Holistic Review of Construction Process Carbon-Reduction Measures: A Systematic Literature Review Approach

Abstract

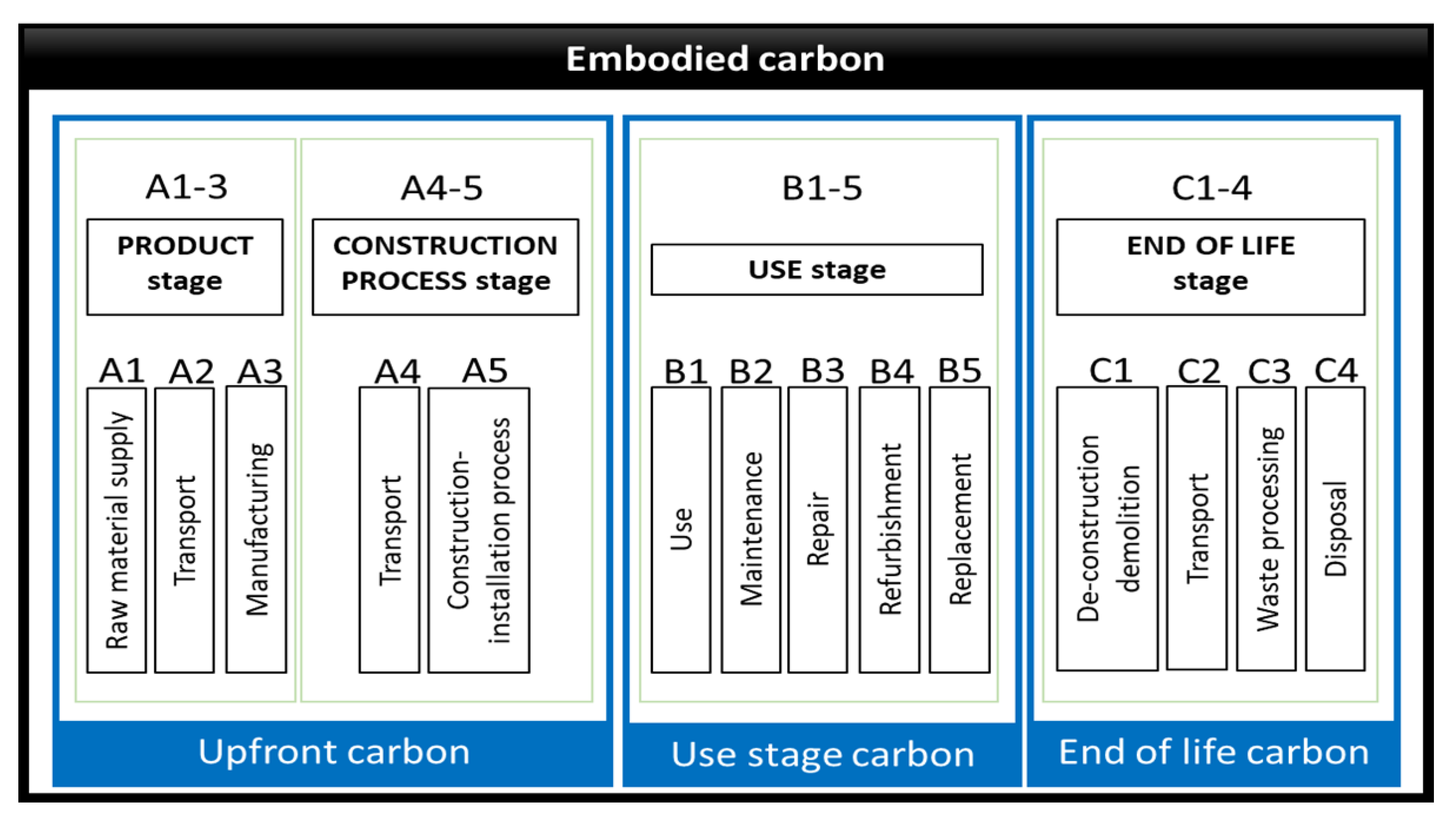

1. Introduction and Theoretical Background

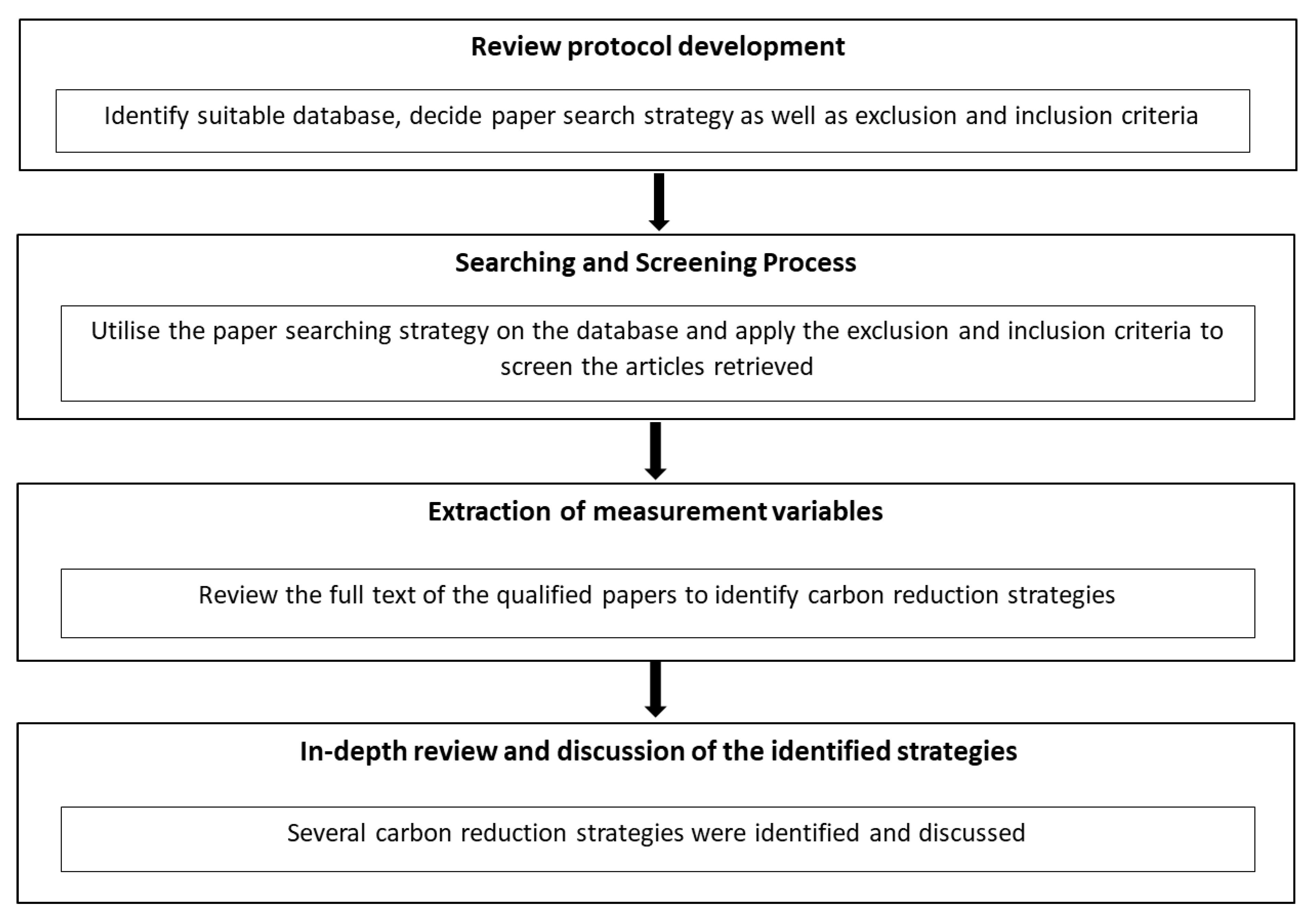

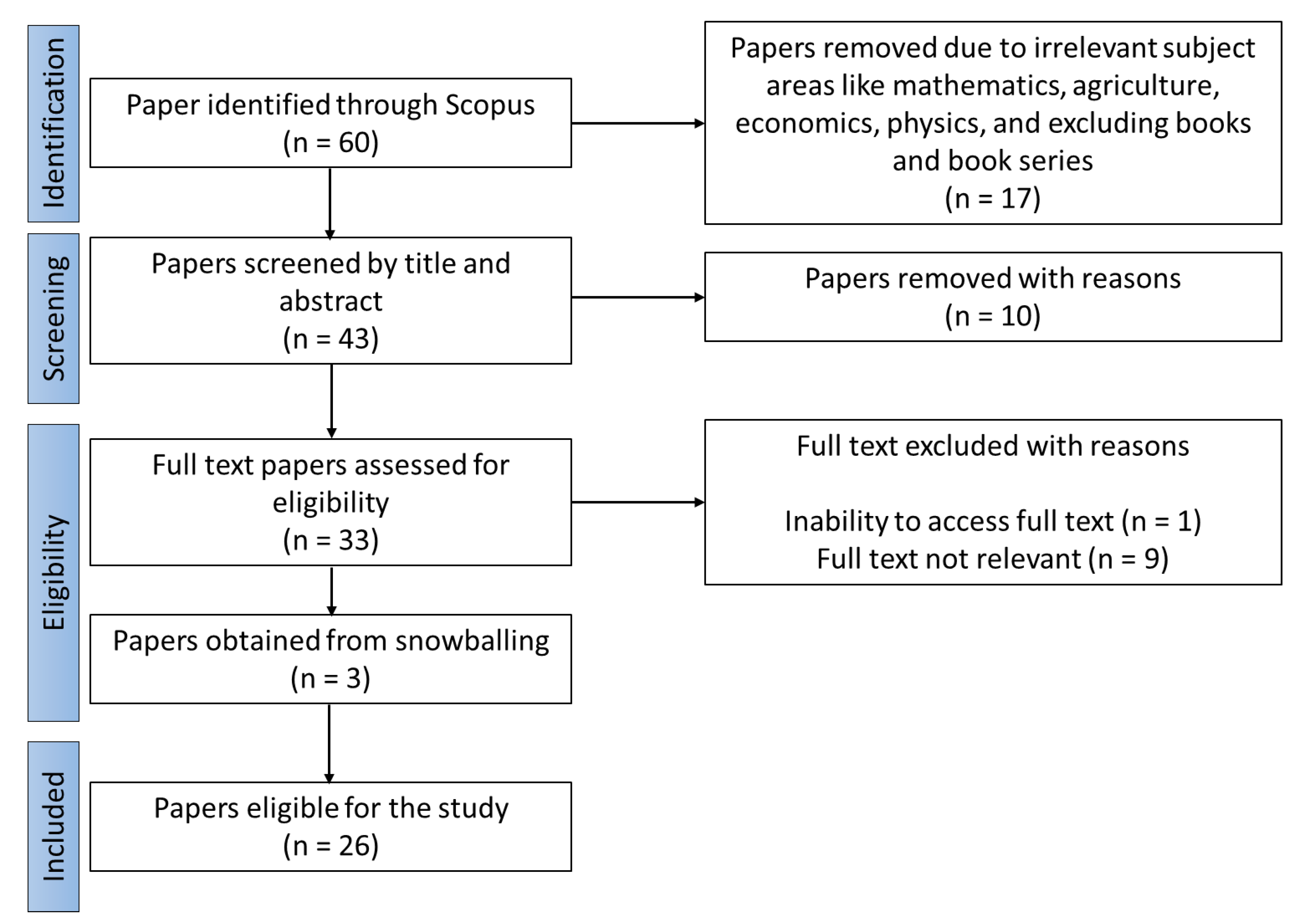

2. Method

- i.

- “construction phase” OR “construction stage” OR “construction process”

- ii.

- “carbon emission reduction” OR “carbon reduction” OR “greenhouse gas emission reduction” OR “ghg reduction” OR “ghg emission reduction” OR “embodied carbon reduction” OR “embodied carbon emission reduction”

3. Results and Discussion

3.1. Construction Process Carbon-Reduction Strategies

3.1.1. Transportation Stage

Material Transport

Waste Transport

3.1.2. Construction-Installation Stage

Machinery and Equipment

Waste

Material

On-Site Lighting

On-Site Office

On-Site Transportation of Material and Equipment

Construction Method

4. Conclusions, Limitations, and Contribution of the Study

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Giesekam, J.; Tingley, D.D.; Cotton, I. Aligning Carbon Targets for Construction with (Inter) National Climate Change Mitigation Commitments. Energy Build. 2018, 65, 106–117. [Google Scholar] [CrossRef]

- Global Alliance for Buildings and Construction; International Energy Agency; United Nations Environment Programme. 2019 Global Status Report for Buildings and Construction: Towards a Zero-Emission, Efficient and Resilient Buildings and Construction Sector. Available online: https://webstore.iea.org/download/direct/2930?fileName=2019_Global_Status_Report_for_Buildings_and_Construction.pdf (accessed on 16 February 2021).

- UN Environment and International Energy Agency. Towards a Zero-Emission, Efficient, and Resilient Buildings and Construction Sector; United Nations Environment Programme: Nairobi, Kenya, 2017. [Google Scholar]

- Huang, L.; Krigsvoll, G.; Johansen, F.; Liu, Y.; Zhang, X. Carbon Emission of Global Construction Sector. Renew. Sustain. Energy Rev. 2018, 81, 1906–1916. [Google Scholar] [CrossRef]

- BS EN 15978:2011; Sustainability of Construction Works—Assessment of Environmental Performance of Buildings—Calculation Method. European Committee for Standardization: Brussels, Belgium, 2011.

- Arogundade, S.; Dulaimi, M.; Ajayi, S. Carbon Reduction during Building Construction Projects—Trend Mapping from Construction Journals. In Proceedings of the CIB International Conference on Smart Built Environment, Virtual, 14–16 December 2021; Dulaimi, M., Elhag, T., Eds.; CIB: Dubai, United Arab Emirates, 2021. [Google Scholar]

- Kong, A.; Kang, H.; He, S.; Li, N.; Wang, W. Study on the Carbon Emissions in the Whole Construction Process of Prefabricated Floor Slab. Appl. Sci. 2020, 10, 2326. [Google Scholar] [CrossRef]

- Pomponi, F.; Giesekam, J.; Hart, J.; D’Amico, B. Embodied Carbon Status Quo and Suggested Roadmap. In Report to Zero Waste Scotland; JH Sustianability: Edinburgh, UK, 2020. [Google Scholar]

- Victoria, M.F.; Perera, S. Managing Embodied Carbon in Buildings: A Pareto Approach. Built Environ. Proj. Asset Manag. 2018, 8, 504–514. [Google Scholar] [CrossRef]

- Hong, J.; Shen, G.Q.; Feng, Y.; Lau, W.S.T.; Mao, C. Greenhouse Gas Emissions during the Construction Phase of a Building: A Case Study in China. J. Clean. Prod. 2015, 103, 249–259. [Google Scholar] [CrossRef]

- Fang, Y.; Lu, X.; Zhang, Y. Carbon Emissions Analysis for Construction Process. In ICCREM 2019; American Society of Civil Engineers: Reston, VA, USA, 2019; pp. 648–654. [Google Scholar]

- World Green Building Council: Annual Report 2015/2016; World GBC: Washington, DC, USA, 2016; pp. 1–19.

- Pomponi, F.; Moncaster, A. Embodied Carbon Mitigation and Reduction in the Built Environment—What Does the Evidence Say? J. Environ. Manag. 2016, 181, 687–700. [Google Scholar] [CrossRef]

- Tranfield, D.; Denyer, D.; Smart, P. Towards a Methodology for Developing Evidence-Informed Management Knowledge by Means of Systematic Review. Br. J. Manag. 2003, 14, 207–222. [Google Scholar] [CrossRef]

- Ershadi, M.; Davis, P.; Newaz, M.T. Systematic Review of Resilience Measures: Construction Management Graduates’ Perspective. Int. J. Constr. Manag. 2020, 22, 2037–2050. [Google Scholar] [CrossRef]

- Darko, A.; Chan, A.P.C. Critical Analysis of Green Building Research Trend in Construction Journals. Habitat Int. 2016, 57, 53–63. [Google Scholar] [CrossRef]

- Oliveros, J.; Vaz-Serra, P. Construction Project Manager Skills: A Systematic Literature Review. In Engaging Architectural Science: Meeting the Challenges of Higher Density, Proceedings of the 52nd International Conference of the Architectural Science Association, Melbourne, Australian, 28 November–1 December 2018; Rajagopalan, P., Andamon, M., Eds.; Architectural Science Association: Perth, Australia, 2018; pp. 185–192. [Google Scholar]

- Saad, A.M.; Dulaimi, M.; Zulu, S.L. A Systematic Review of the Business Contingencies Influencing Broader Adoption: Modern Methods of Construction (MMC). Buildings 2023, 13, 878. [Google Scholar] [CrossRef]

- Deng, F.; Smyth, H. Contingency-Based Approach to Firm Performance in Construction: Critical Review of Empirical Research. J. Constr. Eng. Manag. 2013, 139, 04013004. [Google Scholar] [CrossRef]

- Dikert, K.; Paasivaara, M.; Lassenius, C. Challenges and Success Factors for Large-Scale Agile Transformations: A Systematic Literature Review. J. Syst. Softw. 2016, 119, 87–108. [Google Scholar] [CrossRef]

- Arogundade, S.; Dulaimi, M.; Ajayi, S. The Role of Contractors in Reducing Carbon during Construction—A Preliminary Study Building Construction Projects Lifecycle Stages. In Proceedings of the 7th International Sustainable Ecological Engineering Design for Society Conference, Bristol, UK, 1–3 September 2021; Gorse, C., Dickinson, I., Drotleff, B., Eds.; LSI: Leeds, UK, 2021. [Google Scholar]

- Charef, R.; Alaka, H.; Emmitt, S. Beyond the Third Dimension of BIM: A Systematic Review of Literature and Assessment of Professional Views. J. Build. Eng. 2018, 19, 242–257. [Google Scholar] [CrossRef]

- Cheng, B.; Luo, X.; Mei, X.; Chen, H.; Huang, J. A Systematic Review of Eye-Tracking Studies of Construction Safety. Front. Neurosci. 2022, 16, 891725. [Google Scholar] [CrossRef] [PubMed]

- Saad, A.; Ajayi, S.O.; Alaka, H.A. Trends in BIM-Based Plugins Development for Construction Activities: A Systematic Review. Int. J. Constr. Manag. 2022, 1–13. [Google Scholar] [CrossRef]

- Darko, A.; Zhang, C.; Chan, A.P.C. Drivers for Green Building: A Review of Empirical Studies. Habitat Int. 2017, 60, 34–49. [Google Scholar] [CrossRef]

- Kumari, T.; Kulathunga, U.; Hewavitharana, T.; Madusanka, N. Embodied Carbon Reduction Strategies for High-Rise Buildings in Sri Lanka. Int. J. Constr. Manag. 2020, 22, 2605–2613. [Google Scholar] [CrossRef]

- Sandanayake, M.; Zhang, G.; Setunge, S.; Luo, W.; Li, C.Q. Estimation and Comparison of Environmental Emissions and Impacts at Foundation and Structure Construction Stages of a Building—A Case Study. J. Clean. Prod. 2017, 151, 319–329. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, F. Hybrid Input-Output Analysis for Life-Cycle Energy Consumption and Carbon Emissions of China’s Building Sector. Build. Environ. 2016, 104, 188–197. [Google Scholar] [CrossRef]

- Sattary, S.; Thorpe, D. Potential Carbon Emission Reductions in Australian Construction Systems through Bioclimatic Principles. Sustain. Cities Soc. 2016, 23, 105–113. [Google Scholar] [CrossRef]

- Ko, J. Carbon: Reducing the Footprint of the Construction Process. 2010; pp. 1–64. Available online: www.bis.gov.uk/policies/business-sectors/construction/sustainable-construction (accessed on 26 November 2021).

- Li, Y.F.; Yu, C.C.; Chen, S.Y.; Sainey, B. The Carbon Footprint Calculation of the Gfrp Pedestrian Bridge at Tai-Jiang National Park. Int. Rev. Spat. Plan. Sustain. Dev. 2013, 1, 13–28. [Google Scholar] [CrossRef]

- Wu, W.; Sun, P.; Zhou, H. The Case Study of Carbon Emission in Building Construction Process. IOP Conf. Ser. Earth Environ. Sci. 2019, 371, 022011. [Google Scholar] [CrossRef]

- Jang, W.; You, H.W.; Han, S.H. Quantitative Decision Making Model for Carbon Reduction in Road Construction Projects Using Green Technologies. Sustainability 2015, 7, 11240–11259. [Google Scholar] [CrossRef]

- Truitt, P. Potential for Reducing Greenhouse Gas Emissions in the Construction Sector; US Environmental Protection Agency: Washington, DC, USA, 2009.

- Yanli, S.; Chao, L. Measurement and Analysis of Carbon Emissions from Prefabricated Buildings under the Transition of New and Old Kinetic Energy. IOP Conf. Ser. Earth Environ. Sci. 2021, 813, 012007. [Google Scholar] [CrossRef]

- Shau, H.J.; Liu, T.Y.; Chen, P.H.; Chou, N.N.S. Sustainability Practices for the Suhua Highway Improvement Project in Taiwan. Int. J. Civ. Eng. 2019, 17, 1631–1641. [Google Scholar] [CrossRef]

- Gottsche, J.; Kelly, M.; Taggart, M. Assessing the Impact of Energy Management Initiatives on the Energy Usage during the Construction Phase of an Educational Building Project in Ireland. Constr. Manag. Econ. 2016, 34, 46–60. [Google Scholar] [CrossRef]

- Wong, P.S.; Owczarek, A.; Murison, M.; Kefalianos, Z.; Spinozzi, J. Driving Construction Contractors to Adopt Carbon Reduction Strategies—An Australian Approach. J. Environ. Plan. Manag. 2014, 57, 1465–1483. [Google Scholar] [CrossRef]

- Liu, J. Financial Promotion for Low Carbon Project Implementation Using Public-Private Partnerships (PPPs) during Highway Construction. Am. Soc. Civ. Eng. (ASCE) 2017, 184–196. [Google Scholar] [CrossRef]

- Dalene, F. Technology and Information Management for Low-Carbon Building. J. Renew. Sustain. Energy 2012, 4, 041402. [Google Scholar] [CrossRef]

- Fernández-Sánchez, G.; Berzosa, Á.; Barandica, J.M.; Cornejo, E.; Serrano, J.M. Opportunities for GHG Emissions Reduction in Road Projects: A Comparative Evaluation of Emissions Scenarios Using CO2NSTRUCT. J. Clean. Prod. 2015, 104, 156–167. [Google Scholar] [CrossRef]

- Ding, Z.; Liu, S.; Luo, L.; Liao, L. A Building Information Modeling-Based Carbon Emission Measurement System for Prefabricated Residential Buildings during the Materialization Phase. J. Clean. Prod. 2020, 264, 121728. [Google Scholar] [CrossRef]

- Ghafoor, S.; Crawford, R.H. Comparative Study of the Life Cycle Embodied Greenhouse Gas Emissions of Panelised Prefabricated Residential Walling Systems in Australia. In Proceedings of the International Conference of Architectural Science Association 2020, Auckland, New Zealand, 26–27 November 2020; pp. 256–265. [Google Scholar]

- Teng, Y.; Pan, W. Systematic Embodied Carbon Assessment and Reduction of Prefabricated High-Rise Public Residential Buildings in Hong Kong. J. Clean. Prod. 2019, 238, 117791. [Google Scholar] [CrossRef]

- Lawania, K.; Biswas, W.K. Application of Life Cycle Assessment Approach to Deliver Low Carbon Houses at Regional Level in Western Australia. Int. J. Life Cycle Assess. 2018, 23, 204–224. [Google Scholar] [CrossRef]

- Pan, W.; Teng, Y.; Li, K.; Yu, C. Implications of Prefabrication for the Life Cycle Carbon Emissions of High-Rise Buildings in High-Density Urban Environment. Am. Soc. Civ. Eng. (ASCE) 2018, 2010, 493–502. [Google Scholar]

- Zhang, X.; Zhang, X. A Subproject-Based Quota Approach for Life Cycle Carbon Assessment at the Building Design and Construction Stage in China. Build. Environ. 2020, 185, 107258. [Google Scholar] [CrossRef]

- Fang, Y.; Ng, S.T.; Ma, Z.; Li, H. Quota-Based Carbon Tracing Model for Construction Processes in China. J. Clean. Prod. 2018, 200, 657–666. [Google Scholar] [CrossRef]

- Teng, Y.; Li, K.; Pan, W.; Ng, T. Reducing Building Life Cycle Carbon Emissions through Prefabrication: Evidence from and Gaps in Empirical Studies. Build. Environ. 2018, 132, 125–136. [Google Scholar] [CrossRef]

- Sandanayake, M.; Zhang, G.; Setunge, S.; Li, C.Q. Environmental Emissions in Building Construction—Two Case Studies of Conventional and Pre-Fabricated Construction Methods in Australia. Sustain. Constr. Mater. Technol. 2016, 7–11. [Google Scholar] [CrossRef]

- Hong, J.; Shen, G.Q.; Peng, Y.; Feng, Y.; Mao, C. Reprint of: Uncertainty Analysis for Measuring Greenhouse Gas Emissions in the Building Construction Phase: A Case Study in China. J. Clean. Prod. 2017, 163, S420–S432. [Google Scholar] [CrossRef]

- Shen, J.; Yin, X.; Zhou, Q. Research on a Calculation Model and Control Measures for Carbon Emission of Buildings. Am. Soc. Civ. Eng. (ASCE) 2018, 32–41. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhao, Q.; Ma, Z. Research on a Carbon Emission Calculation Model of Construction Phase. In ICCREM 2014: Smart Construction and Management in the Context of New Technology, Proceedings of the 2014 International Conference on Construction and Real Estate Management, Kunming, China, 27 September 2014; American Society of Civil Engineers: Reston, VA, USA, 2014; pp. 436–441. [Google Scholar]

- Maués, L.M.; Beltrão, N.; Silva, I. Ghg Emissions Assessment of Civil Construction Waste Disposal and Transportation Process in the Eastern Amazon. Sustainability 2021, 13, 5666. [Google Scholar] [CrossRef]

- Sizirici, B.; Fseha, Y.; Cho, C.S.; Yildiz, I.; Byon, Y.J. A Review of Carbon Footprint Reduction in Construction Industry, from Design to Operation. Materials 2021, 14, 6094. [Google Scholar] [CrossRef] [PubMed]

- Wong, P.S.P.; Zapantis, J. Driving Carbon Reduction Strategies Adoption in the Australian Construction Sector—The Moderating Role of Organizational Culture. Build. Environ. 2013, 66, 120–130. [Google Scholar] [CrossRef]

- Seo, M.S.; Kim, T.; Hong, G.; Kim, H. On-Site Measurements of CO2 Emissions during the Construction Phase of a Building Complex. Energies 2016, 9, 599. [Google Scholar] [CrossRef]

- Avetisyan, H.G.; Miller-Hooks, E.; Melanta, S. Decision Models to Support Greenhouse Gas Emissions Reduction from Transportation Construction Projects. J. Constr. Eng. Manag. 2012, 138, 631–641. [Google Scholar] [CrossRef]

- Szamocki, N.; Kim, M.-K.; Ahn Changbum, R.; Brilakis, I. Reducing Greenhouse Gas Emission of Construction Equipment on Construction Sites: A Field Study Approach. Am. Soc. Civ. Eng. (ASCE) 2019, 145, 34. [Google Scholar] [CrossRef]

- Liu, J.; Li, Y.; Wang, Z. The Potential for Carbon Reduction in Construction Waste Sorting: A Dynamic Simulation. Energy 2023, 275, 127477. [Google Scholar] [CrossRef]

- Wibowo, M.A.; Uda, S.A.K.A. Zhabrinna Reducing Carbon Emission in Construction Base on Project Life Cycle (PLC). MATEC Web Conf. 2018, 195, 06002. [Google Scholar] [CrossRef]

- Sanchez, A.X.; Lehtiranta, L.M.; Hampson, K.D. Use of Contract Models to Improve Environmental Outcomes in Transport Infrastructure Construction. J. Environ. Plan. Manag. 2015, 58, 1923–1943. [Google Scholar] [CrossRef]

- Chau, C.K.; Hui, W.K.; Ng, W.Y.; Powell, G. Assessment of CO2 Emissions Reduction in High-Rise Concrete Office Buildings Using Different Material Use Options. Resour. Conserv. Recycl. 2012, 61, 22–34. [Google Scholar] [CrossRef]

- Wu, P.; Xia, B.; Pienaar, J.; Zhao, X. The Past, Present and Future of Carbon Labelling for Construction Materials—A Review. Build. Environ. 2014, 77, 160–168. [Google Scholar] [CrossRef]

- Jamaludin, W.M.R.; Wan, W.M.; Nik Ali, N.H.; Isa, N.A.M. Impact of Incandescent Light and LED on Electricity Fee and Carbon Emission Cost at an Airport in Malaysia. In Proceedings of the 2023 IEEE 3rd International Conference in Power Engineering Applications: Shaping Sustainability Through Power Engineering Innovation, ICPEA 2023, Putrajaya, Malaysia, 6–7 March 2023; pp. 291–295. [Google Scholar]

- Wai, R.J. Systematic Design of Energy-Saving Action Plans for Taiwan Campus by Considering Economic Benefits and Actual Demands. Energies 2022, 15, 6530. [Google Scholar] [CrossRef]

- Carmichael, D.G.; Mustaffa, N.K.; Shen, X. A Utility Measure of Attitudes to Lower-Emissions Production in Construction. J. Clean. Prod. 2018, 202, 23–32. [Google Scholar] [CrossRef]

- Udeaja, C.; Ekundayo, D.; Zhou, L.; Perera, S. Material Waste in the Construction Industry: A Review of the Legislative and Supply Chain Issues. In Green Energy and Technology; Springer: Berlin/Heidelberg, Germany, 2013; pp. 5–27. [Google Scholar]

- BRE. Annex 4—Policy and Legislation. 2007. Available online: https://files.bregroup.com/bre-co-uk-file-library-copy/filelibrary/pdf/rpts/waste/Annex_4_legislation_final.pdf (accessed on 15 July 2022).

- UK Government. Environmental Protection Act 1990; UK Government: London, UK, 2023.

| Category | Carbon-Reduction Strategies | References |

|---|---|---|

| Transportation | ||

| Material Transport | Transport distance optimisation and reduction | [26,27,28] |

| Operational optimisation of transport vehicle (e.g., ensuring the vehicle is loaded to capacity) | [27] | |

| Utilisation of rail or water transport where possible | [26,29] | |

| Ensuring material transport fuel is from renewable source | [30] | |

| Adoption of driving techniques that maximise transport vehicle’s engine efficiency during material transportation to site | [30] | |

| Adoption of lightweight material | [31] | |

| Purchasing materials locally | [29] | |

| Utilisation of locally available material | [26] | |

| Reusing and recycling material on-site | [29] | |

| Waste Transport | Adoption of driving techniques that maximise transport vehicle’s engine efficiency during construction waste transportation | [30] |

| Ensuring fuel utilised during waste transport is from renewable source | [30] | |

| Construction | ||

| Machinery and Equipment | Utilisation of wind or solar energy for powering equipment | [32,33] |

| Utilisation of alternative fuels such as hydrogen and vegetable oils | [30,34] | |

| Usage of low-emission machinery | [32] | |

| Utilisation of multi-purpose and work-specific construction equipment to reduce operation time | [26,30,33,35,36] | |

| Reducing machinery idle time through work scheduling | [26,27,30,36,37] | |

| Reduce number of machinery/equipment through work sequencing | [33] | |

| Provision of training to machine operators on carbon reduction | [33] | |

| Maintaining machinery regularly | [26,30,36] | |

| Selection of fuel-efficient machinery | [30] | |

| Reducing machinery fuel consumption | [38] | |

| Replacing diesel oil machineries with electric ones | [39] | |

| Reducing the usage of cranes on-site | [37] | |

| Waste | Reusing waste material on-site | [26,30,33,40] |

| Utilisation of the correct construction equipment for specific work to reduce waste generated | [26] | |

| Material | Reusing materials (including carbon-intensive material) on-site | [26,29,39,41] |

| Reusing formworks and temporary structure on-site | [26] | |

| Replacing some cement with ground-granulated blast-furnace slag | [26,29,33,36,42,43,44,45,46] | |

| Replacing some cement with coal fly ash | [26,29,36,42,43,44,45,46] | |

| Selection of geopolymer-based cement | [26,29,36,44,45,46] | |

| Reduction in material consumed (e.g., by optimising structural component) | [28,44,47] | |

| Utilisation of recycled material | [27,29,33] | |

| Adequate material resources planning and allocation | [27] | |

| Utilisation of cement in bulk instead of in bags | [39] | |

| Efficiently use temporary construction material on-site | [26] | |

| Purchase of construction materials with carbon labelling scheme | [26] | |

| On-site Lighting | Usage of biodiesel, electricity from renewable sources, etc., for lighting on-site | [41] |

| Reducing the usage of transformer boxes | [37] | |

| Managing night-time electricity | [37] | |

| Usage of light-emitting diode (LED) illuminance control appliances | [39] | |

| Minimising festoon lighting through the use of large stand-alone LED lights | [37] | |

| On-site Office | Utilisation of energy-efficient site accommodation | [30] |

| Switching off office equipment when not in use | [30,37] | |

| Usage of occupant sensor to minimise electricity usage | [30,37] | |

| Utilisation of timer to control heating usage | [37] | |

| On-site Transportation of Material and Equipment | Usage of biodiesel, electricity from renewable sources, etc., for machinery/equipment transportation on-site | [41] |

| Utilisation of intelligent signal lamp (e.g., smart traffic signal) | [39] | |

| Optimise logistics process on-site through adequate work planning | [48] | |

| Optimisation of site management (e.g., by using construction management software) | [26,33] | |

| Construction Method | Proper planning of construction work sequence | [42] |

| Utilisation of prefabrication method of construction | [28,35,42,44,46,49,50] | |

| Adoption of low-emission installation processes minimising waste generation | [43] | |

| Usage of new construction process like modular construction technique | [26,45] | |

| Reducing thickness of the wall | [44] | |

| Usage of energy-measurement management system during construction | [30,39] | |

| Earlier connection of construction site to the grid | [30] | |

| Construction Work Type | Carbon Emission (tCO2) | Percentage (%) |

|---|---|---|

| Civil Engineering | 73.4 | 39.7 |

| RC | 45.5 | 24.6 |

| Steel Frame/Metal and Window/Glazing | 10.1 | 5.5 |

| Interior and Exterior Finishing | 9.6 | 5.2 |

| Ground heat | 46.4 | 25.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Arogundade, S.; Dulaimi, M.; Ajayi, S. Holistic Review of Construction Process Carbon-Reduction Measures: A Systematic Literature Review Approach. Buildings 2023, 13, 1780. https://doi.org/10.3390/buildings13071780

Arogundade S, Dulaimi M, Ajayi S. Holistic Review of Construction Process Carbon-Reduction Measures: A Systematic Literature Review Approach. Buildings. 2023; 13(7):1780. https://doi.org/10.3390/buildings13071780

Chicago/Turabian StyleArogundade, Suhaib, Mohammed Dulaimi, and Saheed Ajayi. 2023. "Holistic Review of Construction Process Carbon-Reduction Measures: A Systematic Literature Review Approach" Buildings 13, no. 7: 1780. https://doi.org/10.3390/buildings13071780

APA StyleArogundade, S., Dulaimi, M., & Ajayi, S. (2023). Holistic Review of Construction Process Carbon-Reduction Measures: A Systematic Literature Review Approach. Buildings, 13(7), 1780. https://doi.org/10.3390/buildings13071780