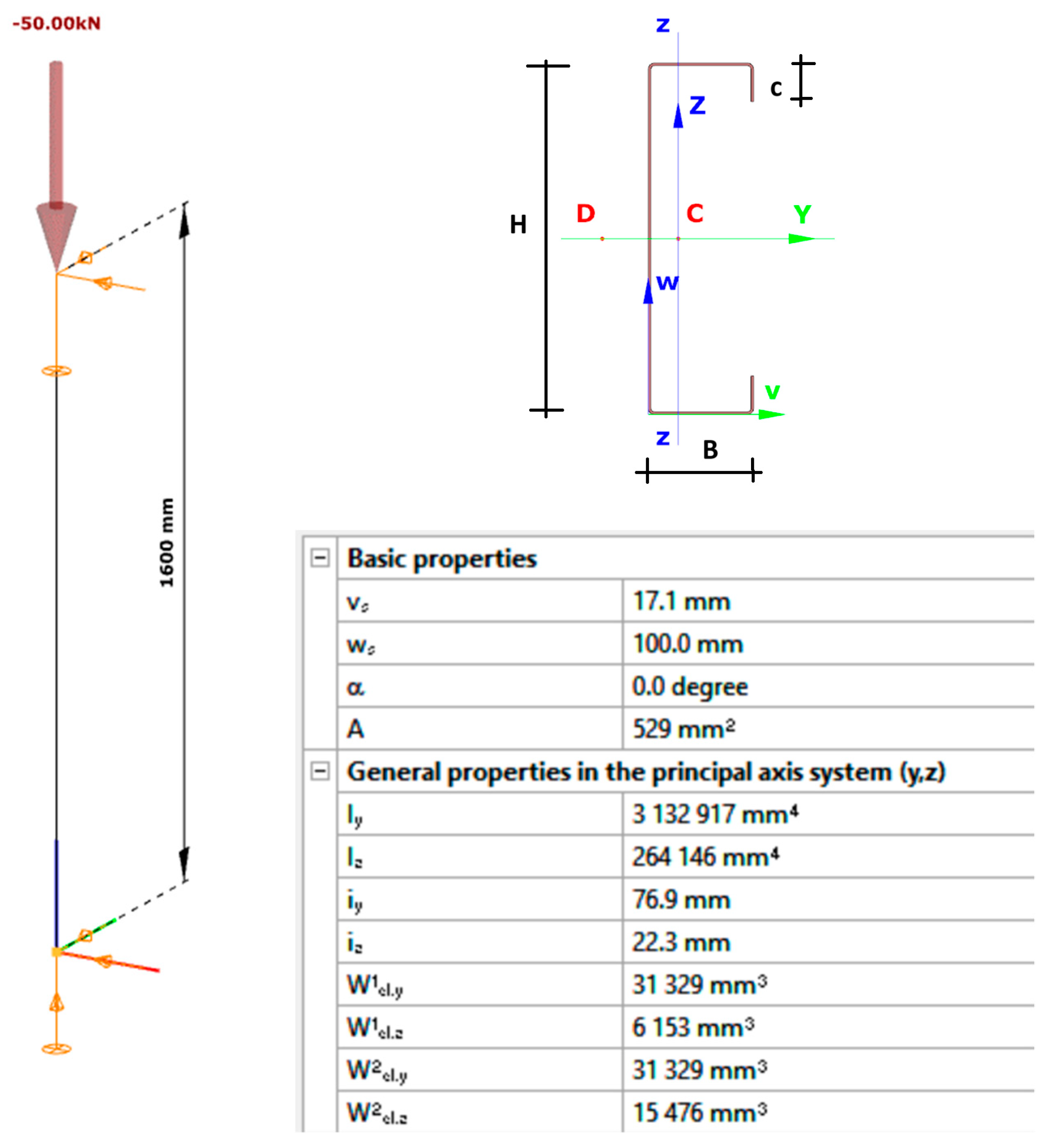

3.2. Mechanics of Centrically Compressed Channel with Slender Web Plates

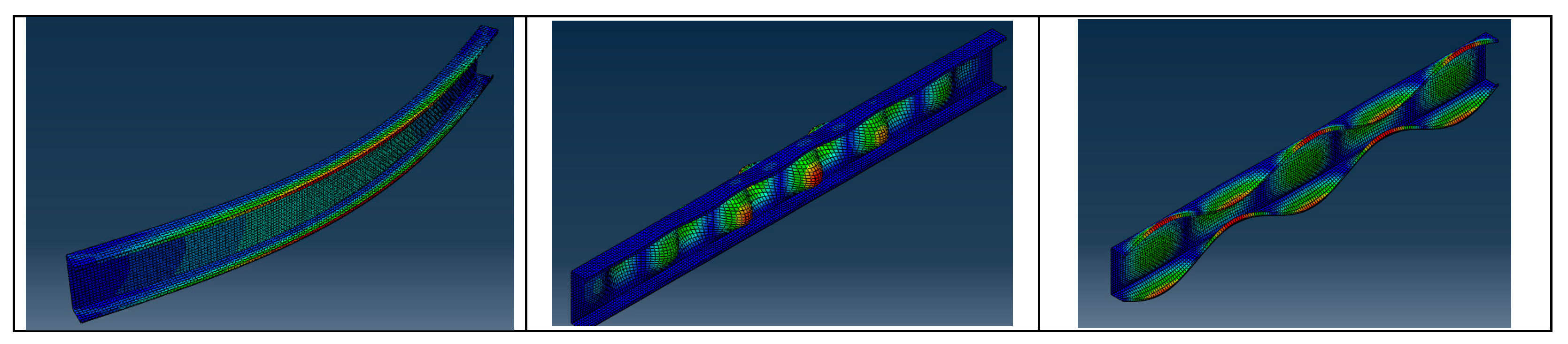

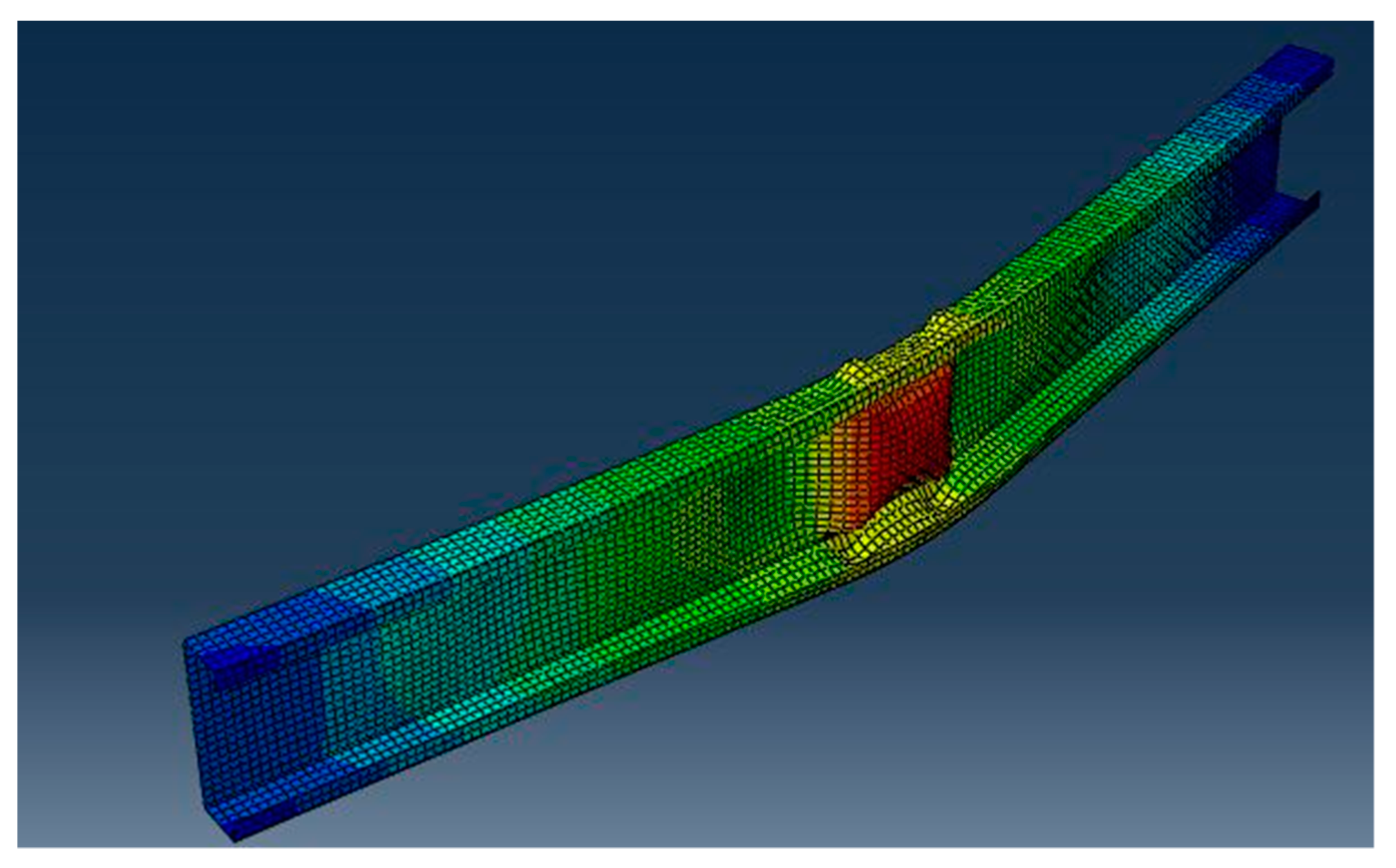

The present paper deals with thin-walled members with slender plates constituting its cross-sections. When local or distortional buckling happens due to the formation of compressive stresses higher than the critical stress of the plates or stiffener zones of the cross-section, an effective cross-section characterized by a shift of the centroid is formed. As the cross-section is singly symmetric about the major axis and the original stress distribution is uniform, the direction of the shift of the effective cross-section is perpendicular to the web plate. This shift of the centroid results in an additional bending moment around the minor axis of the cross-section.

This moment results in a displacement, which is affine with the shape of flexural buckling around the minor axis. In such a case, it is expected that this causes an interaction.

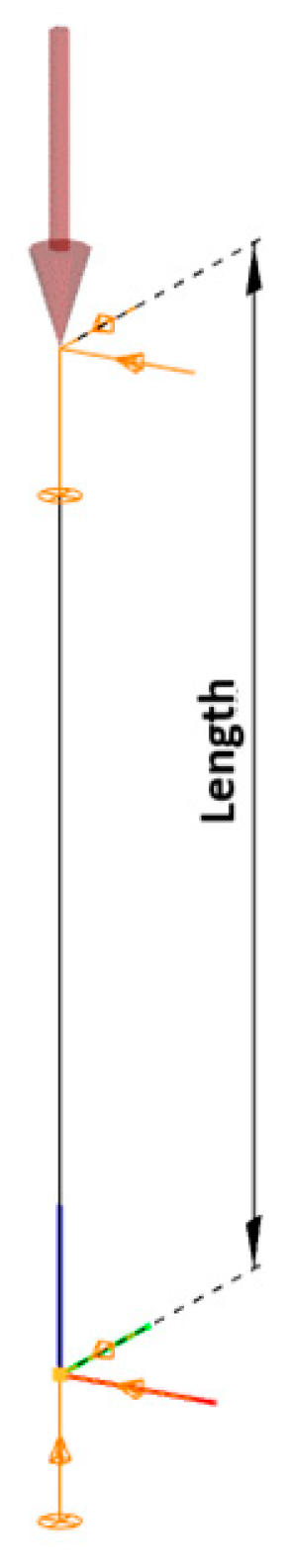

Other flexural buckling modes, such as flexural-torsional or major-axis flexural buckling, are perpendicular to the displacement of the effective centroid and cause no amplified interaction; therefore, they are excluded from this work.

The magnitude of an equivalent imperfection corresponding to flexural buckling can be determined using the Overall Imperfection Method (OIM) by Papp [

22]. The direction of the application of the imperfection plays an important role in cases of monosymmetric cross-sections. When this imperfection is assumed to act in the positive direction, the resulting minor-axis bending moment will increase the stresses along the web and may therefore strongly interact with local buckling. If the imperfection is applied in the negative direction, the stresses are increased around the edge stiffener zone, and this may result in an interaction with distortional buckling.

For a typical C-section with an unstiffened and slender web, the controlling case is the positive imperfection causing an increase in compressive stresses in the web. This paper focuses on this scenario.

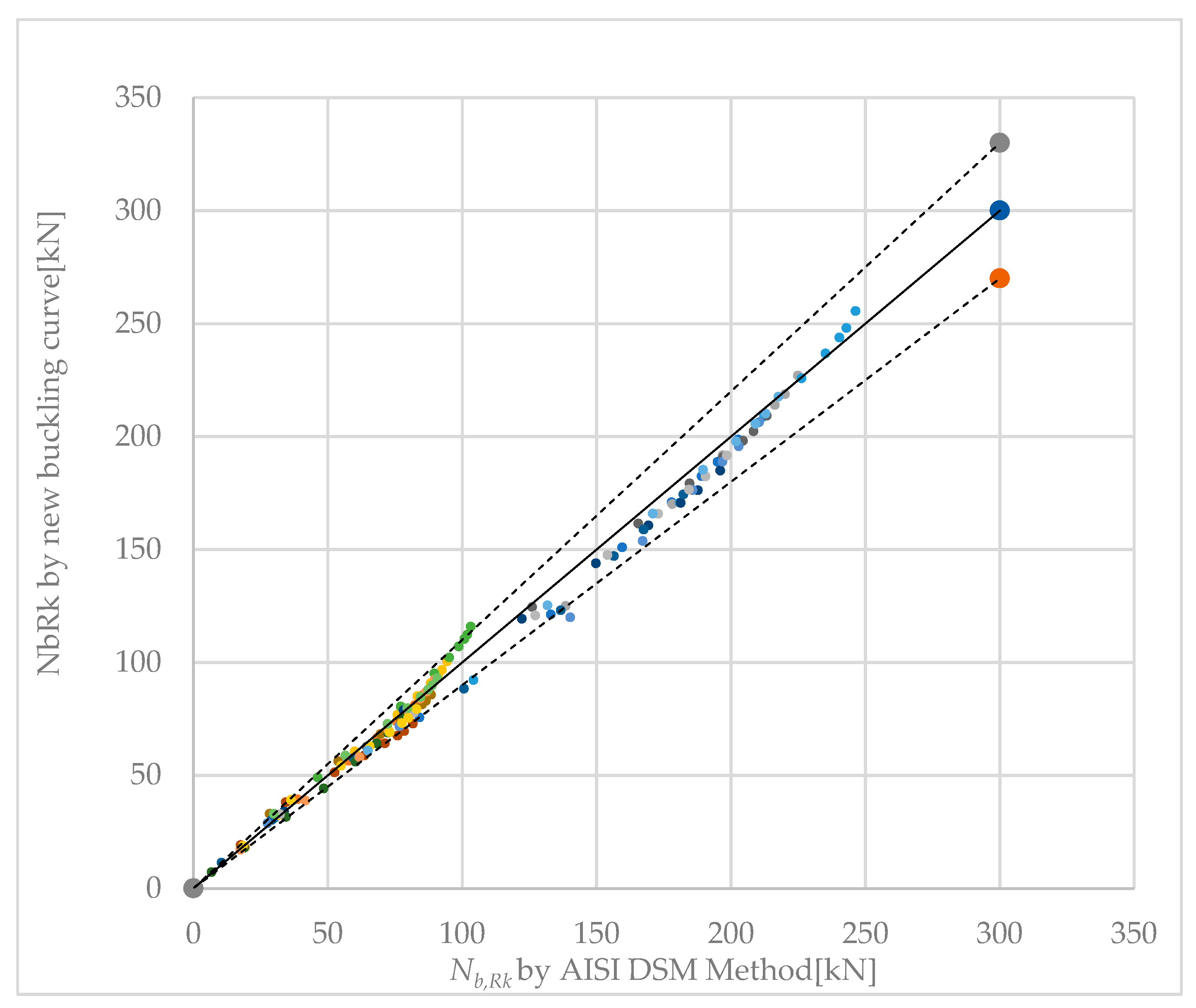

3.3. The New Buckling Curve

For construction of the buckling curve, a simple model is assumed. We assume that at failure of the simple supported column, the compressive stress at the web plate at mid-height, calculated on the effective cross-section, will just reach the yield stress value. The possible elevated tension stresses in the lip-side of the cross-section are not checked against the yield stress; we assume that plastic reserves in the tension zone may be used without any strain limit, as allowed in section 6.1.4.2(1) of EN 1993-1-3. If the stress on the lip-side is a compression, we check the flange-lip zone, with reference to Vaszilievits [

7], as a column for flexural buckling, but using the distortional bucking curve from EN 1993-1-3 instead of the more onerous column buckling curves from EN 1993-1-1.

The failure conditions of this model are defined as:

where

is the reduction factor to consider the distortional buckling effect on the stiffener zones,

is the basic yield strength, and

are partial factors for resistance, according to EN 1993-1-3. The first condition (1a) is directly used for the formulation of the buckling curve, while the second (1b) is presented in the form of an additional verification.

represents the compressive stresses in the web, and

represents the compressive stress in the center of gravity of the lip zone, both calculated on the effective cross-section.

If not only the web but also the flange was slender, determining the effective stress and its effective width would require knowledge of the stress gradient, which, in turn, depends on the unknown compression-to-minor-axis bending moment ratio. Many commonly used cross-sections have narrower flanges, falling under the limiting ratio of Class 4 according to EN 1993-1-1. When applying the solution to such shapes, the general non-linear problem simplifies into a second-order problem, for which a closed-form solution can be built. It can also be added that, if slender flanges were allowed, the formation of effective widths would have no significant effect on either the position of the effective centroid or the calculated stresses, as the inefficient part is usually located very close to the neutral axis of the formed effective cross-section.

In the subsequent discussion, we assume that only the web plate of the cross-section is slender, while the other plates are within the limits of Class 3 of EN 1993-1-1. In this scenario, the formation of effective widths is solely considered on the web plate.

Based on these assumptions, failure is expected when the stress calculated on the effective cross-section reaches the yield strength in the web:

where

and

, as defined by Merchant in [

23]. In addition,

is the equivalent geometrical imperfection, and the elastic buckling multiplier

αcr.g can be computed analytically or in general case with 14 DOF beam-column finite element analysis.

Equations (2) and (3) can be combined into the following second-order equation:

where

Ncr =

αcr,g N.

The characteristic value of buckling resistance is obtained by solving the Equation (4) second-order equation for the smallest positive roof of N. For a simpler presentation, the following expression is introduced:

With its help, the buckling load can be obtained as the smallest positive roof of the second-order equation, Equation (4):

Using the usual form of the characteristic buckling resistance employed by Eurocode 3 of a member with Class 4 sections, as follows,

gives the following equation for the reduction factor:

where

Ncr can be expressed with the member slenderness as

Using Equation (9) in Equation (5) results in the following,

which can be further simplified to

Using this in Equation (8), the final equation of the reduction factor is

or, after rewriting both Equations (11) and (12) equivalently into the well-known formulation used by EN 1993-1-1, is as follows:

where

The buckling resistance is defined as

Under the conditions conforming to this paper, it might happen that compressive stress arises at the lip of the cross-section, and an additional check is therefore necessary to ensure that the second condition Equation (1b), expressed as

from

Section 3.3, is satisfied. The normal stress

at the center of gravity of the lip zone at failure of the member can be calculated as

where

is the member compressive resistance determined with Equation (15), and

is the section modulus referring to the center of gravity of the lip zone, calculated on the effective cross-section.

Using this value, we obtain

At failure, the actual value of

from Equation (2) is

By substituting it into Equation (16), we obtain the following:

Finally, using Equation (15), we obtain the following:

If the resulting stress

is a compressive stress, the verification for distortional buckling can be performed as

which can also be written in a more compact form:

An important remark can be made based on this result. When analyzing non-symmetric sections, it may be necessary to differentiate between the positive and negative directions of flexural buckling. Eurocode 3 provides guidelines for determining the amplitude of applicable imperfections if flexural buckling will occur in the direction resulting in the first yielding, regardless of the actual stress sign. It is crucial to emphasize, particularly for Class 4 sections, that compression may induce buckling, while tension obviously will not. In the case of typical C-sections, the amplitude scaling factor proposed by Eurocode 3, based on the first yielding irrespective of the sign of the stress, may be deemed overly conservative, as it overlooks this inherent difference, thus emphasizing the need for careful consideration in such scenarios.