Flexural Strength of Structural Beams Cast Using Combined Normal-Weight and Lightweight Concrete Mixtures

Abstract

1. Introduction

2. Materials and Test Procedures

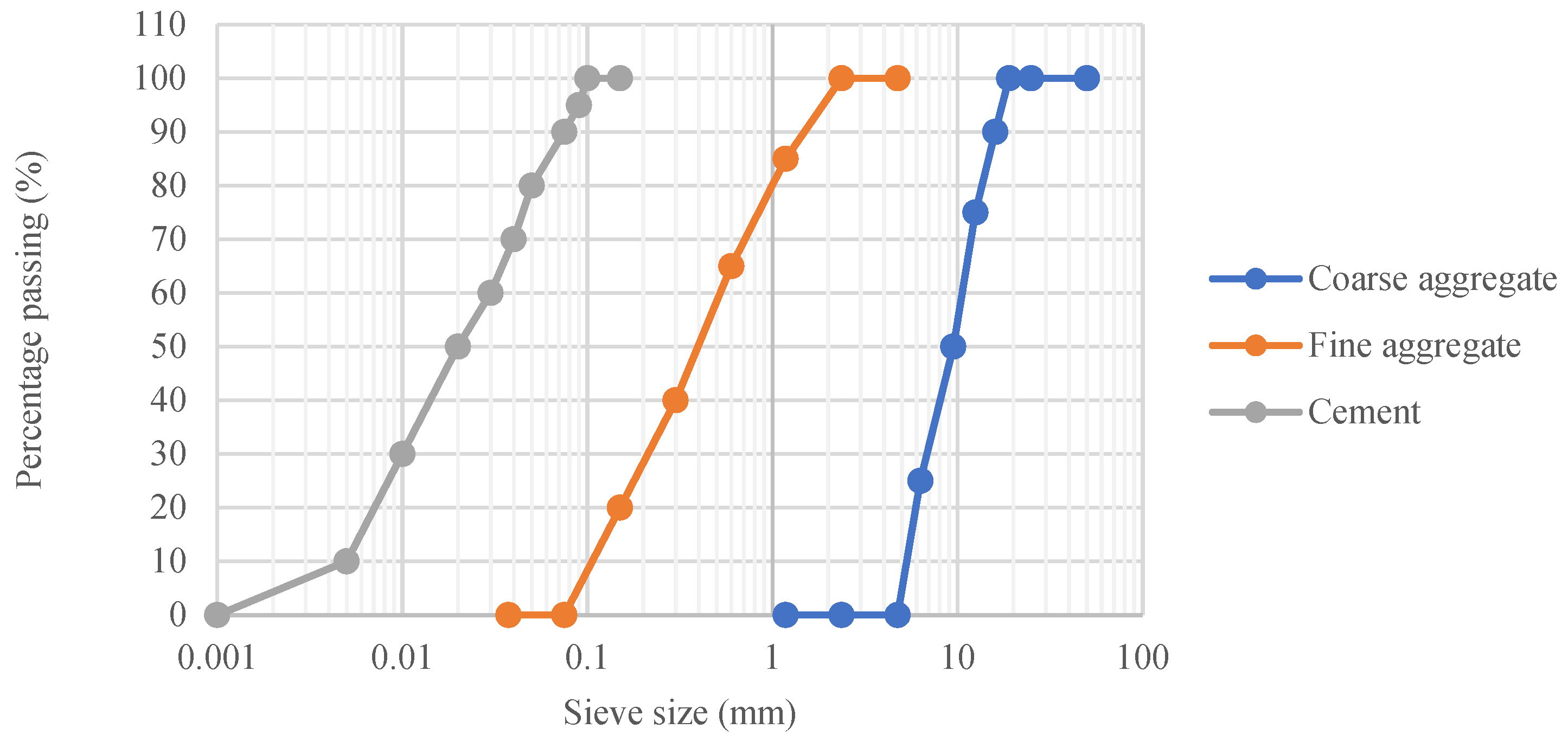

2.1. Materials

2.2. Concrete Mix Proportions

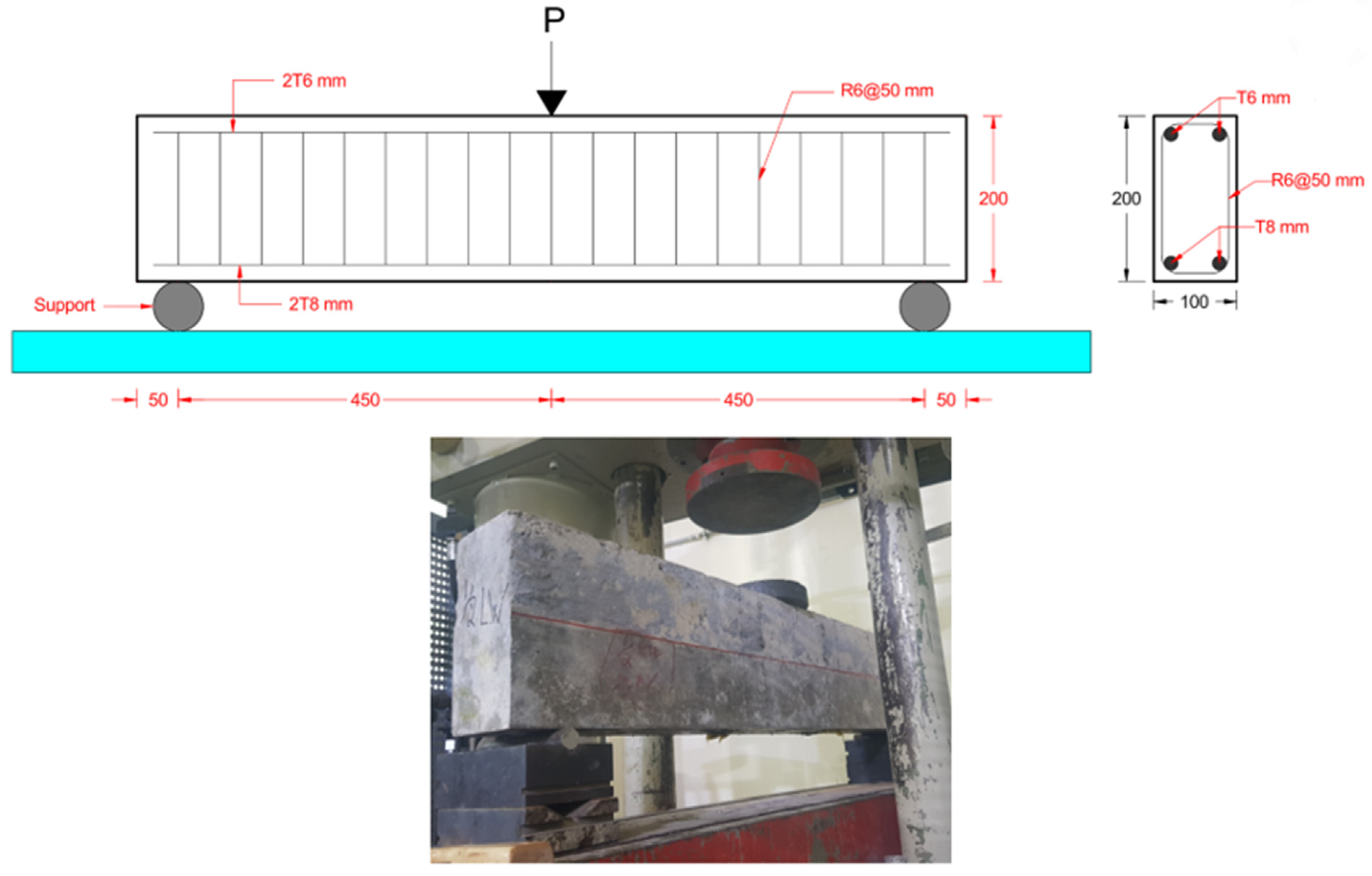

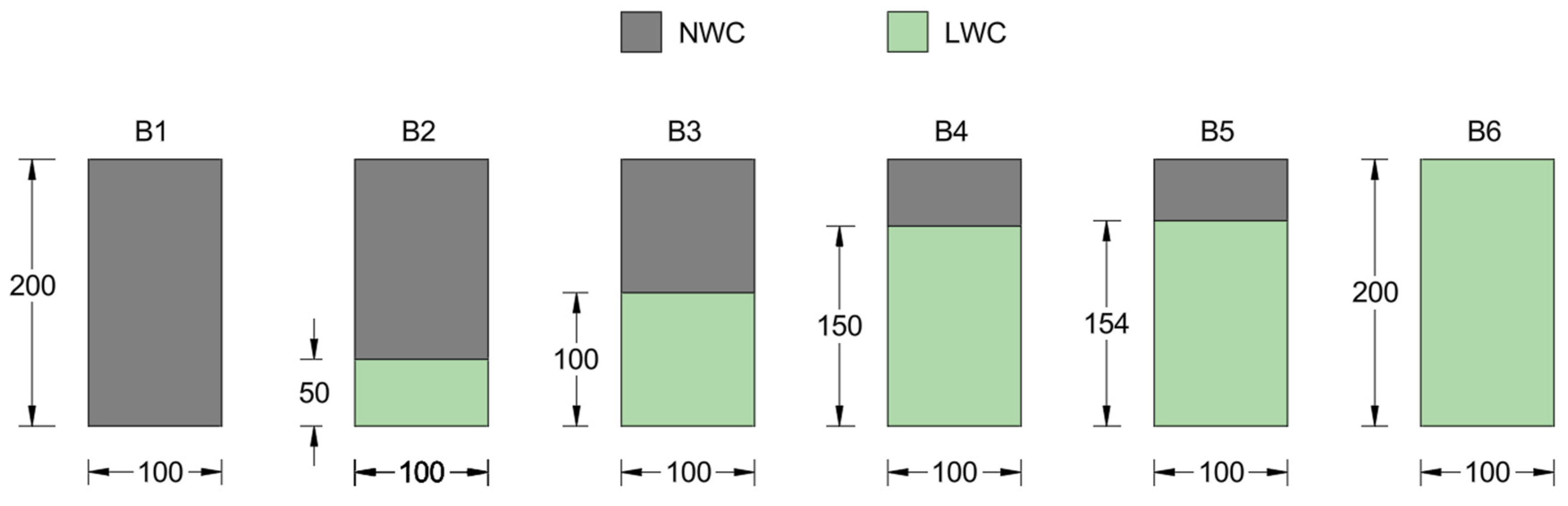

2.3. Preparation of Specimen and Testing Methods

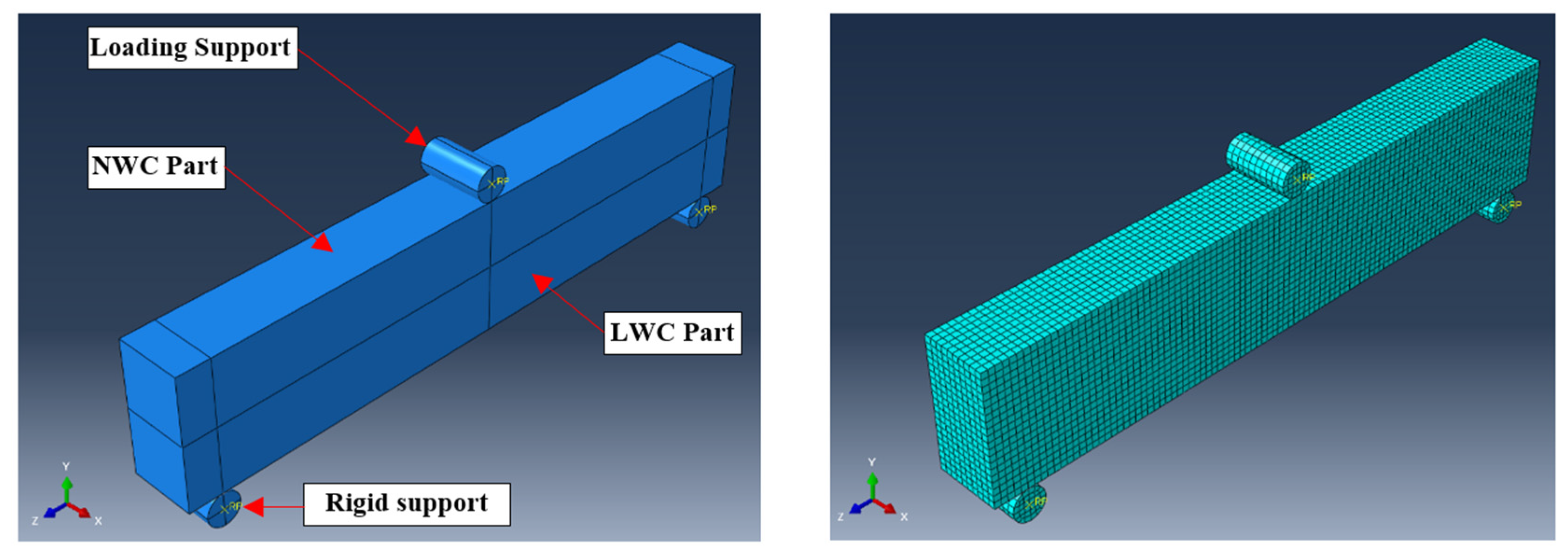

2.4. Numerical Modeling

3. Results and Discussion

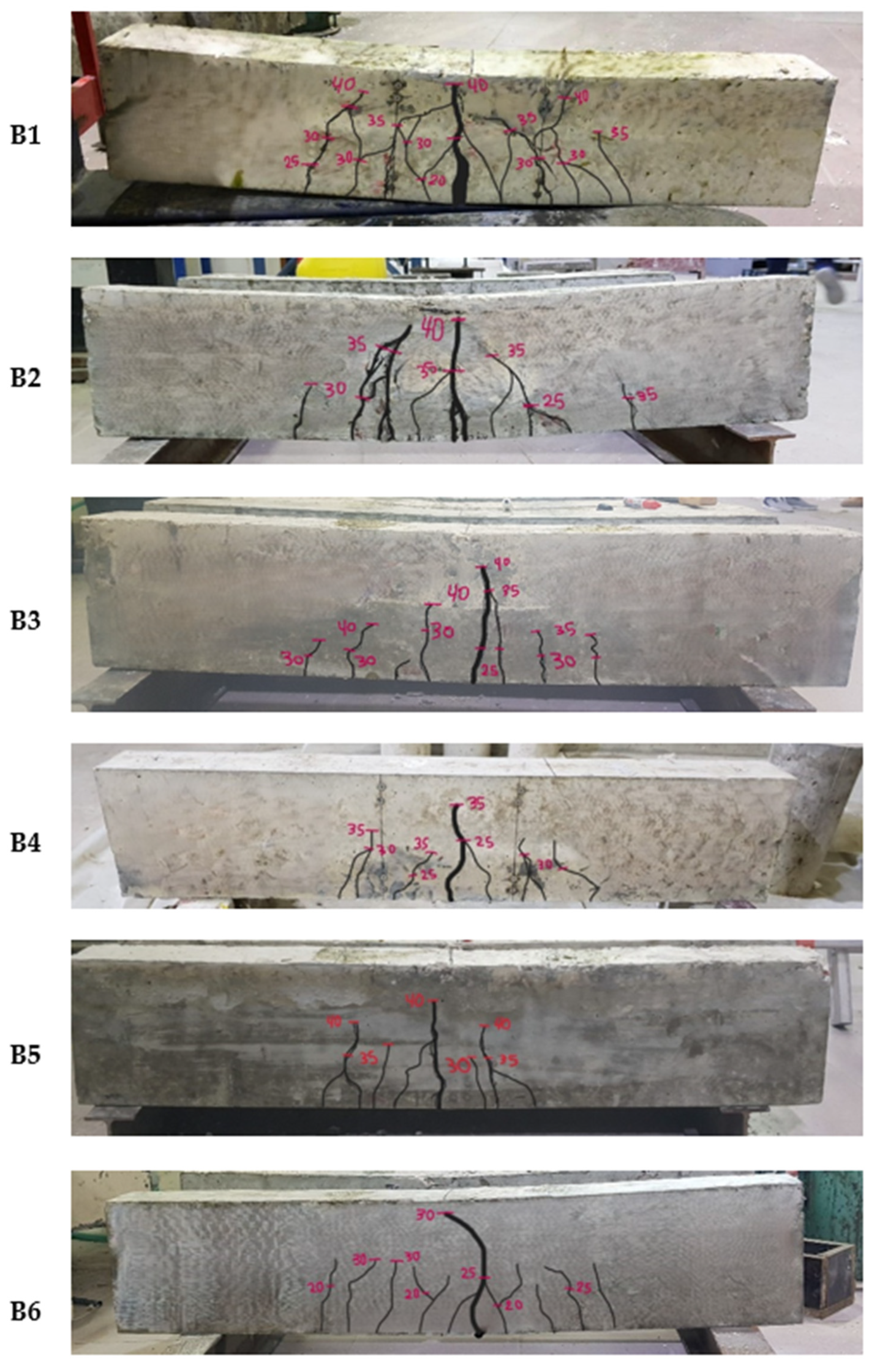

3.1. Failure Patterns

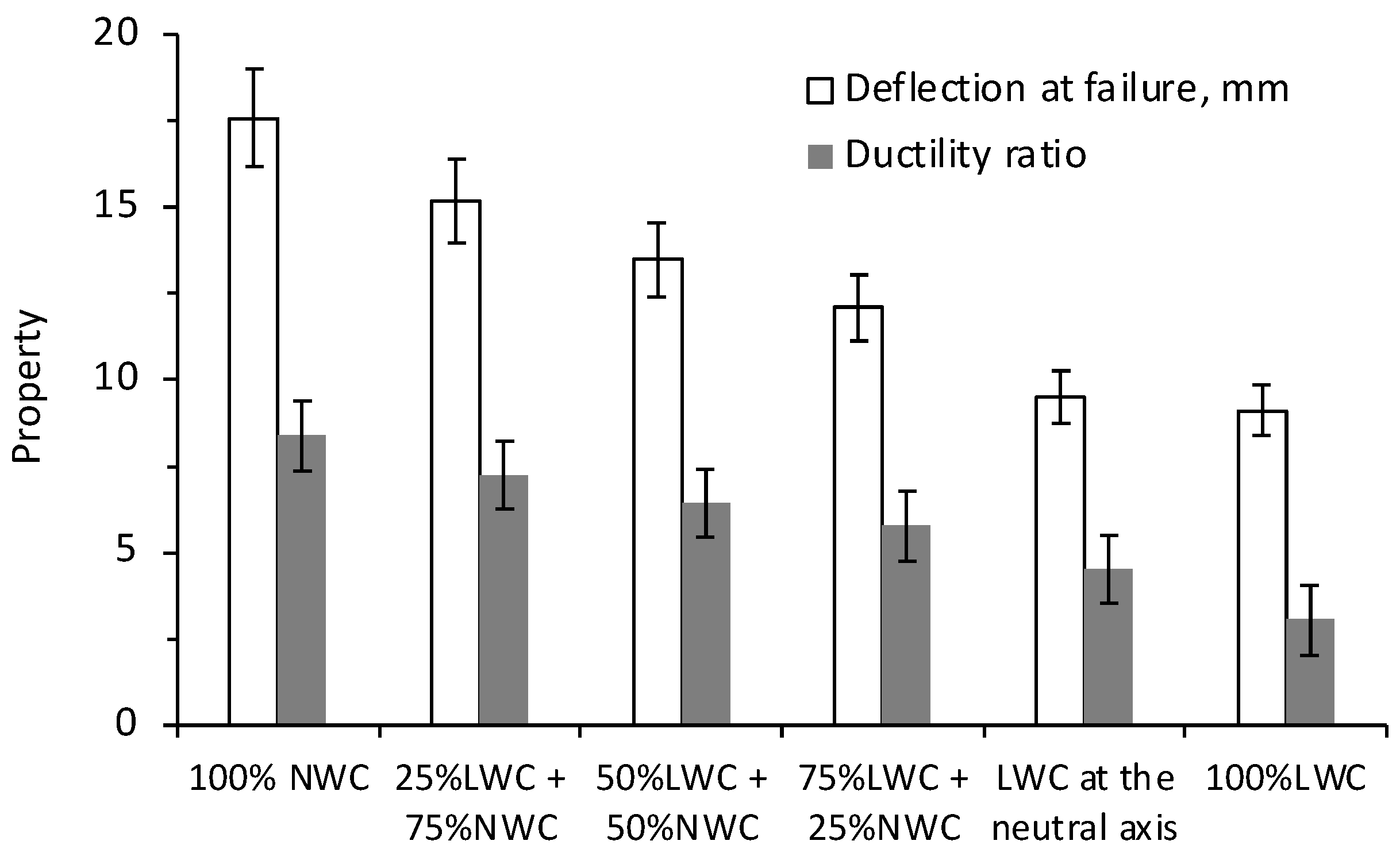

3.2. Load vs. Mid-Span Deflection Curves

3.3. Concrete Strains

3.4. Comparison to ACI 318 Building Code

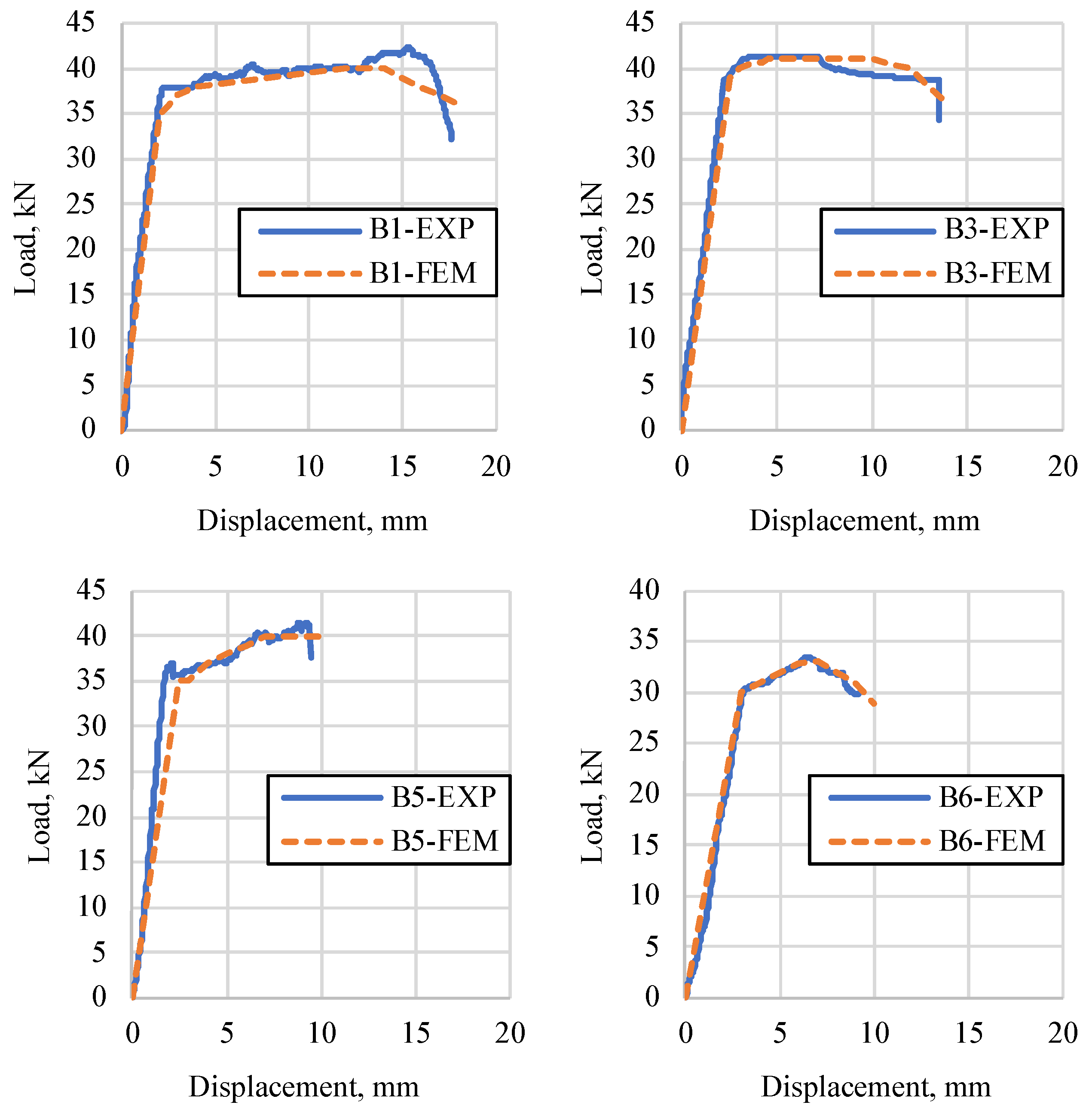

3.5. Numerical Modeling Results

4. Conclusions

- The incorporation of LWC in the tension zones of RC beams significantly reduced crack intensity and size compared to fully cast NWC beams. The crack widths in LWC beams (B2 to B5) ranged from less than 1 to 10 mm, compared to a maximum of 15 mm in fully cast NWC beams. Beams made entirely of LWC (B6) exhibited extensive cracking with widths reaching up to 30 mm.

- The incorporation of LWC in the tension zone did not significantly alter the ultimate flexural strength compared to fully cast NWC beams. However, LWC reduced the deflection at failure from 17.6 mm in the NWC beam to 12.1 mm in beam B4 and 9.1 mm in the fully cast LWC beam (B6). This reduction in deflection is accompanied by a notable drop in the ductility ratio, from 8.38 in the NWC beam to 3.03 in the fully LWC beam. While these beams satisfy serviceability requirements, the reduced ductility ratio raises concerns about their performance under overload or extreme loading conditions. Future studies should explore strategies such as incorporating fiber reinforcement or optimizing the mix design to enhance the post-peak behavior and energy dissipation capacity of LWC beams, ensuring their robustness in such scenarios.

- Beams B1 to B5 exhibited similar strain patterns, with neutral axis positions ranging from 50 to 55 mm. The fully cast LWC beam (B6) showed higher strains, with a recorded value of 0.0024 mm/mm at 30 kN compared to an average of 0.0017 mm/mm for the other beams. The neutral axis in B6 dropped to 40 mm, indicating a significant shift in the structural behavior due to the lower modulus of elasticity.

- The experimental-to-design load ratio (PEXP/PACI) for LWC beams was lower compared to NWC beams. This suggests that the ACI 318-19 code does not fully account for the lower strength of LWC, and there is a need for an additional safety factor when predicting the flexural strength of LWC beams.

- The FEM analysis aligns with the experimental results, showing a marginal error in predicting the load-bearing capacity, deflection, and damage patterns. A strong correlation with R2 of 0.99 was established between the ductility ratios determined experimentally or by FEM analysis.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Jahami, A.; Khatib, J.; Bawab, J. An Experimental and Numerical Evaluation of the Structural Performance of Concrete Beams Containing Bamboo Shear Reinforcement. Steps Civ. Constr. Environ. Eng. 2023, 1, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Awad, Z. Sustainable Restoration Techniques for Historic Buildings in Tyre City. Steps Civ. Constr. Environ. Eng. 2023, 1, 10–17. [Google Scholar] [CrossRef]

- Zeaiter, H.; Jahami, A.; Khatib, J. Bio-Concrete and Beyond: Advancements in Self-Healing Techniques for Durable Infrastructure. Steps Civ. Constr. Environ. Eng. 2023, 1, 18–29. [Google Scholar] [CrossRef]

- Abou Rachied, T.; Dbouk, F.; Hamad, B.; Assaad, J.J. Structural behavior of beams cast using normal and high strength concrete containing blends of ceramic waste powder and blast furnace slag. Clean. Mater. 2023, 7, 100179. [Google Scholar] [CrossRef]

- Amran, M.; Murali, G.; Khalid, N.H.A.; Fediuk, R.; Ozbakkaloglu, T.; Lee, Y.H.; Haruna, S.; Lee, Y.Y. Slag Uses in Making an Ecofriendly and Sustainable Concrete: A Review. Constr. Build. Mater. 2021, 272, 121942. [Google Scholar] [CrossRef]

- Dervishaj, A.; Gudmundsson, K. From LCA to Circular Design: A Comparative Study of Digital Tools for the Built Environment. Resour. Conserv. Recycl. 2024, 200, 107291. [Google Scholar] [CrossRef]

- United Nations. Shifting to a Circular Economy Essential to Achieving Paris Agreement Goals. Available online: https://unfccc.int/news/shifting-to-a-circular-economy-essential-to-achieving-paris-agreement-goals (accessed on 24 November 2024).

- Alharthai, M.; Ozkilic, Y.O.; Karalar, M.; Mydin, M.A.O.; Ozdoner, N.; Celik, A.I. Performance of Aerated Lightweighted Concrete Using Aluminum Lathe and Pumice under Elevated Temperature. Steel Compos. Struct. 2024, 51, 271. [Google Scholar] [CrossRef]

- Korkut, F.; Karalar, M. Investigational and Numerical Examination on Bending Response of Reinforced Rubberized Concrete Beams Including Plastic Waste. Materials 2023, 16, 5538. [Google Scholar] [CrossRef]

- Karalar, M. Experimental and Numerical Investigation on Flexural and Crack Failure of Reinforced Concrete Beams with Bottom Ash and Fly Ash. Iran. J. Sci. Technol. Trans. Civ. Eng. 2020, 44, 331–354. [Google Scholar] [CrossRef]

- Sepe, R.; Bollino, F.; Boccarusso, L.; Caputo, F. Influence of Chemical Treatments on Mechanical Properties of Hemp Fiber Reinforced Composites. Compos. Part B Eng. 2018, 133, 210–217. [Google Scholar] [CrossRef]

- Dahal, R.K.; Acharya, B.; Dutta, A. Mechanical, Thermal, and Acoustic Properties of Hemp and Biocomposite Materials: A Review. J. Compos. Sci. 2022, 6, 373. [Google Scholar] [CrossRef]

- Tran Le, A.D.; Maalouf, C.; Mai, T.H.; Wurtz, E.; Collet, F. Transient Hygrothermal Behaviour of a Hemp Concrete Building Envelope. Energy Build. 2010, 42, 1797–1806. [Google Scholar] [CrossRef]

- Junaid, M.F.; Rehman, Z.; Kuruc, M.; Medveď, I.; Bačinskas, D.; Čurpek, J.; Čekon, M.; Ijaz, N.; Ansari, W.S. Lightweight Concrete from a Perspective of Sustainable Reuse of Waste Byproducts. Constr. Build. Mater. 2022, 319, 126061. [Google Scholar] [CrossRef]

- Martins, R.; Carmo, R.N.F.; Costa, H.; Júlio, E.; Cordeiro, T.; Almeida, V. Interface Role in Composite RC Beams with a Light-Weight Concrete Core and an Ultra High-Durability Concrete Skin. Eng. Struct. 2021, 228, 111524. [Google Scholar] [CrossRef]

- Assaad, J.J.; El Mir, A. Durability of Polymer-Modified Lightweight Flowable Concrete Made using Expanded Polystyrene. Constr. Build. Mater. 2020, 249, 118764. [Google Scholar] [CrossRef]

- Wang, Z.; Li, X.; Jiang, L.; Wang, M.; Xu, Q.; Harries, K. Long-Term Performance of Lightweight Aggregate Reinforced Concrete Beams. Constr. Build. Mater. 2020, 264, 120231. [Google Scholar] [CrossRef]

- Assaad, J.J.; Gerges, N.; Issa, C. Bond to Reinforcement of Polymeric Lightweight Flowable Concrete for Structural Applications. J. Adhes. Sci. Technol. 2019, 33, 595–615. [Google Scholar] [CrossRef]

- Li, H.; Wei, Y.; Hu, Y.; Zhao, L.; Wang, G.; Zhang, Y. Experimental and Theoretical Analysis of FRP-Confined Square Lightweight Aggregate Concrete Columns under Axial Compression. Case Stud. Constr. Mater. 2024, 20, e02982. [Google Scholar] [CrossRef]

- Luo, S.; Bai, T.; Guo, M.; Wei, Y.; Ma, W. Impact of Freeze–Thaw Cycles on the Long-Term Performance of Concrete Pavement and Related Improvement Measures: A Review. Materials 2022, 15, 4568. [Google Scholar] [CrossRef]

- Das, P.; Chakraborty, S.; Barai, S.V. Flexural Behaviour of Fly Ash Incorporated Ferrochrome Slag Aggregate Reinforced Concrete Beam. J. Build. Eng. 2023, 76, 107317. [Google Scholar] [CrossRef]

- Kistan, A.; Kanchana, V.; Parthiban, E.; Vadivel, S.; Sridhar, B. Study on Flexural Behaviour of Polypropylene Fiber Reinforced Fly Ash Concrete Beam. Mater. Today Proc. 2023; in press. [Google Scholar] [CrossRef]

- Khalid, M.A.; Shariq, M.; Arif, M.; Umar, A. Shear Behavior of Fiber Reinforced Concrete Beams with High Fly Ash Content. Mater. Today Proc. 2023; in press. [Google Scholar] [CrossRef]

- Hadi, B.A.; Saleh, S.M. Behavior of Steel–Lightweight Self Compacting Concrete Composite Beams with Various Degrees of Shear Interaction. Civ. Eng. J. 2023, 9, 2689–2705. [Google Scholar] [CrossRef]

- Dragaš, J.; Marinković, S.; Ignjatović, I.; Tošić, N.; Koković, V. Flexural Behaviour and Ultimate Bending Capacity of High-Volume Fly Ash Reinforced Concrete Beams. Eng. Struct. 2023, 277, 115446. [Google Scholar] [CrossRef]

- Liao, Q.; Zhao, X.-D.; Wu, W.-W.; Lu, J.-X.; Yu, K.-Q.; Poon, C.S. A Review on the Mechanical Performance and Durability of Fiber Reinforced Lightweight Cement Composites: The Roles of Fiber and Lightweight Aggregate. J. Build. Eng. 2024, 88, 109121. [Google Scholar] [CrossRef]

- Wibowo, A.P.; Saidani, M. The Effect of Fly Ash as Coating Powder on Compressive Strength of Lightweight Concrete. Mater. Today Proc. 2023, 85, 29–32. [Google Scholar] [CrossRef]

- Zukri, A.; Nazir, R.; Abang, Z.; Mustapha, A.H. Lightweight Expanded Clay Aggregate (LECA) as Replacement Materials for Geotechnical Application. Phys. Chem. Earth Parts A/B/C 2023, 130, 103366. [Google Scholar] [CrossRef]

- Murugan, K.; Palaniappan, M.; Kalappan, K.K. Experimental Studies on Light Weight Concrete Using LECA Material. Mater. Today Proc. 2023, 74, 1035–1041. [Google Scholar] [CrossRef]

- Adhikary, S.K.; Ashish, D.K.; Rudžionis, Ž. Expanded Glass as Light-Weight Aggregate in Concrete—A Review. J. Clean. Prod. 2021, 313, 127848. [Google Scholar] [CrossRef]

- Meng, L.; Zhang, C.; Wei, J.; Li, L.; Liu, J.; Wang, S.; Ding, Y. Mechanical Properties and Microstructure of Ultra-High Strength Concrete with Lightweight Aggregate. Case Stud. Constr. Mater. 2023, 18, e01745. [Google Scholar] [CrossRef]

- Basha, S.I.; Ali, M.R.; Al-Dulaijan, S.U.; Maslehuddin, M. Mechanical and Thermal Properties of Lightweight Recycled Plastic Aggregate Concrete. J. Build. Eng. 2020, 32, 101710. [Google Scholar] [CrossRef]

- Assaad, J.J.; Mikhael, C.; Hanna, R. Recycling of waste expanded polystyrene concrete in lightweight sandwich panels and structural applications. Clean. Mater. 2022, 4, 100095. [Google Scholar] [CrossRef]

- González-Betancur, D.; Hoyos-Montilla, A.A.; Tobón, J.I. Sustainable Hybrid Lightweight Aggregate Concrete Using Recycled Expanded Polystyrene. Materials 2024, 17, 2368. [Google Scholar] [CrossRef] [PubMed]

- Assaad, J.J.; Issa, C. Stability and Bond Properties of Latex-Modified Semi-lightweight Flowable Concrete. ACI Mater. J. 2018, 115, 519–530. [Google Scholar] [CrossRef]

- Ahmad, S.H.; Barker, R. Flexural Behavior of Reinforced High-Strength Lightweight Concrete Beams. ACI Struct. J. 1991, 88, 69–77. [Google Scholar] [CrossRef]

- Swamy, R.N.; Lambert, G.H. Flexural Behaviour of Reinforced Concrete Beams Made with Fly Ash Coarse Aggregates. Int. J. Cem. Compos. Lightweight Concr. 1984, 6, 189–200. [Google Scholar] [CrossRef]

- Hwee Sin, L.; Tiong Huan, W.; Rafiqul Islam, M.; Abul Mansur, M. Reinforced Lightweight Concrete Beams in Flexure. ACI Struct. J. 2011, 108, 3–12. [Google Scholar] [CrossRef]

- Ghannoum, M.; Abdelkhalek, L.; Assaad, J.J. Application of Stochastic Finite Element Modeling to Reinforced Lightweight Concrete Beams Containing Expanded Polystyrene Beads. Buildings 2023, 13, 2294. [Google Scholar] [CrossRef]

- Alshannag, M.J.; Charif, A.; Alqarni, A.S.; Nasser, S. Flexural Performance and Ductility of RC Beams Made Using Natural LWA. Case Stud. Constr. Mater. 2022, 16, e00942. [Google Scholar] [CrossRef]

- Yang, Y.; Yang, H.; Fan, Z.; Mu, Z. Crack Propagation Law of Reinforced Concrete Beams. Appl. Sci. 2024, 14, 409. [Google Scholar] [CrossRef]

- Marid, H.; Vahidi, E.K. Experimental Study on Flexural Behavior of Reinforced Lightweight Concrete Beams Strengthening with a Slurry Infiltrated Fiber Concrete (SIFCON). Asian J. Civ. Eng. 2023, 25, 1811–1823. [Google Scholar] [CrossRef]

- Salahaldin, A.I.; Jomaa’h, M.M.; Naser, D.M. Flexural Behavior of Damaged Lightweight Reinforced Concrete Beams Strengthened by CFRP. J. Eng. Res. 2021, 9, 1–17. [Google Scholar] [CrossRef]

- Assaad, J.J.; Issa, C. Mixture Optimization of Polymer-Modified Lightweight SCC. Mag. Concr. Res. 2017, 69, 745–756. [Google Scholar] [CrossRef]

- Huang, H.; Yuan, Y.; Zhang, W.; Gao, Z. Bond Behavior between Lightweight Aggregate Concrete and Normal Weight Concrete Based on Splitting-Tensile Test. Constr. Build. Mater. 2019, 209, 306–314. [Google Scholar] [CrossRef]

- Wang, J.; Xiao, Z.; Zhu, C.; Feng, C.; Liu, J. Experiment on the Bonding Performance of the Lightweight Aggregate and Normal Weight Concrete Composite Beams. Case Stud. Constr. Mater. 2021, 15, e00565. [Google Scholar] [CrossRef]

- ASTM Standard Specification for Deformed and Plain Carbon-Steel Bars for Concrete Reinforcement. Available online: https://www.astm.org/a0615_a0615m-22.html (accessed on 24 November 2024).

- American Concrete Institute. ACI Education Bulletin E1-07 Aggregates for Concrete; ACI: Farmington Hills, MI, USA, 2007. [Google Scholar]

- ASTM Standard Test Method for Slump of Hydraulic-Cement Concrete. Available online: https://www.astm.org/c0143_c0143m-12.html (accessed on 24 November 2024).

- ASTM C231/C231M-17a; Standard Test Method for Air Content of Freshly Mixed Concrete by the Pressure Method. ASTM: West Conshohocken, PA, USA, 2010. Available online: https://www.astm.org/Standards/C231 (accessed on 24 November 2024).

- ASTM Standard Test Method for Density, Absorption, and Voids in Hardened Concrete. Available online: https://www.astm.org/standards/c642 (accessed on 24 November 2024).

- ASTM Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. Available online: https://www.astm.org/c0039_c0039m-21.html (accessed on 24 November 2024).

- ASTM C496/C496M-17; Standard Test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens. ASTM: West Conshohocken, PA, USA, 2017. Available online: https://www.astm.org/Standards/C496 (accessed on 24 November 2024).

- ASTM Standard Test Method for Static Modulus of Elasticity and Poisson’s Ratio of Concrete in Compression. Available online: https://www.astm.org/standards/c469 (accessed on 24 November 2024).

- ACI Committee. 318 ACI CODE-318-19: Building Code Requirements for Structural Concrete and Commentary. Available online: https://www.concrete.org/store/productdetail.aspx?ItemID=318U19&Language=English&Units=US_Units (accessed on 24 November 2024).

- Ullah, A.; Khan, A.; Tariq, M.; Waqas, H.A.; Khan, A. RC Beam Response to Impact Utilizing Rigid-Viscoplastic Linear Complementarity. Structures 2024, 67, 106927. [Google Scholar] [CrossRef]

- Alharthai, M.; Bahrami, A.; Badawi, M.; Ghalla, M.; Elsamak, G.; Abdelmgeed, F.A. Numerical Study on Enhancing Shear Performance of RC Beams with External Aluminum Alloy Plates Bonded Using Steel Anchors. Results Eng. 2024, 22, 102143. [Google Scholar] [CrossRef]

- You, X.; Wang, P.; Shi, Q.; Rong, C. Study on the Influence of Section Dimensions on the Shear Performance of RC Beam with UHPC Formwork. Structures 2024, 68, 107221. [Google Scholar] [CrossRef]

- Sarkar, S.; Chakraborty, S.; Nayak, S. Identification of Optimum Reinforcement Detailing Using Tuned CDP Parameters in RC Beam under Drop-Weight Impact. Eng. Fail. Anal. 2023, 146, 107116. [Google Scholar] [CrossRef]

- Mohamed, S.S.; Hamdy, O.; Seleem, M.H.; Sharaky, I.A. The Flexural Behavior and Efficiency of RC Beams Strengthened with SNSM Bars under the Effect of Several End Conditions and Material Properties. Eng. Struct. 2024, 308, 117990. [Google Scholar] [CrossRef]

- Ahıskalı, A.; Ahıskalı, M.; Bayraktar, O.Y.; Kaplan, G.; Assaad, J. Mechanical and durability properties of polymer fiber reinforced one-part foam geopolymer concrete: A sustainable strategy for the recycling of waste steel slag aggregate and fly ash. Constr. Build. Mater. 2024, 440, 137492. [Google Scholar] [CrossRef]

- Mccormac, J.C.; Brown, R.H. Design of Reinforced Concrete; Wiley: Hoboken, NJ, USA, 2014; ISBN 9781118129845. [Google Scholar]

- Al-Farttoosi, H.K.A.; Hussain, H.K.; Abdulrazzaq, O.A. Flexural Behavior of Two-Layer Beams Made with Normal and Lightweight Concrete Layers. Period. Eng. Nat. Sci. (PEN) 2021, 9, 1124. [Google Scholar] [CrossRef]

- Elkafrawy, M.; Khalil, A.; AlHamaydeh, M.; Hawileh, R.; Abuzaid, W. Enhancing the Shear Capacity of RC Beams with Web Openings in Shear Zones Using Pre-Stressed Fe-SMA Bars: Numerical Study. Buildings 2023, 13, 1505. [Google Scholar] [CrossRef]

- Siew, J.N.; Tan, Q.Y.; Lim, K.S.; Gimbun, J.; Tee, K.F.; Chin, S.C. Effective Strengthening of RC Beams Using Bamboo-Fibre-Reinforced Polymer: A Finite-Element Analysis. Fibers 2023, 11, 36. [Google Scholar] [CrossRef]

- Chen, H.-J.; Huang, C.-H.; Tang, C.-W. Dynamic Properties of Lightweight Concrete Beams Made by Sedimentary Lightweight Aggregate. J. Mater. Civ. Eng. 2010, 22, 599–606. [Google Scholar] [CrossRef]

- Tat, L.Y. Performance of Reinforced Concrete Beam with Polystyrene Blocks at Various Regions. J. Sci. Appl. Eng. 2021, 3. [Google Scholar] [CrossRef]

- Altun, F.; Aktaş, B. Investigation of Reinforced Concrete Beams Behavior of Steel Fiber Added Lightweight Concrete. Constr. Build. Mater. 2013, 38, 575–581. [Google Scholar] [CrossRef]

- Vives, I.; Varona, F.B.; Tenza-Abril, A.J.; Pereiro-Barceló, J. A Parametric Study to Assess Lightweight Aggregate Concrete for Future Sustainable Construction of Reinforced Concrete Beams. Sustainability 2021, 13, 13893. [Google Scholar] [CrossRef]

- Mergos, P.E. Contribution to Sustainable Seismic Design of Reinforced Concrete Members through Embodied CO2 Emissions Optimization. Struct. Concr. 2017, 19, 454–462. [Google Scholar] [CrossRef]

| NWC | LWC | |

|---|---|---|

| Cement, kg/m3 | 320 | 420 |

| Water, kg/m3 | 185 | 170 |

| Natural sand, kg/m3 | 634 | 540 |

| Coarse aggregate, kg/m3 | 1268 | 712 |

| Plasticizer, kg/m3 | 3.17 | 4.4 |

| f’c, MPa | 29.83/28.28/33.39 = 30.5 | 18.99/23.69/21.81 = 21.5 |

| ft, MPa | 3.43/3.03/2.84 = 3.1 | 3.08/2.89/2.45 = 2.81 |

| E, GPa | 27.36/32.38/32.51 = 30.75 | 18.62/15.71/19.86 = 18.06 |

| Reinforcing Steel | |

|---|---|

| Density, kg/m3 | 7850 |

| Elasticity modulus, GPa | 200 |

| Yield strength, MPa | 500 |

| Yield strain, mm/m | 2.5 |

| Ultimate strength, MPa | 620 |

| Ultimate strain, mm/m | 150 |

| NWC | LWC | |

|---|---|---|

| Density, kg/m3 | 2416 | 1928 |

| Elasticity modulus, GPa | 30.75 | 18.06 |

| Compressive strength, MPa | 30.5 | 21.5 |

| Ultimate compressive strain, mm/m | 2.127 | 1.900 |

| Splitting tensile strength, MPa | 3.10 | 2.81 |

| Poisson ratio | 0.15 | 0.15 |

| Dilation angle | 36 | 36 |

| Eccentricity | 0.1 | 0.1 |

| fb0/fc0 | 1.16 | 1.16 |

| K | 0.667 | 0.667 |

| Viscosity parameter | 0.0001 | 0.0001 |

| Beam Description | Maximum Load (Pmax—kN) | Deflections, mm | Ductility Ratio (δf/δy) | Beam Properties | ||||

|---|---|---|---|---|---|---|---|---|

| At 33% Pmax | At 67% Pmax | At Yield (δy) | At Failure (δf) | Mass (kg) | Drop in Mass (%) | |||

| B1: 100% NWC | 42.31 | 0.60 | 1.36 | 2.10 | 17.60 | 8.38 | 48.3 | - |

| B2: 25%LWC + 75%NWC | 41.80 | 0.75 | 1.55 | 2.08 | 15.20 | 7.24 | 45.9 | 5.0 |

| B3: 50%LWC + 50%NWC | 41.60 | 0.75 | 1.52 | 2.11 | 13.50 | 6.43 | 43.4 | 10.2 |

| B4: 75%LWC + 25%NWC | 41.67 | 0.80 | 1.33 | 2.12 | 12.10 | 5.76 | 41.0 | 15.1 |

| B5: LWC at the neutral axis | 41.48 | 0.73 | 1.56 | 2.08 | 9.50 | 4.52 | 40.8 | 15.5 |

| B6: 100%LWC | 33.30 | 1.35 | 2.37 | 3.00 | 9.10 | 3.03 | 38.6 | 20.1 |

| Description | Maximum Load (kN) | ||

|---|---|---|---|

| PEXP | PACI | ||

| B1: 100% NWC | 42.31 | 32 | 1.32 |

| B2: 25%LWC + 75%NWC | 41.80 | 32 | 1.31 |

| B3: 50%LWC + 50%NWC | 41.61 | 32 | 1.30 |

| B4: 75%LWC + 25%NWC | 41.67 | 32 | 1.30 |

| B5: LWC at the neutral axis | 41.48 | 32 | 1.30 |

| B6: 100%LWC | 33.30 | 30.7 | 1.08 |

| Description | Maximum Load (Pmax—kN) | Deflection at Yield (δy—mm) | Deflection at Failure (δf—mm) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| EXP | FEM | % ER | EXP | FEM | % ER | EXP | FEM | % ER | |

| B1: 100% NWC | 42.3 | 40.1 | 5.49 | 2.1 | 2.15 | −2.33 | 17.6 | 18.1 | −2.76 |

| B2: 25%LWC + 75%NWC | 41.8 | 41 | 1.95 | 2.08 | 2.13 | −1.41 | 15.2 | 15.7 | −3.18 |

| B3: 50%LWC + 50%NWC | 41.6 | 41.3 | 0.73 | 2.11 | 2.15 | −2.33 | 13.5 | 14.2 | −4.93 |

| B4: 75%LWC + 25%NWC | 41.5 | 40.6 | 2.22 | 2.12 | 2.12 | −0.94 | 12.1 | 12.6 | −3.97 |

| B5: LWC at the neutral axis | 41.4 | 40.1 | 3.24 | 2.08 | 2.5 | −16 | 9.5 | 10.1 | −5.94 |

| B6: 100%LWC | 33.3 | 33.1 | 0.60 | 3 | 2.93 | 2.39 | 9.1 | 10 | −9 |

| Beam | Severely Damaged Zones (cm2) | Error % | |

|---|---|---|---|

| EXP | FEM | ||

| B1 | 900 | 1004 | 11.60 |

| B2 | 509 | 576 | 13.16 |

| B3 | 375 | 442 | 17.87 |

| B4 | 412 | 432 | 4.85 |

| B5 | 314 | 396 | 26.11 |

| B6 | 495 | 605 | 22.22 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jahami, A.; Dayaa, L.; Assaad, J.J.; Baalbaki, O.; Khatib, J. Flexural Strength of Structural Beams Cast Using Combined Normal-Weight and Lightweight Concrete Mixtures. Buildings 2024, 14, 3787. https://doi.org/10.3390/buildings14123787

Jahami A, Dayaa L, Assaad JJ, Baalbaki O, Khatib J. Flexural Strength of Structural Beams Cast Using Combined Normal-Weight and Lightweight Concrete Mixtures. Buildings. 2024; 14(12):3787. https://doi.org/10.3390/buildings14123787

Chicago/Turabian StyleJahami, Ali, Lynn Dayaa, Joseph J. Assaad, Oussama Baalbaki, and Jamal Khatib. 2024. "Flexural Strength of Structural Beams Cast Using Combined Normal-Weight and Lightweight Concrete Mixtures" Buildings 14, no. 12: 3787. https://doi.org/10.3390/buildings14123787

APA StyleJahami, A., Dayaa, L., Assaad, J. J., Baalbaki, O., & Khatib, J. (2024). Flexural Strength of Structural Beams Cast Using Combined Normal-Weight and Lightweight Concrete Mixtures. Buildings, 14(12), 3787. https://doi.org/10.3390/buildings14123787