Seismic Performance and LCA Comparison between Concrete and Timber–Concrete Hybrid Buildings

Abstract

1. Introduction

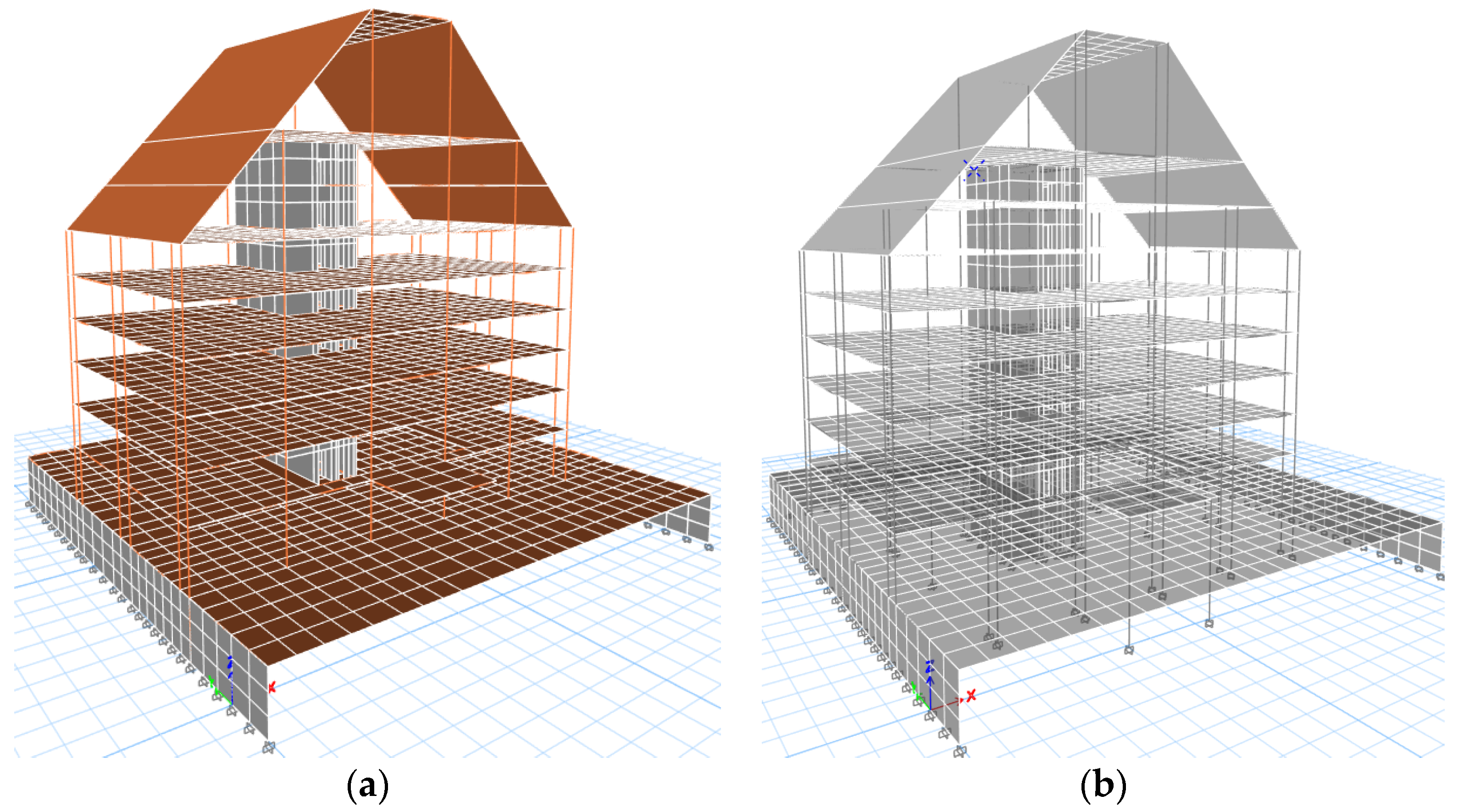

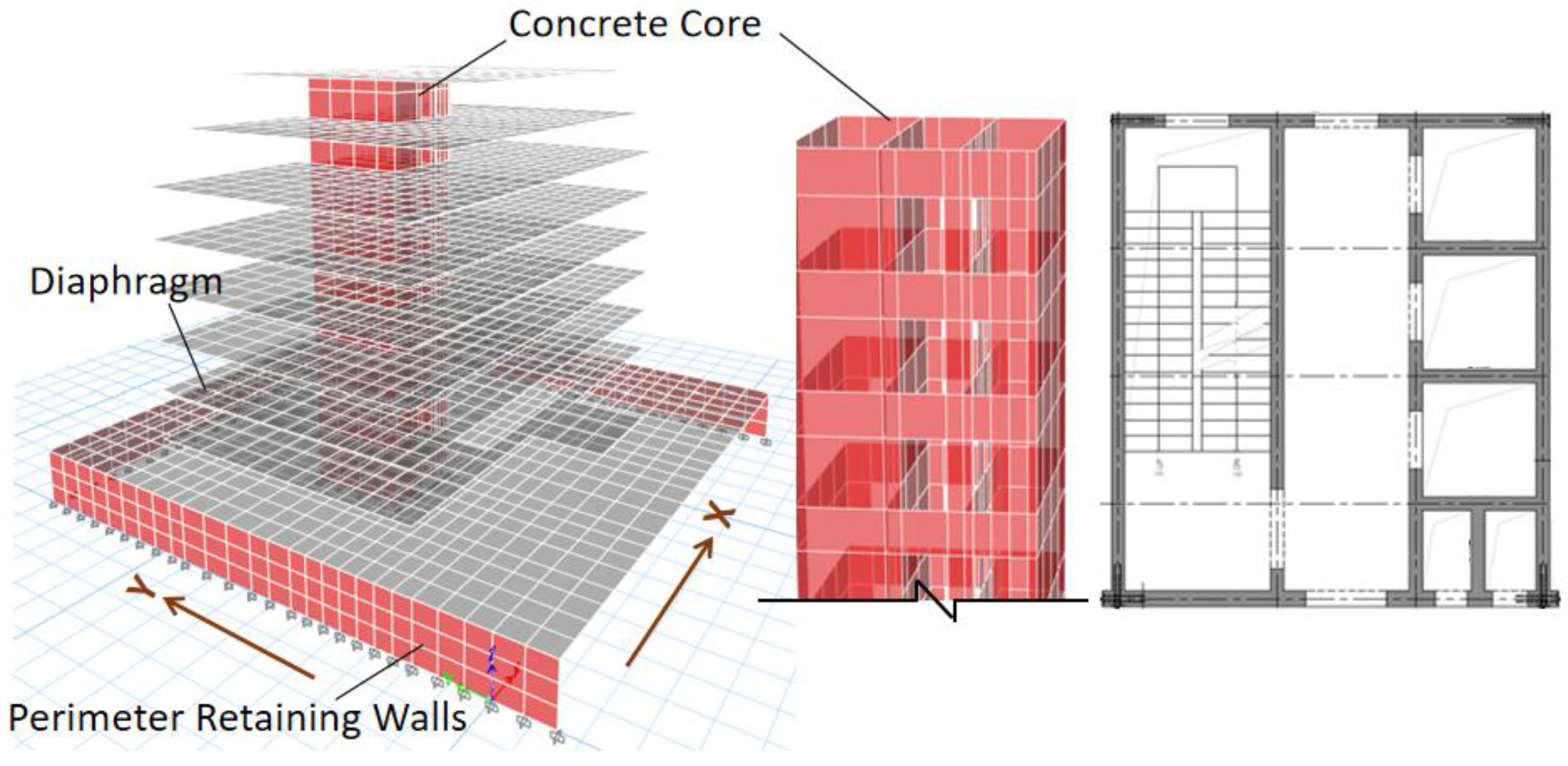

2. Structural Design

2.1. Building Description

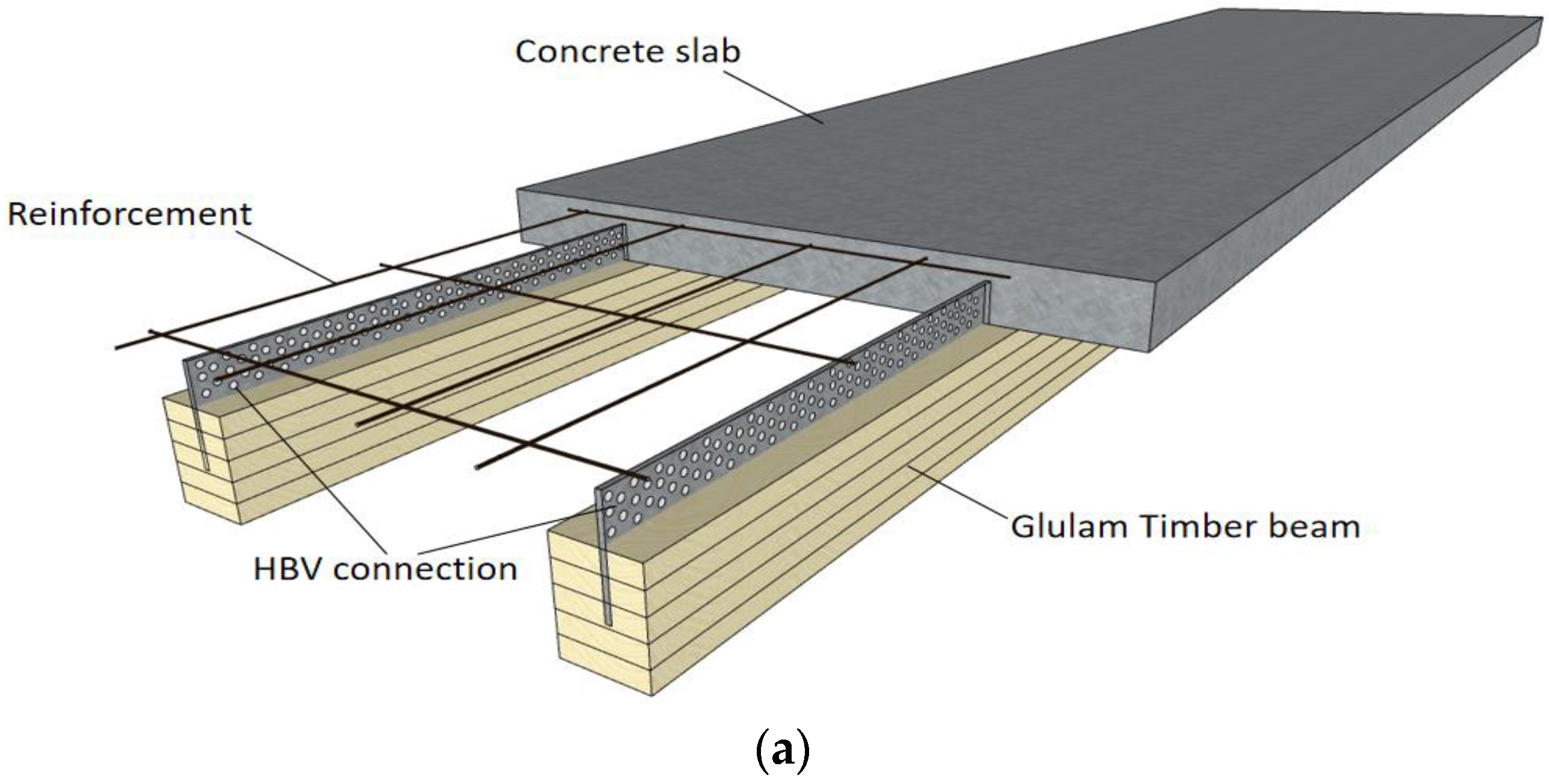

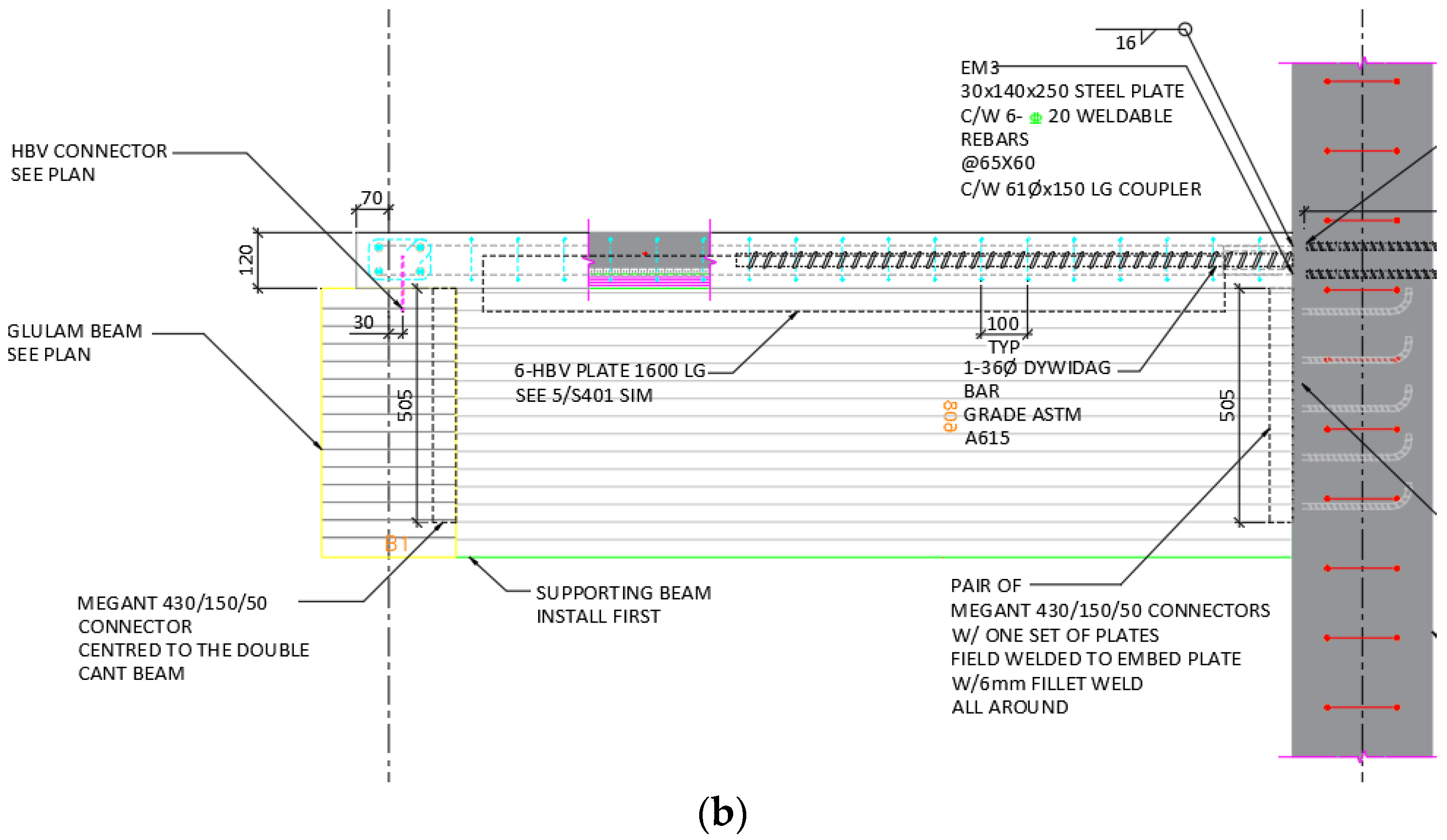

2.2. Structural Design Details

3. Seismic Analysis

3.1. Fundamental Vibration Mode Comparison

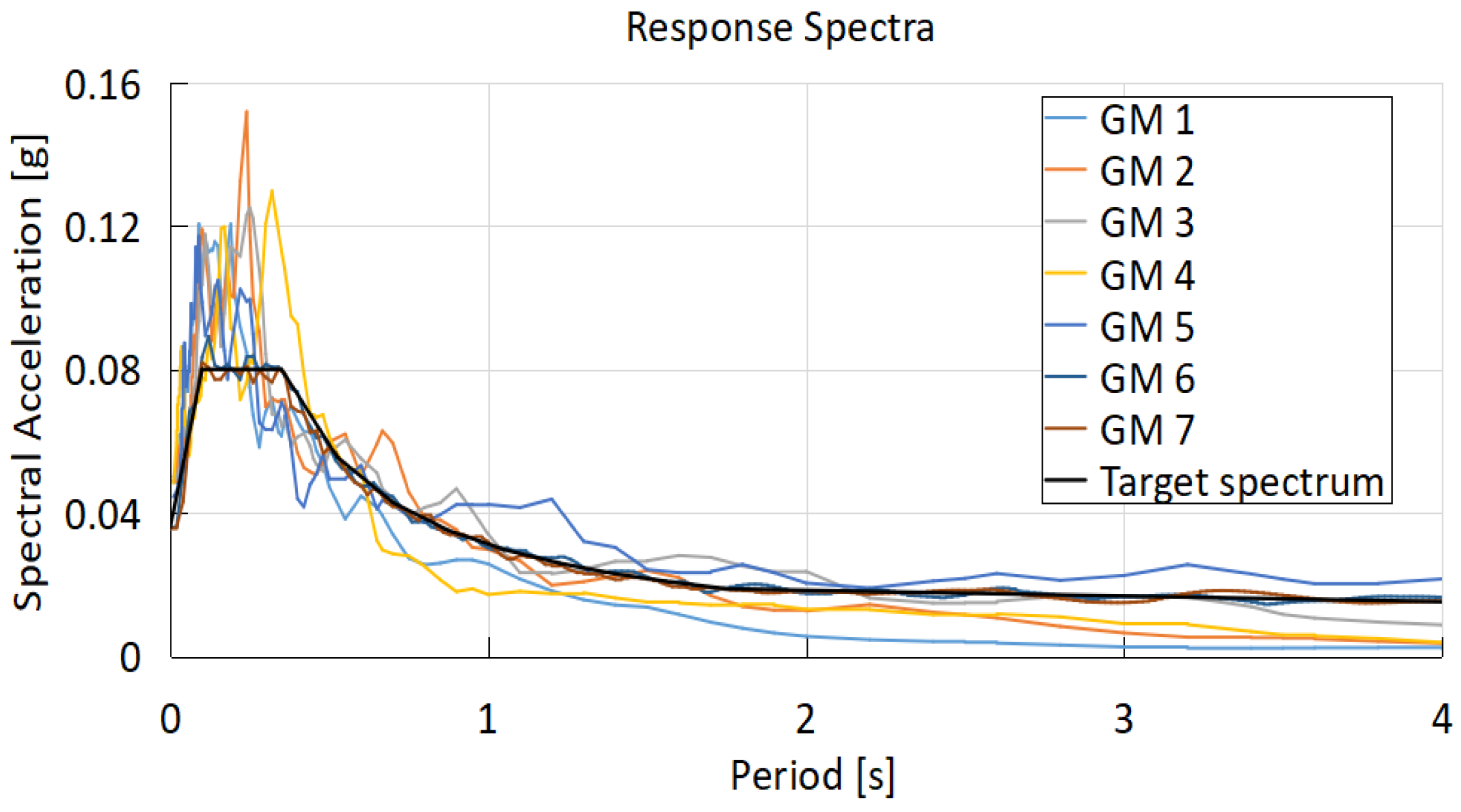

3.2. Ground Motion Selection

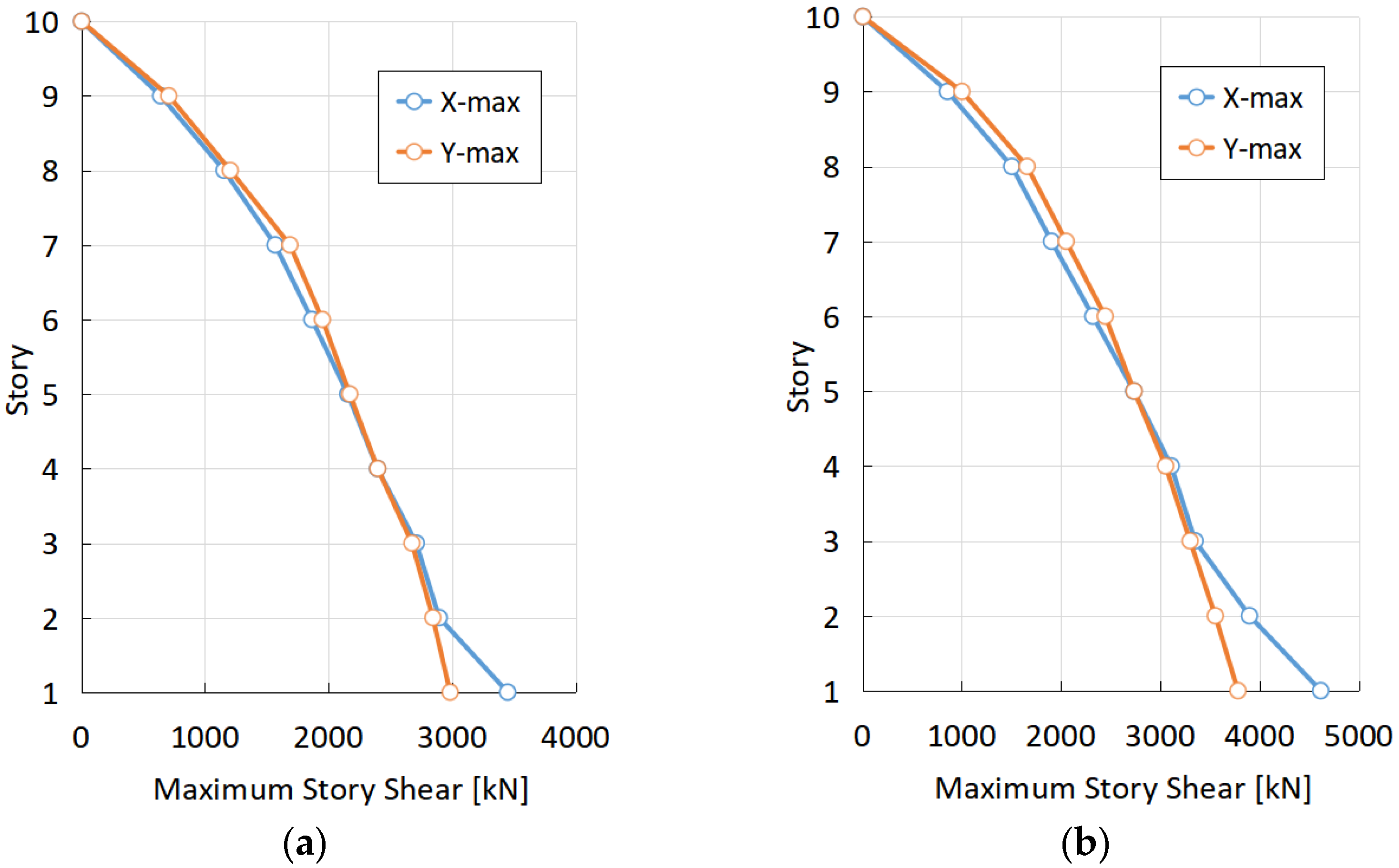

3.3. Base Shear Comparison

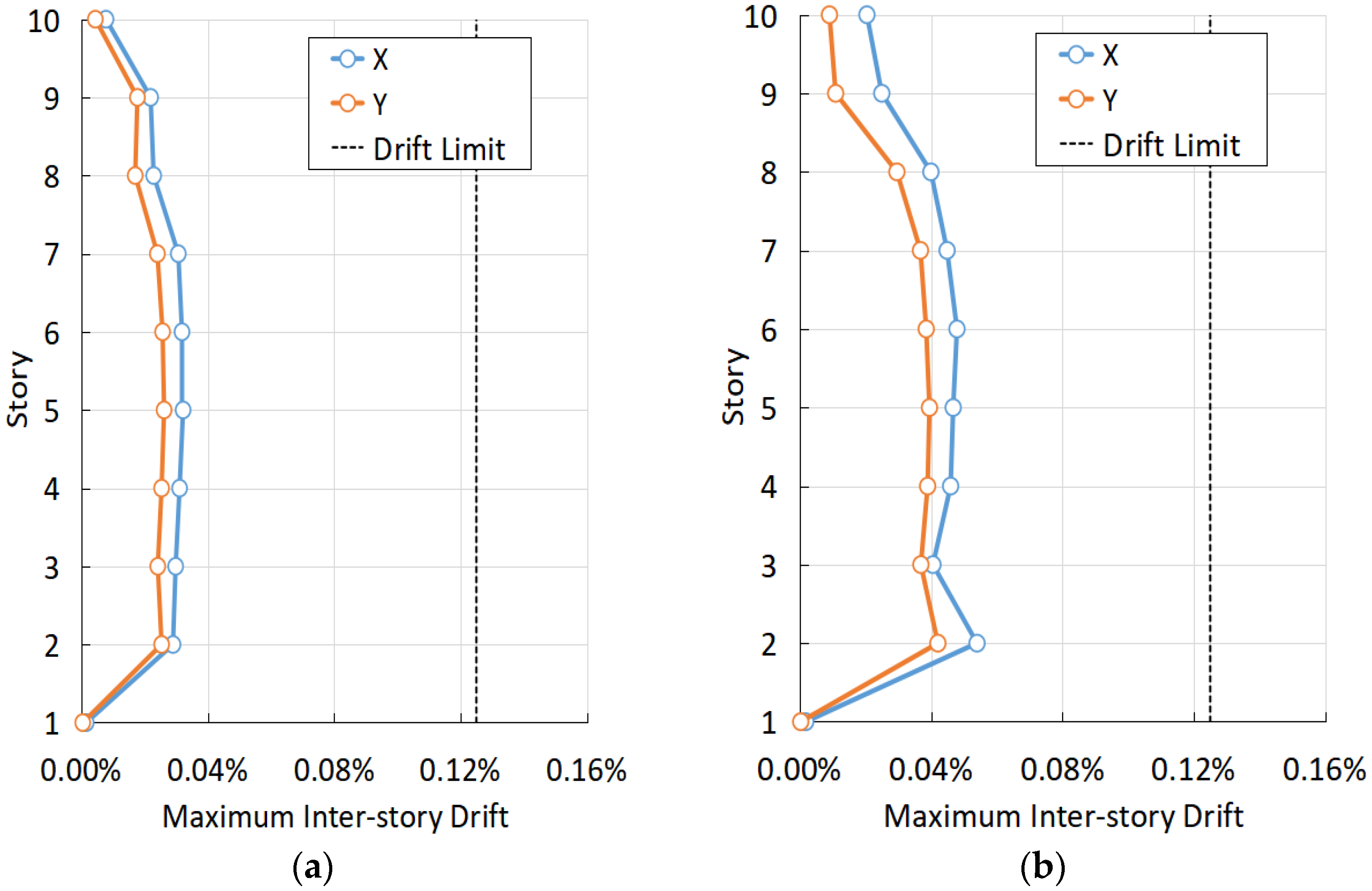

3.4. Inter-Story Drift Comparison

4. Life-Cycle Analyses

4.1. Methods

4.2. Building Material Inventory

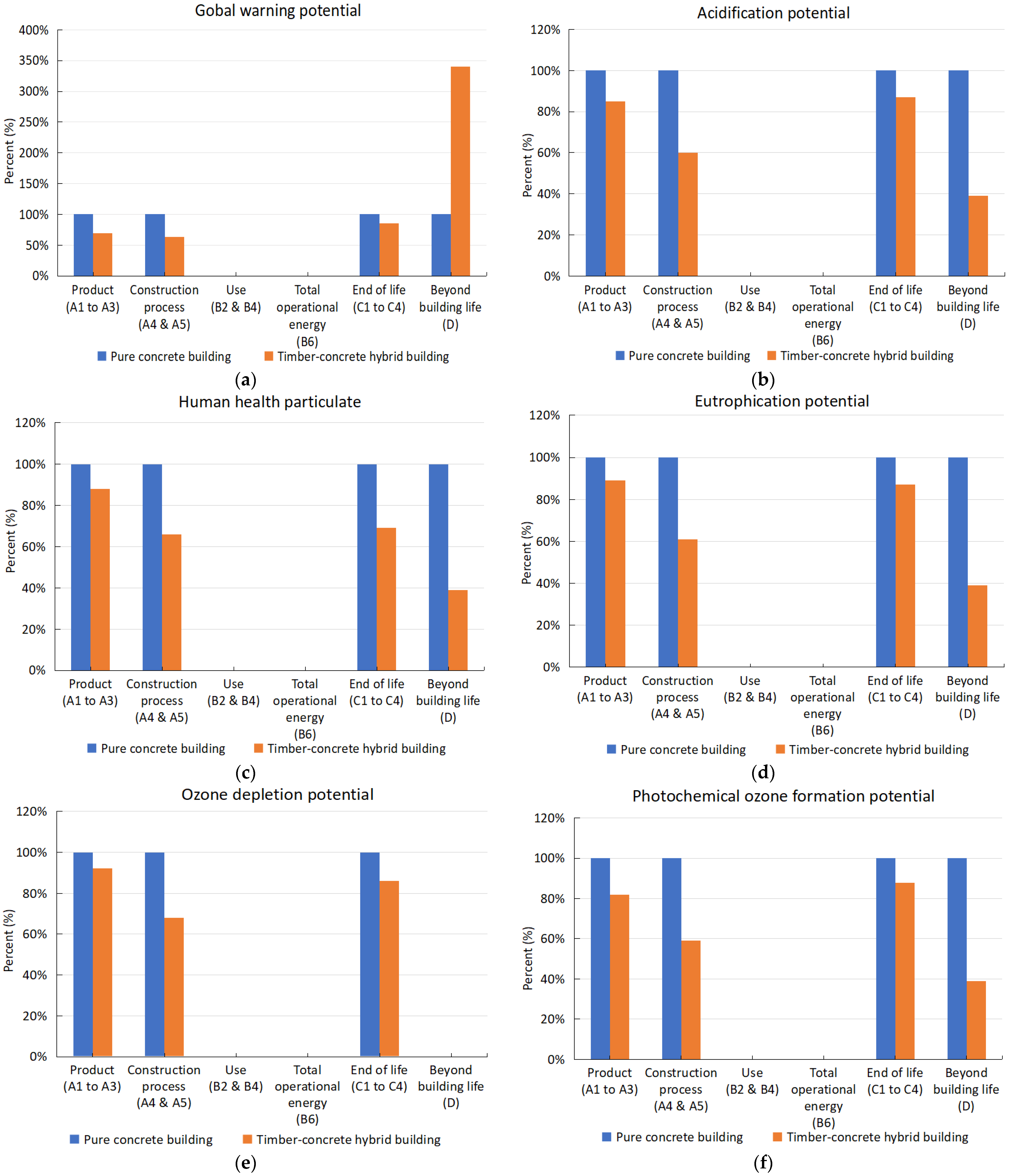

4.3. Environmental Impact Categories Comparison

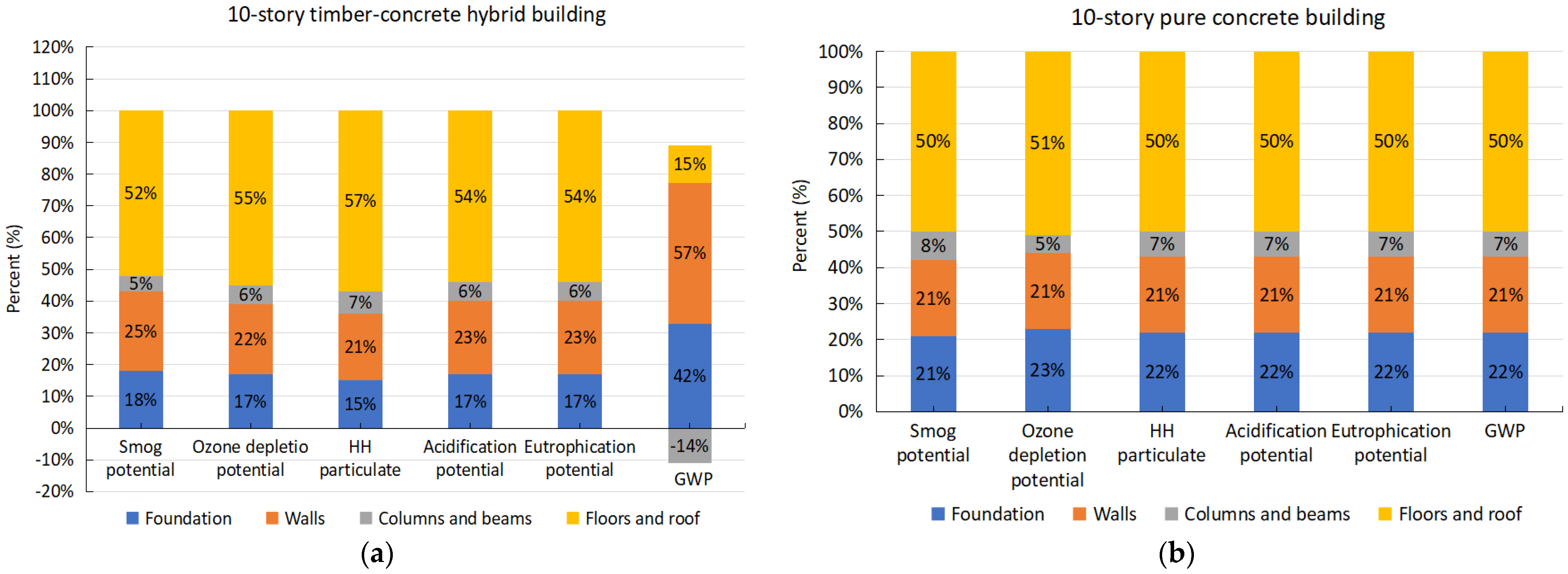

4.4. Building Component Group Comparison

4.5. Environmental Impacts by Life-Cycle Stage Comparison

4.6. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- The Carbon Challenge-Carbon Leadership Forum. Available online: https://carbonleadershipforum.or/ (accessed on 22 June 2022).

- Hasanbeigi, A.; Khanna, N.; Price, L. Air Pollutant Emissions Projections for the Cement and Steel Industry in China and the Impact of Emissions Control Technologies; Lawrence Berkeley National Lab: Berkeley, CA, USA, 2017. [Google Scholar]

- Dong, Y.; Qin, T.; Zhou, S.; Huang, L.; Bo, R.; Guo, H.; Yin, X. Comparative whole building life cycle assessment of energy saving and carbon reduction performance of reinforced concrete and timber stadiums—A case study in China. Sustainability 2020, 12, 1566. [Google Scholar] [CrossRef]

- Kazulis, V.; Muizniece, I.; Zihare, L.; Blumberga, D. Carbon storage in wood products. Energy Procedia 2017, 128, 558–563. [Google Scholar] [CrossRef]

- Kutnar, A.; Hill, C. Life Cycle Assessment—Opportunities for Forest Products Sector. BioProducts Business. 2017, 2, 52–64. [Google Scholar]

- Asdrubali, F.; Ferracuti, B.; Lombardi, L.; Guattari, C.; Evangelisti, L.; Grazieschi, G. A review of structural, thermo-physical, acoustical, and environmental properties of wooden materials for building applications. Build. Environ. 2017, 114, 307–332. [Google Scholar]

- Li, T.; Zhu, M.; Yang, Z.; Song, J.; Dai, J.; Yao, Y.; Hu, L. Wood composite as an energy efficient building material: Guided sunlight transmittance and effective thermal insulation. Adv. Energy Mater. 2016, 6, 1601122. [Google Scholar] [CrossRef]

- Iqbal, A. Developments in tall wood and hybrid buildings and environmental impacts. Sustainability 2021, 13, 11881. [Google Scholar] [CrossRef]

- Chi, Y.; Liu, Z.; Wang, X.; Zhang, Y.; Wei, F. Provincial CO2 emission measurement and analysis of the construction industry under China’s carbon neutrality target. Sustainability 2021, 13, 1876. [Google Scholar] [CrossRef]

- Cement Production Global 2021|Statista. Available online: https://www.statista.com/ (accessed on 16 July 2022).

- Felme, G.; Morales-Vera, R.; Astroza, R.; González, I.; Puettmann, M.; Wishnie, M. A lifecycle assessment of a low-energy mass-timber building and mainstream concrete alternative in central Chile. Sustainability 2022, 14, 1249. [Google Scholar] [CrossRef]

- Karol, S.; Jianli, H.; Isaac, G.; Weiqi, X.; Subo, W.; Zitong, C. Feasibility study on further utilization of timber in China. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Bangkok, Thailand, 24–26 February 2018. [Google Scholar]

- GB 50016-2014; Code for Design on Building Fire Protection and Prevention. China Planning Press: Beijing, China, 2018.

- Minjuan, H.; Duo, T.; Zheng, L. Research progress of multi-story and high-rise timber and timber hybrid structures. J. Build. Struct. 2016, 37, 1–9. [Google Scholar]

- Zhang, X.; Azim, M.R.; Bhat, P.; Popovski, M.; Tannert, T. Seismic performance of embedded steel beam connection in cross-laminated timber panels for tall-wood hybrid system. Can. J. Civ. Eng. 2017, 44, 611–618. [Google Scholar] [CrossRef]

- Zhang, X.; Shahnewaz, M.; Tannert, T. Seismic reliability analysis of a timber steel hybrid system. Eng. Struct. 2018, 167, 629–638. [Google Scholar] [CrossRef]

- Dias, A.M.P.G.; Skinner, J.; Crews, K.; Tannert, T. Timber-concrete-composites increasing the use of timber in construction. Eur. J. Wood Wood Prod. 2016, 74, 443–451. [Google Scholar] [CrossRef]

- Margni, M.; Curran, M.A. Life Cycle Assessment Handbook: A Guide for Environmentally Sustainable Products, 1st ed.; John Wiley & Sons: Hoboken, NJ, USA, 2012; pp. 67–103. [Google Scholar]

- Monteiro, H.; Soares, N. Integrated life cycle assessment of a southern European house addressing different design, construction solutions, operational patterns, and heating systems. Energy Rep. 2022, 8, 526–532. [Google Scholar] [CrossRef]

- Hernandez, P.; Oregi, X.; Longo, S.; Cellura, M. Life-cycle assessment of buildings. In Handbook of Energy Efficiency in Buildings, 2nd ed.; Asdrubali, F., Desideri, U., Eds.; Butterworth-Heinemann: Oxford, UK, 2019; Volume 3, pp. 207–261. [Google Scholar]

- Robertson, A.B.; Lam, F.C.; Cole, R.J. A comparative cradle-to-gate life cycle assessment of mid-rise office building construction alternatives: Laminated timber or reinforced concrete. Buildings 2012, 2, 245–270. [Google Scholar] [CrossRef]

- Basaglia, B.; Lewis, K.; Shrestha, R.; Crews, K. A comparative life cycle assessment approach of two innovative long span timber floors with its reinforced concrete equivalent in an Australian context. In Proceedings of the International Conference on Performance-based and Life-cycle Structural Engineering, Brisbane, Australia, 9–11 December 2015. [Google Scholar]

- Lu, H.R.; El Hanandeh, A.; Gilbert, B.P. A comparative life cycle study of alternative materials for Australian multi-storey apartment building frame constructions: Environmental and economic perspective. J. Clean. Prod. 2017, 166, 458–473. [Google Scholar] [CrossRef]

- Jayalath, A.; Navaratnam, S.; Ngo, T.; Mendis, P.; Hewson, N.; Aye, L. Life cycle performance of Cross Laminated Timber mid-rise residential buildings in Australia. Energy Build. 2020, 223, 110091. [Google Scholar] [CrossRef]

- Zhang, X.; Xuan, L.; Huang, W.; Yuan, L.; Li, P. Structural design and analysis for a timber-concrete hybrid building. Front. Mater. 2022, 9, 844398. [Google Scholar] [CrossRef]

- EN1995 Eurocode 5; Design of Timber Structures. Thomas Telford Ltd.: London, UK, 2014. [CrossRef]

- TiComTec Technical Dossier HBV-System. Available online: https://ticomtec.de/en/ (accessed on 15 July 2022).

- GB 50010-2010; Code for Design of Concrete Structures. China Architecture and Building Press: Beijing, China, 2015.

- Guleria, A. Structural analysis of a multi-storeyed building using ETABS for different plan configurations. Int. J. Eng. Res. Technol. 2014, 3, 1481–1485. [Google Scholar]

- GB 50009-2012; Load Code for the Design of Building Structures. China Architecture and Building Press: Beijing, China, 2012.

- GB 50011-2010; Code for Seismic Design of Buildings. China Architecture and Building Press: Beijing, China, 2016.

- GB 5005-2017; Standard Design of Timber Structures. China Architecture and Building Press: Beijing, China, 2017.

- GB 50206-2012; Code for acceptance of Construction Quality of Timber Structures. China Architecture and Building Press: Beijing, China, 2012.

- GB/T 50329-2002; Standard for Methods Testing of Timber Structures. China Architecture and Building Press: Beijing, China, 2002.

- GB/T 50708-2012; Technical Code of Glued Laminated Timber Structures. China Architecture and Building Press: Beijing, China, 2012.

- Athena Sustainable Materials Institute. LCA, LCI, LCIA, LCC: What’s the Difference? 2018. Available online: http://www.athenasmi.org/resources (accessed on 16 August 2022).

- Wu, T.; Gong, M.; Xiao, J. Preliminary sensitivity study on an life cycle assessment (LCA) tool via assessing a hybrid timber building. J. Bioresour. Bioprod. 2020, 5, 108–113. [Google Scholar] [CrossRef]

- Athena Sustainable Materials Institute. LCI database. 2018. Available online: http://www.athenasmi.org (accessed on 16 August 2022).

- Bare, J.C. TRACI: The tool for the reduction and assessment of chemical and other environmental impacts. J. Ind. Ecol. 2002, 6, 49–78. [Google Scholar] [CrossRef]

- ISO, 14040: 2006; Environmental Management–Life Cycle Assessment–Principles and Framework. ISO: Geneva, Switzerland, 2006.

- EN 15804:2012; CEN Sustainability of Construction Works—Environmental Product Declarations—Core Rules for the Product Category of Construction Products. European Committee for Standardization: Brussels, Belgium, 2013.

- EN 15978:2011; CEN Sustainability of Constructions—Environmental Product Declarations—Core Rules for the Product Category of Construction Products. European Committee for Standardization: Brussels, Belgium, 2011.

- Allan, K.; Phillips, A.R. Comparative cradle-to-grave life cycle assessment of low and mid-rise mass timber buildings with equivalent structural steel alternatives. Sustainability 2021, 13, 3401. [Google Scholar]

| Member | Grade | Material Properties | ||||

|---|---|---|---|---|---|---|

| fm (MPa) | fc (MPa) | ft (MPa) | fv (MPa) | E (MPa) | ||

| Beam | TCT21 | 21 | - | - | 2.2 | 11,700 |

| Column | TCT21 | 21 | 20 | 15 | - | 8000 |

| Model | Mode | Period |

|---|---|---|

| s | ||

| 1 | 1.424 | |

| Hybrid model | 2 | 0.973 |

| 3 | 0.951 | |

| 1 | 1.987 | |

| Concrete model | 2 | 1.323 |

| 3 | 1.230 |

| ID | RSN | Scaling | Earthquake | Year | Station | Magnitude | Rrup (km) |

|---|---|---|---|---|---|---|---|

| GM1 | 72 | 0.275 | San Fernando | 1971 | Lake Hughes #4 | 6.6 | 25.1 |

| GM2 | 1006 | 0.132 | Northridge-01 | 1994 | LA-UCLA | 6.7 | 22.5 |

| GM3 | 4205 | 0.674 | Niigata_Japan | 2004 | NIG015 | 6.6 | 40.1 |

| GM4 | 4870 | 0.265 | Chuetsu-oki_Japan | 2007 | Horinouchi City | 6.8 | 34.5 |

| GM5 | 5750 | 1.001 | Iwate_Japan | 2008 | YMT007 | 6.9 | 58.1 |

| GM6 | AR221_932_1 | 1.000 | artificial | ||||

| GM7 | AR221_932_2 | 1.000 | artificial |

| A1 | A2 | A3 | A4 | A5 | B1 | B2 | B3 | B4 | B5 | B6 | B7 | C1 | C2 | C3 | C4 | D |

| Raw Material Extraction | Transport | Manufacturing in Factory | Transport to Site | Construction installation process | Use | Maintenance | Repair | Replacement | Refurbishment | Operation Energy Use | Operation Water Use | Deconstruction Demolition | Transportation | Waste Processing | Disposal | Reuse and Recycling Recovery potential |

| X | X | X | X | X | X | X | X | X | X |

| Model | Material | Columns | Floor | Foundation | Roof | Wall | Total | Mass |

|---|---|---|---|---|---|---|---|---|

| (m3) | (m3) | (m3) | (m3) | (m3) | (m3) | (103 kg) | ||

| Hybrid model | Concrete (C45) | 0 | 1041 | 599 | 0 | 791 | 2431 | 5843 |

| Glulam | 304 | 1251 | 0 | 0 | 0 | 1555 | 727 | |

| Hot rolled sheet | 0 | 26 | 16 | 0 | 35 | 77 | 77 | |

| Total concrete | 5710 | |||||||

| Total timber | 727 | |||||||

| Total | 6514 | |||||||

| Concrete model | Concrete (C45) | 210 | 1933 | 889 | 0 | 791 | 3823 | 9189 |

| Hot rolled sheet | 42 | 100 | 19 | 0 | 39 | 200 | 200 | |

| Total | 9389 |

| Summary Measure | Unit | Concrete Building | Hybrid Building |

|---|---|---|---|

| Global warming potential | kg CO2 eq | 1.79 × 106 | 6.26 × 105 |

| Stratospheric ozone depletion | kg CFC-11 eq | 1.58 × 10−2 | 1.44 × 10−2 |

| Acidification of land and water | kg SO2 eq | 8.76 × 103 | 7.42 × 103 |

| Eutrophication | kg N eq | 8.02 × 102 | 7.01 × 102 |

| Tropospheric ozone formation | kg O3 eq | 1.84 × 105 | 1.48 × 105 |

| Depletion of nonrenewable resources | MJ | 1.66 × 107 | 1.25 × 107 |

| Life-Cycle Stage | Concrete Building | Hybrid Building |

|---|---|---|

| Global warming potential (103 kg CO2 eq.) | ||

| Production (A1–A3) | 1770 (88%) | 1230 (87%) |

| Construction (A4 & A5) | 147 (7%) | 92.4 (7%) |

| End-of-life (C1–C4) | 103 (5%) | 87.8 (6%) |

| Total | 2020 | 1410 |

| Acidification potential (kg SO2 eq.) | ||

| Production (A1–A3) | 6820 (73%) | 5780 (76%) |

| Construction (A4 & A5) | 1160 (12%) | 698 (9%) |

| End-of-life (C1–C4) | 1310 (14%) | 1140 (15%) |

| Total | 9290 | 7620 |

| HH particulate (kg PM 2.5 eq.) | ||

| Production (A1–A3) | 1150 (89%) | 1010 (91%) |

| Construction (A4 & A5) | 82 (6%) | 54.2 (5%) |

| End-of-life (C1–C4) | 62 (5%) | 42.9 (4%) |

| Total | 1294 | 1107 |

| Eutrophication potential (kg N eq.) | ||

| Production (A1–A3) | 663 (80%) | 598 (83%) |

| Construction (A4 & A5) | 84.4 (10%) | 51.9 (7%) |

| End-of-life (C1–C4) | 81.4 (10%) | 71.2 (10%) |

| Total | 829 | 712 |

| Ozone depletion potential (10−2 kg CFC-11 eq.) | ||

| Production (A1–A3) | 1.5 (95%) | 1.39 (97%) |

| Construction (A4 & A5) | 0.08 (5%) | 0.05 (4%) |

| End-of-life (C1–C4) | 0.04 (3%) | 0.00 (0%) |

| Total | 1.58 | 1.44 |

| Smog potential (103 kg O3 eq.) | ||

| Production (A1–A3) | 114 (60%) | 93.1 (62%) |

| Construction (A4 & A5) | 32.7 (17%) | 19.2 (13%) |

| End-of-life (C1–C4) | 42.9 (23%) | 37.5 (25%) |

| Total | 189 | 150 |

| Model | Stage D GWP (103 kg CO2 eq) | GWP for Stage A–C (103 kg CO2 eq) | GWP for Stage A–D (103 kg CO2 eq) |

|---|---|---|---|

| Concrete building | −229 | 2020 | 1790 |

| Hybrid building | −780 | 1410 | 626 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Huang, W.; Khajehpour, M.; Asgari, M.; Tannert, T. Seismic Performance and LCA Comparison between Concrete and Timber–Concrete Hybrid Buildings. Buildings 2023, 13, 1714. https://doi.org/10.3390/buildings13071714

Zhang X, Huang W, Khajehpour M, Asgari M, Tannert T. Seismic Performance and LCA Comparison between Concrete and Timber–Concrete Hybrid Buildings. Buildings. 2023; 13(7):1714. https://doi.org/10.3390/buildings13071714

Chicago/Turabian StyleZhang, Xiaoyue, Wanru Huang, Mehdi Khajehpour, Mehrdad Asgari, and Thomas Tannert. 2023. "Seismic Performance and LCA Comparison between Concrete and Timber–Concrete Hybrid Buildings" Buildings 13, no. 7: 1714. https://doi.org/10.3390/buildings13071714

APA StyleZhang, X., Huang, W., Khajehpour, M., Asgari, M., & Tannert, T. (2023). Seismic Performance and LCA Comparison between Concrete and Timber–Concrete Hybrid Buildings. Buildings, 13(7), 1714. https://doi.org/10.3390/buildings13071714