Abstract

The objective of this research is to develop an innovative methodology for evaluating the quality of coarse aggregate mixes that incorporate recycled concrete aggregate for use in structural concrete. The proposed approach consists of three steps: measuring the packing density, quantifying the adhered mortar, and characterizing the mechanical resistance of the aggregate mixes containing both natural and recycled concrete aggregate. Comprehensive practical recommendations for each step are discussed in detail to facilitate the broader future utilization of recycled concrete aggregate in structural concrete. The mechanical resistance of aggregate mixes is significantly influenced by both packing density and the quantity of adhered mortar. Predictive models are used to illustrate the mechanical resistance of aggregate mixes based on packing density and adhered mortar amount, recognizing the direct correlation between these properties.

1. Introduction

Coarse aggregate typically makes up over 50% of the volume of concrete, significantly impacting its properties [1]. The use of coarse recycled aggregate (RA) is considered more environmentally and economically beneficial than the use of coarse natural aggregate (NA). From an environmental perspective, the benefits are related to the conservation of NA reserves and a reduction in construction and demolition waste [2,3]. In terms of the economic aspect, it has been shown that using RA instead of NA can result in savings of up to 60% [4]. The most suitable type of coarse RA for closed-loop recycling is the crushed concrete aggregate which is derived from the reuse of structural concrete [5]. Throughout the manuscript, RA mainly refers to coarse recycled concrete aggregate, despite the existence of various types of RA based on the virgin material. In the current literature, standards, and guidelines, the amount of RA suggested to replace NA in structural concrete is typically generic [6]. Concrete design is mainly a packing problem, and the literature has recognized the significant contribution of aggregate packing to concrete’s performance [5,7,8]. Most up-to-date developed concrete mix design methods have been based on packing optimization principles, where the aggregate phase is designed according to well-developed curves built on NA’s empirical data (e.g., Fuller, A&A, modified A&A) [9,10]. It is important to note that simply replacing NA with RA using conventional mix design methods without considering the quality of the RA can lead to inaccurate results when compared to NA. Therefore, it is crucial to consider the quality of the RA when designing concrete mixes.

The production process of RA should be optimized for both quality and quantity. The quality of RA is dependent on the performance of the virgin concrete, the presence of contaminants, and aggregate processing. Researchers have investigated the amount of adhered mortar attached to the RA, and their findings have varied from about 20% to 47% [4]. Numerous methods have been developed to quantify or remove the adhered mortar of the RA, as it is one of the most influential factors in its performance. Various methods have been proposed for treating RA, including carbonation [11], embedding it in epoxy [12], soaking in sodium sulphate and applying freeze–thaw cycles [13], grinding using the rolling vibration effects of a ball mill [14], autogenous cleaning [15], heat treatment [16], ultrasonic cleaning [17], soaking in acidic solutions (e.g., hydrochloric, sulfuric, phosphoric) [18], or a combination of these methods [19]. The methods listed are generally based on three possible treatments or their combinations: mechanical, thermal, and chemical. These procedures require additional steps in aggregate production, which hinders the broader application of RA. Some methods are not applicable for all types of RA, either based on the size (e.g., thermal treatment is not productive for small particles) or origin (e.g., acidic solution treatment for limestone-based RA). Indeed, the simplest approach for utilizing RA in structural concrete is to limit its amount, which will not inferiorly affect the concrete’s performance [19].

RA generally has a low specific gravity ranging from 1.91 to 2.70 and a reported water absorption capacity of 0.5 m% to 14.75 m% [4]. These two parameters are commonly used as classification criteria in various standards and guidelines [19,20]. There is usually a strong correlation between the specific gravity and water absorption capacity of RA, as they are both typically influenced by the porous adhered mortar. The addition of RA has a significant impact on the behavior of fresh and hardened concrete, due to its altered properties compared to NA. This is mainly attributed to RA’s higher absorption capacity, rough surface, and irregular shape [4,6,20,21,22,23,24]. However, due to the complexity of its structure, which includes adhered mortar and NA, the mechanical characterization of RA is not yet fully understood. The mechanical properties of RA are typically defined by the Los Angeles abrasion coefficient, 10% fine value, and soundness [20]. Although the Los Angeles abrasion coefficient is widely used in the literature and recommended in standards and guidelines, it does not consider the influence of particle packing on the mechanical resistance of the bulk aggregate. Furthermore, some previous reports in the literature have evaluated the quality of RA based on the performance of virgin concrete [19]. The assessment of virgin rock’s mechanical properties has been deemed insufficient, and the same can be expected for concrete used in aggregate production. Additionally, the quality assessment method based on virgin concrete cannot be applied to an industrial scale, where recycling plants typically handle concrete waste from multiple sources. It has been acknowledged that examining the bulk aggregate would lead to methods that can more adequately cover the difference in physical properties and future behaviors in concrete, instead of evaluating aggregate quality solely based on the virgin rock/material [1,25].

This study presents a method for the quality assessment of aggregate mixes containing RA. A holistic approach is taken to cover all possible physical variables of RA that influence the mechanical resistance of the aggregate mixes. The experimental study examines particle packing on coarse aggregate containing NA and RA, covering both shape and size effects. Quantifying the amount of adhered mortar in the RA (i.e., quantification of its two phases: adhered mortar and virgin aggregate) is crucial in determining its structural properties. Additionally, the structure of the RA and its impact on the packing density of the coarse aggregate mix are important factors in determining the mechanical behavior of the RA in concrete. As coarse aggregate is not the only constituent of concrete, but it is one of the most responsible for its mechanical resistance, evaluating its mechanical properties separately would provide an advanced tool for designing recycled aggregate concrete mixes. The structural complexity of RA currently limits its wider application in the industry. Developing an approach to comprehensively characterize RA as a raw material for structural concrete would reduce uncertainties in recycled aggregate concrete mix design. To the authors’ knowledge, no method has been developed in the literature that includes all the above criteria. This represents a novelty in the quality assessment of aggregate mixes containing RA for structural concrete. Accurately predicting and evaluating the performance of coarse aggregate as a constituent of concrete requires thorough consideration of its physical and mechanical properties.

2. Materials and Methods

2.1. Materials

Two types of coarse aggregate were used in this study: RA and NA. The RA was produced by crushing concrete blocks and collecting a portion of aggregate that passed a 31.5 mm sieve but was retained on a 4 mm sieve. The production process of RA was conducted in a laboratory using a jaw crusher. Minimal impurities in the form of brick, asphalt, wood chips, and fibers were present, but in marginal amounts. The source concrete properties were unknown, which is often the case when RA is used on an industrial scale.

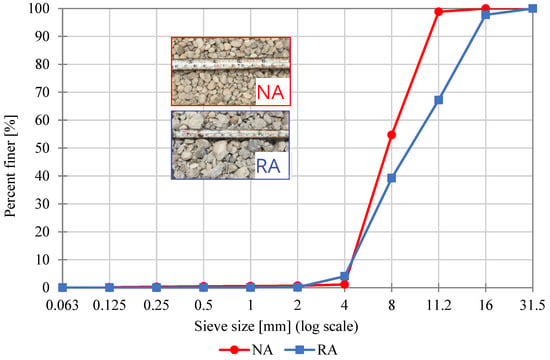

On the other hand, the NA used was quartz gravel, as it is the most commonly used aggregate type in the production of structural concrete in Hungary [26]. The physical properties of RA and NA, including oven-dried density (ρrd), saturated surface-dried density (ρSSD), and water absorption (WA) are presented in Table 1 based on MSZ EN 1097-6 [27]. Additionally, bulk density (ρb) measurements of both types of aggregate are provided in Table 1 based on MSZ EN 1097-3 [28]. Particle size distributions as determined by MSZ EN 933-2 [29] of RA and NA are presented in Figure 1.

Table 1.

Physical properties of aggregate used in this study.

Figure 1.

Particle size distribution of NA and RA.

2.2. Methods

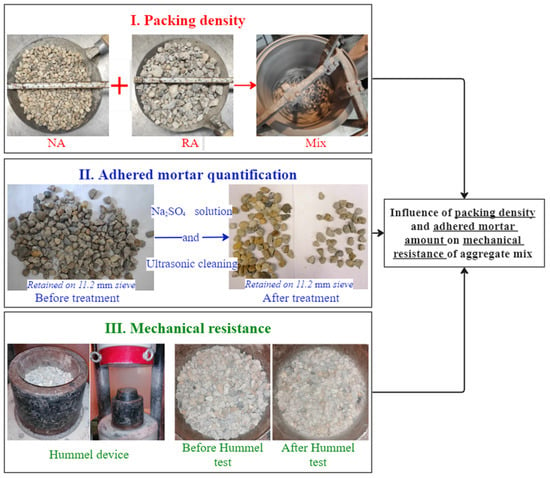

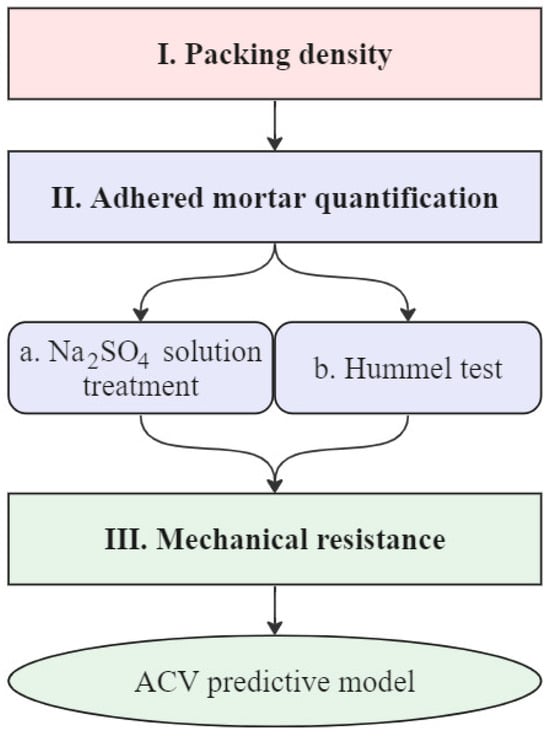

The methodology is based on an experimental investigation of bulk aggregates as aggregates are used in concrete in this configuration. A three-step approach is adopted for the quality assessment of aggregate mixes containing RA, as illustrated in Figure 2:

Figure 2.

A three-step approach for the assessment of aggregate mixes containing RA that was adopted in this study.

- The packing density of the aggregate mixes is examined to define the effect of RA on the particle packing of the coarse aggregate mix, taking into account the difference between NA and RA based on physical properties (e.g., size, shape).

- The two-step treatment was used to measure the adhered mortar amount of RA to provide knowledge of its structural configuration, which has been identified as one of the leading factors in RA’s performance in concrete [4,13,21,30,31].

- The mechanical resistance of aggregate mixes containing both NA and RA was evaluated through a bulk aggregate static loading test, which would depict the future mechanical performance of RA in concrete.

This approach characterizes the influence of both particle packing and adhered mortar amount on the mechanical resistance of the aggregate mixes with RA for future use in structural concrete. The following sections (Section 2.2.1, Section 2.2.2 and Section 2.2.3) provide a detailed procedure guide for each step.

The aggregate mixes were produced by gradually replacing the bulk aggregate volume of NA with RA in 10 V% increments until a complete replacement of 100% was reached. A total of eleven aggregate mixes were tested, two of which utilized solely 100% NA or RA, with the remaining nine mixes containing different quantities of both aggregate types. The designation used in the rest of the study for the aggregate mixes is CRxNy, where C denotes coarse, R represents RA, and N refers to NA. The values x and y indicate the volumetric ratio of RA and NA in the mix, respectively.

2.2.1. Packing Density

It is widely acknowledged that the packing densities of the two phases of concrete, namely aggregate and cement paste, as well as concrete itself, are crucial factors in determining its mechanical properties. Optimizing the cement paste and aggregate in separated phases based on packing density has been recognized as an effective approach for enhancing both the sustainability and material performance of the concrete [32]. In this study, the packing density was determined using the dry packing method according to the following procedure:

- The aggregate was oven-dried (at 60 °C) until the constant mass was achieved and left in a laboratory environment (with a temperature of 20 ± 2 °C and relative humidity of 50 ± 10%) for 24 h before testing.

- The bulk aggregate samples were mixed for two minutes in a 10 L concrete laboratory mixer to achieve a homogenous mix.

- After mixing, the mixture was poured into a 2 L container. The container was filled three times by applying 20 compactions for each layer using a tamping rod in accordance with BS 812-2 [33].

- The mean values were obtained from two sample measurements for each aggregate mix. Therefore, using the known volume of the container (V) and the mass of the sample filling the container (M), packing density (ϕ) could be determined using the following formula:

In this case, ρRA and ρNA are oven-dried densities of RA and NA, respectively. Additionally, RRA and RNA represent the volumetric ratio of RA and NA in the investigated mix.

2.2.2. Adhered Mortar Quantification

Since adhered mortar has been identified as one of the most influential factors in the performance of RA as a structural concrete aggregate, its quantification seems an essential tool for the RA quality assessment. In this study, the method used to measure adhered mortar involved soaking the RA in a sodium sulphate (i.e., Na2SO4) solution and subjecting it to a series of freeze–thaw cycles. Such an approach has been identified as one of the most effective and readily applicable methods [34]. To determine the amount of adhered mortar, the method developed by Abbas et al. [13] was used as a reference. The following procedure was followed:

- A representative sample of RA weighing approximately 3 kg was sieved.

- The RA amounts remaining on each sieve size were separated into their respective containers.

- Samples for each sieve size were submerged in Na2SO4 solution prepared according to ASTM C 88, for 24 h [35].

- The RA samples were then subjected to five freeze–thaw cycles while still submerged in the Na2SO4 solution (16 h at approximately −17 °C and 8 h at about 80 °C).

- After the fifth cycle, the samples were washed above the smallest sieve size (i.e., 63 μm) and then dried in the oven at about 60 °C.

- Once a constant mass was achieved, the RA samples were sieved again.

- To improve the identification of the quantity of adhered mortar, visual inspections were conducted on each sample. This involved separating and weighing the liberated aggregates from their unliberated counterparts.

Upon visual inspection, it was evident that some aggregates were not liberated but had mortar loosely attached to virgin aggregate. To facilitate their liberation, ultrasonic cleaning was employed. Ultrasonic cleaning is a highly efficient method that can displace and eliminate a broad range of surface contaminants, including inorganic dirt and microbiological substances. This is achieved by creating shock waves and forming jets during the collapse of acoustic cavitation bubbles [36]. Katz applied an ultrasonic cleaning process to the RA to eliminate loose particles and enhance the bond with new cement paste. This resulted in a 7% increase in compressive strength [17]. It is anticipated that using ultrasonic cleaning as a secondary treatment would further detach loosely adhered mortar. The ultrasonic cleaning process was repeated multiple times until the water in the bath was clear for each sample, after which the samples were dried in an oven. Steps six and seven of the above procedure were repeated. Finally, this method involves quantifying the amount of the adhered mortar based on chemical, thermal, and mechanical stresses that are introduced to separate the virgin aggregate from the attached mortar. The results presented in Section 3.2 are based on the average values obtained from five samples.

2.2.3. Mechanical Resistance

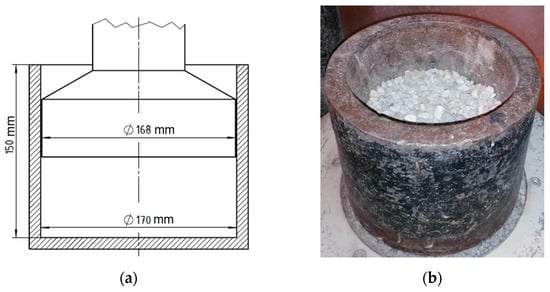

The quality assessment of aggregate mix was carried out by measuring the mechanical resistance of bulk aggregate samples. The Hummel test, which was widely used in the past, is now primarily limited to research [37]. The MSZ 18287-3 standard [38] outlines an indirect strength test that applies a static load to the bulk aggregate [38]. The test method involves the following steps:

- Preparation of a bulk aggregate sample of 2000 cm3.

- Sieving the aggregate sample to acquire particle size distribution.

- Filling the Hummel mortar (Figure 3) with the aggregate sample.

Figure 3. Representation of typical Hummel mortar (a) filled with aggregate mix (b).

Figure 3. Representation of typical Hummel mortar (a) filled with aggregate mix (b). - Executing a static load test on the bulk aggregate by applying the load of 400 kN on the sample in the Hummel mortar in 1.5 min.

- Once the load is adequately applied, unloading the aggregate sample and emptying the Hummel mortar.

- Sieving the sample of crushed aggregate to obtain the particle size distribution.

3. Results and Discussion

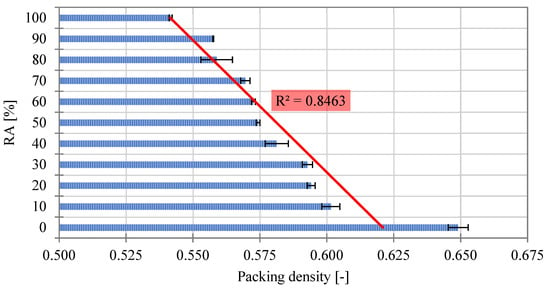

3.1. Packing Density

Figure 4 presents the packing density results of the investigated aggregate mixes. The mixes differ based on the replacement ratio of NA by RA from 0% to 100%, incremented by 10%. The packing density of the aggregate mixes decreases with the increase in RA content, which is supported by a relatively high coefficient of determination. As shown in Figure 1, the maximum aggregate size of RA (i.e., Dmax = 16 mm) is slightly higher than that of NA (i.e., Dmax = 11.2 mm). This choice of particle size distribution is not expected to significantly increase packing density. However, it is the most representative aggregate mix for practical purposes due to its simple production process. No additional steps are required in the production of aggregates, which would otherwise increase the energy consumption and the resulting environmental burden.

Figure 4.

Packing density results of NA and RA mixes based on volumetric replacement ratio.

With the inclusion of RA in aggregate mix by only 10%, the reduction in packing density was about 7.3%. This reduction can be partially attributed to the influence of particle shape on the packing, which can be as much as 12% higher for rounded aggregate mixes than for crushed aggregate mixes [8]. It is worth noting that RA typically has an angular shape due to the crushing process, whereas quartz gravel tends to be more rounded. Therefore, such a variation in the value of a purely NA sample and one with 10% RA could be expected. The average packing density of the nine mixes comprising both RA and NA is 0.578. It is important to note that all mixes containing RA below 50% exceed this value. Moreover, for aggregate mixes containing 10–30% of RA the difference in packing density is negligible. Introducing RA composed of larger particles than NA results in either occupying/wall effect. The occupying effect occurs when small amounts of larger particles are added to smaller particles in order to occupy a solid volume within the bulk and porous volume [39]. Conversely, the wall effect is characterized by the formation of voids due to larger particles pushing smaller particles in the mix [7,39]. Therefore, the coefficient of determination is also affected by these two phenomena based on the amount of RA incorporated.

3.2. Adhered Mortar Quantification

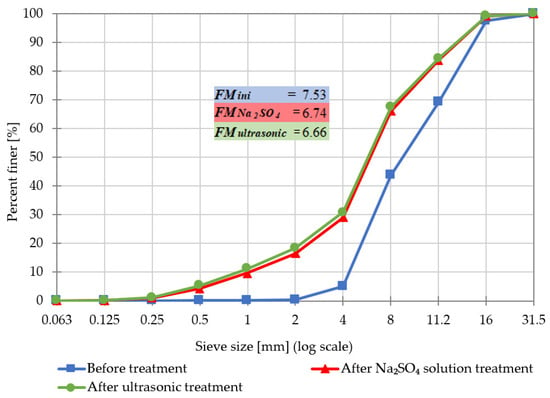

As explained in Section 2.2.2, the adhered mortar quantification was based on a two-step treatment method. Firstly, RA samples underwent five cycles of freezing–thawing while immersed in a Na2SO4 solution, referred to as the Na2SO4 solution treatment throughout the manuscript. Secondly, the specimens were cleaned using an ultrasonic bath, which is referred to as the ultrasonic cleaning treatment. Figure 5 shows a substantial change in particle size distribution between untreated RA samples and those treated with Na2SO4 solution. However, there is no significant difference between RA treated with Na2SO4 solution and ultrasonic cleaning. The application of treatments results in an increase in aggregate retention on the smaller sieve sizes due to the separation of adhered mortar from NA. If an aggregate sample has a higher quantity of fine aggregate, its FM decreases. Therefore, when considering the FM, the reduction in value due to Na2SO4 solution treatment is approximately 10% (see Figure 5). If RA is treated with ultrasonic cleaning in addition to Na2SO4 solution, the decrease in value is only about 1%.

Figure 5.

Particle size distribution and FM results of treated RA.

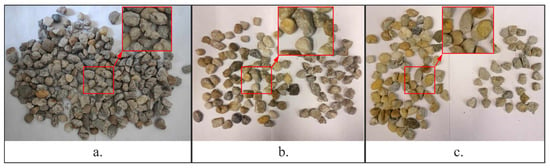

However, these methods do not completely remove the adhered mortar. In addition, while particles may be liberated from the adhered mortar, it does not necessarily mean that the adhered mortar is excluded from the particle size distribution and FM results. RA particles consist of four types of aggregate: i. NA (i.e., virgin aggregate without any adhered mortar); ii. mortar-attached RA (i.e., single virgin aggregate with adhered mortar); iii. mortar-covered RA (i.e., several virgin aggregates covered by mortar) and iv. mortar-only RA (i.e., excluding the presence of any virgin coarse aggregate) [19]. To evaluate the quantity of liberated particles and adhered mortar or unliberated particles, two types of aggregate were manually separated, namely liberated and unliberated particles, as shown in Figure 6. The liberated particles are typically associated with the first and second types presented above (i.e., NA and mortar-attached RA), whereas for mortar-attached RA, the quantity of mortar is minimal. Moreover, the amount of mortar-attached RA that is considered as part of liberated particles decreases following ultrasonic cleaning treatment, resulting in a higher degree of liberation. In contrast, the unliberated RA is mainly composed of RA particles coated with a substantial amount of attached mortar (i.e., type ii.), as well as virgin aggregates covered with mortar (i.e., type iii.) and mortar-only particles (i.e., type iv.).

Figure 6.

Examples of particles that characterized as liberated and unliberated after the treatments and based on classification by Kim: i. NA, ii. mortar-attached RA, iii. mortar-covered RA and iv. mortar-only RA [19].

In Figure 7, the RA sample is shown where the liberated and unliberated particles were manually separated after a two-step treatment (including Na2SO4 solution and ultrasonic cleaning). The particle type (either liberated or unliberated) was identified manually for the aggregate remaining on each sieve size representing coarse aggregate (i.e., 8, 11.2, and 16 mm), except for the 4 mm sieve due to the large number of particles available (about 1 kg). Sieves smaller than 4 mm can be assumed as not representative for the quality assessment of coarse aggregate. In Table 2, the assessment results are indicated where it is visible that the highest amount of liberation can be attributed to a 16 mm sieve-size aggregate after both treatments. However, there is no significant difference in the amount of aggregate liberated on the tested sieves. On average, the samples treated with Na2SO4 solution and ultrasonic cleaning had about 72% and 75% of liberated aggregate, respectively. The minimal difference in values between the two treatments could be attributed to the low effectiveness of the shock waves and jets generated during the ultrasonic treatment in completely detaching the remaining adhered mortar from the virgin aggregate. This is especially evident in the case of unliberated particles that have a significant amount of adhered mortar (i.e., unliberated aggregate type ii. and iii. in Figure 6).

Figure 7.

A representative sample of RA starting from the untreated state (a), after Na2SO4 solution treatment (b), and after ultrasonic cleaning (c).

Table 2.

Quantity of liberated and unliberated particles after respective treatments of RA.

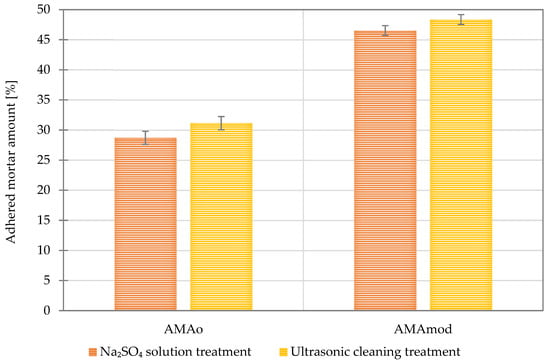

The amount of adhered mortar (AMA0) can be evaluated using the following formula proposed in the literature [11,34]:

Here, mini represents the initial mass of the RA sample before any treatment and mfin is the mass of coarse RA retained on a specific sieve size, typically 4.75 mm or 4 mm (in this study, 4 mm is adopted) [13,40]. However, as shown in Table 2, the method is not fully efficient in liberating all the RA particles. This should be also considered in the equation for the determination of adhered mortar quantity as precise as possible. It should be noted that there are also unliberated particles, especially once characterized as mortar-attached RA (Figure 6 type ii.), that could be part of the coarse aggregate sample if liberated. To ensure precision, percentages for unliberated samples in Table 2 should be rounded down to the lower nearest multiple of five (i.e., 28.38% and 25.13% to 25%). This demonstrates that there are negligible differences in the efficiency of both treatments. Therefore, a modification of the new equation is proposed, where the efficiency of the treatment method is determined by the unliberated particles ratio (UPR) in Equation (3). In this equation, UPR is equal to 25% for mixes treated with Na2SO4 solution and ultrasonic cleaning, respectively:

Finally, in Figure 8, adhered mortar amounts calculated based on the equations above (i.e., Equations (2) and (3)) are presented. The difference between the values calculated using the original equation (i.e., Equation (2)) is higher than when the efficiency of the treatment is considered (Equation (3)). The variation between values for the Na2SO4 solution and ultrasonic cleaning treatment is reduced when UPR is considered. However, it is possible that the efficiency of the treatment method (through UPR) has been underestimated, specifically due to the mortar-attached and covered RA (Figure 6), which could be part of the coarse aggregate if further liberated. Therefore, the adhered mortar amount was calculated using Equation (3) for both treatments (i.e., 46.5% for Na2SO4 solution and 48.4% for ultrasonic treatment) and rounded down to the nearest multiple of five resulting in a value of 45%. This demonstrates that the adhered mortar quantity can be determined without the ultrasonic cleaning step, provided that the treatment’s effectiveness is contemplated. Therefore, excluding the ultrasonic cleaning treatment in future quality assessments could reduce the number of steps in the procedure, resulting in numerous economic and environmental benefits, while still ensuring satisfactory data quality. Furthermore, a methodology for quantifying adhered mortar’s efficiency would benefit the wider application of this approach.

Figure 8.

Adhered mortar amounts calculated based on Equations (2) and (3).

3.3. Mechanical Resistance

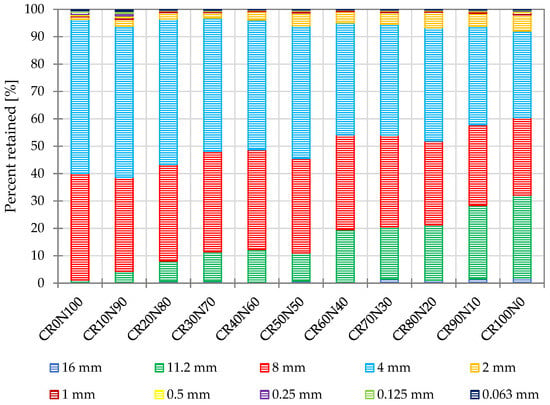

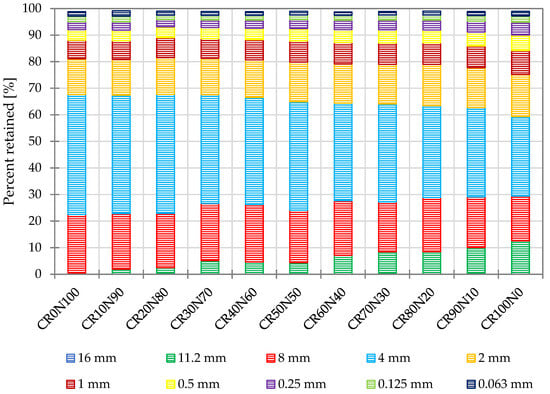

In Figure 9 and Figure 10, the percentages of mass retained on the considered sieve sizes (i.e., 0.063–16 mm) are presented before and after the Hummel test, respectively. All of the aggregate mixes examined had a cumulative mass retained on sieve sizes ranging from 4 to 16 mm above 90% before the static load was applied, aligning with the expected pattern (Figure 9). However, there is an almost linear increase in mass retained on the 11.2 mm sieve and a reduction in mass retained on the 4 mm sieve with the increase in RA amount. On the other hand, the cumulative mass retained on sieve sizes from 4 to 16 mm after the Hummel test is typically above 60%, except for the 100% RA sample (i.e., CR100N0) with a slightly lower value of 59.4% (Figure 10). It can be assumed that the evaluation of coarse aggregate considers the sieve size range between 4 and 16 mm. Based on the adhered mortar amount, as determined for RA samples in Section 3.2 using Equation (3) (about 45%), much of the adhered mortar is crushed when considering the CR100N0 mix results after the applied load. Although the amount of RA subsequently increased from CR0N100 to CR40N60, the cumulative mass retained from the 4 to 16 mm sieve sizes varied between 67% and 68%. Moreover, the aggregate mixes CR20N80 and CR30N70 produced almost identical results to CR0N100 (with a maximum difference of 0.1%). It was observed that mixes containing 50% or more RA content showed a nearly linear decrease in mechanical resistance. These findings indicate that the mechanical resistance of aggregate mixes is directly influenced by their packing density, as substituting more than 50% of NA with RA has been shown to be detrimental to particle packing (refer to Section 3.1).

Figure 9.

Percentage of mass retained on sieves considered (i.e., 0.063–16 mm) before the Hummel test.

Figure 10.

Percentage of mass retained on sieves considered (i.e., 0.063–16 mm) after the Hummel test.

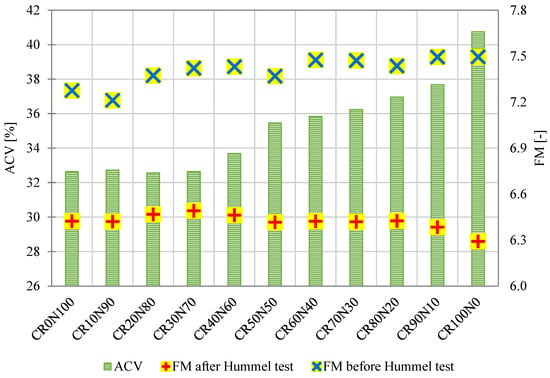

To better assess the increased amount in the fines of aggregate mixes subjected to static load, the aggregate crushing value (ACV), together with FM results of the aggregate mixes before and after the Hummel test, is shown in Figure 11. The ACV is calculated by dividing the cumulative aggregate passing through a 4 mm sieve after the Hummel test by the initial mass of the aggregate mix before the test (miniHT). The cumulative aggregate passing the 4 mm sieve is calculated as the difference between the initial mass and the cumulative mass retained on a 4 mm sieve size (mfinHT):

Figure 11.

ACV for aggregate mixes together with FM results before and after the Hummel test.

The ACV provides information on the increase in fines in the total mix due to the static load applied to the bulk aggregate samples. It can be observed that there is a negligible increase in the ACV between CR0N100 and CR10N90 (less than 1%), considering the variation between FM values before the Hummel test. Additionally, aggregate mixes containing 10%, 20%, and 30% of RA show negligible variations in ACV with a maximum difference of 0.1%. Such a behavior could be attributed to the influence of the packing density of the aggregate mixes on the ACV. The maximum difference in the value of the packing density of the mixes containing RA between 10 and 30% is about 1.5% with similar mechanical resistance. The difference in packing density between CR10N90 and CR40N60 is twice that between CR10N90 and CR30N70, which impacted the substantial increase in the ACV value of CR40N60. An almost linear increase in ACV is noted with a higher substitution ratio of NA with RA exceeding 30%. The ACV value for the CR100NO sample is 40.8%, which is close to the adhered mortar amount determined for RA considering the efficiency of the treatments (i.e., 45%). This indicates that there is a direct relationship between the adhered mortar amount and ACV for RA. However, the packing density can also affect the ACV of the aggregate mixes containing RA. Therefore, using the Hummel test for the adhered amount quantification could be applied simultaneously with the evaluation of RA’s mechanical resistance. This could simplify the quality assessment method for aggregate mixes.

When evaluating samples before the Hummel test, the inclusion of RA clearly decreased the FM value. As the amount of RA increased, there was mainly a rise in FM value. After the Hummel test, a steady increase in FM value was observed with the increase in RA amount until the substitution ratio of 40% NA by RA. This is consistent with the ACV results, where the performance of aggregate mixes between CR10N90 and CR30N70 did not degrade regardless of the increase in RA quantity. The mechanical resistance of a sample containing only RA (i.e., CR100N0) was distinctly lower, with the lowest FM value obtained after the Hummel test. When considering the reduction in the FM values considering particle size distribution before and after the Hummel test, the average value for all of the mixes was 13.3%. All mixes containing 50% or less RA showed lower results than average. The CR100NA0 mix showed the highest decrease, with a value of 16.1%. The following section evaluates the potential dependency level of mechanical resistance in aggregate mixes on the amount of adhered mortar of RA and the packing density values of the aggregate mixes. This will provide a better understanding of the behavior of the aggregate mixes.

3.4. Relationship between Packing Density, Adhered Mortar, and Mechanical Resistance of Aggregate Mixes

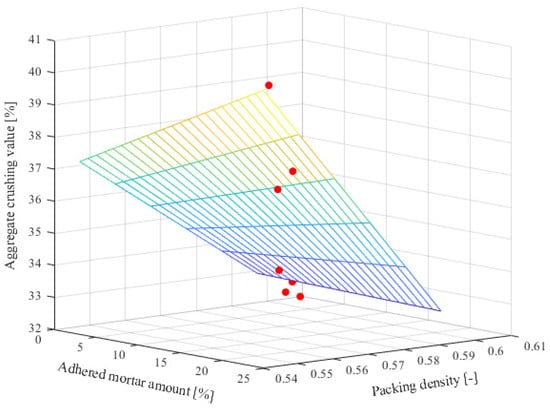

To develop a predictive model for the mechanical resistance of aggregate mixes containing RA, we introduce a multiple regression model (Figure 12) with a coefficient of determination equal to 0.978. The model uses ACV as a dependent variable, representing the mechanical resistance of aggregate mixes. Additionally, the model is based on two predictor variables: adhered mortar amount (AMAmix) and packing density (PD). In order to examine the impact of adhered mortar on the mechanical resistance of aggregate mixes, an AMAmix value is assigned to each mix containing RA (i.e., all mixes except CR0N100) based on the volumetric ratio of RA present. The values obtained in 3.2 were rounded to the lower nearest multiple of five and the AMAmix for 100% RA samples was multiplied by the mass ratio of the RA in a specific aggregate mix. Incremental AMAmix values were obtained for all investigated mixes based on the amount of RA present. For the second predictor variable (PD), packing density values were obtained from Section 3.1. The models in Table 3 have been identified as suitable for predicting the mechanical resistance of aggregate mixes containing RA, assuming that both AMAmix and PD are known.

Figure 12.

Multiple linear regression model representation for Na2SO4 solution treatment considering AMA0.

Table 3.

Predictive models of ACV for the aggregate mixes containing RA considering AMA and PD.

The models proposed can be utilized to determine the mechanical resistance of the aggregate mixes without requiring sophisticated equipment and could be conducted in a relatively short time frame. For determining the packing density, the required equipment is almost the same as that used for bulk density measurement of the aggregate (except for a mixer). The method for determining adhered mortar is similar to that used for conducting the soundness test of the aggregate (except for manually separating liberated and unliberated particles). However, the ultrasonic cleaning step may impose an additional burden on the execution of the method. It is recommended to exclude the step of using both an Na2SO4 solution and ultrasonic cleaning in the quality assessment procedure of the aggregate mix as there is minimal difference in the adhered mortar amount value when compared to using only the Na2SO4 solution treatment. In the findings of this study, there are two possible approaches to quality assessment of the aggregate mix containing RA, as shown in Figure 13, using the ACV predictive model. Since adhered mortar amount values determined using the Na2SO4 solution treatment (when the efficiency of the method is considered using Equation (3)) and ACV of CRN100NO based on the Hummel test are similar, both methods could be used for the second step of the approach (i.e., adhered mortar quantification of RA). In the case when the Hummel test is used, the ACV would be equated with adhered mortar value. The influence of the confinement would need to be taken into concern resulting in possibly not full detachment of the adhered mortar from some particles, especially when the particle size is smaller. Since the efficiency of the method could not be evaluated, rounding the calculated value to the upper closest multiple of five would be viable (i.e., in this study, 40.8% rounded to 45%). However, a larger dataset must be evaluated in the future to establish a reliable ACV predictive model.

Figure 13.

Two possible approaches to quality assessment of the aggregate mixes containing RA are based on the ACV predictive model.

However, the aggregate mixes investigated in this study that contained RA could be classified into three groups based on their ACV. The classification method compares the ACV of RA with aggregate mixes containing both RA and NA. If the difference in ACV between CR100N0 and a mix comprising NA and RA is 15% or higher, the mix is classified in group A (Table 4). Group B is characterized by a decrease in ACV of between 10% and 15%, whereas for group C, the reduction is equal to or less than 10%. The classification can predict the future behavior of an aggregate mix in the structural concrete and should be verified or expanded upon with a larger dataset. Nevertheless, this approach could be used for the development of a lean tool that provides practitioners with a straightforward mix design method for recycled aggregate concrete, reducing the time spent on the trial-and-error process. Reducing the number of steps in sustainable product development by establishing predictive models is a promising area in the construction industry for the application of rapidly developing machine learning tools. Approaches that leverage developments in data science, rather than require large investments in sophisticated technology, could provide sustainable solutions that are globally applicable, regardless of the level of technological development.

Table 4.

Classification of aggregate mixes containing RA based on ACV.

4. Conclusions

The utilization of recycled concrete aggregate (RA) in structural concrete faces constraints arising from uncertainties about its quality and potential impact on concrete’s performance. Moreover, the lack of knowledge regarding the properties of virgin concrete in industrial applications complicates the effective characterization of RA. To address this issue, a streamlined tool for evaluating the quality of aggregate mixes incorporating RA was developed, comprising a three-step process: 1. assessment of packing density; 2. quantification of adhered mortar; and 3. determination of mechanical resistance in bulk aggregate mixes with RA. The findings of the experimental study led to the following conclusions:

- The integration of RA in the aggregate mix results in a nearly linear reduction in packing density, with a coefficient of determination of 0.8463. This trend is attributed to variations in shape and size between RA and natural aggregate (NA).

- The method for adhered mortar quantification, involving a two-step treatment with Na2SO4 solution (approximately 72% efficiency) and ultrasonic cleaning (around 75% efficiency), did not completely liberate aggregate samples. Given minimal differences in adhered mortar values post-treatment, the use of Na2SO4 solution is recommended for future assessments.

- A novel equation is proposed for quantifying adhered mortar, incorporating a correction factor related to treatment efficiency. This offers a more practical approach to evaluating aggregate mixes with RA.

- Mechanical resistance of aggregate mixes with RA is significantly influenced by particle packing and adhered mortar content. Furthermore, a predictive model linking aggregate crushing value to packing density and adhered mortar amount is proposed.

The study suggests that future research should extend the proposed approach to a broader dataset, encompassing various fractions, RA types based on the crushing process, virgin aggregate, and concrete. Additionally, further evaluation of the impact of mechanical resistance classes on concrete properties is essential. Increasing the dataset could facilitate the development of machine learning tools for the mix design and performance assessment of recycled aggregate concrete.

Author Contributions

Conceptualization, A.D. and M.A.; Methodology, A.D. and O.F.; Experimental work, A.D.; Formal analysis, A.D. and M.A.; Data curation, A.D. and O.F., Writing—original draft preparation, A.D.; Writing—review and editing, O.F. and M.A.; Visualization, A.D. and M.A.; Supervision, O.F. and M.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research was partially funded by the Stipendium Hungaricum Scholarship Programme as part of the PhD studies of the first author.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Góra, J.; Piasta, W. Impact of Mechanical Resistance of Aggregate on Properties of Concrete. Case Stud. Constr. Mater. 2020, 13, e00438. [Google Scholar] [CrossRef]

- Abed, M.A.; Tayeh, B.A.; Abu Bakar, B.H.; Nemes, R. Two-Year Non-Destructive Evaluation of Eco-Efficient Concrete at Ambient Temperature and after Freeze-Thaw Cycles. Sustainability 2021, 13, 10605. [Google Scholar] [CrossRef]

- Abed, M.A. Indirect Evaluation of the Compressive Strength of Recycled Aggregate Concrete at Long Ages and after Exposure to Freezing or Elevated Temperatures. Russ. J. Nondestruct. Test. 2021, 57, 195–202. [Google Scholar] [CrossRef]

- Verian, K.P.; Ashraf, W.; Cao, Y. Properties of Recycled Concrete Aggregate and Their Influence in New Concrete Production. Resour. Conserv. Recycl. 2018, 133, 30–49. [Google Scholar] [CrossRef]

- Sadagopan, M.; Malaga, K.; Nagy, A. Improving Recycled Aggregate Quality by Mechanical Pre-Processing. Materials 2020, 13, 4342. [Google Scholar] [CrossRef] [PubMed]

- Tošić, N.; Torrenti, J.M.; Sedran, T.; Ignjatović, I. Toward a Codified Design of Recycled Aggregate Concrete Structures: Background for the New Fib Model. Code 2020 and Eurocode 2. Struct. Concr. 2021, 22, 2916–2938. [Google Scholar] [CrossRef]

- De Larrard, F. Concrete Mixture Proportioning: A Scientific Approach; CRC Press: Boca Raton, FL, USA, 2014; ISBN 978-1-4822-7205-5. [Google Scholar]

- Antunes, R.; Tia, M. Effects of Aggregate Packing on Concrete Strength and Consistency. Adv. Civ. Eng. Mater. 2018, 7, 479–495. [Google Scholar] [CrossRef]

- Ghasemi, Y. Aggregates in Concentrate Mix Design; Luleå University of Technology: Luleå, Sweden, 2017; ISBN 9789175838007. [Google Scholar]

- De Larrard, F.; Sedran, T. Optimization of Ultra-High-Performance Concrete by the Use of a Packing Model. Cem. Concr. Res. 1994, 24, 997–1009. [Google Scholar] [CrossRef]

- Park, J.; Lee, J.; Chung, C.W.; Wang, S.; Lee, M. Accelerated Carbonation of Recycled Aggregates Using the Pressurized Supercritical Carbon Dioxide Sparging Process. Minerals 2020, 10, 486. [Google Scholar] [CrossRef]

- Pin, K.; Nancy, V.; Whiting, M.; Olek, J.; Jain, J.; Snyder, M.B. Using Recycled Concrete as Aggregate in Concrete Pavements to Reduce Materials Cost; JTRP Technical Reports; Indiana Department of Transportation and Purdue University: West Lafayette, IN, USA, 2013. [Google Scholar] [CrossRef]

- Abbas, A.; Fathifazl, G.; Burkan Isgor, O.; Razaqpur, A.G.; Fournier, B.; Foo, S. Proposed Method for Determining the Residual Mortar Content of Recycled Concrete Aggregates. J. ASTM Int. 2007, 5, 1–12. [Google Scholar] [CrossRef]

- Montgomery, D.G. Workability and Compressive Strength Properties of Concrete Containing Recycled Concrete Aggregate. In Proceedings of the Sustainable Construction: Use of Recycled Concrete Aggregate—Proceedings of the International Symposium held at Department of Trade and Industry Conference Centre, London, UK, 11–12 November 1998; pp. 213–225. [Google Scholar]

- Pepe, M.; Toledo Filho, R.D.; Koenders, E.A.B.; Martinelli, E. Alternative Processing Procedures for Recycled Aggregates in Structural Concrete. Constr. Build. Mater. 2014, 69, 124–132. [Google Scholar] [CrossRef]

- Bru, K.; Touzé, S.; Bourgeois, F.; Lippiatt, N.; Ménard, Y. Assessment of a Microwave-Assisted Recycling Process for the Recovery of High-Quality Aggregates from Concrete Waste. Int. J. Miner. Process 2014, 126, 90–98. [Google Scholar] [CrossRef]

- Katz, A. Treatments for the Improvement of Recycled Aggregate. J. Mater. Civ. Eng. 2004, 16, 597–603. [Google Scholar] [CrossRef]

- Tam, V.W.Y.; Tam, C.M.; Le, K.N. Removal of Cement Mortar Remains from Recycled Aggregate Using Pre-Soaking Approaches. Resour. Conserv. Recycl. 2007, 50, 82–101. [Google Scholar] [CrossRef]

- Kim, J. Influence of Quality of Recycled Aggregates on the Mechanical Properties of Recycled Aggregate Concretes: An Overview. Constr. Build. Mater. 2022, 328, 127071. [Google Scholar] [CrossRef]

- Martín-Morales, M.; Zamorano, M.; Valverde-Palacios, I.; Cuenca-Moyano, G.M.; Sánchez-Roldán, Z. Quality Control of Recycled Aggregates (RAs) from Construction and Demolition Waste (CDW). In Handbook of Recycled Concrete and Demolition Waste; Elsevier Inc.: Amsterdam, The Netherlands, 2013; pp. 270–303. ISBN 9780857096906. [Google Scholar]

- Rakshvir, M.; Barai, S.V. Studies on Recycled Aggregates-Based Concrete. Waste Manag. Res. 2006, 24, 225–233. [Google Scholar] [CrossRef]

- Abed, M.; Nemes, R. Los Angeles Index and Water Absorption Capacity of Crushed Aggregates. Pollack Period. 2020, 15, 65–78. [Google Scholar] [CrossRef]

- Neville, A.M. Properties of Concrete, 5th ed.; Pearson: Harlow, UK; New York, NY, USA, 2011; ISBN 978-0-273-75580-7. [Google Scholar]

- Abed, M.A.; Alrefai, M.; Alali, A.; Nemes, R.; Yehia, S. Effect of Nominal Maximum Aggregate Size on Performance of Recycled Aggregate Self-Consolidating Concrete: Experimental and Numerical Investigation. ACI Mater. J. 2022, 119, 37–50. [Google Scholar] [CrossRef]

- Dacić, A.; Fenyvesi, O. Investigating Mechanical Resistance of Recycled Concrete Aggregate. In Proceedings of the Next Generation of Concrete Engineering for Post-Pandemic Europe, Zakopane, Polland, 13–14 September 2022; pp. 417–422. [Google Scholar]

- György, B.L. Innovative Materials and Technologies for Concrete Structures. In Proceedings of the Innovative Materials and Technologies for Concrete Structures, Budapest, Hungary, 23–25 May 2005; Balázs, G.L., Nehme, S.G., Eds.; Fib: Visegrad, Hungary, 2007; pp. 1–12. [Google Scholar]

- MSZ EN 1097-6; Kőanyaghalmazok Mechanikai És Fizikai Tulajdonságainak Vizsgálata 6. Rész: A Testsűrűség És a Vízfelvétel Meghatározása. CEN: Brussels, Belgium, 2013.

- MSZ EN 1097-3; Kőanyaghalmazok Mechanikai És Fizikai Tulajdonságainak Vizsgálata. 3. Rész: A Halmazsűrűség És a Hézagtérfogat Meghatározása. CEN: Brussels, Belgium, 2000.

- MSZ EN 933-2; Kőanyaghalmazok Geometriai Tulajdonságainak Vizsgálata. 2. Rész: A Szemmegoszlás. Vizsgálósziták, a Szitanyílások Névleges Mérete. CEN: Brussels, Belgium, 2020.

- Adams, M.P.; Fu, T.; Cabrera, A.G.; Morales, M.; Ideker, J.H.; Isgor, O.B. Cracking Susceptibility of Concrete Made with Coarse Recycled Concrete Aggregates. Constr. Build. Mater. 2016, 102, 802–810. [Google Scholar] [CrossRef]

- González-Taboada, I.; González-Fonteboa, B.; Martínez-Abella, F.; Carro-López, D. Study of Recycled Concrete Aggregate Quality and Its Relationship with Recycled Concrete Compressive Strength Using Database Analysis. Mater. Constr. 2016, 66, e089. [Google Scholar] [CrossRef]

- Chen, J.J.; Guan, G.X.; Ng, P.L.; Kwan, A.K.H.; Chu, S.H. Packing Optimization of Paste and Aggregate Phases for Sustainability and Performance Improvement of Concrete. Adv. Powder Technol. 2021, 32, 987–997. [Google Scholar] [CrossRef]

- BS 812-2; Testing Aggregates. Part 2: Methods of Determination of Density. British Standards Institution: London, UK, 1995; ISBN 0580242579.

- Gao, X.X.; Cyr, M.; Multon, S.; Sellier, A. A Three-Step Method for the Recovery of Aggregates from Concrete. Constr. Build. Mater. 2013, 45, 262–269. [Google Scholar] [CrossRef]

- ASTM C88; Standard Test Method for Soundness of Aggregates by Use of Sodium Sulfate or Magnesium Sulfate. ASTM: West Conshohocken, PA, USA, 2005.

- Mason, T.J. Ultrasonic Cleaning: An Historical Perspective. Ultrason. Sonochem 2016, 29, 519–523. [Google Scholar] [CrossRef] [PubMed]

- Biró, A.; Lublóy, É. Classification of Aggregates for Fire. Constr. Build. Mater. 2021, 266, 121024. [Google Scholar] [CrossRef]

- MSZ 18287-3; Építési Kőanyagok Szilárdság—Vizsgálata Próbahalmazon Hummel—Viszgálat. Hungarian Standards Institute: Budapest, Hungary, 1983.

- Wong, H.H.C.; Kwan, A.K.H. Packing Density of Cementitious Materials: Measurement and Modelling. Mag. Concr. Res. 2015, 60, 165–175. [Google Scholar] [CrossRef]

- De Juan, M.S.; Gutiérrez, P.A. Study on the Influence of Attached Mortar Content on the Properties of Recycled Concrete Aggregate. Constr. Build. Mater. 2009, 23, 872–877. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).