A Study on the Effects of Punch-to-Span Ratio and Longitudinal Reinforcement Eigenvalues on the Bearing Capacity of RC Slab–Column Connections

Abstract

1. Introduction

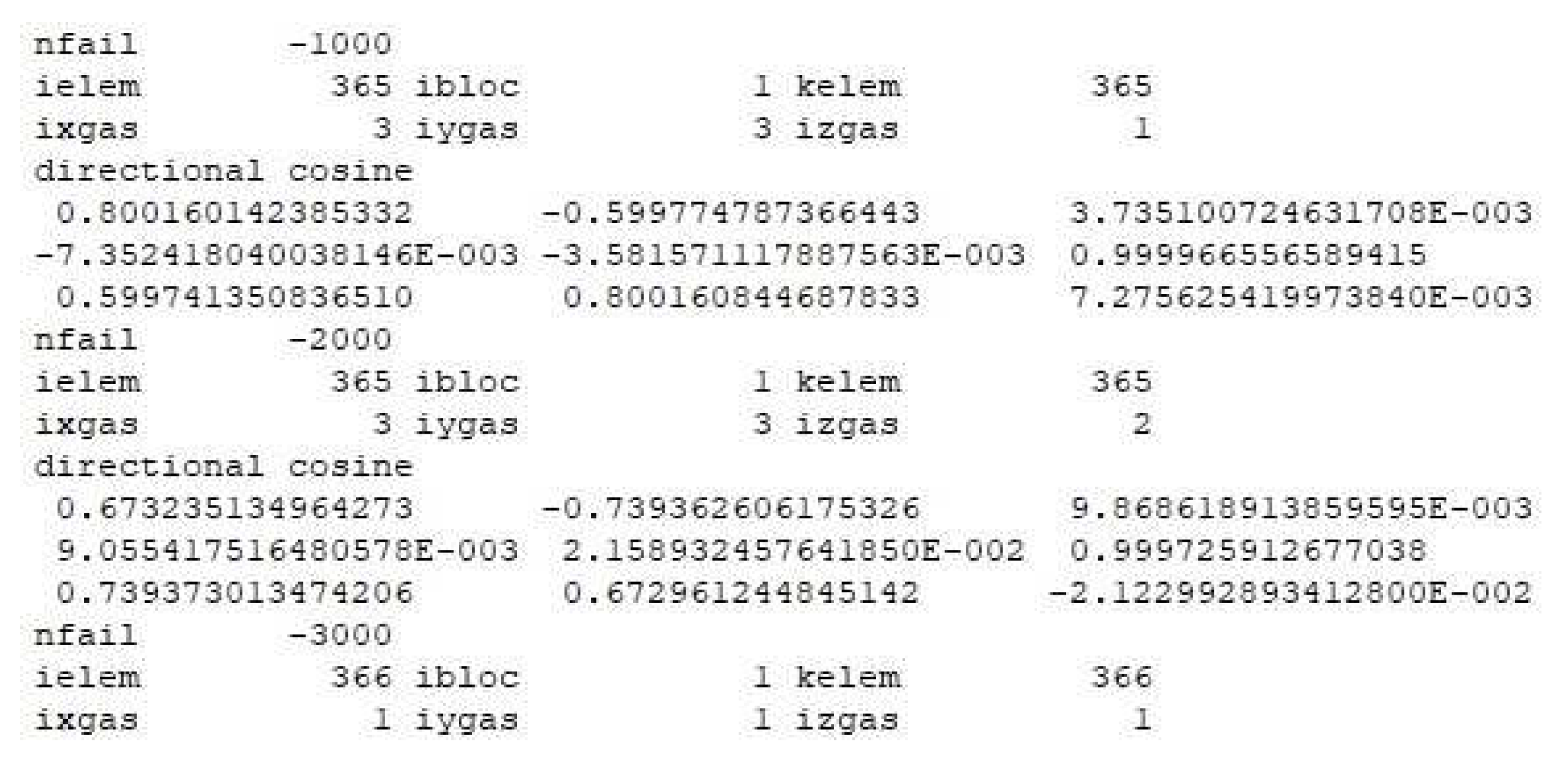

2. Simulation Methods and Comparison with Experiments

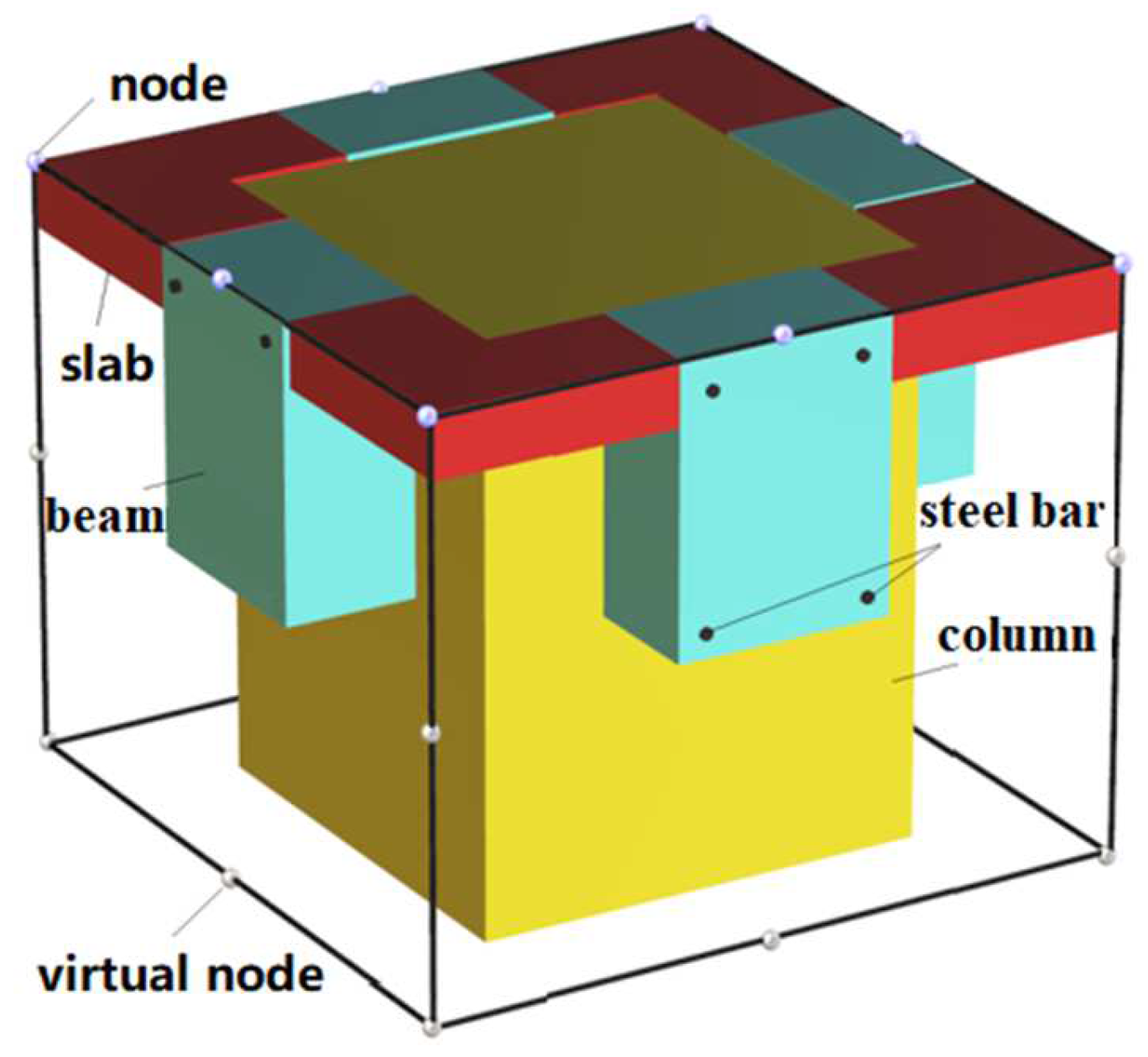

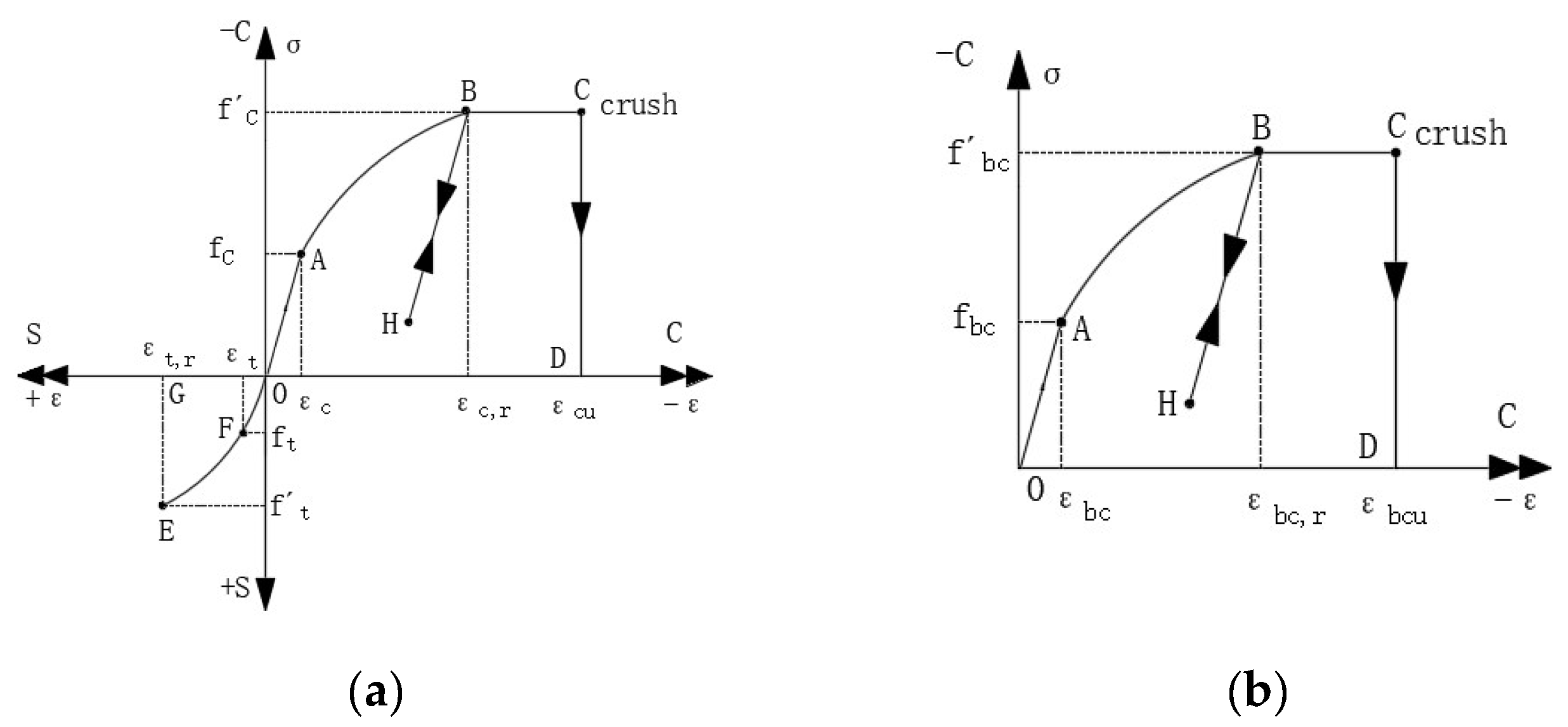

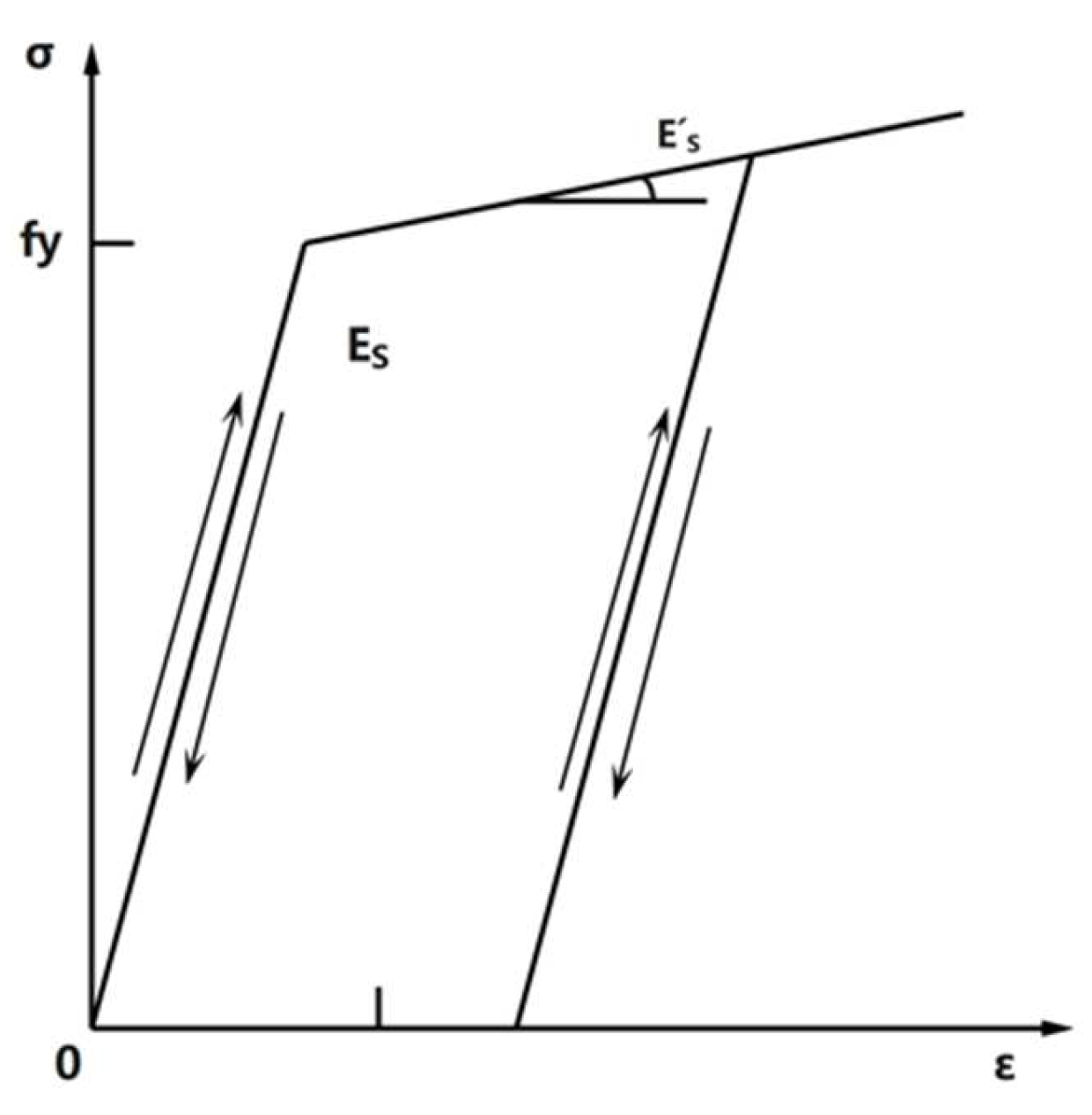

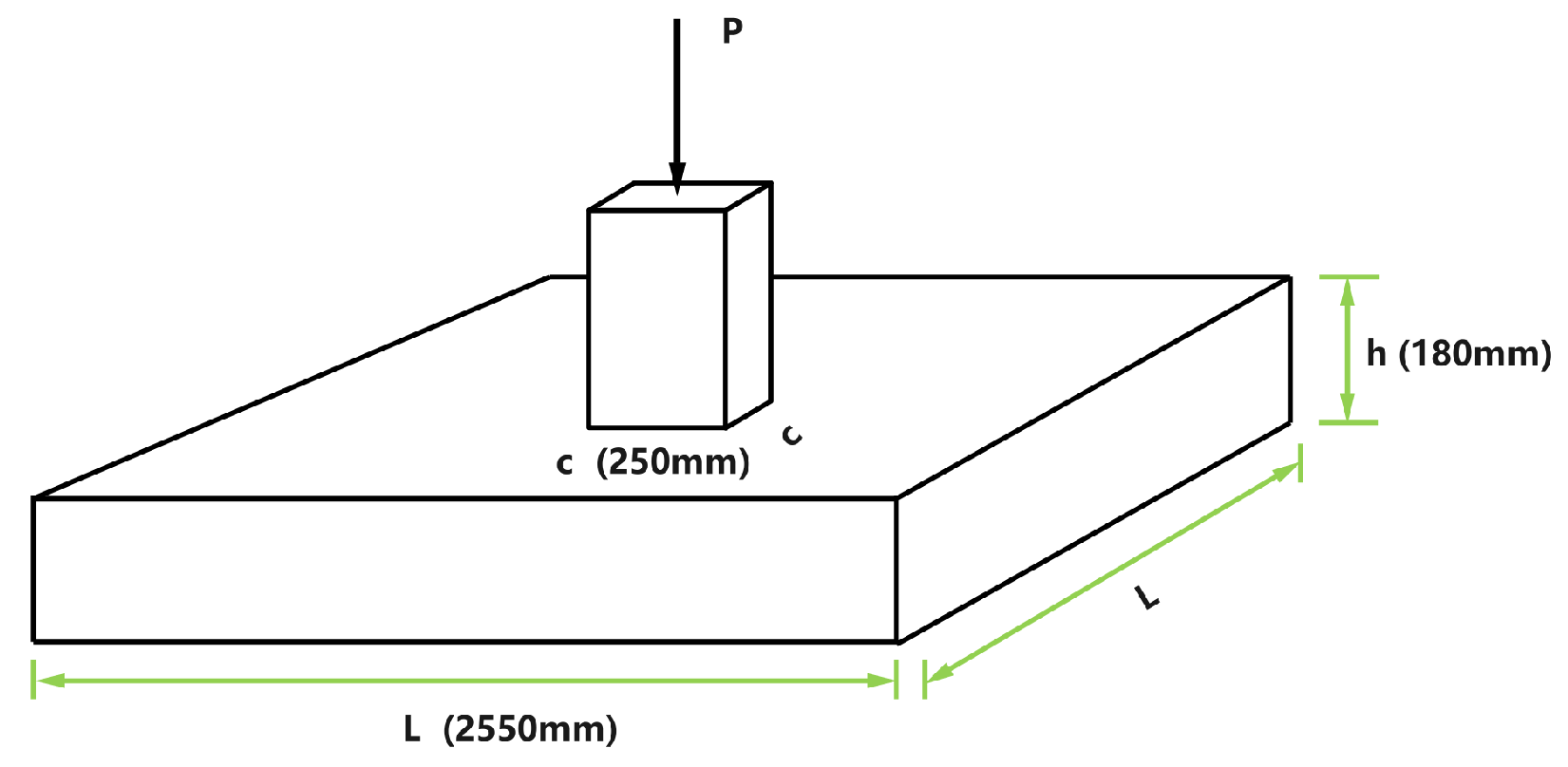

2.1. Simulation Methodology

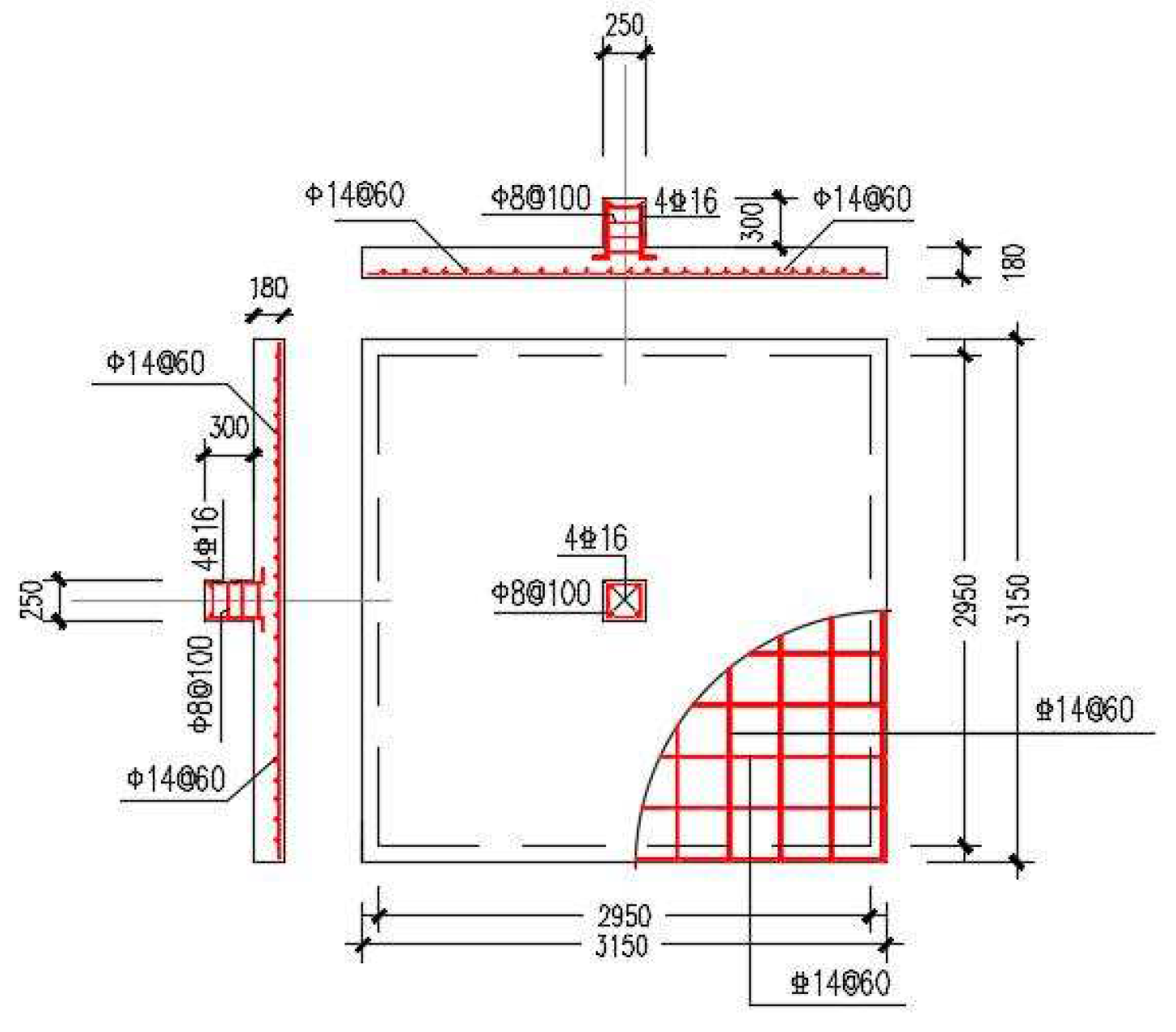

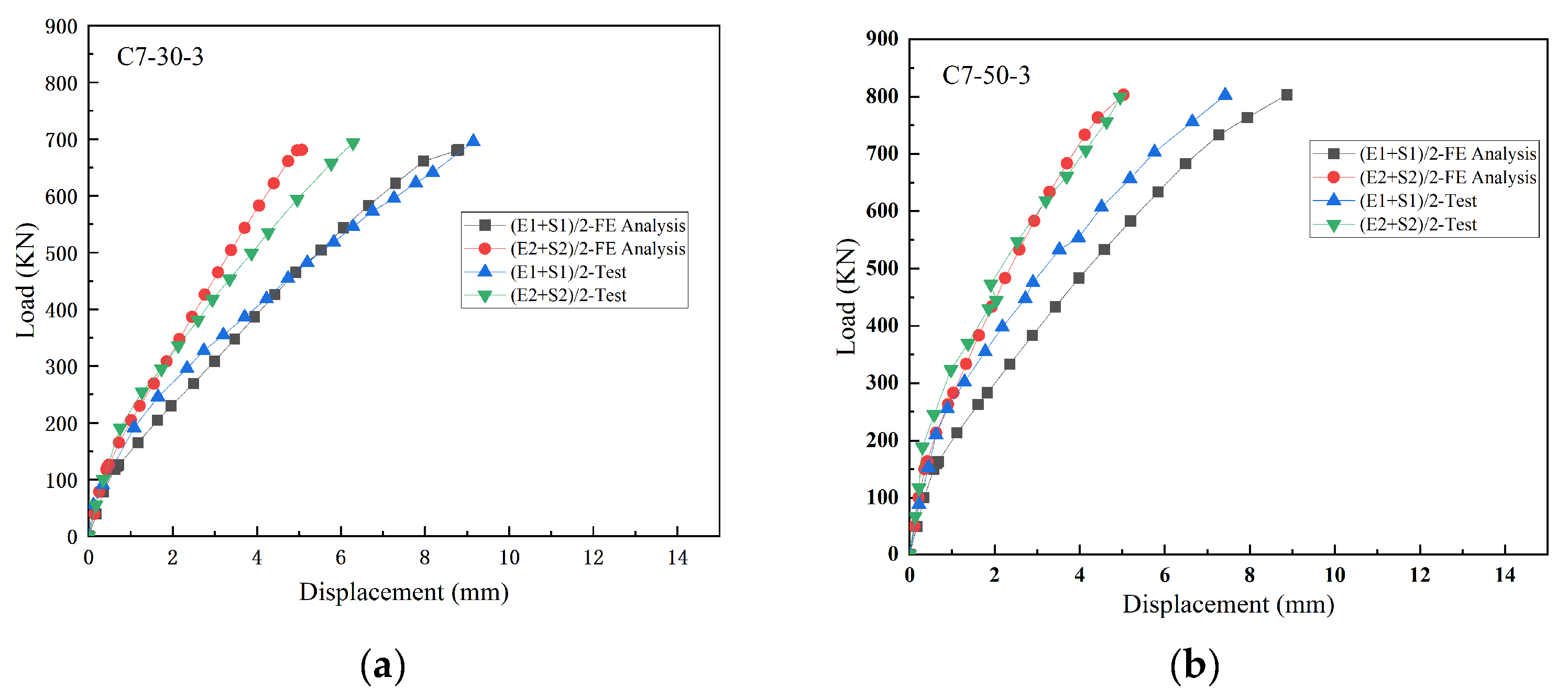

2.2. Comparison with Experiments

3. Parametric Simulation Analysis of Impact and Flexural Performance

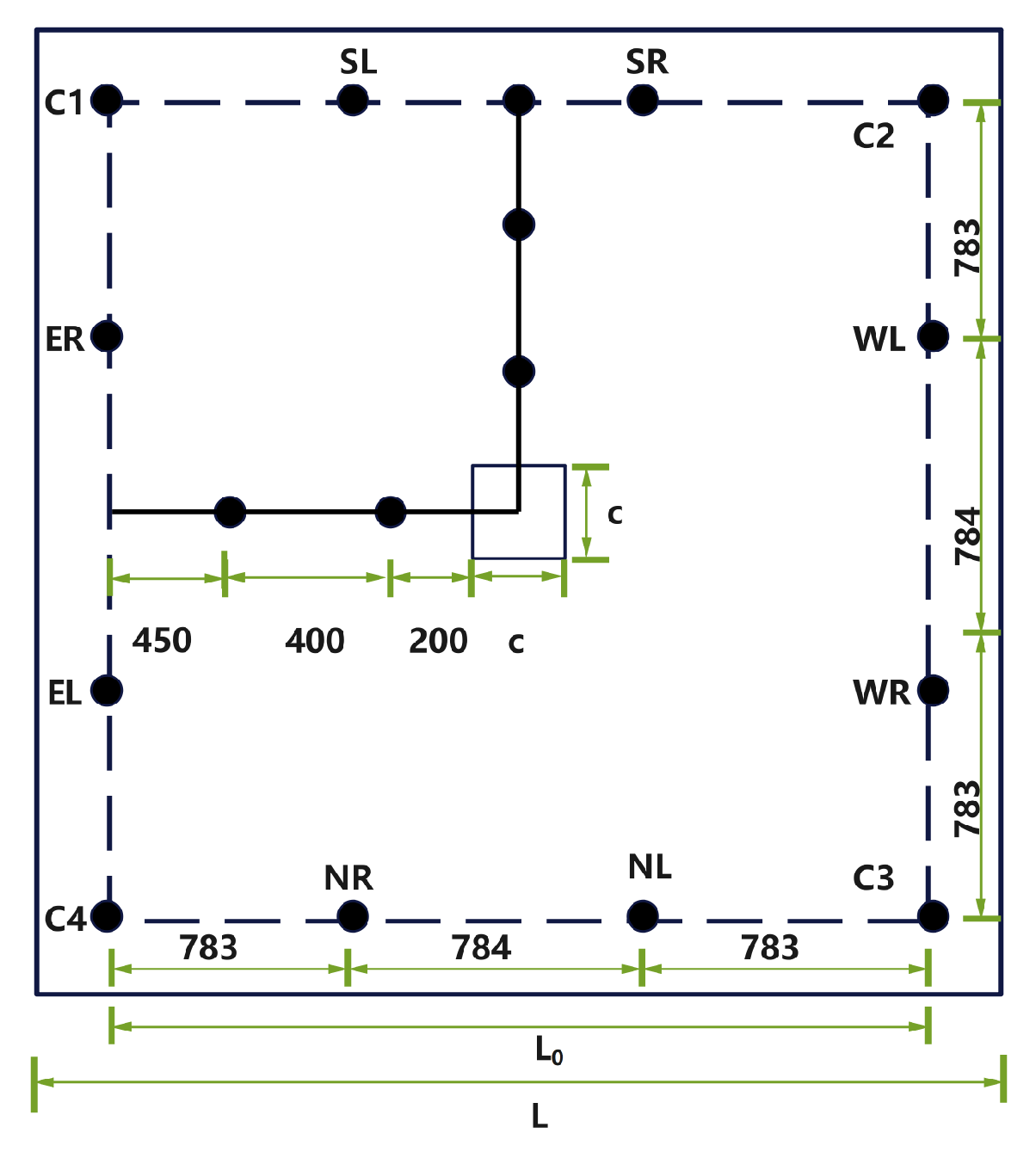

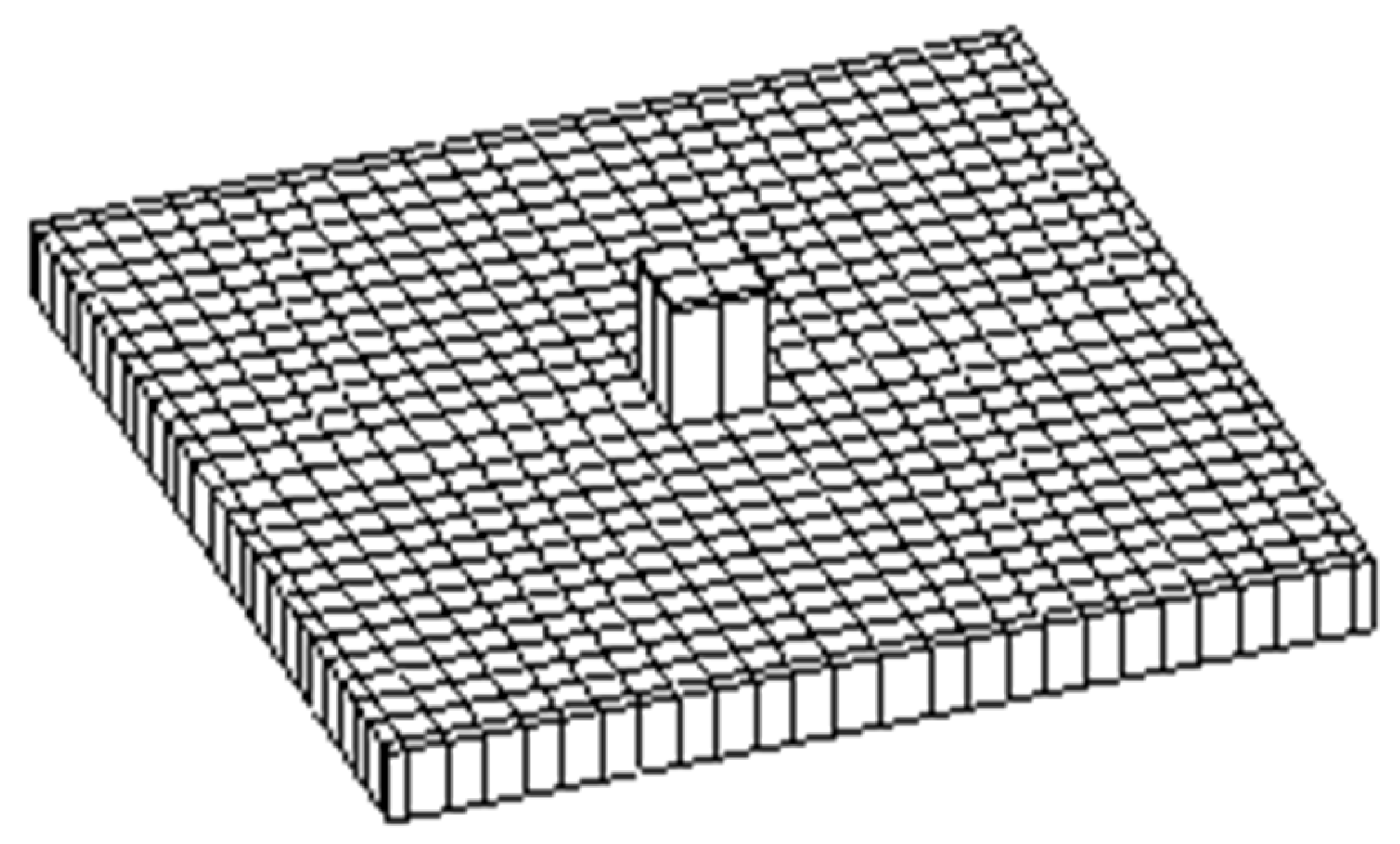

3.1. Model and Parameters

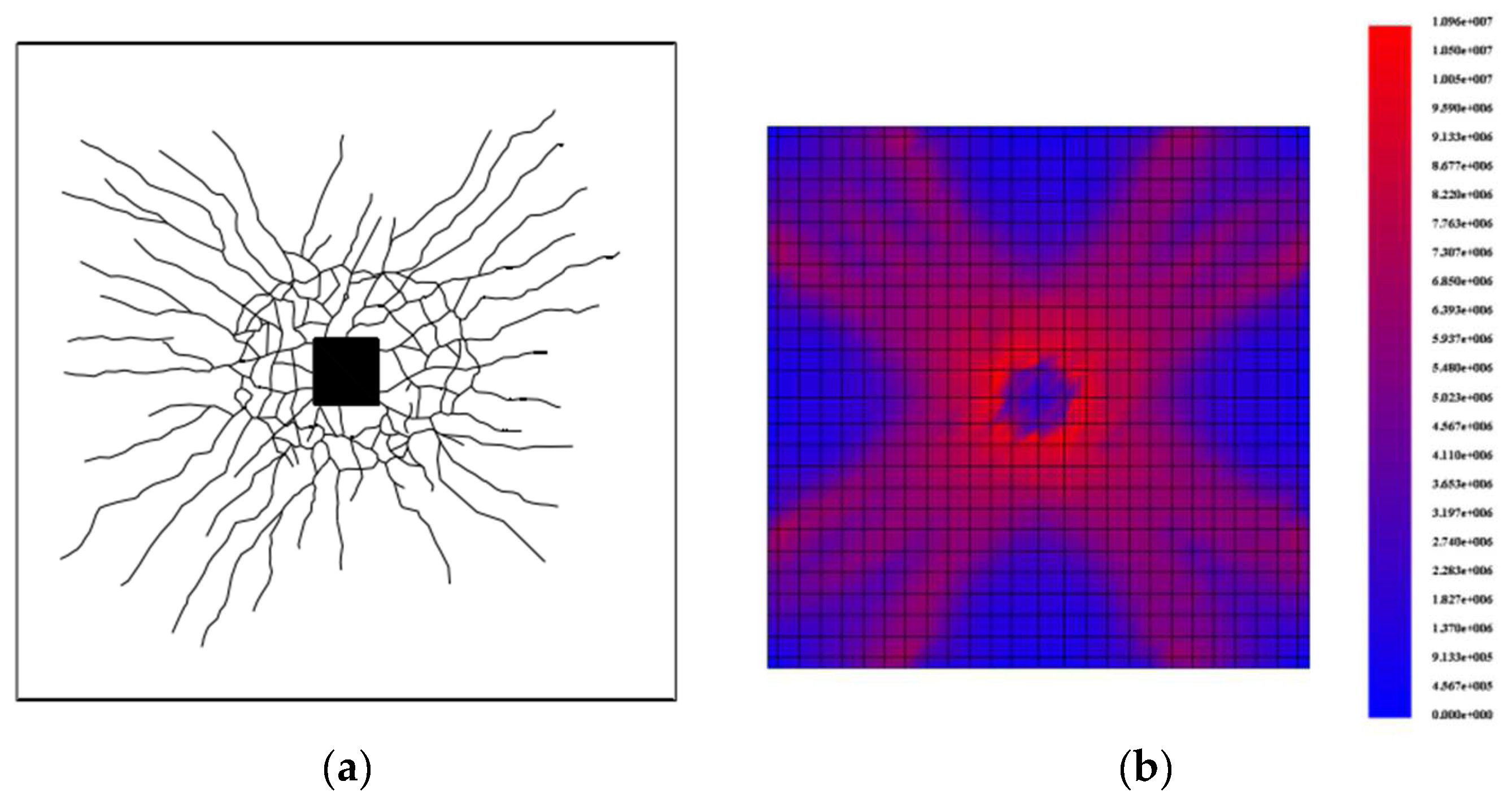

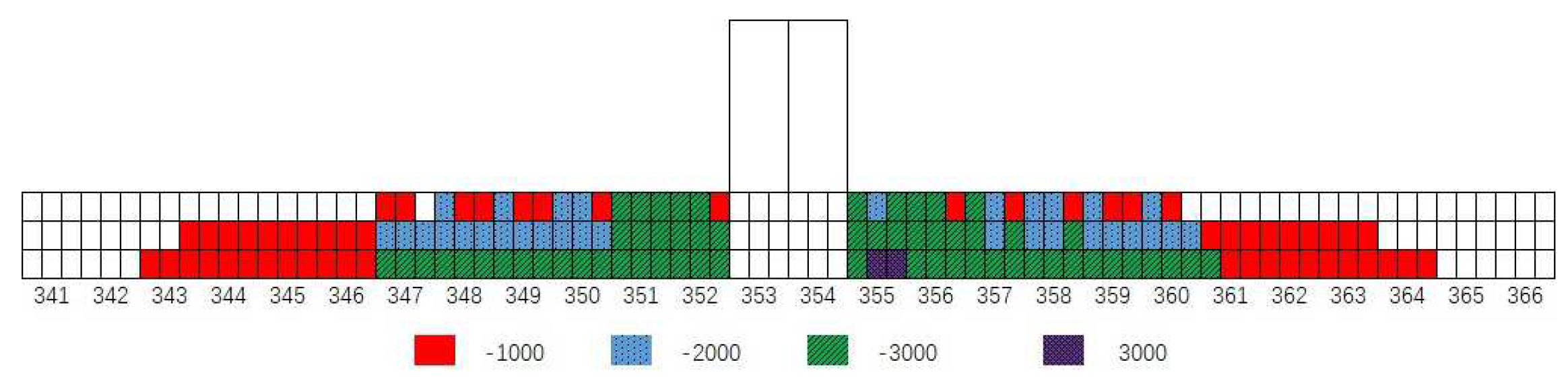

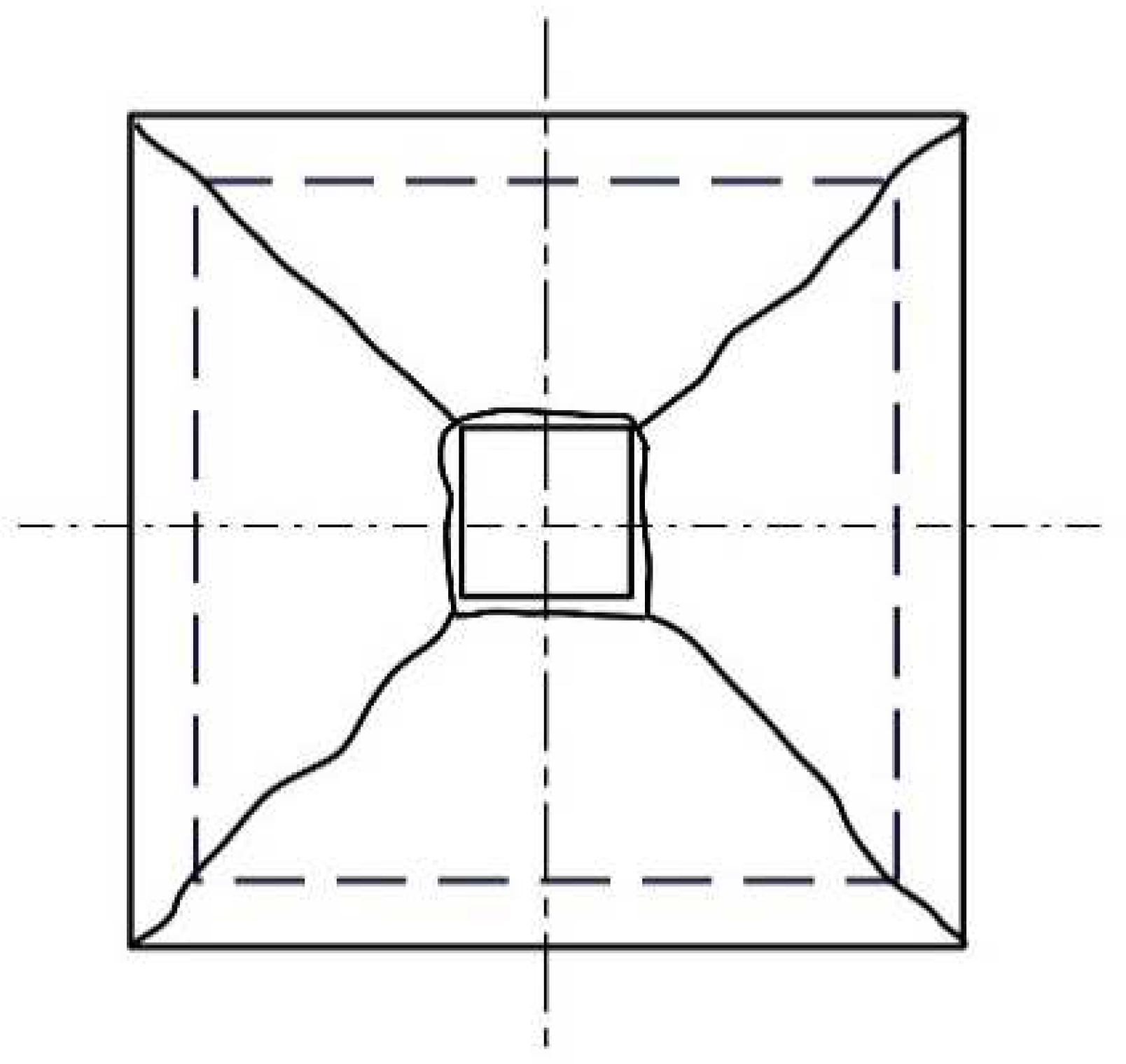

3.2. Analysis of Failure Modes

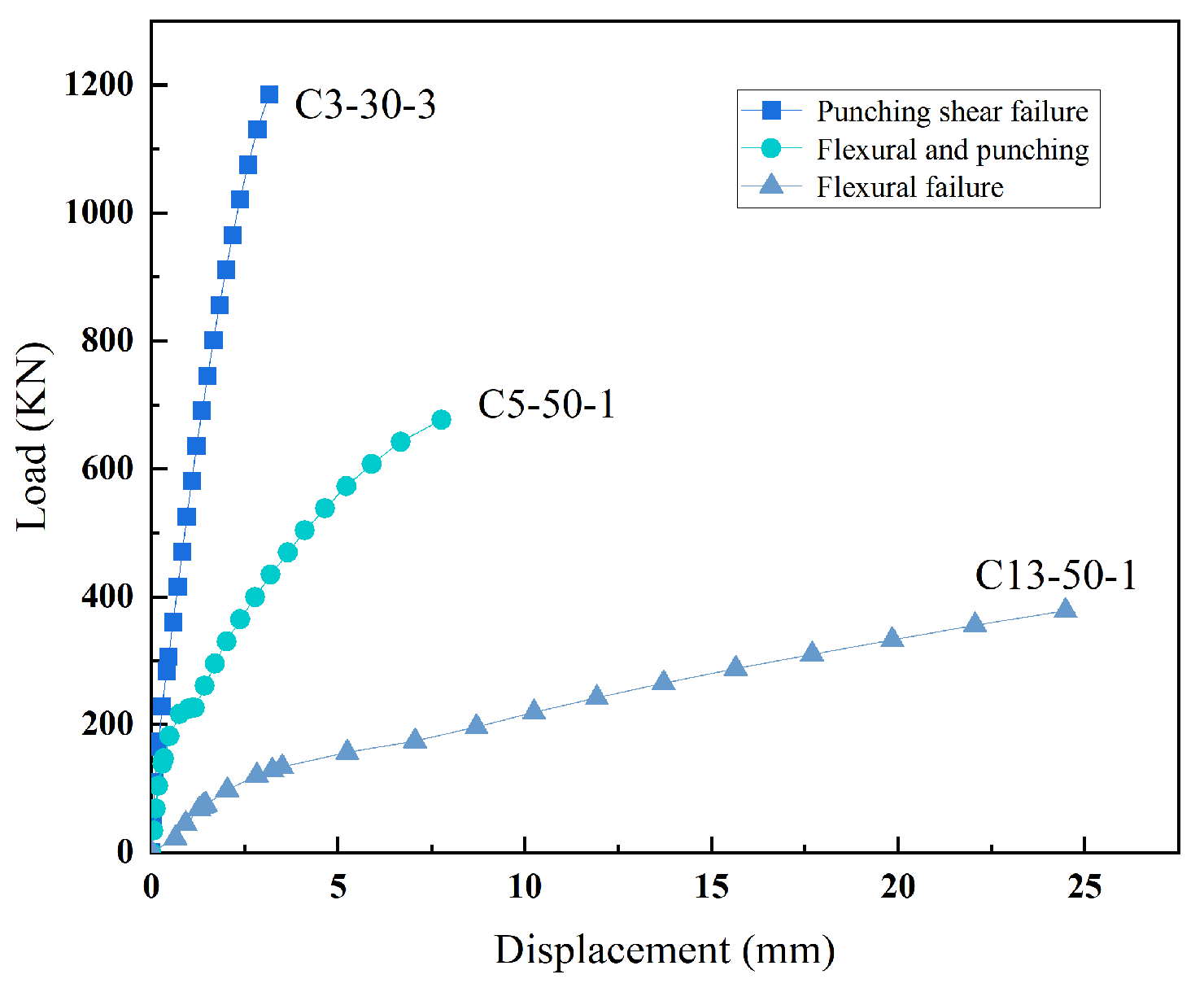

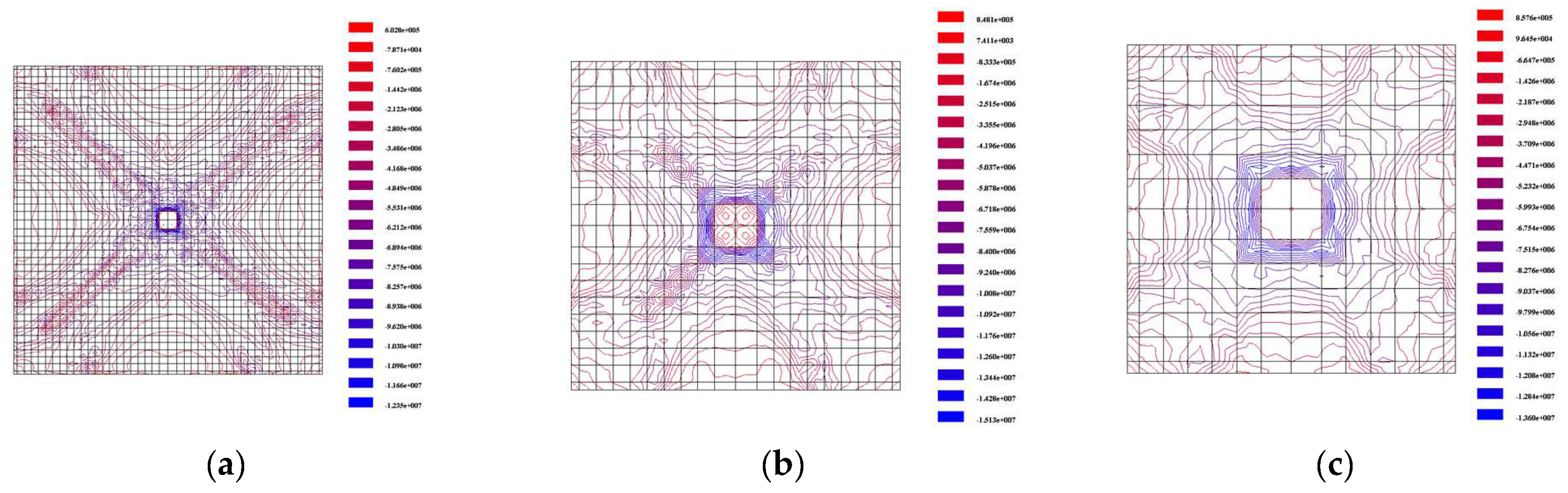

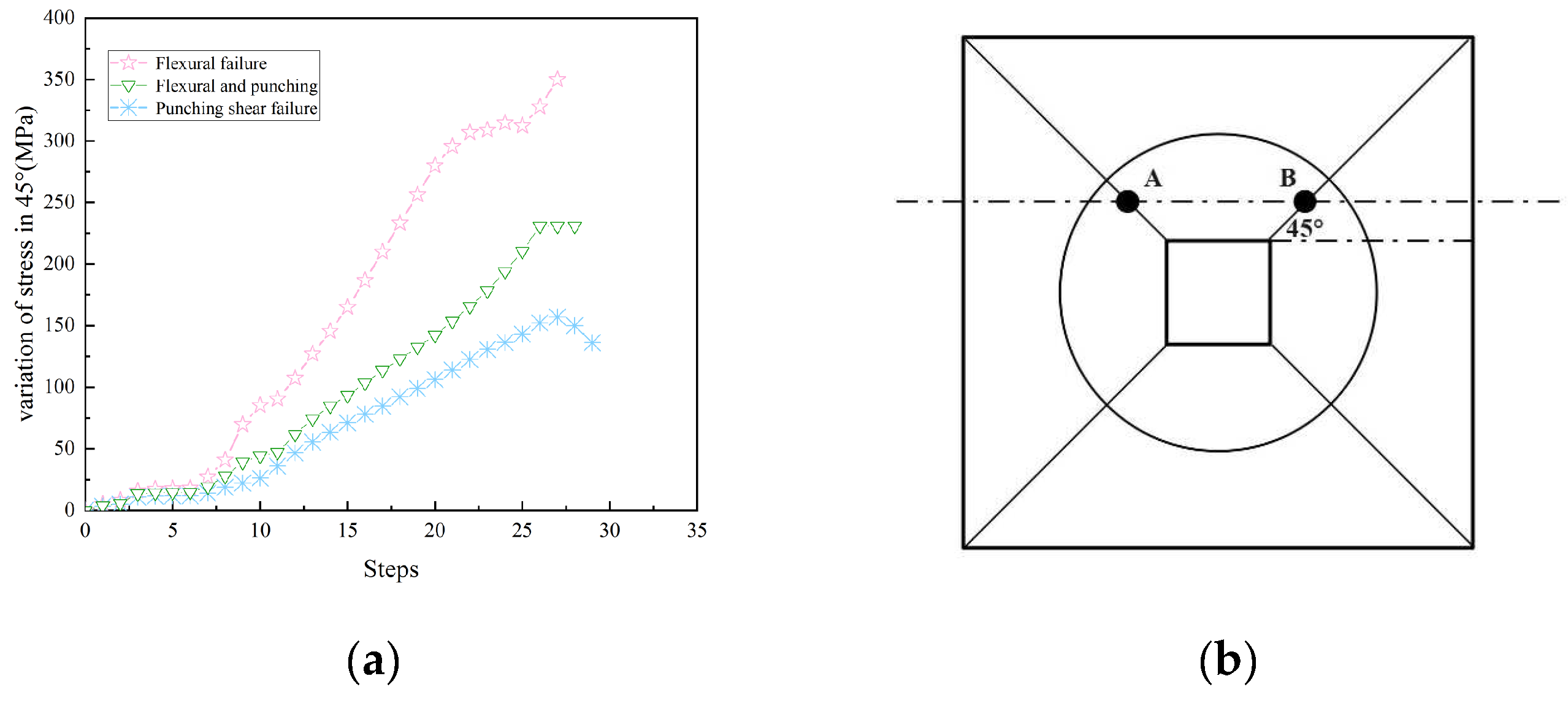

3.2.1. Three Failure Modes

| Load–Deflection Curve (Figure 13) | Stress Contour Plot (Figure 14) | Column Head Reinforcement | Stress Change in Rebar at 45° (Figure 15) | Failure Mode |

|---|---|---|---|---|

| Formation of a plateau with a significant change in slope and greater ductility | Formation of distinct plastic hinge lines | Early yielding | Multiple rising segments in rebar stress | Flexural |

| Slight change in slope, slightly more ductile | No plastic hinge line formed | Late yielding | Rebar stresses did not show multiple rising segments | Flexural–punching |

| The slope hardly changes and the brittleness phenomenon is obvious | No plastic hinge line formed | Unyielding | No rise in rebar stress | Punching |

3.2.2. Influence of Punch–Span Ratio and Longitudinal Reinforcement Eigenvalues on Failure Modes

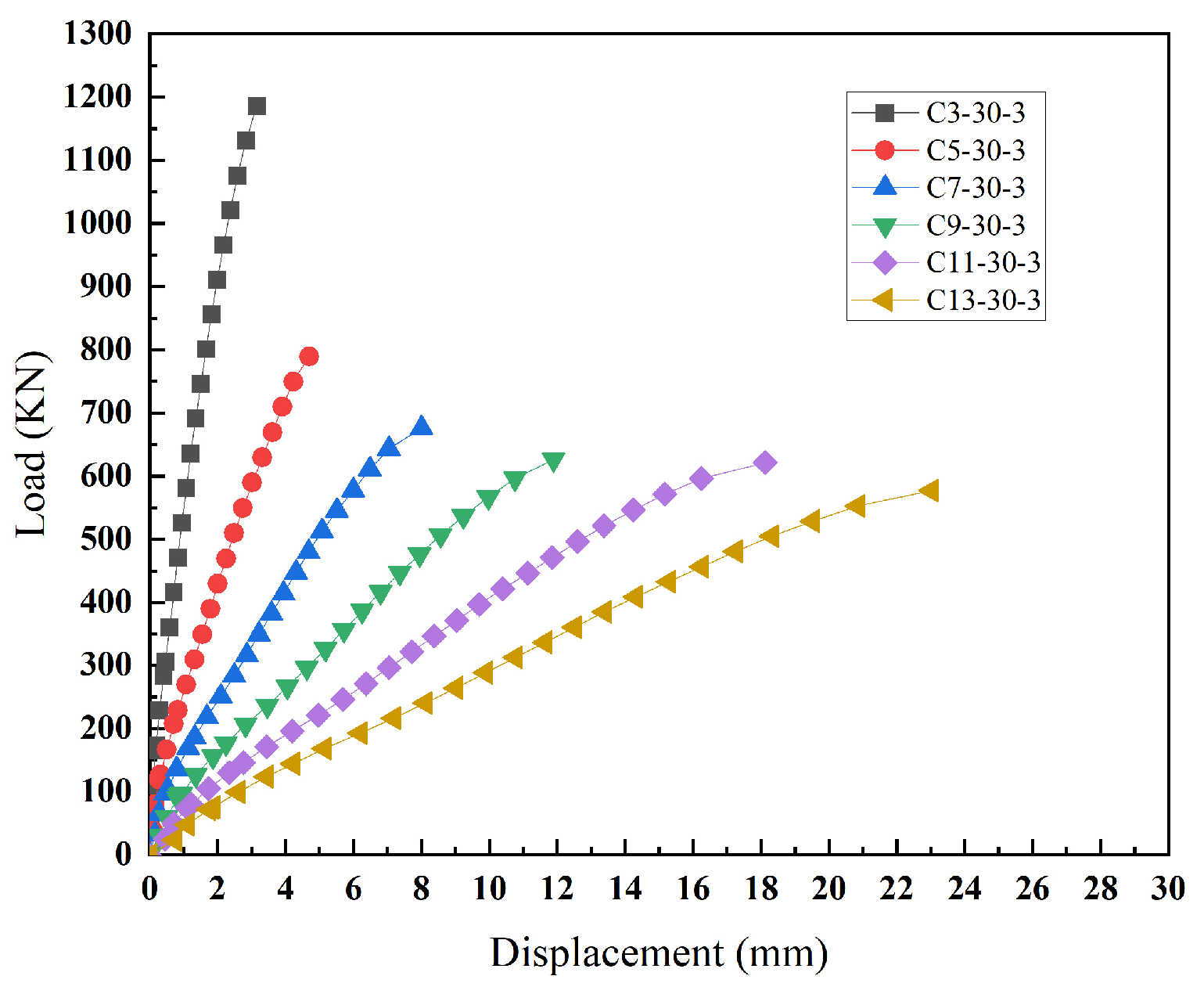

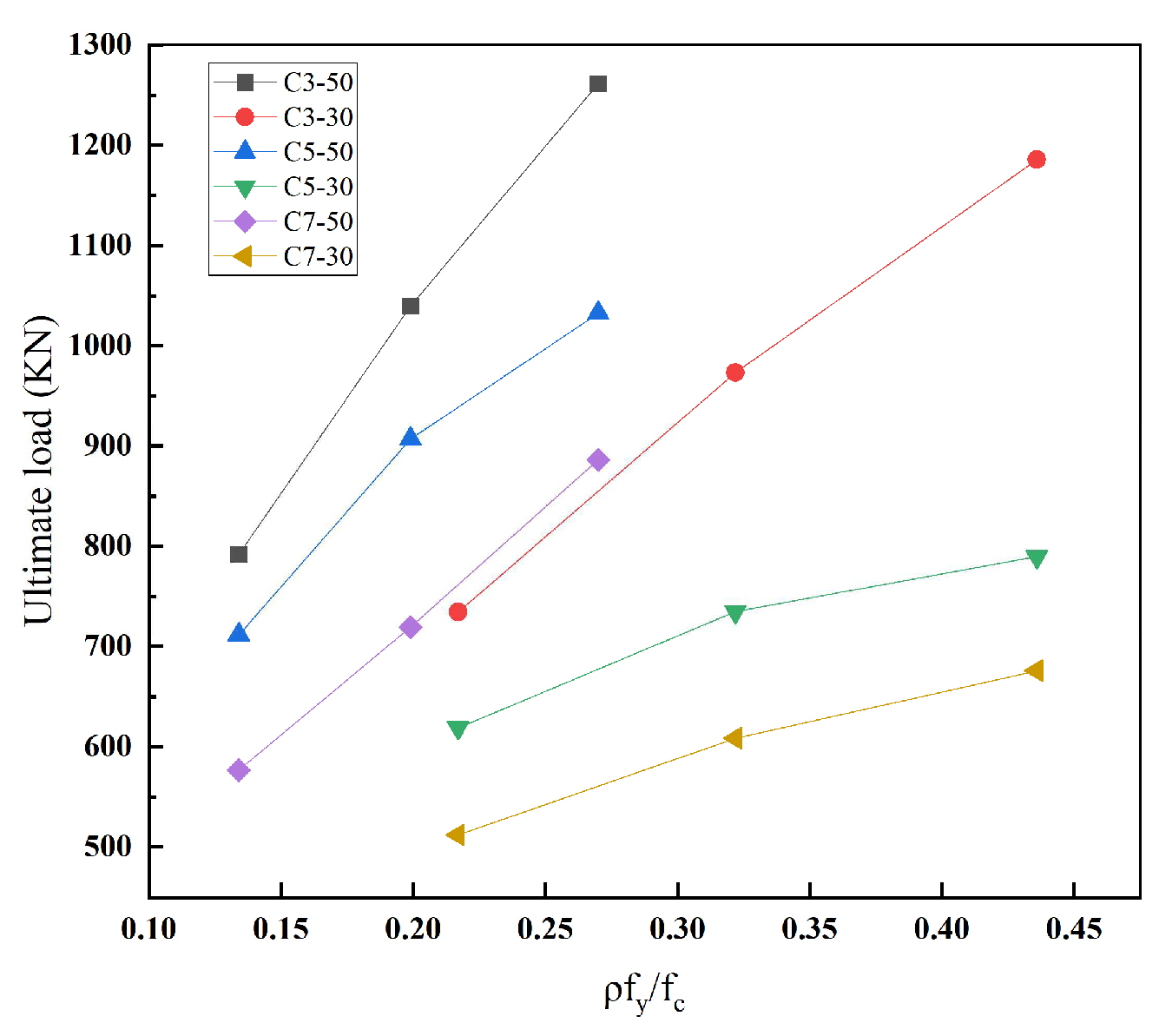

3.3. Analysis of Ultimate Bearing Capacity

3.3.1. Effect of Punch–Span Ratio

3.3.2. Effect of Longitudinal Reinforcement of Eigenvalues

4. Calculation Formula for Ultimate Load Capacity

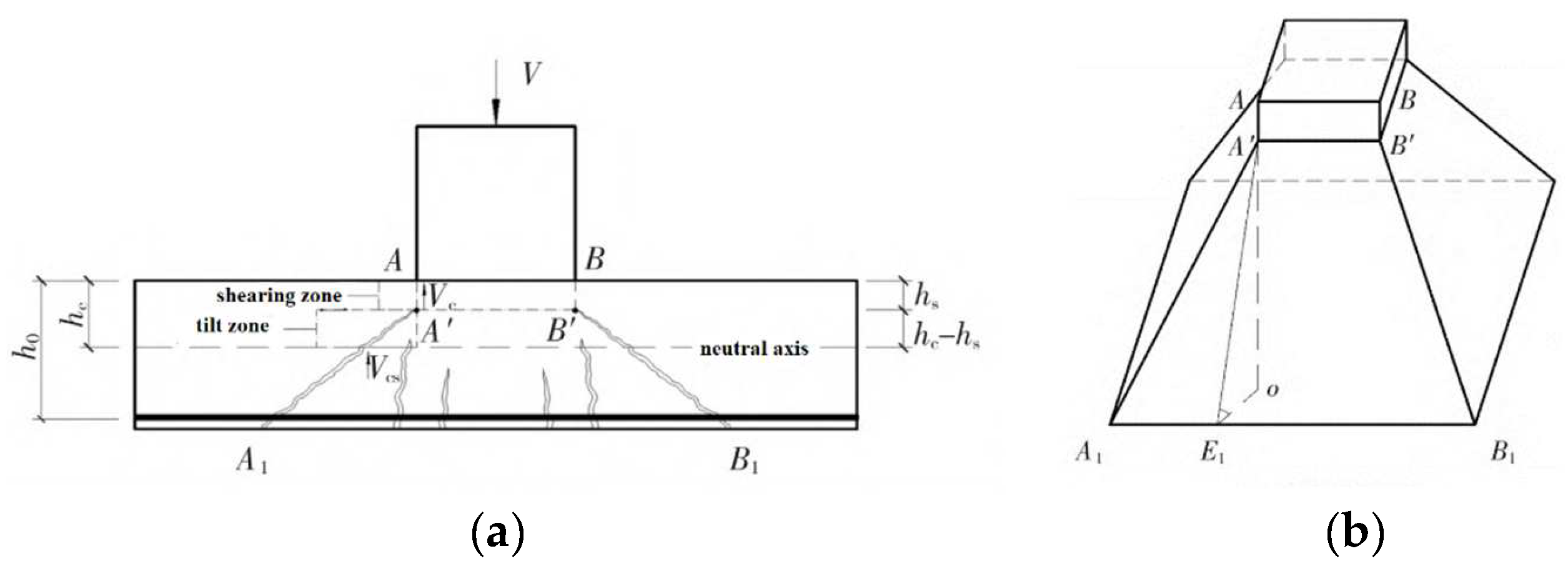

4.1. Model of Anti-Shear and Formulation of Bearing Capacity

4.2. Flexural (Punching) Models and Their Load-Bearing Capacity Expressions

4.3. Fitting and Analysis of the Formulas for Calculating Punching and Flexural Failure Capacity

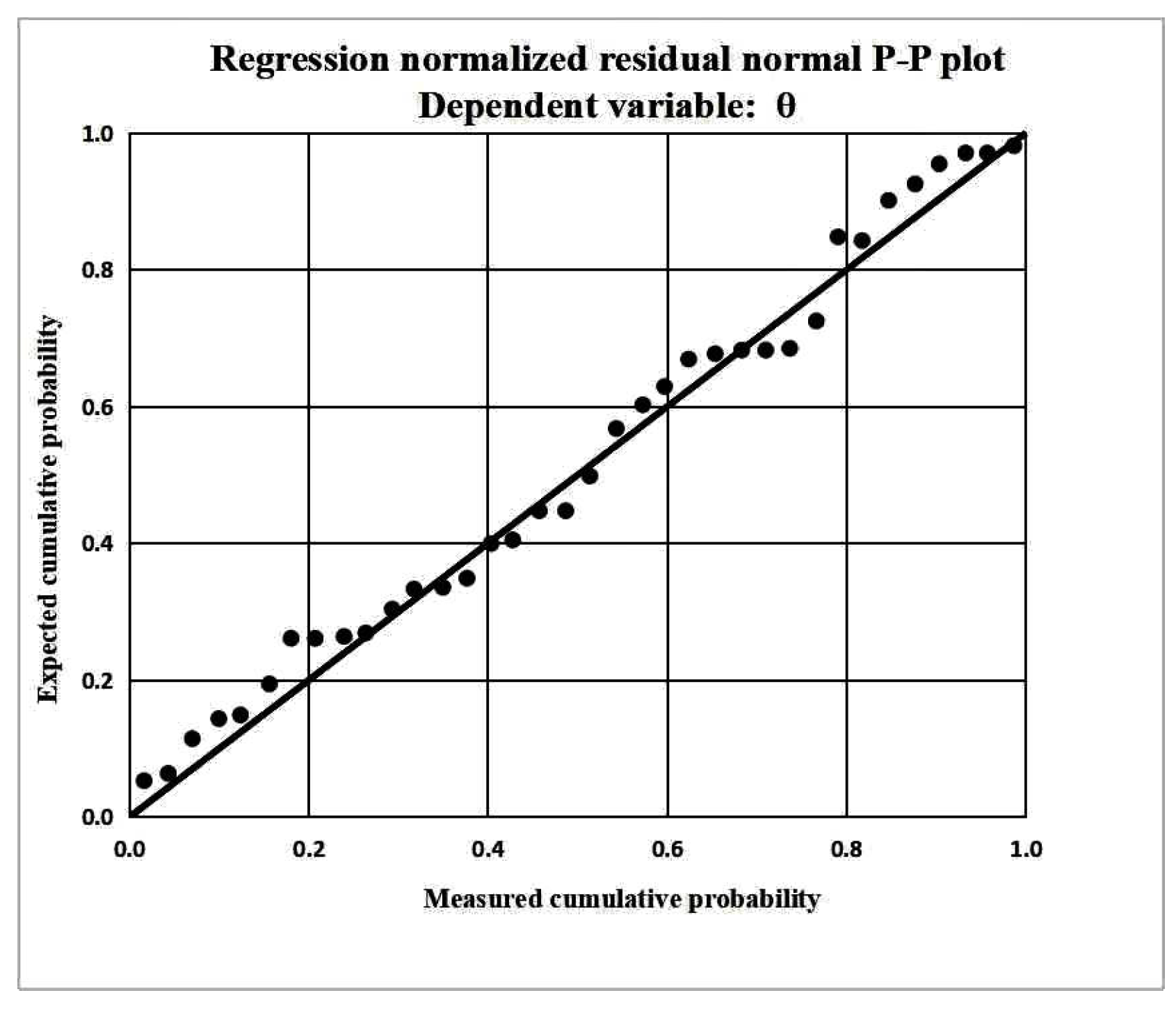

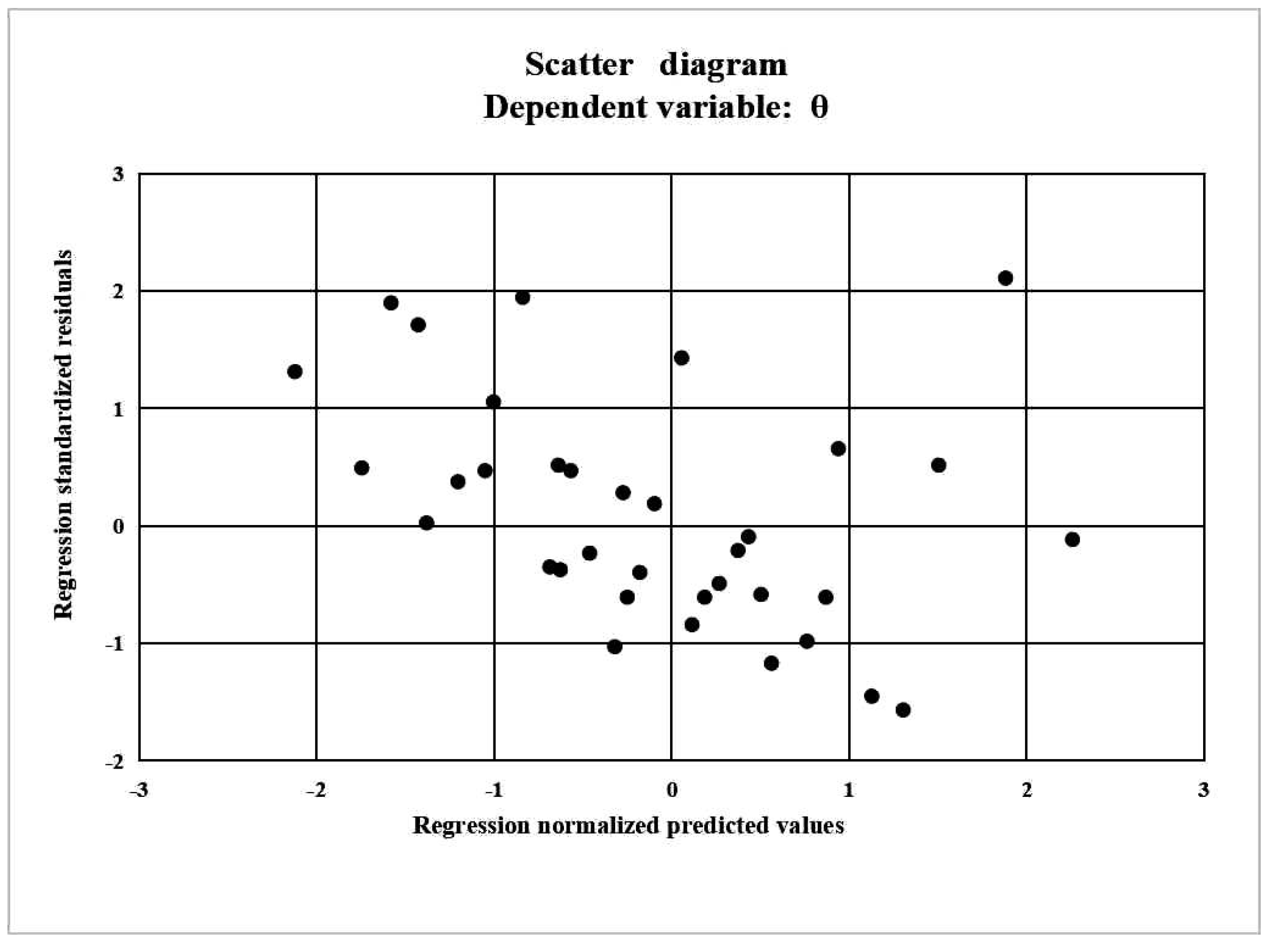

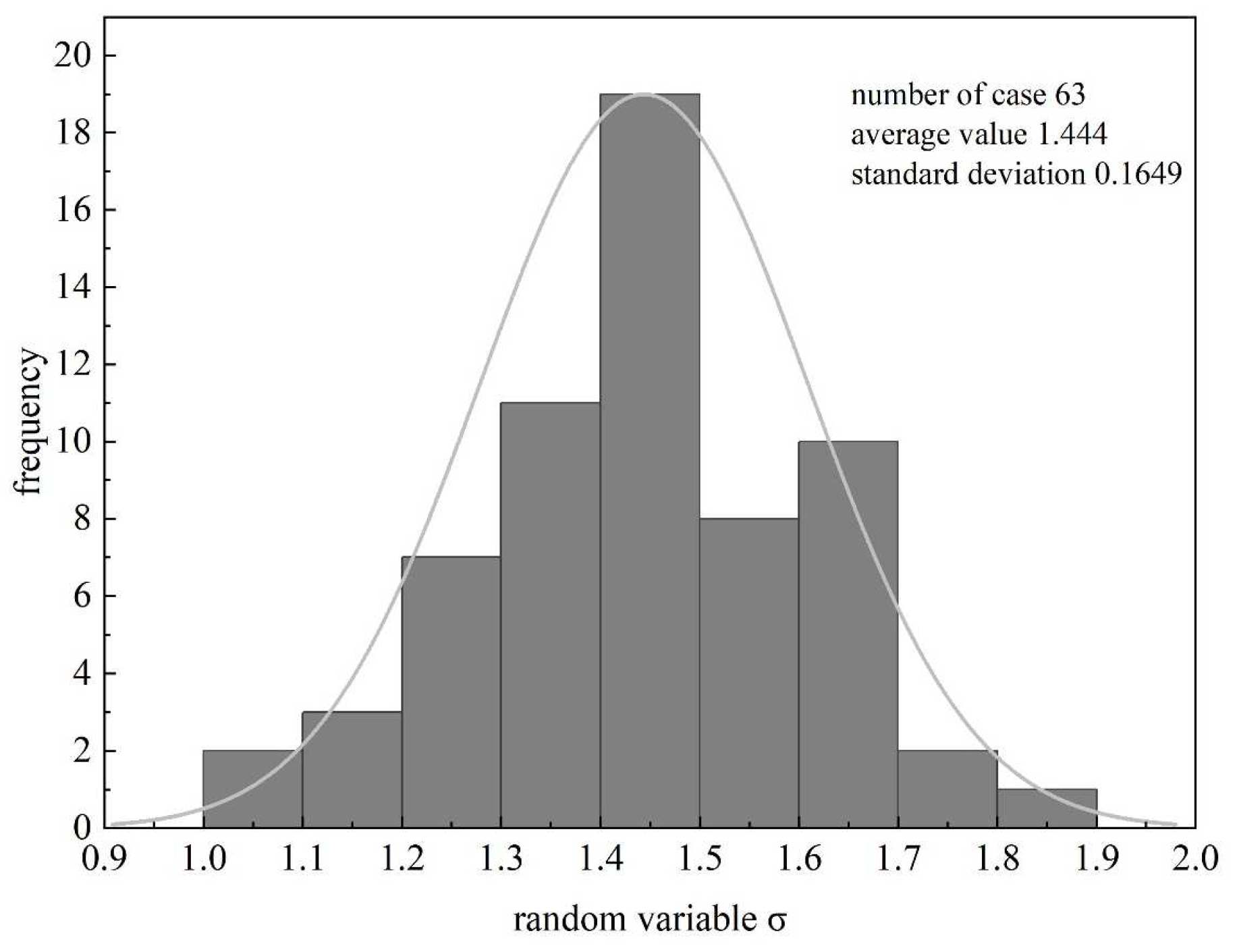

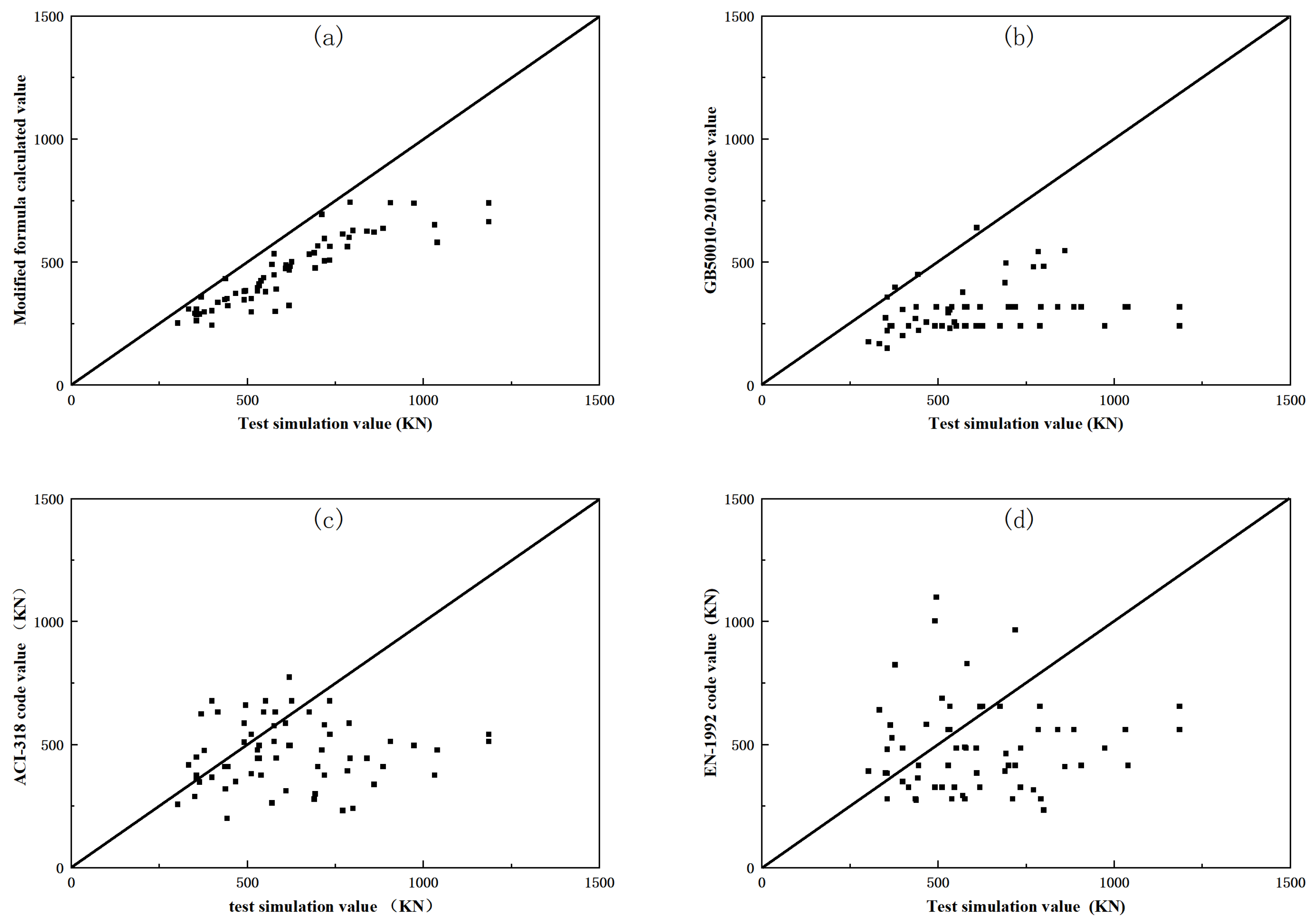

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zheng, W.; Wang, G.; Wang, Y. Research Progress in Bearing Capacity Calculation Methods of Slab-Column Connections. J. Harbin Inst. Technol. 2022, 54, 1–7. [Google Scholar] [CrossRef]

- Huang, X.-N.; Li, Q.-H.; Tong, J.-Z.; Xu, S.-L.; Lu, Y.-C. Punching Shear Behavior and Strength Prediction of UHTCC-Enhanced RC Slab-Column Joints. Eng. Struct. 2023, 286, 116162. [Google Scholar] [CrossRef]

- Hernández Fraile, D.; Setiawan, A.; Borges Dos Santos, J.; Muttoni, A. Punching Tests on Edge Slab-Column Connections with Refined Measurements. Eng. Struct. 2023, 288, 116166. [Google Scholar] [CrossRef]

- Beaulieu, P.M.; Polak, M.A. Finite Element Model for Concrete Slab-Column Connections with Shear Reinforcement. J. Struct. Eng. 2023, 149, 04023177. [Google Scholar] [CrossRef]

- Yankelevsky, D.Z.; Karinski, Y.S.; Feldgun, V.R. Damage and Failure of a Column-Supported RC Flat Slab Subjected to Impulsive Loading. Appl. Sci. 2023, 13, 1933. [Google Scholar] [CrossRef]

- DI, Z.; Yang, X.; Lin, X. Punching Shear Failure Test and Joint Bearing Capacity Analysis of Building Slab Column Structure. J. JILIN Univ. Eng. Technol. Ed. 2022, 53, 2879–2885. [Google Scholar] [CrossRef]

- Liu, L. Experimental Study on Punching Shear Strength of RC Slabs with the Effect of Column Aspect Ratios and Flexural Reinforcement Ratios; Institute of Building Structures China Academy of Building Research: Beijing, China, 2006. [Google Scholar]

- Xia, C.; Shi, Q.; Wang, Z. Calculation of Punching Shear Capacity of RC Slab-Columnconnections without Shear Reinforcement. J. HARBIN Inst. Technol. 2022, 54, 18–24. [Google Scholar] [CrossRef]

- Tian, Y.; Chen, J.; Said, A.; Zhao, J. Nonlinear Modeling of Flat-Plate Structures Using Grid Beam Elements. Comput. Concr. 2012, 10, 489–505. [Google Scholar] [CrossRef]

- Wang, R. Study on Punching Shear Strength of Reinforced Concrete Slabs. Master’s Thesis, Hunan University, Changsha, China, 2013. [Google Scholar]

- Li, L. ABAOUS FEM Analysis on Edge Column-Slab Connections. Sichuan Build. Sci. 2013, 39, 32–35. [Google Scholar]

- Deng, Q. Study on Punching Shear Behavior and Capacity of Reinforced Concrete Slab-Column Connections. Ph.D. Thesis, Hunan University, Changsha, China, 2018. [Google Scholar]

- Tong, Y.; Sun, J.; Wu, L.; Liang, S. Finite Element Analysis of Plate-Column Node Resistance to Finite Element Analysis of Punching Performance. Water Resour. Plan. Des. 2022, 12, 9584. [Google Scholar]

- Xu, X.; Guo, Y.; Shen, Y. Nonlinear Finite Element and Programming; Zhejiang University Press: Hangzhou, China, 1993. [Google Scholar]

- Zararis, P.D. Shear Compression Failure in Reinforced Concrete Deep Beams. J. Struct. Eng. 2003, 129, 544–553. [Google Scholar] [CrossRef]

- Michael, C.P.; Frank, V.J. The Modified Compression-Field Theory for Reinforced Concrete Elements Subjected to Shear. ACI J. Proc. 1986, 83, 219–231. [Google Scholar] [CrossRef]

- Yu, Z. Calculation of Ultimate Load Capacity of Reinforced Alkaline Slabs and Foundations and Determination of Damage Types. J. Build. Struct. 1994, 11, 46–54. [Google Scholar] [CrossRef]

- Xu, X.; Lin, D. Physical Degradation Unit Series. Chin. J. Solid Mech. 2001, 22, 1–12. [Google Scholar]

- Chen, H.; Sapri, A.F. Constitutive Equations for Concrete and Soil; China Architecture & Building Press: Beijing, China, 2004. [Google Scholar]

- Guo, Z.; Shi, X. Reinforced Concrete Theory and Analyse; Tsinghua University Press: Beijing, China, 2003. [Google Scholar]

- Willam, K. Plasticity in Reinforced Concrete. Comput. Methods Appl. Mech. Eng. 1982, 31, 363. [Google Scholar] [CrossRef]

- Wang, X.; Shao, M. Finite Element and Numerical Method; Tsinghua University Press: Beijing, China, 1997. [Google Scholar]

- Bergan, P.; Holand, I.; Soreide, T. Use of Current Stiffness Parameter in Solution of Nonlinear Problems, Energy Methods in Finite Element Analysis; John Wiley & Sons: Hoboken, NJ, USA, 1979. [Google Scholar]

- Zhan, M. Study on Load-Carrying Mechanism to Resist Progressive Collapse of RC Structures Considering Cast-in-Place Slab. Master’s Thesis, Nanchang University, Nanchang, China, 2021. [Google Scholar]

- Wen, Z. Nonlinear Analysis of Temperature Effect to Over-Long RC Frame Structures. Master’s Thesis, Nanchang University, Nanchang, China, 2020. [Google Scholar]

- Jia, Y.; Wu, G.; Yang, C.; Zhang, Q.; Yuan, Z. Simulation Analysis on Lateral Stiffness Degradation and Storey Shear Force Redistribution of RC Frame Shear Wall Structure with Different Axial Compression Ratios. Build. Struct. 2016, 46, 50–55. [Google Scholar] [CrossRef]

- Wu, G.; Lin, W.; Wang, J.; Jia, Y.; Xiang, Y. Study on the Effect of Effective Prestressing on the Ultimate Bearing Capacity of Large-Span P. C. Bridges. Chin. J. Comput. Mech. 2013, 30, 362–369. [Google Scholar] [CrossRef]

- Wang, J.; Wu, G.; Xiang, Y.; Ye, G.; Lin, D.; Xu, X. Nonlinear Simulation Study of Prestressed Concrete Bridge Structures. Chin. J. Comput. Mech. 2010, 27, 1–7. [Google Scholar]

- Wu, G. Nonlinearity Analysis Theory and Ultimate Bearing Capacity Calculation Study on Long-Span Pre-Stressed Concrete Bridge. Ph.D. Thesis, Zhejiang University, Hangzhou, China, 2006. [Google Scholar]

- Hong, F. Experimental Study on Punching Shear Failure of Reinforced Concrete Slabs-Column Connection. Ph.D. Thesis, Hunan University, Changsha, China, 2015. [Google Scholar]

- GB 50010-2010; Code for the Design of Coagulation Structures. China Construction Industry Press: Beijing, China, 2015; pp. 28–30.

- Zhen, J.; Zhen, Z. Experimental Study of Punching Strength of Reinforced Concrete Slabs. J. Fuzhou Univ. Sci. 1992, 20, 65–71. [Google Scholar]

- Elstner, R.C.; Hognestad, E. Shearing Strength of Reinforced Concrete Slabs. ACI J. Proc. 1956, 53, 29–58. [Google Scholar] [CrossRef]

- Yi, W.; Hong, F.; Peng, J. Experimental Investigation of Punching Shear Failure of’ Reinforced Concrete Slab-Column Connections. Build. Struct. 2016, 46, 1–9. [Google Scholar]

- ACI 318-19; Building Code Requirements for Structural Concrete. The American Concrete Institute: Farmington Hills, MI, USA, 2019.

- EN 1992–1–1:2004; Eurocode 2, Design of Concrete Structures. British Standards Institution: Brussels, Belgium, 2004.

| Specimen | h0/mm | h/mm | L/mm | c/mm | Concrete Grade | Longitudinal Reinforcement | ρ |

|---|---|---|---|---|---|---|---|

| C7-30-3 | 150 | 180 | 2550 | 250 | C30 | 14@60 | 1.73% |

| C7-50-3 | 2550 | C50 | 14@60 | 1.73% | |||

| C7-70-3 | 2550 | C70 | 14@60 | 1.73% | |||

| C7-50-2 | 2550 | C70 | 14@80 | 1.28% | |||

| C7-30-1 | 2550 | C70 | 14@120 | 0.86% |

| Specimen | L/mm | ρfy/fc | Concrete Grade | Longitudinal Reinforcement | ρ | λ | Failure Mode |

|---|---|---|---|---|---|---|---|

| C3-30-1 | 1350 | 0.217 | C30 | 14@120 | 0.86% | 3 | punching |

| C3-30-2 | 1350 | 0.322 | C30 | 14@80 | 1.28% | 3 | punching |

| C3-30-3 | 1350 | 0.436 | C30 | 14@60 | 1.73% | 3 | punching |

| C3-50-1 | 1350 | 0.134 | C50 | 14@120 | 0.86% | 3 | punching |

| C3-50-2 | 1350 | 0.199 | C50 | 14@80 | 1.28% | 3 | punching |

| C3-50-3 | 1350 | 0.270 | C50 | 14@60 | 1.73% | 3 | punching |

| C5-30-1 | 1950 | 0.217 | C30 | 14@120 | 0.86% | 5 | punching |

| C5-30-2 | 1950 | 0.322 | C30 | 14@80 | 1.28% | 5 | punching |

| C5-30-3 | 1950 | 0.436 | C30 | 14@60 | 1.73% | 5 | punching |

| C5-50-1 | 1950 | 0.134 | C50 | 14@120 | 0.86% | 5 | flexural and punching |

| C5-50-2 | 1950 | 0.199 | C50 | 14@80 | 1.28% | 5 | punching |

| C5-50-3 | 1950 | 0.270 | C50 | 14@60 | 1.73% | 5 | punching |

| C7-30-1 | 2250 | 0.217 | C30 | 14@120 | 0.86% | 7 | punching |

| C7-30-2 | 2250 | 0.322 | C30 | 14@80 | 1.28% | 7 | punching |

| C7-30-3 | 2250 | 0.436 | C30 | 14@60 | 1.73% | 7 | punching |

| C7-50-1 | 2250 | 0.134 | C50 | 14@120 | 0.86% | 7 | flexural and punching |

| C7-50-2 | 2550 | 0.199 | C50 | 14@80 | 1.28% | 7 | punching |

| C7-50-3 | 2250 | 0.270 | C50 | 14@60 | 1.73% | 7 | punching |

| C9-30-1 | 3150 | 0.217 | C30 | 14@120 | 0.86% | 9 | punching |

| C9-30-2 | 3150 | 0.322 | C30 | 14@80 | 1.28% | 9 | punching |

| C9-30-3 | 3150 | 0.436 | C30 | 14@60 | 1.73% | 9 | punching |

| C9-50-1 | 3150 | 0.134 | C50 | 14@120 | 0.86% | 9 | flexural and punching |

| C9-50-2 | 3150 | 0.199 | C50 | 14@80 | 1.28% | 9 | flexural and punching |

| C9-50-3 | 3150 | 0.270 | C50 | 14@60 | 1.73% | 9 | flexural and punching |

| C11-30-1 | 3750 | 0.217 | C30 | 14@120 | 0.86% | 11 | flexural |

| C11-30-2 | 3750 | 0.322 | C30 | 14@80 | 1.28% | 11 | flexural and punching |

| C11-30-3 | 3750 | 0.436 | C30 | 14@60 | 1.73% | 11 | punching |

| C11-50-1 | 3750 | 0.134 | C50 | 14@120 | 0.86% | 11 | flexural |

| C11-50-2 | 3750 | 0.199 | C50 | 14@80 | 1.28% | 11 | flexural |

| C11-50-3 | 3750 | 0.270 | C50 | 14@60 | 1.73% | 11 | flexural and punching |

| C13-30-1 | 4350 | 0.217 | C30 | 14@120 | 0.86% | 13 | flexural |

| C13-30-2 | 4350 | 0.322 | C30 | 14@80 | 1.28% | 13 | flexural |

| C13-30-3 | 4350 | 0.436 | C30 | 14@60 | 1.73% | 13 | flexural and punching |

| C13-50-1 | 4350 | 0.134 | C50 | 14@120 | 0.86% | 13 | flexural |

| C13-50-2 | 4350 | 0.199 | C50 | 14@80 | 1.28% | 13 | flexural |

| C13-50-3 | 4350 | 0.270 | C50 | 14@60 | 1.73% | 13 | flexural |

| C15-30-1 | 4350 | 0.217 | C30 | 14@120 | 0.86% | 15 | flexural |

| C15-30-2 | 4350 | 0.322 | C30 | 14@80 | 1.28% | 15 | flexural |

| C15-30-3 | 4350 | 0.436 | C30 | 14@60 | 1.73% | 15 | flexural |

| C15-50-1 | 4350 | 0.134 | C50 | 14@120 | 0.86% | 15 | flexural |

| C15-50-2 | 4350 | 0.199 | C50 | 14@80 | 1.28% | 15 | flexural |

| C15-50-3 | 4350 | 0.270 | C50 | 14@60 | 1.73% | 15 | flexural |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wei, X.; Lu, L.; Ke, N.; Jia, Y.; Wu, G. A Study on the Effects of Punch-to-Span Ratio and Longitudinal Reinforcement Eigenvalues on the Bearing Capacity of RC Slab–Column Connections. Buildings 2024, 14, 208. https://doi.org/10.3390/buildings14010208

Wei X, Lu L, Ke N, Jia Y, Wu G. A Study on the Effects of Punch-to-Span Ratio and Longitudinal Reinforcement Eigenvalues on the Bearing Capacity of RC Slab–Column Connections. Buildings. 2024; 14(1):208. https://doi.org/10.3390/buildings14010208

Chicago/Turabian StyleWei, Xianglan, Liangjian Lu, Naiwen Ke, Yigang Jia, and Guangyu Wu. 2024. "A Study on the Effects of Punch-to-Span Ratio and Longitudinal Reinforcement Eigenvalues on the Bearing Capacity of RC Slab–Column Connections" Buildings 14, no. 1: 208. https://doi.org/10.3390/buildings14010208

APA StyleWei, X., Lu, L., Ke, N., Jia, Y., & Wu, G. (2024). A Study on the Effects of Punch-to-Span Ratio and Longitudinal Reinforcement Eigenvalues on the Bearing Capacity of RC Slab–Column Connections. Buildings, 14(1), 208. https://doi.org/10.3390/buildings14010208