Bayesian Inference and Condition Assessment Based on the Deflection of Aging Reinforced Concrete Hollow Slab Bridges

Abstract

1. Introduction

2. Materials and Methods

2.1. Stochastic Field of the Damage States of Hollow Slab Bridge

2.2. Bayesian Inference Considering the Stochastic Field of the Damage States of Hollow Slab Bridge

2.3. Kriging Surrogate of the FEM

2.3.1. Formulation of the Kriging Surrogate

2.3.2. Selection of DOEs

- (i)

- Divide the interval [0, 1] into N equal-length intervals;

- (ii)

- Assuming a variable U that follows a uniform distribution over the range [0, 1]. Draw a sample from U, and map this sample to the inverse of the cumulative distribution function (CDF) of the standard Gauss distribution. The sample in the n-th interval is derived as the following:

2.4. MCMC Sampler for the Posterior Distribution

3. Case Study

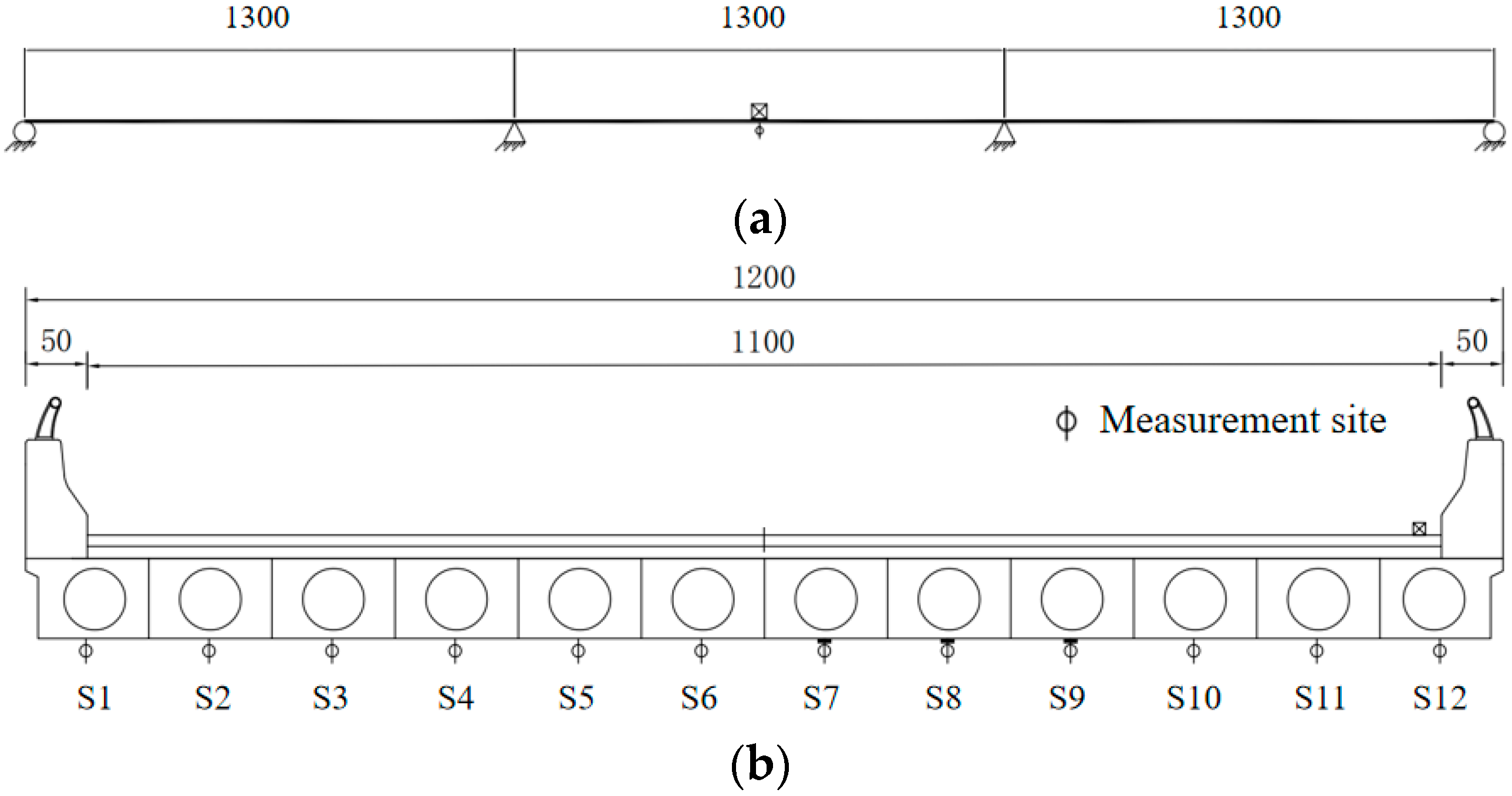

3.1. Case Description

3.2. Model Setup

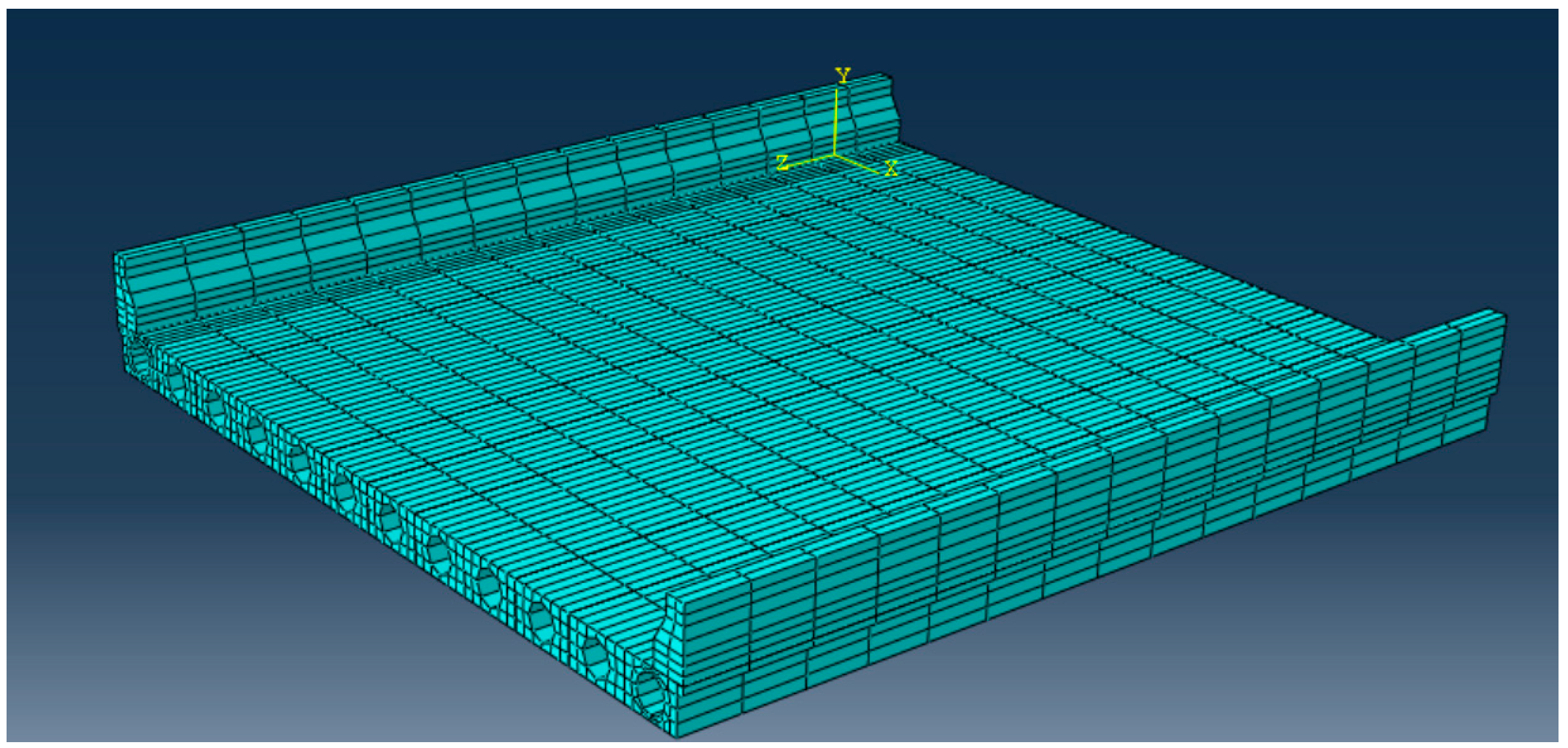

3.2.1. The FEM to Compute the Bridge Deflection

3.2.2. Kriging Surrogate of the FEM

3.2.3. Model Parameters for the MCMC Sampler

3.3. Results and Discussion

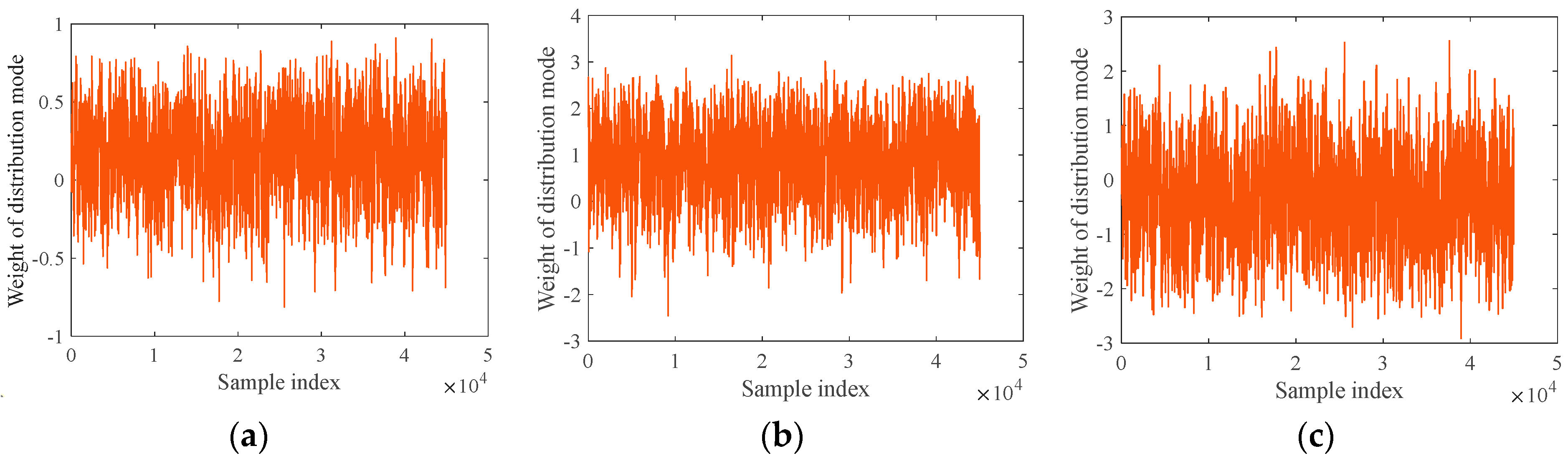

3.3.1. Inference Results of the Weights of Damage Distribution Modes

3.3.2. Inference Results of the Damage States

4. Conclusions

- The structural rigidity ratio of the aging RC bridge is modeled as a stochastic field along the hollow RC slabs using the KL transform, and the weights of the distribution modes of structural rigidity were used as the model parameters subject to Bayes inference, which can capture the spatial correlation and variation of the structural rigidity.

- The structural rigidity ratio of the aging RC bridge was updated based on the Bayesian inference using the deflection measured during a static loading test. The Bayesian inference leverages the information from a FEM that computes the deflection of the bridge, and a Kriging surrogate model of the FEM was constructed to improve the computation efficiency. The posterior distribution of the structural rigidity ratio was derived by an MCMC sampler, and the drawn samples were used to approximate the statistics of the posterior distributions.

- The proposed method was applied on a RC case bridge with hollow slabs, based on two sets of deflection measurements before and after the reinforcement of the case bridge. The Bayes updates using the deflection measurements suggest higher structural rigidity ratios among the hollow slabs after the reinforcement, which quantitatively justifies the effectiveness of the reinforcement. The deflection calculated by the updated models can well match deflection measurements, with the 95% CBs of deflection including most of the measurements, which justifies the validity and robustness of the proposed method.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ministry of Transport of the People’s Republic of China. Annual Report on China’s Roadway Network; Ministry of Transport of the People’s Republic of China: Beijing, China, 2023.

- Pimentel, M.; Garcez, C. Challenges in the maintenance of concrete bridges. J. Civ. Eng. Manag. 2018, 24, 125–136. [Google Scholar]

- Bian, L.; Wang, G.; Liu, P. Reliability analysis for multi-component systems with interdependent competing failure processes. Appl. Math. Model. 2021, 90, 543–556. [Google Scholar] [CrossRef]

- Yang, Y.; Wang, H.; Sangwongwanich, A. Design for reliability of power electronic systems. Power Electron. 2018, 12, 130–141. [Google Scholar] [CrossRef]

- Alaswad, S.; Xiang, Y. A review on condition-based maintenance optimization models for stochastically deteriorating systems. Reliab. Eng. Syst. Saf. 2017, 159, 399–414. [Google Scholar] [CrossRef]

- Zhai, W.; Han, Z.; Chen, Z.; Ling, L.; Zhu, S. Train–track–bridge dynamic interaction: A state-of-the-art review. Veh. Syst. Dyn. 2019, 57, 1139–1176. [Google Scholar] [CrossRef]

- Sun, L.; Shang, Z.; Xia, Y.; Bhowmick, S. Review of bridge structural health monitoring aided by big data and artificial intelligence: From condition assessment to damage detection. J. Struct. Eng. 2020, 146, 04020144. [Google Scholar] [CrossRef]

- Wang, L.; Wang, X.; Su, H.; Lin, G. Reliability estimation of fatigue crack growth prediction via limited measured data. Int. J. Mech. Sci. 2017, 131–132, 1065–1078. [Google Scholar] [CrossRef]

- Tidriri, K.; Chatti, N.; Verron, S.; Tiplica, T. Bridging data-driven and model-based approaches for process fault diagnosis and health monitoring: A review of researches and future challenges. Annu. Rev. Control 2016, 42, 63–81. [Google Scholar] [CrossRef]

- Melchers, R.E.; Beck, A.T. Structural reliability analysis and prediction. J. Struct. Saf. 2018, 9, 210–221. [Google Scholar] [CrossRef]

- Li, W.; Liu, Y. A new method for the fatigue life prediction of bridge structures. J. Bridge Eng. 2018, 23, 04518013. [Google Scholar] [CrossRef]

- Guan, H.; Zhong, J.; Bai, L. Reliability assessment of large-span bridge structures under multi-hazard conditions. Struct. Infrastruct. Eng. 2020, 16, 128–143. [Google Scholar]

- Gunawan, F.E. A new damage indicator in time and frequency domains for structural health monitoring: The case of beam with a breathing crack. Int. J. Innov. Comput. Inf. Control 2020, 16, 507–519. [Google Scholar]

- Boscato, G.; Fragonara, L.Z.; Cecchi, A.; Reccia, E. Structural health monitoring through vibration-based approaches. Shock Vib. 2019, 2019, 2380616. [Google Scholar] [CrossRef]

- Peng, X.; Yang, Q.; Qin, F.; Sun, B. Structural Damage Detection Based on Static and Dynamic Flexibility: A Review and Comparative Study. Coatings 2023, 14, 31. [Google Scholar] [CrossRef]

- Wang, F.; Li, R.; Xiao, Y.; Deng, Q.; Li, X.; Song, X. A strain modal flexibility method to multiple slight damage localization combined with a data fusion technique. Measurement 2021, 178, 109442. [Google Scholar] [CrossRef]

- Gharehbaghi, V.R.; Noroozinejad Farsangi, E. A critical review on structural health monitoring: Definitions, methods, and perspectives. Arch. Comput. Methods Eng. 2022, 29, 1687–1715. [Google Scholar] [CrossRef]

- Ali, J.; Bandyopadhyay, D. Condition monitoring of structures using limited noisy data modal slope and curvature of mode shapes. Int. J. Struct. Integr. 2020, 11, 309–321. [Google Scholar] [CrossRef]

- Zhang, J.; Li, A.; Wang, T. Monitoring of deflections in bridges: A review. J. Bridge Eng. 2013, 18, 321–330. [Google Scholar] [CrossRef]

- Brownjohn, J.M.W. Structural health monitoring of civil infrastructure. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2007, 365, 589–622. [Google Scholar] [CrossRef]

- Cross, E.J.; Worden, K.; Farrar, C.R. Structural health monitoring for civil infrastructure. Annu. Rev. Civil Eng. 2013, 5, 429–462. [Google Scholar] [CrossRef]

- Peeters, B.; De Roeck, G. One-year monitoring of the Z24-Bridge: Environmental effects versus damage events. Earthquake Eng. Struct. Dyn. 2001, 30, 149–171. [Google Scholar] [CrossRef]

- Hedegaard, C.M.; Schmidt, J.W.; Ravn, J.D. Structural health monitoring of the Great Belt Bridge. Bridge Struct. 2015, 11, 124–133. [Google Scholar]

- Yan, A.M.; Kerschen, G.; De Boe, P.; Golinval, J.C. Structural damage diagnosis under varying environmental conditions—Part I: A linear analysis. Mech. Syst. Signal Process. 2005, 19, 847–864. [Google Scholar] [CrossRef]

- Sanayei, M.; Samaan, M.; Morgan, R.Q.; Brenner, B.R. Damage localization and finite-element model updating using multi-response NDT data. J. Bridge Eng. 2001, 6, 238–247. [Google Scholar] [CrossRef]

- Sanayei, M.; Samaan, M.; Morgan, R.Q.; Brenner, B.R. Analysis and identification of structural stiffness from displacement measurements. J. Struct. Eng. 1997, 123, 1148–1155. [Google Scholar]

- Sanayei, M.; Douglas, B.S.; Burke, J.C. Structural model updating using experimental static measurements. J. Struct. Eng. 1991, 117, 1993–2008. [Google Scholar] [CrossRef]

- Sanayei, M.; White, T.L.; Charnis, D.J. Stiffness calibration of truss model for supporting structure of large radio antennas. J. Aerosp. Eng. 1999, 12, 24–34. [Google Scholar]

- Sanayei, M.; Bell, E.S. Structural model updating using deflection data from static tests. J. Bridge Eng. 2004, 9, 391–398. [Google Scholar] [CrossRef]

- Banan, M.R.; Hjelmstad, K.D. Parameter estimation of structures from static response. I. Computational aspects. J. Struct. Eng. 1994, 120, 3243–3258. [Google Scholar] [CrossRef]

- Banan, M.R.; Hjelmstad, K.D. Parameter estimation of structures from static response. II. Numerical simulation studies. J. Struct. Eng. 1994, 120, 3259–3283. [Google Scholar] [CrossRef]

- Beck, J.L.; Katafygiotis, L.S. Updating models and their uncertainties. I: Bayesian statistical framework. J. Eng. Mech. 1998, 124, 455–461. [Google Scholar] [CrossRef]

- Beck, J.L.; Katafygiotis, L.S. Updating models and their uncertainties. II: Model identifiability. J. Eng. Mech. 1998, 124, 463–467. [Google Scholar] [CrossRef]

- Nettis, A.; Nettis, A.; Ruggieri, S.; Uva, G. Corrosion-induced fragility of existing prestressed concrete girder bridges under traffic loads. Eng. Struct. 2024, 314, 118302. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhang, Q.; Karbhari, V.M. Applications of the Karhunen–Loève transform for health monitoring of bridge systems. Smart Mater. Struct. 2006, 15, 131–139. [Google Scholar] [CrossRef]

- Han, B.; Xiang, T.Y.; Xie, H.B. A Bayesian inference framework for predicting the long-term deflection of concrete structures caused by creep and shrinkage. Eng. Struct. 2017, 142, 46–55. [Google Scholar] [CrossRef]

- Sun, L.; Mahadevan, S. Reliability assessment of structural systems using Kriging-based models. Struct. Saf. 2007, 29, 97–112. [Google Scholar]

- Santner, T.; Williams, B.; Notz, W. The Design and Analysis of Computer Experiments; Springer: New York, NY, USA, 2003. [Google Scholar]

- Iman, R.L.; Helton, J.C.; Campbell, J.E. An Approach to Sensitivity Analysis of Computer Models: Part I—Introduction, Input Variable Selection and Preliminary Variable Assessment. J. Qual. Technol. 1981, 13, 174–183. [Google Scholar] [CrossRef]

- Beck, J.L.; Au, S.K. Bayesian updating of structural models and reliability using Markov chain Monte Carlo simulation. J. Eng. Mech. 2002, 128, 380–391. [Google Scholar] [CrossRef]

- Chib, S.; Greenberg, E. Understanding the Metropolis-Hastings Algorithm. Am. Stat. 1995, 49, 327–335. [Google Scholar] [CrossRef]

| Axial Weight (t) | Distance (cm) | ||||

|---|---|---|---|---|---|

| Axe 1 | Axe 2 | Axe 3 | A | B | C |

| 6.24 | 12.24 | 11.88 | 445 | 140 | 185 |

| |||||

| Variables | θ1 | θ2 | θ3 | θ4 | θ5 | θ6 | θ7 | θ8 | θ9 | θ10 | θ11 | θ12 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Before Reinforcement | Mean | −0.081 | −0.091 | 0.035 | 0.055 | −0.045 | −0.067 | −0.105 | −0.089 | −0.033 | 0.023 | 0.059 | 0.006 |

| Stdev | 1.006 | 0.980 | 0.974 | 1.016 | 0.987 | 0.959 | 0.986 | 1.065 | 0.987 | 0.974 | 0.991 | 0.302 | |

| Before Reinforcement | Mean | 0.184 | −0.158 | 0.155 | −0.119 | −0.194 | −0.169 | −0.205 | −0.417 | −0.363 | −0.365 | 0.873 | 0.167 |

| Stdev | 0.960 | 0.963 | 0.954 | 0.979 | 0.973 | 0.953 | 0.951 | 0.937 | 0.949 | 0.820 | 0.755 | 0.258 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, X.; Jia, S.; Jia, S.; Gao, J.; Peng, J. Bayesian Inference and Condition Assessment Based on the Deflection of Aging Reinforced Concrete Hollow Slab Bridges. Buildings 2024, 14, 2920. https://doi.org/10.3390/buildings14092920

Yan X, Jia S, Jia S, Gao J, Peng J. Bayesian Inference and Condition Assessment Based on the Deflection of Aging Reinforced Concrete Hollow Slab Bridges. Buildings. 2024; 14(9):2920. https://doi.org/10.3390/buildings14092920

Chicago/Turabian StyleYan, Xuliang, Siyi Jia, Shuyang Jia, Jian Gao, and Jiayu Peng. 2024. "Bayesian Inference and Condition Assessment Based on the Deflection of Aging Reinforced Concrete Hollow Slab Bridges" Buildings 14, no. 9: 2920. https://doi.org/10.3390/buildings14092920

APA StyleYan, X., Jia, S., Jia, S., Gao, J., & Peng, J. (2024). Bayesian Inference and Condition Assessment Based on the Deflection of Aging Reinforced Concrete Hollow Slab Bridges. Buildings, 14(9), 2920. https://doi.org/10.3390/buildings14092920