The Effect of RHA as a Supplementary Cementitious Material on the Performance of PCM Aggregate Concrete

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

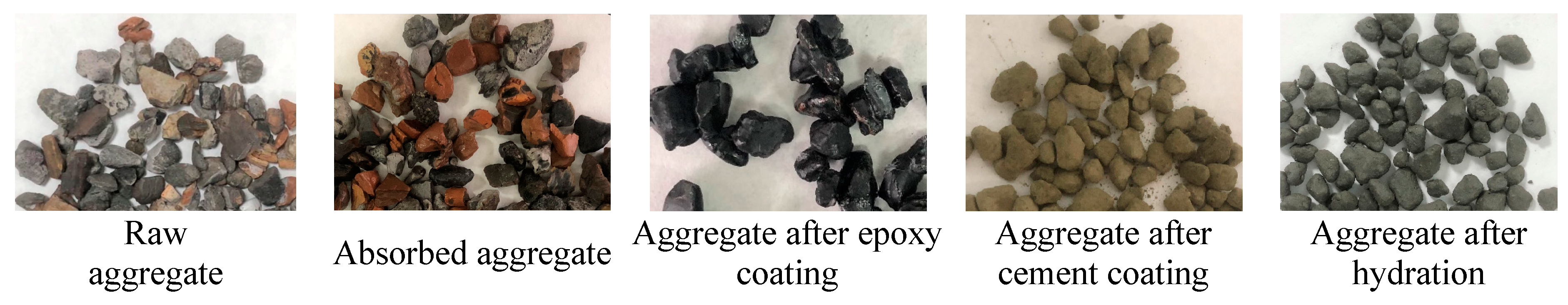

2.2. Preparation of Concrete

- (1)

- Cement, RHA, FA, and sand were placed into a mixer and thoroughly mixed for 60 s.

- (2)

- Then 50% water and superplasticizer were poured and mixed for 120 s.

- (3)

- The remaining 50% water and PCM aggregate were mixed for 120 s.

- (4)

- The concrete specimens were placed into the mold and compacted by vibration. After 1 day, these specimens were demolded and placed in a curing room.

2.3. Test Techniques

3. Results and Discussion

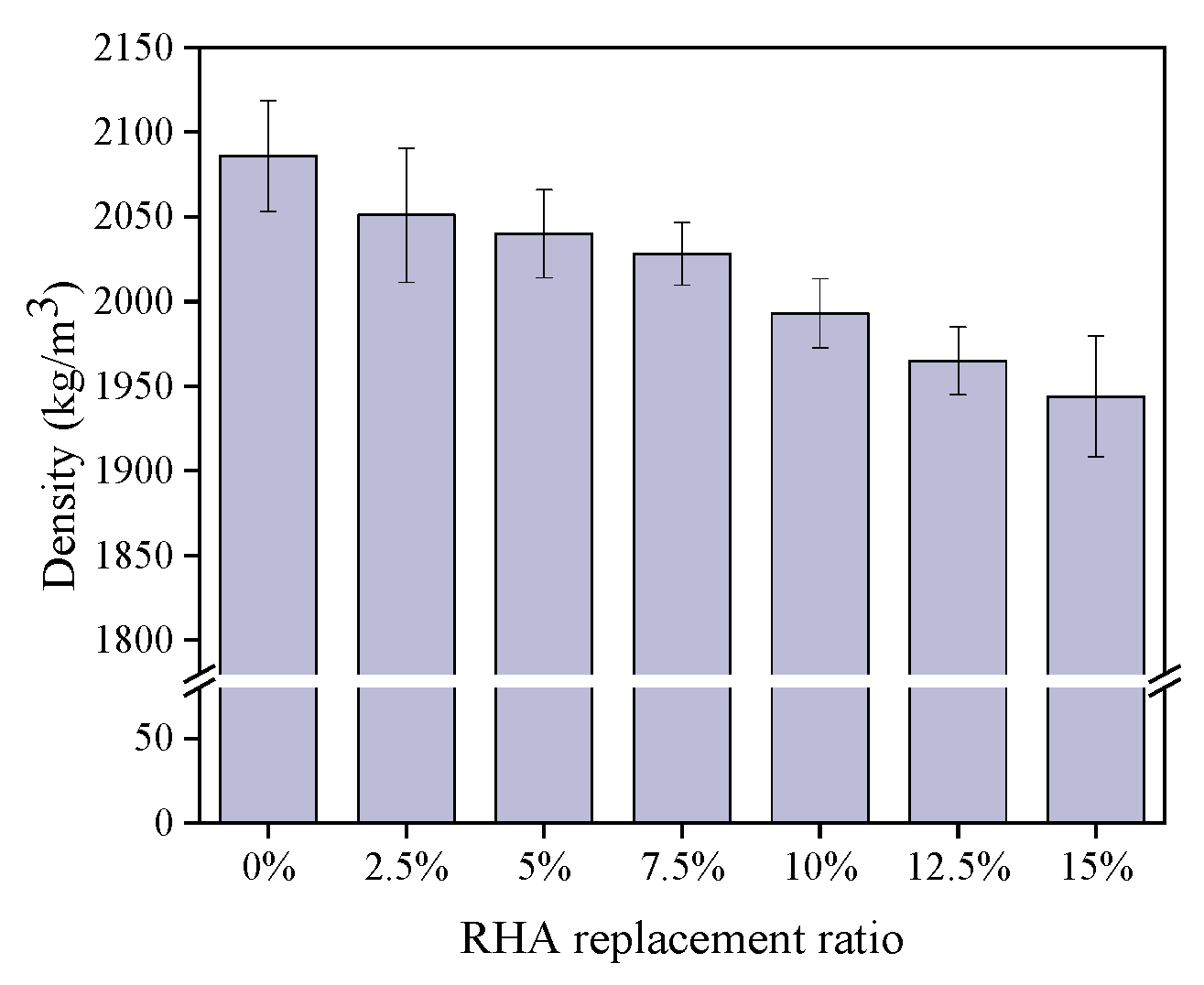

3.1. Density

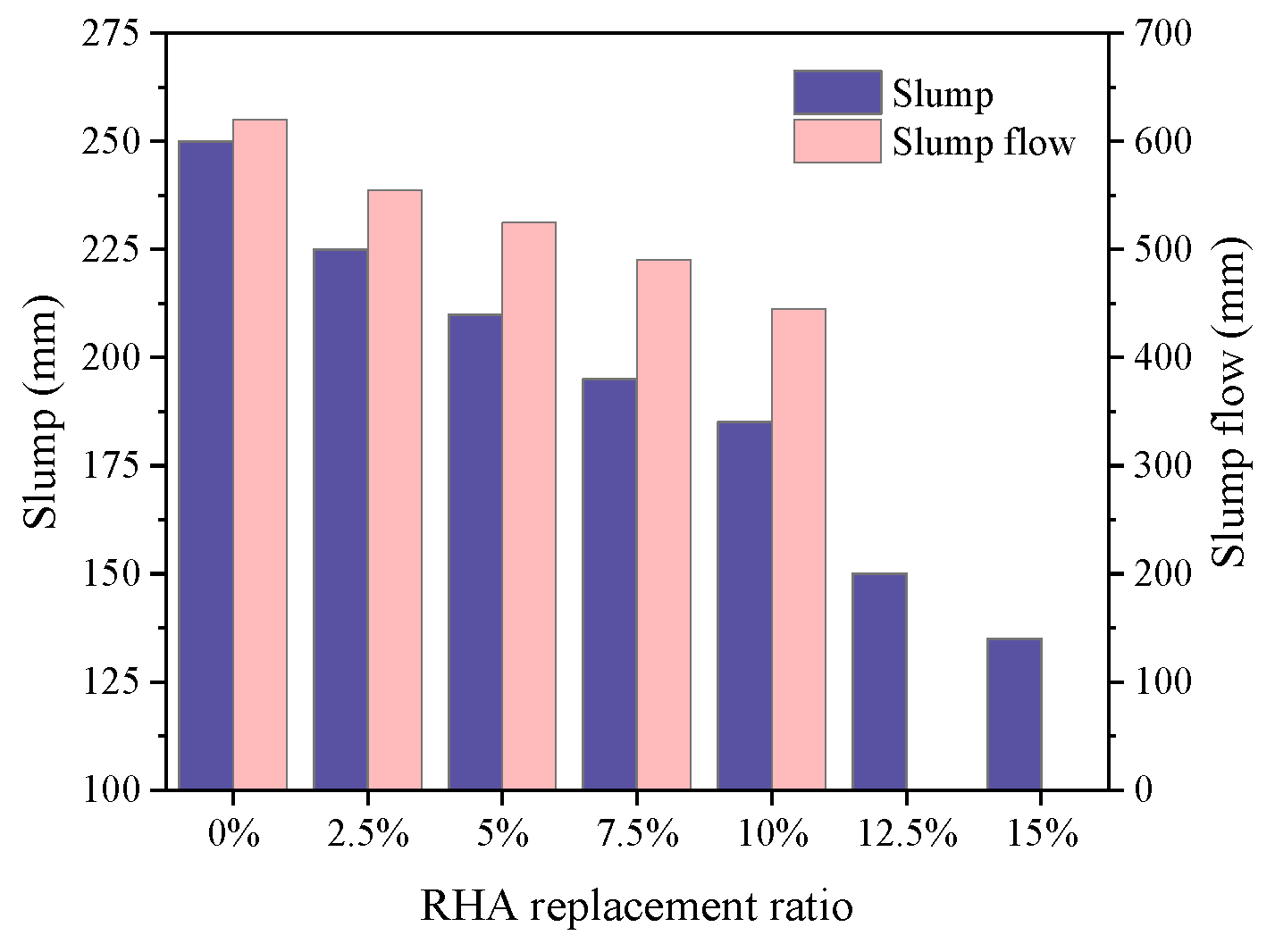

3.2. Fluidity

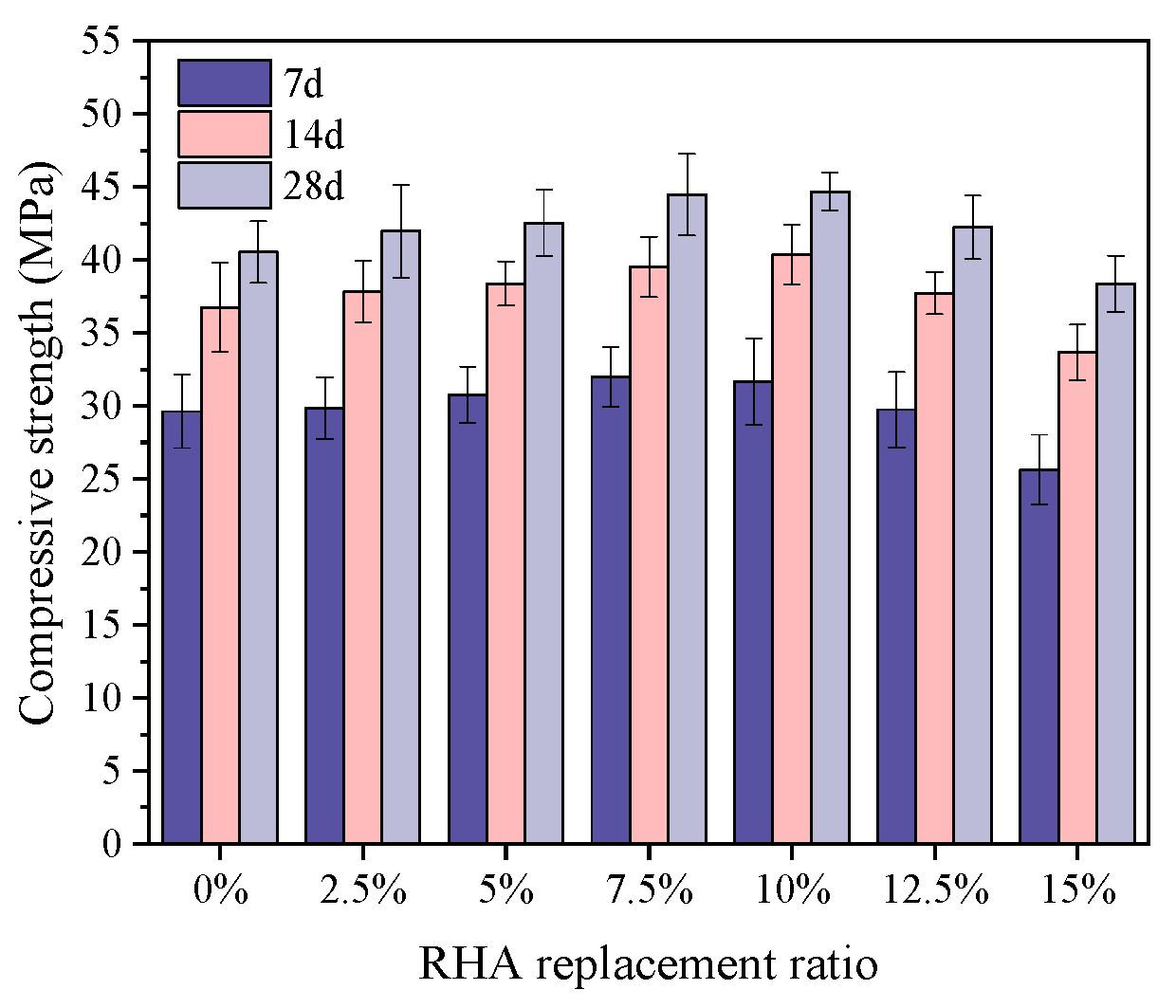

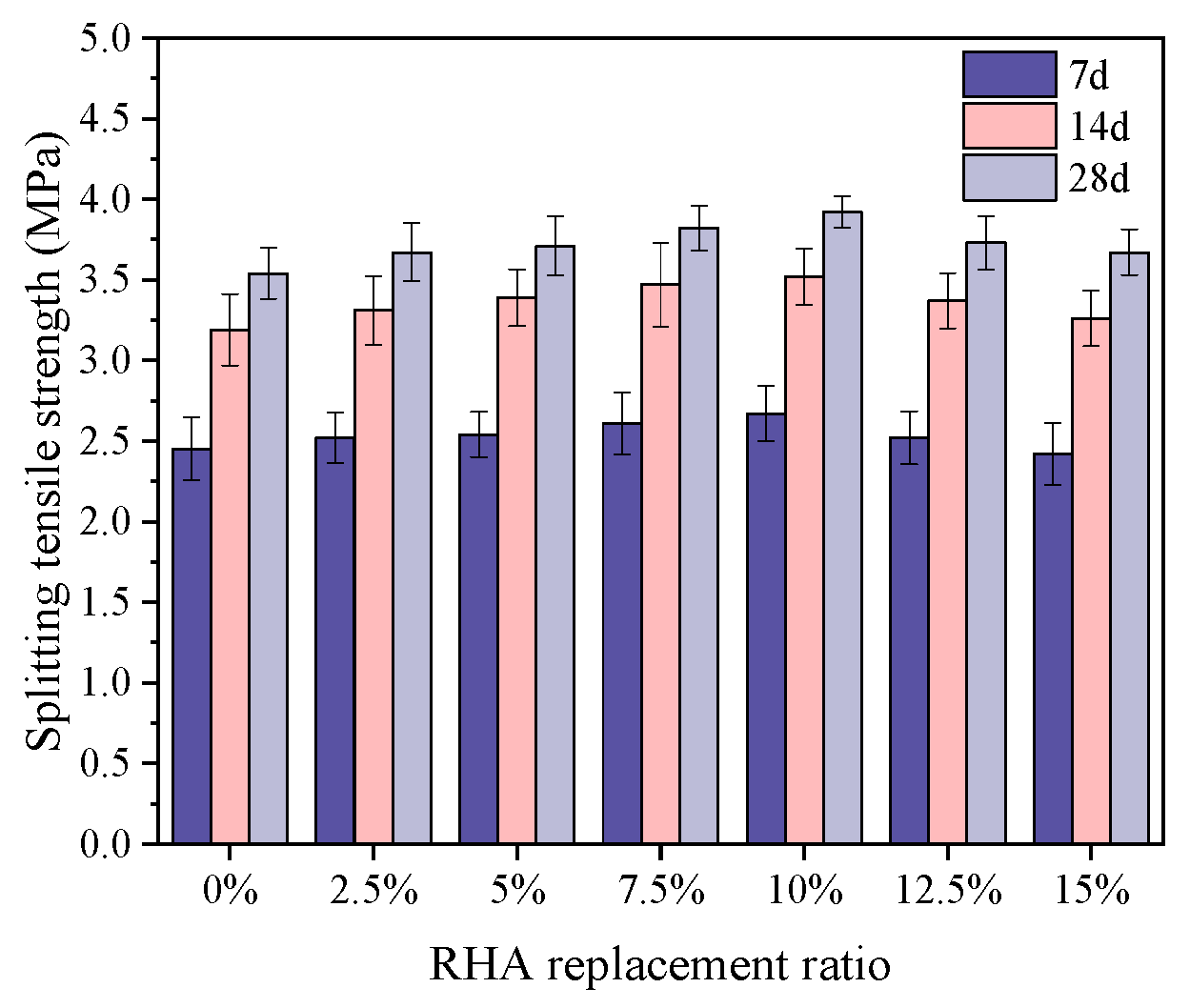

3.3. Compressive Strength

3.4. Thermal Conductivity

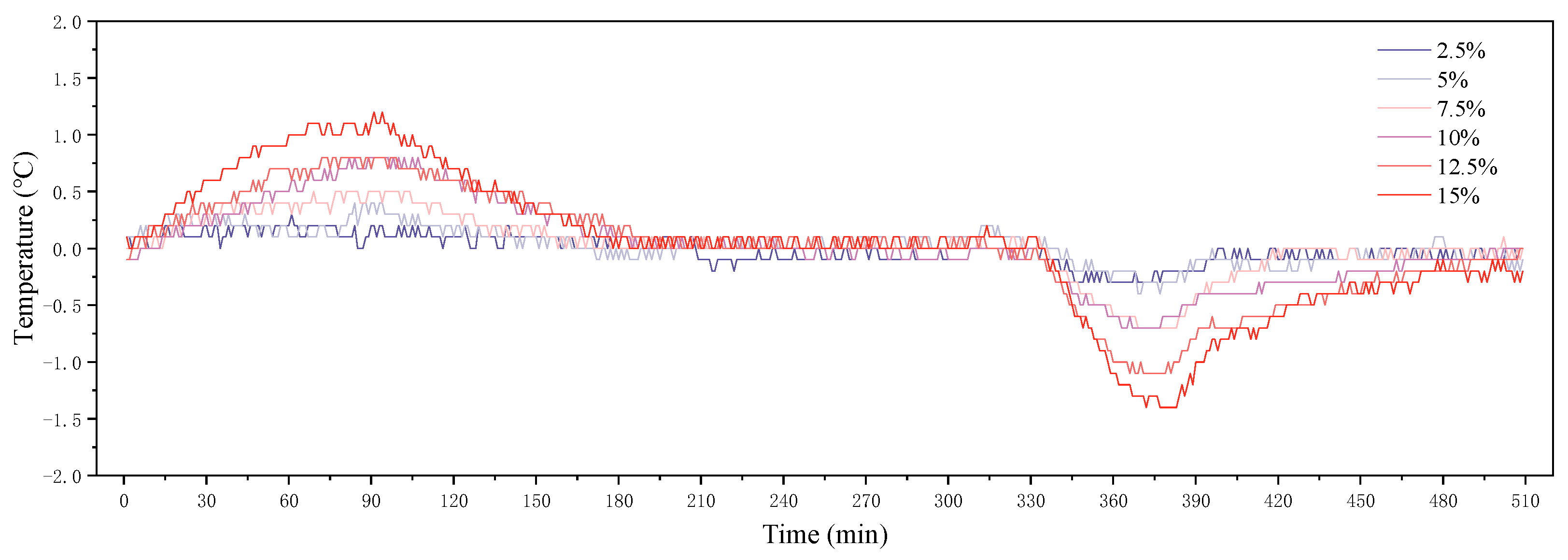

3.5. Time–Temperature Curve

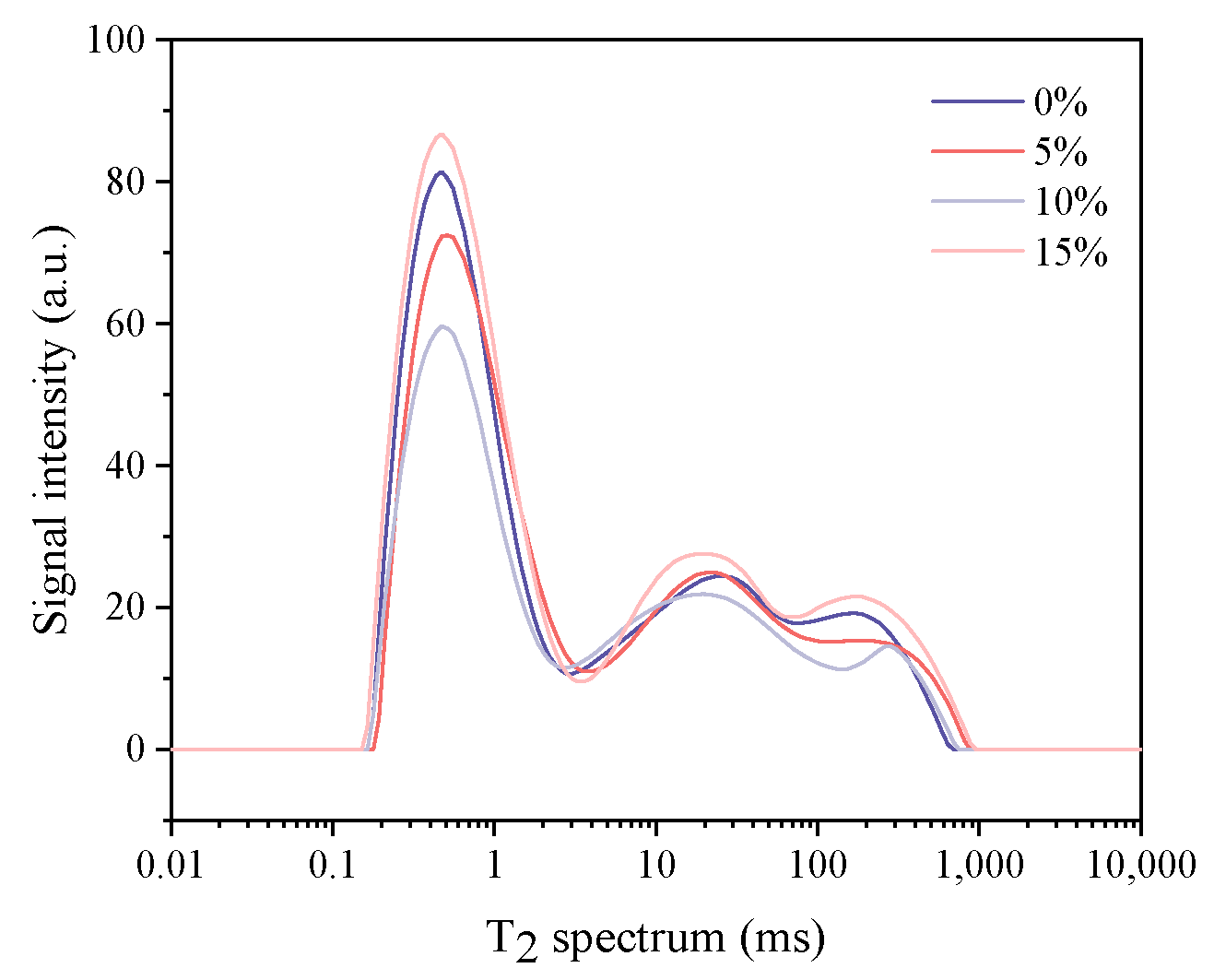

3.6. Nuclear Magnetic Resonance

4. Conclusions

- Since the density of RHA is lower than that of cement, the density of concrete decreases with an increase in the amount of RHA replacement. The high porosity and specific surface area of RHA cause a decrease in the workability of the concrete. Additionally, the slump flow of the concrete disappears with the addition of 15% RHA.

- RHA exhibits pozzolanic activity and has a different particle size compared to cement particles. Consequently, the strength of concrete initially increases and then decreases with an increase in RHA substitution content. The strength increase is due to the filling effect and pozzolanic effect of RHA. When 10% RHA replaces cement in concrete, it exhibits the highest mechanical properties. However, beyond this percentage, the strength decreases.

- The incorporation of RHA reduces the thermal conductivity of concrete, which helps improve the temperature damping of concrete. The decrease in thermal conductivity suggests that incorporating RHA is effective in increasing the thermal insulation properties of the cement matrix. The time–temperature curves at ambient temperature conditions show that adding more RHA during the cooling stage helps to slow down the temperature drop of the concrete; the maximum temperature difference can reach 1.2 °C and also delay the time to reach the peak temperature.

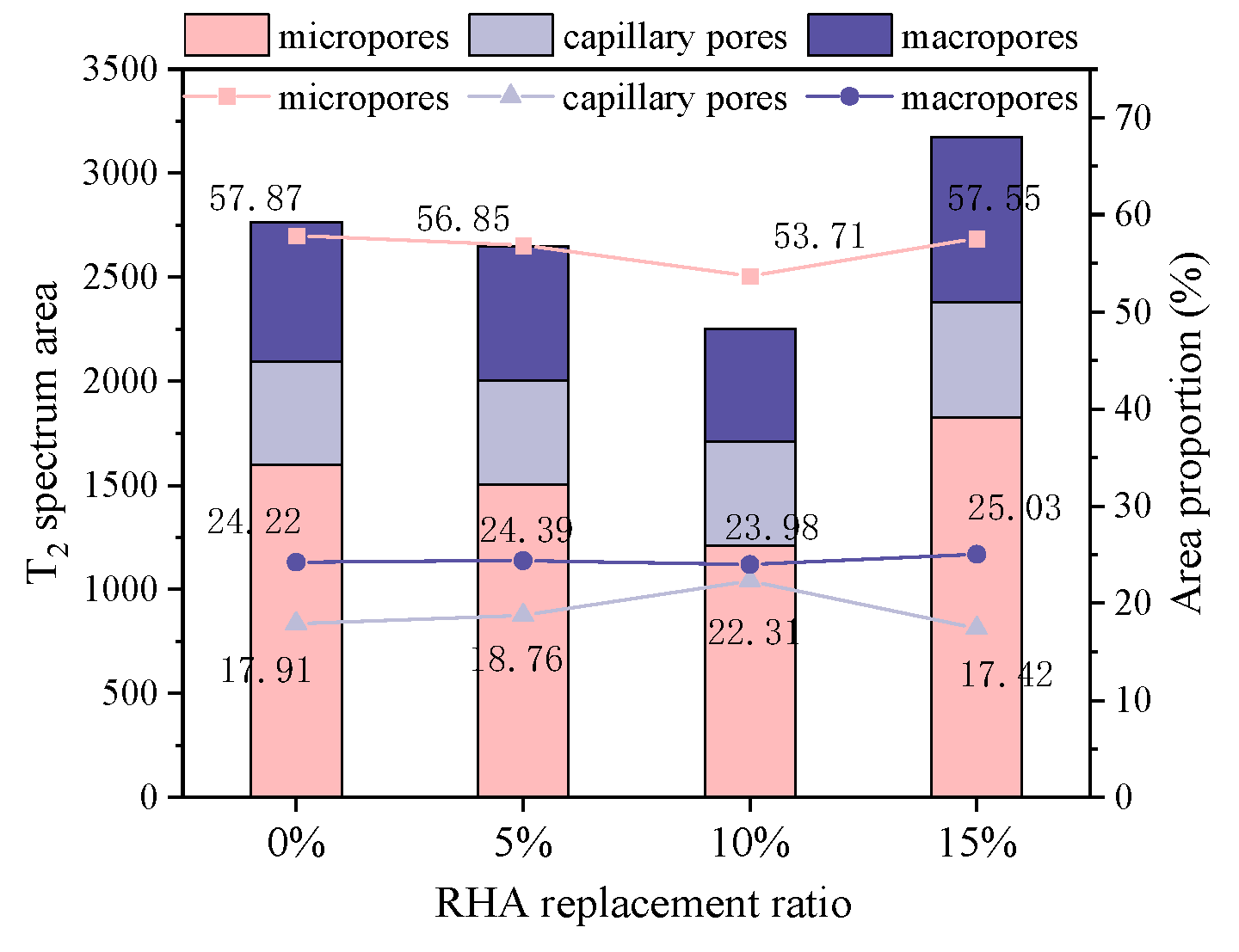

- Ten percent RHA replacing cement facilitates pore refinement and reduces pore volume compared to the control concrete. The increase in pore volume is mainly attributed to the addition of RHA as its internal pores consist of micron-sized pores. Therefore, the amount of RHA used has a significant impact on the capillary pores. With the increase in RHA content, the volume of small and large pores initially decreases and then increases, which is consistent with the trend of strength change.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ni, S.; Zhu, N.; Hou, Y.; Zhang, Z. Research on indoor thermal comfort and energy consumption of zero energy wooden structure buildings in severe cold zone. J. Build. Eng. 2023, 67, 105965. [Google Scholar] [CrossRef]

- Xiao, L.; Qin, L.-L.; Wu, S.-Y. Proposal and application of comprehensive thermal comfort evaluation model in heating seasons for buildings with solar Trombe wall. Appl. Therm. Eng. 2022, 213, 118774. [Google Scholar] [CrossRef]

- Wu, W.; Skye, H.M. Net-zero nation: HVAC and PV systems for residential net-zero energy buildings across the United States. Energy Convers. Manag. 2018, 177, 605–628. [Google Scholar] [CrossRef]

- Plytaria, M.T.; Bellos, E.; Tzivanidis, C.; Antonopoulos, K.A. Numerical simulation of a solar cooling system with and without phase change materials in radiant walls of a building. Energy Convers. Manag. 2019, 188, 40–53. [Google Scholar] [CrossRef]

- Wang, X.; Yu, H.; Li, L.; Zhao, M. Experimental assessment on the use of phase change materials (PCMs)-bricks in the exterior wall of a full-scale room. Energy Convers. Manag. 2016, 120, 81–89. [Google Scholar] [CrossRef]

- Xie, N.; Gao, X.; Zhong, Y.; Ye, R.; Chen, S.; Ding, L.; Zhong, T. Enhanced thermal performance of Na2HPO4·12H2O composite phase change material supported by sepiolite fiber for floor radiant heating system. J. Build. Eng. 2022, 56, 104747. [Google Scholar] [CrossRef]

- Amantino, G.M.; Hasparyk, N.P.; Tiecher, F.; Toledo Filho, R.D. Assessment of bio-aggregate concretes’ properties with rice residue. J. Build. Eng. 2022, 52, 104348. [Google Scholar] [CrossRef]

- da Rosa, L.C.; Santor, C.G.; Lovato, A.; da Rosa, C.S.; Güths, S. Use of rice husk and sunflower stalk as a substitute for glass wool in thermal insulation of solar collector. J. Clean. Prod. 2015, 104, 90–97. [Google Scholar] [CrossRef]

- Sua-iam, G.; Makul, N. Utilization of high volumes of unprocessed lignite-coal fly ash and rice husk ash in self-consolidating concrete. J. Clean. Prod. 2014, 78, 184–194. [Google Scholar] [CrossRef]

- Zhang, Z.; Yang, F.; Liu, J.-C.; Wang, S. Eco-friendly high strength, high ductility engineered cementitious composites (ECC) with substitution of fly ash by rice husk ash. Cem. Concr. Res. 2020, 137, 106200. [Google Scholar] [CrossRef]

- Xu, W.; Lo, T.Y.; Wang, W.; Ouyang, D.; Wang, P.; Xing, F. Pozzolanic Reactivity of Silica Fume and Ground Rice Husk Ash as Reactive Silica in a Cementitious System: A Comparative Study. Materials 2016, 9, 146. [Google Scholar] [CrossRef] [PubMed]

- Huang, H.; Gao, X.; Wang, H.; Ye, H. Influence of rice husk ash on strength and permeability of ultra-high performance concrete. Constr. Build. Mater. 2017, 149, 621–628. [Google Scholar] [CrossRef]

- Saraswathy, V.; Song, H.-W. Corrosion performance of rice husk ash blended concrete. Constr. Build. Mater. 2007, 21, 1779–1784. [Google Scholar] [CrossRef]

- Srikanth, G.; Fernando, A.; Selvaranjan, K.; Gamage, J.C.P.H.; Ekanayake, L. Development of a plastering mortar using waste bagasse and rice husk ashes with sound mechanical and thermal properties. Case Stud. Constr. Mater. 2022, 16, e00956. [Google Scholar] [CrossRef]

- Jofrishal, J.; Adlim, M.; Yusibani, E.; Akhyar, A.; Inda Rahmayani, R.F.; Fajri, R. Preparation and characterization of indoor heat blockage panel composites made of polyurethane-hybrid-foam-concrete and rice-husk-ash. Heliyon 2023, 9, e18925. [Google Scholar] [CrossRef]

- Onyenokporo, N.C.; Taki, A.; Montalvo, L.Z.; Oyinlola, M. Thermal performance characterization of cement-based masonry blocks incorporating rice husk ash. Constr. Build. Mater. 2023, 398, 132481. [Google Scholar] [CrossRef]

- Hosseinzadehfard, E.; Mobaraki, B. Investigating concrete durability: The impact of natural pozzolan as a partial substitute for microsilica in concrete mixtures. Constr. Build. Mater. 2024, 419, 135491. [Google Scholar] [CrossRef]

- Mobaraki, B.; Ma, H.; Lozano Galant, J.A.; Turmo, J. Structural Health Monitoring of 2D Plane Structures. Appl. Sci. 2021, 11, 2000. [Google Scholar] [CrossRef]

- Šavija, B.; Zhang, H.; Schlangen, E. Influence of Microencapsulated Phase Change Material (PCM) Addition on (Micro) Mechanical Properties of Cement Paste. Materials 2017, 10, 863. [Google Scholar] [CrossRef]

- Ying, H.; Wang, S.; Lu, Z.; Liu, B.; Cui, L.; Quan, X.; Liu, K.; Zhao, N. Development and thermal response of concrete incorporated with multi-stage phase change materials-aggregates for application in seasonally frozen regions. J. Build. Eng. 2023, 71, 106562. [Google Scholar] [CrossRef]

- Elahi, M.M.A.; Shearer, C.R.; Naser Rashid Reza, A.; Saha, A.K.; Khan, M.N.N.; Hossain, M.M.; Sarker, P.K. Improving the sulfate attack resistance of concrete by using supplementary cementitious materials (SCMs): A review. Constr. Build. Mater. 2021, 281, 122628. [Google Scholar] [CrossRef]

- Li, L.; Wan, Y.; Chen, S.; Tian, W.; Long, W.; Song, J. Prediction of optimal ranges of mix ratio of self-compacting mortars (SCMs) based on response surface method (RSM). Constr. Build. Mater. 2022, 319, 126043. [Google Scholar] [CrossRef]

- Jittin, V.; Bahurudeen, A.; Ajinkya, S.D. Utilisation of rice husk ash for cleaner production of different construction products. J. Clean. Prod. 2020, 263, 121578. [Google Scholar] [CrossRef]

- GB/T 50080-2016; Standard for Test Method of Performance on Ordinary Fresh Concrete. National Standards of the People’s Republic of China: Beijing, China, 2016.

- El-Seidy, E.; Chougan, M.; Sambucci, M.; Al-Kheetan, M.J.; Biblioteca, I.; Valente, M.; Hamidreza Ghaffar, S. Lightweight alkali-activated materials and ordinary Portland cement composites using recycled polyvinyl chloride and waste glass aggregates to fully replace natural sand. Constr. Build. Mater. 2023, 368, 130399. [Google Scholar] [CrossRef]

- Al-Awabdeh, F.W.; Al-Kheetan, M.J.; Jweihan, Y.S.; Al-Hamaiedeh, H.; Ghaffar, S.H. Comprehensive investigation of recycled waste glass in concrete using silane treatment for performance improvement. Results Eng. 2022, 16, 100790. [Google Scholar] [CrossRef]

- Mayooran, S.; Ragavan, S.; Sathiparan, N. Comparative study on open air burnt low- and high-carbon rice husk ash as partial cement replacement in cement block production. J. Build. Eng. 2017, 13, 137–145. [Google Scholar] [CrossRef]

- Celik, F.; Canakci, H. An investigation of rheological properties of cement-based grout mixed with rice husk ash (RHA). Constr. Build. Mater. 2015, 91, 187–194. [Google Scholar] [CrossRef]

- Liu, C.; Zhang, W.; Liu, H.; Zhu, C.; Wu, Y.; He, C.; Wang, Z. Recycled aggregate concrete with the incorporation of rice husk ash: Mechanical properties and microstructure. Constr. Build. Mater. 2022, 351, 128934. [Google Scholar] [CrossRef]

- Zerbino, R.; Giaccio, G.; Isaia, G.C. Concrete incorporating rice-husk ash without processing. Constr. Build. Mater. 2011, 25, 371–378. [Google Scholar] [CrossRef]

- Chao-Lung, H.; Anh-Tuan, B.L.; Chun-Tsun, C. Effect of rice husk ash on the strength and durability characteristics of concrete. Constr. Build. Mater. 2011, 25, 3768–3772. [Google Scholar] [CrossRef]

- Puthipad, N.; Ouchi, M.; Rath, S.; Attachaiyawuth, A. Enhancement in self-compactability and stability in volume of entrained air in self-compacting concrete with high volume fly ash. Constr. Build. Mater. 2016, 128, 349–360. [Google Scholar] [CrossRef]

- Sata, V.; Jaturapitakkul, C.; Kiattikomol, K. Influence of pozzolan from various by-product materials on mechanical properties of high-strength concrete. Constr. Build. Mater. 2007, 21, 1589–1598. [Google Scholar] [CrossRef]

- Jamil, M.; Khan, M.N.N.; Karim, M.R.; Kaish, A.B.M.A.; Zain, M.F.M. Physical and chemical contributions of Rice Husk Ash on the properties of mortar. Constr. Build. Mater. 2016, 128, 185–198. [Google Scholar] [CrossRef]

- Liu, C.; Zhang, W.; Liu, H.; Lin, X.; Zhang, R. A compressive strength prediction model based on the hydration reaction of cement paste by rice husk ash. Constr. Build. Mater. 2022, 340, 127841. [Google Scholar] [CrossRef]

- Selvaranjan, K.; Navaratnam, S.; Gamage, J.C.P.H.; Thamboo, J.; Siddique, R.; Zhang, J.; Zhang, G. Thermal and environmental impact analysis of rice husk ash-based mortar as insulating wall plaster. Constr. Build. Mater. 2021, 283, 122744. [Google Scholar] [CrossRef]

- Ying, H.; Wang, S.; Lu, Z.; Liu, B.; Zhao, N.; Liu, K.; Quan, X. Incorporation of multi-stage phase change material aggregates into concrete: Effect of aggregate replacement on mechanical-thermal properties and pore structure change. Constr. Build. Mater. 2024, 411, 134355. [Google Scholar] [CrossRef]

- Cordeiro, G.C.; Toledo Filho, R.D.; Tavares, L.M.; Fairbairn, E.M.R. Experimental characterization of binary and ternary blended-cement concretes containing ultrafine residual rice husk and sugar cane bagasse ashes. Constr. Build. Mater. 2012, 29, 641–646. [Google Scholar] [CrossRef]

| SiO2 | CaO | Al2O3 | Fe2O3 | MgO | SO3 | Na2O | K2O | TiO2 | MnO | P2O5 | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| RHA | 86.82 | 1.70 | 0.47 | 1.71 | 0.61 | 0.55 | 0.20 | 5.12 | 0.05 | 0.45 | 1.89 |

| FA | 43.46 | 10.05 | 30.57 | 9.12 | 2.08 | 0.53 | 1.02 | 0.67 | 0.55 | 0.05 | 1.30 |

| Cement | 18.68 | 64.27 | 4.01 | 3.97 | 2.87 | 3.26 | 0.12 | 0.43 | 0.57 | 0.10 | 1.05 |

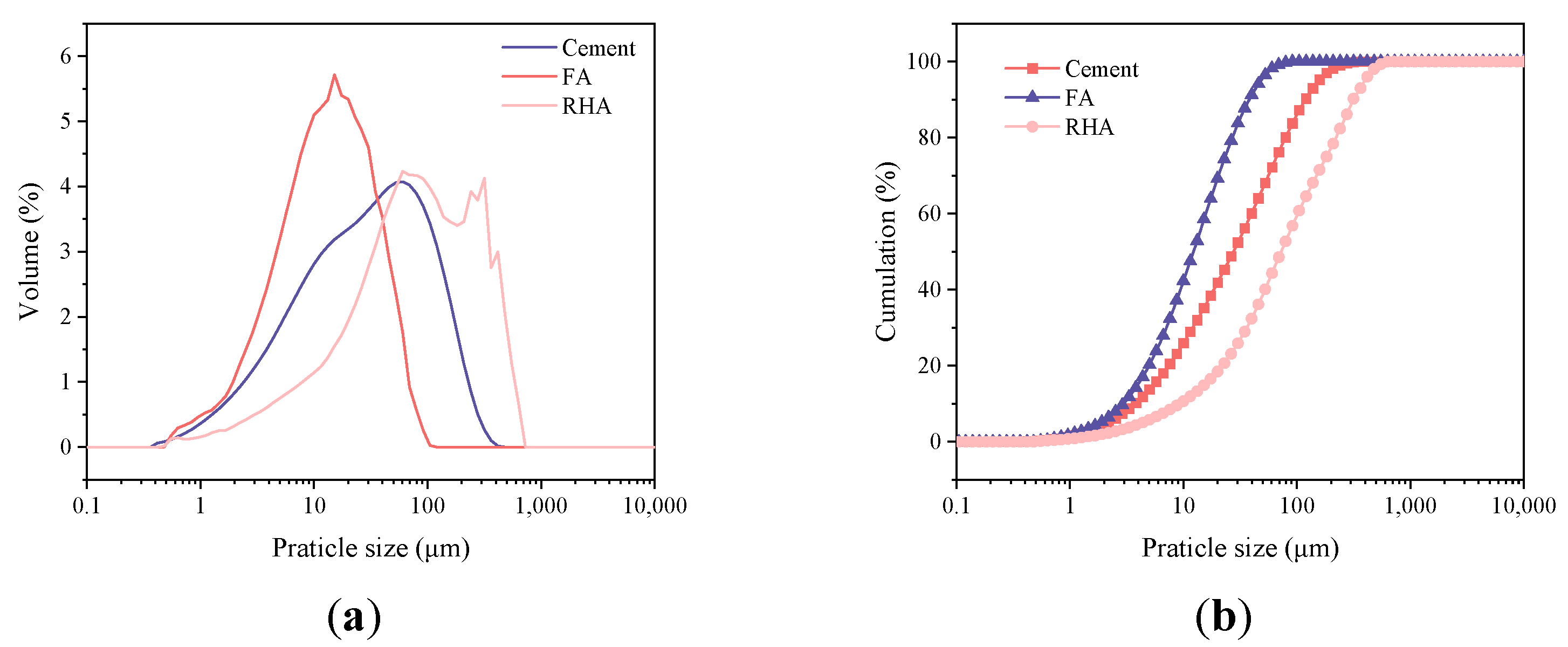

| d10 | d50 | d90 | |

|---|---|---|---|

| RHA | 9.26 | 72.86 | 313.83 |

| FA | 2.95 | 12.28 | 38.03 |

| Cement | 3.74 | 27.63 | 118.66 |

| PCM | Dodecane | Tridecane | Tetradecane |

|---|---|---|---|

| Density (g/mL) | 0.7487 | 0.7560 | 0.7628 |

| Solidifying temperature (°C) | −12.86 | −7.84 | 4.26 |

| Melting temperature (°C) | −10.96 | −7.26 | 4.85 |

| Latent heat (J/g) | 200.5 | 142.9 | 206.3 |

| Mixture | Cement | RHA | FA | Sand | PCM Aggregate | Water | SP |

|---|---|---|---|---|---|---|---|

| No. 1 | 467.5 | 0 | 82.5 | 652 | 560 | 176 | 5.5 |

| No. 2 | 453.75 | 13.75 | 82.5 | 652 | 560 | 176 | 5.5 |

| No. 3 | 440 | 27.5 | 82.5 | 652 | 560 | 176 | 5.5 |

| No. 4 | 426.25 | 41.25 | 82.5 | 652 | 560 | 176 | 5.5 |

| No. 5 | 412.5 | 55 | 82.5 | 652 | 560 | 176 | 5.5 |

| No. 6 | 398.75 | 68.75 | 82.5 | 652 | 560 | 176 | 5.5 |

| No. 7 | 385 | 82.5 | 82.5 | 652 | 560 | 176 | 5.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, B.; Wang, S.; Jia, W.; Ying, H.; Lu, Z.; Hong, Z. The Effect of RHA as a Supplementary Cementitious Material on the Performance of PCM Aggregate Concrete. Buildings 2024, 14, 2150. https://doi.org/10.3390/buildings14072150

Liu B, Wang S, Jia W, Ying H, Lu Z, Hong Z. The Effect of RHA as a Supplementary Cementitious Material on the Performance of PCM Aggregate Concrete. Buildings. 2024; 14(7):2150. https://doi.org/10.3390/buildings14072150

Chicago/Turabian StyleLiu, Bo, Sheliang Wang, Wurong Jia, Honghao Ying, Zhe Lu, and Zhilong Hong. 2024. "The Effect of RHA as a Supplementary Cementitious Material on the Performance of PCM Aggregate Concrete" Buildings 14, no. 7: 2150. https://doi.org/10.3390/buildings14072150

APA StyleLiu, B., Wang, S., Jia, W., Ying, H., Lu, Z., & Hong, Z. (2024). The Effect of RHA as a Supplementary Cementitious Material on the Performance of PCM Aggregate Concrete. Buildings, 14(7), 2150. https://doi.org/10.3390/buildings14072150