Considering the Effect of Various Silica Types on Chemical, Physical and Mechanical Properties in Cement Mortar Production via Substitution with Cement Content

Abstract

1. Introduction

2. Experimental Studies

2.1. Materials

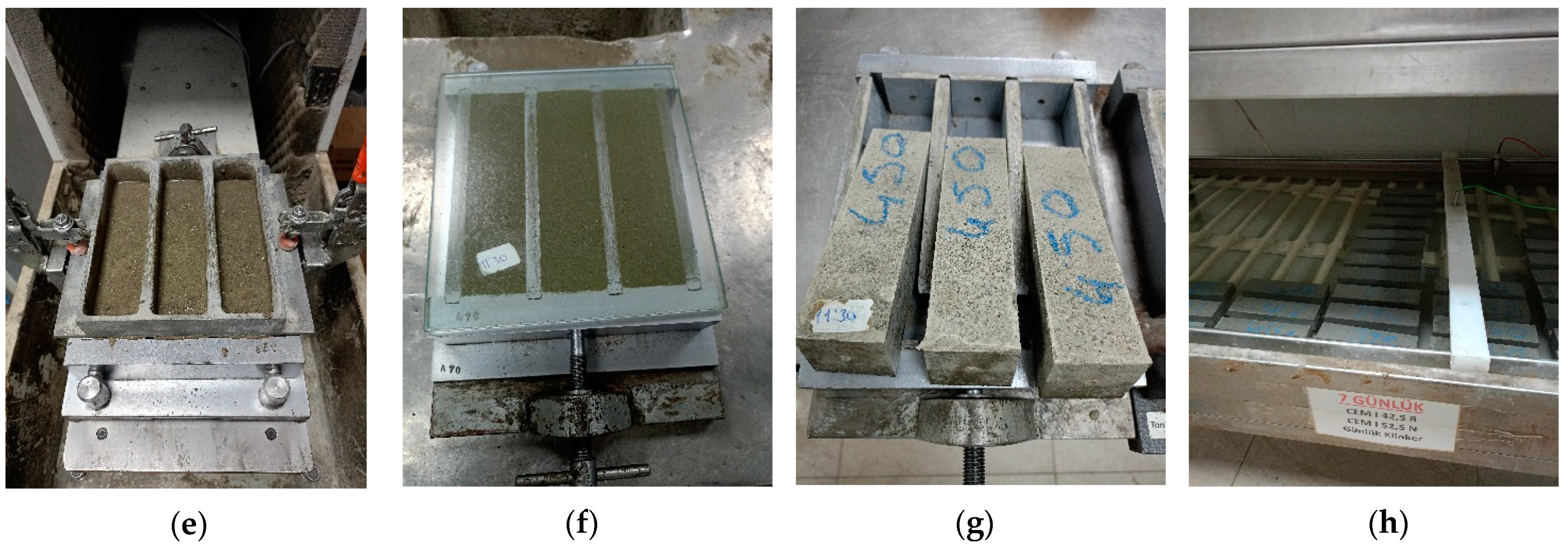

2.2. Mixture Proportioning and Sample Preparation

2.3. Test Procedure

3. Results and Discussion

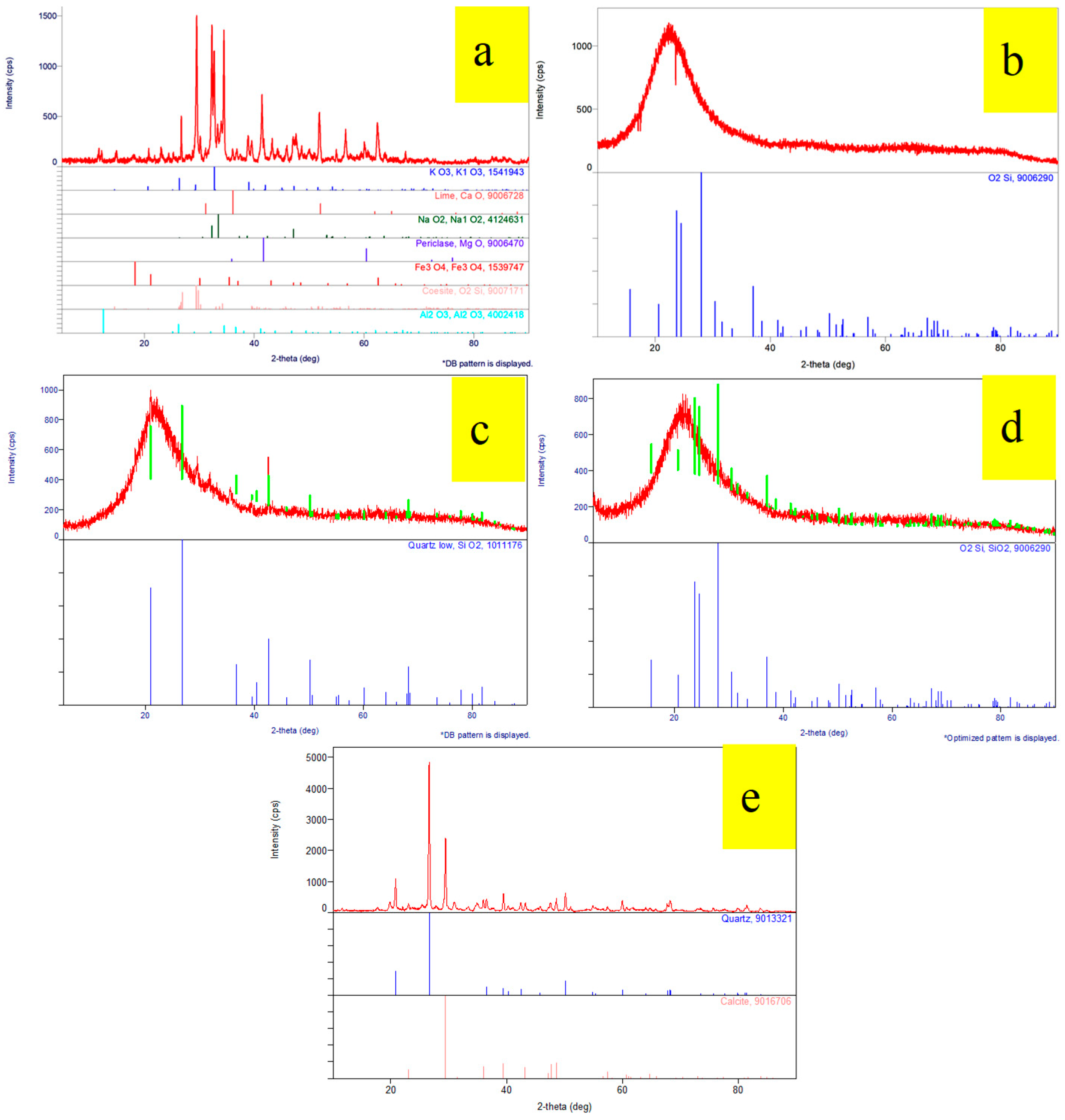

3.1. Dry Mix Results

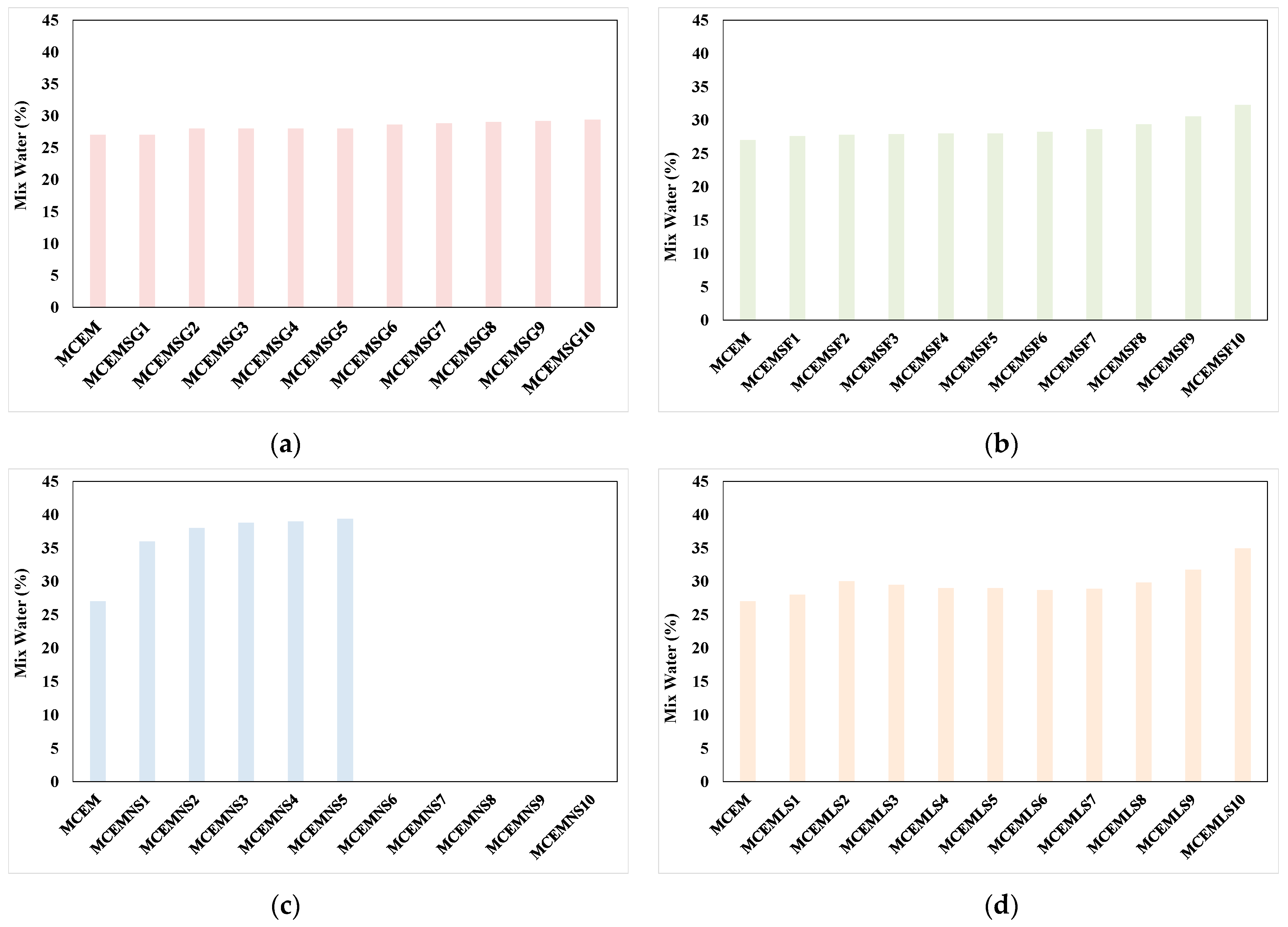

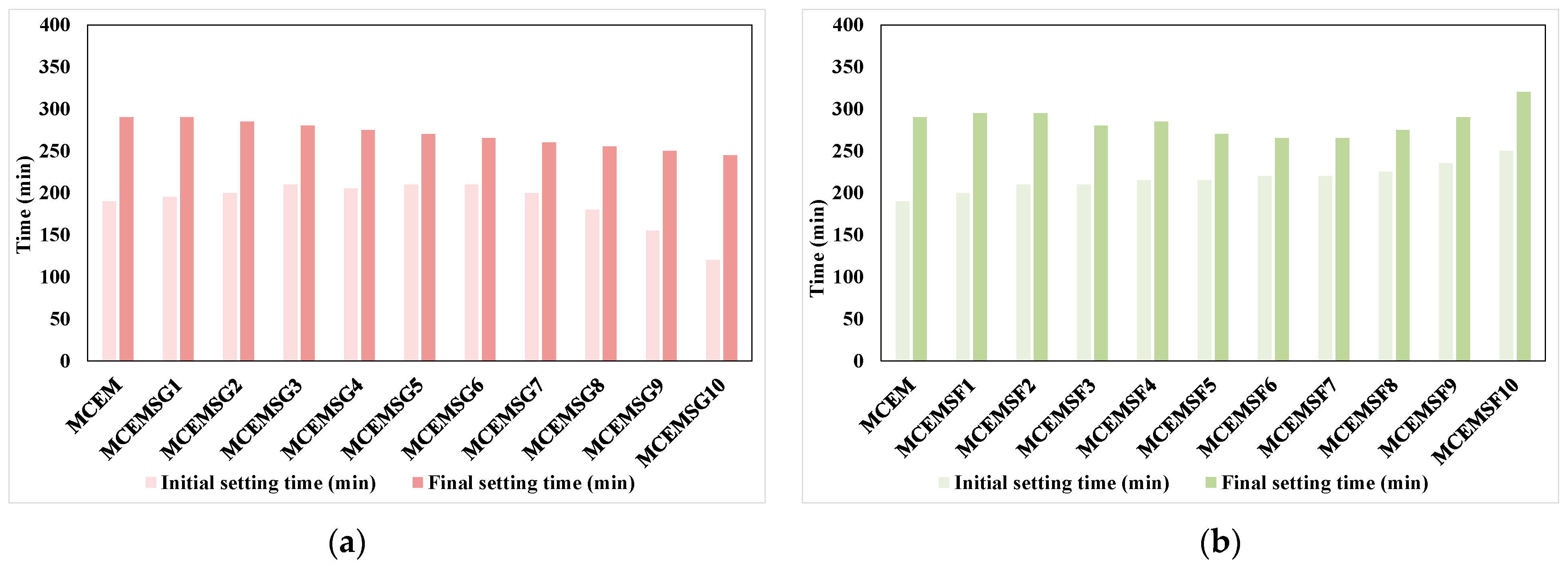

3.2. Fresh State Results

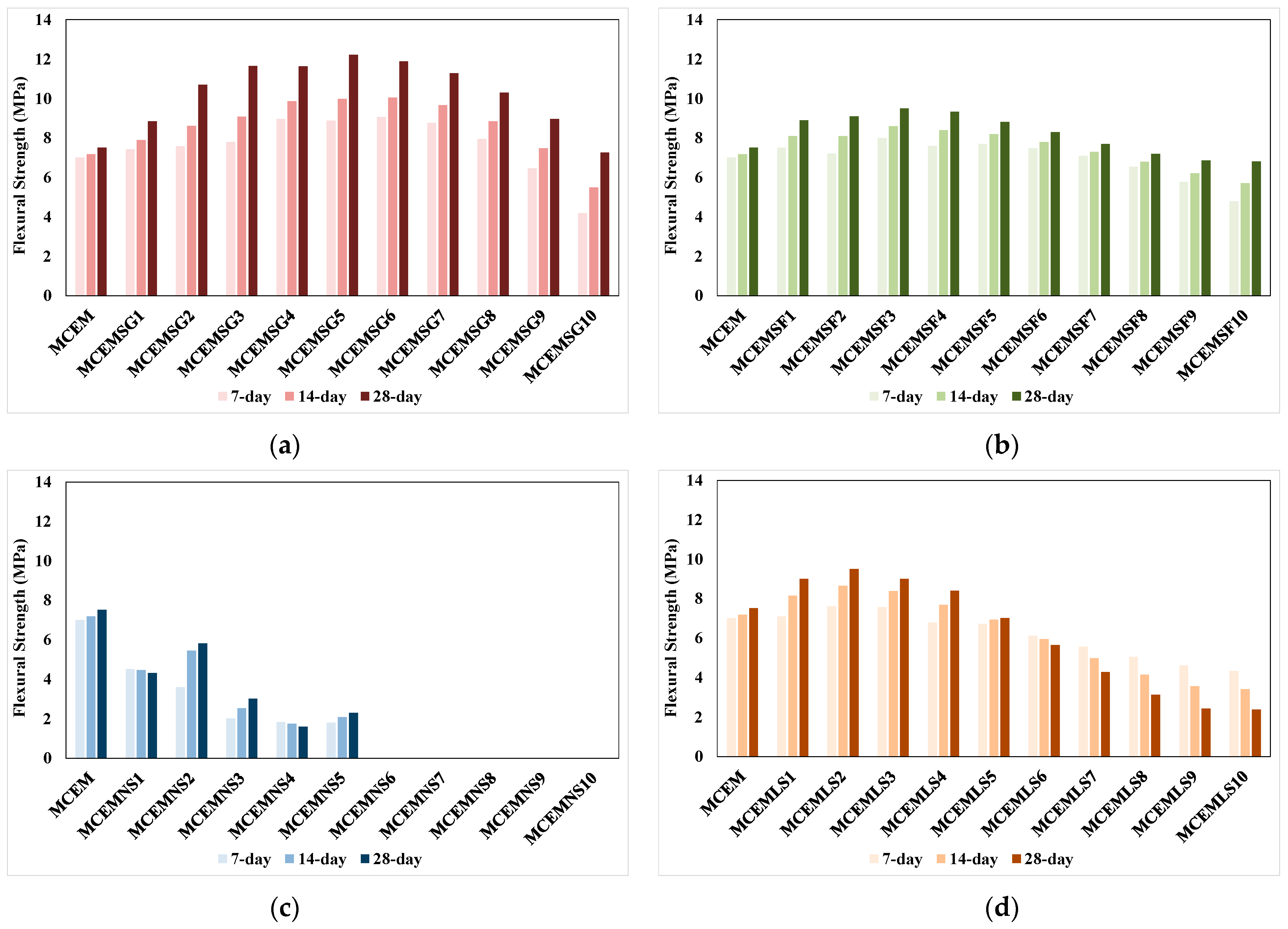

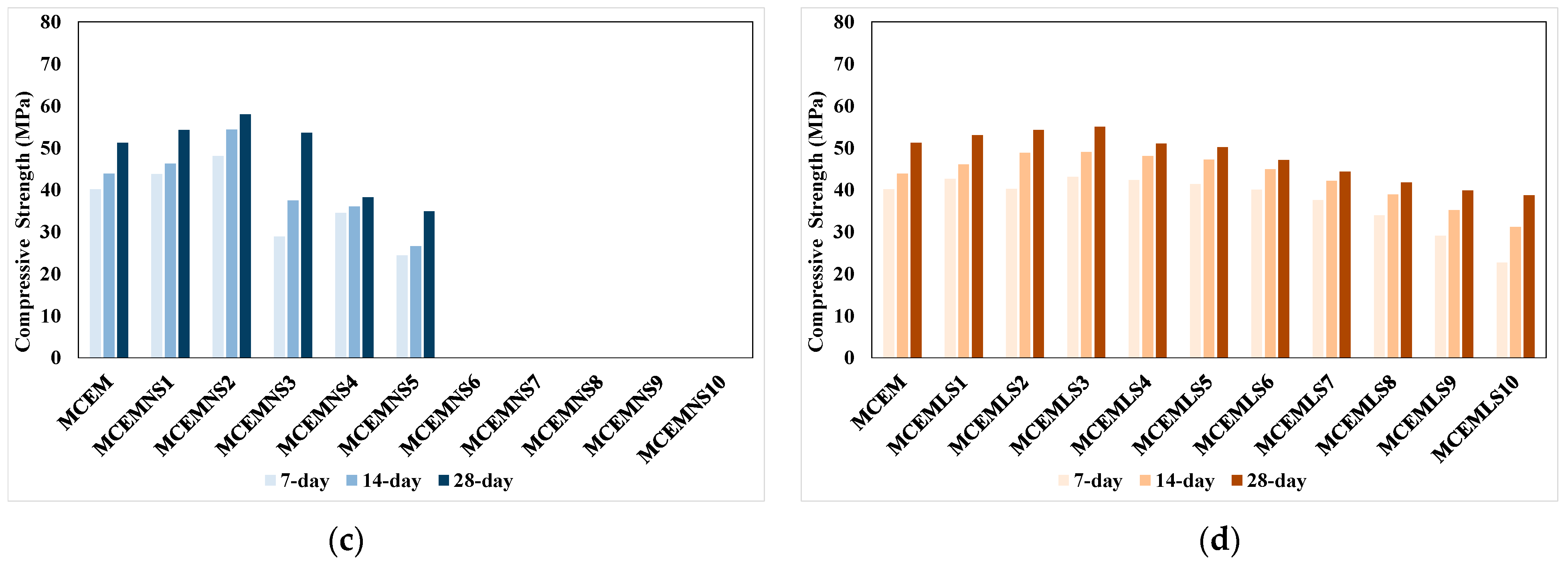

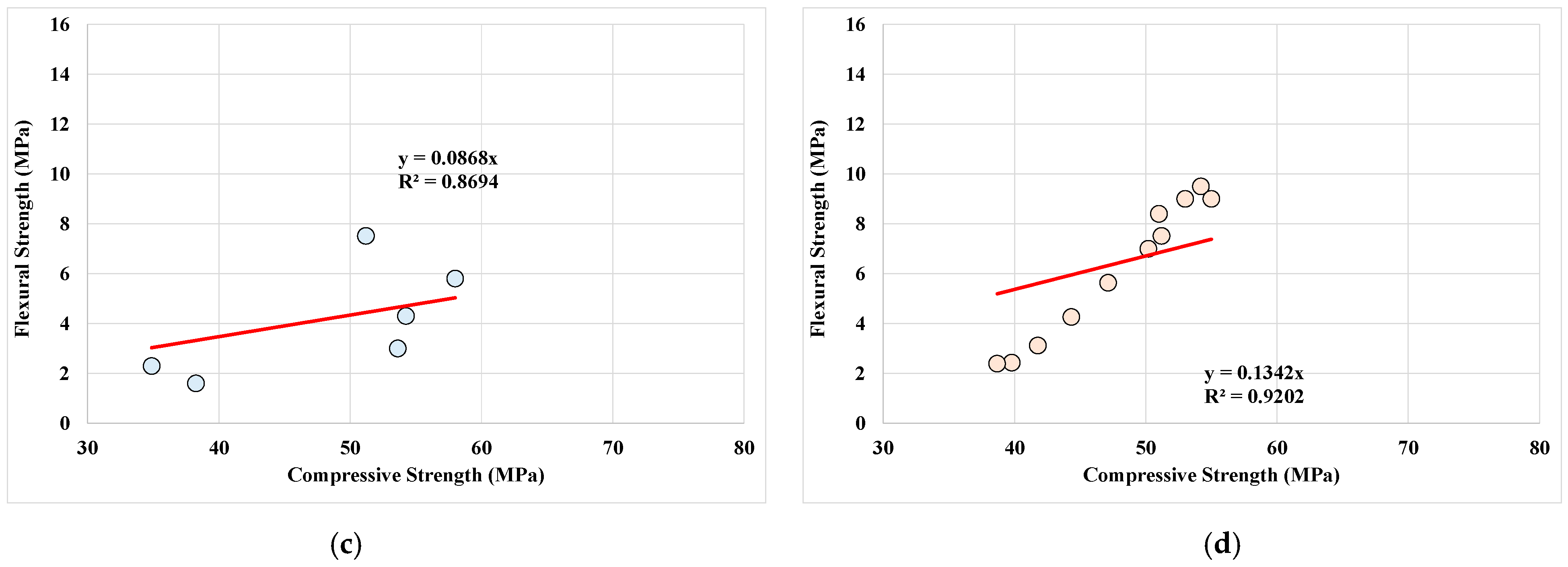

3.3. Flexural Strength Results

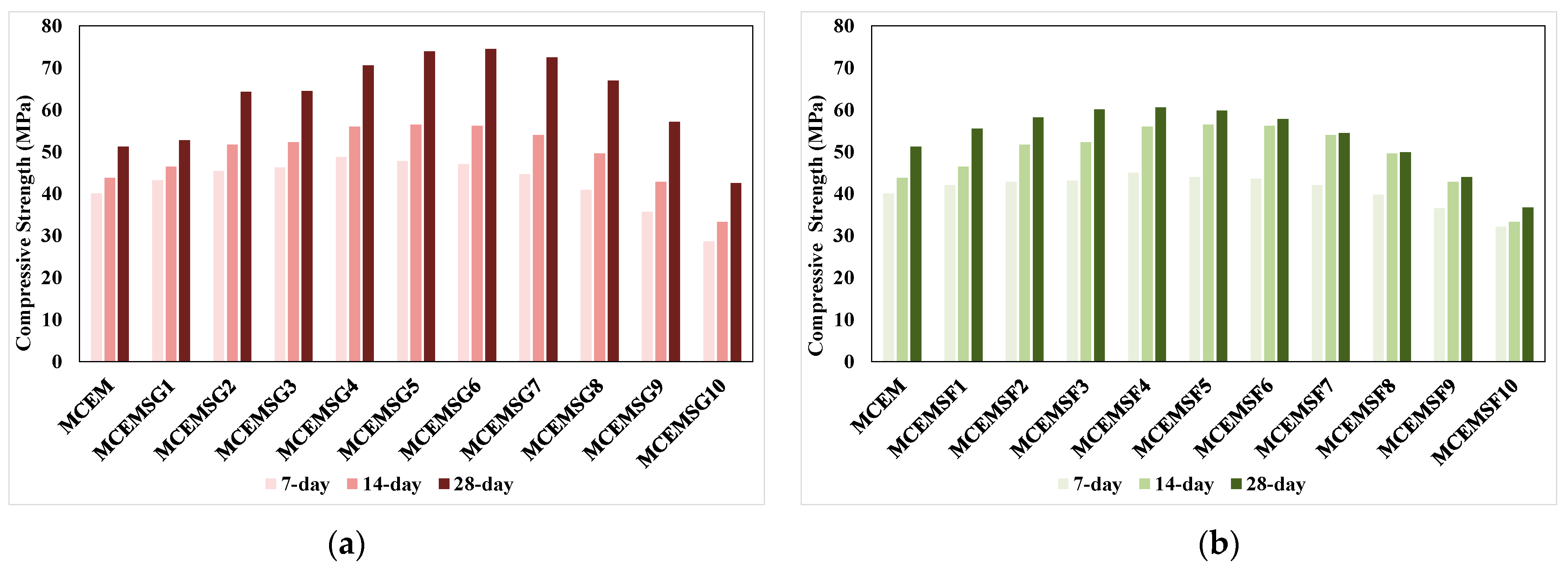

3.4. Compressive Strength Results

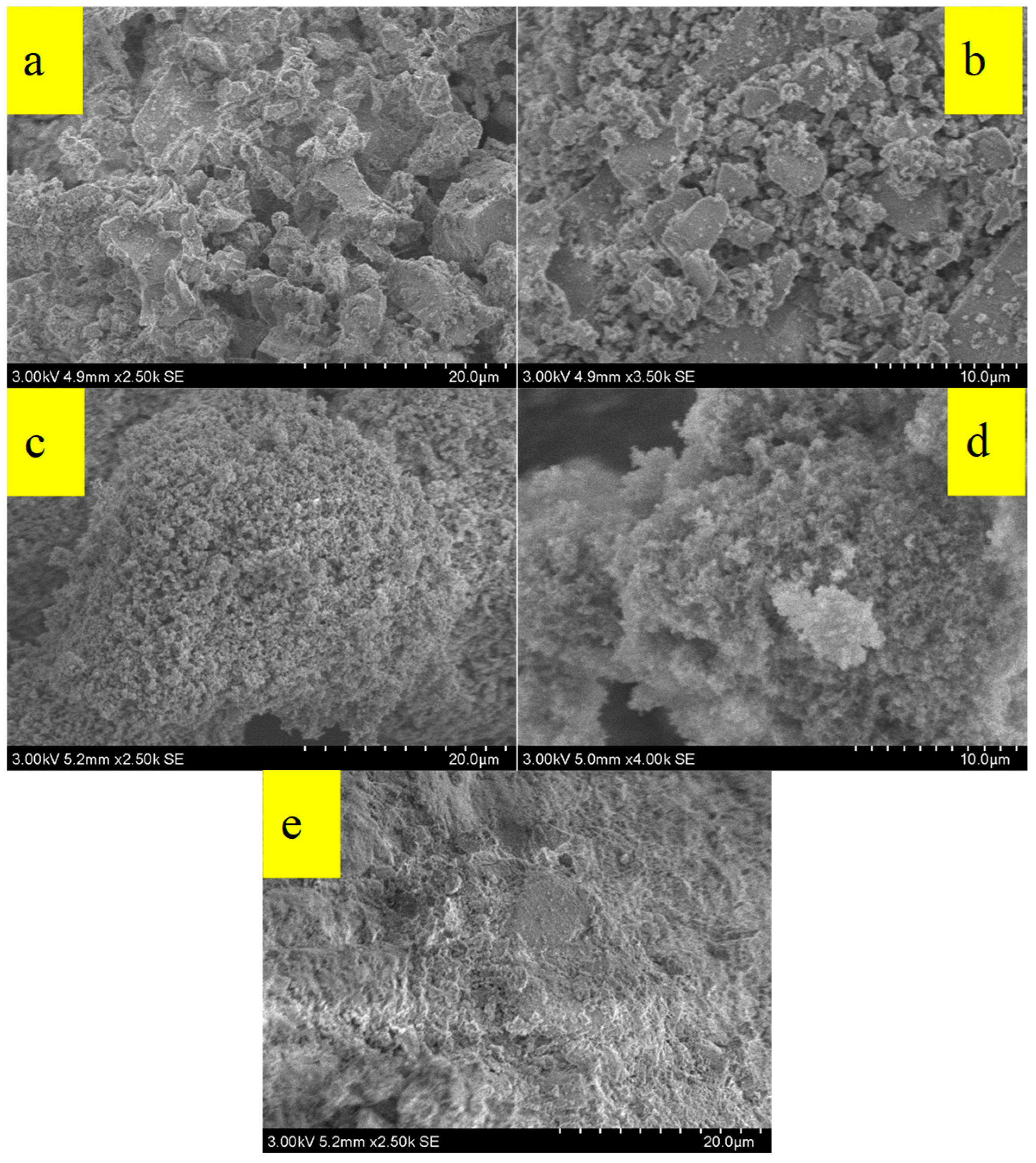

3.5. Micro-Structure Results

4. Conclusions

- Among the substitutes used, the highest water demand is observed in mixtures containing NS. This is also the biggest cause of strength losses; the main reason for the water requirement may be due to the specific surface area. On the other hand, there is no significant difference in water demand for the SG substitute.

- Regarding setting time, which is an important parameter in field studies, increases in SG content show significant gains in final setting time. In MLS substitutions, the final setting time values increase and the time between the initial and final setting times increases.The largest flexural strength gains were obtained for SG substitutes collected as waste. Substitutions of around 5% for SG result in significant gains. SF and MLS also show increases in flexural tensile strength tests, but substitution rates of only 3% in these materials provide optimum gains in both replacement amounts and strength.

- The largest gains in compressive strength were obtained for SG substitutions, as in flexural tensile strength. In contrast to flexural tensile strength, substitutions of around 6% for SG result in significant gains. SF and MLS also show increases in compressive strength tests, but these materials show optimum gains in strength and amount of substitution at around 4% and 3% substitution rates, respectively.

- In terms of strength and workability properties of SG substitutes, it is revealed that 3–10% by-weight substitution with cement is highly effective relative to SF, NS and MLS.

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Etli, S.; Yılmaz, T.; Hansu, O. Effect of White-Portland Cement Containing Micro and Nano Silica on the Mechanical and Freeze-Thaw Properties of Self Compacting Mortars. Eng. Sci. Technol. Int. J. 2024, 50, 101614. [Google Scholar] [CrossRef]

- Etli, S. Effect of Glass Sand Used as Aggregate on Micro-Concrete Properties. J. Croat. Assoc. Civ. Eng. 2023, 75, 39–51. [Google Scholar] [CrossRef]

- Etli, S. Mechanical Properties of Self-Compacting Mortars Containing Rubber Waste Particles as Fine Aggregate in Freeze–Thaw Cycles. J. Mater. Civ. Eng. 2024, 36, 04024246. [Google Scholar] [CrossRef]

- Akgül, M.; Etli, S. Investigation of the Variation of Mechanical and Durability Properties of Elements Manufactured with Rubber Substituted SCMs with Element Height. Constr. Build. Mater. 2024, 428, 136300. [Google Scholar] [CrossRef]

- Etli, S. Effect of Recycled Brick Powder on the Properties of Self-Compacting Fiber Reinforced Mortars Produced with Different Cement Types. Front. Struct. Civ. Eng. 2024, 18, 743–759. [Google Scholar] [CrossRef]

- Etli, S. Evaluation of the Effect of Silica Fume on the Fresh, Mechanical and Durability Properties of Self-Compacting Concrete Produced by Using Waste Rubber as Fine Aggregate. J. Clean. Prod. 2023, 384, 135590. [Google Scholar] [CrossRef]

- Cemalgil, S.; Onat, O.; Tanaydın, M.K.; Etli, S. Effect of Waste Textile Dye Adsorbed Almond Shell on Self Compacting Mortar. Constr. Build. Mater. 2021, 300, 123978. [Google Scholar] [CrossRef]

- Cemalgil, S.; Etli, S.; Onat, O. Curing Effect on Mortar Properties Produced with Styrene-Butadiene Rubber. Comput. Concr. 2018, 21, 705–715. [Google Scholar] [CrossRef]

- Gesoglu, M.; Güneyisi, E.; Hansu, O.; Etli, S.; Alhassan, M. Mechanical and Fracture Characteristics of Self-Compacting Concretes Containing Different Percentage of Plastic Waste Powder. Constr. Build. Mater. 2017, 140, 562–569. [Google Scholar] [CrossRef]

- Etli, S.; Cemalgil, S.; Onat, O. Effect of Pumice Powder and Artificial Lightweight Fine Aggregate on Self-Compacting Mortar. Comput. Concr. 2021, 27, 241–252. [Google Scholar] [CrossRef]

- Quercia, G.; Spiesz, P.; Hüsken, G.; Brouwers, H.J.H. SCC Modification by Use of Amorphous Nano-Silica. Cem. Concr. Compos. 2014, 45, 69–81. [Google Scholar] [CrossRef]

- Shokravi, H.; Mohammadyan-Yasouj, S.E.; Koloor, S.S.R.; Petrů, M.; Heidarrezaei, M. Effect of Alumina Additives on Mechanical and Fresh Properties of Self-Compacting Concrete: A Review. Processes 2021, 9, 554. [Google Scholar] [CrossRef]

- Nasr, D.; Behforouz, B.; Borujeni, P.R.; Borujeni, S.A.; Zehtab, B. Effect of Nano-Silica on Mechanical Properties and Durability of Self-Compacting Mortar Containing Natural Zeolite: Experimental Investigations and Artificial Neural Network Modeling. Constr. Build. Mater. 2019, 229, 116888. [Google Scholar] [CrossRef]

- Gupta, N.; Siddique, R.; Belarbi, R. Sustainable and Greener Self-Compacting Concrete Incorporating Industrial By-Products: A Review. J. Clean. Prod. 2021, 284, 124803. [Google Scholar] [CrossRef]

- Amran, M.; Makul, N.; Fediuk, R.; Lee, Y.H.; Vatin, N.I.; Lee, Y.Y.; Mohammed, K. Global Carbon Recoverability Experiences from the Cement Industry. Case Stud. Constr. Mater. 2022, 17, e01439. [Google Scholar] [CrossRef]

- Bekun, F.V.; Alola, A.A.; Gyamfi, B.A.; Kwakwa, P.A.; Uzuner, G. Econometrics Analysis on Cement Production and Environmental Quality in European Union Countries. Int. J. Environ. Sci. Technol. 2023, 20, 4265–4280. [Google Scholar] [CrossRef]

- Guo, Y.; Luo, L.; Liu, T.; Hao, L.; Li, Y.; Liu, P.; Zhu, T. A Review of Low-Carbon Technologies and Projects for the Global Cement Industry. J. Environ. Sci. 2024, 136, 682–697. [Google Scholar] [CrossRef]

- Etli, S. Investigation of the Effect of Glass Sand Used in SCC on the Behavior of the SCC Stress-Strain Relationship. Int. J. Innov. Eng. Appl. 2022, 6, 237–244. [Google Scholar] [CrossRef]

- Etli, S. Evaluation of Curing Time for Micro Concrete Mixes Containing Silica Fume, Nano-Silica And Fly Ash. İstanbul Ticaret Üniversitesi Fen. Bilim. Derg. 2022, 21, 304–316. [Google Scholar] [CrossRef]

- Hani, N.; Nawawy, O.; Ragab, K.S.; Kohail, M. The Effect of Different Water/Binder Ratio and Nano-Silica Dosage on the Fresh and Hardened Properties of Self-Compacting Concrete. Constr. Build. Mater. 2018, 165, 504–513. [Google Scholar] [CrossRef]

- Badogiannis, E.G.; Sfikas, I.P.; Voukia, D.V.; Trezos, K.G.; Tsivilis, S.G. Durability of Metakaolin Self-Compacting Concrete. Constr. Build. Mater. 2015, 82, 133–141. [Google Scholar] [CrossRef]

- Askarian, M.; Fakhretaha Aval, S.; Joshaghani, A. A Comprehensive Experimental Study on the Performance of Pumice Powder in Self-Compacting Concrete (SCC). J. Sustain. Cem. Based Mater. 2018, 7, 340–356. [Google Scholar] [CrossRef]

- Tome, S.; Nana, A.; Tchakouté, H.K.; Temuujin, J.; Rüscher, C.H. Mineralogical Evolution of Raw Materials Transformed to Geopolymer Materials: A Review. Ceram. Int. 2024, 50, 35855–35868. [Google Scholar] [CrossRef]

- Lawrence, P.; Cyr, M.; Ringot, E. Mineral Admixtures in Mortars. Cem. Concr. Res. 2003, 33, 1939–1947. [Google Scholar] [CrossRef]

- Rashad, A.M.; Mosleh, Y.A.; Mokhtar, M.M. Thermal Insulation and Durability of Alkali-Activated Lightweight Slag Mortar Modified with Silica Fume and Fly Ash. Constr. Build. Mater. 2024, 411, 134255. [Google Scholar] [CrossRef]

- Singh, A.; Singh, N. Mechanical Properties of Silica Fume Based Concrete: A Review. Mater. Today Proc. 2024. [Google Scholar] [CrossRef]

- Fattouh, M.S.; Tayeh, B.A.; Agwa, I.S.; Elsayed, E.K. Improvement in the Flexural Behaviour of Road Pavement Slab Concrete Containing Steel Fibre and Silica Fume. Case Stud. Constr. Mater. 2023, 18, e01720. [Google Scholar] [CrossRef]

- Amin, M.; Zeyad, A.M.; Tayeh, B.A.; Saad Agwa, I. Effect of Ferrosilicon and Silica Fume on Mechanical, Durability, and Microstructure Characteristics of Ultra High-Performance Concrete. Constr. Build. Mater. 2022, 320, 126233. [Google Scholar] [CrossRef]

- Abhilash, P.P.; Nayak, D.K.; Sangoju, B.; Kumar, R.; Kumar, V. Effect of Nano-Silica in Concrete; a Review. Constr. Build. Mater. 2021, 278, 122347. [Google Scholar] [CrossRef]

- Mohtasham Moein, M.; Rahmati, K.; Saradar, A.; Moon, J.; Karakouzian, M. A Critical Review Examining the Characteristics of Modified Concretes with Different Nanomaterials. Materials 2024, 17, 409. [Google Scholar] [CrossRef] [PubMed]

- Hamdadou, M.N.; Bignonnet, F.; Deboucha, W.; Ranaivomanana, H.; Leklou, N.; Arroudj, K. Hydration, Mechanical and Transfer Properties of Blended Cement Pastes and Mortars Prepared with Recycled Powder or Limestone Filler. J. Build. Eng. 2023, 78, 107541. [Google Scholar] [CrossRef]

- Radović, A.; Carević, V.; Marinković, S.; Plavšić, J.; Tešić, K. Prediction Model for Calculation of the Limestone Powder Concrete Carbonation Depth. J. Build. Eng. 2024, 86, 108776. [Google Scholar] [CrossRef]

- Her, S.-W.; Yang, K.-H.; Bae, S.-C.; Kwon, S.-J.; Wang, X.-Y. Effect of Particle Size Distribution and Content of Limestone Powder on Compressive Response of High-Early-Strength Cement Mortars. J. Build. Eng. 2024, 97, 110964. [Google Scholar] [CrossRef]

- ASTM C1240-20; Standard Specification for Silica Fume Used in Cementitious Mixtures. American Society for Testing and Materials International: West Conshohocken, PA, USA, 2020.

- TSI TS EN 196-2; Methods of Testing Cement. Part 2: Chemical Analysis of Cement. Turkish Standards Institution: Ankara, Turkey, 2002.

- ASTM C1437-20; Standard Test Method for Flow of Hydraulic Cement Mortar. American Society for Testing and Materials International: West Conshohocken, PA, USA, 2020.

- ASTM C348; Standard Test Method for Flexural Strength of Hydraulic-Cement Mortars. American Society for Testing and Materials International: West Conshohocken, PA, USA, 2008.

- ASTM C349; Standard Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or [50-Mm] Cube Specimens). American Society for Testing and Materials International: West Conshohocken, PA, USA, 2013.

- ASTM C403; Standard Test Method for Time of Setting of Concrete Mixtures by Penetration Resistance. American Society for Testing and Materials International: West Conshohocken, PA, USA, 2008.

- ASTM C187; Standard Test Method for Amount of Water Required for Normal Consistency of Hydraulic Cement Paste. American Society for Testing and Materials International: West Conshohocken, PA, USA, 2011.

- Mather, B.; Ozyildirim, C. SP-1 (02): Concrete Primer; American Concrete Institute: SP0102; American Concrete Institute: Farmington Hills, MI, USA, 2002; Available online: https://www.concrete.org/store (accessed on 8 November 2024).

- Liew, J.Y.R.; Xiong, M.-X.; Lai, B.-L. Design of Steel-Concrete Composite Structures Using High-Strength Materials; Elsevier: Amsterdam, The Netherlands, 2021; ISBN 9780128233962. [Google Scholar]

- Fagerlund, G. Imaginable Effects of Limestone Filler on Chloride Transport; Lund University: Lund, Sweden, 2005. [Google Scholar]

- Dhir, R.K.; Limbachiya, M.C.; McCarthy, M.J.; Chaipanich, A. Evaluation of Portland Limestone Cements for Use in Concrete Construction. Mater. Struct. 2007, 40, 459–473. [Google Scholar] [CrossRef]

- Lin, Y.; Alengaram, U.J.; Ibrahim, Z. Effect of Treated and Untreated Rice Husk Ash, Palm Oil Fuel Ash, and Sugarcane Bagasse Ash on the Mechanical, Durability, and Microstructure Characteristics of Blended Concrete—A Comprehensive Review. J. Build. Eng. 2023, 78, 107500. [Google Scholar] [CrossRef]

- Singh, L.P.; Goel, A.; Bhattachharyya, S.K.; Ahalawat, S.; Sharma, U.; Mishra, G. Effect of Morphology and Dispersibility of Silica Nanoparticles on the Mechanical Behaviour of Cement Mortar. Int. J. Concr. Struct. Mater. 2015, 9, 207–217. [Google Scholar] [CrossRef]

- Franklin, S.O.; Kangootui, F.I. Tensile/Compressive/Flexural Strength Relationships for Concrete Using Kgale Aggregates with Botchem as Binder. Int. J. Sci. Eng. Res. 2020, 11. [Google Scholar]

- Marín-Uribe, C.R.; Navarro-Gaete, R. Empirical Relationships between Compressive and Flexural Strength of Concrete Containing Recycled Asphalt Material for Pavement Applications Using Different Specimen Configurations. Mater. De. Construcción 2021, 71, e249. [Google Scholar] [CrossRef]

- Neville, A.M. Properties of Concrete; Ad Wes Lon Higher ed: West London, UK, 1995. [Google Scholar]

- Ahmed, M.; El Hadi, K.M.; Hasan, M.A.; Mallick, J.; Ahmed, A. Evaluating the Co-Relationship between Concrete Flexural Tensile Strength and Compressive Strength. Int. J. Struct. Eng. 2014, 5, 115–131. [Google Scholar] [CrossRef]

- Popovics, S. Strength and Related Properties of Concrete: A Quantitative Approach; John Wiley & Sons: Hoboken, NJ, USA, 1998. [Google Scholar]

- Ahmed, M.; Mallick, J.; Hasan, M.A. A Study of Factors Affecting the Flexural Tensile Strength of Concrete. J. King Saud. Univ. -Eng. Sci. 2016, 28, 147–156. [Google Scholar] [CrossRef]

- Moropoulou, A.; Bakolas, A.; Moundoulas, P.; Aggelakopoulou, E.; Anagnostopoulou, S. Strength Development and Lime Reaction in Mortars for Repairing Historic Masonries. Cem. Concr. Compos. 2005, 27, 289–294. [Google Scholar] [CrossRef]

- Malathy, R.; Shanmugam, R.; Chung, I.-M.; Kim, S.-H.; Prabakaran, M. Mechanical and Microstructural Properties of Composite Mortars with Lime, Silica Fume and Rice Husk Ash. Processes 2022, 10, 1424. [Google Scholar] [CrossRef]

| Cement | Silica Gel | Silica Fume | Nano-Silica | Micritic Limestone | |

|---|---|---|---|---|---|

| SiO2 | 18.00 | 86.47 | 94.64 | 96.49 | 16.87 |

| Al2O3 | 4.79 | 0.41 | 0.59 | 0.05 | 0.82 |

| Fe2O3 | 3.27 | 0.00 | 0.57 | 0.00 | 0.23 |

| CaO | 63.06 | 0.00 | 0.54 | 0.00 | 43.62 |

| MgO | 3.19 | 0.00 | 0.81 | 0.00 | 2.28 |

| SO3 | 2.79 | 0.02 | 0.00 | 0.01 | 0.46 |

| K2O | 0.55 | 0.03 | 0.97 | 0.04 | 0.21 |

| Na2O | 0.39 | 0.20 | 0.39 | 0.06 | 0.06 |

| Ignition loss | 2.83 | 14.09 | 1.74 | 1.98 | 35.52 |

| MIX | SiO2 (%) | Al2O3 (%) | Fe2O3 (%) | CaO (%) | MgO (%) | SO3 (%) | K2O (%) | Na2O (%) | Other Components (%) | Ignition Loss (%) | Blaine (cm2/g) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| MCEM | 18 | 4.79 | 3.27 | 63.06 | 3.19 | 2.79 | 0.55 | 0.39 | 0.94 | 3.02 | 3380 |

| MCEMSG1 | 19 | 4.63 | 3.21 | 61.95 | 3.11 | 2.66 | 0.54 | 0.38 | 1.36 | 3.16 | 3400 |

| MCEMSG2 | 20 | 4.64 | 3.19 | 61.55 | 3.11 | 2.74 | 0.51 | 0.33 | 0.8 | 3.13 | 3530 |

| MCEMSG3 | 20.9 | 4.57 | 3.19 | 60.85 | 3.04 | 2.73 | 0.52 | 0.36 | 0.63 | 3.21 | 3560 |

| MCEMSG4 | 21.7 | 4.56 | 3.16 | 60.71 | 3.05 | 2.64 | 0.51 | 0.41 | 0.04 | 3.22 | 3650 |

| MCEMSG5 | 22.25 | 4.49 | 3.11 | 59.51 | 3 | 2.66 | 0.51 | 0.37 | 0.83 | 3.27 | 3710 |

| MCEMSG6 | 23.33 | 4.44 | 3.09 | 59.05 | 2.97 | 2.63 | 0.5 | 0.38 | 0.12 | 3.49 | 3781 |

| MCEMSG7 | 24.2 | 4.38 | 3.07 | 58.32 | 2.93 | 2.61 | 0.49 | 0.38 | 0.03 | 3.59 | 3851 |

| MCEMSG8 | 24.96 | 4.33 | 3.04 | 57.69 | 2.89 | 2.59 | 0.48 | 0.38 | 0.05 | 3.59 | 3920 |

| MCEMSG9 | 25.9 | 4.28 | 3.01 | 56.95 | 2.85 | 2.56 | 0.47 | 0.38 | 0.01 | 3.59 | 3990 |

| MCEMSG10 | 26.59 | 4.23 | 2.98 | 56.12 | 2.73 | 2.51 | 0.46 | 0.39 | 0.1 | 3.89 | 4059 |

| MCEMSF1 | 19.82 | 4.72 | 3.23 | 62.08 | 3.16 | 2.78 | 0.56 | 0.42 | 0.36 | 2.87 | 3640 |

| MCEMSF2 | 20.21 | 4.64 | 3.23 | 61.84 | 3.15 | 2.69 | 0.55 | 0.4 | 0.46 | 2.83 | 3840 |

| MCEMSF3 | 20.39 | 4.63 | 3.23 | 61.75 | 3.12 | 2.68 | 0.56 | 0.39 | 0.5 | 2.75 | 4050 |

| MCEMSF4 | 21.89 | 4.62 | 3.19 | 60.33 | 3.08 | 2.71 | 0.57 | 0.42 | 0.44 | 2.75 | 4310 |

| MCEMSF5 | 22.72 | 4.54 | 3.17 | 60.03 | 3.07 | 2.65 | 0.55 | 0.39 | 0.04 | 2.84 | 4460 |

| MCEMSF6 | 23.25 | 4.52 | 3.16 | 59.16 | 3.04 | 2.63 | 0.56 | 0.39 | 0.52 | 2.77 | 4693 |

| MCEMSF7 | 24 | 4.48 | 3.15 | 59.04 | 3.02 | 2.6 | 0.56 | 0.39 | 0.01 | 2.75 | 4904 |

| MCEMSF8 | 24.75 | 4.44 | 3.13 | 58.12 | 2.99 | 2.58 | 0.56 | 0.38 | 0.31 | 2.74 | 5115 |

| MCEMSF9 | 25.19 | 4.4 | 3.11 | 58.02 | 2.97 | 2.56 | 0.56 | 0.38 | 0.09 | 2.72 | 5326 |

| MCEMSF10 | 26.21 | 4.36 | 3.1 | 57.18 | 2.94 | 2.53 | 0.56 | 0.38 | 0.03 | 2.71 | 5537 |

| MCEMNS1 | 19.14 | 4.68 | 3.25 | 62.77 | 3.16 | 2.71 | 0.53 | 0.39 | 0.51 | 2.86 | 3140 |

| MCEMNS2 | 21.16 | 4.57 | 3.19 | 60.98 | 3.07 | 2.74 | 0.53 | 0.38 | 0.56 | 2.82 | 3640 |

| MCEMNS3 | 22.51 | 4.5 | 3.12 | 59.93 | 3.03 | 3.18 | 0.51 | 0.31 | 0.02 | 2.89 | 4990 |

| MCEMNS4 | 23.82 | 4.46 | 3.09 | 59.11 | 2.99 | 2.57 | 0.47 | 0.3 | 0.36 | 2.83 | 4890 |

| MCEMNS5 | 26.71 | 4.31 | 2.95 | 56.74 | 2.83 | 2.53 | 0.46 | 0.31 | 0.36 | 2.8 | 5110 |

| MCEMMLS1 | 18.74 | 4.76 | 3.25 | 63.1 | 3.17 | 2.7 | 0.55 | 0.38 | 0.21 | 3.14 | 3370 |

| MCEMMLS2 | 18.66 | 4.68 | 3.19 | 62.65 | 3.16 | 2.7 | 0.54 | 0.41 | 0.5 | 3.51 | 3460 |

| MCEMMLS3 | 18.71 | 4.67 | 3.2 | 62.39 | 3.18 | 2.76 | 0.53 | 0.36 | 0.35 | 3.85 | 3460 |

| MCEMMLS4 | 18.44 | 4.57 | 3.15 | 61.98 | 3.1 | 2.72 | 0.52 | 0.34 | 0.98 | 4.2 | 3490 |

| MCEMMLS5 | 18.55 | 4.55 | 3.14 | 61.96 | 3.13 | 2.73 | 0.53 | 0.35 | 0.51 | 4.55 | 3580 |

| MCEMMLS6 | 18.44 | 4.49 | 3.11 | 61.53 | 3.11 | 2.75 | 0.52 | 0.33 | 0.82 | 4.9 | 3607 |

| MCEMMLS7 | 18.38 | 4.43 | 3.08 | 61.24 | 3.09 | 2.75 | 0.51 | 0.32 | 0.95 | 5.25 | 3652 |

| MCEMMLS8 | 18.32 | 4.38 | 3.06 | 60.94 | 3.08 | 2.76 | 0.5 | 0.3 | 1.05 | 5.61 | 3697 |

| MCEMMLS9 | 18.26 | 4.33 | 3.03 | 60.65 | 3.06 | 2.77 | 0.5 | 0.29 | 1.15 | 5.96 | 3742 |

| MCEMMLS10 | 18.2 | 4.28 | 3 | 60.35 | 3.05 | 2.78 | 0.49 | 0.28 | 1.26 | 6.31 | 3787 |

| MIX | Substitution Ratio (%) | Cement | Silica Gel | Silica Fume | Nano-Silica | Micritic Limestone | Water |

|---|---|---|---|---|---|---|---|

| MCEM | 0 | 500 | 0 | 0 | 0 | 0 | 135 |

| MCEMSG1 | 1 | 495 | 5 | 0 | 0 | 0 | 135 |

| MCEMSG2 | 2 | 490 | 10 | 0 | 0 | 0 | 140 |

| MCEMSG3 | 3 | 485 | 15 | 0 | 0 | 0 | 140 |

| MCEMSG4 | 4 | 480 | 20 | 0 | 0 | 0 | 140 |

| MCEMSG5 | 5 | 475 | 25 | 0 | 0 | 0 | 140 |

| MCEMSG6 | 6 | 470 | 30 | 0 | 0 | 0 | 143 |

| MCEMSG7 | 7 | 465 | 35 | 0 | 0 | 0 | 144 |

| MCEMSG8 | 8 | 460 | 40 | 0 | 0 | 0 | 145 |

| MCEMSG9 | 9 | 455 | 45 | 0 | 0 | 0 | 146 |

| MCEMSG10 | 10 | 450 | 50 | 0 | 0 | 0 | 147 |

| MCEMSF1 | 1 | 495 | 0 | 5 | 0 | 0 | 137 |

| MCEMSF2 | 2 | 490 | 0 | 10 | 0 | 0 | 136 |

| MCEMSF3 | 3 | 485 | 0 | 15 | 0 | 0 | 135 |

| MCEMSF4 | 4 | 480 | 0 | 20 | 0 | 0 | 134 |

| MCEMSF5 | 5 | 475 | 0 | 25 | 0 | 0 | 133 |

| MCEMSF6 | 6 | 470 | 0 | 30 | 0 | 0 | 133 |

| MCEMSF7 | 7 | 465 | 0 | 35 | 0 | 0 | 133 |

| MCEMSF8 | 8 | 460 | 0 | 40 | 0 | 0 | 135 |

| MCEMSF9 | 9 | 455 | 0 | 45 | 0 | 0 | 139 |

| MCEMSF10 | 10 | 450 | 0 | 50 | 0 | 0 | 145 |

| MCEMNS1 | 1 | 495 | 0 | 0 | 5 | 0 | 178 |

| MCEMNS2 | 2 | 490 | 0 | 0 | 10 | 0 | 186 |

| MCEMNS3 | 3 | 485 | 0 | 0 | 15 | 0 | 188 |

| MCEMNS4 | 4 | 480 | 0 | 0 | 20 | 0 | 187 |

| MCEMNS5 | 5 | 475 | 0 | 0 | 25 | 0 | 187 |

| MCEMMLS1 | 1 | 495 | 0 | 0 | 0 | 5 | 136 |

| MCEMMLS2 | 2 | 490 | 0 | 0 | 0 | 10 | 135 |

| MCEMMLS3 | 3 | 485 | 0 | 0 | 0 | 15 | 134 |

| MCEMMLS4 | 4 | 480 | 0 | 0 | 0 | 20 | 133 |

| MCEMMLS5 | 5 | 475 | 0 | 0 | 0 | 25 | 133 |

| MCEMMLS6 | 6 | 470 | 0 | 0 | 0 | 30 | 132 |

| MCEMMLS7 | 7 | 465 | 0 | 0 | 0 | 35 | 131 |

| MCEMMLS8 | 8 | 460 | 0 | 0 | 0 | 40 | 130 |

| MCEMMLS9 | 9 | 455 | 0 | 0 | 0 | 45 | 130 |

| MCEMMLS10 | 10 | 450 | 0 | 0 | 0 | 50 | 129 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hansu, O. Considering the Effect of Various Silica Types on Chemical, Physical and Mechanical Properties in Cement Mortar Production via Substitution with Cement Content. Buildings 2025, 15, 74. https://doi.org/10.3390/buildings15010074

Hansu O. Considering the Effect of Various Silica Types on Chemical, Physical and Mechanical Properties in Cement Mortar Production via Substitution with Cement Content. Buildings. 2025; 15(1):74. https://doi.org/10.3390/buildings15010074

Chicago/Turabian StyleHansu, Osman. 2025. "Considering the Effect of Various Silica Types on Chemical, Physical and Mechanical Properties in Cement Mortar Production via Substitution with Cement Content" Buildings 15, no. 1: 74. https://doi.org/10.3390/buildings15010074

APA StyleHansu, O. (2025). Considering the Effect of Various Silica Types on Chemical, Physical and Mechanical Properties in Cement Mortar Production via Substitution with Cement Content. Buildings, 15(1), 74. https://doi.org/10.3390/buildings15010074