System Optimization and Operating Strategy of Single-Stage Air Source Heat Pump with Thermal Storage to Reduce Wind Power Curtailment

Abstract

1. Introduction

2. Materials and Methods

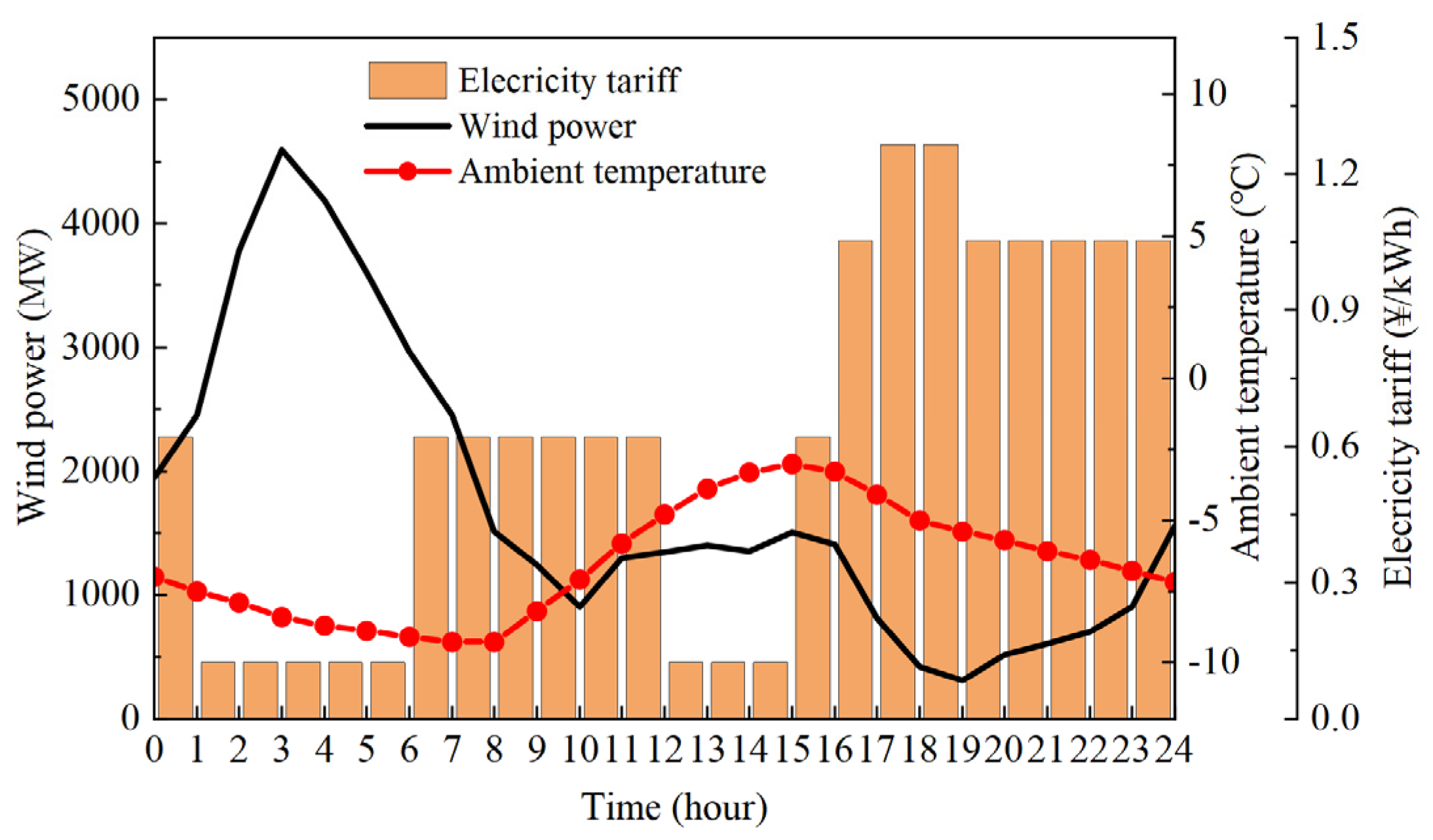

2.1. Basic Data

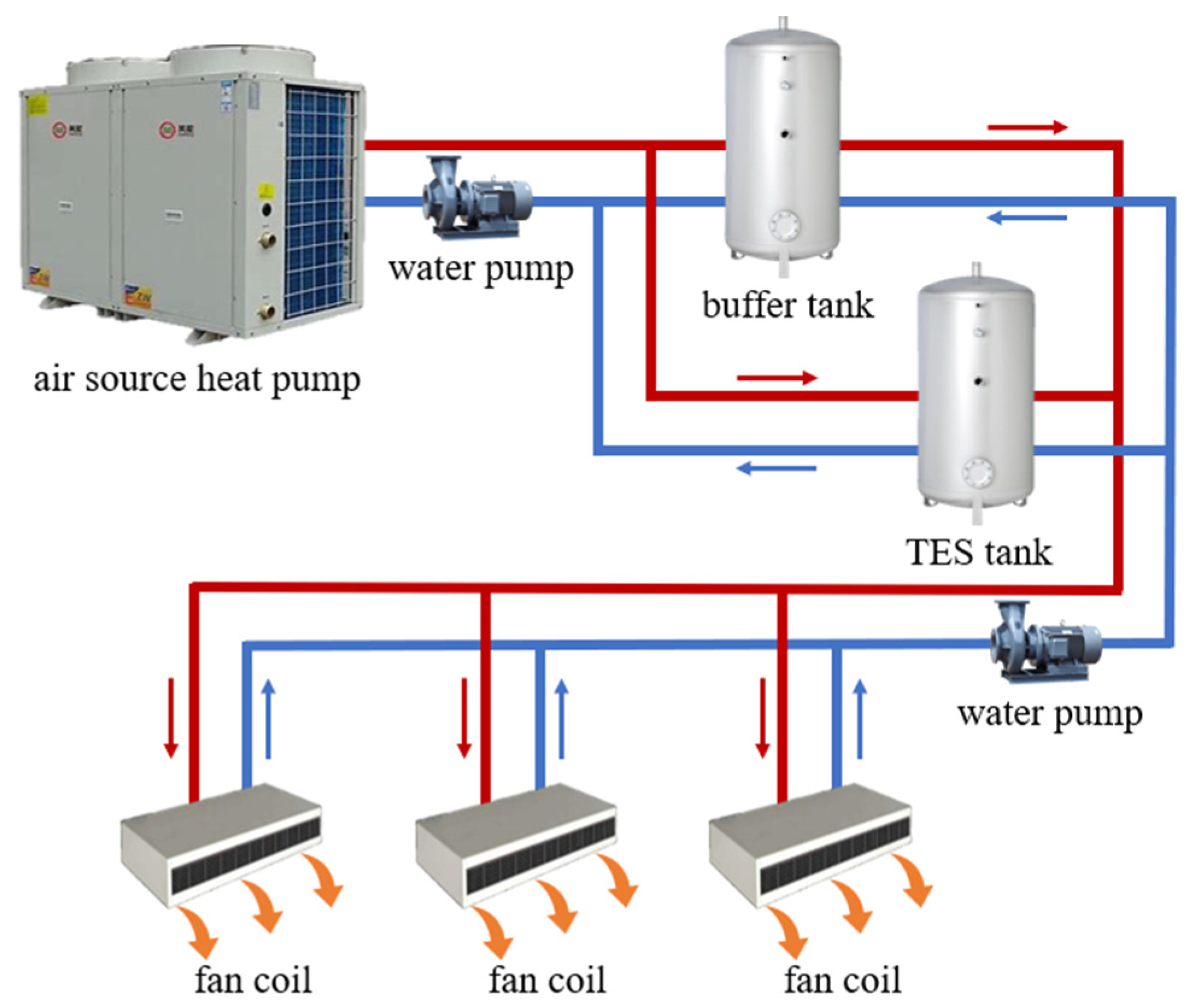

2.2. Integrated Heating System Configuration

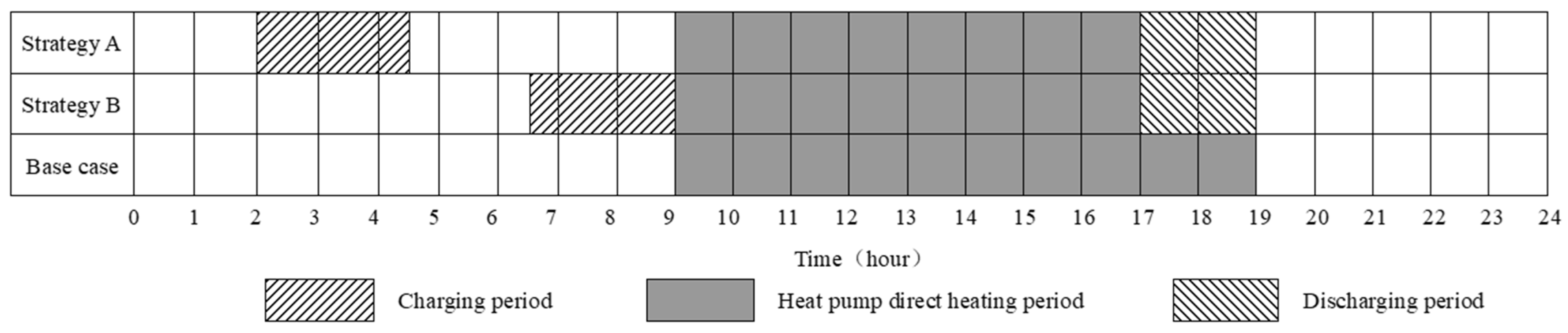

2.3. Operating Strategies

2.3.1. Strategy A

2.3.2. Strategy B

2.4. TRNSYS Modeling

2.4.1. Target Building

2.4.2. Equipment Selection

- αi = 1, if fluid from heat source enters node i, 0 otherwise

- βi = 1, if fluid returning from load enters node i, 0 otherwise

- γi = 1, if the net flow m(i−1) enters node i from the node above

- = −1, if the net flow m(i−1) goes from node i to the node above

- = 0, if there is no flow stream between node i and the node above

- δi = 1, if the net flow m(i+1) enters node i from the node below

- = −1, if m(i+1) goes from node i to the node below

- = 0, if m(i+1) = 0

- ε = 1, if auxiliary electric heater is on, 0 otherwise

3. Results and Discussion

3.1. Water Tank Size and Storage Temperature Set Point

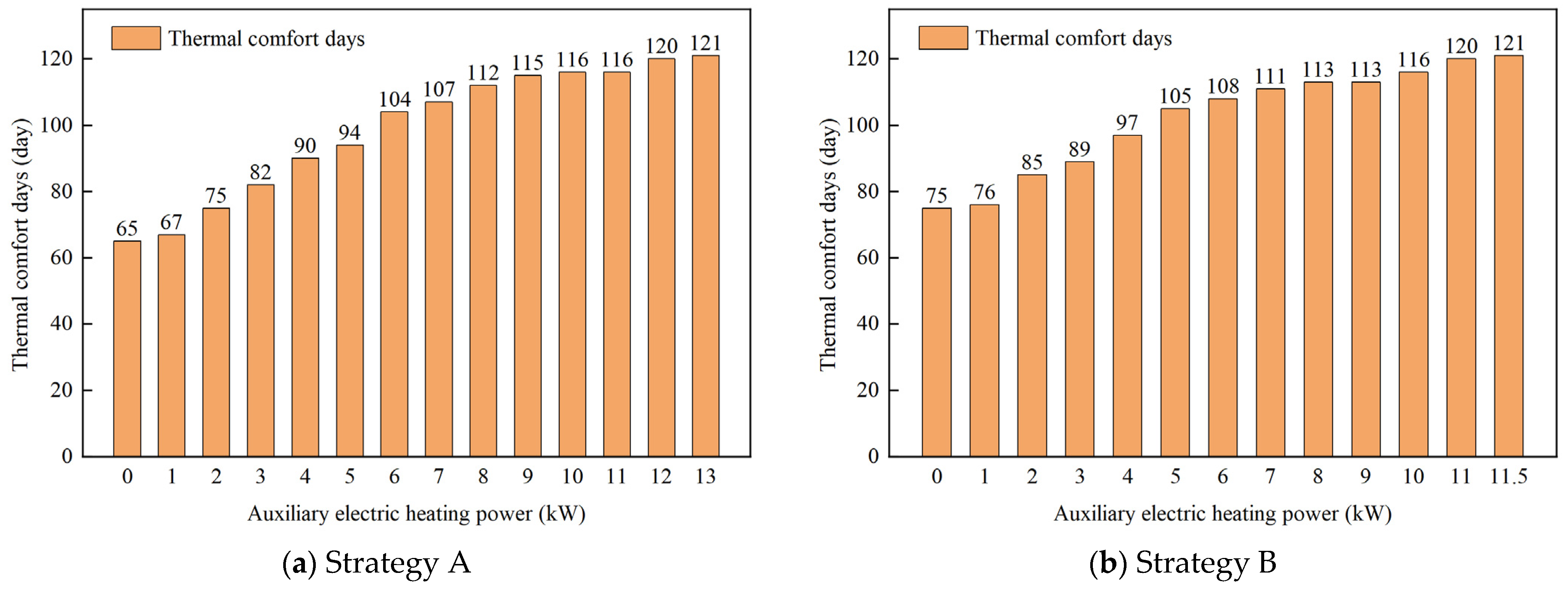

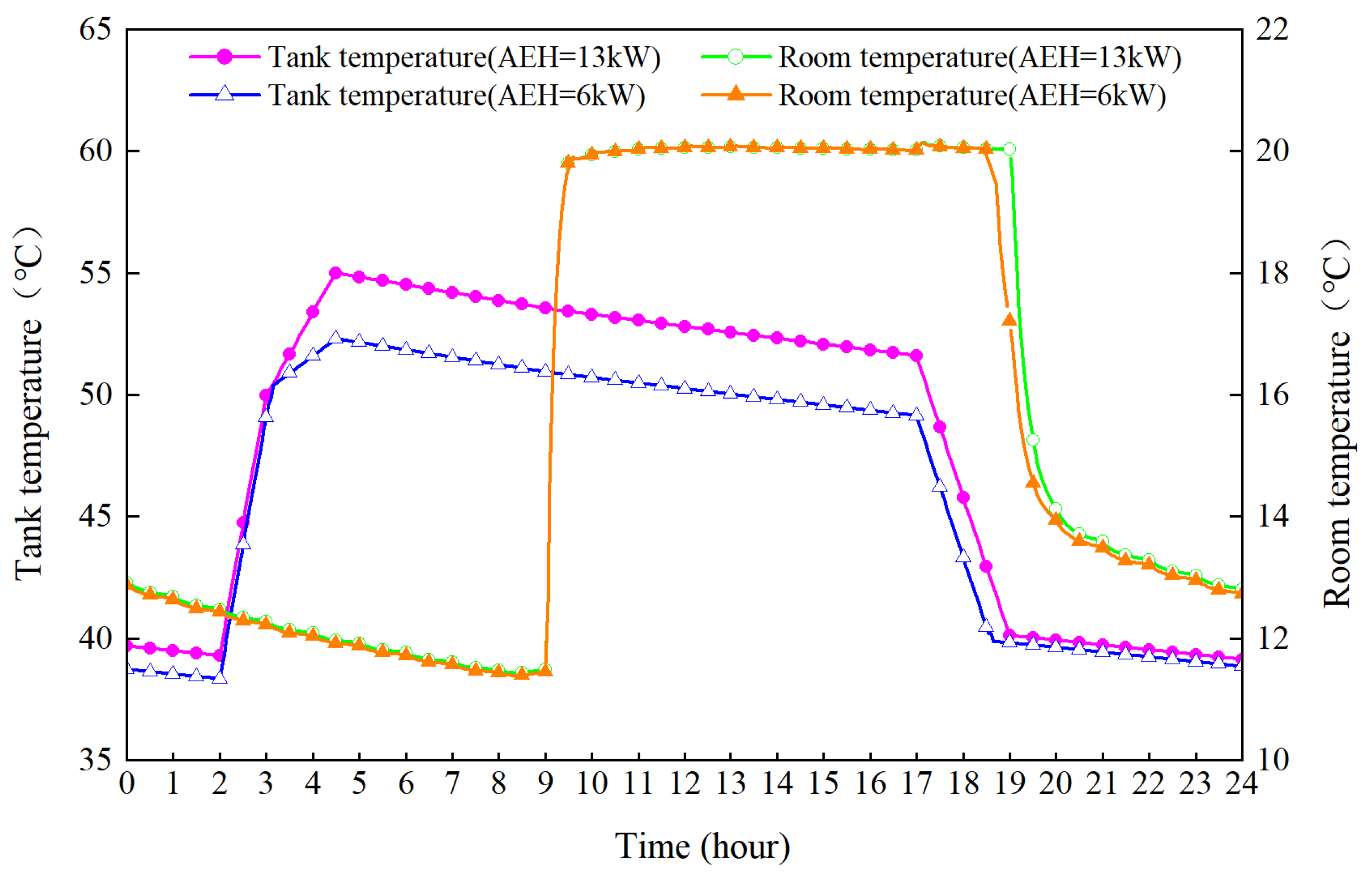

3.2. Auxiliary Electric Heating Power

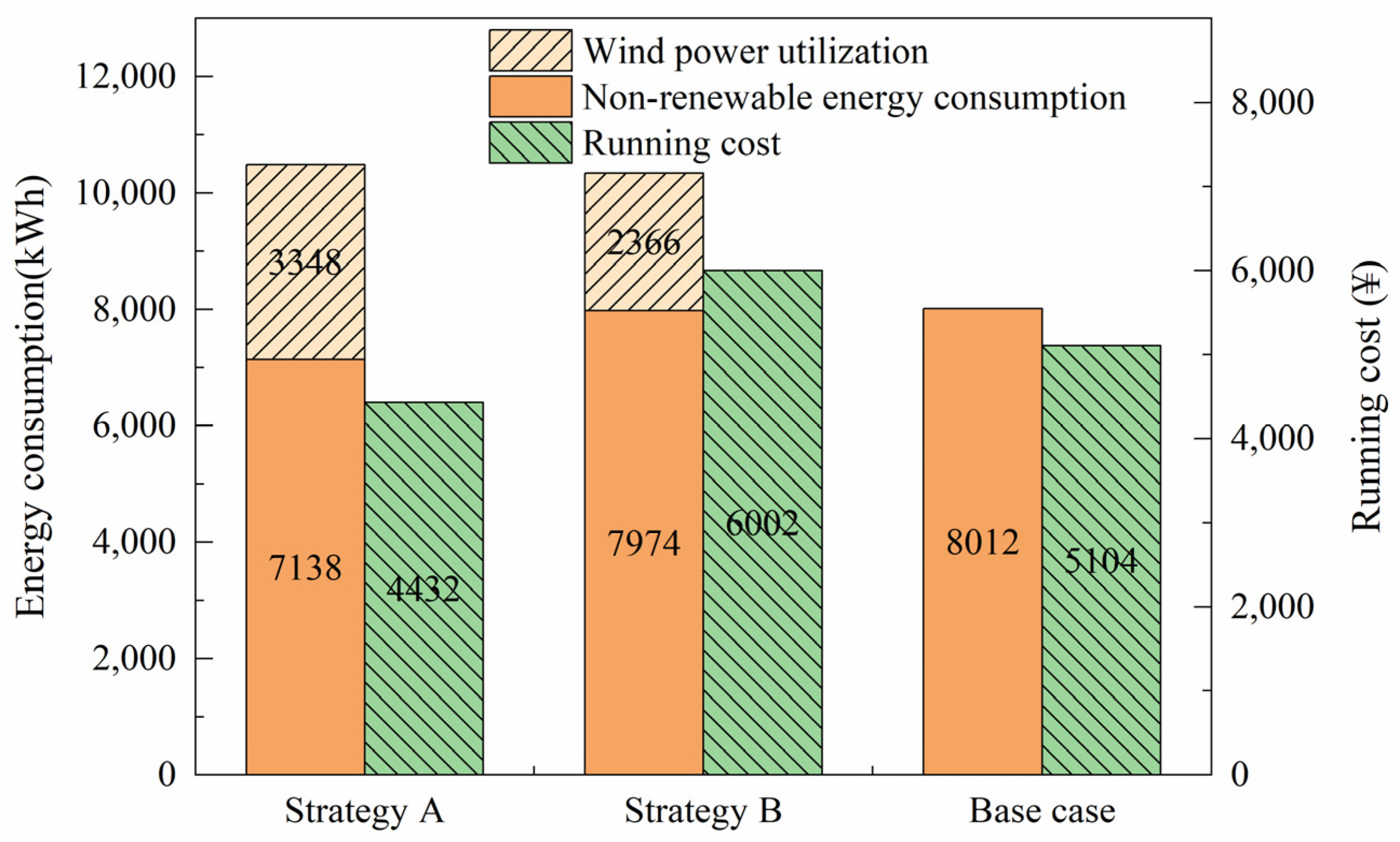

3.3. Comparison of Operating Strategies

4. Conclusions

- The size of the water tank and the storage temperature set point determined the system’s ability to shift during peak load. For specific applications, a proper combination of the two parameters existed to minimize energy consumption while satisfying the heating demand of users.

- The use of auxiliary electric heating to raise the storage temperature was necessary for conventional single-stage air source heat pumps to participate in wind curtailment reduction. Different system operating strategies require different capacities for auxiliary heating.

- By implementing a proper operating strategy, the non-renewable power consumption could be reduced by 11% for the studied building, with a total wind power utilization of 3348 kWh during the heating season while still satisfying the heating demand of users.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| m | fluid flow rate (kg/s) |

| C | fluid heat transfer coefficient (kJ/kg·K) |

| T | temperature (°C) |

| Q | heat flow rate (kW) |

| V | volume of tank (m3) |

| H | height of the tank (m) |

| U | heat loss coefficient (W/(m2·K)) |

| L | circumference of tank (m) |

| Subscript | |

| i | the ith node |

| fl | fluid |

| heat | heat source side |

| load | load side |

| aux | auxiliary electric heater |

| loss | loss of heat |

| bot | bottom of the tank |

| top | top of the tank |

| N | number of tank layers |

| t | tank |

| env | environment |

References

- Hewitt, J.N. Heat pumps and energy storage—The challenges of implementation. Appl. Energy 2012, 89, 37–44. [Google Scholar] [CrossRef]

- Hedegaard, K.; Mathiesen, B.V.; Lund, H.; Heiselberg, P. Wind power integration using individual heat pumps—Analysis of different heat storage options. Energy 2012, 47, 284–293. [Google Scholar] [CrossRef]

- Bloess, A.; Schill, W.; Zerrahn, A. Power-to-heat for renewable energy integration: A review of technologies, modeling approaches, and flexibility potentials. Appl. Energy 2018, 212, 1611–1626. [Google Scholar] [CrossRef]

- Wu, P.; Wang, Z.; Li, X.; Xu, Z.; Yang, Y.; Yang, Q. Energy-saving analysis of air source heat pump integrated with a water storage tank for heating applications. Build. Environ. 2020, 180, 107029. [Google Scholar] [CrossRef]

- Ermel, C.; Bianchim, V.; Cardoso, A.P.; Schneider, P.S. Thermal storage integrated into air-source heat pumps to leverage building electrification: A systematic literature review. Appl. Therm. Eng. 2022, 215, 118975. [Google Scholar] [CrossRef]

- Le, K.X.; Huang, M.J.; Wilson, C.; Shah, N.N.; Hewitt, N.J. Tariff-based load shifting for domestic cascade heat pump with enhanced system energy efficiency and reduced wind power curtailment. Appl. Energy 2020, 257, 113976. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, Y.; Wang, F.; Li, G.; Xu, K. Performance Optimization and Economic Evaluation of CO2 Heat Pump Heating System Coupled with Thermal Energy Storage. Sustainability. 2021, 13, 13683. [Google Scholar] [CrossRef]

- Zhang, D.; Fang, C.; Shen, C.; Chen, S.; Li, H.; Qin, X.; Liu, H.; Wu, X. 4E analysis and multi-objective optimization of compression/ejection transcritical CO2 heat pump with latent thermal heat storage. J. Energy Storage 2023, 72, 108475. [Google Scholar] [CrossRef]

- Vivian, J.; Prataviera, E.; Cunsolo, F.; Pau, M. Demand Side Management of a pool of air source heat pumps for space heating and domestic hot water production in a residential district. Energy Convers. Manag. 2020, 225, 113457. [Google Scholar] [CrossRef]

- Fitzpatrick, P.; D’Ettorre, F.; Rosa, D.M.; Yadack, M.; Eicker, U.; Finn, D.P. Influence of electricity prices on energy flexibility of integrated hybrid heat pump and thermal storage systems in a residential building. Energy Build. 2020, 223, 110142. [Google Scholar] [CrossRef]

- Maarten, E.; Alice, M.; Alessia, A. Design energy flexibility characterisation of a heat pump and thermal energy storage in a Comfort and Climate Box. Appl. Therm. Eng. 2022, 216, 119154. [Google Scholar]

- Badescu, V. Model of a thermal energy storage device integrated into a solar assisted heat pump system for space heating. Energy Convers. Manag. 2003, 44, 1589–1604. [Google Scholar] [CrossRef]

- Lyu, W.; Wang, Z.; Li, X.; Deng, G.; Xu, Z.; Li, H.; Yang, Y.; Zhan, B.; Zhao, M. Influence of the Water tank size and air source heat pump size on the energy saving potential of the energy storage heating system. J. Energy Storage 2022, 55, 105542. [Google Scholar] [CrossRef]

- Miara, M.; Günther, D.; Leitner, Z.L.; Wapler, J. Simulation of an Air-to-Water Heat Pump System to Evaluate the Impact of Demand-Side-Management Measures on Efficiency and Load-Shifting Potential. Energy Technol. 2014, 2, 90–99. [Google Scholar] [CrossRef]

- Arteconi, A.; Hewitt, N.; Polonara, F. Domestic demand-side management (DSM): Role of heat pumps and thermal energy storage (TES) systems. Appl. Therm. Eng. 2013, 51, 155–165. [Google Scholar] [CrossRef]

- Kelly, N.J.; Tuohy, P.G.; Hawkes, A.D. Performance assessment of tariff-based air source heat pump load shifting in a UK detached dwelling featuring phase change-enhanced buffering. Appl. Therm. Eng. 2014, 71, 809–820. [Google Scholar] [CrossRef]

- Wang, Y.; Qiu, J.; Tao, Y. Robust energy systems scheduling considering uncertainties and demand side emission impacts. Energy 2022, 239, 122317. [Google Scholar] [CrossRef]

- Li, Z.; Wu, L.; Xu, Y.; Zheng, X. Stochastic-Weighted Robust Optimization Based Bilayer Operation of a Multi-Energy Building Microgrid Considering Practical Thermal Loads and Battery Degradation. IEEE Trans. Sustain. Energy 2022, 13, 668–682. [Google Scholar] [CrossRef]

- Ding, B.; Li, Z.; Li, Z.; Xue, Y.; Chang, X.; Su, J.; Jin, X.; Sun, H. A CCP-based distributed cooperative operation strategy for multi-agent energy systems integrated with wind, solar, and buildings. Appl. Energy 2024, 365, 123275. [Google Scholar] [CrossRef]

- Hao, J.; Gou, X.; Wang, S.; Chen, Q.; Gao, K. Dynamic Modeling and Flexibility Analysis of an Integrated Electrical and Thermal Energy System with the Heat Pump–Thermal Storage. Front. Energy Res. 2022, 10, 817503. [Google Scholar] [CrossRef]

- Fischer, D.; Madani, H. On heat pumps in smart grids: A review. Renew. Sustain. Energy Rev. 2017, 70, 342–357. [Google Scholar] [CrossRef]

- Salpakari, J.; Lund, P. Optimal and rule-based control strategies for energy flexibility in buildings with PV. Appl Energy 2016, 161, 425–436. [Google Scholar] [CrossRef]

- Le, H.; Li, H.; Jiang, Y. Realization of Substituting Coal with Electricity and Enhancing the Efficiency of Electricity Allocation by Using Air Source Heat Pump. Energy China 2016, 38, 9–15. [Google Scholar]

- The People’s Government of Hebei Province: Hebei Provincial Development and Reform Commission Notice on Further Improving the Time-Sharing Electricity Pricing Policy for Industrial, Commercial and Other Users in Hebei South Network. Available online: https://hbdrc.hebei.gov.cn/xxgk_2232/zc/wzcwj/202309/t20230907_92155.html (accessed on 28 October 2022).

| Parameter | Value |

|---|---|

| Rated heating capacity (kW) | 63 |

| Rated Input Power (kW) | 16.5 |

| Rated COP | 3.82 |

| Rated air volume of evaporator (m3/h) | 22,000 |

| Rated air volume of evaporator (m3/h) | 10.9 |

| Component | Parameter | TRNSYS Type |

|---|---|---|

| Thermal storage pump | Rated power = 0.75 kW; Rated flow rate = 10,980 kg/h | Type114 |

| water pump | Rated power = 0.55 kW; Rated flow rate = 3760 kg/h | Type114 |

| PID controller | Proportional coefficient = 4 Integral coefficient = 1.7 | Type23 |

| Fan coil unit | Discharge air temperature = 30 °C Rated air flow = 10,200 m3/h | Type753e |

| Storage Temperature Set Point (°C) | Water Tank Size (m3) | Strategy A | Strategy B | ||

|---|---|---|---|---|---|

| Hours of Thermal Discomfort | Thermal Storage Energy Consumption (kWh) | Hours of Thermal Discomfort | Thermal Storage Energy Consumption (kWh) | ||

| 50 | 2.00 | 113 | 1108.73 | 91 | 1178.53 |

| 50 | 2.20 | 98 | 1238.94 | 78 | 1304.27 |

| 50 | 2.40 | 90 | 1366.97 | 68 | 1425.43 |

| 50 | 2.60 | 72 | 1523.29 | 54 | 1533.11 |

| 50 | 2.80 | 58 | 1630.47 | 42 | 1634.19 |

| 50 | 3.00 | 49 | 1724.90 | 33 | 1722.13 |

| 55 | 2.00 | 44 | 2330.70 | 32 | 2435.88 |

| 55 | 2.20 | 30 | 2546.44 | 18 | 2639.00 |

| 55 | 2.40 | 19 | 2789.02 | 7 | 2841.17 |

| 55 | 2.60 | 7 | 2986.21 | 2 | 3023.50 |

| 55 | 2.80 | 5 | 3167.49 | 0 | 3206.68 |

| 55 | 3.00 | 0 | 3352.91 | 0 | 3243.54 |

| 60 | 2.00 | 5 | 3453.57 | 2 | 3486.88 |

| 60 | 2.20 | 2 | 3735.23 | 0 | 3740.52 |

| 60 | 2.40 | 0 | 3995.01 | 0 | 3988.44 |

| 60 | 2.60 | 0 | 4233.84 | 0 | 4215.70 |

| 60 | 2.80 | 0 | 4424.49 | 0 | 4416.32 |

| 60 | 3.00 | 0 | 5013.63 | 0 | 5020.79 |

| Energy Consumption by Heat Pump (kWh) | Energy Consumption by Electric Heater (kWh) | Heat Pump COP during Charging Period | |

|---|---|---|---|

| Strategy A | 956 | 2349 | 2.71 |

| Strategy B | 968 | 2190 | 2.64 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ren, Q.; Gao, C.; Jia, J. System Optimization and Operating Strategy of Single-Stage Air Source Heat Pump with Thermal Storage to Reduce Wind Power Curtailment. Buildings 2024, 14, 1993. https://doi.org/10.3390/buildings14071993

Ren Q, Gao C, Jia J. System Optimization and Operating Strategy of Single-Stage Air Source Heat Pump with Thermal Storage to Reduce Wind Power Curtailment. Buildings. 2024; 14(7):1993. https://doi.org/10.3390/buildings14071993

Chicago/Turabian StyleRen, Qianyue, Chuang Gao, and Jie Jia. 2024. "System Optimization and Operating Strategy of Single-Stage Air Source Heat Pump with Thermal Storage to Reduce Wind Power Curtailment" Buildings 14, no. 7: 1993. https://doi.org/10.3390/buildings14071993

APA StyleRen, Q., Gao, C., & Jia, J. (2024). System Optimization and Operating Strategy of Single-Stage Air Source Heat Pump with Thermal Storage to Reduce Wind Power Curtailment. Buildings, 14(7), 1993. https://doi.org/10.3390/buildings14071993