Abstract

Azulejos are part of Portugal’s most important cultural heritage. However, a large part of this heritage is at risk due to lack of or improper conservation treatments. There are, however, not many studies dedicated to the procedures and materials used in their conservation to guide the choices of conservators/restorers. Through this work, the performances of the adhesives commonly used in azulejo conservation are studied considering the extreme conditions they may experience when in an outdoor environment. Three types of adhesives were studied: acrylics, epoxies, and cellulose nitrates. The adhesives were evaluated for their workability and characterized by FTIR, DMA, and bending tests to obtain information on their adhesion effectiveness and compatibility with the azulejo ceramic substrate before and after artificial and natural ageing. When subjected to mechanical loads, the high strength and stiffness of the epoxy resins could lead to the development of new fractures in the previously undamaged ceramic matrix, making them less suitable for the adhesion of historic tile fragments. Cellulose nitrates revealed a high chemical alteration and the highest degradation rate in the mechanical properties with ageing, showing it to be the least stable in the studied conditions. The acrylic resins proved to be the most chemically stable, with less yellowing and with physical properties that revealed to be the most compatible for the adhesion of the studied azulejo fragments in outdoor environments.

1. Introduction and State of the Art

Architectural ceramic tiles (azulejos) are part of Portugal’s most important cultural heritage. This importance is recognized worldwide due to their uniqueness in terms of artistic craftsmanship, the way they have been applied in architectural settings, the extensive presence of azulejos throughout the country, and the fact that they are part of a long-lasting tradition that started in the 16th century [1,2,3].

Azulejos are a composite material constituting a glaze layer and porous ceramic body and are usually fixed to the building’s walls by aerial lime-based mortars. Besides their aesthetic function, they perform their role as a protective building layer by preventing water from leaking into the wall [4,5]. Humidity in the tiles is considered their main cause of degradation, mainly because it can lead to the transport and dissolution/crystallization of soluble salts that can cause efflorescence and staining; it may induce the bio-colonization [6,7] and hydric expansion of the porous ceramic biscuit [8,9]. When this expansion cannot be accommodated by the glaze, it may cause cracking, which can even lead to the fissuring of the entire tile (as is often observed in highly dampened areas), therefore creating discontinuities at the glaze and azulejo body levels [4,5,10,11]. The fracture of the tiles can also be provoked by other mechanical actions, such as external impacts and stresses due to deformations of the wall.

Despite the importance of this heritage, and the fact that many tile panels are at risk of being lost due to lack of or improper conservation issues, the studies dedicated to the procedures and materials [12,13,14] for their conservation such as consolidation treatments [15,16,17,18,19,20], desalination [21,22], glaze lacunae infill [23,24,25,26], and retouching [27] remain relatively scarce. Regarding adhesives, many types have been or are being used in the restoration treatments of outdoor-located tiles. Acrylic-, epoxy-, and cellulose nitrate-based resins are some of the most commonly used ones to repair ceramic objects, and especially, to bond historic azulejos in Portugal (Figure 1) [12,13]. The harsh conditions of the outdoor environment with the direct sunlight, humidity, and temperature variations make the choice of an outdoor adhesive highly difficult. For an adequate adhesive performance [28,29,30], besides the efficiency, chemical/physical compatibility, workability, stability, and satisfactory ageing behaviour [31,32] even under harsh conditions, a suitable tile adhesive would ideally also have a certain capacity to accommodate the deformations of the supporting wall. Other criteria such as the reversibility of the adhesion and applied products (removal of adhesive remaining in the joints and inside the porous ceramic) and the retreatability (possibility of subsequent readhesion actions), whilst considered relevant, are not the subject of this study [33,34,35]. Therefore, in this article, the study of the tile fragments adhesives involves the evaluation of their compatibility with azulejo materials, their bond/adhesive strength, flexibility, and ageing properties. Understanding these characteristics helps to ensure that the chosen adhesive is adequate for the specific requirements of azulejo conservation, balancing the need for long-term stability with the preservation of the original tiles. This work reports on the study of commonly used adhesives for the bonding of azulejo fragments in Portugal, with the aim of providing information to support the conservation of azulejo architectural heritage.

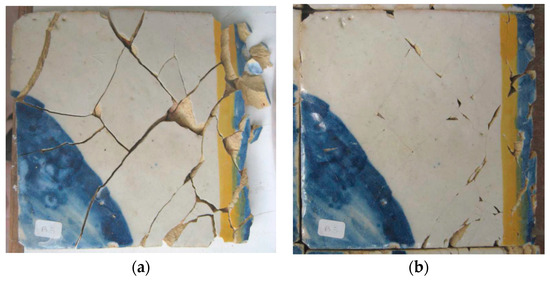

Figure 1.

Tile fragment adhesion. (a) Fragmented tile and (b) tile after fragment adhesion treatment. Images by L. Esteves.

2. Materials and Methods

2.1. Materials

Three types of adhesives commonly used for restoring ceramics or historic tiles were studied (Table 1): acrylic resins (Paraloid® B44, Paraloid® B67, and Paraloid® B72 from Rohm and Haas, Philadelphia, PA, USA); epoxies (Hxtal Nyl® 1 from HXTAL Adhesive, Coconut Grove, Australia; Fynebond® from Fyne Conservation Services, Argyll, Scotland; and Araldite® 2020 from Huntsman, TX, USA); and cellulose nitrates (HMG® cellulose nitrate from HMG Paints Ltd., Manchester, UK, UHU® Hart from UHU® GmbH & Co., Baden, Germany, and Archaocoll® 2000 from Kremer Pigmente Gmbh & Co, Aichstetten, Germany). The test ceramic bodies (NTer) used are from New Terracota Lda (Mortágua, Portugal). Their elemental chemical compositions (SEM-EDS) and main physical properties are indicated in Table 2 and Table 3 and compared with reference values from historic tiles up to the 18th century. While lower in Ca and Fe contents (Table 1), the NTer ceramic bodies have physical properties similar to the historic azulejos (Table 2). Some samples of historic azulejos (18th century) were used for the result validation.

Table 1.

Studied adhesives.

Table 2.

SEM-EDS elemental composition (data in % weight of oxides).

Table 3.

NTer ceramics and historic azulejo physical properties.

2.2. Samples Preparation

Solutions of 40% (w:w) were prepared for Paraloid® B72 on acetone and Paraloid® B44 and Paraloid® B67 on toluene. The two components (resin and hardener) of the epoxy resins were mixed according to the manufacturer’s recommendations. The cellulose nitrates were acquired as ready-to-use products. To estimate the resin’s solid content, about 2 g of each prepared solution was left to dry in an atmosphere-controlled room (temp = 20 ± 1 °C; RH = 50 ± 5%), and their weight loss was controlled over time until no significant change had been observed (100 h).

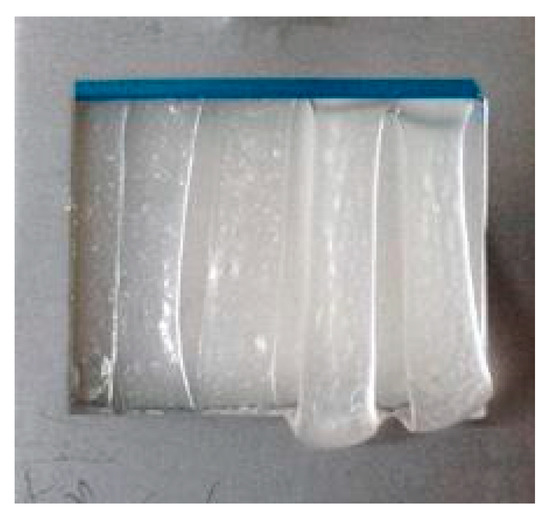

The specimens for the dynamical mechanical analysis (DMA) (measuring 60 × 10 × 3 mm3) were prepared by applying the resins to the mould cavities and cured for two weeks in a controlled laboratory environment (T = 20 ± 1 °C; RH = 50 ± 5%). Since the solvent-based acrylic resins and cellulose nitrates showed a high degree of bubbling during the solvent evaporation stage, the samples were cured inside a plastic bag to reduce the evaporation rate, and hence, the bubbling effect. After solidifying, all samples were allowed to complete the curing process in a controlled environment (T = 20 ± 1 °C; RH = 50 ± 5%) for at least two weeks.

The tiles of the test ceramic bodies (NTer) were cut in test specimens of 70 × 30 × 10 mm3. These were separated into two fragments of similar dimensions using a 3-point bending machine (Gabrielly CRAB424), which created a rough surface on which the adhesives were applied with a brush. Each adhesive was applied to at least four samples of the NTer ceramic and to one historic tile sample for validation. The adhered fragments were allowed to cure for at least 2 weeks at 21 ± 1 °C and 50 ± 5% RH in a sandbox (Figure 2).

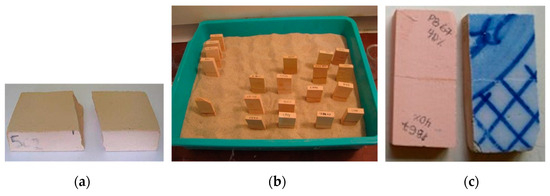

Figure 2.

Sample fragments in different adhesion stages: (a) fragmented, (b) curing in a sandbox, and (c) bonded.

2.3. Ageing Procedures

The adhesive materials were subjected to accelerated weathering in a climatic chamber aiming to age them in conditions simulating the exterior climate in Portugal. The radiation source was a xenon arc lamp with daylight filters, and the main climatic chamber parameters were as follows: irradiance between 290 and 400 nm (ultraviolet UVA radiation) with 550 ± 50 W/m2; test chamber air temperature of 38 ± 3 °C; black panel temperature of 65 ± 2 °C; and a cycle of 102 min of radiation at a relative humidity of 50 ± 10%, alternating with 18 min of wetting with demineralized water. The test duration was 500 h.

For the bonded ceramic fragments, the effects of temperature and relative humidity variation were obtained by artificially ageing the samples in a climatic chamber according to EN ISO 9142:2003-cycle D7 [37]. After 64 h of initial immersion in demineralized water at 23 °C, cycles of 8 h at 55 °C and 20% RH followed by 16 h of immersion at 23 °C were completed, with a total duration of 144 h. Natural ageing was simulated by exposing the samples to an outdoor environment according to ISO 2810:2020 [38] positioning recommendations for one year.

2.4. Methods

The Fourier transform infrared spectroscopy (FTIR) analysis was performed on a MATTSON GALAXY GC/FTIR SERIES 200 spectrophotometer. The surface of the polymerized adhesives was scratched and analysed in KBr pellets. The parameters for analysis in transmission mode were as follows: 32 interferometer scans; 0.633 cm/s scan speed; detector DTGS; and spectral resolution of 4 cm−1. The results were analysed using Omnic 6.0 software.

For the dynamic mechanical analysis (DMA), a dynamic mechanical analyser, model Q 800 (TA Instruments, New Castle, DE, USA), was used, following the recommendations of parts 1 and 5 of ISO 6721:2019 [39]. The samples were tested in a dual cantilever mode, in which the test specimen was anchored at both ends using a fixed clamp and the drive shaft applied a flexural load at the midpoint. The test specimens of epoxies were heated from 25 to 150 °C at a rate of 2 °C/min, while being sinusoidally loaded in a dual cantilever clamp system at a constant frequency of 1 Hz. For the DMA analysis of acrylics and cellulose nitrate resins, the experimental procedure was the same, but the temperature range started at −50 °C, using liquid nitrogen as the cooling medium.

The 3-point bending tests were performed in a testing machine (Gabbrielli CRAB424) with a 3-point setup, a span of 48 mm between supports, and a load increase rate of 1 MPa/s until rupture.

3. Results and Discussion

3.1. FTIR Analysis

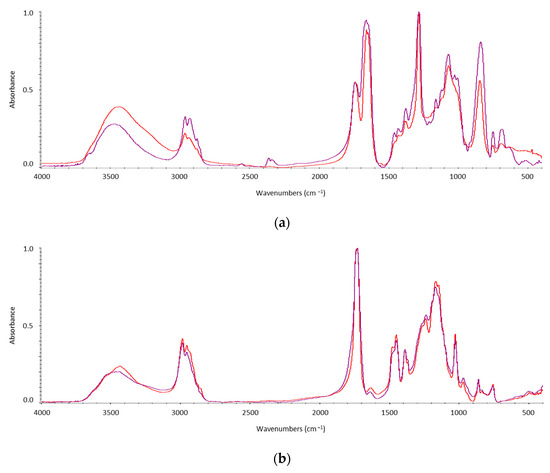

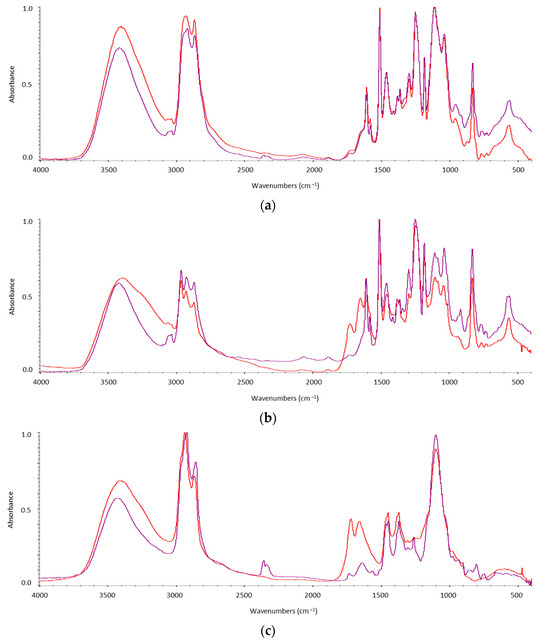

The three types of studied resins were analysed using FTIR before and after the accelerated ageing in the Xenon climatic chamber to determine the main observable changes in their chemical constitutions (Figure 3 and Figure 4, Appendix A).

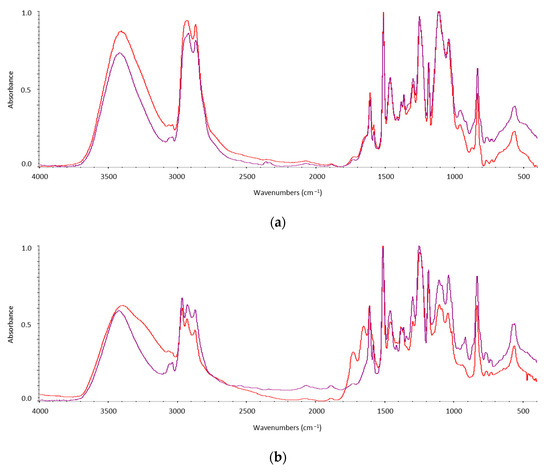

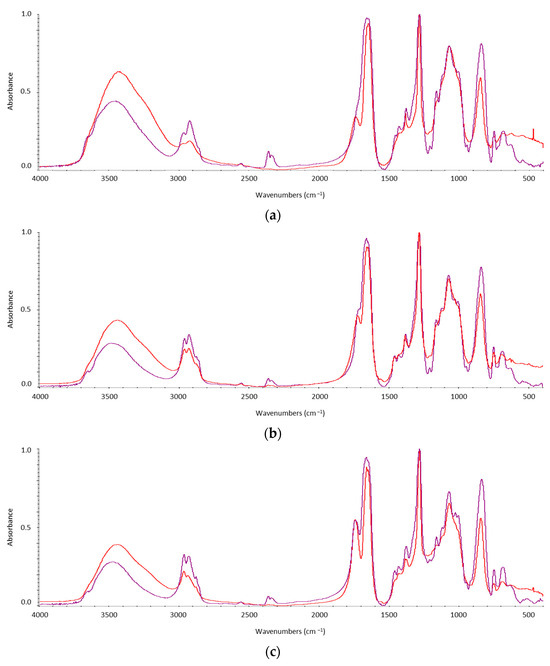

Figure 3.

FTIR spectra of the epoxy resins before (purple) and after (red) ageing in the climatic chamber: (a) Araldite® 2020; (b) Fynebond®; and (c) Hxtal Nyl® 1.

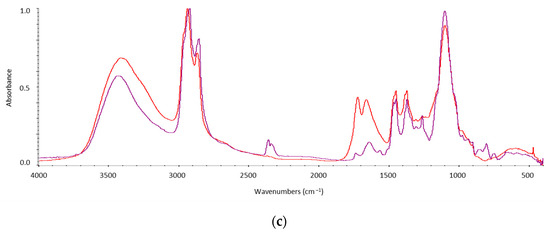

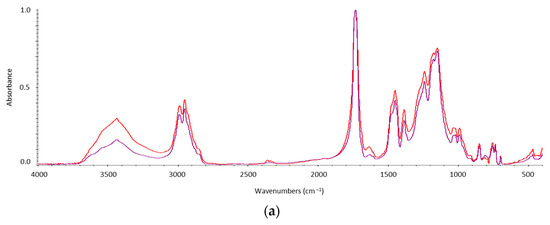

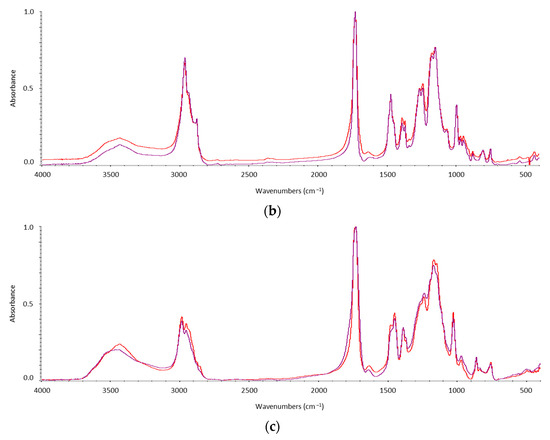

Figure 4.

FTIR spectra of example cellulose nitrate and acrylic resins before (purple) and after (red) ageing in the climatic chamber: (a) UHU® Hart and (b) Paraloid® B72. For all the resin FTIR spectra, see Appendix A.

The epoxy resins studied were composed of a first component based on the aromatic bisphenol A diglycidyl ether (DGEBA) for Fynebond® and Araldite®, and the aliphatic diglycidyl ether of hydrogenated bisphenol-A (HDGEBA) for Hxtal Nyl® 1; and a second component based on different hardeners for each adhesive. The FTIR analysis shows the characteristic bands of the epoxy resins, where the 915 cm−1 band is attributed to the unreacted C–O deformation of the epoxide ring [40,41]. In the FTIR spectra, the presence of the bands at 1380 cm−1 and 1360 cm−1 may be noted, which corresponds to the C–H3 bending of the gem-dimethyl group characteristic of bisphenol A. The higher aromatic natures of the Fynebond® and Araldite® 2020 resins are evidenced by the presence of the bands at 1610 cm−1 and 1510 cm−1, attributed to the C=C stretching of the aromatic nucleus [42,43]. In these resins, we also observed the presence of the band at 830 cm−1, characteristic of the C–H out-of-plane bending vibration on the para-disubstituted aromatic ring [42,44]. After ageing, all epoxy resins showed evidence of post-cure, with the disappearance of the oxirane ring characteristic band (at 915 cm−1) [42]. In Fynebond® and Hxtal Nyl® 1, the appearances of the bands at 1725 cm−1 and 1660 cm−1, due to the formation of the carbonyl bonds, are indicative of the photo-oxidative degradation of the polymers due to the ageing process [41,43,44].

All FTIR spectra of the cellulose nitrates (Figure 4, Appendix A) exhibited the typical absorption bands at 1650 cm−1 due to the asymmetric stretching of the NO2 groups, and around 1280 cm−1 and 840 cm−1, which were attributed to NO2 and the beta-anomeric linkage in cellulose, respectively [42,45,46]. The degradation of cellulose nitrate polymers has been reported in previous studies [43,45,47,48]. When comparing the spectra registered before and after ageing, it is possible to notice some variations in the intensities and shapes of the characteristic bands, namely, the decrease in the NO2 asymmetric stretching band at 1650 cm−1 and decrease in the 840 cm−1 beta-anomeric linkage band, both of which are related to cellulose nitrate degradation processes [45]. Nitrous oxides are one of the first products of thermal deterioration, since the N–O bonds joining the ring are the weakest bonds in the molecule [45].

The acrylic resins studied are methacrylate homopolymers or copolymers: Paraloid® B72 (PEMA/PMA) is a poly-(ethyl methacrylate) poly-(methyl acrylate) copolymer; Paraloid® B44 (PMMA/PEA) is a poly-(methyl methacrylate) and ethyl acrylate; and Paraloid® B67 (PiBMA) is a poly-(isobutyl methacrylate) [49]. In all the acrylic resins, their characteristic bands can be observed, namely, the bands corresponding to the carbonyl absorption around 1730 cm−1 and the bands between 1270 and 1150 cm−1 characteristic of C–O–C stretching of an ester group [42,46]. The FTIR spectra of the three acrylic adhesives are similar before and after ageing, suggesting that the acrylic resins do not undergo chemical changes during the ageing process.

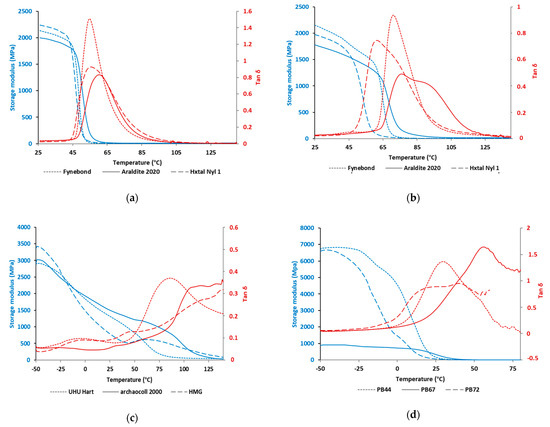

3.2. Dynamic Mechanical Analysis (DMA)

In its glass state, a polymeric material exhibits a relatively stable mechanical behaviour, with stiffness and mechanical properties that do not vary much with temperature changes [32]. As the temperature rises, the polymer chains undergo increased vibration and movement, leading to a less stable mechanical behaviour as evidenced by a decline in the storage modulus (E’) [32,50].

The glass transition temperature (Tg) interval refers to the temperature range over which the material undergoes this transition from a glassy, rigid state, to a more flexible and rubbery state [50,51]. The Tg interval can be defined by the two following temperatures: (i) lower Tg: the temperature at which the material begins the transition (below this temperature, the material is in a glassy state, exhibiting high stiffness) and (ii) upper Tg: the temperature at which the material completes its transition to a more rubbery or viscous state [51].

DMA is particularly well suited for characterizing the glass transition of polymers, because it can directly measure the changes in the mechanical properties of the material as the temperature is varied [50,52,53].

After curing at room temperature, all three epoxies presented a vitreous state and high rigidity (Figure 5a). The epoxies presented a well-defined Tg range, measured from the onset to the final point of the storage modulus curves (E’), namely, 43.8–49.3 °C for Hxtal Nyl® 1, 45.9–50.3 °C for Fynebond®, and 47.5–54.8 °C for Araldite® 2020. The results for Hxtal Nyl® 1 and Araldite® 2020 are consistent with those that have been reported from DSC measurements (47.4 °C and 49.8 °C for Hala Nyl® 1 and Araldite® 2020, respectively) [54]. However, Araldite® 2020 showed a lower Tg range compared to the manufacturer’s reported value of approximately 39.5 °C [55]. The difference between the measured and literature values can be explained by the fact that Tg is not a first order transition, and its measurement is highly dependent on the experiment method, time scale, presence of solvents, sample age, and history [56].

Figure 5.

DMA of the selected resins: (a) epoxies after curing, (b) epoxies after 500 h of artificial ageing in climatic chamber, (c) cellulose nitrates after curing, and (d) acrylics after curing. Blue: Storage Modulus; Red: Tan δ.

After artificial ageing, the three epoxy resins exhibit a shift in the Tg range to higher values (47.9–57.5 °C for Hxtal Nyl® 1, 59.7–67.7 °C for Fynebond®, and 63.0–73.6 °C for Araldite® 2020) which is particularly evident in the E’ curves of Fynebond® and Araldite® 2020. This phenomenon is common when room-temperature-cured epoxy resins are later exposed to higher temperatures (as happened here, with the exposure in a climatic chamber) because they continue to polymerize and cure. As a result of this change, the resins retain their stiffness at higher temperatures, and the glass transition temperature range is shifted to higher values. For Araldite® 2020 and Hxtal Nyl® 1, the tan δ curve (a dimensionless parameter that represents the ratio of the loss modulus to the storage modulus, which measures the energy dissipation or the damping characteristics of the material) also shows an enlarged peak base and an inflection on the descending branch. This effect has previously been described as being due to the presence of different components, regions with different reticulation densities, or the formation of a drier skin at the surface of the sample and a less dry interior [32].

Cellulose nitrates before ageing (Figure 5c) do not depict a well-defined onset or final points in the storage modulus curves (E’), and therefore, also the glass transition temperature range. All three cellulose nitrate adhesives are characterized by high stiffness at very low temperatures (−50 °C) but are softer than the epoxies at ambient temperatures. They exhibit a viscous–elastic behaviour up to temperatures around 70–100 °C, when the storage modulus decays. After artificial ageing in the climatic chamber, the cellulose nitrate resins presented alterations (they became extremely fragile and broke during the mounting on the instrument) that precluded a DMA analysis.

Thermoplastic acrylic resins also have a less pronounced glass transition temperature range than the epoxy resins. Compared to the cellulose nitrate resins, Paraloid® B72 and Paraloid® B44 show much higher stiffness values at −50 °C but also the fastest decrease in the storage modulus with temperature increase. Paraloid® B67 shows a distinct behaviour, with very low stiffness values and little influence of the temperature on the storage modulus up to about 25 °C. From temperatures around −40, −15, and 15 °C for Paraloid® B72, Paraloid® B44, and Paraloid® B67, respectively, the resins showed a viscoelastic behaviour up to around 25–35 °C, after which the viscous behaviour of all the resins prevailed. The determination of the glass transition temperature from the tan δ peak (which usually provides higher values for Tg than the one measured by the onset of the storage modulus) indicates maximum values of around 40 °C for Paraloid® B72, while Paraloid® B44 presents a peak at 30 °C, and Paraloid® B67 at 56 °C. As said before, the experimental method, time scale, presence of solvents, sample age, and history [56] may further explain the differences from the Tg values reported in the literature for Paraloid® B67 and B44 (40 °C for Paraloid® B72, 60 °C for Paraloid® B44, and 50 °C for Paraloid® B67). During ageing, the acrylics altered their shape (Figure 5), which did not allow them to be analysed using DMA.

3.3. Resins Solid Content

The epoxy resins showed no significant shrinkage or weight loss after curing, while the acrylic resins lost around 60% of their initial weight corresponding to the solvent weight used in their preparation. The solid content of the commercial cellulose nitrate resins was 26% for Archaocoll® 200, 31% for HMG®, and 38% for UHU® Hart.

3.4. Colour Alterations Due to Ageing

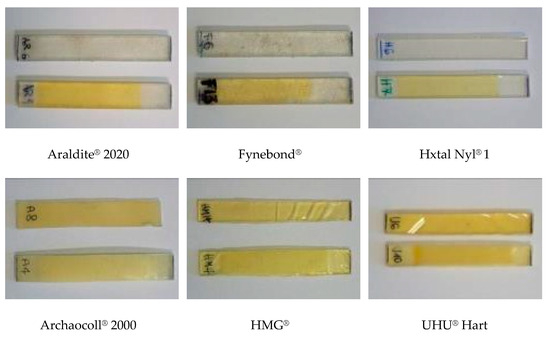

Polymer degradation due to ageing is a complex phenomenon that occurs at the molecular level and can also be detectable at the macroscopic level as visual changes.

Figure 6 shows the samples before and after artificial ageing in the Xenon radiation chamber, depicting the yellowing of the test specimens resulting from the exposure to the ageing test. It was observed that the three cellulose nitrates already presented a yellowish colour since their preparation, while only a slight increase in colour occurred after the ageing. All the epoxies were transparent after curing and yellowed after ageing, where the aliphatic Hxtal Nyl® 1 appeared to be the least affected by this factor. Acrylics (Paraloid® B72, B44, and B67) were not particularly affected by the yellowing, but there was a change in their shape which occurred due to softening caused by the temperature (55 °C) reached in the climatic chamber (Figure 7).

Figure 6.

Comparison of samples before (top of each image) and after (bottom) 500 h artificial ageing in the climatic chamber.

Figure 7.

Example of Paraloid® B72 softening after 500 h in the Xenon climatic chamber.

3.5. Adhesion of the Ceramic Fragments

3.5.1. Workability

All adhesives were easily applied by brushing to bond the ceramic fragments. At dissolutions of 40% (w:w) Paraloid® B44 and Paraloid® B67 presented an observable lower viscosity than 40% Paraloid® B72, which led to a higher absorption by the porous ceramic, making the joining process more difficult. The cellulose nitrate had a higher viscosity for tile fragment adhesion. The viscosity of the reactive epoxy resins increased with time, and only several hours after its preparation, a suitable viscosity was achieved. For the application of these resins, a two-step application was adopted, where the first had the purpose of surface consolidation, and the second, of adhesion. An alternative would be to monitor the viscosity over time and apply the resin when the correct viscosity is achieved, resulting in a short workability time. The epoxies showed a short pot life, but the high solvent content of the acrylic polymers and cellulose nitrates induced shrinkage and bubble formation during curing due to the solvent’s evaporation.

3.5.2. Flexural Strength

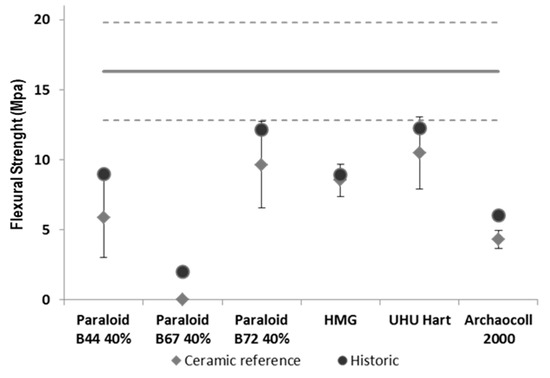

Figure 8 presents the results obtained from the flexural strength test samples. These were tested in a three-point bending setup. When the rupture of the sample occurs in the bonded joint or in its close vicinity, the flexural strength measurement gives an indication of the resin adhesive strength.

Figure 8.

Flexural strength through bending tests after curing. The solid and dashed grey lines mark the average flexural strength and standard deviation of the ceramic reference matrix.

The results obtained after curing showed that the epoxies did not fail in the bonded joint but failed in the ceramic matrix (Figure 9c), showing that the adhesive’s strength was higher than the ceramic matrix flexural strength. This means that mechanical stress applied to the tile panel would probably create new fracture surfaces in previously undamaged areas. The results obtained therefore indicate that under mechanical stresses, such as movements in the building structure, epoxy bonding could cause further damage to the historic tiles. Methods for reducing the epoxy bond strength and/or improving its reversibility by, for instance, firstly applying a different adhesive coat layer, could potentially mitigate these issues [33].

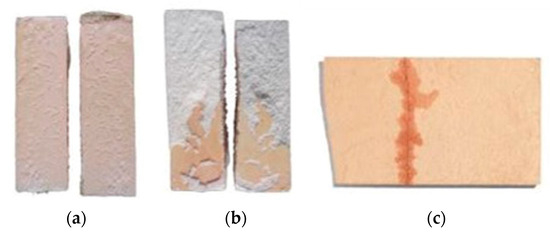

Figure 9.

Depiction of the failure mode types of the bonded ceramic fragments through bending tests. (a) failure in the adhesive, (b) mixed adhesive–ceramic failure, and (c) ceramic failure.

Paraloid® B72 and UHU® Hart showed intermediate bond strengths, resulting in a mixed adhesive/ceramic failure near the bonded joint. Paraloid® B67, Paraloid® B44, HMG®, and Archaocoll® showed a lower flexural strength to bending, with failure occurring in the adhesive layer. Paraloid® B67, on the other hand, was too brittle and showed a bond strength close to nil at the studied concentration and application procedure. The test with historic tiles has validated the results obtained with the NTer ceramic tiles (Figure 8).

The type of failure observed is proportional to the flexural bond strength obtained (Figure 9), where the adhesives with a low strength (Paraloid® B67, Paraloid® B44, HMG®, and Archaocoll®) result in adhesive failures, those with a medium strength (Paraloid® B72 and UHU® hart) show adhesive–ceramic failure, and those with high strength, such as the epoxies, produce fractures in the ceramic body and not in the bond layer.

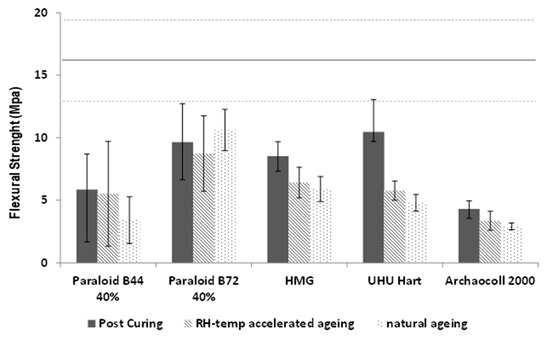

After artificial ageing (Figure 10) in the climatic chamber with variations in the temperature and relative humidity, all the Paraloid® B67 samples presented with adhesive failure and did not allow the bending test to be performed. The bond strength observed after ageing revealed a small decrease for Paraloid® B44 and maintenance or even improvement for Paraloid® B72. A higher loss in effectiveness is observed for the cellulose nitrates. After ageing, Paraloid® B72 continues to impart some degree of strength to the joint, where the mixed adhesive–ceramic failure after the test remains. These breakages do not create new fracture surfaces but correspond to fragments of ceramic in the vicinity of the joint that remain attached to the opposite side (Figure 9b). After ageing, the cellulose nitrates mainly showed adhesive failures.

Figure 10.

Results of bending tests before and after artificial and natural ageing. The solid and dashed grey lines mark the average flexural strength and standard deviation of the ceramic reference matrix.

After natural ageing, the results of artificial ageing generally confirmed a high loss in the efficacy of the cellulose nitrates, a decreased performance of Paraloid® B44, and an apparent improvement in the performance of Paraloid® B72 (Figure 10).

4. Conclusions

Several analytical techniques were used to characterize a set of selected adhesives commonly used in the restoration of historic azulejos in Portugal. All the epoxies revealed a tendency to yellow, had high stiffness (DMA) at an ambient temperature, as well as a chemical alterability revealed using FTIR when exposed in the climatic chamber. Bending tests also showed that their strengths were very high, which may lead, when subjected to mechanical stresses, to breakage in other areas of the ceramic material rather than in the bond joint. High-strength adhesives can be important to assure the structural role of objects, but for compatibility reasons, adhesives with a breaking strength clearly superior to those of the materials to be joined should be avoided in conservation treatments. These results showed that in the case of azulejos in a common architectural context, epoxies are less appropriate for the bonding of fragments, since a structural function is not essential, because the tiles are held to the wall by a mortar.

The cellulose nitrate adhesives appeared already yellow after curing when a sufficiently thick (approximately 3 mm) adhesive sample was prepared. A chemical alteration was also detected using FTIR after temperature–UV–RH cycles with ageing, and they also presented the highest degradation rates in the mechanical properties with ageing, possibly showing them as the least stable for use in outdoor conditions.

The acrylic resins studied showed a high variability between them in terms of their properties and adhesion performance. Paraloid® B72 (followed by Paraloid® B44) showed the most suitable characteristics for bonding tile fragments in terms of its workability, adhesion strength, low chemical alteration, and yellowing fastness. Since the tile fragments are held to the wall by the mortar, the softening and viscous–elastic or viscous behaviour of the acrylic resins at ambient temperatures do not necessarily impose structural risks, and even allow for some adjustment of the resin to minor wall movements. Although Paraloid® B72 did not induce new fracture lines, it presented, however, a mixed adhesive–ceramic failure mode that could lead to the partial damage of the original material in the vicinity of the bonded joint.

The results obtained allowed for a better understanding of the characteristics and ageing behaviours of some of the most used adhesives for the bonding of tile fragments, which will hopefully aid in the practice of azulejo conservation.

Author Contributions

Conceptualization, S.R.M.P., J.M., J.D.R. and M.P.R.; FTIR analysis, H.M.A.R.S., J.M. and S.R.M.P.; DMA analysis, S.C.-F. and J.M.; data curation, S.R.M.P., J.M., H.M.A.R.S. and S.C.-F.; writing—original draft preparation, J.M. and S.R.M.P.; writing—review and editing, H.M.A.R.S., S.C.-F., L.E. and J.D.R.; supervision, S.R.M.P.; funding acquisition, S.R.M.P. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Fundação para a Ciência e Tecnologia, project number PTDC/CTM-CER/119085/2010 and DOI 10.54499/2021.01998.CEECIND/CP1703/CT0001.

Data Availability Statement

Data are contained within the article.

Acknowledgments

New Terracota SA is thanked for their donation of azulejo ceramic biscuits. J. M. Mimoso and Doria Costa are acknowledged for their fruitful discussions and support.

Conflicts of Interest

The authors declare no conflicts of interest.

Appendix A. FTIR Spectra

Appendix A.1. Epoxy Resins

Figure A1.

FTIR spectra of the epoxy resins before (purple) and after (red) ageing in the climatic chamber: (a) Araldite 2020; (b) Fynebond; and (c) Hxtal Nyl® 1.

Appendix A.2. Cellulose Nitrate Resins

Figure A2.

FTIR spectra of the cellulose nitrate resins before (purple) and after (red) ageing in the climatic chamber: (a) Archaocoll® 2000; (b) HMG®; and (c) UHU® Hart.

Appendix A.3. Acrylic Resins

Figure A3.

FTIR spectra of the acrylic resins before (purple) and after (red) ageing in the climatic chamber: (a) Paraloid® B44; (b) Paraloid® B67; and (c) Paraloid® B72.

References

- Pereira, S.R.; Conte, G.; Esteves, L.; Pais, A.N.; Mimoso, J.M. Evolution of azulejo glaze technology in Portugal from the 16th to the onset of the 19th century. J. Eur. Ceram. Soc. 2023, 43, 3804–3815. [Google Scholar] [CrossRef]

- Pais, A.; da Conceição Reis, M.; Campelo, J.; Mimoso, J.M.; Silva, M.A. The beginning of the production of majolica azulejos in Portugal-João and Filipe de Góis in 16th century Lisbon. Stud. Herit. Glazed Ceram. 2019, 1, 1–23. [Google Scholar]

- Ferreira, L.V.; Machado, I.F.; Pereira, M.; Mangucci, C. Archaeometry of tiles (azulejos) produced in the region of Lisbo–16th to 18th centuries. A comparison of Lisbon and Seville pastes for the cuerda seca and arista tiles. J. Archaeol. Sci. Rep. 2023, 49, 104041. [Google Scholar] [CrossRef]

- Mimoso, J.M.; Pereira, S.R. Sobre a Degradação Física dos Azulejos de Fachada em Lisboa; LNEC Report 303/2011–NPC; LNEC: Lisbon, Portugal, 2011. [Google Scholar]

- Mimoso, J.M.; Pereira, S.R.M.; Silva, A.S. A Research on Manufacturing Defects and Decay by Glaze Loss in Historical Portuguese Azulejos; LNEC Report 24/2011; LNEC: Lisbon, Portugal, 2011. [Google Scholar]

- Coutinho, M.; Miller, A.; Gutierrez-Patricio, S.; Hernandez-Marine, M.; Gomez-Bolea, A.; Rogerio-Candelera, M.; Philips, A.; Jurado, V.; Saiz-Jimenez, C.; Macedo, M. Microbial communities on deteriorated artistic tiles from Pena National Palace (Sintra, Portugal). Int. Biodeterior. Biodegrad. 2013, 84, 322–332. [Google Scholar] [CrossRef]

- Coutinho, M.L.; Miller, A.Z.; Martin-Sanchez, P.M.; Mirão, J.; Gomez-Bolea, A.; Machado-Moreira, B.; Cerqueira-Alves, L.; Jurado, V.; Saiz-Jimenez, C.; Lima, A.; et al. A multi-proxy approach to evaluate biocidal treatments on biodeteriorated majolica glazed tiles. Environ. Microbiol. 2016, 18, 4794–4816. [Google Scholar] [CrossRef] [PubMed]

- Zvezdin, D.F.; Kir’yanov, A.V. Wet expansion of double-fired ceramic-tile engobes. Glas. Ceram. 2006, 63, 315–316. [Google Scholar] [CrossRef]

- Geller, R.; Creamer, A. Moisture Expansion of Ceramic White Ware. Bur. Stand. J. Res. 1941, 9, 291–307. [Google Scholar] [CrossRef]

- Mimoso, J.M. Levantamento em Obra de Patologias em Azulejos Históricos_Visitas Realizadas em 2009–2010; LNEC RELATÓRIO 22/2011–NPC; LNEC: Lisbon, Portugal, 2011. [Google Scholar]

- Pereira, S.R.M.; Mimoso, J. Salt Degradation of Historic Portuguese Azulejos. In Azulejar; Universidade de Aveiro: Aveiro, Portugal, 2012; p. 10. [Google Scholar]

- Pereira, S.R.M.; Esteves, L.; Mendes, M.T.; Musacchi, J.; Rodrigues, J.D.; Mimoso, J.M. Cerazul: Assessment and development of materials and techniques for the conservation of historic azulejos. In Azulejar; Universidade de Aveiro: Aveiro, Portugal, 2012; p. 8. [Google Scholar]

- Mendes, M.T.; Pereira, S.; Ferreira, T.; Mirão, J.; Candeias, A. In situ preservation and restoration of architectural tiles, materials and procedures: Results of an international survey. Int. J. Cons. Sci. 2015, 6, 51–62. [Google Scholar]

- Ferreira, M.I.M. Azulejos Tradicionais de Fachada, em Ovar: Contributos para uma Metodologia de Conservação e Restauro; Câmara Municipal de Ovar/ACRA: Ovar, Portugal, 2009. [Google Scholar]

- Cultrone, G.; Madkour, F. Evaluation of the effectiveness of treatment products in improving the quality of ceramics used in new and historical buildings. J. Cult. Herit. 2013, 14, 304–310. [Google Scholar] [CrossRef]

- Costa, D.; Leal, A.S.; Mimoso, J.M.; Pereira, S.R. Consolidation treatments applied to ceramic tiles: Are they homogeneous? Mater. Constr. 2017, 67, 113. [Google Scholar] [CrossRef]

- Vaz, M.; Pires, J.; Carvalho, A. Effect of the impregnation treatment with Paraloid B-72 on the properties of old Portuguese ceramic tiles. J. Cult. Herit. 2008, 9, 269–276. [Google Scholar] [CrossRef]

- Santos, T.J.P. Estudos de Consolidação de Azulejos Cerâmicos. Ph.D. Thesis, Lisbon University, Lisbon, Portugal, 2013. Available online: https://repositorio.ul.pt/handle/10451/9896 (accessed on 13 February 2022).

- Prudêncio, M.; Pereira, M.S.; Marques, J.; Dias, M.; Esteves, L.; Burbidge, C.; Trindade, M.; Albuquerque, M. Neutron tomography for the assessment of consolidant impregnation efficiency in Portuguese glazed tiles (16th and 18th centuries). J. Archaeol. Sci. 2012, 39, 964–969. [Google Scholar] [CrossRef]

- Constâncio, C.; Franco, L.; Russo, A.; Anjinho, C.; Pires, J.; Vaz, M.F.; Carvalho, A.P. Studies on polymeric conservation treatments of ceramic tiles with Paraloid B-72 and two alkoxysilanes. J. Appl. Polym. Sci. 2010, 116, 2833–2839. [Google Scholar] [CrossRef]

- Ottosen, L.M.; Ferreira, C.M.D.; Christensen, I.V. Electrokinetic desalination of glazed ceramic tiles. J. Appl. Electrochem. 2010, 40, 1161–1171. [Google Scholar] [CrossRef]

- Ribeiro, A. Electrochemical desalination of historic Portuguese tiles—Removal of chlorides, nitrates and sulfates. J. Cult. Herit. 2014, 16, 712–718. [Google Scholar]

- Geraldes, C. Geopolymers as Infill Material for Conservation of Azulejos. Master’s Thesis, Universidade Nova de Lisboa, Lisboa, Portugal, 2015. [Google Scholar]

- Geraldes, C.F.M. Conservação Dos Azulejos Modernos Portugueses (1950–1974). Ph.D. Thesis, Nova University of Lisbon, Almada, Portugal, 2021. [Google Scholar]

- Mendes, M.T.; Esteves, L.; Ferreira, T.A.; Candeias, A.; Tennent, N.H.; Rodrigues, J.D.; Pereira, S.R.M. Lacunae infills for in situ treatment of historic glazed tiles. Appl. Phys. A 2016, 122, 547. [Google Scholar] [CrossRef]

- Geraldes, C.F.M.; Lima, A.M.; Delgado-Rodrigues, J.; Mimoso, J.M.; Pereira, S.R.M. Geopolymers as potential repair material in tiles conservation. Appl. Phys. A 2016, 122, 197. [Google Scholar] [CrossRef]

- Araújo, S. Filling and Retouching Techniques in Outdoor Tiles with Saline Efflorescence Problems. A Case Study. Ge-Conservacion 2020, 18, 238–246. [Google Scholar] [CrossRef]

- Allen, K. Adhesion and adhesives—Some fundamentals. Stud. Conserv. 1984, 29, 5–12. [Google Scholar] [CrossRef]

- Down, J.L.; MacDonald, M.A.; Williams, R.S.; Tetreault, J. Adhesive Testing at the Canadian Conservation Institute: An Evaluation of Selected Poly(Vinyl Acetate) and Acrylic Adhesives. Stud. Conserv. 1996, 41, 19. [Google Scholar] [CrossRef]

- Nel, P. Issues associated with adhesives used on archaeological pottery. In Vessels: Inside and Outside, Proceedings of the 9th European Meeting on Archaeological Ceramics (EMAC’07), Budapest, Hungary, 24–27 October 2007; Hungarian National Museum: Budapest, Hungary, 2009; pp. 187–195. [Google Scholar]

- Alexiou, K.; Müller, N.S.; Karatasios, I.; Kilikoglou, V. The performance of different adhesives for archaeological ceramics under mechanical stress. Appl. Clay Sci. 2013, 82, 10–15. [Google Scholar] [CrossRef]

- Fonseca, S.C. Durabilidade de Materiais Compósitos de Matriz Polimérica Reforçados com Fibras Usados na Reabilitação de Estruturas de Betão. Ph.D. Thesis, University of Minho, Braga, Portugal, 2008. Available online: http://repositorium.sdum.uminho.pt/ (accessed on 12 May 2023).

- Podany, J.; Garland, K.M.; Freeman, W.R.; Rogers, J. Paraloid B-72 as a Structural Adhesive and as a Barrier within Structural Adhesive Bonds: Evaluations of Strength and Reversibility. J. Am. Inst. Conserv. 2001, 40, 15–33. [Google Scholar] [CrossRef]

- Hamilton, D.L. Basic Methods of Conserving Underwater Archaeological Material Culture; U.S. Department of Defense, Legacy Resource Management Program: Washington, DC, USA, 1996. [Google Scholar]

- Koob, S.P. Conservation and Care of Glass Objects; Published in Association with the Corning Museum of Glass; Archetype Publications: London, UK; New York, NY, USA, 2006. [Google Scholar]

- Pereira, S.R.M.; Mimoso, J.M.; Silva, A.S. Physical-Chemical Characterization of Historic Portuguese Tiles. LNEC, Report, January 2011. Available online: http://repositorio.lnec.pt:8080/xmlui/handle/123456789/1001892 (accessed on 15 October 2023).

- ISO 9142:2003 Cycle D7; Adhesives: Guide to the Selection of Standard Laboratory Ageing Conditions for Testing Bonded Joints. ISO: Geneva, Switzerland, 2003.

- ISO 2810:2020; Paints and Varnishes—Natural Weathering of Coatings—Exposure and Assessment. ISO: Geneva, Switzerland, 2020.

- ISO 6721:2019; Plastics—Determination of Determination of Dynamic Mechanical Properties. ISO: Geneva, Switzerland, 2019.

- González, M.G.; Cabanelas, J.C.; Baselga, J. Applications of FTIR on Epoxy Resins—Identification, Monitoring the Curing Process, Phase Separation and Water Uptake. In Infrared Spectroscopy-Materials Science, Engineering and Technology; Theophanides, T., Ed.; InTech: Rijeka, Croatia, 2012. [Google Scholar] [CrossRef]

- Tennent, N.H. Clear and Pigmented Epoxy Resins for Stained Glass Conservation: Light Ageing Studies. Stud. Conserv. 1979, 24, 153. [Google Scholar] [CrossRef]

- Brezinski, D.R. An Infrared Spectroscopy Atlas for the Coatings Industry, 4th ed.; Federation of Societies for Coatings Technology: Blue Bell, PA, USA, 1991. [Google Scholar]

- Derrick, M.R.; Stulik, D.; Landry, J.M. Infrared Spectroscopy in Conservation Science. In Scientific Tools for Conservation; Getty Conservation Institute: Los Angeles, CA, USA, 1999. [Google Scholar]

- Tennent, N. The Identification and Long-Term Stability of Polymer Fills in Ceramics and Glass Artifacts: A Retrospective Assessment Involving FTIR Characterisation. In Proceedings of the Recent Advances in Glass and Ceramics Conservation, London, UK, 5–7 September 2019; pp. 121–129. [Google Scholar]

- Shashoua, Y.; Bradley, S.M.; Daniels, V.D. Degradation of Cellulose Nitrate Adhesive. Stud. Conserv. 1992, 37, 113. [Google Scholar] [CrossRef]

- Noake, E.; Lau, D.; Nel, P. Identification of cellulose nitrate based adhesive repairs in archaeological pottery of the University of Melbourne’s Middle Eastern archaeological pottery collection using portable FTIR-ATR spectroscopy and PCA. Herit. Sci. 2017, 5, 3. [Google Scholar] [CrossRef]

- Koob, S.P. The instability of cellulose nitrate adhesives. Conservator 1982, 6, 31–34. [Google Scholar] [CrossRef]

- Selwitz, C. Cellulose Nitrate in Conservation. In Research in Conservation; Getty Conservation Institute: Marina del Rey, CA, USA, 1988. [Google Scholar]

- Lazzari, M.; Chiantore, O. Thermal-ageing of paraloid acrylic protective polymers. Polymer 2000, 41, 6447–6455. [Google Scholar] [CrossRef]

- Menard, K.P.; Menard, N.R. Dynamic Mechanical Analysis in the Analysis of Polymers and Rubbers. In Encyclopedia of Polymer Science and Technology; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2015; pp. 1–33. [Google Scholar] [CrossRef]

- Menard, K. Dynamic Mechanical Analysis: A Practical Introduction; CRC Press: Boca Raton, FL, USA, 1999. [Google Scholar] [CrossRef]

- Seyler, R.J. Assignment of the Glass Transition; ASTM Special Technical Publication; ASTM: Philadelphia, PA, USA, 1994. [Google Scholar]

- Foreman, J. Dynamic Mechanical Analysis of Polymers; American Laboratory: San Francisco, CA, USA, 1997; pp. 1–3. [Google Scholar]

- Coutinho, I.; Lima, A.; Fernandes, F.B.; Ramos, A. Studies on Degradation of Epoxy Resins Used for Conservation of Glass. In Holding It All Together, Ancient and Modern Approaches to Joining, Repair and Consolidation; Archetype in Association with The British Museum: London, UK, 2008. [Google Scholar] [CrossRef]

- Huntsman. Araldite 2020 Technical Data Sheet. Available online: https://www.farnell.com/datasheets/1640467.pdf (accessed on 30 November 2023).

- Brandrup, J.; Immergut, E.H. (Eds.) Polymer Handbook, 3rd ed.; John Wiley & Sons: New York, NY, USA, 1989. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).