Abstract

In this paper, we study the influence of density and the water–cement (W/C) ratio on the slurry fluidity, compressive strength, and water absorption of foamed concrete (FC) and its mechanism of action, with the aim of proposing an optimal mix ratio for FC to reduce cement usage and carbon emissions in the construction industry and ensure the good overall performance of FC. In this experiment, two groups of experiments were designed using the control variable method. Fluidity and uniaxial compression tests showed that when the density was 600 kg/m3 and the W/C ratio was 0.6, the FC slurry had maximum fluidity, but its mechanical properties were poor and it collapsed easily. Conversely, by analyzing the uniaxial compressive strength/cement (UCS/C) ratio, it was observed that the mix ratio had a maximum cement utilization rate (W/C ratio) of 0.5 and a density of 1000 kg/m3. Nondestructive testing methods were used to measure the ultrasonic pulse velocity (UPV) and rebound value of the FC test block, and the strength and durability of FC were analyzed. The water absorption rate of the FC test block was tested, and the final analysis showed that the optimal mix ratio of FC in this test was W/C = 0.5, with a density of 1000 kg/m3.

1. Introduction

FC is also known as lightweight concrete or bubble concrete [1]. It is a lightweight building material with a cellular structure and is usually composed of cement mortar and foam [2,3]. By changing the volume of foam in the cement mortar, some of the volume in the concrete is replaced by foam and the density of FC can be adjusted in the range of 400–1900 kg/m3 [4,5]. This method not only reduces the amount of cement used but also reduces the carbon emissions associated with the production of cement. FC is a new lightweight environmental protection material appropriate for thermal insulation, heat insulation, fire resistance, sound insulation, and frost resistance [6,7,8,9]. The slurry is self-leveling and self-compacting, the construction workability is good, and it is easy to pump. At present, FC is mainly used in subgrade load reduction in roads, load reduction and reinforcement in bridges, load reduction in underground structures, cavity grouting in tunnels, load reduction in building structures, thermal insulation in buildings, guardrail collision prevention in roads, subgrade backfilling in railways, and other fields [10,11,12,13,14,15,16,17].

For FC, the determination of density and the water–cement ratio not only indirectly determines the content of its components, it also plays an important role in influencing the workability and mechanical properties of FC [6]. In recent years, many scholars have conducted relevant research on the design of the density and W/C ratio of FC. Through experimental research on the mechanical properties and microstructure characteristics of roadbed FC with different densities, Wen Huang found that the density of roadbed FC has an exponential positive correlation with its compressive strength, which is because the increase in its density reduces harmful macropores, strengthens beneficial pores, and optimizes the sphericity and distribution density of pores. Moreover, the mass loss of roadbed FC at high temperatures is also related to density [18]. Hongbo Zhang found in his research on the characteristics of FC based on silt that the compressive strength of FC increased with an increase in wet density. For example, when the silt content is 40%, the compressive strength of FC at 28 days increases by 0.81 MPa, with the simultaneous increase in wet density and 100 kg/m3 [19]. This result is roughly the same as the conclusion obtained by Ma Cong in his study on the characteristics of FC with soil as filler [20]. Falliano studied the relationship between compressive strength and bending strength of FC with different density grades; the test results show that the compressive strength and bending strength of FC increased linearly with the increase in density [21]. By using soil and fly ash, Lei-lei Guan prepared FC for backfilling urban underground spaces. In this study of its mechanical properties, it was found that its uniaxial compressive strength rapidly decreased with an increase in the contents of foam, soil, and fly ash, while it increased with increases in the water–solid ratio—the foam content increased from 0.40 to 0.60, the uniaxial compressive strength decreased sharply from 3.92 MPa to 0.41 MPa, and the relationship between uniaxial compressive strength and foam content was well fitted with the allometric growth function (R2 = 0.9670) [22]. This finding is consistent with the research results of Hoff, Kearsley, and Wainwright [23,24]. Li found that the compressive strength of FC increases with increases in the water–cement ratio (0.4~0.5) [25], while the cracking time of FC is shortened by 1–5 h and the degree of shrinkage cracking increases [26]. By studying the microstructure of FC specimens with different water–cement ratios, Zhang found that when the W/C ratio was 0.42, the specimens had a relatively dense matrix structure and more closed holes on the surface; when the water–cement ratio was 0.58, the number of connected holes of the specimens increased significantly [27]. Meera proposed a prediction model for the compressive strength of FC based on the effective water–cement ratio, and verified the effectiveness of the model using a large amount of literature data. It was observed that with the increase in the effective water–cement ratio, the compressive strength of FC gradually decreased [28]. The above scholars separately studied some effects of density and W/C ratio on FC performance, but they did not conduct comprehensive analyses of FC performance while considering density and W/C ratio at the same time. In their design processes, existing research rarely considers how to better reduce the cement level while ensuring the basic comprehensive performance of FC, so as to help reduce the carbon emissions created by the construction industry and to better reflect the green environmental protection performance of FC.

The aim of this study is to reveal the optimal W/C ratio and density design value of FC through the comprehensive consideration of fluidity, mechanical properties, and water absorption. Two groups of experiments were designed using the control variable method, the mix ratio was calculated based on the solid phase volume method, and the FC sample was prepared. By measuring the fluidity of cement slurry, the change in FC fluidity was analyzed. The uniaxial compression test was used to analyze the influence level of density and W/C ratio on the compressive strength of FC, and thus the internal correlation was obtained. When analyzing UCS/C, the mixing ratio with the lowest amount of cement was utilized in order to observe mechanical properties. The UPV and rebound value of the FC test block were measured through nondestructive testing, and the conclusions obtained via the uniaxial compression test were further verified. Finally, the water absorption of FC was tested, and the reason why the density and W/C ratio caused a change in the water absorption of the FC was analyzed.

2. Materials and Methods

2.1. Preparation Method and Material Introduction

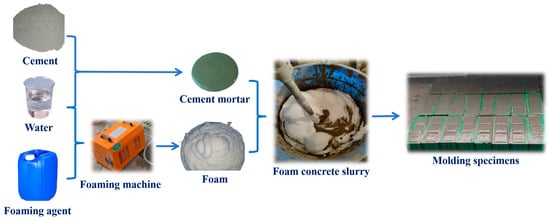

Figure 1 illustrates the preparation process of FC samples. First, we configured the diluent of the blowing agent needed for the test. The dilution ratio of the blowing agent used in this test was 1:20 (blowing agent/water), and a large amount of the diluent was evenly configured according to the dilution ratio. Second, the cement and water were weighed according to the mix ratio table of each test group. Third, the cement was poured into the mixing bucket and tap water was slowly added. During this process, the cement mortar mixer was used to stir the mixture at a high speeds (30 r/min) for 5 min until the cement slurry entered the flowing state; this was carried out to ensure that the cement and water were evenly mixed [29]. Fourth, water was added into the cement foam through the machine inlet pipe in order to remove the air from within the pipe. The inlet pipe was then completely immersed in the diluent to prevent outside air from entering during the foaming process. Fifth, the pump switch of the foaming machine was turned on, followed by the air pump after 5 s, and finally a uniform and delicate foam was obtained.

Figure 1.

Preparation process of FC.

In order to reduce the error in the weighing of the foam, we injected the foam directly into the cement slurry. The measured foam ejection speed from the bubble tube was 0.041 kg/s. The foam ejection time during each test can be obtained using Formula (1).

Here, T is foam ejection time (s); is foam mass required for each group (kg); and is the foam ejection speed of the foaming machine (g/s).

After the foam was injected into the cement slurry, it was mixed with an electric drill mixer at a low speed (20 r/min) for 2 min until no more foam was observed on the surface of the slurry, which is the best way to prevent the mixing time from being too long or the speed from being too high. Then, the release oil was evenly applied to the inner wall of the test mold, sized 100 mm × 100 mm × 100 mm, and the FC slurry was injected into the test mold. In order to reduce the overflow of a large number of internal bubbles, 10 s manual vibration was adopted in this test to help compaction.

A scraper was used to remove excess paste from the mold surface and flatten it. Finally, the mold was placed in a concrete curing chamber (temperature of 23 °C and humidity of 95%), demolded after 24 h, and continued to be cured in the curing chamber for 28 days. Table 1 lists the models and manufacturers of the equipment used in this test, Table 2 lists the types and specifications of raw materials, and Table 3 lists the main chemical composition of the cement.

Table 1.

Test equipment models and manufacturers.

Table 2.

Raw materials and specifications.

Table 3.

Main chemical composition of the cement.

The measurement and calculation process of the foaming agent used in this test mainly follows the “Foaming agents for foamed concrete” standard [30]. First, the foaming foam is filled with the calibrated 1L container, and the excess foam is scraped off the upper surface of the container with a scraper. The foam mass of the corresponding volume is weighed to 35 g using an electronic scale (with an accuracy of 0.1 g), and thus the mass of the consumed diluter was calculated as 35 g. If the density of diluent is 1 g/mL, the volume of diluent before foaming can be obtained through Formula (2), and the foaming multiple of the foaming agent used in this test was approximately 28×, determined using Formula (3).

Here, is the volume of diluent before foaming (mL); is the measured foam mass of 1 L (g); is diluent density (g/mL); is the foaming multiple of the foaming machine; and is the foam volume (1000 mL).

2.2. Calculation Method of the Mix Ratio

In this experiment, in accordance with the relevant literature, the density of FC was first designed to be 800 kg/m3, and five groups of tests were designed by changing the W/C ratio to 0.4~0.6 (see Table 4 for the mix ratio) to obtain the optimal W/C ratio. The W/C ratio was designed to be 0.5, and four groups of tests were designed by changing the density to 600 kg/m3–1200 kg/m3 (see Table 5 for the mix ratio table) to obtain the optimal density. The following is the mix design process of this experiment.

Table 4.

Mix ratio of FC with different W/C ratios.

Table 5.

Mix ratio of FC with different densities.

The mix ratio design method used in this experiment is the “solid phase volume method”. This method essentially involves the process of controlling the design dosage and volume of each component in the unit volume to determine the composition of the material. The specific formulae are as follows:

Here, is the mass of FC per unit volume; is the cement mass per unit volume of FC; is foam mass per unit volume of FC; is the density of cement (3100 kg/m3); is the density of tap water (1000 kg/m3); is the density of the foam (35 kg/m3); and is the W/C ratio.

3. Sample Performance Test Method

The main values of this experiment were the fluidity, compressive strength, UPV, rebound value, and water absorption of FC. The compressive strength of the FC block was tested using a uniaxial compression test, and the UPV and rebound value of the FC block were tested through nondestructive testing. The following are the theoretical bases and the detailed introductions to each part of the test process.

3.1. Fluidity Test

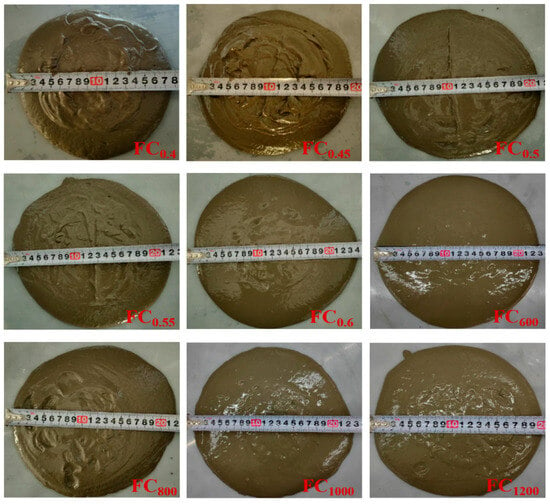

This test measures the fluidity of the foamed cement slurry according to the “Foam Concrete” standard [31]. First, the glass plate was placed on a horizontal tabletop. Second, the FC mixture was slowly poured into the 1 L hollow container, and then the outside of the hollow mold was struck with a scraper, so that the FC mixture filled the entire hollow mold and excess cement paste was removed. Third, the container was inverted on the glass plate and then lifted up vertically at a slower speed so that the foam cement slurry was able to flow freely onto the glass plate. After 60 s, the maximum diffusion diameter of the FC mixture and its vertical diameter were measured with a steel ruler, accurate to 1 mm. Ultimately, fluidity is the arithmetic average of the diffusion diameter of the foamed cement slurry measured in both directions. The flow measurement samples from each group are shown in Figure 2.

Figure 2.

Fluidity tests of FC.

3.2. Uniaxial Compressive Strength Test

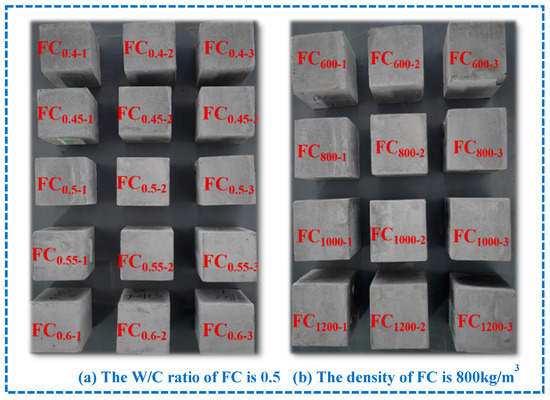

According to the provisions of the “Foam Concrete” standard [31], the uniaxial compressive test was performed using an HCT306A micro-computer-controlled electro-hydraulic servo pressure testing machine, and the loading was carried out using the stress control method at a loading rate of 0.25 MPa/s. The loading specimens used in this test are shown in Figure 3.

Figure 3.

Two groups of FC test blocks.

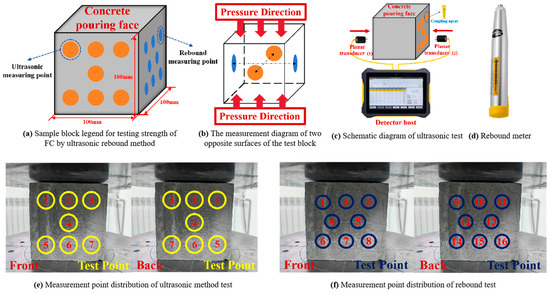

3.3. Nondestructive Testing

The surface of the FC specimen should be polished before the detection of the rebound value and UPV. After the surface of the specimen has been made smooth and flat, it is placed on a plane with large stiffness and stability. In accordance with the “Technical regulations for Testing Compressive Strength of Concrete by Rebound Method” [32], the rebound value of FC specimens was measured using the HT-450A concrete rebound instrument. One test area was arranged on each of the two opposite sides of the specimen, and eight rebound values were taken from each test area. A total of sixteen rebound values were recorded, and three larger and three smaller datapoints were removed. The average value of the remaining test points was used as the rebound value of the specimen. In accordance with the “Technical Regulations for Testing Compressive Strength of Concrete by Ultrasonic Rebound Method” [33], a HC-U91 non-metallic sonic detector was used to measure the UPV of FC specimens. Measuring areas were chosen on the specimen using the pair measurement method, and seven measuring points were selected for each measuring area. The average UPV of the seven measuring points was taken as the UPV of the specimen. The schematic diagram of ultrasonic resilience synthesis test is shown in Figure 4.

Figure 4.

Testing the strength of FC by using ultrasonic rebound method.

3.4. Water Absorption Test

Before the test, three specimens were placed into the electric blast drying oven, and the specimens were dried at (60 ± 5) °C for 4 h, and this was carried out a second time after the test. The mass difference was less than 1g, and the constant mass was determined.

When the specimen was cooled to room temperature, it was placed into a constant temperature tank at a water temperature of (20 ± 5) °C, and then water was added to 1/3 of the height of the specimen; this was left for 24 h. Then, water was added to 2/3 of the height of the specimen. After 24 h, more water was added until the water level was 30 mm higher than the specimen; this was left for 24 h. Finally, the specimen was removed from the water, the surface moisture was wiped off with a damp cloth, and each piece of mass was immediately weighed, with an accuracy of 1 g. The obtained quality data were input into Formula (7) to calculate the water absorption of the specimen

Here, is water absorption; is the mass of the test block after absorbing water; and is the mass of the test block after drying.

4. Results and Analysis

4.1. Fluidity Analysis of FC Slurry

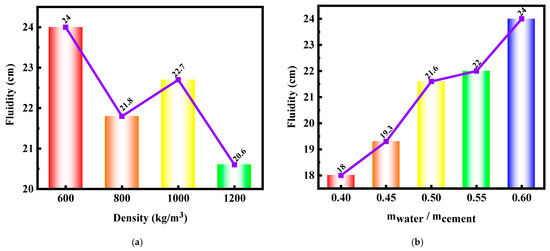

The fluidity of FC slurry with different densities with a designed W/C ratio of 0.5 is shown in Table 6, and the corresponding column pattern is shown in Figure 5a. The test results show that when the density of FC slurry designed with a W/C ratio of 0.5 increases from 600 kg/m3 to 1200 kg/m3, the fluidity first decreases, then increases, and then decreases again, and the change rates are −9.2%, 4.1%, and −9.3% in that order. When the density was 600 kg/m3, the fluidity of the cement slurry was the highest; the fluidity was second-highest when the density was 1000 kg/m3; and the fluidity was the lowest when the density was 1200 kg/m3. This is because when the cement content increases, the moisture contained in the foam liquid film decreases, and the foam can easily be destroyed, resulting in greater internal friction in the slurry, which is manifested as a decrease in slurry fluidity on a macro level. When the density is 1000 kg/m3, the fluidity of cement slurry increases slightly, indicating that 1000 kg/m3 is a more reasonable density value under the condition of W/C = 0.5.

Table 6.

Fluidity of FC with fixed W/C ratios and different density test groups.

Figure 5.

Fluidity curves of test groups with different densities (a) and different W/C ratios (b).

The slurry flow of FC with a fixed design density of 800 kg/m3 and different W/C ratios is shown in Table 7, and the corresponding column pattern is shown in Figure 5b. The measured results show that the fluidity of FC slurry with a design density of 800 kg/m3 increases gradually with the W/C ratio, increasing from 0.4 to 0.6 (the gradient is 0.05). When the W/C ratio increases from 0.45 to 0.5, the increase in mobility is the largest, namely, 11.9%. This is because increasing the W/C ratio can increase the moisture contained in the foam liquid film, effectively weakening the friction between the bubble and the matrix and thus ensuring the stability of the bubble and increasing the fluidity of the slurry.

Table 7.

Fluidity of FC with fixed density and different W/C ratios.

4.2. Analysis of Compressive Performance of FC

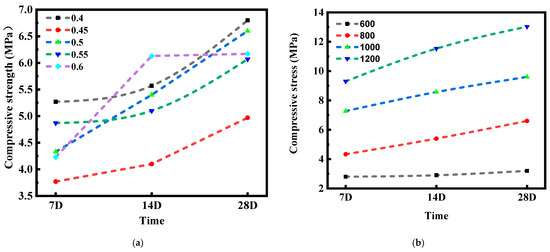

The change in the compressive strength of FC with different W/C ratios and design densities is shown in Figure 6. It can be seen from the figure that the compressive strength of the FC specimen gradually increases with the increase in curing time. During the curing process, the FC is continuously hydrated, and the strength of the test block increases rapidly. At 28 d, the strength of the test block essentially leveled off.

Figure 6.

Compressive strength curves of FC with different W/C ratios (a) and densities (b) at different stages.

For conditions in which the design density of FC is controlled to 800 kg/m3 and the W/C ratio is changed, the compressive strength of the FC test block is shown in Figure 6a. The term W/C refers to the ratio of the mass of water to the mass of cement in a unit volume of FC. When the curing time is 7 days, the W/C ratios corresponding to the strength of the test block from large to small are 0.4, 0.55, 0.5, 0.6, and 0.45. When the curing time is 14 d, the W/C ratios corresponding to the strength of the test block from large to small are 0.6, 0.4, 0.5, 0.55, and 0.45. When the curing time is 28 d, the W/C ratios corresponding to the strength of the test block from large to small are 0.4, 0.5, 0.6, 0.55, and 0.45 in turn. Therefore, according to the comprehensive strength of specimens in different periods, the axial compressive strength of FC is the highest when the W/C ratio is 0.4. This is because the prepared FC specimens contain a relatively high cement content, and at the same time ensure good fluidity; that is, the foam is evenly distributed in the slurry. Its influence on the internal structure of the test block is reflected in the closer interaction relationship between the material particles, which reduces the internal porosity of the test block and the probability of large, connected holes in the test block, improving the density of the test block, so that the force and force transmission of the material are more reasonable and the uniaxial compressive resistance of the material is improved. When the W/C ratio increases, the excess free water that does not undergo a hydration reaction evaporates out of the FC during the hardening process, resulting in the formation of connected pores in the FC, which greatly reduces the compactness and strength of the FC [34]. In this test, we did not just pursue a high compressive strength, but also considered the utilization rate of the cement. Therefore, in the analysis of the test results, we defined a new variable UCS/C as the ratio of the uniaxial compressive strength of FC test block to the amount of cement used. UCS/C intuitively reflects the contribution of cement content in FC to its compressive strength, and reflects the utilization rate of cement to a certain extent. Improving the utilization rate of cement can reduce the amount of cement used and reduce carbon emissions. At the same time, the FC test block with the lowest 28 d compressive strength was used as the benchmark to calculate the relative growth rate of the compressive strength of other test blocks, and then the FC test block with the highest cement utilization rate was used as the benchmark to calculate the relative reduction rate of the cement use of other test blocks (see Table 8).

Table 8.

The relative rate of change in cement content, the compressive strength of test block, and the UCS/C value.

The results show that when the W/C ratio is 0.5, the relative growth rate of compressive strength of the foamed concrete test block is high. Compared with the FC test block with a W/C ratio of 0.4, the 28 d compressive strength is not significantly different, but the amount of cement in the preparation process is greatly reduced, and the highest UCS/C in all test groups indicates the highest cement utilization rate. Therefore, in this test, the optimal W/C ratio of FC is 0.5.

In this test, it was observed that when the W/C ratio was 0.45, the uniaxial compressive resistance of the test block was the lowest. It can be speculated that the mix ratio calculated under this condition is unreasonable, its foam content is relatively large, and it cannot be evenly mixed with the cement slurry, resulting in the formation of a large number of connected holes in the test block, which constitutes a dangerous area. When the test block receives external loading, stress concentration occurs at the connecting hole wall, resulting in the rapid failure of the test block. To sum up, the relationships between the 28 d uniaxial compressive strength of the experimental group and the different W/C ratios in this paper are the result of the joint action of multiple factors, such as W/C ratio and fluidity.

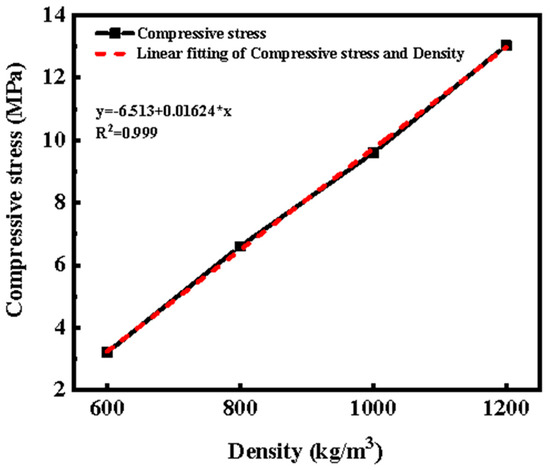

When the W/C ratio of FC was controlled as 0.5 and the design densities of test groups were set as 600 kg/m3, 800 kg/m3, 1000 kg/m3, and 1200 kg/m3, respectively, their corresponding compressive strengths were 3.2 MPa, 6.6 MPa, 9.6 MPa, and 13.03 MPa, respectively; the compressive strength of the FC test block is shown in Figure 6b. Through comparison, it was found that the compressive strength of the foamed concrete obtained in this test was higher than that of the foamed concrete with the same density grade in the “Technical specification for application of foamed concrete” [35]. It was obvious that with the increase in density, due to the decrease in foam consumption, the voids and porosity of the cement slurry were reduced, and the voids led to weaker cement slurry strength. In addition, many researchers have also pointed out that with the increase in foam utilization rate, more voids were created, and the compressive strength of FC was lower [36,37,38,39,40,41,42]. In this group of tests, the linear regression analysis shows that there is a strong positive correlation between the compressive strength and the density of the FC test block, and the fitting degree is R2 = 0.999. The model is very well constructed; that is, under the same raw material composition, the same design mix ratio, the same preparation conditions, and the same production technology, the relationships between compressive strength and density of FC essentially correspond to each other. The linear regression equation and fitting degree are shown in Figure 7.

Figure 7.

Correlation curve of FC density and compressive strength.

4.3. Failure Mode of Foam Concrete Test Block

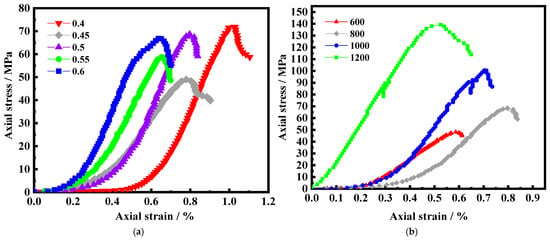

The axial stress–strain curve of FC during uniaxial compression can be classified into four distinct stages. In this test, the stress–strain curves of experimental groups with different W/C ratios (a) and different densities (b) are shown in Figure 8.

Figure 8.

Stress–strain curves of FC with different W/C ratios (a) and different densities (b).

- (1)

- Compaction stage: Under the action of small axial stress, there are slight deformations on the specimen surface and internal micropores. The axial stress of the test block increases gradually with the increase of the axial strain.

- (2)

- Elastic stage: Under the action of axial stress, the particle gap and the closed pore structure in FC show elastic deformation. It is shown that the stress increment of FC is proportional to the strain increment, and this proportion is named the elastic modulus of FC.

- (3)

- Yield stage: At this stage, the relative position of the particles changes and the closed pore structure is damaged, resulting in local stress concentration in the FC. This stage is characterized by a rapid increase in strain and a slow increase in stress. The slope of the curve gradually flattens until the maximum load is reached. The peak stress can be taken as the compressive strength of FC.

- (4)

- Failure stage: A very significant plastic compression deformation occurs after the specimen reaches the maximum axial stress. The axial stress is gradually reduced and stabilized. Due to the high compressibility of FC, it shows load retention during the failure stage. On a macro level, the surface of the FC sample is not broken, and the residual strength remains stable [30].

4.4. Rebound Value and UPV

Table 9 and Table 10 show the measured UPV and rebound values of FC specimens with different W/C ratios and different design densities under curing conditions for 7 d, 14 d, and 28 d.

Table 9.

The rebound value and UPV of FC with different W/C ratios at each stage.

Table 10.

Rebound value and UPV of FC with different densities at each stage.

Firstly, it can be seen that the measured UPV and rebound value of FC specimens increase with increases in curing time. This is due to the continuous generation of hydration under the effect of steaming, which gradually increases its internal solid components and plays a certain role in improving the compactness of the FC. The sound propagation speed in the solid is the largest, so the measured sound velocity of the FC specimen is constantly increasing. It is also due to the occurrence of hydration that the internal filling of FC increases and the porosity decreases, while its compressive strength and firmness are both improved, resulting in the resilience value also increasing.

In the lateral comparison of the experimental group shown in Table 9, it was found that when the curing time was fixed, the UPV of the FC specimen showed a general decreasing trend as the W/C ratio increased from 0.4 to 0.6. This is because the increase in W/C ratio indirectly reflects an increase in cement content, so the UPV would also increase in accordance with the above analysis. However, the rebound value, which represents the strength of FC, does not show a specific correlation with the W/C ratio. For the test results of 28 d, the W/C ratios, corresponding to the rebound value from large to small, are as follows: 0.5, 0.6, 0.55, 0.4, and 0.45. These results are basically consistent with the above-measured uniaxial compressive strength results, but when the W/C ratio is 0.4, the corresponding rebound value is lower than that when the W/C ratio is 0.55, which may be due to the large friction between the foam and the slurry and the low fluidity of the slurry, as well as the uneven filling of the slurry at the edge of the test block during pouring, resulting in the formation of large, connected holes. Therefore, the rebound value collected in this weak area is too small.

In the lateral comparison of the experimental group shown in Table 10, it can be seen that when the curing time is fixed, the UPV and rebound value of the FC specimen will increase with the increase in its design density. Cement is the only cementing material in the FC in this test, and hydration products are generated after the hydration reaction. Within a certain range, a greater cement content means that the number of cementing particles and hydration products inside the FC increases, and they both fill the gaps, reducing the porosity and increasing cohesion and internal friction, thus forming a solid structure. Therefore, the UPV and rebound value of the FC specimen will increase with increases in the design density.

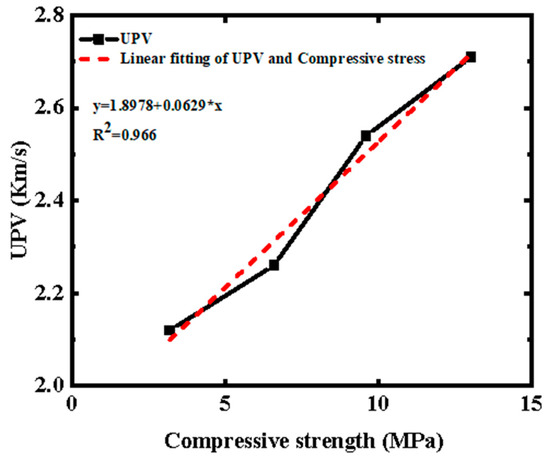

In this set of tests, linear regression analysis shows that when the W/C ratio of FC is constant and the density changes uniformly, there is a strong positive correlation between the compression stress of the FC test block and UPV [43], and the fitting degree is R2 = 0.966. The model is very well constructed; that is, under the same raw material composition, the same design mix ratio and the same preparation conditions and production technology, the relationships between compressive stress and UPV of FC are essentially equal. The linear regression equations and fitting degrees are shown in Figure 9. The linear regression analysis shows that when the density of FC is constant and the W/C ratio changes, the compressive stress of the FC test block has no correlation with UPV.

Figure 9.

Linear fitting of UPV and compressive stress.

4.5. Analysis of Water Absorption of FC

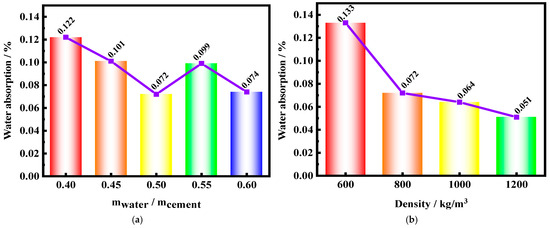

The results of the water absorption test explain the transport characteristics and motion of the fluid and gas in the FC sample. Table 11 and Figure 10 describe the results of the water absorption tests conducted on FC samples in the two sets of tests. This experiment was conducted after 28 d of curing of the FC.

Table 11.

The 28 d water absorption of FC with different W/C ratios and different densities.

Figure 10.

The 28 d water absorption curve of FC with different W/C ratios (a) and different densities (b).

The test results show that when the W/C ratio is kept constant and the design densities of experimental groups are 600 kg/m3, 800 kg/m3, 1000 kg/m3, and 1200 kg/m3, respectively, the 28 d water absorption of the FC test blocks decreases with the increase in density, and the decreasing rates are 45.9%, 11.1%, and 20.3%, in order. This is because the cement content in FC increases with the increase in design density. Through the hydration reaction occurring continuously during curing, cement particles and hydration compounds cement and solidify each other, so that the pores in the test block become independent and closed, and the density of FC increases [44]. The water absorption test is a process in which external water fills the pores and the tested block absorbs it. Because there are fewer pores in the dense test block, the ability of water to enter the test block is relatively low, which leads to a low water absorption rate. For FC with a density of 600 kg/m3, the water absorption rate is very high compared with the other three groups. The difference is as high as 45.9%, because the low-density FC has more internal pores—in addition to the pores formed by the foam—and the pore wall is relatively thin, which is caused by a large number of adjacent coalesced bubbles [45]. These pores provide more paths and greater volume, allowing water to penetrate and be absorbed into the test block more easily, resulting in a higher water absorption rate. For FC with a density of 1200 kg/m3, although the water absorption rate is the lowest, the cement content is much higher than that of other test groups. Considering the factors of cement usage, it can be seen that FC with a density of 1000 kg/m3 is more in line with the concept explored in this paper.

When the design density is controlled at 800 kg/m3 and the W/C ratios of FC are changed to 0.4, 0.45, 0.5, 0.55, or 0.6, it was found that when the W/C ratio was 0.4, the water absorption rate was the highest at 12.2%, and when the W/C ratio was 0.5, the water absorption rate was the lowest at 7.2%. The water absorption rates corresponding to the following W/C ratio were, in turn, 17.2%, 28.7%, 37.5%, and 25.2%, as shown in Figure 10a. It can be inferred that the smaller the W/C ratio, the higher the cement content in FC, and the final porosity of the test block should be reduced to reduce the water absorption rate. However, in this test, it was found that the water absorption rate was the highest when the W/C ratio was 0.4.

Through analysis, it was found that this is because when the W/C ratio is 0.4, the FC slurry has poor fluidity, which leads to compaction difficulties during the pouring vibration phase, and the internal pores and gaps caused by non-foam factors result in the water absorption rate of the test block being higher. The tests show that when the W/C ratio is 0.5, the water absorption rate of the test block is the lowest, which was assumed to be because the FC slurry has greater fluidity in this scenario (see Figure 10), and the ideal compaction effect could be achieved through manual vibration. Compared with the W/C ratio of 0.6, the cement content is higher when the W/C ratio is 0.5, and the remaining pores rate in the test block was lower after 28 days of curing. Under the action of the two dual factors, the water absorption rate was the lowest.

5. Conclusions

In order to further refine the study of the effects of density and the W/C ratio on the mobility, water absorption, and mechanical properties of FC, we designed two sets of tests based on the control variable method, referring to relevant norms. The conclusions are as follows:

- (1)

- Through mathematical analysis, it was found that the 28 d compressive strength of the FC test block has a very strong correlation with the density. The fitting curve is , and the fitting degree is R2 = 0.999;

- (2)

- It was found that when the W/C ratio is 0.5, the maximum UCS/C of FC is 0.0127, the relative change rate of compressive strength is 32.80%, and the cement utilization rate at this time is significantly improved compared with other W/C ratios;

- (3)

- It was found that when the W/C ratio is 0.5, the test block forms a large number of closed holes to minimize its water absorption, which greatly enhances the durability of the FC;

- (4)

- It was found that when the density decreased from 1200 kg/m3 to 1000 kg/m3, the cement usage of FC decreased by 20.73%, the fluidity increased by 10.19%, the water absorption increased by 25.49%, and the compressive strength decreased by 26.32%. However, the compressive strength of the FC test block at this time was 9.6 MPa, which met the application standards. Therefore, the optimal density, as obtained in this paper, is 1000 kg/m3;

- (5)

- The optimal W/C ratio, as determined by this experiment, is 0.5, and the optimal density is 1000 kg/m3.

The results of this experiment can be used as a reference for basic experimental research in the field of foamed concrete. Further experiments are needed to investigate the effects of density and W/C ratio on other types of concrete, as well as to determine whether the working performance of foam concrete will change in actual construction environments.

Author Contributions

Conceptualization, A.J. and H.L.; methodology, A.J.; software, H.L.; validation, C.W. and Y.C.; formal analysis, Y.C.; investigation, X.W.; resources, A.J.; data curation, H.L. and Y.C.; writing—original draft preparation, H.L.; writing—review and editing, A.J.; visualization, H.Y.; supervision, A.J.; project administration, A.J.; funding acquisition, A.J. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the National Natural Science Foundation of China (grant No. 52368051) and the Natural Science Foundation of Xinjiang Uygur Autonomous (grant No. 2022D01C685). The above-mentioned funders and their support are gratefully acknowledged.

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Valore, R.C. Cellular concretes Part 1 composition and methods of preparation. J. Proc. 1954, 50, 773–796. [Google Scholar]

- Jin, Y.; Wang, X.; Huang, W.; Li, X.; Ma, Q. Mechanical and durability properties of hybrid natural fibre reinforced roadbed foamed concrete. Constr. Build. Mater. 2023, 409, 134008. [Google Scholar] [CrossRef]

- Ramamurthy, K.; Nambiar, E.K.; Ranjani, G.I.S. A classification of studies on properties of foam concrete. Cem. Concr. Compos. 2009, 31, 388–396. [Google Scholar] [CrossRef]

- Raj, A.; Sathyan, D.; Mini, K. Physical and functional characteristics of foam concrete: A review. Constr. Build. Mater. 2019, 221, 787–799. [Google Scholar] [CrossRef]

- Ge, Z.; Yuan, H.; Sun, R.; Zhang, H.; Wang, W.; Qi, H. Use of green calcium sulphoaluminate cement to prepare foamed concrete for road embankment: A feasibility study. Constr. Build. Mater. 2020, 237, 117791. [Google Scholar] [CrossRef]

- Xu, L.; Duan, Y.; Li, Y. Porosity, gradient and impact velocity effects on compressive response of foamed concrete. Constr. Build. Mater. 2022, 315, 125616. [Google Scholar] [CrossRef]

- Shi, J.; Liu, B.; Liu, Y.; Wang, E.; He, Z.; Xu, H.; Ren, X. Preparation and characterization of lightweight aggregate foamed geopolymer concretes aerated using hydrogen peroxide. Constr. Build. Mater. 2020, 256, 119442. [Google Scholar] [CrossRef]

- Amran, Y.H.M.; Farzadnia, N.; Ali, A.A.A. Properties and applications of foamed concrete; a review. Constr. Build. Mater. 2015, 101, 990–1005. [Google Scholar] [CrossRef]

- Lezgy-Nazargah, M.; Vidal, P.; Polit, O. A 1D nonlinear finite element model for analysis of composite foam-insulated concrete sandwich panels. Compos. Struct. 2019, 210, 663–675. [Google Scholar] [CrossRef]

- Guo, Y.; Chen, X.; Chen, B.; Wen, R.; Wu, P. Analysis of foamed concrete pore structure of railway roadbed based on X-ray computed tomography. Constr. Build. Mater. 2021, 273, 121773. [Google Scholar] [CrossRef]

- Hashim, M.; Tantray, M. Comparative study on the performance of protein and synthetic-based foaming agents used in foamed concrete. Case Stud. Constr. Mater. 2021, 14, e00524. [Google Scholar] [CrossRef]

- Dhasindrakrishna, K.; Pasupathy, K.; Ramakrishnan, S.; Sanjayan, J. Progress, current thinking and challenges in geopolymer foam concrete technology. Cem. Concr. Compos. 2021, 116, 103886. [Google Scholar] [CrossRef]

- SatySatyanarayana, G.V.V.; Ranjith, A. Experimental Studies on Compressive Strength of Aerated Concrete with Varying Percentage of Aluminium Powder. In E3S Web of Conferences; EDP Sciences: Les Ulis, France, 2021; Volume 309, p. 01197. [Google Scholar]

- Jiang, L.; Wang, K.; Fang, H.; Chen, B.; Zhu, L.; Zhang, Q.; Zhang, X. Protection performance of a novel anti-collision guardrail with recycled foamed concrete under vehicle collision. Eng. Struct. 2024, 305, 117795. [Google Scholar] [CrossRef]

- Liu, K.W.; Yue, F.; Su, Q.; Zhou, C.; Xiong, Z.; He, Y. Assessment of the use of fiberglass-reinforced foam concrete in high-speed railway bridge approach involving foundation cost comparison. Adv. Struct. Eng. 2020, 23, 388–396. [Google Scholar] [CrossRef]

- Baghban, S.; Mo, K.H.; Ibrahim, Z.; Radwan, M.K.; Shah, S.N. Effect of basalt and polypropylene fibers on crumb rubber mortar with Portland cement and calcium aluminate cement binders: Strength and artificial neural network prediction model. Prog. Rubber Plast. Recycl. Technol. 2022, 38, 99–124. [Google Scholar] [CrossRef]

- Han, W.; Lee, J.S.; Jeong, S.H.; Lim, D.S.; Byun, Y.H. Evaluation of engineering properties of expandable foam grout with admixture content. Constr. Build. Mater. 2021, 293, 123488. [Google Scholar] [CrossRef]

- Huang, W.; Chen, X.; Feng, L.; Ji, T.; Ning, Y.; Wang, J. Experimental investigation of mechanical behavior and microstructural properties in roadbed foam concrete at different densities and correlation analysis. Case Stud. Constr. Mater. 2023, 19, e02565. [Google Scholar] [CrossRef]

- Zhang, H.; Qi, X.; Wan, L.; Zuo, Z.; Ge, Z.; Wu, J.; Song, X. Properties of silt-based foamed concrete: A type of material for use in backfill behind an abutment. Constr. Build. Mater. 2020, 261, 119966. [Google Scholar] [CrossRef]

- Cong, M.; Bing, C. Properties of a foamed concrete with soil as filler. Constr. Build. Mater. 2015, 76, 61–69. [Google Scholar] [CrossRef]

- Falliano, D.; De Domenico, D.; Ricciardi, G.; Gugliandolo, E. Experimental investigation on the compressive strength of foamed concrete: Effect of curing conditions, cement type, foaming agent and dry density. Constr. Build. Mater. 2018, 165, 735–749. [Google Scholar] [CrossRef]

- Guan, L.L.; Chen, Y.G.; Ye, W.M.; Wu, D.B.; Deng, Y.F. Foamed concrete utilizing excavated soil and fly ash for urban underground space backfilling: Physical properties, mechanical properties, and microstructure. Tunn. Undergr. Space Technol. 2023, 134, 104995. [Google Scholar] [CrossRef]

- Hoff, G.C. Porosity-strength considerations for cellular concrete. Cem. Concr. Res. 1972, 2, 91–100. [Google Scholar] [CrossRef]

- Kearsley, E.P.; Wainwright, P.J. Porosity and permeability of foamed concrete. Cem. Concr. Res. 2001, 31, 805–812. [Google Scholar] [CrossRef]

- Li, C.; Li, X.; Guan, D.; Li, S.; Lv, W.; Cong, Z.; Soloveva, V.Y.; Dalerjon, H.; Qin, P.; Liu, X. Study on influence factors of compressive strength of low density backfill foamed concrete used in natural gas pipeline tunnel. Sustainability 2022, 14, 8333. [Google Scholar] [CrossRef]

- Li, C.; Li, X.; Li, S.; Guan, D.; Xiao, C.; Xu, Y.; Soloveva, V.Y.; Dalerjon, H.; Qin, P.; Liu, X. Effect of Maintenance and Water–Cement Ratio on Foamed Concrete Shrinkage Cracking. Polymers 2022, 14, 2703. [Google Scholar] [CrossRef]

- Zhang, S.; Qi, X.; Guo, S.; Zhang, L.; Ren, J. A systematic research on foamed concrete: The effects of foam content, fly ash, slag, silica fume and water-to-binder ratio. Constr. Build Mater. 2022, 339, 127683. [Google Scholar] [CrossRef]

- Meera, M.; Gupta, S. Development of a strength model for foam concrete based on water–cement ratio. Mater. Today Proc. 2020, 32, 923–927. [Google Scholar] [CrossRef]

- Liu, X.; Huang, F.; Zheng, A. Investigation of foam concrete’s mechanical properties and multi-scale damage evolution characteristics under uniaxial loading. Constr. Build. Mater. 2024, 430, 136503. [Google Scholar] [CrossRef]

- JC/T2199-2013; Ministry of Industry and Information Technology of the People’s Republic of China. Foaming Agents for Foamed Concrete. China Construction Science And Technology Press: Beijing, China, 2013. (In Chinese)

- JG/T266-2011; Ministry of Housing and Urban-Rural Development of the People’s Republic of China. Foam Concrete. China Standards Press: Beijing, China, 2011. (In Chinese)

- JGJ/T23-2011; Ministry of Housing and Urban-Rural Development of the People’s Republic of China. Technical Specification for Inspecting of Concrete Compressive Strength by Rebound Method. China Construction Industry Press: Beijing, China, 2011. (In Chinese)

- T/CECS02-2020; China Engineering Construction Standardization Association. Technical Specification for Inspecting Compressive Strength of Concrete by Ultrasonic-Rebound Combined Method. China Planning Press: Beijing, China, 2020. (In Chinese)

- Zhang, X.; Yang, Q.; Shi, Y.; Zheng, G.; Li, Q.; Chen, H.; Cheng, X. Effects of different control methods on the mechanical and thermal properties of ultra-light foamed concrete. Constr. Build. Mater. 2020, 262, 120082. [Google Scholar] [CrossRef]

- JGJ/T341-2014; Ministry of Housing and Urban-Rural Development of the People’s Republic of China. Technical Specification for Application of Foamed Concrete. China Construction Industry Press: Beijing, China, 2014. (In Chinese)

- Nambiar, E.K.K.; Ramamurthy, K. Models relating mixture composition to the density and strength of foam concrete using response surface methodology. Cem. Concr. Compos. 2006, 28, 752–760. [Google Scholar] [CrossRef]

- Nambiar, E.K.K.; Ramamurthy, K. Influence of filler type on the properties of foam concrete. Cem. Concr. Compos. 2006, 28, 475–480. [Google Scholar] [CrossRef]

- Tan, X.; Chen, W.; Hao, Y.; Wang, X. Experimental study of ultralight (<300 kg/m3) foamed concrete. Adv. Mater. Sci. Eng. 2014, 2014, 514759. [Google Scholar]

- Bing, C.; Zhen, W.; Ning, L. Experimental research on properties of high-strength foamed concrete. J. Mater. Civ. Eng. 2012, 24, 113–118. [Google Scholar] [CrossRef]

- Chung, S.Y.; Abd Elrahman, M.; Kim, J.S.; Han, T.S.; Stephan, D.; Sikora, P. Comparison of lightweight aggregate and foamed concrete with the same density level using image-based characterizations. Constr. Build. Mater. 2019, 211, 988–999. [Google Scholar] [CrossRef]

- Abd Elrahman, M.; El Madawy, M.E.; Chung, S.Y.; Sikora, P.; Stephan, D. Preparation and characterization of ultra-lightweight foamed concrete incorporating lightweight aggregates. Appl. Sci. 2019, 9, 1447. [Google Scholar] [CrossRef]

- He, J.; Gao, Q.; Song, X.; Bu, X.; He, J. Effect of foaming agent on physical and mechanical properties of alkali-activated slag foamed concrete. Constr. Build. Mater. 2019, 226, 280–287. [Google Scholar] [CrossRef]

- Bensaber, A.; Boudaoud, Z.; Seghir, N.T.; Czarnecki, S.; Sadowski, Ł. The assessment of concrete subjected to compressive and flexural preloading using nondestructive testing methods, correlation between concrete strength and combined method (SonReb). Measurement 2023, 222, 113659. [Google Scholar] [CrossRef]

- Hao, Y.; Yang, G.; Liang, K. Development of fly ash and slag based high-strength alkali-activated foam concrete. Cem. Concr. Compos. 2022, 128, 104447. [Google Scholar] [CrossRef]

- Oren, O.H.; Gholampour, A.; Gencel, O.; Ozbakkaloglu, T. Physical and mechanical properties of foam concretes containing granulated blast furnace slag as fine aggregate. Constr. Build. Mater. 2020, 238, 117774. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).