Effects of Steel and Glass Fibers on the Compressive Behavior of Rubberized Concrete: An Experimental Study and Constitutive Modeling

Abstract

1. Introduction

- (1)

- The potential fiber synergy with the hybrid use of steel/glass fibers in rubberized concrete has not been explored, except for a previous companion study showing that this fiber combination positively impacted the fracture properties of rubberized concrete, enhancing its flexural strength, fracture toughness, and fracture energy to the maximum at a total fiber content of 0.8% and with the steel-to-glass fiber ratio set at 3:1 [50];

- (2)

- It remains uncertain how the hybrid use of steel/glass fibers affects the compressive performance of rubberized concrete, which is a fundamental property of the material;

- (3)

- Experimental data for constitutive modelling of such rubberized concrete are lacking.

2. Materials and Method

2.1. Raw Materials

2.2. Specimen Preparation

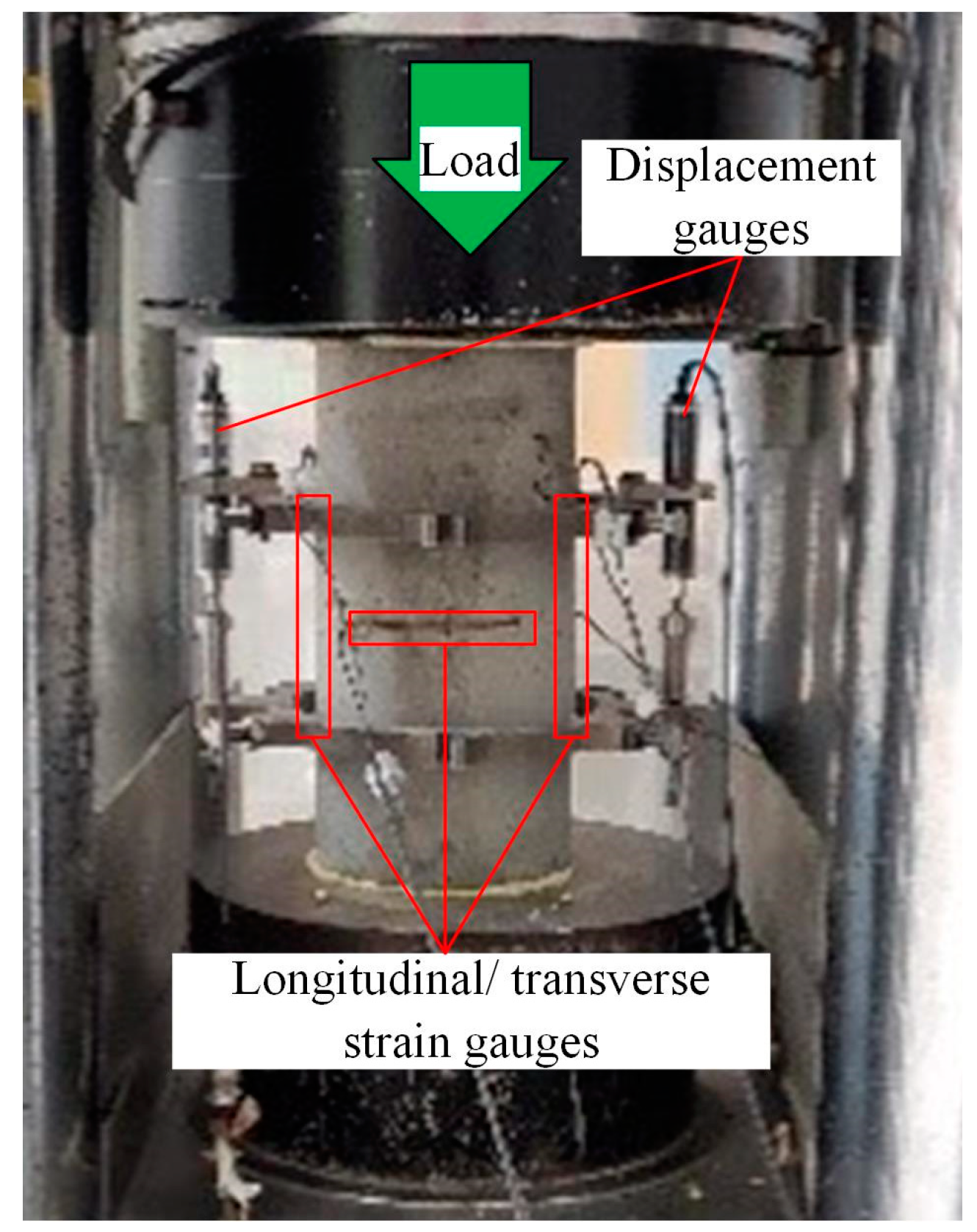

2.3. Methods

3. Results and Discussion

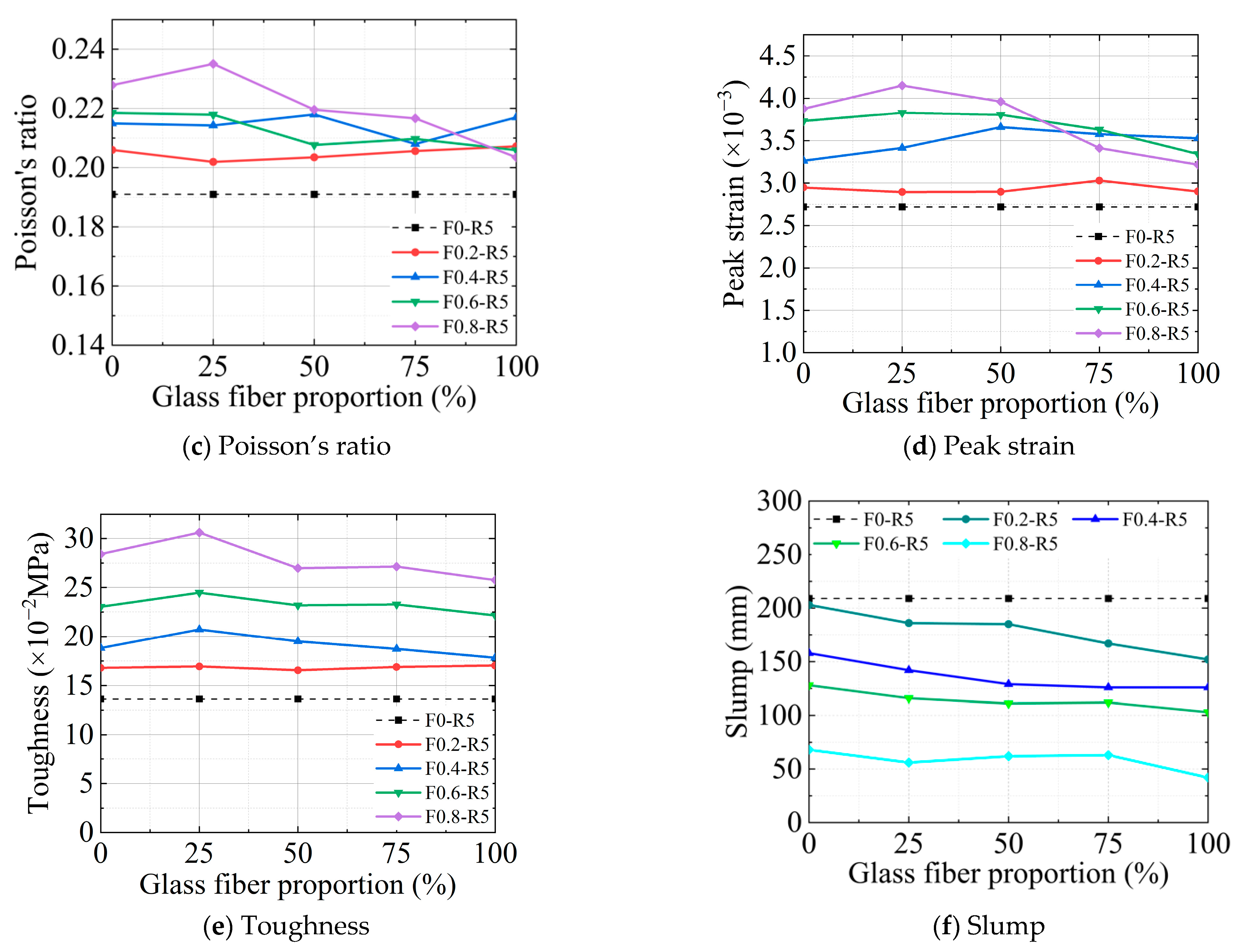

3.1. Slump Test Results

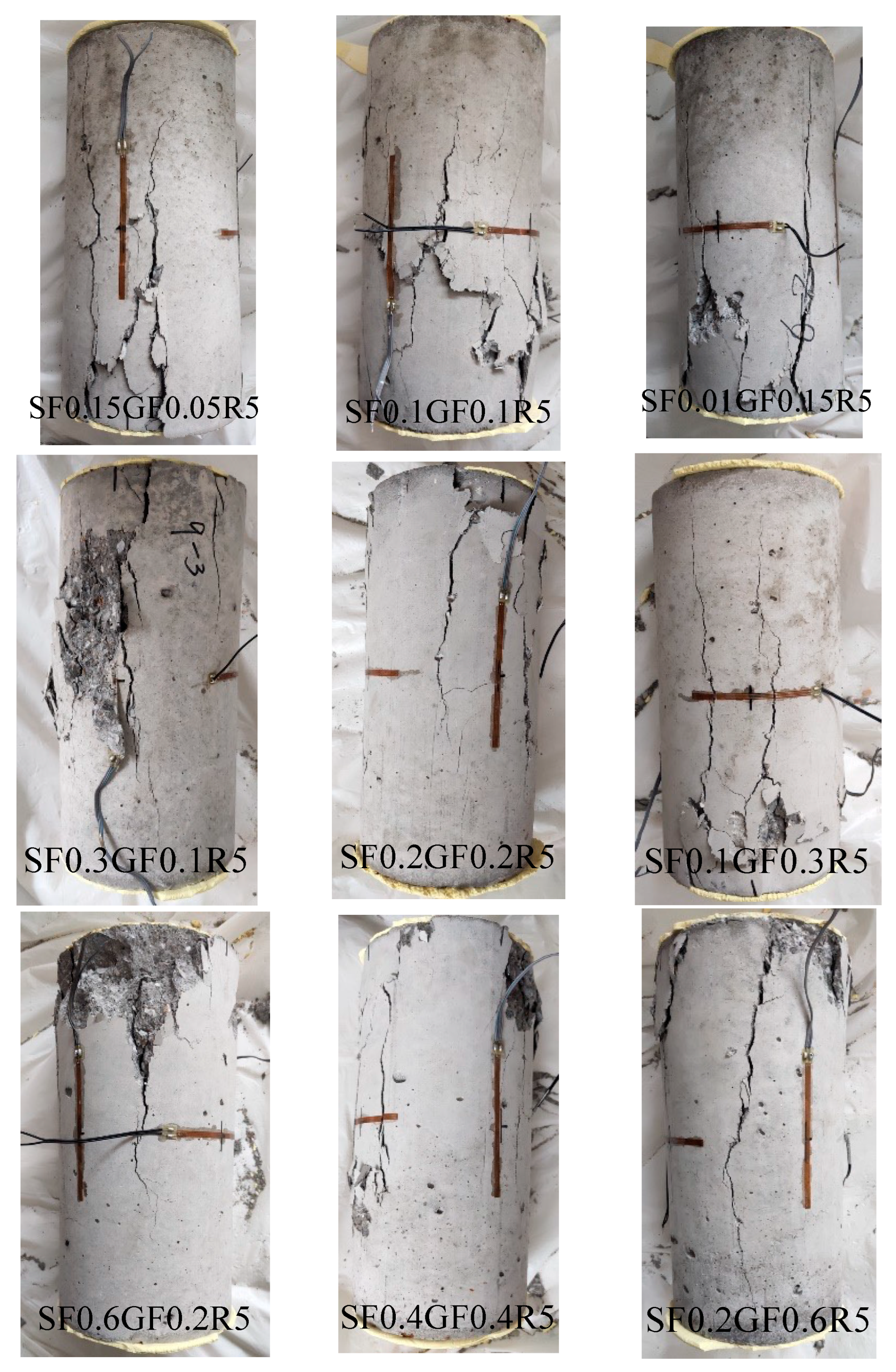

3.2. Failure Mode

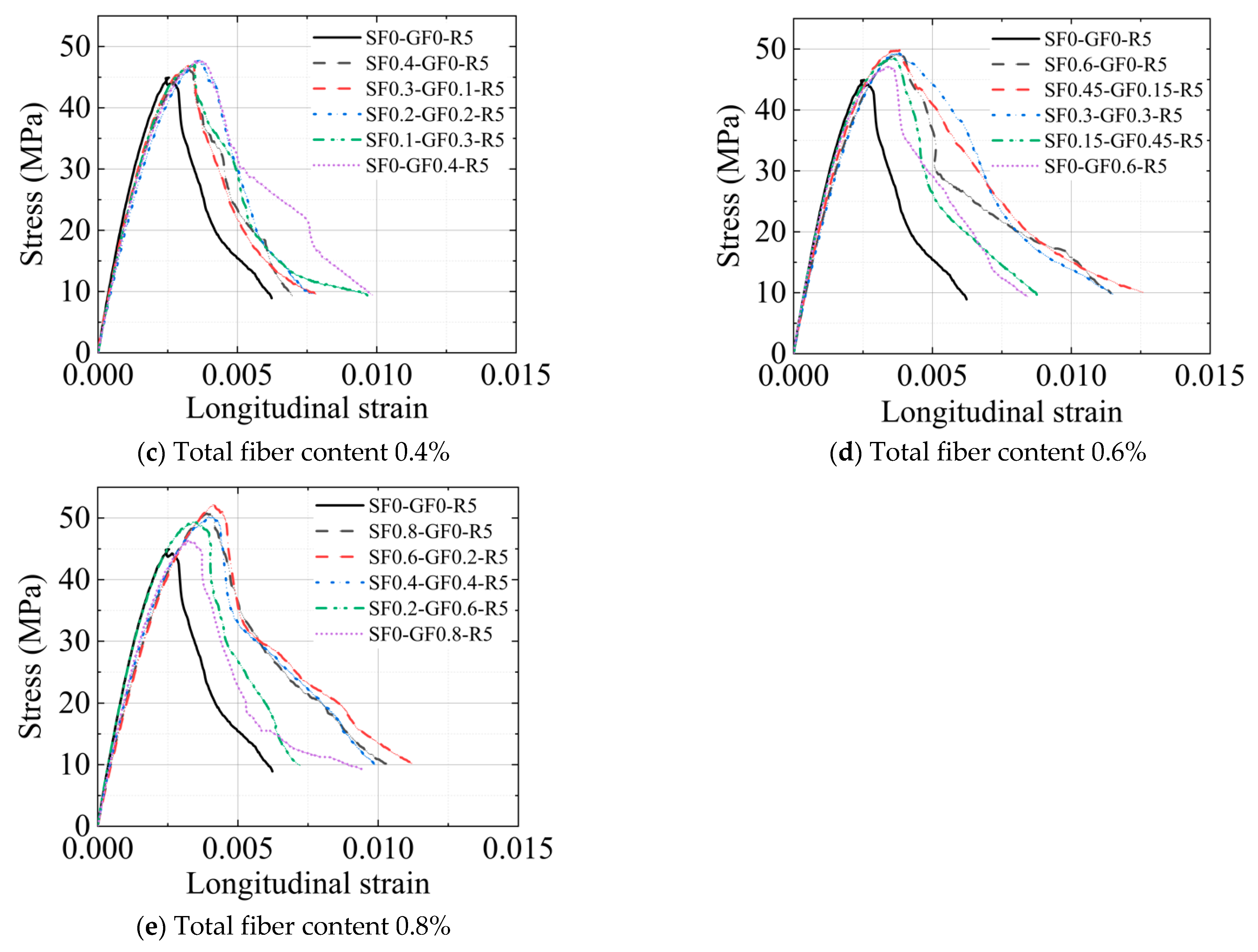

3.3. Compression Test Results

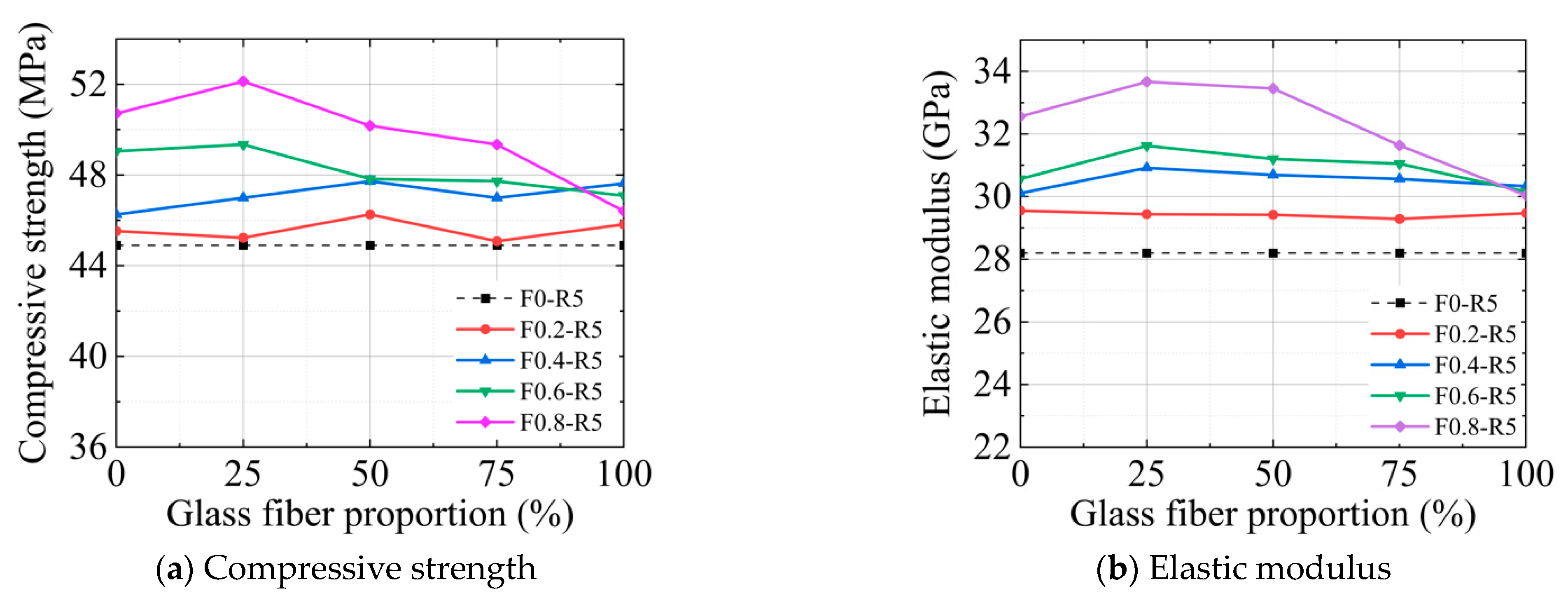

3.4. Compressive Strength

3.5. Elastic Modulus

3.6. Poisson’s Ratio

3.7. Peak Strain

3.8. Compressive Toughness

3.9. Discussion on the Effects of the Fibers on Compressive Performances

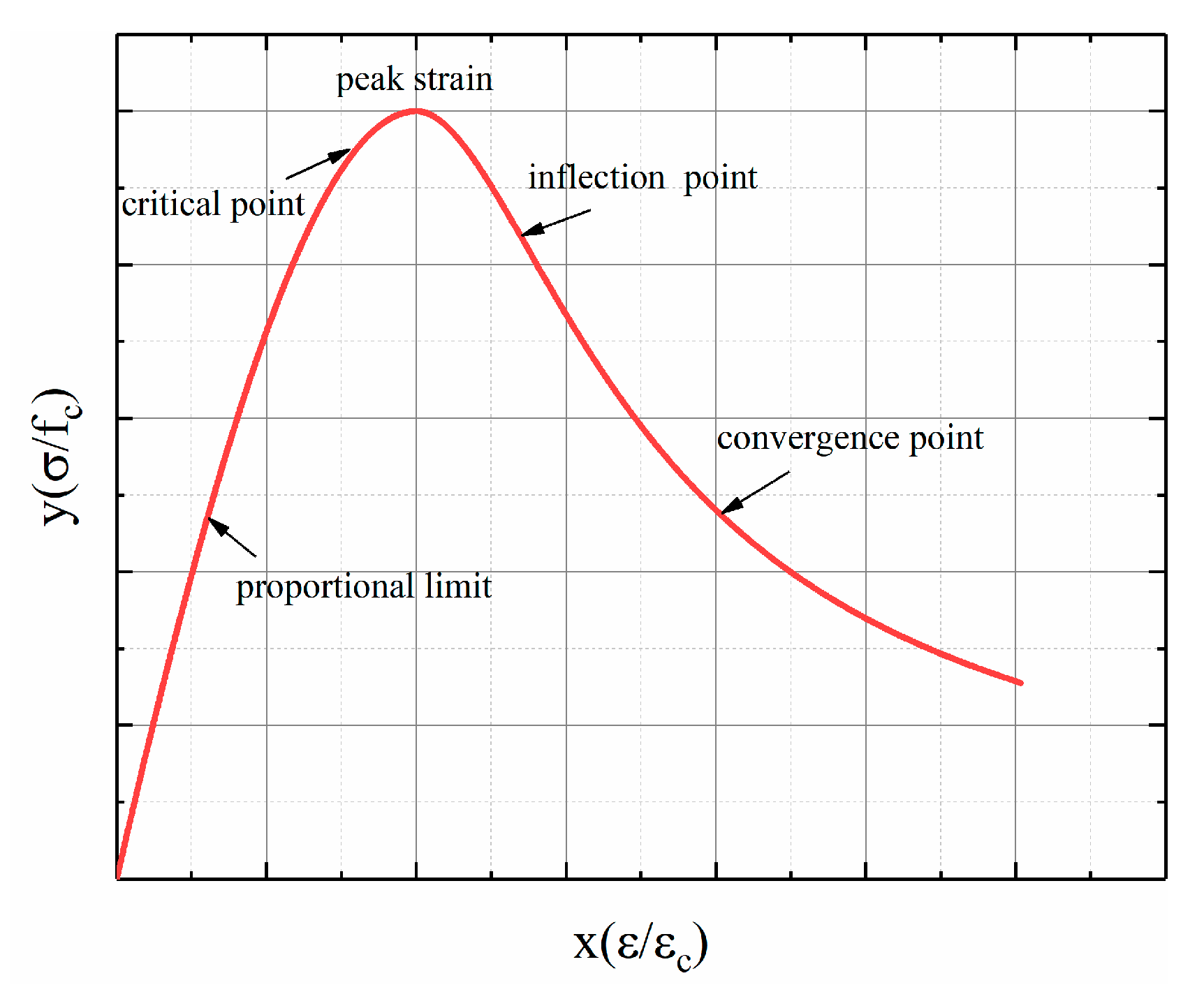

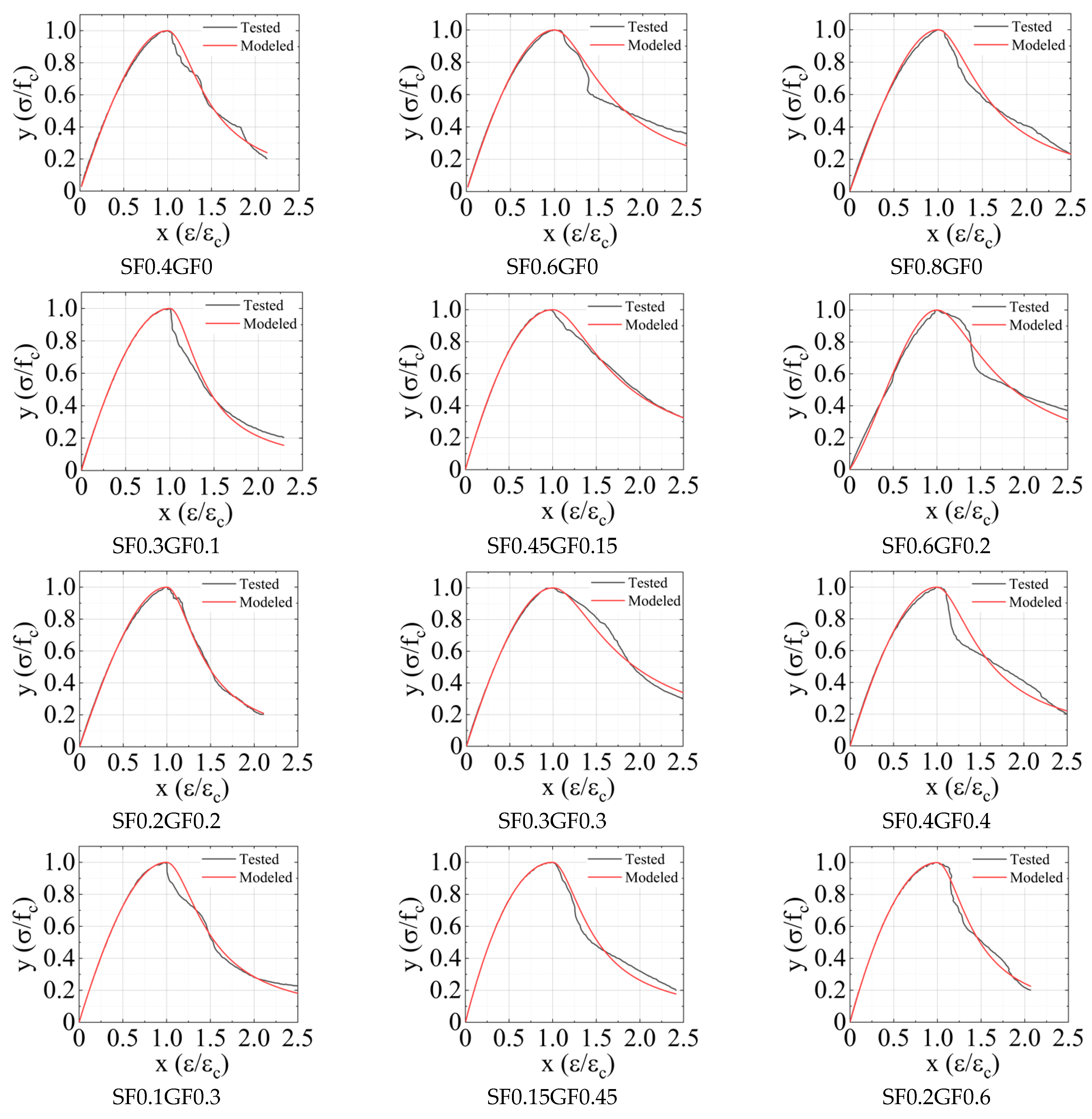

3.10. Stress–Strain Curve and Constitutive Model Simulation

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| GF | Glass fiber |

| PET | Polyethylene terephthalate |

| PP | polypropylene |

| R | Rubber particles |

| SF | Steel fiber |

| SP | Superplasticizer |

References

- Guo, Z.; Qiu, J.; Kirichek, A.; Zhou, H.; Liu, C.; Yang, L. Recycling waste tyre polymer for production of fibre reinforced cemented tailings backfill in green mining. Sci. Total Environ. 2024, 908, 168320. [Google Scholar] [CrossRef] [PubMed]

- Elchalakani, M. High strength rubberized concrete containing silica fume for the construction of sustainable road side barriers. Structures 2015, 20, 20–38. [Google Scholar] [CrossRef]

- Longvinenko, A. Use of rubber crumbs in cement concrete. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Tomsk, Russian Federation, 4–6 December 2017; IOP Publishing: Bristol, UK, 2018. [Google Scholar]

- Khelaifa, H.; Boudaoud, Z.; Benouis, A. Effect of adding rubber aggregates on the behaviour of compacted sand concrete. Innov. Infrastruct. Solut. 2021, 6, 143. [Google Scholar] [CrossRef]

- Wang, L.; Xie, X.G.; Fan, L.L. Study of Road Performance between Rub-concrete and Normal Concrete Materials. Advanced Engineering Forum. 2012, 5, 358–363. [Google Scholar] [CrossRef]

- Meng, X.; Yang, J.; Ding, N.; Lu, B. Identification of the potential environmental loads of waste tire treatment in China from the life cycle perspective. Resour. Conserv. Recycl. 2023, 193, 106938. [Google Scholar] [CrossRef]

- Hosseinzadehfard, E.; Mobaraki, B. Investigating concrete durability: The impact of natural pozzolan as a partial substitute for microsilica in concrete mixtures. Constr. Build. Mater. 2024, 419, 135491. [Google Scholar] [CrossRef]

- Fayed, S.; Aksoylu, C.; Ecemiş, A.S.; Madenci, E.; Özkılıç, Y.O. Tensile Behavior of Green Concrete Made of Fine/Coarse Recycled Glass and Recycled Concrete Aggregates. Buildings 2024, 14, 2969. [Google Scholar] [CrossRef]

- Fu, X.; Chung, D.D.L. Vibration damping admixtures for cement. Cem. Concr. Res. 1996, 26, 69–75. [Google Scholar] [CrossRef]

- Li, H.B.; Wang, B.; Zou, Y.Y. Experimental Study on Force-Bearing Performance of Road Concrete which Modified by Fiber and Rubber Powder. Appl. Mech. Mater. 2012, 204, 4015–4021. [Google Scholar] [CrossRef]

- Eltayeb, E.; Ma, X.; Zhuge, Y.; Xiao, J.; Youssf, O. Dynamic performance of rubberised concrete and its structural applications–An overview. Eng. Struct. 2021, 234, 111990. [Google Scholar] [CrossRef]

- Liu, H.; Wang, X.; Jiao, Y.; Sha, T. Experimental investigation of the mechanical and durability properties of crumb rubber concrete. Materials 2016, 9, 172. [Google Scholar] [CrossRef] [PubMed]

- Suchat, S.; Aditapsatit, P. On the Performance of Hybrid Natural Rubber Rubberized Concrete. Adv. Mater. Res. 2014, 844, 186–189. [Google Scholar] [CrossRef]

- Zhang, H.B. Influence of Rubber Crumb Addition to Portland Cement Concrete. Adv. Mater. Res. 2012, 391, 600–605. [Google Scholar] [CrossRef]

- Youssf, O.; Mills, J.E.; Benn, T.; Zhuge, Y.; Ma, X.; Roychand, R.; Gravina, R. Development of crumb rubber concrete for practical application in the residential construction sector–design and processing. Constr. Build. Mater. 2020, 260, 119813. [Google Scholar] [CrossRef]

- Ahmed, S.; Elshazli, M.T.; Zaghlal, M.; Alashker, Y.; Abdo, A. Improving Shear Behavior of Rubberized Concrete Beams through Sustainable Integration of Waste Tire Steel Fibers and Treated Rubber. J. Build. Eng. 2024, 96, 110649. [Google Scholar] [CrossRef]

- Hassanean, M.A.M.; Hussein, S.A.M.; Elsayed, M. Shear behavior of reinforced concrete beams comprising a combination of crumb rubber and rice husk ash. Eng. Struct. 2024, 319, 118862. [Google Scholar] [CrossRef]

- Chen, L.; Chen, X.; Liu, Z.; Lu, K.; Liu, J.; Wang, Z. Mechanical properties of macro-synthetic fiber reinforced rubber concrete under uniaxial loading. Constr. Build. Mater. 2024, 445, 137821. [Google Scholar] [CrossRef]

- Cao, Y.; Liu, Y.; Li, X.; Wu, Y. Axial stress strain behavior of FRP-confined rectangular rubber concrete columns with different aspect ratio. Eng. Struct. 2023, 297, 116987. [Google Scholar] [CrossRef]

- Khan, I.; Shahzada, K.; Bibi, T.; Ahmed, A.; Ullah, H. Seismic performance evaluation of crumb rubber concrete frame structure using shake table test. Structures 2021, 30, 41–49. [Google Scholar] [CrossRef]

- Alshaikh, I.M.H.; Bakar, B.H.A.; Alwesabi, E.A.H.; Zeyad, A.M.; Magbool, H.M. Finite element analysis and experimental validation of progressive collapse of reinforced rubberized concrete frame. Structures 2021, 33, 2361–2373. [Google Scholar] [CrossRef]

- Merwad, A.M.; El-Sisi, A.A.; Mustafa, S.A.A.; Sallam, H.E.-D.M. Lateral impact response of rubberized-fibrous concrete-filled steel tubular columns: Experiment and numerical study. Buildings 2022, 12, 1566. [Google Scholar] [CrossRef]

- Liu, B.; Zhang, L.; Feng, M.; Sun, H.; Chai, Y. Experimental study of rubber-concrete-filled CST composite column under axial compression. Int. J. Steel Struct. 2023, 23, 247–262. [Google Scholar] [CrossRef]

- Ganjian, E.; Khorami, M.; Maghsoudi, A.A. Scrap-tyre-rubber replacement for aggregate and filler in concrete. Constr. Build. Mater. 2009, 23, 1828–1836. [Google Scholar] [CrossRef]

- Mohammed, B.S.; Awang, A.B.; San Wong, S.; Nhavene, C.P. Properties of nano silica modified rubbercrete. J. Clean. Prod. 2016, 119, 66–75. [Google Scholar] [CrossRef]

- He, L.; Ma, Y.; Liu, Q.; Mu, Y. Surface modification of crumb rubber and its influence on the mechanical properties of rubber-cement concrete. Constr. Build. Mater. 2016, 120, 403–407. [Google Scholar] [CrossRef]

- Wongthong, P.; Nakason, C.; Pan, Q.; Rempel, G.L.; Kiatkamjornwong, S. Modification of deproteinized natural rubber via grafting polymerization with maleic anhydride. Eur. Polym. J. 2013, 49, 4035–4046. [Google Scholar] [CrossRef]

- Gupta, T.; Chaudhary, S.; Sharma, R.K. Assessment of mechanical and durability properties of concrete containing waste rubber tire as fine aggregate. Constr. Build. Mater. 2014, 73, 562–574. [Google Scholar] [CrossRef]

- He, L.; Cai, H.; Huang, Y.; Ma, Y.; Van Den Bergh, W.; Gaspar, L.; Valentin, J.; Vasiliev, Y.E.; Kowalski, K.J.; Zhang, J. Research on the properties of rubber concrete containing surface-modified rubber powders. J. Build. Eng. 2021, 35, 101991. [Google Scholar] [CrossRef]

- Liang, J.; Zhu, H.; Chen, L.; Han, X.; Guo, Q.; Gao, Y.; Liu, C. Rebar corrosion investigation in rubber aggregate concrete via the chloride electro-accelerated test. Materials 2019, 12, 862. [Google Scholar] [CrossRef]

- Pan, Z.; Liu, F.; Li, H.; Li, X.; Wang, D.; Ling, Z.; Zhu, H.; Zhu, Y. Performance evaluation of thermal insulation rubberized mortar modified by fly ash and glass fiber. Buildings 2024, 14, 221. [Google Scholar] [CrossRef]

- Zhen, H.; Xiong, Z.; Song, Y.; Li, L.; Qiu, Y.; Zou, X.; Chen, B.; Chen, D.; Liu, F.; Ji, Y. Early mechanical performance of glass fibre-reinforced manufactured sand concrete. J. Build. Eng. 2024, 83, 108440. [Google Scholar] [CrossRef]

- Li, H.; Liu, F.; Pan, Z.; Li, H.; Wu, Z.; Li, L.; Xiong, Z. Use of supplementary cementitious materials in seawater–sea sand concrete: State-of-the-art review. Constr. Build. Mater. 2024, 425, 136009. [Google Scholar] [CrossRef]

- Wang, J.; Dai, Q.; Si, R.; Guo, S. Mechanical, durability, and microstructural properties of macro synthetic polypropylene (PP) fiber-reinforced rubber concrete. J. Clean. Prod. 2019, 234, 1351–1364. [Google Scholar] [CrossRef]

- Zhu, H.; Xiong, Z.; Song, Y.; Zhou, K.; Su, Y. Effect of expansion agent and glass fiber on the dynamic splitting tensile properties of seawater–sea-sand concrete. Buildings 2024, 14, 217. [Google Scholar] [CrossRef]

- Alsaif, A.; Garcia, R.; Figueiredo, F.P.; Neocleous, K.; Christofe, A.; Guadagnini, M.; Pilakoutas, K. Fatigue performance of flexible steel fibre reinforced rubberised concrete pavements. Eng. Struct. 2019, 193, 170–183. [Google Scholar] [CrossRef]

- Alwesabi, E.A.H.; Bakar, B.H.A.; Alshaikh, I.M.H.; Zeyad, A.M.; Altheeb, A.; Alghamdi, H. Experimental investigation on fracture characteristics of plain and rubberized concrete containing hybrid steel-polypropylene fiber. Structures 2021, 33, 4421–4432. [Google Scholar] [CrossRef]

- Alwesabi, E.A.H.; Bakar, B.H.A.; Alshaikh, I.M.H.; Akil, H.M. Experimental investigation on mechanical properties of plain and rubberised concretes with steel–polypropylene hybrid fibre. Constr. Build. Mater. 2020, 233, 117194. [Google Scholar] [CrossRef]

- Alwesabi, E.A.; Bakar, B.H.A.; Alshaikh, I.M.H.; Akil, H.M. Impact resistance of plain and rubberized concrete containing steel and polypropylene hybrid fiber. Mater. Today Commun. 2020, 25, 101640. [Google Scholar] [CrossRef]

- Khan, M.; Cao, M.; Xie, C.; Ali, M. Effectiveness of hybrid steel-basalt fiber reinforced concrete under compression. Case Stud. Constr. Mater. 2022, 16, e00941. [Google Scholar] [CrossRef]

- Su, Q.; Xu, J.-M.; Wang, Y.-D. Mechanical properties of hybrid fiber reinforced rubber concrete. Materials 2021, 14, 6028. [Google Scholar] [CrossRef]

- Huang, J.K.; Jiang, P.W.; Qian, Y.D.; Cheng, P.; Lou, R.; Luo, X. Research on mechanical property and impact performance of composite rubber hybrid fiber concrete. Arab. J. Sci. Eng. 2023, 48, 4339–4355. [Google Scholar] [CrossRef]

- Qadir, I.M.A.; Noaman, A.T. Effect of combination between hybrid fibers and rubber aggregate on rheological and mechanical properties of self-compacting concrete. Constr. Build. Mater. 2024, 414, 135038. [Google Scholar] [CrossRef]

- Yuan, Z.; Jia, Y. Mechanical properties and microstructure of glass fiber and polypropylene fiber reinforced concrete: An experimental study. Constr. Build. Mater. 2021, 266, 121048. [Google Scholar] [CrossRef]

- Kizilkanat, A.B.; Kabay, N.; Akyüncü, V.; Chowdhury, S.; Akça, A.H. Mechanical properties and fracture behavior of basalt and glass fiber reinforced concrete: An experimental study. Constr. Build. Mater. 2015, 100, 218–224. [Google Scholar] [CrossRef]

- Ahmad, J.; González-Lezcano, R.A.; Majdi, A.; Ben Kahla, N.; Deifalla, A.F.; El-Shorbagy, M.A. Glass fibers reinforced concrete: Overview on mechanical, durability and microstructure analysis. Materials 2022, 15, 5111. [Google Scholar] [CrossRef] [PubMed]

- Blazy, J.; Blazy, R. Polypropylene fiber reinforced concrete and its application in creating architectural forms of public spaces. Case Stud. Constr. Mater. 2021, 14, e00549. [Google Scholar] [CrossRef]

- Rodrigues, A.; Figueiredo, L.; Diogo, H.; Bordado, J. Mechanical behavior of PET fibers and textiles for Stent-Grafts using video extensometry and image analysis. Sci. Technol. Mater. 2018, 30, 23–33. [Google Scholar] [CrossRef]

- Wu, H.; Qin, X.; Huang, X.; Kaewunruen, S. Engineering, mechanical and dynamic properties of basalt fiber reinforced concrete. Materials 2023, 16, 623. [Google Scholar] [CrossRef]

- Xiong, Z.; Li, H.; Pan, Z.; Li, X.; Lu, L.; He, M.; Li, H.; Liu, F.; Feng, P.; Li, L. Fracture properties and mechanisms of steel fiber and glass fiber reinforced rubberized concrete. J. Build. Eng. 2024, 86, 108866. [Google Scholar] [CrossRef]

- Li, X.; Pan, Z.; Zhen, H.; Luo, W.; Chen, Z.; Li, H.; Wu, Z.; Liu, F.; Li, L. Combined Effects of Steel and Glass Fibres on the Fracture Performance of Recycled Rubber Concrete. Buildings 2024, 14, 864. [Google Scholar] [CrossRef]

- GB/T 50080-2016; Standard for Test Method of Performance on Ordinary Fresh Concrete. Ministry of Housing and Urban-Rural Development: Beijing, China, 2016.

- C469/C469M-22; A Standard Test Method for Static Modulus of Elasticity and Poisson’s Ratio of Concrete in Compression. ASTM International: West Conshohocken, PA, USA, 2022.

- Guo, Z. Strength and Stress-Strain Model of Concrete: Theory and Applications; China Architecture and Building Press: Beijing, China, 2004. [Google Scholar]

- Ouyang, X.; Wu, Z.; Shan, B.; Chen, Q.; Shi, C. A critical review on compressive behavior and empirical constitutive models of concrete. Constr. Build. Mater. 2022, 323, 126572. [Google Scholar] [CrossRef]

- Richardson, A.; Coventry, K.; Edmondson, V.; Dias, E. Crumb rubber used in concrete to provide freeze–thaw protection (optimal particle size). J. Clean. Prod. 2016, 112, 599–606. [Google Scholar] [CrossRef]

- Liu, W.; Zhu, Y.; Qian, C.; Dai, H.; Fu, Y.; Dong, Y. Interfacial modification between glass fiber and polypropylene using a novel waterborne amphiphilic sizing agent. Compos. Part B Eng. 2022, 241, 110029. [Google Scholar] [CrossRef]

- Belyadi, H.; Fathi, E.; Belyadi, F. Hydraulic Fracturing in Unconventional Reservoirs: Theories, Operations, and Economic Analysis; Gulf Professional Publishing: Oxford, UK, 2019. [Google Scholar]

- Paktiawal, A.; Alam, M. Alkali-resistant glass fiber high strength concrete and its durability parameters. Mater. Today Proc. 2021, 47, 4758–4766. [Google Scholar] [CrossRef]

- Bengar, H.A.; Shahmansouri, A.A.; Sabet, N.A.Z.; Kabirifar, K.; Tam, V.W.Y. Impact of elevated temperatures on the structural performance of recycled rubber concrete: Experimental and mathematical modeling. Constr. Build. Mater. 2020, 255, 119374. [Google Scholar] [CrossRef]

- Nematzadeh, M.; Shahmansouri, A.A.; Zabihi, R. Innovative models for predicting post-fire bond behavior of steel rebar embedded in steel fiber reinforced rubberized concrete using soft computing methods. Structures 2021, 31, 1141–1162. [Google Scholar] [CrossRef]

- Bengar, H.A.; Shahmansouri, A.A. Post-fire behavior of unconfined and steel tube confined rubberized concrete under axial compression. Structures 2021, 32, 731–745. [Google Scholar] [CrossRef]

- Mousavimehr, M.; Nematzadeh, M. Predicting post-fire behavior of crumb rubber aggregate concrete. Constr. Build. Mater. 2019, 229, 116834. [Google Scholar] [CrossRef]

- Nematzadeh, M.; Karimi, A.; Fallah-Valukolaee, S. Compressive performance of steel fiber-reinforced rubberized concrete core detached from heated CFST. Constr. Build. Mater. 2020, 239, 117832. [Google Scholar] [CrossRef]

- Mousavimehr, M.; Nematzadeh, M. Post-heating flexural behavior and durability of hybrid PET–Rubber aggregate concrete. Constr. Build. Mater. 2020, 265, 120359. [Google Scholar] [CrossRef]

- Nematzadeh, M.; Mousavimehr, M. Residual compressive stress–strain relationship for hybrid recycled PET–crumb rubber aggregate concrete after exposure to elevated temperatures. J. Mater. Civ. Eng. 2019, 31, 04019136. [Google Scholar] [CrossRef]

| Mix Name | Cement | SP | Water | SF | GF | R | Sand | Gravel |

|---|---|---|---|---|---|---|---|---|

| SF0GF0R0 | 560.0 | 2.8 | 220.2 | 0.00 (0%) | 0.00 (0%) | 0.00 (0%) | 791.9 | 844.73 |

| SF0GF0R5 | 560.0 | 2.8 | 220.2 | 0.00 (0%) | 0.00 (0%) | 14.82 (5%) | 752.3 | 844.73 |

| SF0.2GF0R5 | 560.0 | 2.8 | 220.2 | 14.87 (0.2%) | 0.00 (0%) | 14.77 (5%) | 749.8 | 841.92 |

| SF0.15GF0.05R5 | 560.0 | 2.8 | 220.2 | 11.15 (0.15%) | 1.34 (0.05%) | 14.77 (5%) | 749.8 | 841.92 |

| SF0.1GF0.1R5 | 560.0 | 2.8 | 220.2 | 7.44 (0.1%) | 2.68 (0.1%) | 14.77 (5%) | 749.8 | 841.92 |

| SF0.05GF0.15R5 | 560.0 | 2.8 | 220.2 | 3.72 (0.05%) | 4.02 (0.15%) | 14.77 (5%) | 749.8 | 841.92 |

| SF0GF0.2R5 | 560.0 | 2.8 | 220.2 | 0.00 (0%) | 5.36 (0.2%) | 14.77 (5%) | 749.8 | 841.92 |

| SF0.4GF0R5 | 560.0 | 2.8 | 220.2 | 29.74 (0.4%) | 0.00 (0%) | 14.72 (5%) | 747.3 | 839.10 |

| SF0.3GF0.1R5 | 560.0 | 2.8 | 220.2 | 22.31 (0.3%) | 2.68 (0.1%) | 14.72 (5%) | 747.3 | 839.10 |

| SF0.2GF0.2R5 | 560.0 | 2.8 | 220.2 | 14.87 (0.2%) | 5.36 (0.2%) | 14.72 (5%) | 747.3 | 839.10 |

| SF0.1GF0.3R5 | 560.0 | 2.8 | 220.2 | 7.44 (0.1%) | 8.04 (0.3%) | 14.72 (5%) | 747.3 | 839.10 |

| SF0GF0.4R5 | 560.0 | 2.8 | 220.2 | 0.00 (0%) | 10.7 (0.4%) | 14.72 (5%) | 747.3 | 839.10 |

| SF0.6GF0R5 | 560.0 | 2.8 | 220.2 | 44.62 (0.6%) | 0.00 (0%) | 14.67 (5%) | 744.8 | 836.28 |

| SF0.45GF0.15R5 | 560.0 | 2.8 | 220.2 | 33.46 (0.45%) | 4.02 (0.15%) | 14.67 (5%) | 744.8 | 836.28 |

| SF0.3GF0.3R5 | 560.0 | 2.8 | 220.2 | 22.31 (0.3%) | 8.04 (0.3%) | 14.67 (5%) | 744.8 | 836.28 |

| SF0.15GF0.45R5 | 560.0 | 2.8 | 220.2 | 11.15 (0.15%) | 12.1 (0.45%) | 14.67 (5%) | 744.8 | 836.28 |

| SF0GF0.6R5 | 560.0 | 2.8 | 220.2 | 0.00 (0%) | 16.1 (0.6%) | 14.67 (5%) | 744.8 | 836.28 |

| SF0.8GF0R5 | 560.0 | 2.8 | 220.2 | 59.49 (0.8%) | 0.00 (0%) | 14.62 (5%) | 742.3 | 833.47 |

| SF0.6GF0.2R5 | 560.0 | 2.8 | 220.2 | 44.62 (0.6%) | 5.36 (0.2%) | 14.62 (5%) | 742.3 | 833.47 |

| SF0.4GF0.4R5 | 560.0 | 2.8 | 220.2 | 29.74 (0.4%) | 10.7 (0.4%) | 14.62 (5%) | 742.3 | 833.47 |

| SF0.2GF0.6R5 | 560.0 | 2.8 | 220.2 | 14.87 (0.2%) | 16.1 (0.6%) | 14.62 (5%) | 742.3 | 833.47 |

| SF0 GF0.8R5 | 560.0 | 2.8 | 220.2 | 0.00 (0%) | 21.4 (0.8%) | 14.62 (5%) | 742.3 | 833.47 |

| Mix Name | Compressive Strength (MPa) | Elastic Modulus (GPa) | Poisson’s Ratio | Peak Strain (×10−3) | Toughness (×10−2 MPa) |

|---|---|---|---|---|---|

| SF0GF0R0 | 47.3 | 29.0 | 0.191 | 2.72 | 13.6 |

| SF0GF0R5 | 44.9 (0.0%) | 28.2 (0.0%) | 0.178 (0.0%) | 2.54 (0.0%) | 15.2 (0.0%) |

| SF0.2GF0R5 | 45.5 (1.3%) | 29.6 (4.8%) | 0.206 (15.7%) | 2.95 (16.1%) | 16.8 (10.6%) |

| SF0.15GF0.05R5 | 45.2 (0.7%) | 29.4 (4.4%) | 0.202 (13.5%) | 2.89 (13.8%) | 16.9 (11.6%) |

| SF0.1GF0.1R5 | 45.9 (2.2%) | 29.4 (4.4%) | 0.203 (14.0%) | 2.90 (14.2%) | 16.6 (9.0%) |

| SF0.05GF0.15R5 | 45.1 (0.4%) | 29.3 (3.9%) | 0.206 (15.7%) | 3.03 (19.3%) | 16.9 (11.2%) |

| SF0GF0.2R5 | 45.8 (2.0%) | 29.5 (4.5%) | 0.207 (16.3%) | 2.90 (14.2%) | 17.0 (12.2%) |

| SF0.4GF0R5 | 46.3 (3.1%) | 30.1 (6.8%) | 0.215 (20.8%) | 3.27 (28.7%) | 18.8 (23.9%) |

| SF0.3GF0.1R5 | 47.0 (4.7%) | 30.9 (9.7%) | 0.214 (20.2%) | 3.42 (34.6%) | 20.7 (36.4%) |

| SF0.2GF0.2R5 | 47.7 (6.3%) | 30.7 (8.9%) | 0.218 (22.5%) | 3.66 (44.1%) | 19.5 (28.5%) |

| SF0.1GF0.3R5 | 47.0 (4.7%) | 30.6 (8.4%) | 0.208 (16.9%) | 3.58 (40.9%) | 18.7 (23.4%) |

| SF0GF0.4R5 | 47.6 (6.1%) | 30.3 (7.6%) | 0.217 (21.9%) | 3.53 (39.0%) | 17.8 (17.5%) |

| SF0.6GF0R5 | 49.1 (9.2%) | 30.6 (8.4%) | 0.218 (22.5%) | 3.73 (46.9%) | 23.0 (51.7%) |

| SF0.45GF0.15R5 | 49.8 (11.0%) | 31.6 (12.2%) | 0.218 (22.5%) | 3.83 (50.8%) | 24.5 (61.1%) |

| SF0.3GF0.3R5 | 49.3 (9.7%) | 31.2 (10.7%) | 0.208 (16.9%) | 3.81 (50.0%) | 23.2 (52.6%) |

| SF0.15GF0.45R5 | 48.4 (7.9%) | 31.1 (10.1%) | 0.210 (18.0%) | 3.63 (42.9%) | 23.3 (53.4%) |

| SF0GF0.6R5 | 47.1 (4.9%) | 30.2 (7.0%) | 0.206 (15.7%) | 3.34 (31.5%) | 22.2 (45.9%) |

| SF0.8GF0R5 | 50.7 (12.9%) | 32.6 (15.5%) | 0.223 (25.3%) | 3.88 (52.8%) | 28.4 (87.2%) |

| SF0.6GF0.2R5 | 52.1 (16.1%) | 33.7 (19.4%) | 0.235 (32.0%) | 4.15 (63.4%) | 30.6 (101.7%) |

| SF0.4GF0.4R5 | 50.2 (11.7%) | 33.5 (18.7%) | 0.220 (23.6%) | 3.96 (55.9%) | 27.0 (77.9%) |

| SF0.2GF0.6R5 | 49.3 (9.9%) | 31.6 (12.2%) | 0.217 (21.9%) | 3.41 (34.3%) | 27.2 (78.9%) |

| SF0GF0.8R5 | 46.4 (3.4%) | 30.0 (6.6%) | 0.204 (14.6%) | 3.22 (26.8%) | 25.8 (69.8%) |

| Group | Abbreviation | A | B |

|---|---|---|---|

| GF-0% | SF0.4GF0 | 1.667 | 5.270 |

| SF0.6GF0 | 1.717 | 2.814 | |

| SF0.8GF0 | 1.526 | 3.681 | |

| GF-25% | SF0.3GF0.1 | 1.836 | 7.483 |

| SF0.45GF0.15 | 1.930 | 2.318 | |

| SF0.6GF0.2 | 0.870 | 2.431 | |

| GF-50% | SF0.2GF0.2 | 1.611 | 6.480 |

| SF0.3GF0.3 | 1.703 | 2.163 | |

| SF0.4GF0.4 | 1.773 | 3.936 | |

| GF-75% | SF0.1GF0.3 | 1.809 | 5.016 |

| SF0.15GF0.45 | 2.123 | 5.607 | |

| SF0.2GF0.6 | 1.991 | 6.248 | |

| GF-100% | SF0GF0.4 | 1.694 | 2.801 |

| SF0GF0.6 | 2.034 | 4.324 | |

| SF0GF0.8 | 1.531 | 4.426 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lv, H.; Li, L.; Zhu, W.; Li, X.; Wang, D.; Ling, Z.; Feng, P.; Liu, F. Effects of Steel and Glass Fibers on the Compressive Behavior of Rubberized Concrete: An Experimental Study and Constitutive Modeling. Buildings 2024, 14, 3474. https://doi.org/10.3390/buildings14113474

Lv H, Li L, Zhu W, Li X, Wang D, Ling Z, Feng P, Liu F. Effects of Steel and Glass Fibers on the Compressive Behavior of Rubberized Concrete: An Experimental Study and Constitutive Modeling. Buildings. 2024; 14(11):3474. https://doi.org/10.3390/buildings14113474

Chicago/Turabian StyleLv, Hongjie, Lijuan Li, Weiping Zhu, Xiaohui Li, Daochu Wang, Zao Ling, Pandeng Feng, and Feng Liu. 2024. "Effects of Steel and Glass Fibers on the Compressive Behavior of Rubberized Concrete: An Experimental Study and Constitutive Modeling" Buildings 14, no. 11: 3474. https://doi.org/10.3390/buildings14113474

APA StyleLv, H., Li, L., Zhu, W., Li, X., Wang, D., Ling, Z., Feng, P., & Liu, F. (2024). Effects of Steel and Glass Fibers on the Compressive Behavior of Rubberized Concrete: An Experimental Study and Constitutive Modeling. Buildings, 14(11), 3474. https://doi.org/10.3390/buildings14113474