Deformation Behaviors and Failure Mechanism of Coal Under Various Loading Rates Using Acoustic Emission and Digital Image Correlation

Abstract

1. Introduction

2. Test Summary

2.1. Specimen Preparation

2.2. Testing System

2.3. Experimental Methods

3. Results and Discussion

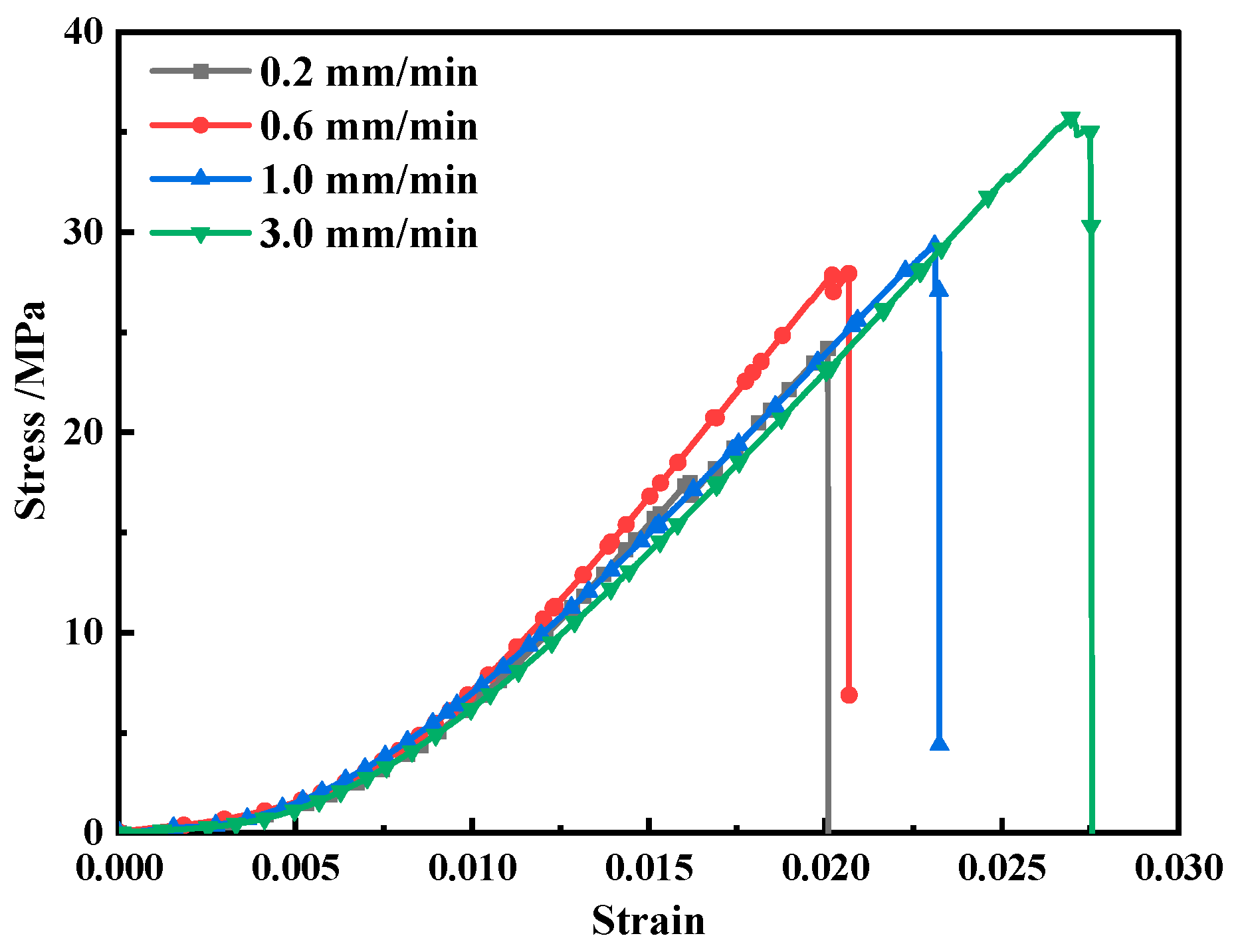

3.1. Stress–Strain Characteristics

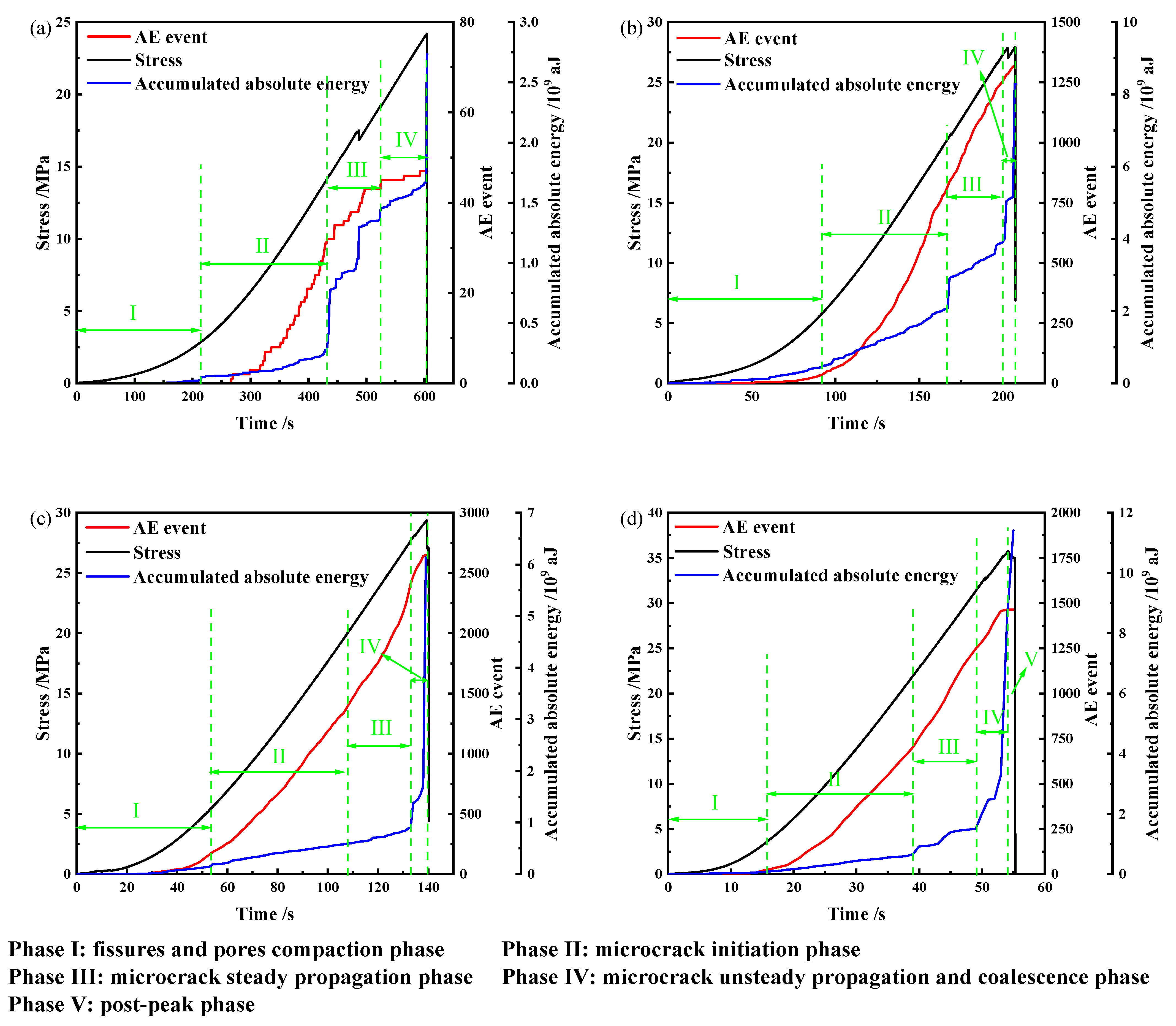

3.2. AE Evolution Characteristics

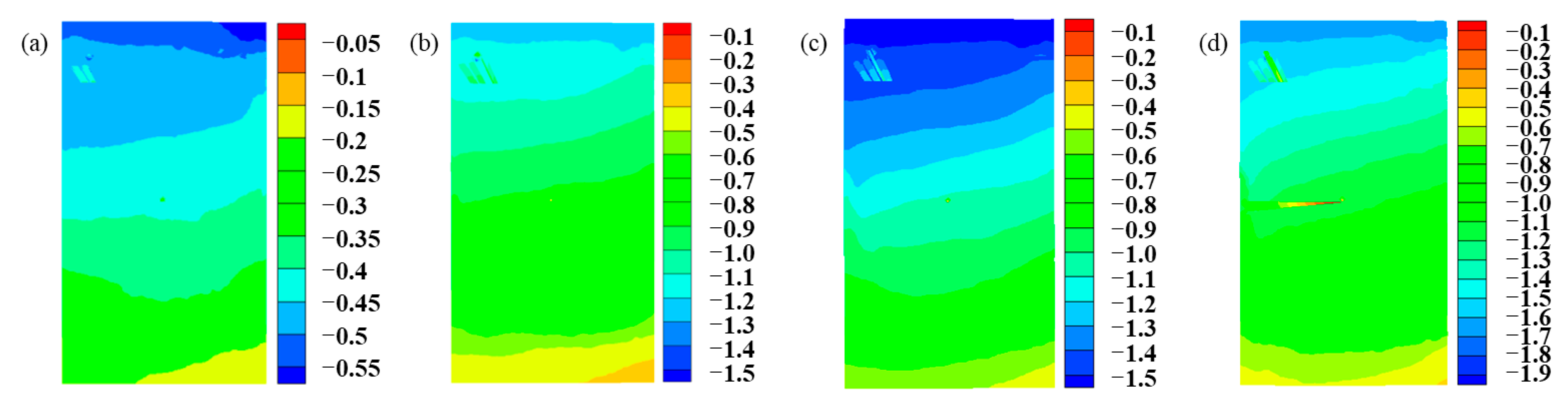

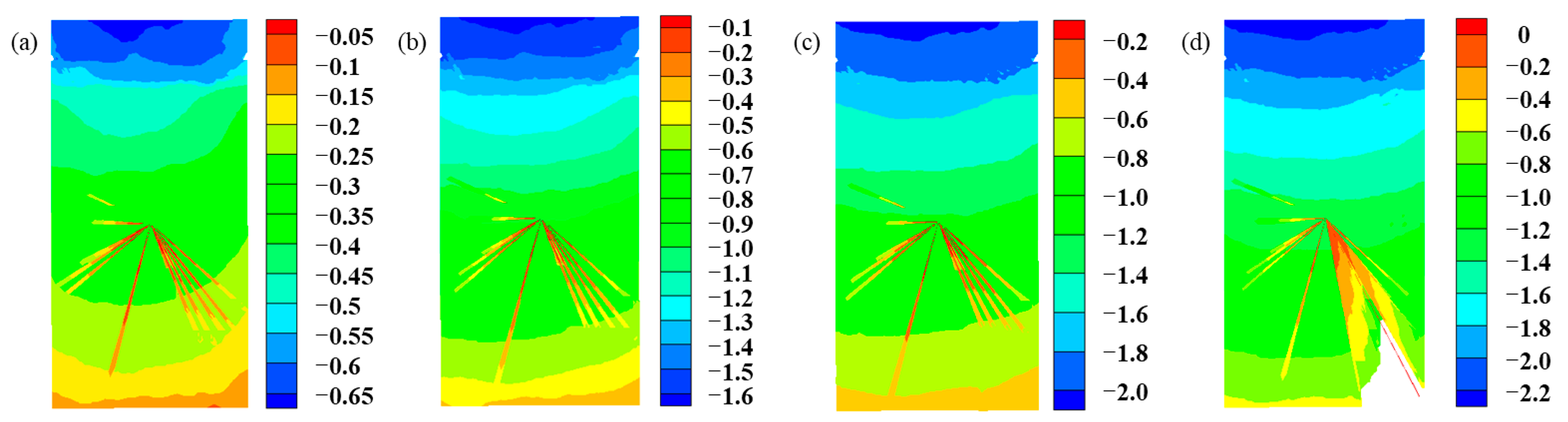

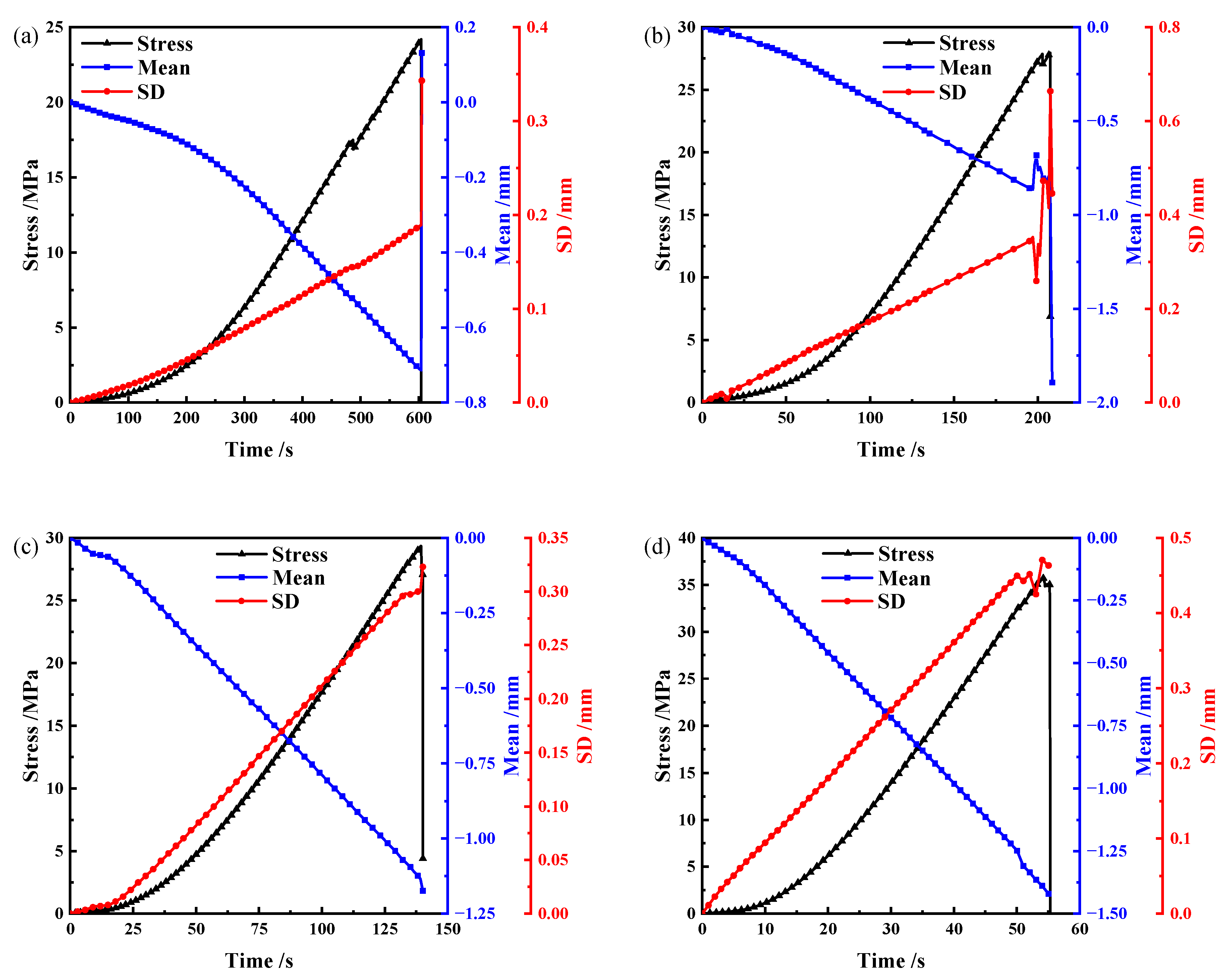

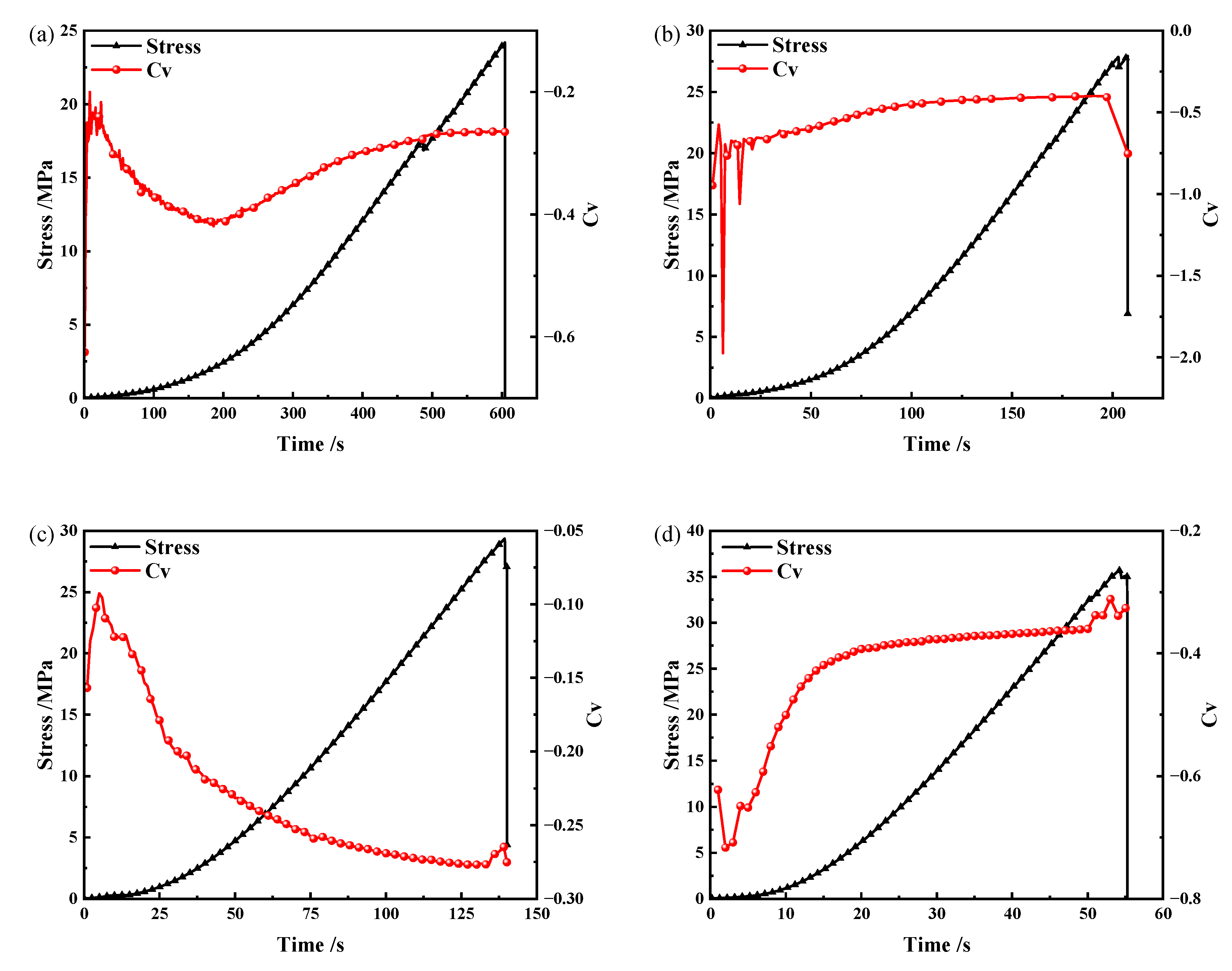

3.3. Deformation Field Evolution

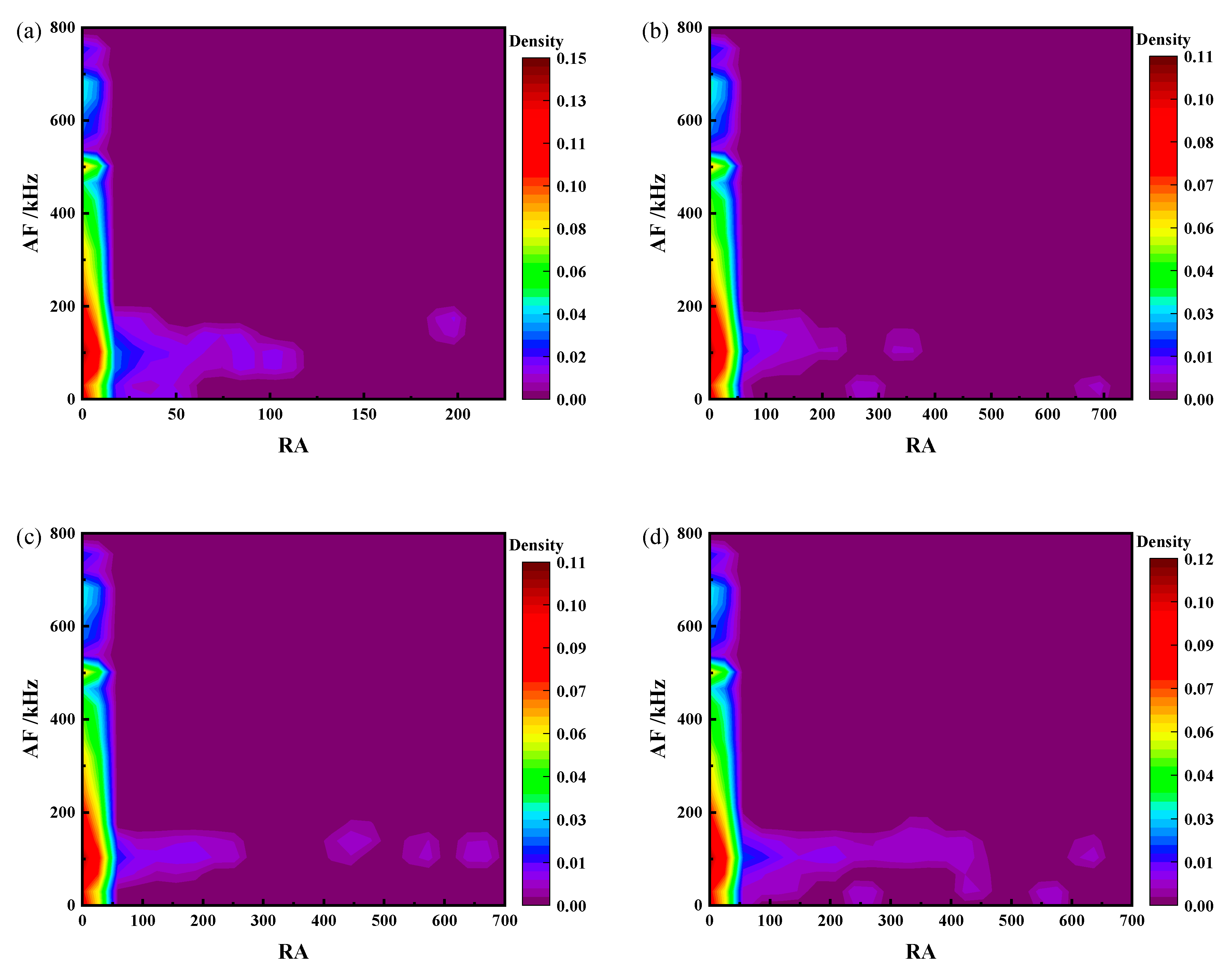

3.4. Microfailure Mechanism

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gu, D.Z. Theory Framework and Technological System of Coal Mine Underground Reservoir. Meitan Xuebao/J. China Coal Soc. 2015, 40, 239–246. [Google Scholar] [CrossRef]

- Gu, D.; Yan, Y.; Zhang, Y.; Wang, E.; Cao, Z. Experimental Study and Numerical Simulation for Dynamic Response of Coal Pillars in Coal Mine Underground Reservoir. Meitan Xuebao/J. China Coal Soc. 2016, 41, 1589–1597. [Google Scholar] [CrossRef]

- Gu, D.; Cao, Z.; Li, J.; Wu, B.; Zhang, Y.; Jiang, B.; Guo, Q.; Wang, H.; Wu, Y.; Shi, X.; et al. Original Experimental Platform System and Application of Underground Coal Mine Reservoirs. Meitan Xuebao/J. China Coal Soc. 2024, 49, 100–113. [Google Scholar] [CrossRef]

- Yao, Q.; Liu, Y.; Chen, T.; Li, X.; Yang, S.; Duan, H. Experimental Study of Damage Evolution of Artificial Dam Strength of Underground Reservoir. Meitan Xuebao/J. China Coal Soc. 2018, 43, 1111–1117. [Google Scholar] [CrossRef]

- Wu, W.; Li, J.; Zhao, J. Loading Rate Dependency of Dynamic Responses of Rock Joints at Low Loading Rate. Rock Mech. Rock Eng. 2012, 45, 421–426. [Google Scholar] [CrossRef]

- Gong, F.; Zhao, G. Dynamic Indirect Tensile Strength of Sandstone Under Different Loading Rates. Rock Mech. Rock Eng. 2014, 47, 2271–2278. [Google Scholar] [CrossRef]

- Li, H.; Zhou, H.; Jiang, Y.; Wang, H. An Evaluation Method for the Bursting Characteristics of Coal Under the Effect of Loading Rate. Rock Mech. Rock Eng. 2016, 49, 3281–3291. [Google Scholar] [CrossRef]

- Wang, X.; Wang, E.; Liu, X.; Zhou, X. Failure Mechanism of Fractured Rock and Associated Acoustic Behaviors under Different Loading Rates. Eng. Fract. Mech. 2021, 247, 107674. [Google Scholar] [CrossRef]

- Dou, L.; He, J.; Cao, A.; Gong, S.; Cai, W. Rock Burst Prevention Methods Based on Theory of Dynamic and Static Combined Load Induced in Coal Mine. Meitan Xuebao/J. China Coal Soc. 2015, 40, 1469–1476. [Google Scholar] [CrossRef]

- Liu, B.; Zhao, Y.; Wang, H.; Gao, Y.; Sun, Z. Tensile Properties and Multiparameter Response Characteristics of Coal under Different Loading Rates. Nat. Resour. Res. 2022, 31, 2787–2803. [Google Scholar] [CrossRef]

- Zhao, Y.; Liu, B. Deformation Field and Acoustic Emission Characteristics of Weakly Cemented Rock under Brazilian Splitting Test. Nat. Resour. Res. 2021, 30, 1925–1939. [Google Scholar] [CrossRef]

- Liu, B.; Zhao, Y.; Zhang, C.; Zhou, J.; Li, Y.; Sun, Z. Characteristic Strength and Acoustic Emission Properties of Weakly Cemented Sandstone at Different Depths under Uniaxial Compression. Int. J. Coal Sci. Technol. 2021, 8, 1288–1301. [Google Scholar] [CrossRef]

- Zhao, Y.; Liu, B.; Ling, C.; Gao, Y.; Wang, X.; Danesh, N.N. Infrared Radiation and Acoustic Emission Characteristics of Sandstone with Different Granularities under Uniaxial Compression. Bull. Eng. Geol. Environ. 2023, 82, 24. [Google Scholar] [CrossRef]

- Wang, M.; Zhang, J.; Jia, B.; Du, W.; Chen, Z.; Liu, S. Research on Prediction of Coal Sample Deformation Based on Acoustic-Emission Sensitive Index. Sustainability 2022, 14, 14875. [Google Scholar] [CrossRef]

- Liu, B.; Sun, X.; Ling, C.; Huang, Z.; Zhang, H. Mechanical Behaviors and Acoustic Emission Fractal Characteristics of Bump-Prone Coal under Different Loading Rates. Fractal Fract. 2023, 7, 45. [Google Scholar] [CrossRef]

- Wang, S.; Zhao, Y.; Guo, J.; Liu, B. Investigation on Prediction of Sandstone Failure Under Uniaxial Compression Based on Supervised Deep Learning. Rock Mech. Rock Eng. 2023, 56, 8485–8501. [Google Scholar] [CrossRef]

- Gao, Y.; Zhao, Y.; Wang, H.; Liu, B.; Hartlieb, P.; Gao, S. Loaded Failure Characteristics of Anthracite Derived from Microwave Irradiation: Acoustic Emission Evaluation. Rock Mech. Rock Eng. 2023, 56, 8809–8831. [Google Scholar] [CrossRef]

- Zou, Q.; Chen, C.; Chen, Z.; Peng, K.; Lv, H.; Zhan, J. Characterization and Differences of Acoustic Signals Response of Semi-Circular Red Sandstone under Combined Monotonous and Cyclic Loadings. Geomech. Geophys. Geo-Energy Geo-Resour. 2024, 10, 146. [Google Scholar] [CrossRef]

- Liu, B.; Zhao, Y.; Gao, S.; Zhang, H.; Teng, T.; He, X. Effects of Displacement Rate on Mechanical Behaviors and Failure Mechanism of Non-Caking Coal in Brazilian Splitting Tests. Bull. Eng. Geol. Environ. 2024, 83, 179. [Google Scholar] [CrossRef]

- Peng, S.; Yang, Y.; Xu, Q.; Xu, J.; Qin, C.; Nong, X. Study on Impact Tendency and Damage Characteristics of Rock-Like Materials Based on Acoustic and Thermal Responses. Rock Mech. Rock Eng. 2024, 57, 10367–10383. [Google Scholar] [CrossRef]

- Gao, C.; Wang, L.; Lin, M.; Zheng, L.; Zhu, L.; He, Y.; An, C.; Liang, X. Study on the Acoustic-Thermal Effects and Damage Models during Uniaxial Compression Failure Process of Phosphorite with Different H/Di. Infrared Phys. Technol. 2024, 138, 105267. [Google Scholar] [CrossRef]

- Liu, Y.; Li, D.; Cheng, J.; Asad, M.W.A.; Gao, Z.; Jiao, J. The Multifractal Characteristics of Acoustic Emission for Composite Samples Subject to Simulated Field Loading Condition. Int. J. Min. Reclam. Environ. 2024, 38, 596–618. [Google Scholar] [CrossRef]

- Kong, X.; Zhan, M.; Lin, H.; Cai, Y.; Ji, P.; He, D.; Muhammad, A. Time-Varying Characteristics of Acoustic Emission and Fractals Based on Information Dimension during Structural Failure of Coal Subjected to Uniaxial Compression. Meas. J. Int. Meas. Confed. 2024, 236, 115088. [Google Scholar] [CrossRef]

- Lin, Q.; Labuz, J.F. Fracture of Sandstone Characterized by Digital Image Correlation. Int. J. Rock Mech. Min. Sci. 2013, 60, 235–245. [Google Scholar] [CrossRef]

- Wei, Z.; Yang, K.; Chi, X.; He, X.; Zhao, X.; Zhang, J. Dynamic Tensile Properties, Deformation, and Failure Testing of Impact-Loaded Coal Samples with Various Water Content. Sci. Rep. 2021, 11, 7096. [Google Scholar] [CrossRef]

- Zhang, T.; Liu, B.; Wei, Z.; Jiao, Z.; Song, Z.; Zhang, H. Dynamic Mechanical Responses and Crack Evolution of Burst-Prone Coal with a Single Prefabricated Fissure. Theor. Appl. Fract. Mech. 2022, 121, 103494. [Google Scholar] [CrossRef]

- Zhang, H.; Fu, D.; Song, H.; Kang, Y.; Huang, G.; Qi, G.; Li, J. Damage and Fracture Investigation of Three-Point Bending Notched Sandstone Beams by DIC and AE Techniques. Rock Mech. Rock Eng. 2015, 48, 1297–1303. [Google Scholar] [CrossRef]

- Ashraf, S.; Rucka, M. Comparative Study on Fracture Evolution in Steel Fibre and Bar Reinforced Concrete Beams Using Acoustic Emission and Digital Image Correlation Techniques. Case Stud. Constr. Mater. 2024, 20, e03359. [Google Scholar] [CrossRef]

- Yang, L.; Zhang, F.; You, J.; Man, D.; Gao, J.; Liu, W. Mechanical Behaviour and Spatial Fracture Characteristics of Weakly Filled Granite with Different Diameters under Uniaxial Loading Revealed by 3D DIC and AE Monitoring. Bull. Eng. Geol. Environ. 2024, 83, 217. [Google Scholar] [CrossRef]

- Xing, T.; Zhu, H.; Song, Y. Experimental Study on Rock Deformation Localization Using Digital Image Correlation and Acoustic Emission. Appl. Sci. 2024, 14, 5355. [Google Scholar] [CrossRef]

- Ye, Y.; Yang, Q.; Xiao, S.; Qiu, X.; Xiong, Y.; Yang, W. Fracture Evolution Characteristics of Asphalt Concrete Using Digital Image Correlation and Acoustic Emission Techniques. Constr. Build. Mater. 2024, 447, 138100. [Google Scholar] [CrossRef]

- Wang, X.; Liu, S.; Liu, X.; Shan, T.; Zhou, X.; Xie, H.; Wang, J. Mode I Fracture Propagation and Post-Peak Behavior of Sandstone: Insight from AE and DIC Observation. Eng. Fract. Mech. 2024, 302, 110093. [Google Scholar] [CrossRef]

- Wang, Z.; Liang, W.; Lian, H.; Chen, Y.; Li, W.; Xiao, H. Study on the Effect of Bedding Plane and Loading Style on Fracture Process Zone in Coal. Rock Mech. Rock Eng. 2024, 57, 3863–3883. [Google Scholar] [CrossRef]

- Mahesh, P.; Chinthapenta, V.; Raju, G.; Ramji, M. Experimental Investigation on Open-Hole CFRP Laminate under Combined Loading Using Acoustic Emission and Digital Image Correlation. Theor. Appl. Fract. Mech. 2024, 130, 104300. [Google Scholar] [CrossRef]

- Liu, B.; Zhao, Y.; Zhang, H.; Yuan, Y. Acoustic Emission Characteristics of Coal under Uniaxialcompression and Brazilian Splitting. Caikuang yu Anquan Gongcheng Xuebao/J. Min. Saf. Eng. 2020, 37, 613–621. [Google Scholar] [CrossRef]

- Lou, Q.; He, X. Experimental Study on Infrared Radiation Temperature Field of Concrete under Uniaxial Compression. Infrared Phys. Technol. 2018, 90, 20–30. [Google Scholar] [CrossRef]

- Aggelis, D.G. Classification of Cracking Mode in Concrete by Acoustic Emission Parameters. Mech. Res. Commun. 2011, 38, 153–157. [Google Scholar] [CrossRef]

- Elfergani, H.A.; Pullin, R.; Holford, K.M. Damage Assessment of Corrosion in Prestressed Concrete by Acoustic Emission. Constr. Build. Mater. 2013, 40, 925–933. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zou, X.; Li, P.; Liu, B.; Wu, Y. Deformation Behaviors and Failure Mechanism of Coal Under Various Loading Rates Using Acoustic Emission and Digital Image Correlation. Buildings 2024, 14, 3856. https://doi.org/10.3390/buildings14123856

Zou X, Li P, Liu B, Wu Y. Deformation Behaviors and Failure Mechanism of Coal Under Various Loading Rates Using Acoustic Emission and Digital Image Correlation. Buildings. 2024; 14(12):3856. https://doi.org/10.3390/buildings14123856

Chicago/Turabian StyleZou, Xin, Peng Li, Bin Liu, and Yang Wu. 2024. "Deformation Behaviors and Failure Mechanism of Coal Under Various Loading Rates Using Acoustic Emission and Digital Image Correlation" Buildings 14, no. 12: 3856. https://doi.org/10.3390/buildings14123856

APA StyleZou, X., Li, P., Liu, B., & Wu, Y. (2024). Deformation Behaviors and Failure Mechanism of Coal Under Various Loading Rates Using Acoustic Emission and Digital Image Correlation. Buildings, 14(12), 3856. https://doi.org/10.3390/buildings14123856