Abstract

This study addresses the issue of poor construction labor productivity, exploring the process and methodology for increasing construction workers’ participation in labor productivity improvement, as well as a situational awareness (SA) development approach for construction workers based on lean construction (LC). A framework for enhancing labor productivity through SA has been developed. A case study approach is utilized to describe the LC improvement process, which includes enhancing construction workers’ SA for waste minimization and process optimization and engaging them in LC with improved value stream mapping (VSM). The labor productivity measurement approach, combined with VSM, is used to evaluate the labor productivity improvement with labor productivity improvement rate, resource efficiency, and flow efficiency. The results demonstrate that the labor productivity of the case project has increased by 24.07%, with 11.54% contributing resource efficiency and 88.46% contributing flow efficiency, indicating a greater increase in flow efficiency. This study fills a research gap in terms of the combination of construction workers’ SA enhancement and the involvement of LC practices to boost labor productivity. Furthermore, this study proposes an SA development approach based on LC at three levels: waste perception, VSM implementation, and labor productivity improvement assessment. This provides new perspectives for leveraging construction workers’ SA to increase labor productivity. The improved VSM approach and labor productivity measurements provide an operationalization of workers’ participation in continuous improvement. This research is of great practical relevance for augmenting the competencies of construction laborers and inspiring them to engage in labor productivity enhancement.

1. Introduction

Low productivity is a common problem faced by the world’s construction industry [1]. Lean construction (LC) suggests using new production theories to boost the construction industry’s performance [2]. As a labor-intensive industry, the labor productivity indicator is widely used to indicate the performance of the construction industry. Therefore, LC is also regarded as the most famous labor productivity intervention method [3,4].

Early research on factors affecting labor productivity identified factors such as worker characteristics, management, technology, and incentives [5,6]. As a result, boosting worker skills through training and increasing labor productivity through material incentives became the primary improvement strategies [7]. However, LC is thought to be more effective in increasing worker productivity by eliminating waste, optimizing processes, using resources more efficiently, and encouraging full participation and co-operation [8]. While earlier strategies were considered to be more focused on resource efficiency improvements, LC focuses on flow efficiency improvements [9]. It has been demonstrated that by identifying waste sources and applying LC principles such as “just-in-time”, “multi-skilled teams”, etc., the cycle time of a construction project was reduced by 13%, technical efficiency was improved by 141%, average productivity increased by 268%, and labor costs were reduced by 96% [10].

Although LC emphasizes full participation, in current practice, it mostly only covers frontline managers, such as foremen and superintendents, whereas the involvement at the worker level is ignored [11,12,13]. As construction workers are the most direct operators, they can obtain and respond to information on site promptly, such as the status of materials and equipment, staffing levels, and construction conditions. The workers’ understanding and processing ability toward this real-time information make them an indispensable part of lean improvement. However, the workers’ perspective has not yet received enough attention, and workers are usually in a passive role in construction projects, with a low involvement in project improvements [14]. Therefore, improving worker participation in order to better utilize their potential in LC and thus improve labor productivity has become a pressing issue in the current construction industry.

Situational awareness (SA) is the capacity to adequately apply various forms of human cognition to a task scenario, to accurately detect environmental changes, and to predict future developments through comprehension and discretion in the process of processing information [15]. Workers with higher SA are able to comprehensively analyze and process work information, allowing them to perceive issues such as waste on a construction site. It enables workers to quickly and accurately identify inefficient operations and process bottlenecks and then take timely measures to improve them. Some researchers have pointed out that the construction industry is facing the situation that the SA of its field participants is not fully utilized [16]. On one hand, SA has great potential to improve labor productivity. On the other hand, the involvement at the construction worker level is relatively weak. Although some studies have proposed integrating workers’ SA to support on-site decision-making to improve productivity, they have ignored the lack of cognition and knowledge of LC among construction workers. Therefore, in order to fill the knowledge gap in terms of the combination of construction workers’ SA enhancement and the involvement of LC practice to boost labor productivity, this study aims to address the following two problems:

- (1)

- How can we improve construction workers’ SA of on-site waste identification and process improvement?

- (2)

- How can we help workers to participate in LC practices by mastering VSM tools for labor productivity improvement?

On the one hand, workers are not able to enhance their SA and participate in improvement activities if they lack LC knowledge concerning on-site waste identification and process improvement. On the other hand, only when workers understand and apply the instruments for LC process improvement will the focus of labor productivity improvement be shifted from resource efficiency to flow efficiency.

Based on the above assumptions, the purpose of this study was to investigate how to engage construction workers in labor productivity improvement by enhancing their SA. Taking workers’ perception of waste minimization and process optimization as the focus of SA, we utilized the VSM as a tool for workers’ involvement in LC practices and the enhancement of labor productivity. Given that construction workers are not well educated and have greater difficulties learning to apply specialized VSM tools, an improved Gantt chart method of drawing VSM is proposed to make VSM more intuitive and operationally feasible.

Through the exploration in this study, we intended to draw managers’ attention to the SA of construction workers, particularly strengthening workers’ awareness of on-site waste minimization and construction process optimization. Workers are progressively evolving into a more autonomous and proactive group engaged in the construction process, as opposed to obediently following commands and decisions from their leaders. These changes support the application of lean construction, boost labor productivity, and achieve more efficient, higher-quality construction projects.

2. Literature Review

2.1. Factors Affecting Construction Labor Productivity

For a long time, the low productivity of China’s construction industry has been regarded as the main obstacle to its rapid and sustainable development [17]. China’s regional development policies have caused regional differences to some extent [18]. Ming Luo et al. [19] examined construction productivity in regions at different economic levels in China and found that the eastern coastal provinces led the way. They suggested that the central region should increase investment in vocational training, while the western region should raise workers’ wages to attract labor. Globally, Rathnayake and Middleton [20] compared the construction productivity of the United States, Germany, France, and Britain. The results show that the United States is ahead because of its high capital intensity and more efficient construction sector, while Britain is the worst.

Facing the challenge of low labor productivity, each region needs to adopt different coping strategies according to its own situation. This regional difference shows that it is necessary to understand and study the factors that affect the labor productivity of a specific country or region. Ghodrati et al. [21] collected data from 111 general construction projects in New Zealand. The research results showed that management strategies such as communication and incentive programs have a strong positive correlation with labor productivity. Aghayeva and Ślusarczyk [7] found that both employees and managers are motivated and inhibited by the level and timely payment of salaries, job security, bonuses, and fringe benefits. Hao Lu et al. [22] analyzed data from 31 regions in China from 2000 to 2018 and found that information technology has played a significant role in improving construction labor productivity, but this influence will be weakened with the development of the regional construction industry. Relying on technological innovation alone may not lead to an increase in construction labor productivity. Practitioners should focus on the training and re-educating of workers to improve their cultural and technical literacy.

2.2. Situational Awareness in Construction

Situational awareness (SA), which was first used in the military context, refers to the perception of environmental elements in a particular moment and place, the understanding of the meaning of these elements, and, ultimately, the prediction of the future state of these elements [15]. Endsley [23] categorized situational awareness into three tiers: the perception of elements of the current situation (Level 1: Data Stage), the understanding of the current situation (Level 2: Information Stage), and the prediction of future states (Level 3: Knowledge Stage). Various industries, including industrial production, cyber security, and energy, have utilized the concept of SA [24,25,26].

In the field of construction, the research on SA primarily focuses on construction safety. Most workplace accidents are caused by poor SA in workers [27]. Ibrahim et al. [28] used wearable sensors to track the physical fatigue of individuals in real time, discovering that physical fatigue would reduce the SA of workers and increase dangerous behaviors. Lee and Hasanzadeh [29] conducted a study using panoramic video and wearable sensors. They investigated the influence of the spatial and temporal characteristics of dynamic hazards on construction workers’ identification and prediction of hazards. The finding revealed that most workers failed to develop the correct SA to predict potential hazards due to the incorrect allocation of attention and the timing of cue perception. In recent years, SA has been gradually applied to the on-site management of construction projects. Martinez et al. investigated the connection between production planners’ SA and workflow quality. Their findings suggested that accurate and trustworthy information can enhance planners’ comprehension of the status of the site, leading to a better workflow and increased productivity [30]. Görsch et al. [16] proposed a method for capturing construction workers’ SA, arguing that integrating workers’ SA can provide management with more complete information and improve the quality of decision-making.

Workers are typically simply information recipients and task performers due to their poor education and literacy levels [31], but this does not negate their value in contributing to process improvement. Workers possess construction knowledge and experience, which can provide the data required for process optimization [32]. Workers with high levels of SA can more acutely identify problems and propose solutions, which can be translated into experience after they have been validated in practice. Studies have demonstrated that those with high SA typically perform better at work [33,34].

2.3. Lean Construction and Its Applications

Lean construction (LC) extends from lean manufacturing, with the core concept of maximizing value and minimizing waste [3]. The concept of LC was first introduced by Ballard at the IGLC (International Group of Lean Construction) conference in 1993. Subsequently, experts and scholars from all over the world began to pay attention to LC and apply its ideological principles to actual construction. Studies have shown that the adoption of LC can save about 20% to 30% of time and increase productivity [35].

The construction industry has implemented at least 32 different lean practices, with the Last Planner System (LPS) and Just-In-Time (JIT) being two of the most popular [36]. JIT meets the immediate needs of the construction site by optimizing the delivery and storage of materials. Bamana et al. [37] found, through a comparative case study, that the use of a material-sorting package can facilitate JIT material delivery and improve workplace utilization and labor productivity. LPS can improve the reliability of planning by reducing the variability in the construction process. Shehab et al. [38] showed how tracking design-planning performance with LPS metrics can facilitate the adoption of LPS in architectural design, pointing out that the participation and commitment of workers represent the direct embodiment of collaboration and enhance the reliability of the design process.

Although LC can improve productivity, there are some problems with its application in practice. Mano et al. [39] analyzed the barriers to the implementation of LC and identified leadership characteristics and cultural and structural aspects as key barriers. Abu et al. [40] highlighted several challenges that can impede the successful implementation of LC techniques. Among these challenges are illiteracy or insufficient knowledge among workers, a lack of adequate training and information-sharing, difficulties in grasping lean concepts, and inadequate exposure to the importance of lean implementation.

2.4. Labor Productivity Improvement in Lean Construction

Liu et al. [41] argued that the use of LC concepts is expected to decrease waste and increase productivity. Labor productivity improvement in LC is achieved in two main ways. One is to increase worker engagement to improve resource efficiency, and the other is to increase flow efficiency by reducing waste. Culture and people are regarded as the most critical factors in the practice of lean construction in China [42]. Hamzeh and Albanna [43] asserted that all human resources participating in the process must be integrated, empowered, and trained in order to fully reap the benefits of lean construction. Financial incentives are frequently utilized to increase worker engagement [44]. In addition to money, intangible incentives such as recognition and teamwork can make workers feel respected and realize their own value, thereby improving their satisfaction [45,46].

In order to raise the direct work rate of the workers, Sriya Muralidhara et al. [47] offered a number of improvement solutions for the non-value-added activities of workers on site. Neve [48] discovered through a case study that using lean tools in construction projects could decrease non-value-added activity and raise labor productivity. Jiang Li Xuan et al. [49] evaluated the combination of “worker’s home” and “lean work package” management. Through the application of the “lean work package” management model, technologies such as the Last Planner System (LPS) and Just-In-Time (JIT) system, etc., were implemented to improve flow efficiency. Additionally, the “worker’s home” management model achieved resource efficiency by increasing work motivation.

Therefore, the LC philosophy emphasizes the importance both of sparking enthusiasm among workers to enhance resource efficiency and of implementing process optimization to reduce waste and improve flow efficiency.

In summary, many factors need to be considered comprehensively to improve labor productivity. In China, besides technological innovation, we need to pay more attention to the training and re-education of workers to improve their overall quality. LC not only pays attention to the application of technology and tools but also emphasizes the importance of people. By strengthening the participation and training of workers, we can deepen the team’s understanding of LC, effectively overcome obstacles in implementation, and improve construction efficiency and project management quality.

Thus, the goal of this study was to train workers in lean methodology, enhance their SA of waste minimization on construction sites and process optimization, teach them how to apply VSM tools effectively, incorporate their practical experience into the process of improvement, boost worker motivation, and, ultimately, improve labor productivity while upgrading skills.

3. Research Design

3.1. Research Framework

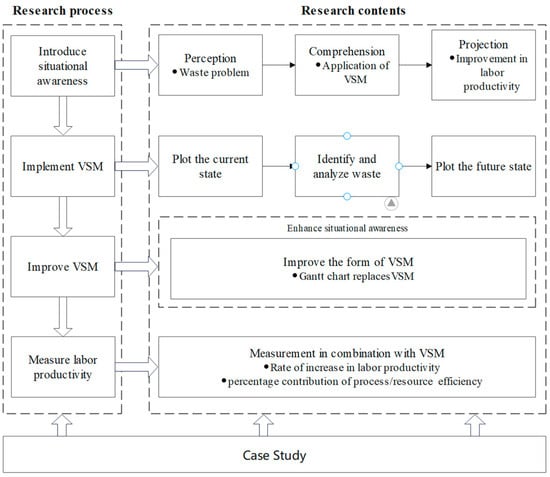

In this study, we designed a process framework to explore workers’ participation in project improvement and improve labor productivity based on SA, as shown in Figure 1. Firstly, the concept of SA was introduced, and three levels of SA were developed. Secondly, VSM was used to improve the construction process. Considering the limitations of workers’ cultural level, a more intuitive and easily understandable Gantt chart was proposed as an alternative to facilitate worker understanding and drawing. Finally, a labor productivity measurement method combined with VSM was put forward, which enabled workers to predict the improvement of labor productivity. The feasibility of this research framework was verified through a case study, and the value of workers’ participation in project improvement based on SA was determined, providing new methods and strategies for improving labor productivity.

Figure 1.

The research framework.

3.1.1. Introduction of SA

We introduced SA and developed three levels of SA, “perception-comprehension-projection”, based on LC. First of all, by providing relevant lean training and education to workers, we aimed to enhance the SA of the overall construction site, especially the around issue of waste. Secondly, using VSM as a tool for workers to practice LC helped them understand value-added and non-value-added activities in the workflow. Value stream analysis was conducted through current and future diagrams to identify and eliminate waste. Finally, the labor productivity measurement method combined with VSM was developed for workers to predict and continuously improve labor productivity.

3.1.2. Implementation of VSM

VSM is a visualization tool used to describe logistics and information flow within the framework of the lean manufacturing system popularized by Rother and Shook [50]. It is used to visualize the material and information flow of the production process, analyze the current state of events, and design the future state. VSM requires a distinction between value-added and non-value-added activities and targeted improvement measures. Therefore, VSM includes data related to the entire process, involving the duration of different types of activities. The team is able to map current and future state maps based on actual, quantifiable data, and make decisions for improvement based on the ratio of value-added activities. Typically, VSM is an LC improvement tool used by managers. In this study, workers’ participation in the implementation of VSM was explored.

3.1.3. Improvements in VSM

The traditional VSM uses complex symbols and arrows to represent the relationship between tasks and processes, which demands a high level of expertise from both the graphic creators and readers. Workers with lower levels of education may encounter certain difficulties in understanding and applying VSM. For workers with lower levels of education, understanding and applying complex VSM graphics poses certain difficulties. Therefore, the more intuitive and easily understandable Gantt chart is considered as an alternative tool, helping workers understand the representation of value-added activities and non-value-added activities in the graph, the connotations of the current and the future maps, and their roles in improving labor productivity.

Which demands a high level of expertise from both the graphic creators and readers. Workers with lower levels of education may encounter certain difficulties in understanding and applying VSM.

3.1.4. Improvements in Labor Productivity

Modig and Åhlström [9] proposed the concepts of flow efficiency and resource efficiency. Flow efficiency emphasizes eliminating or shortening non-value-added links in the production process, while resource efficiency focuses on maximizing the efficiency of people, materials, equipment, etc. Enhancing the SA of construction workers regarding waste and process improvements, on the other hand, can boost workers’ enthusiasm and involvement, thereby improving resource efficiency. On the other hand, fully leveraging workers’ on-site experience can enhance flow efficiency. In addition, combining the improvement of labor productivity with the improvement of VSM can strengthen workers’ understanding and application of VSM tools.

3.2. Research Methodology

3.2.1. Case Study

Based on the framework proposed in the previous section, the feasibility of the framework was assessed mainly by using the case study approach. Case studies are usually classified into exploratory, descriptive, and explanatory categories [51]. The case study method, which is appropriate for answering “how-to”-type research questions, emphasizes the situation’s realism while portraying and exploring the mechanics underlying the organizational phenomena. A single case study design allows for a rich description of the phenomenon [52], which helps ensure the depth of the case study. The case study in this study involved five workers who directly participated in the actual construction project. For exploratory research, a single-case-study approach is feasible. This article demonstrates the development strategy of SA for construction workers based on LC and the practical process of improving labor productivity through case studies. In addition to the three levels of SA development, the case study also included methods for implementing and improving VSM, as well as measurement methods for labor productivity improvement. The combination of these methods led to the participation of construction workers in labor productivity improvement based on SA having not only a conceptual framework but also strong operability.

3.2.2. Measurement Method of Labor Productivity Improvement

Combined with VSM improvement, the improvement rate of activity productivity was adopted as an indicator of labor productivity improvement [53]. The contribution ratio of flow efficiency to resource efficiency in improving labor productivity was distinguished to reflect the improvement process of VSM, as shown in Table 1. A time-and-motion study was used to measure the working duration.

Table 1.

Calculation formulas.

4. Case Implementation Process and Analysis

4.1. Case Description

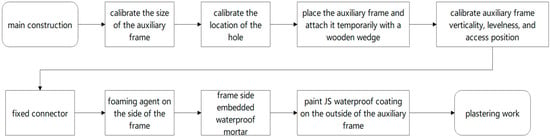

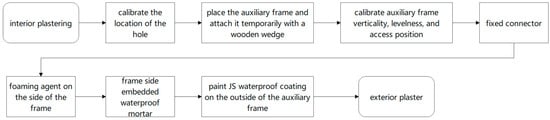

The case project is a finely decorated student apartment building project constructed by a school in Changzhou, China. It has 22 floors above ground and 1 floor underground, with a building area of 20,166 square meters. The structure is a frame shear wall structure and adopts a general construction contracting model. Considering that worker participation requires starting from the end of the process-level operation, for the practice case, we chose the construction process of installing exterior window auxiliary frames as the object of worker participation improvement. This was an operational level that workers can actually participate in and was a more appropriate object for establishing and improving workers’ SA. The installation was carried out after the completion of the main structure. Each layer had 24 exterior window auxiliary frames. Three installers installed the frames, and two tile workers carried out waterproof construction on the outside of the frame with the progress of the installation of the frames. This construction activity involved a total of five workers. The specific installation timeline of the construction process is shown in Figure 2.

Figure 2.

Construction process for exterior window auxiliary frame installation.

The general contractor has over ten years of experience in LC practice. It has also established a relatively complete LC culture system, technical system, and employee training system. However, the participation of construction workers in LC practice is still limited to passive execution through operational standards. This case study revolved around two questions raised in this article. It involved LC training sessions where workers were introduced to lean principles and tools. Specifically, they learnt about the recognition and identification of waste, the distinction between value-added and non-value-added activities, the application of VSM, and the measurement of labor productivity. The goal was to enhance construction workers’ awareness of waste and process improvement, empowering them to actively participate in enhancing labor productivity.

4.2. VSM with Worker Involvement

In the case study project, workers were empowered and encouraged to participate in the VSM improvement process. They improved labor productivity by collecting and analyzing measurement data. Therefore, the project management team adopted a variety of incentive measures. In addition to allowing workers to have a higher income and be paid on time, this strengthened the professional training of workers so that they could acquire more skills and career development opportunities. At the same time, the management created more open communication channels to ensure that the opinions and suggestions of workers were effectively listened to and respected, continuously improving their self-efficacy and problem-solving abilities. Workers’ knowledge, experience, and insights provided new perspectives for optimizing the construction process.

- (1)

- Analysis of value-added and non-value-added activities

Two value-added and eight non-value-added activities are identified among the ten current activities. Among them, activities 4 and 7 are categorized as value-added activities, since they affect the ultimate form of products. However, the preparation time of all activities is non-value-added time. See Table 2 for a detailed analysis.

Table 2.

Analysis of value-added and non-value-added activities.

- (2)

- Improvement of value-added activities

The improvement of value-added activities is mainly reflected in improving the quality of the activities themselves and reducing the preparation time. Activity 4 can optimize the preparation time by standardizing the size and shape of wooden wedges and supplying wooden wedges prepared in advance. For activity 7, workers pay attention to the accuracy of temporary fixation during installation, which can facilitate the installation of connectors and reduce the preparation time. At the same time, workers reserve the enterprise opening on one side of the auxiliary frames, which can reduce the time required for installing fixed connectors and improve the installation quality.

- (3)

- Improvement of non-value-added activities

Non-value-added activities include non-value-added but essential activities and pure waste. We aimed to cancel pure waste and optimize non-value-added but essential activities.

Pure waste 1 and 2 were eliminated. The worker suggested marking the window openings with the specifications of the exterior window auxiliary frames before transporting them to the respective floors. This would allow the transport staff to position the frames according to the marked dimensions, reducing the need for secondary verification and increasing flow efficiency. The workers decided to install the auxiliary frames after finishing the interior plastering. They also planned to perform secondary trimming on parts of the external window openings where there were size or position deviations of more than 4 mm noticed during the plastering stage. In this way, workers only needed to check the centerline and horizontal line of the window frame installation positions, reducing the number of items needed to check the dimensions and positions of the openings.

For activity 5, which is a non-value-added but necessary activity, it was convenient for workers to correct and improve the positioning accuracy of the auxiliary frame by standardizing the pre-positioning of the opening prior to construction. To improve the efficiency of activity 8, the workers believed that it was essential to ensure that the exterior window standing openings met the specifications and standards. Additionally, they suggested making a secondary adjustment to the partial openings during the plastering stage to ensure consistent gaps on the sides of the auxiliary frames. For Activities 9 and 10, workers decided to focus on the preparation of waterproof mortar and waterproof coating. The bricklayer would handle centralized waterproof construction after installing the auxiliary frame. This approach prevented material and time wastage and optimized preparation and transportation procedures. Simultaneously, the construction of embedded waterproof mortar and foaming agent would be carried out alternately to maximize time efficiency. These measures aimed to improve overall work efficiency by ensuring that necessary steps were taken.

4.3. Improved VSM: Gantt Chart

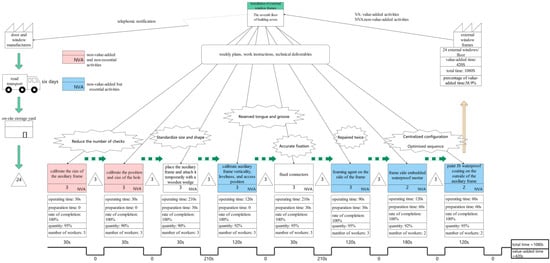

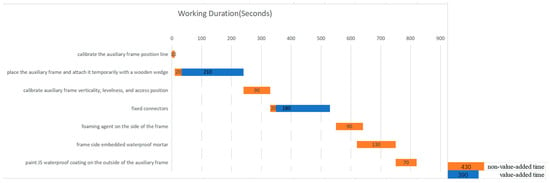

According to the above analysis process, the current state diagrams drawn by the manager are shown in Figure 3.

Figure 3.

Value stream mapping of current state of exterior door frame installation.

As can be seen, the various arrows, icons, and symbols in the diagram are intertwined to form a complex network. This type of graphic design challenges the comprehension ability of the viewer, and the workers have a low cultural level, which poses difficulties in understanding. In contrast, Gantt charts are simpler, more intuitive, and easier to create and can replace the traditional VSM [54]. Therefore, using the Gantt chart to improve the VSM drawing form makes it more convenient and intuitive for workers to understand and draw current and future VSM drawings, as shown in Figure 4 and Figure 5.

Figure 4.

Current-state diagram of auxiliary frame installation.

Figure 5.

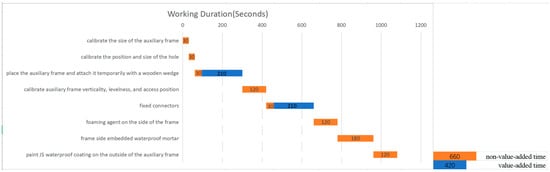

Future-state diagram of auxiliary frame installation.

A Gantt chart with the vertical axis showing construction operations and the horizontal axis indicating the duration of each step assisted workers in understanding the timetable and sequence of the workflow, allowing them to better grasp the project’s progress. Furthermore, the Gantt chart clearly divided value-added time from non-value-added time in distinct colors, making it easier for workers to spot possible waste and bottlenecks. The adjusted chart provided workers with a more operational and practical tool, which was expected to improve the management of construction projects and enhance worker participation.

4.4. Results: Analysis of Labor Productivity Improvement

The improvements suggested by the workers were accepted by the management, and the optimized installation and construction process is shown in Figure 6. As a result of the improvement, the total time taken by the installation and construction activities of the outer window frame was shortened from 1080 s to 820 s, and labor productivity increased by 24.07%. See Table 3 for the specific improvement rate of each process. Among them, the percentage of value-added activities increased from 38.9% to 47.6%, with an improvement percentage of 22.4%. This improvement was mainly achieved by enhancing the fixed connectors, thus improving resource efficiency with a contribution rate of 11.54%. The duration of another value-added activity reached the current ideal optimization level. The remaining improvements all came from the improvement of flow efficiency, with a contribution rate of 88.46%. Among them, activities 9 and 10 contributed the most, reaching 19.23%.

Figure 6.

Optimized construction process for external window auxiliary frame installation.

Table 3.

The results regarding the improvement of labor productivity.

5. Discussion

5.1. Improvement of Workers’ SA

The three levels of SA based on LC developed in this study achieved good practice results in the case study project. Through LC training, workers’ perception of waste in specific work improved. By introducing simplified VSM, workers could understand the process of waste identification and process improvement, enhancing their insights into the entire construction process. Improvement was achieved by understanding and mastering the labor productivity measurement method. In this process, workers become proactive participants who could identify problems and propose solutions and communicate with colleagues and management to jointly promote workflow improvement. There was an increase in workers’ SA of construction waste, labor productivity improvement, and process improvement. They focused not only on task completion but also on how to identify and eliminate waste and complete tasks more efficiently.

5.2. Improvement of Worker Motivation

Workers have a unique insight into bottlenecks, pitfalls, and opportunities for improvement in processes through their work and accumulated experience. For example, they can keenly observe the inconvenient storage of materials, irrational layout of tools and equipment, and other details that may affect work efficiency and safety. When we empower workers to participate in process improvement discussions and decisions, we can capitalize on their experience and knowledge and increase their motivation. This increased motivation stems from their realization that they can directly influence and improve the work environment. Workers feel the importance and value of themselves in the project when their suggestions for improvement are implemented by the project team. This helps enhance their sense of belonging and responsibility, inspiring them to be passionate about continuous improvement and optimizing the work environment. This increased motivation does not just exist at the individual level but also has an impact on the whole team. The interaction and joint efforts of team members create a more positive, collaborative, and productive work atmosphere. In addition, the improved VSM method also makes it feasible for workers to actively participate.

5.3. Improvement of Labor Productivity

The focus of labor productivity improvement has shifted from resource efficiency to flow efficiency. The overall labor productivity in the case project increased by 24.07%. The resource efficiency contribution rate was 11.54%, involving only one process, which primarily stemmed from reducing the operation time for fixed connectors. The flow efficiency contribution rate was 88.46%, involving all processes, indicating that there is greater room for improvement in flow efficiency. Workers’ sensitivity to waste enabled them to observe the work process more carefully. They understood the relationship and dependence between each link and identified the factors that may have led to the interruption or delay of the process. Therefore, improving the SA of workers toward waste, process optimization, and utilizing their rich on-site experience and knowledge to participate in the process of process optimization was very beneficial for improving flow efficiency.

6. Conclusions

In this paper, we designed a framework for improving labor productivity based on SA and improved VSM. A case study was conducted to verify its effectiveness. Construction workers have extensive practical experience, as they are the real operators and direct subjects when it comes to increasing labor productivity. A three-level LC-based SA development strategy was put forward to increase construction workers’ SA, to make full use of their experience and knowledge. Considering the specialty and complexity of VSM, a concise Gantt chart was proposed as a replacement, which made it more operable for workers to participate in the VSM process to improve labor productivity. The research also adopted a labor productivity measurement method combined with VSM to evaluate the actual improvement effects. Distinguishing the contribution of resource efficiency and flow efficiency to labor productivity made the labor productivity improvement paths based on SA and improved VSM clearer and easier to quantify.

At the theoretical level, this study provides a comprehensive framework and establishes a bridge between improving workers’ SA and participating in labor productivity improvements. On one hand, it provides theoretical and practical support for worker participation and SA improvement in LC. It also offers inspiration for improving worker participation in labor productivity, from resource efficiency to flow efficiency.

At the practical level, a specific case project is presented to demonstrate the entire process of construction workers’ participation in labor productivity improvement. Integrating workers’ enthusiasm and autonomy into daily operation processes not only makes full use of workers’ experience and knowledge to improve work efficiency but also enhances workers’ sense of participation. The application of the improved VSM tool makes the framework feasible and operational.

However, there are certain limitations to this study. First, the scope of this study was somewhat limited, only involving the installation and construction of external window auxiliary frames in a relatively simple school dormitory project. In future research, more workers and different construction teams should be included to achieve more comprehensive SA promotion at different levels in the construction process. Secondly, it is not enough to focus on the awareness of waste perception and process improvement to enhance workers’ SA; with the increasing adoption of digital technology, construction workers’ real-time perception and response capabilities also should be developed.

Future research should further delve into the implementation of lean construction to last stage of the workflow to comprehensively increase workers’ SA and enhance workers’ competence. Increasing labor productivity and project performance will allow the advancement of more effective and environmental friendly construction engineering practices.

Author Contributions

Conceptualization, L.J. and H.S.; Formal analysis, L.J. and H.S.; Methodology, L.J. and H.S.; Resources, J.Z.; Software, H.S. and J.Z.; Supervision, L.J.; Writing—original draft, L.J., H.S. and J.Z.; Writing—review and editing, L.J., H.S. and J.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This work was funded by the Soft Science Research Project of the Ministry of Housing and Urban–Rural Development of China (No. 2019-R-017).

Data Availability Statement

The data analysis results presented in the paper are available from the corresponding author by request.

Conflicts of Interest

Author Jinhua Zhang was employed by the company Beijing Glodon Cailiang Technology Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Neve, H.H.; Wandahl, S.; Lindhard, S.; Teizer, J.; Lerche, J. Determining the relationship between direct work and construction labor productivity in North America: Four decades of insights. J. Constr. Eng. Manag. 2020, 146, 04020110. [Google Scholar] [CrossRef]

- Koskela, L. Application of New Production Philosophy to the Construction Industry; Technical Report No. 72; Centre for Integrated Facilities Engineering, Stanford University: Stanford, CA, USA, 1992. [Google Scholar]

- Koskela, L.; Howell, G.; Ballard, G.; Tommelein, I. The foundations of lean construction. Des. Constr. Build. Value 2002, 291, 211–226. [Google Scholar]

- Kenley, R. Productivity improvement in the construction process. Constr. Manag. Econ. 2014, 32, 489–494. [Google Scholar] [CrossRef]

- Gupta, M.; Hasan, A.; Jain, A.K.; Jha, K.N. Site amenities and workers’ welfare factors affecting workforce productivity in Indian construction projects. J. Constr. Eng. Manag. 2018, 144, 04018101. [Google Scholar] [CrossRef]

- Hasan, A.; Baroudi, B.; Elmualim, A.; Rameezdeen, R. Factors affecting construction productivity: A 30 year systematic review. Eng. Constr. Archit. Manag. 2018, 25, 916–937. [Google Scholar] [CrossRef]

- Aghayeva, K.; Ślusarczyk, B. Analytic hierarchy of motivating and demotivating factors affecting labor productivity in the construction industry: The case of Azerbaijan. Sustainability 2019, 11, 5975. [Google Scholar] [CrossRef]

- Besklubova, S.; Zhang, X. Improving construction productivity by integrating the lean concept and the Clancey heuristic model. Sustainability 2019, 11, 4535. [Google Scholar] [CrossRef]

- Modig, N.; Åhlström, P. This Is Lean: Resolving the Efficiency Paradox; Rheologica Publishing: Gothenburg, Sweden, 2015. [Google Scholar]

- Son, P.V.H.; Van Tien, P. Apply EZStrobe to simulate the finishing work for reducing construction process waste. Sci. Rep. 2024, 14, 349. [Google Scholar] [CrossRef] [PubMed]

- Ann, D.; Brady, D.; Tzortopoulos, P.; Rooke, J. An Examination of the Barriers to Last Planner Implementation; University of Salford: Salford, UK, 2011. [Google Scholar]

- Berroir, F.; Harbouche, L.; Boton, C. Top down vs. bottom up approaches regarding the implementation of lean construction through a French case study. In Proceedings of the 23th International Group for Lean Construction Conference, Perth, Australia, 29–31 July 2015; pp. 73–82. [Google Scholar]

- Friblick, F.; Olsson, V.; Reslow, J. Prospects for implementing Last Planner in the construction industry. In Proceedings of the 17th International Group for Lean Construction Conference, Taipei, Taiwan, 15–17 July 2009; pp. 197–206. [Google Scholar]

- Loosemore, M. Improving construction productivity: A subcontractor’s perspective. Eng. Constr. Arch. Manag. 2014, 21, 245–260. [Google Scholar] [CrossRef]

- Endsley, M.R. Situation awareness global assessment technique. In Proceedings of the IEEE 1988 National Aerospace and Electronics Conference, Dayton, OH, USA, 23–27 May 1988; pp. 789–795. [Google Scholar]

- Görsch, C.; Seppänen, O.; Peltokorpi, A.; Lavikka, R. Construction workers’ situational awareness–an overlooked perspective. In Proceedings of the 28th International Group for Lean Construction Conference, Berkeley, CA, USA, 6–12 July 2020; pp. 937–948. [Google Scholar]

- Wang, X.; Chen, Y.; Liu, B.; Shen, Y.; Sun, H. A total factor productivity measure for the construction industry and analysis of its spatial difference: A case study in China. Constr. Manag. Econ. 2013, 31, 1059–1071. [Google Scholar] [CrossRef]

- Wei, Y.D. Regional Development in China: States; Globalization and Inequality; Routledge: London, UK, 2013. [Google Scholar]

- Luo, M.; Fan, H.; Liu, G. Measuring regional differences of construction productive efficiency in China: A distance friction minimization approach. Eng. Constr. Arch. Manag. 2020, 27, 952–974. [Google Scholar] [CrossRef]

- Rathnayake, A.; Middleton, C. Systematic review of the literature on construction productivity. J. Constr. Eng. Manag. 2023, 149, 03123005. [Google Scholar] [CrossRef]

- Ghodrati, N.; Yiu, T.W.; Wilkinson, S.; Shahbazpour, M. Role of management strategies in improving labor productivity in general construction projects in New Zealand: Managerial perspective. J. Manag. Eng. 2018, 34, 04018035. [Google Scholar] [CrossRef]

- Lu, H.; Zhang, Q.; Cui, Q.; Luo, Y.; Pishdad-Bozorgi, P.; Hu, X. How can information technology use improve construction labor productivity? An empirical analysis from China. Sustainability 2021, 13, 5401. [Google Scholar] [CrossRef]

- Ensley, M.R. Toward a theory of situation awareness in dynamic systems. Hum. Factors 1995, 37, 85–104. [Google Scholar]

- Rapuzzi, R.; Repetto, M. Building situational awareness for network threats in fog/edge computing: Emerging paradigms beyond the security perimeter model. Future Gener. Comput. Syst. 2018, 85, 235–249. [Google Scholar] [CrossRef]

- Zhang, T.; Liu, S.; Qiu, W.; Lin, Z.; Zhu, L.; Zhao, D.; Qian, M.; Yang, L. KPI-based Real-time Situational Awareness for Power Systems with a High Proportion of Renewable Energy Sources. CSEE J. Power Energy Syst. 2020, 8, 1060–1073. [Google Scholar]

- Chen, Z.; Xu, Y.; Pan, M.; Wang, T.; Yuan, J.; Chen, L.; Tao, S. Multi-round load control method considering the safe electricity consumption for industrial users based on situational awareness. IET Gener. Transm. Distrib. 2024, 18, 353–367. [Google Scholar] [CrossRef]

- Uddin, S.J.; Albert, A.; Alsharef, A.; Pandit, B.; Patil, Y.; Nnaji, C. Hazard recognition patterns demonstrated by construction workers. Int. J. Environ. Res. Public Health 2020, 17, 7788. [Google Scholar] [CrossRef]

- Ibrahim, A.; Nnaji, C.; Namian, M.; Koh, A.; Techera, U. Investigating the impact of physical fatigue on construction workers’ situational awareness. Saf. Sci. 2023, 163, 106103. [Google Scholar] [CrossRef]

- Lee, K.; Hasanzadeh, S. Understanding Cognitive Anticipatory Process in Dynamic Hazard Anticipation Using Multimodal Psychophysiological Responses. J. Constr. Eng. Manag. 2024, 150, 04024008. [Google Scholar] [CrossRef]

- Martinez, J.G.; Yeung, T.; Sacks, R.; Shahaf, Y.; Sharoni, L.-O. Situational Awareness in Construction Using a Serious Game. J. Constr. Eng. Manag. 2023, 149, 04022183. [Google Scholar] [CrossRef]

- Guo, Z.; Sun, L.; Zhang, H.; Yuan, X.; Cui, K. Effects of video display terminal fatigue on situational awareness ability of operators and modeling study. Nucl. Eng. Des. 2023, 414, 112534. [Google Scholar] [CrossRef]

- Bashir, A.M.; Suresh, S.; Oloke, D.A.; Proverbs, D.G.; Gameson, R. Overcoming the challenges facing lean construction practice in the UK contracting organizations. Int. J. Archit. Eng. Constr. 2015, 4, 10–18. [Google Scholar] [CrossRef]

- Mehta, R.K.; Peres, S.C.; Shortz, A.E.; Hoyle, W.; Lee, M.; Saini, G.; Chan, H.-C.; Pryor, M.W. Operator situation awareness and physiological states during offshore well control scenarios. J. Loss Prev. Process Ind. 2018, 55, 332–337. [Google Scholar] [CrossRef]

- Raza, M.; Kiran, R.; Ghazal, S.; Jeon, J.; Salehi, S.; Kang, Z.; Cokely, E. An eye tracking based framework for safety improvement of offshore operations. J. Eye Mov. Res. 2023, 16, 2. [Google Scholar] [CrossRef] [PubMed]

- Locatelli, G.; Mancini, M.; Gastaldo, G.; Mazza, F. Improving projects performance with lean construction: State of the art, applicability and impacts. Organ. Technol. Manag. Constr. Int. J. 2013, 5, 775–783. [Google Scholar] [CrossRef]

- Babalola, O.; Ibem, E.O.; Ezema, I.C. Implementation of lean practices in the construction industry: A systematic review. Build. Environ. 2019, 148, 34–43. [Google Scholar] [CrossRef]

- Bamana, F.; Lehoux, N.; Cloutier, C. Simulation of a construction project: Assessing impact of just-in-time and lean principles. J. Constr. Eng. Manag. 2019, 145, 05019005. [Google Scholar] [CrossRef]

- Shehab, L.; Al Hattab, M.; Khalife, S.; El Samad, G.; Abbas, Y.; Hamzeh, F. Last Planner System Framework to Assess Planning Reliability in Architectural Design. Buildings 2023, 13, 2684. [Google Scholar] [CrossRef]

- Mano, A.P.; Gouvea da Costa, S.E.; Pinheiro de Lima, E. Criticality assessment of the barriers to Lean Construction. Int. J. Product. Perform. Manag. 2020, 70, 65–86. [Google Scholar] [CrossRef]

- Abu Aisheh, Y.I.; Tayeh, B.A.; Alaloul, W.S.; Almalki, A. Health and safety improvement in construction projects: A lean construction approach. Int. J. Occup. Saf. Ergon. 2022, 28, 1981–1993. [Google Scholar] [CrossRef] [PubMed]

- Liu, M.; Ballard, G.; Ibbs, W. Work flow variation and labor productivity: Case study. J. Manag. Eng. 2011, 27, 236. [Google Scholar] [CrossRef]

- Jiang, L.; Zhong, H.; Chen, J.; Su, Z.; Zhang, J.; Wang, X. Lean construction practice: Culture, standardization and informatization—A case from China. In Proceedings of the 27th International Group for Lean Construction Conference, Dublin, Ireland, 1–7 July 2019; pp. 949–960. [Google Scholar]

- Hamzeh, F.R.; Albanna, R.M. Developing a tool to assess workers’ understanding of lean concepts in construction. In Proceedings of the 27th International Group for Lean Construction Conference, Dublin, Ireland, 1–7 July 2019; pp. 179–190. [Google Scholar]

- Alinaitwe, H.; Mwakali, J.A.; Hansson, B. Organizational effectiveness of Ugandan building firms as viewed by craftsmen. J. Civ. Eng. Manag. 2009, 15, 281–288. [Google Scholar] [CrossRef]

- Azeez, M.; Gambatese, J.; Hernandez, S. What do construction workers really want? A study about representation, importance, and perception of US construction occupational rewards. J. Constr. Eng. Manag. 2019, 145, 04019040. [Google Scholar] [CrossRef]

- Hashiguchi, N.; Sengoku, S.; Kubota, Y.; Kitahara, S.; Lim, Y.; Kodama, K. Age-Dependent influence of intrinsic and extrinsic motivations on construction worker performance. Int. J. Environ. Res. Public Health 2021, 18, 111. [Google Scholar] [CrossRef]

- Muralidharan, S.; Krishnankutty, P.; Hwang, B.G.; Caldas, C.; Mulva, S. Enhancing labour productivity in petrochemical construction and maintenance projects. In Proceedings of the 26th International Group for Lean Construction Conference, Chennai, India, 18–22 July 2018; pp. 18–22. [Google Scholar]

- Neve, H.H.; Lerche, J.; Wandahl, S. Combining lean methods to improve construction labour efficiency in renovation projects. In Proceedings of the 29th International Group for Lean Construction Conference, Lima, Peru, 14–17 July 2021; pp. 14–17. [Google Scholar]

- Jiang, L.; Zhong, H.; Chen, J.; Cheng, J.; Chen, S.; Gong, Z.; Lun, Z.; Zhang, J.; Su, Z. Study on the construction workforce management based on lean construction in the context of COVID-19. Eng. Constr. Archit. Manag. 2023, 30, 3310–3329. [Google Scholar] [CrossRef]

- Rother, M.; Shook, J. Learning to See: Value Stream Mapping to Add Value and Eliminate Muda; Lean Enterprise Institute: Boston, MA, USA, 1999. [Google Scholar]

- Yin, R.K. Case Study Research: Design and Methods; Sage: London, UK, 2009. [Google Scholar]

- Siggelkow, N. Persuasion with case studies. Acad. Manag. J. 2007, 50, 20–24. [Google Scholar] [CrossRef]

- Saini, A.; Thomas, A. Development of a machine learning based-labour productivity prediction tool to practice lean construction. In Proceedings of the 31th International Group for Lean Construction Conference, Lille, France, 26 June–2 July 2023; pp. 1326–1336. [Google Scholar]

- Yasaman, A.; Zofia, K. Rybkowski. Developing & Testing a Value Stream Map Simulation: Helping the Construction Industry Learn to See. In Proceedings of the 30th International Group for Lean Construction Conference, Edmonton, AB, Canada, 25–31 July 2022; pp. 342–353. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).