 12667; Thermal Performance of Building Materials and Products–Determination of Thermal Resistance by Means of Guarded Hot Plate and Heat Flow Meter Methods–Products of High and Medium Thermal Resistance. German Institute for Standardization: Berlin, Germany, 2001.

- Sova, V.; Sova, M.; Sova, D. Termotechnic—Machines and Thermal Installations—Theory and Applications; Transilvania University Press: Braşov, Romania, 1998; pp. 424–428. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).