Study on Fractal Damage of Concrete Cracks Based on U-Net

Abstract

1. Introduction

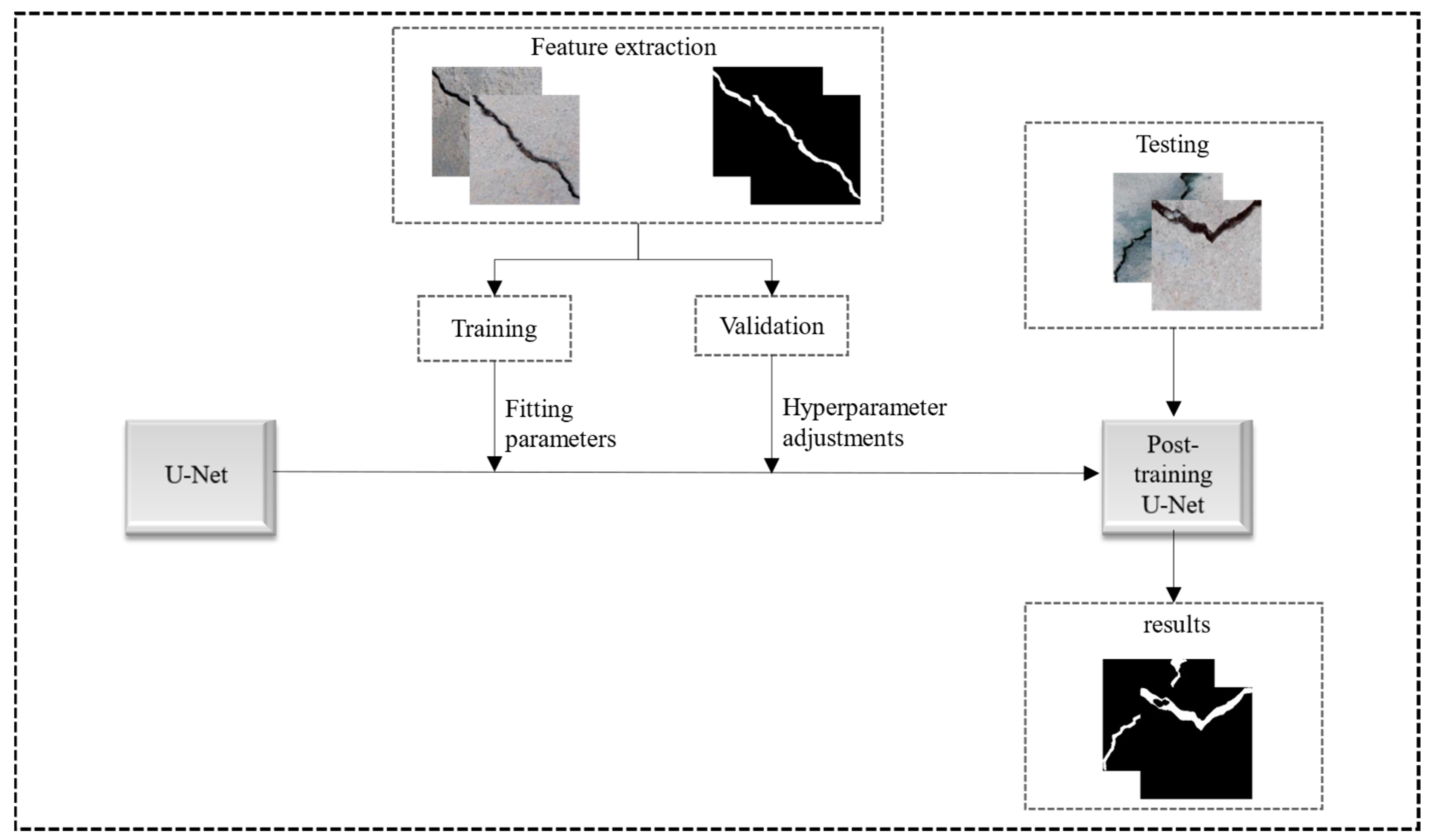

2. U-Net Crack Detection Framework

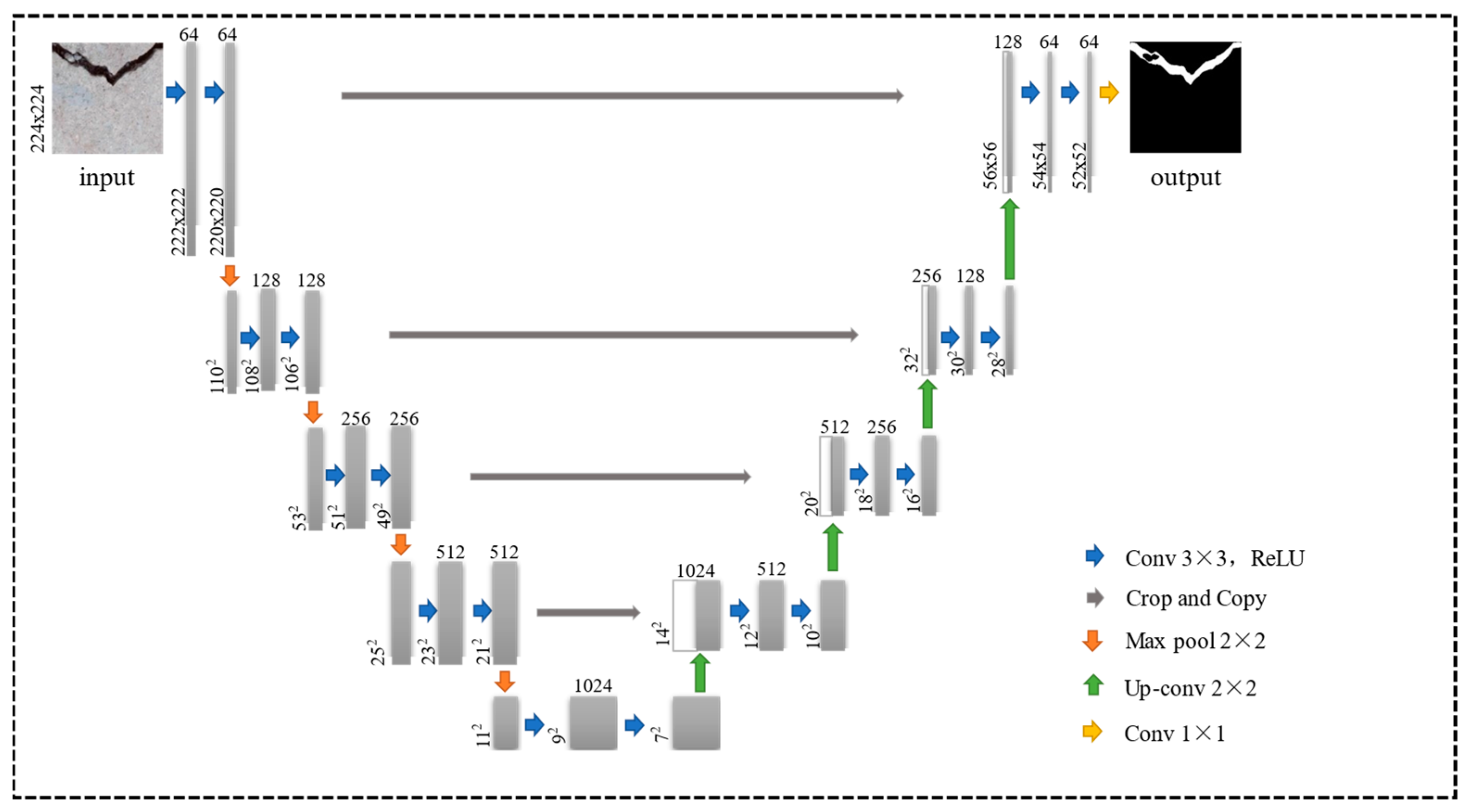

2.1. Model Framework

2.2. Dataset

2.3. U-Net Semantic Segmentation

2.4. U-Net Evaluation Criteria

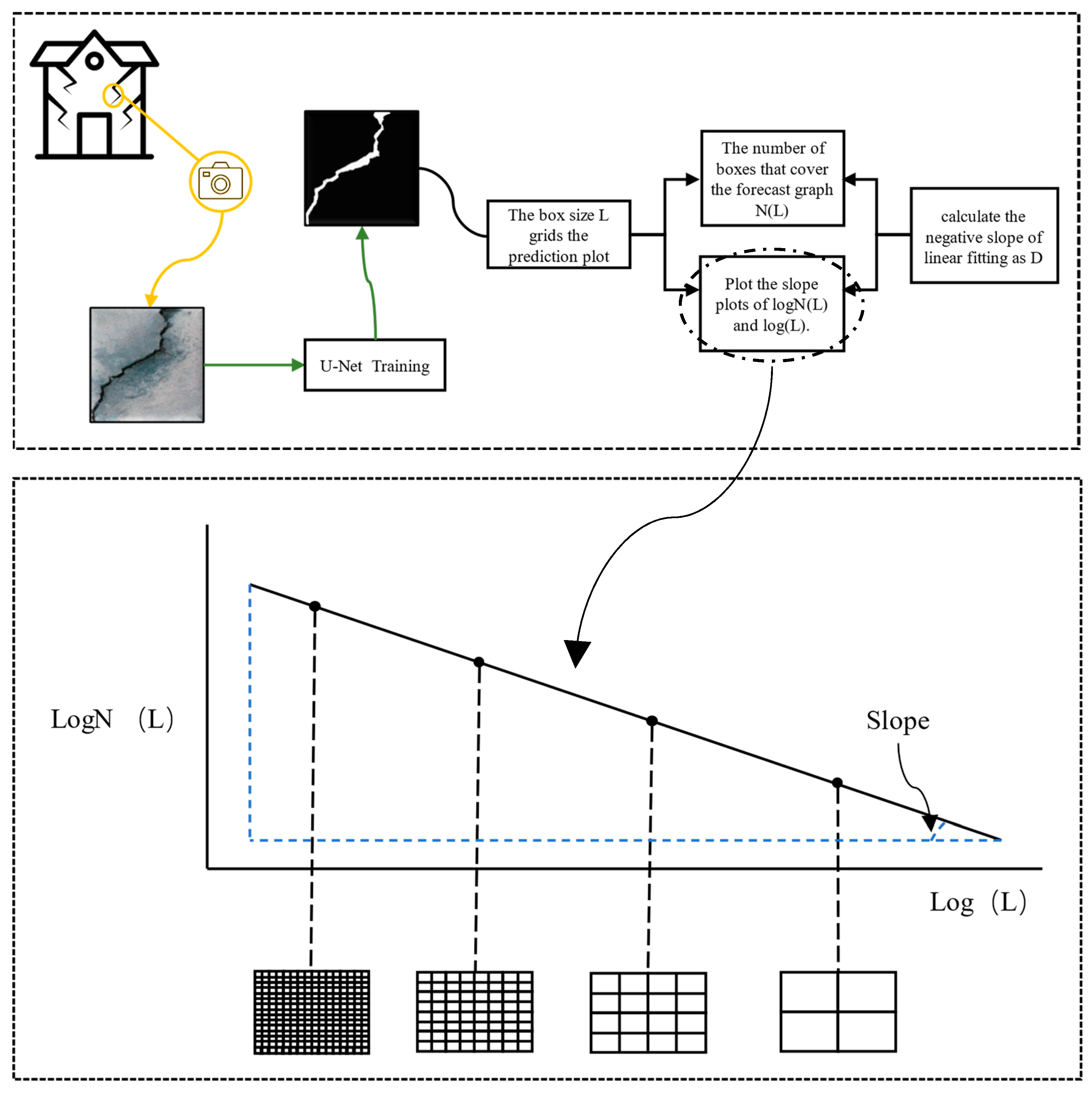

3. Fractal Fusion

3.1. Fractal Dimension of a Crack

3.2. The Relationship between Fractal Dimension and Damage Degree of Concrete Members

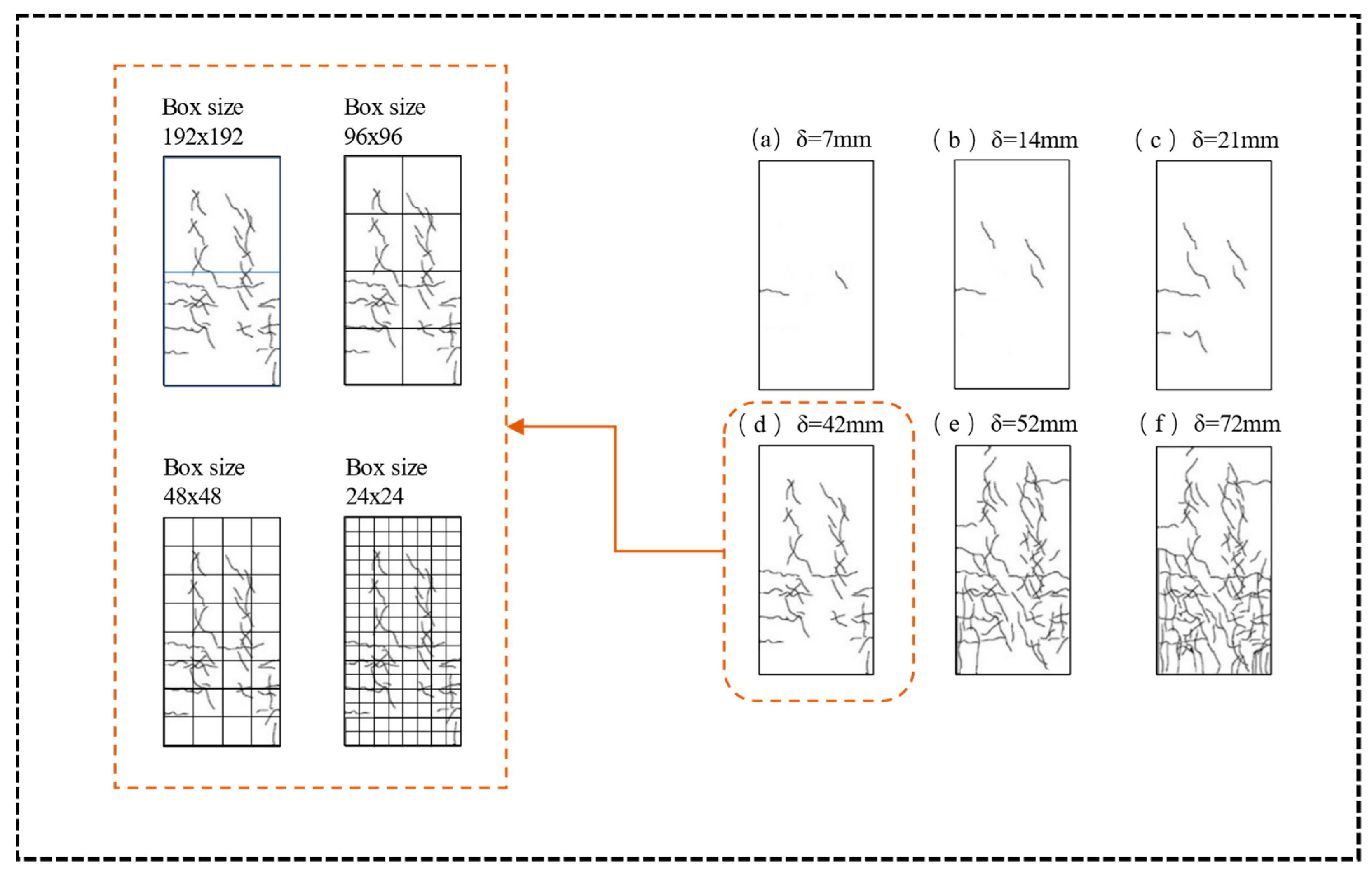

3.2.1. The Relationship between the Fractal Dimension of Cracking of Concrete Columns and the Degree of Damage

3.2.2. The Relationship between the Fractal Dimension of Cracking of Concrete Beams and the Degree of Damage

3.2.3. Establishment of Regression Models

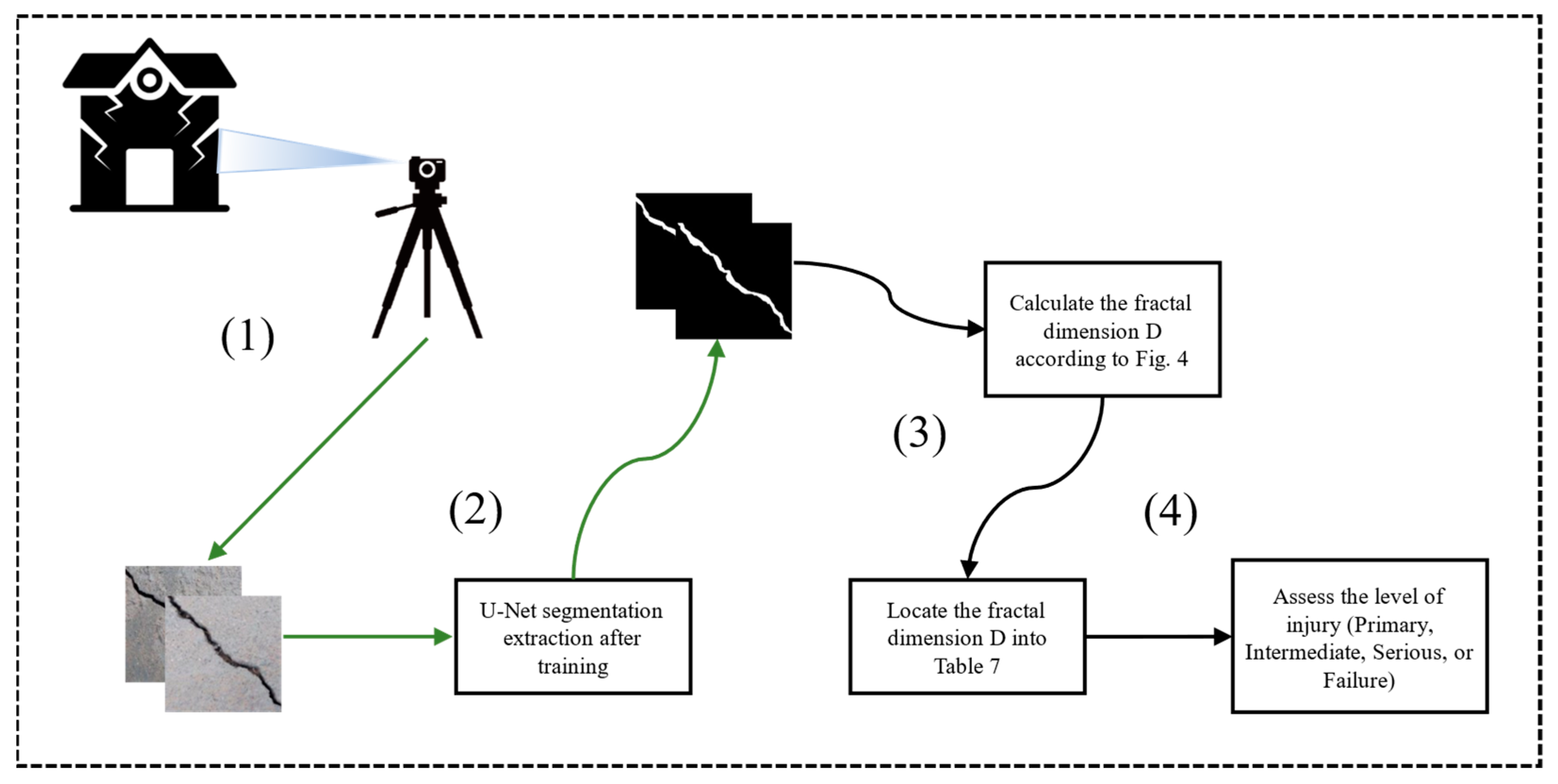

4. Damage Assessment Method Based on Fractal Dimensions of Surface Cracks

4.1. Boundary Fractal Dimension

4.2. Concrete Component Damage Assessment Procedure

4.3. Damage Assessment and Verification of Concrete Components

5. Conclusions

- (1)

- In this study, the U-Net deep learning model was introduced and subjected to a quantitative comparative analysis with the traditional local thresholding method. The results of the analysis demonstrated that the U-Net model outperformed the traditional local thresholding method across key performance metrics, including precision (Pr), recall (Re), and F1 score. The superiority of these metrics indicates that the U-Net model possesses greater robustness in crack detection tasks. Consequently, the crack damage information extracted using the U-Net model more accurately reflects the actual damage condition of concrete structural components.

- (2)

- The empirical relationship between the fractal characteristics of surface cracks and the damage degree of concrete components is proposed, which provides a concise and efficient tool for the structural damage assessment of concrete components. To improve the accuracy of damage assessment, quantitative relationships can be continuously optimized by following steps similar to those in this study, and more experimental data can be supplemented.

- (3)

- Upon the comparative analysis of the damage classification results from experiments utilizing the U-Net deep learning model and traditional local thresholding methods, it has been observed that the accuracy of the damage classification based on the U-Net model significantly surpasses that of the traditional local thresholding. This enhancement in performance underscores the superior efficacy and precision of the U-Net model, thereby validating its robustness in the context of crack detection. Consequently, the application of the U-Net model in the assessment of damage to concrete structures presents a more accurate reflection of the actual condition of the structural integrity, suggesting a promising application potential within the field of concrete structural damage assessment.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Alaskar, A.; Alqarni, A.S.; Alfalah, G.; El-Sayed, A.K.; Mohammadhosseini, H.; Alyousef, R. Performance evaluation of reinforced concrete beams with corroded web reinforcement: Experimental and theoretical study. J. Build. Eng. 2021, 35, 102038. [Google Scholar] [CrossRef]

- Yin, Y.; Ren, Q.; Lei, S.; Zhou, J.; Xu, L.; Wang, T. Mesoscopic crack pattern fractal dimension-based concrete damage identification. Eng. Fract. Mech. 2024, 296, 109829. [Google Scholar] [CrossRef]

- Carrillo, J.; Avila, W. Assessment of seismic damage of thin and lightly reinforced concrete walls using the fractal dimension of cracking. Earthq. Eng. Struct. Dyn. 2017, 46, 661–675. [Google Scholar] [CrossRef]

- He, H.; Tian, S.; Zhang, Y. Refined fatigue damage assessment of RC beam based on fractal characteristics of cracks. Structures 2022, 46, 1595–1603. [Google Scholar] [CrossRef]

- Dolatshahi, K.M.; Beyer, K. Stiffness and strength estimation of damaged unreinforced masonry walls using crack pattern. J. Earthq. Eng. 2022, 26, 837–856. [Google Scholar] [CrossRef]

- Liu, Y.; Dai, K.; Li, D.; Luo, M.; Liu, Y.; Shi, Y.; Xu, J.; Huang, Z. Structural performance assessment of concrete components based on fractal information of cracks. J. Build. Eng. 2021, 43, 103177. [Google Scholar] [CrossRef]

- Woods, J.E.; Yang, Y.S.; Chen, P.C.; Lau, D.T.; Erochko, J. Automated crack detection and damage index calculation for RC structures using image analysis and fractal dimension. J. Struct. Eng. 2021, 147, 04021019. [Google Scholar] [CrossRef]

- An, Q.; Chen, X.; Wang, H.; Yang, H.; Yang, Y.; Huang, W.; Wang, L. Segmentation of concrete cracks by using fractal dimension and UHK-net. Fractal Fract. 2022, 6, 95. [Google Scholar] [CrossRef]

- Hamidia, M.; Ganjizadeh, A. Post-earthquake damage evaluation of non-ductile RC moment frames using surface crack patterns. Struct. Control Health Monit. 2022, 29, e3024. [Google Scholar] [CrossRef]

- Jin, Z.; Xie, F.; Yang, T.; Han, X.; Chen, X.; Zhang, Y. Fractal dimension analysis of concrete specimens under different strain rates. J. Build. Eng. 2023, 76, 107044. [Google Scholar] [CrossRef]

- Yang, Y.; Zhao, Z.; Su, L.; Zhou, Y.; Li, H. Research on pavement crack detection algorithm based on deep residual UNET neural network. J. Phys. Conf. Ser. 2022, 2278, 012020. [Google Scholar] [CrossRef]

- Xu, H.; Su, X.; Wang, Y.; Cai, H.; Cui, K.; Chen, X. Automatic Bridge Crack Detection Using a Convolutional Neural Network. Appl. Sci. 2019, 9, 2867. [Google Scholar] [CrossRef]

- Mandelbrot, B.B.; Passoja, D.E.; Paulley, A.J. Fractal character of the fracture surface of metals. Nature 1984, 308, 721–722. [Google Scholar] [CrossRef]

- Carpinteri, A.; Chiaia, B.; Cornetti, P. A fractal theory for the mechanics of elastic materials. Mater. Sci. Eng. A 2004, 365, 235–240. [Google Scholar] [CrossRef]

- Cherepanov, G.P.; Balankin, A.S.; Ivanova, V.S. Fractal fracture mechanics—A review. Eng. Fract. Mech. 1995, 51, 997–1033. [Google Scholar] [CrossRef]

- Farhidzadeh, A.; Dehghan-Niri, E.; Moustafa, A.; Salamone, S.; Whittaker, A. Damage assessment of reinforced concrete structures using fractal analysis of residual crack patterns. Exp. Mech. 2013, 53, 1607–1619. [Google Scholar] [CrossRef]

- Yin, X.; Lü, X.; Lu, W. Resilience model of SRC columns with cross-shaped encase steel. Eng. Mech. 2014, 31, 97–103. [Google Scholar]

- Zang, P. The Experimental Study on Bending Behavior of RC Beams with 500 MPa Steel Bar. Master’s Thesis, Hebei University of Technology, Tianjin, China, 2007. [Google Scholar]

- Xing, G.; Ozbulut, O.E. Flexural performance of concrete beams reinforced with aluminum alloy bars. Eng. Struct. 2016, 126, 53–65. [Google Scholar] [CrossRef]

- Biolzi, L.; Cattaneo, S. Response of steel fiber reinforced high strength concrete beams: Experiments and code predictions. Cem. Concr. Compos. 2017, 77, 1–13. [Google Scholar] [CrossRef]

- Hossein Saghafi, M.; Shariatmadar, H. Enhancement of seismic performance of beam-column joint connections using high-performance fiber reinforced cementitious composites. Constr. Build. Mater. 2018, 180, 665–680. [Google Scholar] [CrossRef]

| Noise Type | Training | Validation | Testing |

|---|---|---|---|

| Rough surface | 80 | 10 | 4 |

| Bright light | 80 | 10 | 4 |

| Dark noise | 80 | 10 | 4 |

| Dirt noise | 80 | 10 | 4 |

| Rough surface + strong light | - | - | 6 |

| Rough surface + dark noise | - | - | 5 |

| Rough surface + dirt noise | - | - | 8 |

| Strong light + crack | - | - | 5 |

| Total | 320 | 40 | 40 |

| Index | Pr | Re | F1 |

|---|---|---|---|

| U-Net | 0.9137 | 0.9068 | 0.9102 |

| Partial threshold | 0.8326 | 0.8287 | 0.8306 |

| Damage Level | Damage Index DI |

|---|---|

| Primary | <20% |

| Intermediate | 20–50% |

| Serious | 50–70% |

| Failure | >70% |

| References | Specimen | Specimen | Constraints | Loading Method | Size |

|---|---|---|---|---|---|

| Yin et al. (2014) [17] | concrete columns | 8 | Top fixed; bottom fixed | Low-frequency cyclic loading | 500 mm × 500 mm |

| Zang (2007) [18] | RC beams | 9 | Simply supported | 4-point bending | 400 mm × 200 mm |

| Xing et al. (2016) [19] | RC beams | 11 | Simply supported | 4-point bending | 200 mm × 120 mm |

| Biolzi et al. (2017) [20] | Steel fiber RC beams | 36 | Simply supported | 4-point bending | 300 mm × 150 mm |

| Saghafi (2018) [21] | Beam–Column joint | 6 | Top free; bottom fixed | Low-frequency cyclic loading | 250 mm × 250 mm |

| Development Stage | a | b | c | d | e | f |

|---|---|---|---|---|---|---|

| Displacement δ (mm) | 7 | 14 | 21 | 42 | 52 | 72 |

| Fractal dimension D | 1.16 | 1.25 | 1.39 | 1.58 | 1.72 | 1.78 |

| Damage index DI (%) | 11.6 | 21.1 | 35.8 | 55.8 | 70.5 | 76.8 |

| Development Stage | a | b | c | d | e | f |

|---|---|---|---|---|---|---|

| Concentrate the load (KN) | 20 | 40 | 60 | 80 | 150 | 190 |

| Fractal dimension D | 1.14 | 1.19 | 1.32 | 1.45 | 1.69 | 1.75 |

| Damage index DI (%) | 9.5 | 14.7 | 28.4 | 42.1 | 67.4 | 73.7 |

| Damage Level | Primary | Intermediate | Serious | Failure |

|---|---|---|---|---|

| Fractal dimension | <1.24 | 1.24–1.525 | 1.525–1.715 | >1.715 |

| Development Stage | a | b | c | d | e | f |

|---|---|---|---|---|---|---|

| Concentrate the load (KN) | 100.5 | 118 | 147.6 | 184.6 | 205.6 | 221.4 |

| Fractal dimension D | 1.23 | 1.44 | 1.49 | 1.57 | 1.61 | 1.77 |

| Damage index DI (%) | 18.9 | 41 | 46.3 | 54.7 | 58.9 | 75.8 |

| Load (KN) | D Based on U-Net | D Based on Local Threshold | Based on U-Net | Based on the Local Threshold | Actual Damage Level |

|---|---|---|---|---|---|

| 100.5 | 1.23 | 1.23 | Primary | Primary | Intermediate |

| 118 | 1.44 | 1.46 | Intermediate | Intermediate | Intermediate |

| 147.6 | 1.49 | 1.54 | Intermediate | Serious | Intermediate |

| 184.6 | 1.57 | 1.60 | Serious | Serious | Serious |

| 205.6 | 1.61 | 1.63 | Serious | Serious | Serious |

| 221.4 | 1.77 | 1.81 | Failure | Failure | Failure |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xie, M.; Wang, Z.; Yin, L.; Xu, F.; Wu, X.; Xu, M. Study on Fractal Damage of Concrete Cracks Based on U-Net. Buildings 2024, 14, 3262. https://doi.org/10.3390/buildings14103262

Xie M, Wang Z, Yin L, Xu F, Wu X, Xu M. Study on Fractal Damage of Concrete Cracks Based on U-Net. Buildings. 2024; 14(10):3262. https://doi.org/10.3390/buildings14103262

Chicago/Turabian StyleXie, Ming, Zhangdong Wang, Li’e Yin, Fangbo Xu, Xiangdong Wu, and Mengqi Xu. 2024. "Study on Fractal Damage of Concrete Cracks Based on U-Net" Buildings 14, no. 10: 3262. https://doi.org/10.3390/buildings14103262

APA StyleXie, M., Wang, Z., Yin, L., Xu, F., Wu, X., & Xu, M. (2024). Study on Fractal Damage of Concrete Cracks Based on U-Net. Buildings, 14(10), 3262. https://doi.org/10.3390/buildings14103262