Health Index-Based Maintenance of Prestressed Concrete Bridges Considering Building Information Modeling Application

Abstract

1. Introduction

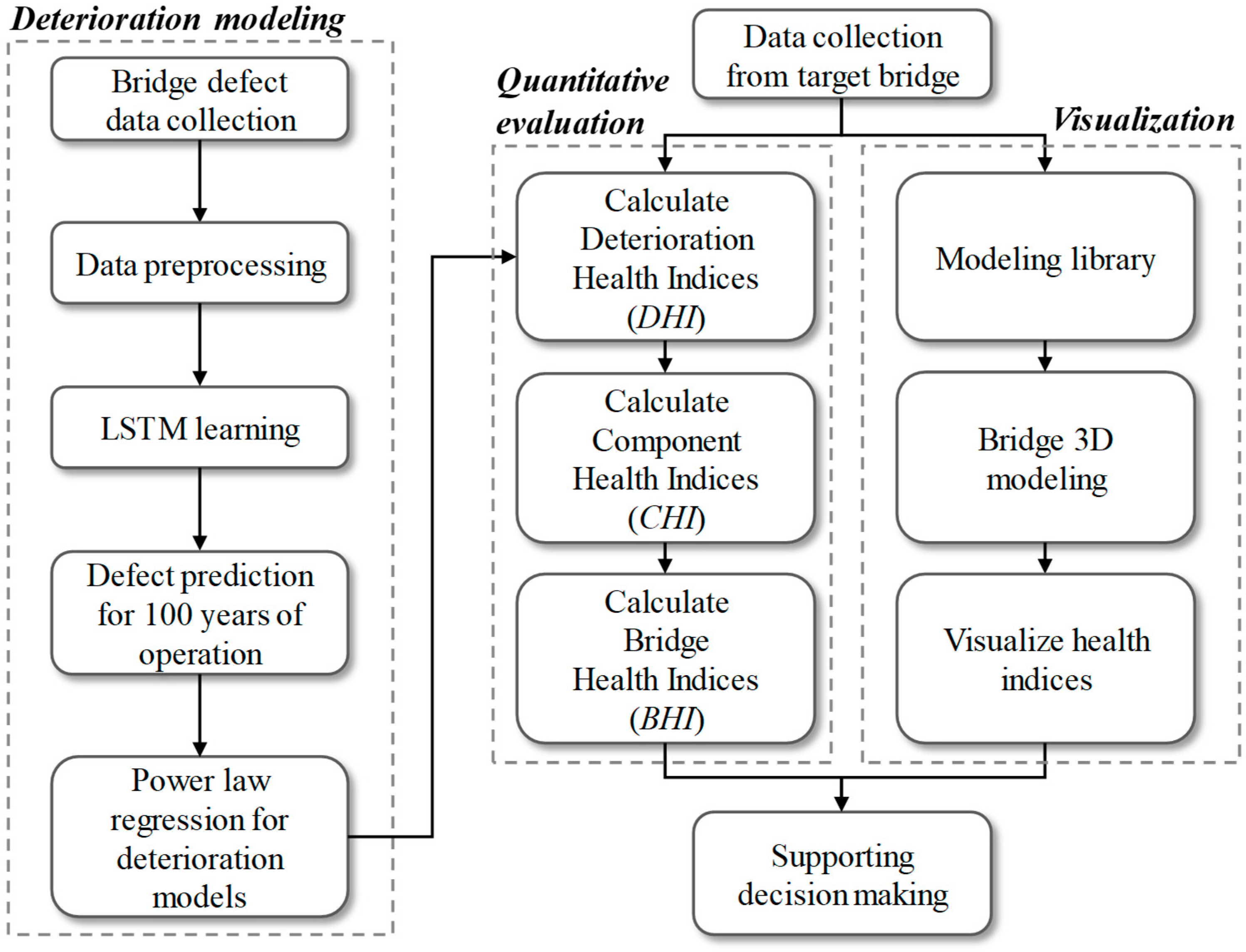

2. Analysis of Existing Evaluation Systems

3. Development of an HI-Based Bridge Evaluation System

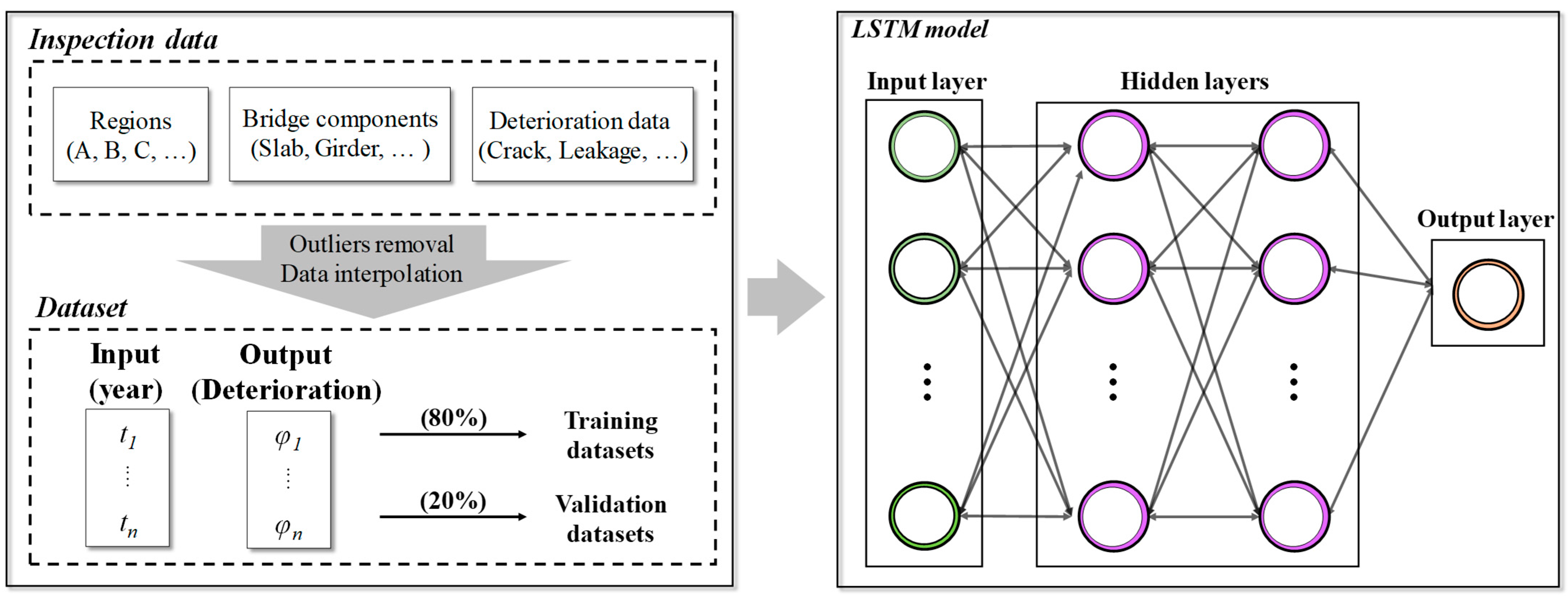

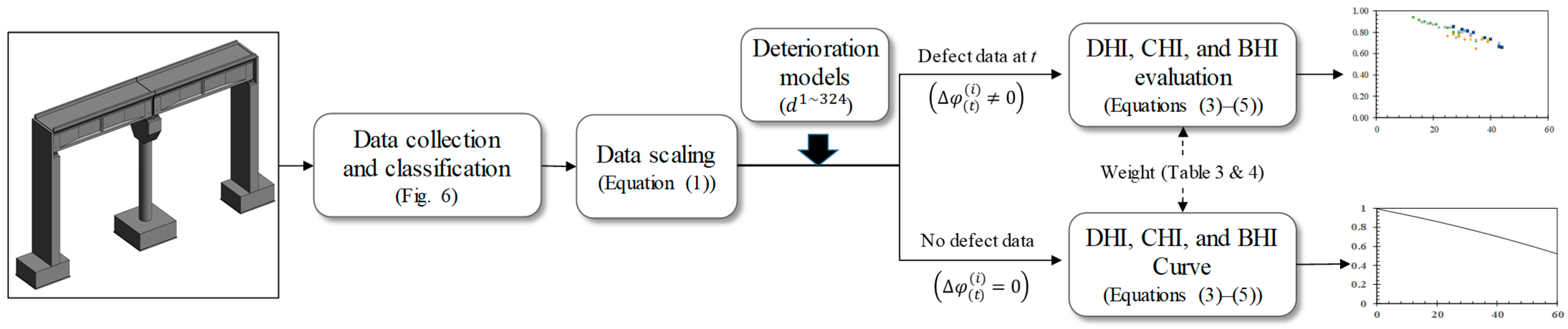

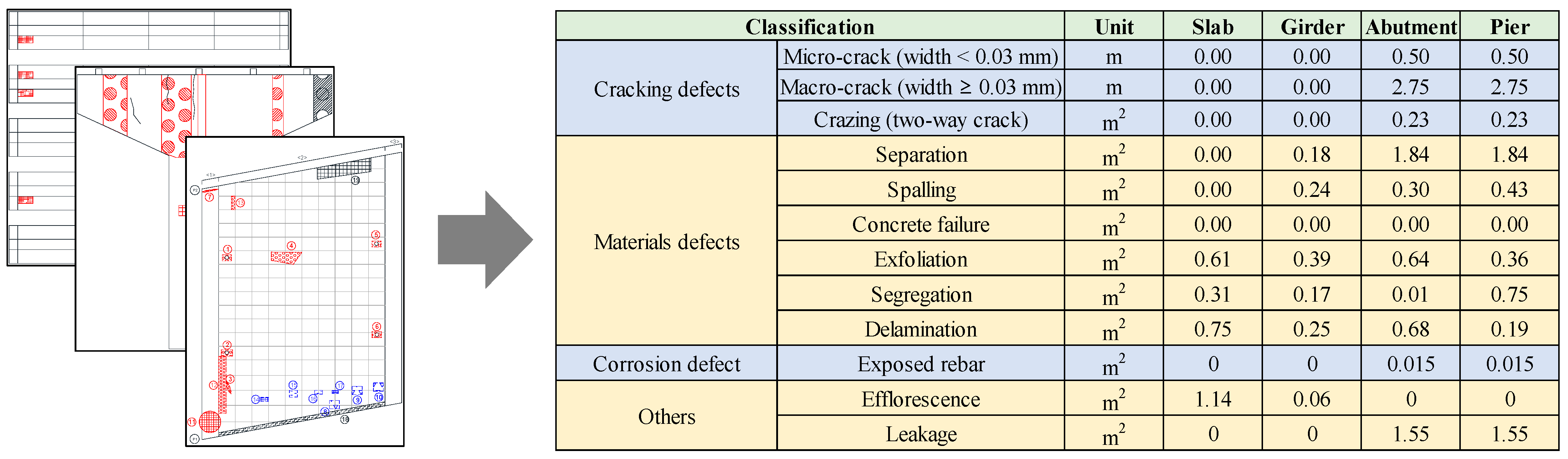

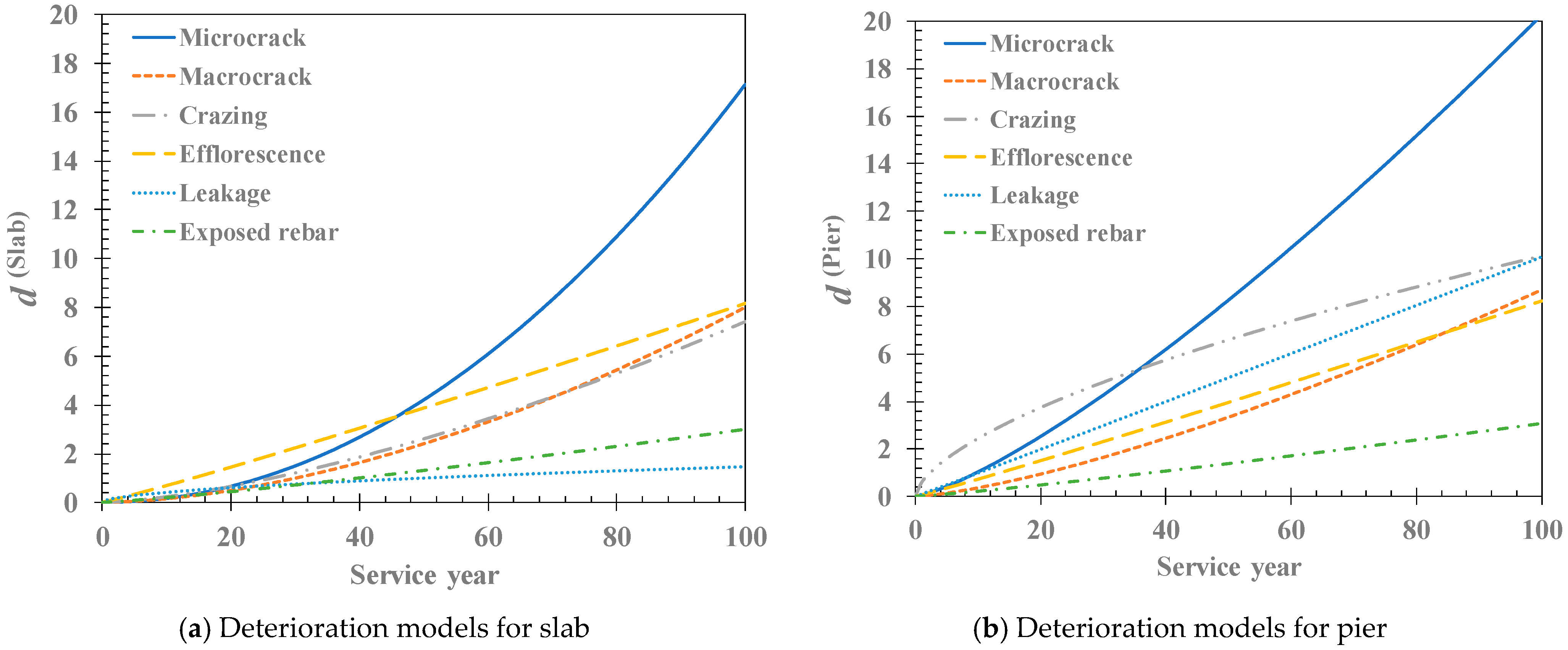

3.1. Deterioration Models

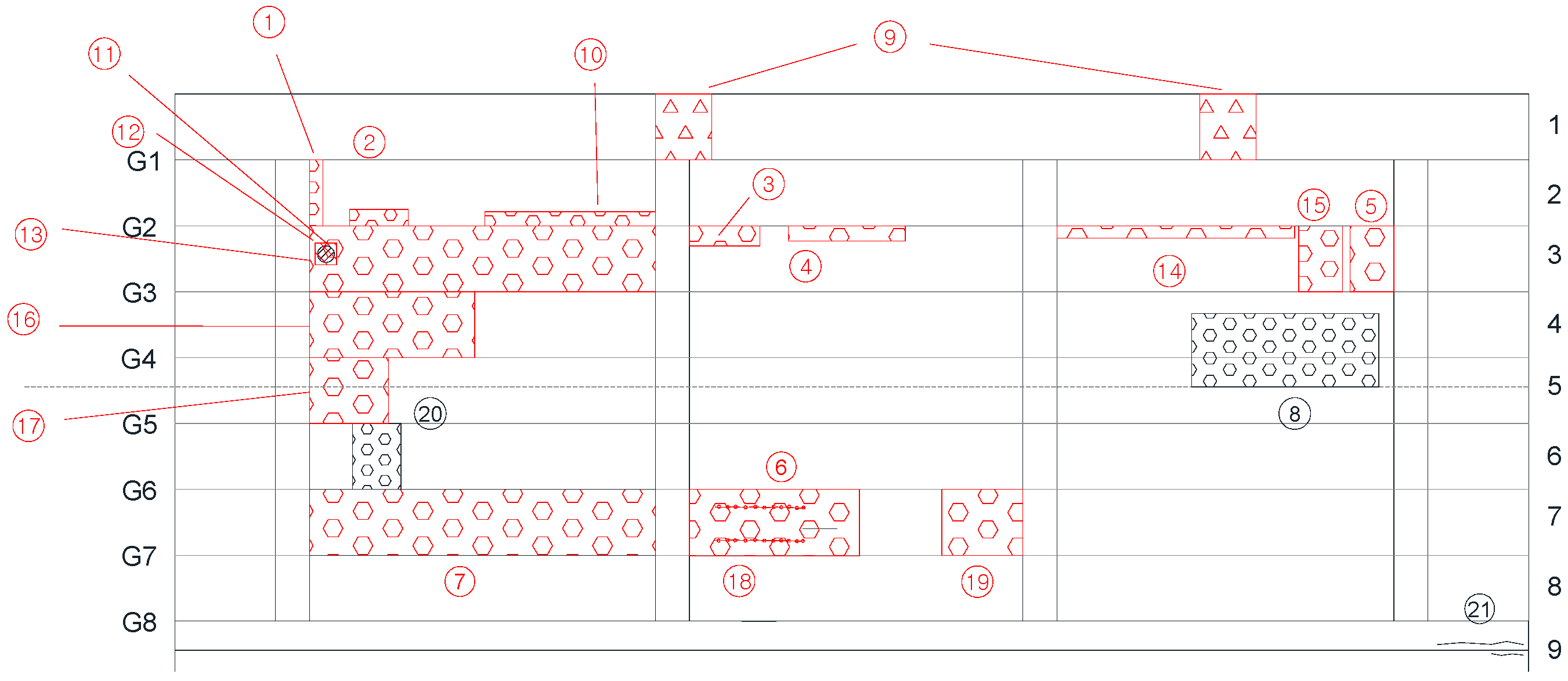

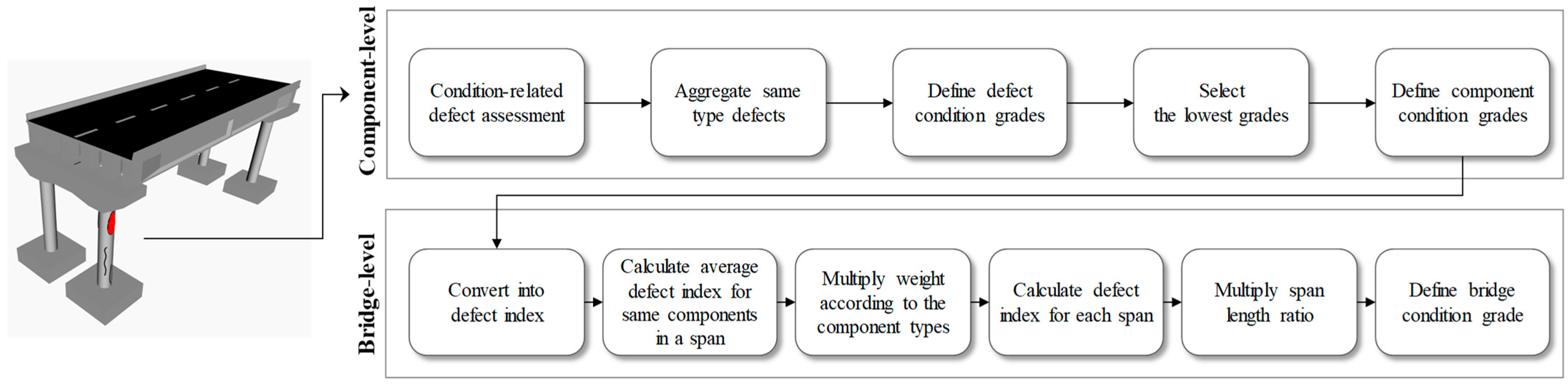

3.2. Bridge Evaluation Using HI

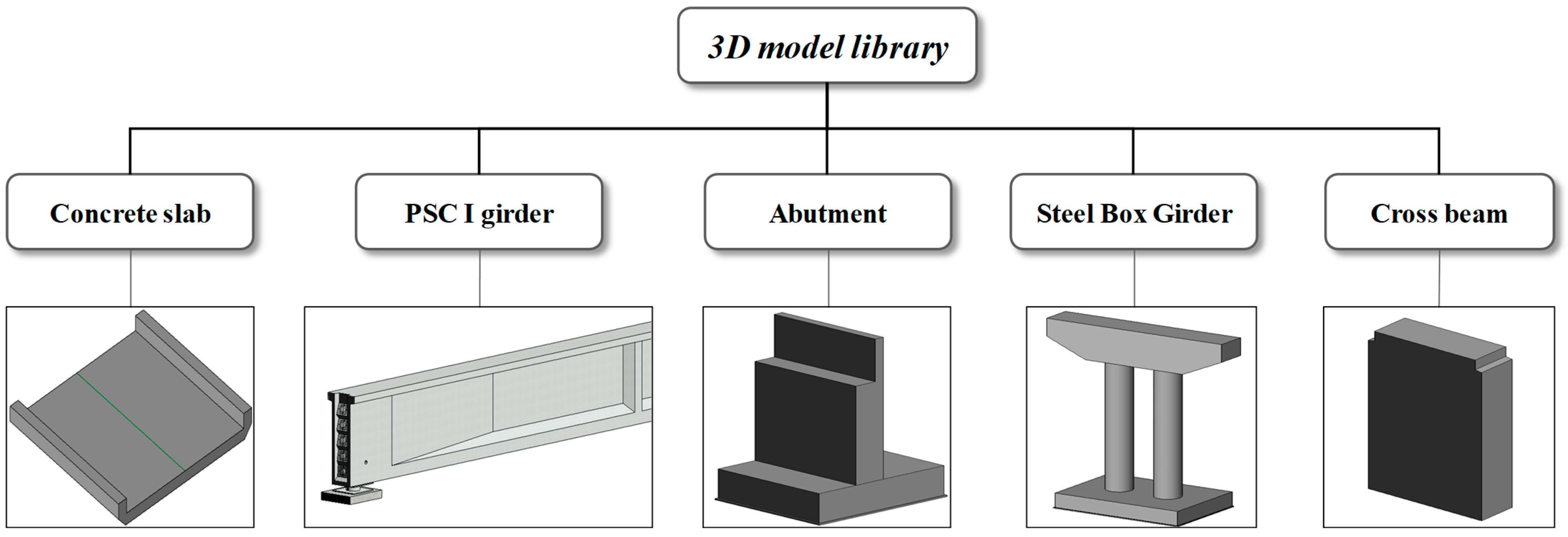

3.3. 3D Modeling

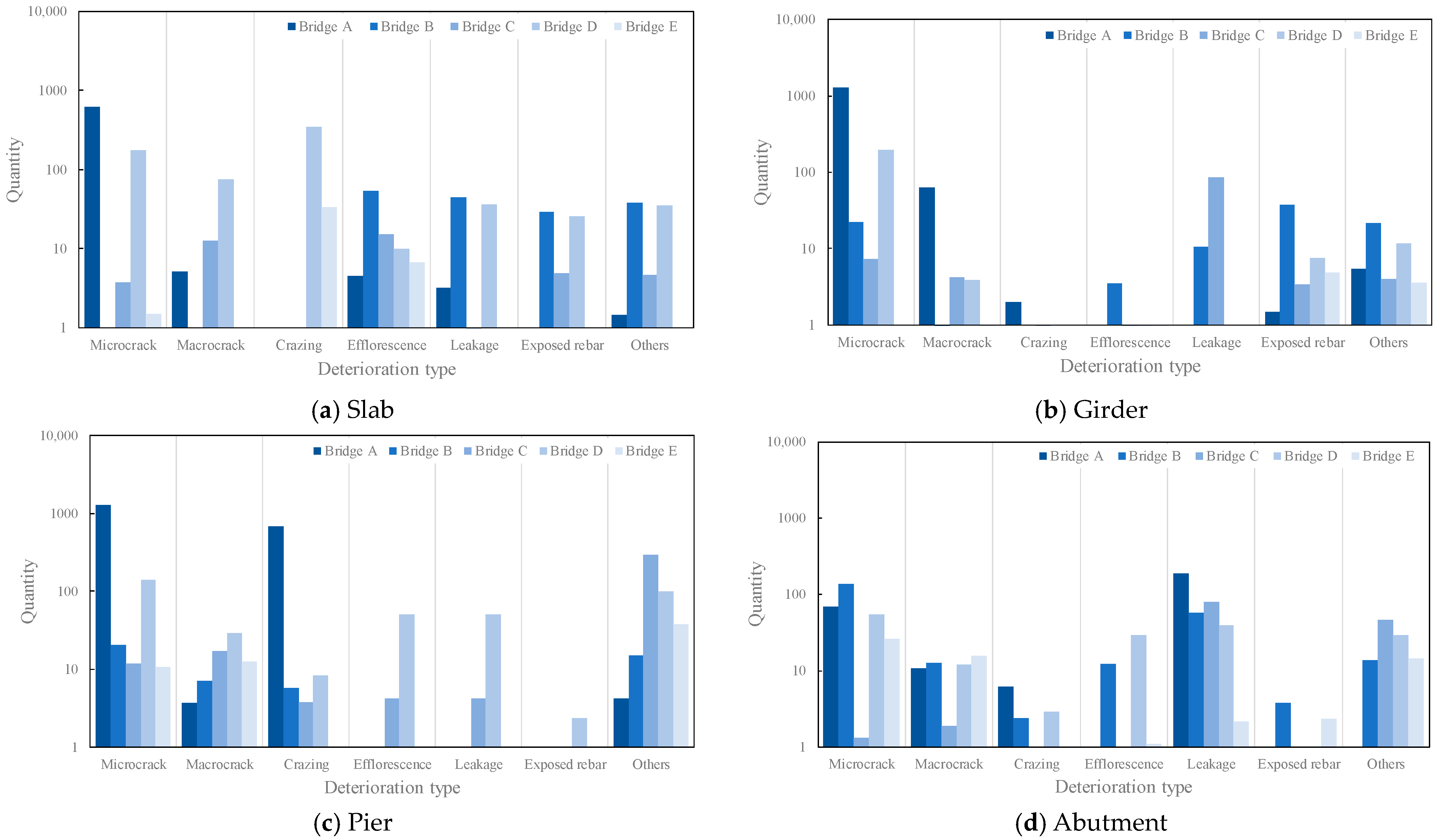

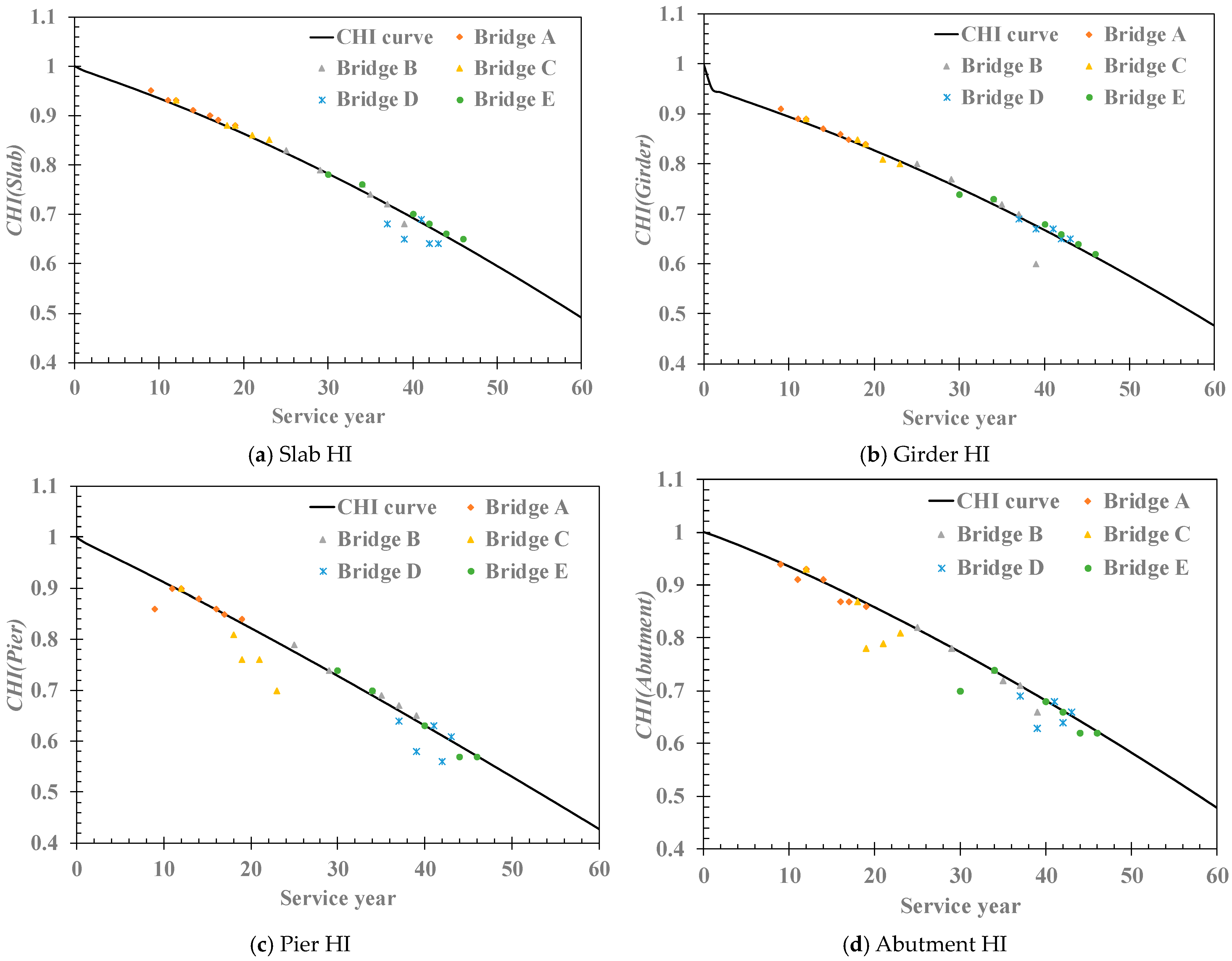

4. Case Application

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Shim, C.S.; Lee, K.M.; Kang, L.S.; Hwang, J.; Kim, Y. Three-dimensional information model-based bridge engineering in Korea. Struct. Eng. Int. J. Int. Assoc. Bridge Struct. Eng. (IABSE) 2012, 22, 8–13. [Google Scholar] [CrossRef]

- Shim, C.; Kang, H.; Dang, N.S.; Lee, D. Development of BIM-based bridge maintenance system for cable-stayed bridges. Smart Struct. Syst. 2017, 20, 697–708. [Google Scholar] [CrossRef]

- Jeon, C.-H.; Nguyen, D.-C.; Roh, G.; Shim, C.-S. Development of BrIM-Based Bridge Maintenance System for Existing Bridges. Buildings 2023, 13, 2332. [Google Scholar] [CrossRef]

- McGuire, B.; Atadero, R.; Clevenger, C.; Ozbek, M. Bridge Information Modeling for Inspection and Evaluation. J. Bridge Eng. 2016, 21, 04015076. [Google Scholar] [CrossRef]

- Tanaka, F.; Hori, M.; Onosato, M.; Date, H.; Kanai, S. Bridge Information Model Based on IFC Standards and Web Content Providing System for Supporting an Inspection Process. In Proceedings of the 16th International Conference on Computing in Civil and Building Engineering (ICCCBE 2016), Osaka, Japan, 6–8 July 2016; pp. 1140–1147. [Google Scholar]

- Wan, C.; Zhou, Z.; Li, S.; Ding, Y.; Xu, Z.; Yang, Z.; Xia, Y.; Yin, F. Development of a bridge management system based on the building information modeling technology. Sustainability 2019, 11, 4583. [Google Scholar] [CrossRef]

- Byun, N.; Han, W.S.; Kwon, Y.W.; Kang, Y.J. Development of bim-based bridge maintenance system considering maintenance data schema and information system. Sustainability 2021, 13, 4858. [Google Scholar] [CrossRef]

- Li, S.; Zhang, Z.; Lin, D.; Zhang, T.; Han, L. Development of a BIM-based bridge maintenance system (BMS) for managing defect data. Sci. Rep. 2023, 13, 846. [Google Scholar] [CrossRef] [PubMed]

- Hüthwohl, P.; Brilakis, I.; Borrmann, A.; Sacks, R. Integrating RC Bridge Defect Information into BIM Models. J. Comput. Civ. Eng. 2018, 32, 04018013. [Google Scholar] [CrossRef]

- Park, S.I.; Park, J.; Kim, B.G.; Lee, S.H. Improving applicability for information model of an IFC-based steel bridge in the design phase using functional meanings of bridge components. Appl. Sci. 2018, 8, 2531. [Google Scholar] [CrossRef]

- Jeong, S.; Hou, R.; Lynch, J.P.; Sohn, H.; Law, K.H. An information modeling framework for bridge monitoring. Adv. Eng. Softw. 2017, 114, 11–31. [Google Scholar] [CrossRef]

- Chase, S.B.; Adu-Gyamfi, Y.; Aktan, A.E.; Minaie, E. Synthesis of National and International Methodologies Used for Bridge Health Indices. Federal Highway Administration, 2016. Available online: https://www.fhwa.dot.gov/publications/research/infrastructure/structures/bridge/15081/index.cfm (accessed on 12 August 2024).

- Korea Authority of Land and Infrastructure Safety (KALIS). Detailed Guideline for Safety and Maintenance Implementation of Facilities (Safety Inspection and Diagnosis); Korea Authority of Land and Infrastructure Safety (KALIS): Jinju, Republic of Korea, 2021. Available online: https://www.kalis.or.kr/www/brd/m_27/view.do?seq=117&srchFr=&srchTo=&srchWord=&srchTp=&itm_seq_1=0&itm_seq_2=0&multi_itm_seq=0&company_cd=&company_nm= (accessed on 30 August 2024).

- Korea Authority of Land and Infrastructure Safety (KALIS). Detailed Guideline for Safety and Maintenance Implementation of Facilities (Performance Evaluation); Korea Authority of Land and Infrastructure Safety (KALIS): Jinju, Republic of Korea, 2021. Available online: https://www.kalis.or.kr/www/brd/m_27/view.do?seq=117&srchFr=&srchTo=&srchWord=&srchTp=&itm_seq_1=0&itm_seq_2=0&multi_itm_seq=0&company_cd=&company_nm= (accessed on 30 August 2024).

- Miao, P.; Yokota, H.; Zhang, Y. Deterioration prediction of existing concrete bridges using a LSTM recurrent neural network. Struct. Infrastruct. Eng. 2023, 19, 475–489. [Google Scholar] [CrossRef]

- Xia, Y.; Lei, X.; Wang, P.; Sun, L. A data-driven approach for regional bridge condition assessment using inspection reports. Struct. Control Health Monit. 2022, 29, 1–18. [Google Scholar] [CrossRef]

- Federal Highway Administration (FHWA). Recording and Coding Guide for the Structure Inventory and Appraisal of the Nation’s Bridges; FHWA: Washington, DC, USA, 1995.

- Highways Agency. DMRB Volume 3 Section 1 Part 4 (BD 63/07) Highway Structures: Inspection and Maintenance. 2007. Available online: https://www.thenbs.com/PublicationIndex/documents/details?Pub=HA&DocId=281590 (accessed on 30 August 2024).

- Hsien-Ke, L.; Jallow, M.; Nie-Jia, Y.; Ming-Yi, J.; Jyun-Hao, H.; Cheng-Wei, S.; Po-Yuan, C. Comparison of bridge inspection methodologies and evaluation criteria in Taiwan and foreign practices. In Proceedings of the 34th International Symposium on Automation and Robotics in Construction, ISARC 2017, Taipei, Taiwan, 28 June–1 July 2017; pp. 317–324. [Google Scholar] [CrossRef]

- Norwegian Public Roads Administration. Handbook for Bridge Inspections. 2005. Available online: https://www.tsp2.org/library-tsp2/uploads/48/Handbook_of_Bridge_Inspections_Part_1.pdf (accessed on 30 August 2024).

- Choi, Y.; Kong, J. Development of Data-based Hierarchical Learning Model for Predicting Condition Rating of Bridge Members over Time. KSCE J. Civ. Eng. 2023, 27, 4406–4426. [Google Scholar] [CrossRef]

- Saremi, S.G.; Goulias, D.; Zhao, Y. Alternative Sequence Classification of Neural Networks for Bridge Deck Condition Rating. J. Perform. Constr. Facil. 2023, 37, 04023025. [Google Scholar] [CrossRef]

- He, Z.; Li, W.; Salehi, H.; Zhang, H.; Zhou, H.; Jiao, P. Integrated structural health monitoring in bridge engineering. Autom. Constr. 2022, 136, 104168. [Google Scholar] [CrossRef]

- Seo, J.; Hu, J.W.; Lee, J. Summary Review of Structural Health Monitoring Applications for Highway Bridges. J. Perform. Constr. Facil. 2016, 30, 04015072. [Google Scholar] [CrossRef]

- Sonbul, O.S.; Rashid, M. Algorithms and Techniques for the Structural Health Monitoring of Bridges: Systematic Literature Review. Sensors 2023, 23, 4230. [Google Scholar] [CrossRef] [PubMed]

- Mekjavić, I. Identification of structural damage in bridges using high-frequency vibrational responses. Shock Vib. 2015, 2015, 906062. [Google Scholar] [CrossRef]

- Li, B.; Lei, Y.; Zhou, D.; Deng, Z.; Yang, Y.; Huang, M. Bearing Damage Detection of a Bridge under the Uncertain Conditions Based on the Bayesian Framework and Matrix Perturbation Method. Shock Vib. 2021, 2021, 5576362. [Google Scholar] [CrossRef]

- Xu, Z.D.; Wu, Z. Energy damage detection strategy based on acceleration responses for long-span bridge structures. Eng. Struct. 2007, 29, 609–617. [Google Scholar] [CrossRef]

- Jeon, C.H.; Shim, C.S.; Lee, Y.H.; Schooling, J. Prescriptive maintenance of prestressed concrete bridges considering digital twin and key performance indicator. Eng. Struct. 2024, 302, 117383. [Google Scholar] [CrossRef]

- Lee, I.; Kim, D.-H. Highway Bridge Inspection Period Based on Risk Assessment. J. Korea Inst. Struct. Maint. Insp. 2015, 19, 64–72. [Google Scholar] [CrossRef][Green Version]

- Kwon, T.H.; Kim, J.; Park, K.T.; Jung, K.S. Long Short-Term Memory-Based Methodology for Predicting Carbonation Models of Reinforced Concrete Slab Bridges: Case Study in South Korea. Appl. Sci. 2022, 12, 12470. [Google Scholar] [CrossRef]

- Jeon, C.; Kwon, T.H.; Kim, J.; Jung, K.; Park, K. Quantitative Evaluation of Reinforced Concrete Slab Bridges Using a Novel Bridge Health Index and LSTM-Based Deterioration Models. Appl. Sci. 2024, 14, 10530. [Google Scholar] [CrossRef]

- Yory, R.; Kim, M.; Kirby, L. Mastering Autodesk Revit 2020. Sybex: San Francisco, CA, USA, 2019. [Google Scholar]

| Aspect | HI-Based Evaluation | EP-Based Evaluation |

|---|---|---|

| Purpose | Quantifies the overall condition of the bridge using a simple index | Identifies the cause and location of damage by analyzing dynamic properties |

| Evaluation criteria | Represents the bridge’s condition with a single index (e.g., 0–1 or percentage) | Analyzes detailed damage mechanisms based on eigenvalue and eigenvector changes |

| Focus | Overall performance condition and remaining service life | Localization and characterization of damage causes |

| Complexity | Relatively simple and comprehensive | Involves complex mathematical or physical modeling |

| Data processing | Uses machine learning or statistical weighting to calculate the HI | Analyzes the changes in stiffness, mass, damping, and dynamic parameters. |

| Accuracy | Suitable for overall condition assessment; limited in detailed damage analysis. | Enables detailed analysis of physical causes behind eigenvalue changes, offering high precision. |

| Application | Prioritizing maintenance and long-term monitoring of bridges. | Diagnosing damage causes, assessing urgent repair needs, and verifying models. |

| No. | Year | Defect Type | Quantity | ||

|---|---|---|---|---|---|

| Width (mm) | Length (m) | Volume (m2) | |||

| 1 | 2014 | Efflorescence | 1.20 | 2.30 | 0.36 |

| 2 | 2014 | Efflorescence | 0.60 | 2.00 | 1.20 |

| 3 | 2014 | Efflorescence | 0.60 | 1.00 | 0.60 |

| 4 | 2014 | Efflorescence | 0.50 | 1.50 | 0.75 |

| 5 | 2014 | Efflorescence | 1.20 | 1.20 | 1.44 |

| 6 | 2014 | Crack | 0.10 | 1.50 | 1.50 |

| 7 | 2014 | Efflorescence | 1.00 | 6.00 | 6.00 |

| 8 | 2018 | Efflorescence | 1.00 | 3.00 | 3.00 |

| 9 | 2016 | Separation | 0.80 | 0.80 | 0.64 |

| 10 | 2016 | Efflorescence | 0.50 | 3.00 | 1.50 |

| 11 | 2016 | Leakage | 0.40 | 0.40 | |

| 12 | 2016 | Efflorescence | 0.80 | 0.80 | 0.64 |

| 13 | 2016 | Efflorescence | 1.00 | 6.00 | 6.00 |

| 14 | 2016 | Efflorescence | 0.40 | 0.40 | 0.16 |

| 15 | 2016 | Efflorescence | 1.00 | 2.00 | 2.00 |

| 16 | 2016 | Efflorescence | 1.00 | 3.00 | 3.00 |

| 17 | 2016 | Efflorescence | 1.00 | 1.20 | 1.20 |

| 18 | 2018 | Efflorescence | 1.00 | 3.00 | 3.00 |

| 19 | 2018 | Efflorescence | 1.00 | 1.50 | 1.50 |

| 20 | 2018 | Efflorescence | 0.60 | 1.00 | 0.60 |

| 21 | 2018 | Leakage | 1.00 | 1.00 | |

| Deterioration Type | Deterioration Weight | Module | Module Weight |

|---|---|---|---|

| Microcrack | 0.25 | Cracking defects | 0.3 |

| Macrocrack | 0.375 | ||

| Crazing | 0.375 | ||

| Separation | 0.167 | Materials defects | 0.15 |

| Spalling | 0.167 | ||

| Concrete failure | 0.167 | ||

| Exfoliation | 0.167 | ||

| Segregation | 0.167 | ||

| Delamination | 0.167 | ||

| Efflorescence | 0.5 | Other types of defects | 0.15 |

| Leakage | 0.5 | ||

| Exposed rebar | 1 | Corrosion defect | 0.4 |

| Bridge Component | Weight |

|---|---|

| Slab | 0.43 |

| Girder | 0.29 |

| Pier | 0.18 |

| Abutment | 0.18 |

| Name | Construction Year | No. of Inspection Reports | Width (m) | Length (m) | Height (m) | No. of Spans | Maximum Span Length (m) |

|---|---|---|---|---|---|---|---|

| Bridge A | 1999 | 7 | 18 | 510 | 9 | 15 | 18 |

| Bridge B | 1979 | 6 | 30 | 120 | 12 | 4 | 30 |

| Bridge C | 1995 | 5 | 50 | 175 | 3 | 7 | 25 |

| Bridge D | 1975 | 5 | 34 | 90 | 6 | 5 | 25 |

| Bridge E | 1971 | 6 | 40 | 60 | 3 | 3 | 20 |

| Report Number | Condition Grade | ||||

|---|---|---|---|---|---|

| Bridge A | Bridge B | Bridge C | Bridge D | Bridge E | |

| #1 | B | B | A | B | B |

| #2 | B | B | B | B | B |

| #3 | B | B | B | B | B |

| #4 | B | B | B | B | B |

| #5 | B | B | B | A | B |

| #6 | B | B | - | - | B |

| #7 | B | - | - | - | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jeon, C.-H.; Kwon, T.H.; Kim, J.; Jung, K.-S.; Park, K.-T. Health Index-Based Maintenance of Prestressed Concrete Bridges Considering Building Information Modeling Application. Buildings 2024, 14, 4032. https://doi.org/10.3390/buildings14124032

Jeon C-H, Kwon TH, Kim J, Jung K-S, Park K-T. Health Index-Based Maintenance of Prestressed Concrete Bridges Considering Building Information Modeling Application. Buildings. 2024; 14(12):4032. https://doi.org/10.3390/buildings14124032

Chicago/Turabian StyleJeon, Chi-Ho, Tae Ho Kwon, Jaehwan Kim, Kyu-San Jung, and Ki-Tae Park. 2024. "Health Index-Based Maintenance of Prestressed Concrete Bridges Considering Building Information Modeling Application" Buildings 14, no. 12: 4032. https://doi.org/10.3390/buildings14124032

APA StyleJeon, C.-H., Kwon, T. H., Kim, J., Jung, K.-S., & Park, K.-T. (2024). Health Index-Based Maintenance of Prestressed Concrete Bridges Considering Building Information Modeling Application. Buildings, 14(12), 4032. https://doi.org/10.3390/buildings14124032