1. Introduction

The present state of development in the field of cement concrete construction can be traced back to ancient civilizations, such as those of the Egyptians, Romans, and Greeks [

1]. In ancient times, the most common building materials were mud bricks, cement made from gypsum, or a mixture of crushed limestone and volcanic ash, small stones, and iron bars, which was utilized to construct buildings, bridges, colosseums, etc. The ancient methods of cement concrete construction were lost during the Middle Ages, and it was not until the 18th century that modern cement was developed [

2]. However, the ancient techniques and materials used continue to influence modern building practices.

According to the United States Geological Survey report, global cement consumption was estimated to be around 4.1 billion metric tons in 2020, which notes that China is the largest producer and consumer of cement, followed by India and the United States. The increasing global population and urbanization rates, along with the development of infrastructure and construction projects, are expected to increase the growth in cement consumption in the future [

3]. However, this growth could be influenced by several factors, including economic conditions, concerns over the environmental impact of cement production, and a shift towards alternative construction materials and techniques. Production of concrete with high strength is possible by increasing the maximum cement content required for 1 m

3 of concrete [

4,

5]. However, the maximum cement content in concrete shall be limited by Indian Standard (IS) 456 guidelines as 450 kg/m

3 [

6]. These cement contents may vary depending on the specific requirements of the concrete.

Polymer concrete (PC) is a type of concrete that is reinforced with a polymeric resin, which includes synthetic materials made from long chains of molecules, and it did not exist in ancient times. It provides additional strength and durability to the concrete, making it ideal for use in construction appliances. Development of PC can be traced back to the 1950s, when researchers began experimenting with using polymers as a reinforcing agent for concrete. In the 1960s and 1970s, PC gained popularity as a construction material, particularly in the aerospace and defense industries for the construction of airport runways, missile silos, etc. [

7,

8,

9]. In recent times, PC has been used widely for the construction of walls, bridges, and tunnels because of its high strength and durability.

Polyurethane resin (PR) is a highly versatile polymer widely used in construction due to its exceptional adhesive properties, flexibility, and resistance to water and chemical corrosion. When added to concrete mixes, PR forms durable and flexible elements that can withstand extreme conditions, such as temperature variations, UV radiation, and exposure to chemicals [

10,

11,

12,

13]. It strengthens the concrete, enhances its ductility and toughness, and improves resistance to cracking and deformation under load. Based on brief research in previous studies, it is proposed that utilizing PR in concrete demonstrates acceptable results compared to other kinds of thermosetting resins (see

Table 1). PR also enhances the durability and resistance of high-strength concrete (HSC) to various types of damage, including chemical and environmental corrosion. Compared to other thermosetting resins, such as epoxy, polyester, and acrylic, PR offers a balance of mechanical properties, being flexible and possessing excellent impact resistance. PR is created by mixing polyisocyanate, polyol, and reactive substances, and it can be further enhanced with reinforcement fillers for various applications [

14,

15,

16].

The construction industry has witnessed recent developments that enable the production of concrete mixes with high strengths ranging from M40 to M100. High-strength concrete (HSC) is designed to have compressive strength significantly higher than traditional concrete, typically exceeding 41 MPa [

17,

18]. The increased use of HSC is driven by advancements in concrete technology and the demand for more durable and resilient infrastructure. High strength can be achieved by reducing the water-to-cement (w/c) ratio, incorporating special additives, or adding reinforcing elements, such as fibers, to the concrete mix [

19,

20,

21]. Fibers enhance the strength properties of concrete and can be either natural or artificial. Different fiber types offer varying mechanical properties, costs, availability, and manufacturability. Aramid fibers (AF) are well-known for their exceptional tensile strength, heat and chemical resistance, and relatively low density. AF has a lower Young’s modulus than carbon fibers (CF) but higher than glass fibers (GF), making it less stiff than CF but stiffer than GF. AF is advantageous for structures that require flexibility, such as those subject to vibrations and impact (

Table 2). It improves the durability of concrete by reducing cracking, shrinkage, and enhancing resistance to abrasion, impact, and chemical attack [

22,

23,

24,

25]. Furthermore, AF enhances toughness and energy absorption capacity. Incorporating microfibrous elements in high-rise structures subjected to periodic loading conditions is crucial to minimize serious damage and prevent structural collapse.

The amount of AF and PR used in concrete can affect the resulting properties of the concrete depending on the specific application and desired properties of the concrete [

26,

27,

28]. The resulting or final properties of concrete include the fresh and hardened properties of concrete, such as workability properties, strength properties, durability, and structural properties, after the prescribed system of mixing, casting, and curing. Hence, in this study, it is proposed to create HSC with varying percentages of PR addition (from 0% to 6% at an interval of 1%) and AF (from 0% to 3% at an interval of 0.5%).

Along with the experimental investigation, the structural properties of RC beams were numerically analyzed by ANSYS software and compared with each other with finite element analysis being used to simulate the behavior of RC beams under different loading conditions. ANSYS provides advanced tools for modeling, simulation, and analysis of structures. A 3D model of the RC beam is created, and FEA is used to calculate the stresses, strains, and deformation. The results are used to evaluate the strength, deformation, and failure modes of the RC beam, and to optimize its design. This method is an efficient and cost-effective way to study the structural behavior of RC beams and identify areas for improvement in their design.

Benmokrane et al. investigated the use of aramid- and carbon-fiber-reinforced plastic (FRP) tendons for prestressed ground anchors. These tendons have high corrosion resistance, high tensile strength, electromagnetic neutrality, and light weight, making them a good alternative to steel tendons in situations where corrosion protection is difficult or expensive to achieve [

29]. Wattanapanich et al. investigated the behavior of prestressed concrete slabs strengthened with fiber-reinforced polymer (FRP) sheets. Increasing FRP thickness or modulus of elasticity negatively affects bonding efficiency and leads to early debonding failures. A tapering technique is proposed, gradually reducing FRP thickness towards the plate end, which reduces bond stress concentrations by up to 15% and prevents debonding. The study improves understanding of FRP-strengthened elements and advances computational tools for structural analysis [

30]. Ortiz et al. provide an overview of the environmental and mechanical factors affecting the durability and mechanical properties of fiber-reinforced polymer (FRP) composites used in reinforced concrete (RC) structures, highlighting the potential effects of harsh environmental conditions and mechanical phenomena on FRP composites. The study emphasizes the need for proper understanding of these factors to ensure the effective use of FRP materials in concrete structures and discusses serviceability criteria for FRP-reinforced concrete elements. Overall, the findings contribute to enhancing the long-term performance of RC elements using FRP materials [

31]. Imjai et al. introduced a new macro-mechanical model to accurately calculate the bend capacity of bent fiber-reinforced polymer (FRP) bars in reinforced concrete elements. The model incorporates the Tsai–Hill failure criterion and factors influencing bend capacity, including a section factor that considers strength degradation at the bent portion of the bar. By calibrating the model using experimental data, it demonstrates improved accuracy in predicting bend strength compared to existing equations. The proposed model offers potential cost savings of up to 15% through more economical design [

32]. Pilakoutas et al. present an outline of the approach proposed by fib task group 9.3 for the next generation of design guidelines for fiber-reinforced polymer (FRP) reinforced concrete structures [

33]. Imjai et al. discuss the limitations of curved fiber-reinforced polymer (FRP) reinforcements in concrete structures and their reduced structural performance, highlighting the strength degradation of bent FRP bars under multiaxial stresses and the overestimation of their bend capacity in current design recommendations. The article also proposes a more accurate predictive model based on the Tsai–Hill failure criteria. Future research directions and challenges for utilizing curved/shaped FRP composites in civil engineering applications are identified [

34].

3. Materials and Methods

The mechanical strength and durability properties of fiber-reinforced polymer concrete are influenced by the type, quality, and quantity of individual ingredients used. For the production of HSC, along with the conventional ingredients of concrete, such as cement, aggregates, and water, few supplementary cementitious materials, such as fly ash and silica fume, are required to fill the pores between the cement particles. It is essential to mention the individual properties of every ingredient in detail.

3.1. Cement

Commercially available 53-grade Portland cement was used in this investigation, with a specific surface area and specific gravity of 295 m2/kg and 3.17, respectively. It has gray color and bulk density of 1660 kg/m3. Its setting time is quick, with an initial setting time of 1.25 h and final setting time of 6 h. It possesses good strength properties, which show 45.53 MPa at 14 days and 56.28 MPa at 28 days. Chemical composition of cement majorly comprises the following compounds, such as CaO 63.11%, SiO2 24.51%, Al2O3 6.86%, Fe2O3 3.49%, MgO 2.15%, SO3 1.41%, and K2O 0.62%.

3.2. Fine and Coarse Aggregates

In this investigation, river sand and crushed granite stones from local sources were used as fine and coarse aggregates, respectively. Numerous studies have explored alternative options to river sand in concrete production. The research literature highlights several reasons for utilizing river sand, including higher quality, consistent size and shape, and improved workability. For this investigation, natural river sand was employed as the fine aggregate.

Table 3 provides information on the various properties of the fine and coarse aggregates used.

The above-mentioned properties of river sand and crushed granite stones make them suitable material for use as fine and coarse aggregate in concrete. The shape of aggregates helps to produce a smooth and workable concrete mix.

3.3. Fly Ash

This study uses class F fly ash from a power plant in Mettur, Tamil Nadu. The characteristics of fly ash have been measured according to IS 3812-2013 guidelines [

35]. The specific surface area measured by Blaine’s air permeability test is 440 m

2/kg, which makes it suitable for use as a pozzolanic material in cement concrete, where it can react with calcium hydroxide to form additional cementitious compounds. It has a bulk density of 1320 kg/m

3 and specific gravity of 2.33. It has a low autoclave expansion of 0.045%, indicating it is less likely to experience swelling or cracking due to exposure to moisture.

3.4. Silica Fume

Silica fume is a gray-colored powder material, by product from the production of silicon metal in electric arc furnaces. It consists of very fine particles of amorphous silicon dioxide, with an average particle size of 0.1 micron. It has a specific gravity and specific surface area of 2.4 and 16.5 m2/gm.

3.5. Polyurethane Resin

Polyurethane resin is a type of polymer resin that is derived from petrochemical feedstocks and can be used in the production of HSC due to its low water absorption and excellent bonding tendencies [

36]. It is brown in color and has a solidity of 100%. The properties include a specific gravity of 1.2 and density of 1120 kg/m

3. Special handling, care, and curing methods are essential when the concrete is made with polyurethane resin. Maximum moisture content of the resin is 20%, which is the amount of water that can be absorbed by it.

3.6. Aramid Fibers

Aramid fibers are synthetic fibers made from polymers that contain at least 85% of the amide linkages in their molecular chains, with a density of 1.42 g/cc. These fibers are known for their high strength to weight ratio, exceptional resistance to abrasion, and thermal stability, with a tensile strength of 3350 MPa, which are commonly used in aerospace, military, and industry applications [

37]. They exhibit excellent resistance to cut or impact, showing 3.3% elongation at breaking point.

3.7. Super Plasticizers

In this study, commercially available polycarboxylate-ether-based super plasticizers are used in the production of HSC. It is a slight yellowish liquid and has the ability to improve the workability of concrete without compromising the strength and durability, thereby reducing the water content in concrete. The properties include density and pH values of 1.11 g/cc and 6.1 at 250 C, respectively.

3.8. Experimental Program

In this study, varying percentages of polyurethane resin and aramid fibers are incorporated in the production of M50-grade HSC. Mix design for the conventional mix was made in accordance with the guidelines mentioned in IS 10262:2019 and illustrated in

Table 4 [

38]. Initially, AF was added into the HSC mixes from 0.5% to 3% by weight of cementitious content used in the HSC mixes from 2.4 kg/m

3 to 14.4 kg/m

3, which will be helpful to identify the workability and strength enhancement of M50-grade concrete. According to the desired mix design, the ingredients were weighed and dry mixing was conducted. Addition of AF and mixing occurred for a specific duration to ensure uniform distribution of fibers in the mix. Then, wet mixing was completed with water and super plasticizers. During the later stages of the investigation, optimized AF content was utilized and varying percentages of PR from 0% to 6% was added into the concrete mix by weight of cementitious content from 4.65 kg/m

3 to 27.9 kg/m

3.

The experimental investigation involved sampling of concrete specimens according to IS 1199:1959 at varying curing periods of 7, 14, and 28 days [

39]. A wide range of experiments were conducted on both fresh and hardened concrete during these curing periods. To predict the true strength and durability behavior of HSC mixes with AF and PR, a list of experiments were conducted on the concrete at the different curing periods.

Table 5 provides a detailed list of the experiments carried out. The purpose of these experiments was to gather comprehensive data on the strength and durability of the HSC, which can help in the development of more accurate predictive models for future applications.

Structural performance of HSC specimens was analyzed by conducting flexural strength test on reinforced concrete (RC) beams of size 125 × 200 × 1500 mm under two-point linear loading conditions, which are simply supported at the ends with a span of 1.2 m in accordance with the guidelines mentioned in IS 456:2000 [

6]. RC beam specimens were made for CC mixes and optimized ingredients (AF-2.5 and PR-4/AF-2.5). The beams are casted with 2 numbers of 16 mm diameter bars at tension zone spaced apart at a distance that excludes 20 mm cover on each side, whereas 2 numbers of 12 mm diameter bars are placed at top to resist the compressive forces. In order to take care of shear forces in the beams, 8 mm diameter 2-legged stirrups were provided at 150 mm apart. Steel elements used in the investigation are commercially available Fe500D bars with ultimate tensile strength of 600 MPa and 18% of elongation index. In this investigation, structural properties, such as load and deflection behavior, crack analysis, and stiffness behavior, were assessed on RC beam specimens, which are cured for 28 days [

40].

The specimens were cast using steel molds and HSC mixes. Concrete was poured into the formwork; excess was scraped off and smoothed out. After 24 h, the beams were removed and stored for the specified curing time. Prior to testing, the beams were cleaned and whitewashed, and a 50 mm grid was drawn on the surfaces, which helps to identify or enlarge the cracks on the surface of concrete. The formwork was made of thick steel angles and held in place with bolts and nuts. Sealant was applied to joints and oil was added to inner surfaces to facilitate removal of the samples.

3.9. RC Beam Test Setup and Instrumentation

According to Indian standards, the test was conducted at room temperature using a linear two-point load on beams supported over a length of 1200 mm from a 500 kN loading frame. The deflections were measured using a linear variable differential transformer (LVDT) with a minimum measuring capacity of 0.001 mm at the central zone and L/3 zone. The beam deflected towards the load direction and deflections were measured at three different points using LVDTs (

Figure 1). A rolled steel joist (RSJ) was used to divide the concentrated load into two-point loads and a load cell was used to measure the load. The middle thirds of the gauge length deviation were recorded during the loading and unloading experiment. The displacement sensor had a range of 50 mm and a smallest measurement value of 0.001 mm. The rate of loading was kept constant throughout the investigation.

To measure the deflection of beams, a symmetrical grid of DEMEC target points was used for 2-point loading. This grid was placed in three different zones of the beams, and 10 mm diameter hollow aluminum discs were fixed as DEMEC targets to measure the strain. To measure beam displacement, a Berry-type mechanical strain gauge with a gauge length of 200 mm, a least count of 0.01 mm, and a range of 40 mm was used. The strain and deflection readings were taken at precise load intervals, and cracks were identified with a marker and named according to the load value. Since the cracks are microscopic, their widths were observed using a Brinell microscope with a least count of 0.01 mm. To measure the angular measurement of the cracks, fractions of the cracks were confined within square grids, and the ordinate and abscissa values of the crack fragment were manually measured. The reading taken from the dial gauge was then converted into millimeters by multiplying the least count with the reading.

4. Results and Discussion

4.1. Strength Properties

Dry and wet mixing were repeatedly carried out until the entire mixture became homogeneous. Conventional curing methods were employed to cure the samples. In order to identify the true behavior of concrete mixes, the specimens are examined for workability (slump), strength properties (such as compressive strength—CS, split tensile strength—SPTS, flexural strength—FS, Young’s modulus—YM), durability properties, and structural properties.

According to

Table 6, it is observed that the addition of AFs in HSC greatly affects the workability parameters of HSC. Inclusion of AF improves the viscosity of the HSC mixes, thereby reducing the slump values, which makes the concrete more difficult to work with (

Figure 2). It is essential to consider the dosage of AF in HSC; the concrete must maintain its desired workability.

The results show that, as the curing days increase, the strength and stiffness of the concrete mixes generally increase. Among the various AF combinations, those with higher concentrations of AF (AF-2, AF-2.5, and AF-3) tend to have higher mechanical properties than those with lower concentrations (AF-0.5 and AF-1). It is observed that the use of AF in HSC enhances the strength properties to a great extent up to 2.5% addition; furthermore, increases in AF concentrations demonstrate notable reductions in strength properties [

40]. It is also observed that the addition of AF enhances the tensile and flexural strength more compared to compressive strength. Replacement of cement with fly ash and silica fume that can react with calcium hydroxide produced during the hydration of cement formed additional calcium silicate hydrate gel [

41]. Addition of AF will further enhance the interfacial bonding between the cementitious matrix and fibers, which will result in overall mechanical properties of HSC. At 28 days of curing, AF-2.5 mixes increase their FS by 28.73% and their SPTS by 31.1%. However, the effect on CS demonstrates comparatively notable significant improvement of 28.71% compared to the conventional concrete (CC) mixes, which show 78.18 MPa with a YM of 45.28 GPa. AF-3 mixes also show increases in CS by 23.91%, SPTS by 25%, and FS by 27.27% compared to the CC mixes.

Hence, these reductions in strength properties were observed due to increases in AF dosage in concrete. Along with the strength properties, addition of AF improves the cracking behavior of HSC, which will result in improved durability and resistance to damage under static or dynamic loading conditions. Hence, it is considered regarding AF-2.5 mixes as the optimum dosage of AF, and the same was utilized in the further stages of investigation. PR was added into the HSC mixes starting from 1% to 6% (

Table 7). According to Dhanesh et al. (2021), the results show that the hybrid-reinforced concrete (combination of aramid fiber and carbon fiber) with a mixing ratio of 2% has the highest compressive strength and elastic modulus, and the carbon-reinforced concrete with a mixing ratio of 2.5% has the best anti-carbonation capacity [

37].

From

Table 7, it is clearly observed that the addition of PR in HSC greatly affects and improves the workability parameters by improving the slump value of concrete. Addition of AF in concrete mixes gradually reduces the workability properties, but addition of PR in optimized AF enhances the slump value of HSC mixes made with optimum dosages of AF (

Figure 3). It is concluded that the production of HSC is possible with the addition of AF without compromising the workability properties of concrete, thereby adding the PR [

29,

30,

31,

32].

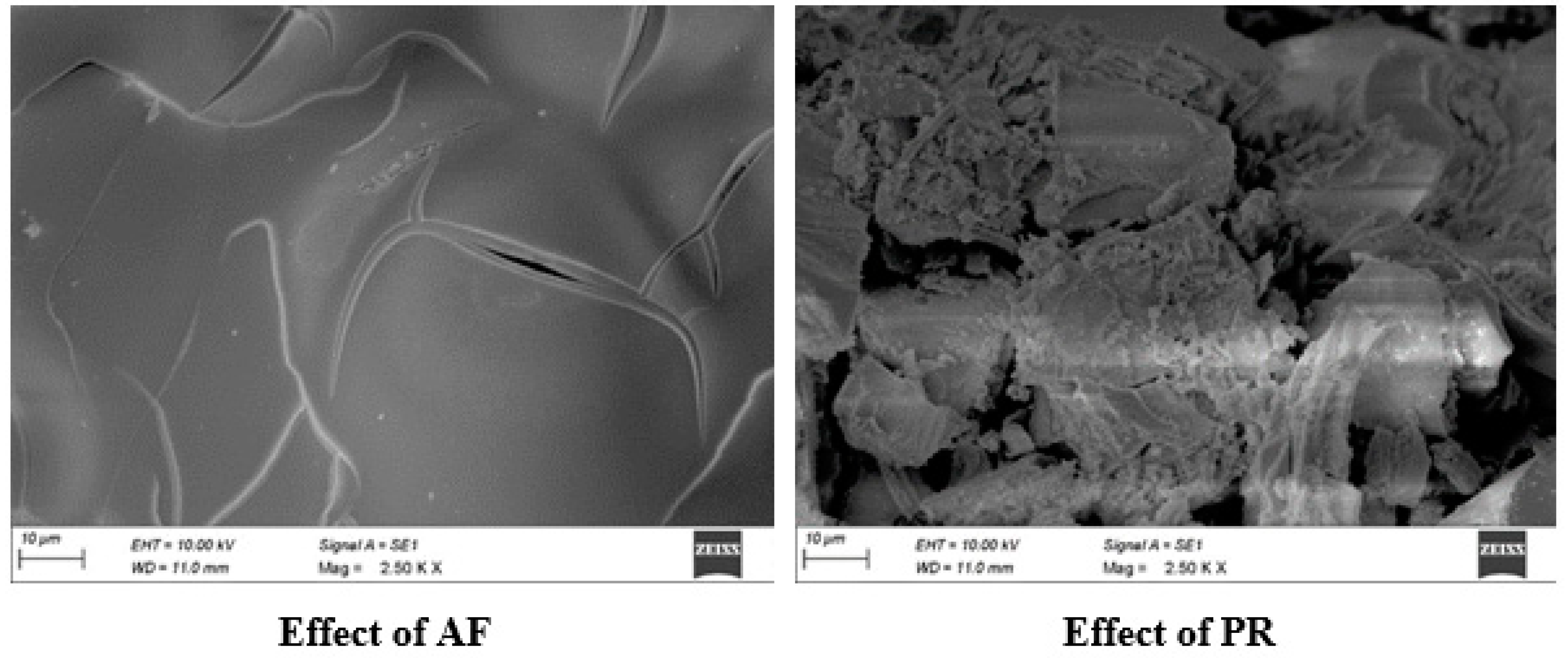

The results show that the increase in percentage addition of PR enhances the strength properties of HSC at all ages of curing. When compared with CC mixes, specimens made with varying proportions of AF and PR target mean strength were achieved at earlier stages of curing from 7 to 14 days. Addition of PR up to 4% in HSC mixes shows notable results, which shows CS of 42.15%, SPTS of 50%, and FS of 34.18% compared to the CC mixes. It regulates the permeation of water and volume of voids, thereby improving the calcium silicate hydrate (CSH) gel formation in concrete along with the addition of AF. Further, 5% addition of PR shows stable and slightly lower strength properties than the previous stages of PR addition. Furthermore, an increase in PR in HSC reduces the strength properties at all ages of curing. It happens because of the better bonding between the ingredients of HSC, which is clearly shown in

Figure 2 at a magnification level of 2.5 kx, obtained from the scanning electron microscopy (SEM) analysis conducted on AF2.5 and PR4 specimens cured for 28 days. It is also noted that the ingredients are closely arranged and improve the bond strength of concrete [

42]. According to Noumowe, use of fibers in HSC affects the porosity of the concrete and results in reduction in pore pressure inside the concrete. The fibers affect the porosity and then the release of moisture from the material [

43]. Based on the investigation regarding strength properties, it is concluded that addition of PR and AF can greatly influence the strength properties of M50-grade concrete without increasing the cementitious content, and it is possible to produce 86.34 MPa strength with the addition of 2.5% AF and 4% of PR.

The investigation involved adding two different ingredients, AF and PR, to HSC mixes in order to optimize their impact on concrete properties. The prioritization of AF was based on its significant influence on concrete properties. To determine the optimal combination of factors with fewer experiments, a design of experiments approach was used. However, it was found that the addition of 3% AF reduced the strength properties at all curing ages. To determine the optimal combination of PR and AF, varying levels of PR were added to HSC mixes with a fixed 2.5% AF content. The results showed that the addition of 4% PR yielded better results compared to other mixes. To further investigate the behavior of PR with different combinations of AF, computer modeling can be utilized.

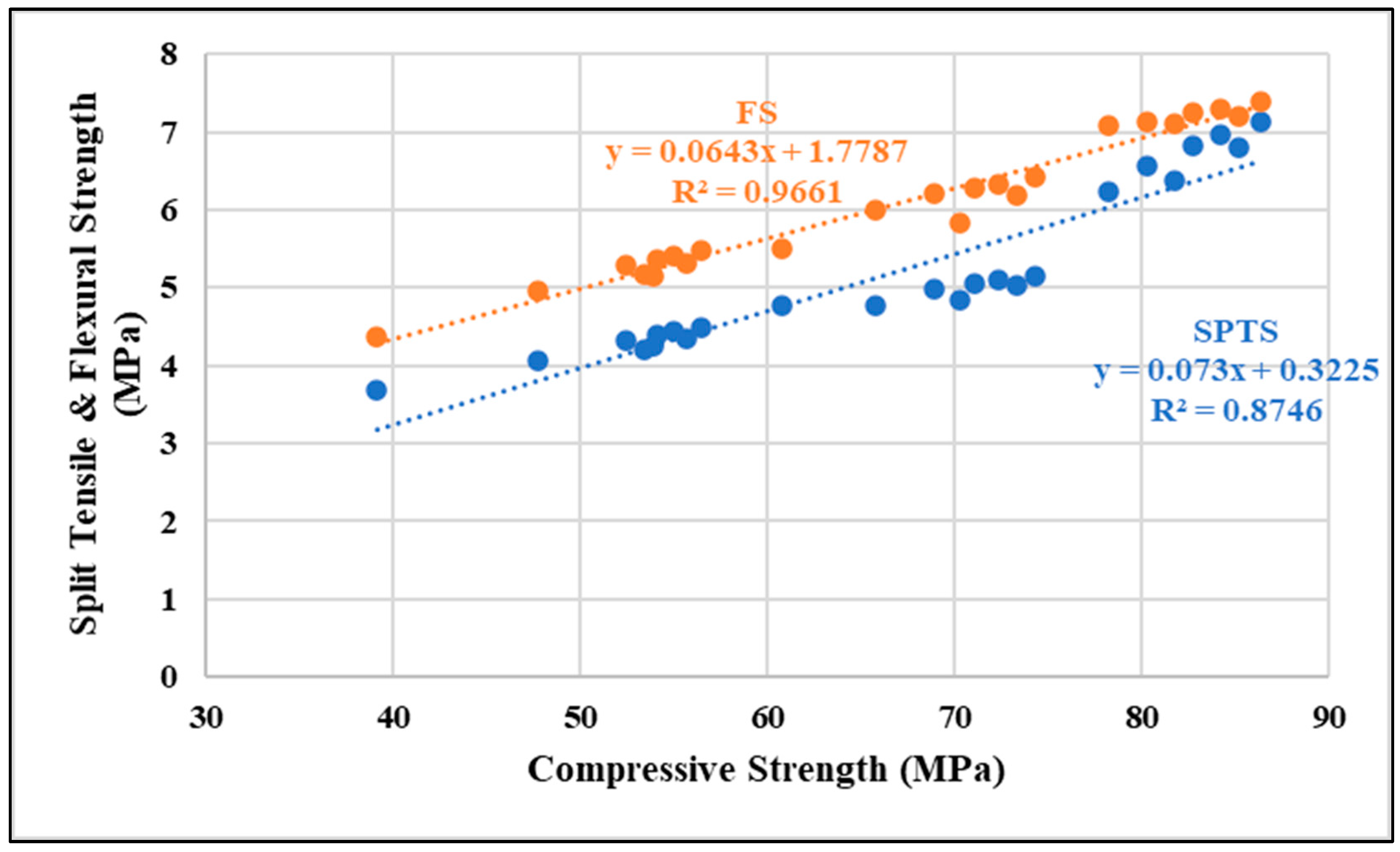

Correlation study was completed between the CS and SPTS and FS of HSC mixes by plotting the strength values in an XY scatter graph. It is observed that a better correlation was observed between the CS and SPTS and FS, with correlation coefficient values of 0.8746 and 0.9661, respectively (as shown in

Figure 3). A strong positive correlation was observed while the data points cluster around the trendline with a positive slope value. Positive correlation was essential to make informed decisions about the design mix and construction of concrete structures [

44].

A correlation study examining the relationship between compressive strength, split tensile strength, and flexural strength in concrete provides valuable insights into the material’s mechanical properties and behavior. It has several practical uses, including quality control in concrete production, design optimization for specific applications, informing structural analysis and design, enhancing material characterization, and facilitating predictive modeling for estimating behavior and assessing performance. The investigation determined that SPTS had a weaker correlation with CS compared to FS, as indicated by its lower R2 value. This suggests that there is a larger absolute variation in the relationship between SPTS and CS. However, it is possible that the correlation between FS and CS may have a lower variation in relative terms. This means that the dots in the scatter plot for FS may be more closely grouped around the line of best fit, indicating a stronger relationship between the two properties in terms of their values’ ratio. Therefore, it is crucial to consider both absolute and relative variation when assessing the correlation between different properties. Ultimately, the choice of which strength property to use depends on the specific project or application’s needs and requirements.

4.2. Durability Properties

In order to identify the true behavior of HSC mixes, it is essential to understand the behavior of concrete specimens against aggressive environmental conditions. Hence, the specimens were subjected to chemical attack and water. After the prescribed period of curing (28 days), the specimen’s surface was cleaned and weighed. Then, the samples were immersed in different solutions, such as 5% concentrated sulfuric acid, 5% concentrated hydrochloric acid (HCl), 5% concentrated sodium sulfate (Na

2SO

4), and potable water for a period of 30, 60, or 90 days. Different solutions were prepared according to the test standards or procedures. Solutions were diluted with water to achieve the desired concentration. A calibrated pH meter was used to confirm the initial concentration of the solution before the commencement of testing. During the test, the pH value of the solution was monitored regularly. If the pH starts to drop, it is an indication that the concentration of the solution is decreasing. If this happened, small amounts of acid/sulfate solution were added to maintain the desired concentration. The solution was monitored regularly to ensure a constant concentration during the experimentation. Percentage of weight loss and average loss of CS throughout the period of immersion were studied for the conventional M50-grade concrete and optimized ingredients of AF and PR and are illustrated in

Table 8.

The results from

Table 8 show that HSC made with an optimum dosage of AF and PR exhibits excellent resistance against various chemical attacks and resistance to water absorption [

33,

34,

35,

36,

37]. In the sulfuric acid attack test, CC and optimized concrete specimens show losses in CS by 15.39% and 11.72% at 90 days of immersion in acid solution. The investigation found that, in absolute terms, CC and PR-4/AF-2.5 led to losses in CS of 9.35 and 10.12 MPa, respectively, after 90 days of immersion. This was attributed to a chemical reaction between the PR and the H

2SO

4 solution. When the CC and optimized concrete specimens (PR-4/AF-2.5) are exposed to hydrochloric acid for 90 days, it shows losses in CS by 9.81% and 5.50%, respectively. In the sulfate attack test, CC and optimized concrete specimens (PR-4/AF-2.5) show losses in CS by 10.49% and 8.20% at 90 days of immersion in sulfate solution. Since the impact of HCl and Na

2SO

4 on HSC mixes shows less of an effect on strength properties, in absolute terms, PR-4/AF-2.5 show losses in CS by 4.75 MPa and 7.08 MPa, whereas CC specimens show losses in CS by 5.96 MPa and 9.37 MPa.

The specimens created with optimized ingredients (PR-4/AF-2.5) also show excellent resistance against water absorption, absorbing 23.69% less water content than the CC specimens for the same period of immersion (90 days). It is concluded that there are significant improvements in strength and durability compared to traditional HSC, making it suitable to suggest for applications where these properties are significant.

The air content in concrete can have a significant impact on the strength properties of concrete. However, excessive air content can decrease the strength of concrete as air voids can act as weak spots within the concrete. When concrete is mixed, air can be entrained by the mechanical mixing process. Typically, a small amount of air (between 1% and 2%) is added to concrete, which is enough to provide the desired durability benefits without significantly affecting the strength of the material. In this investigation, the air content present in the concrete specimens is less than 1% based on density measurements. It is also observed that a reduction in the presence of air voids will have no major impact on the CS.

4.3. Structural Properties

The structural performance of HSC specimens was analyzed by conducting flexural strength tests on reinforced concrete (RC) beams of size 125 × 200 × 1500 mm under two-point linear loading conditions, which are simply supported at the ends with a span of 1.2 m in accordance with the guidelines mentioned in IS 456:2000 [

6]. A range of properties are identified through experimental investigation to assess the structural behavior of RC beams. These properties include load vs. deflection behavior, crack analysis, and ductility characteristics. To validate the experimental investigation, the finite element software package ANSYS was utilized. The observed results on load vs. deflection curves were illustrated in

Table 9.

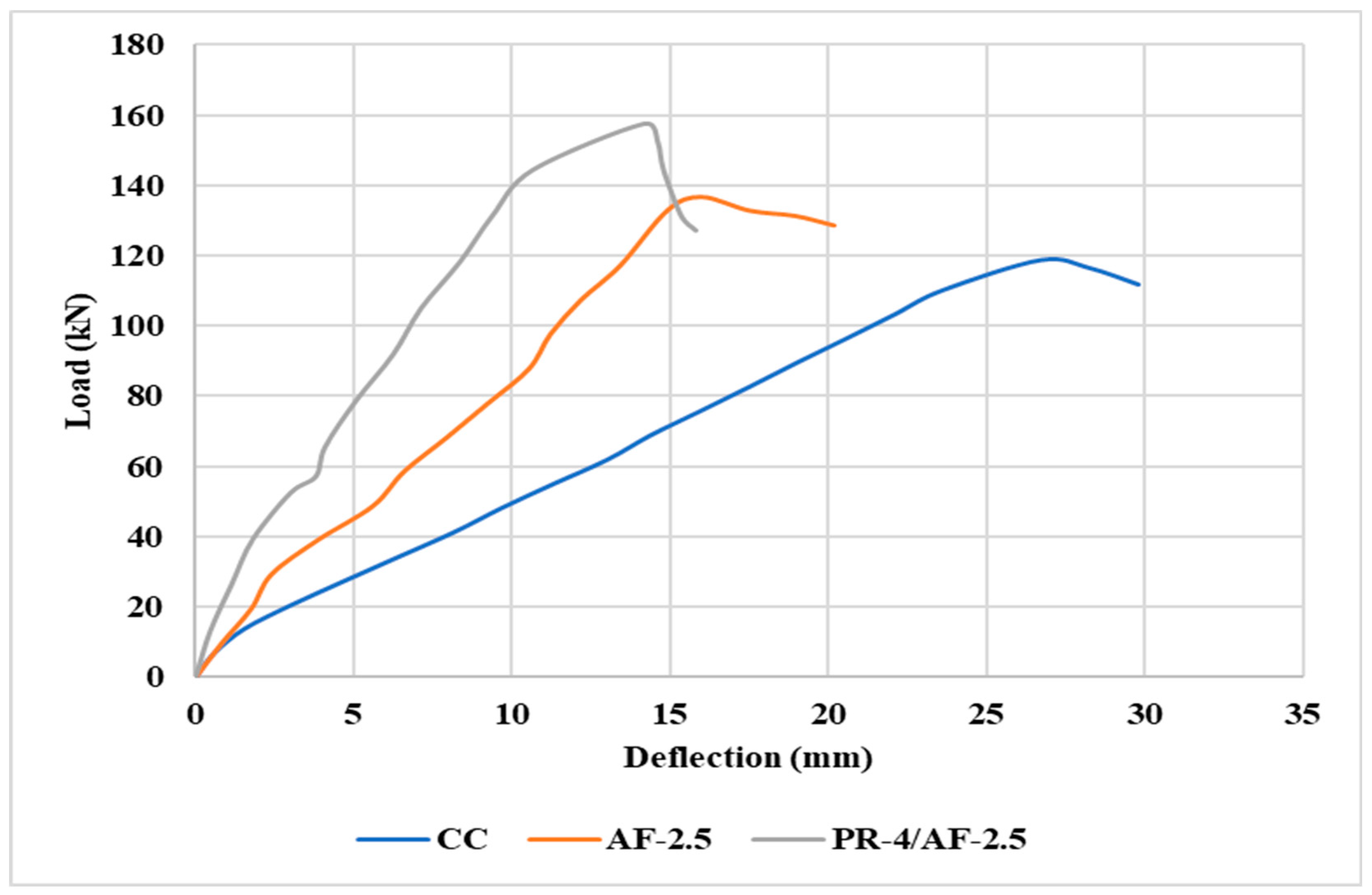

The behavior of the RC beam specimens under loading was analyzed, and it was observed that the relationship between load and deflection was linear until flexural cracking occurred just below the loading point. This led to a significant decrease in the beam’s stiffness. As the load increased, new cracks formed and existing cracks propagated towards the top of the beam in a vertical direction. The crack pattern was found to be almost identical in all beam specimens, with already formed cracks being widened and new cracks forming at higher loads. The first crack typically originated from the center and propagated vertically towards the top.

Figure 4 shows different elastic, plastic, and transitional zonal properties of RC beams. The deflection characteristics of each beam were almost identical to those of conventional specimens. During the initial stages of loading, the beam specimens behave perfectly elastically. In the transitional zone of loading, minor cracks occurred on the surfaces of concrete and propagated linearly, which results in failure of specimens in flexure, while the application of loading, the initial crack load (ICL), and ultimate load (UL) at failure were noted and summarized in

Table 10 along with the generation and propagation of crack length and width.

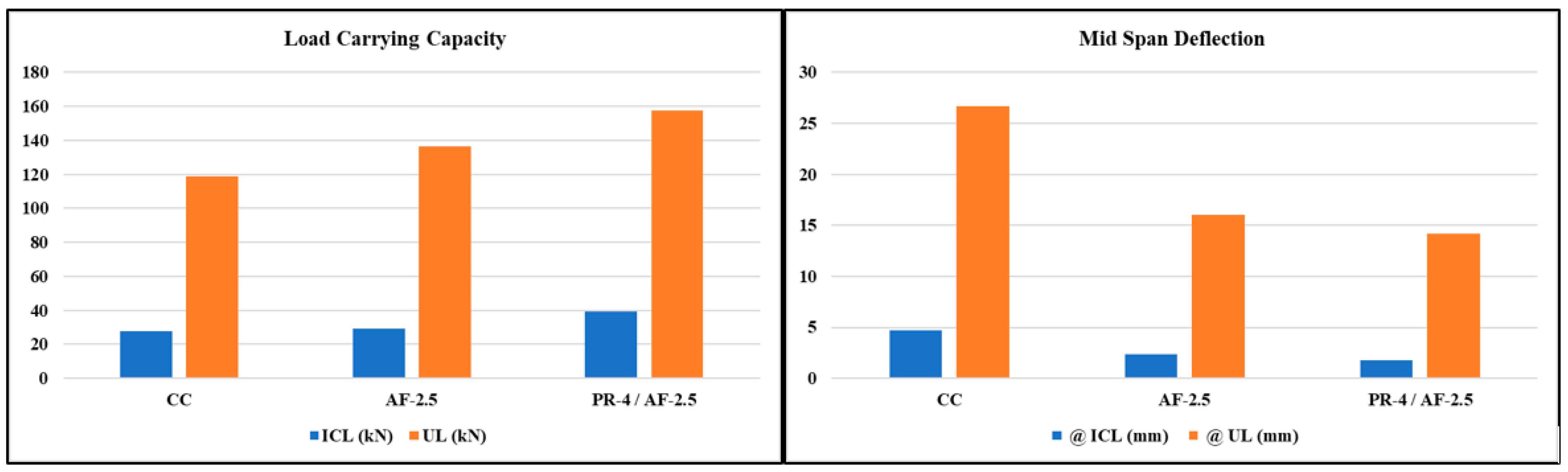

At the initial crack load stage, the load required to initiate the crack, which is represented by initial crack load (ICL), was found to be the highest for PR-4/AF-2.5 (39.45 kN), followed by AF-2.5 (29.29 kN) and CC (27.54 kN). This implies that PR-4/AF-2.5 requires more load to initiate the crack as compared to the other two specimens. Moreover, the corresponding deflection at ICL was found to be the highest for CC (4.72 mm), followed by AF-2.5 (2.40 mm) and PR-4/AF-2.5 (1.81 mm), indicating that the CC specimen is more flexible at the initial crack stage. The crack load stiffness, which is the slope of the load–deflection curve at the initial crack stage, was found to be the highest for PR-4/AF-2.5 (21.80 kN/mm), followed by AF-2.5 (12.20 kN/mm) and CC (5.83 kN/mm). This suggests that PR-4/AF-2.5 is the most rigid among the three specimens at the initial crack stage. Furthermore, the crack length and crack width were found to be the highest for CC at ICL, indicating that CC is more susceptible to cracking at the initial stage (

Figure 5).

At the failure stage, the ultimate load (UL) required to cause failure was found to be the highest for PR-4/AF-2.5 (157.81 kN), followed by AF-2.5 (136.62 kN) and CC (118.74 kN). This implies that PR-4/AF-2.5 has the highest load carrying capacity among the three specimens. Additionally, the corresponding deflection at UL was found to be the highest for CC (26.72 mm), followed by AF-2.5 (16.03 mm) and PR-4/AF-2.5 (14.20 mm), indicating that the CC specimen is the most flexible at the failure stage. The ultimate stiffness, which is the slope of the load–deflection curve at the failure stage, was found to be the highest for PR-4/AF-2.5 (11.11 kN/mm), followed by AF-2.5 (8.52 kN/mm) and CC (4.44 kN/mm). This suggests that PR-4/AF-2.5 is the most rigid among the three specimens at the failure stage.

The initial crack load stiffness of the AF-2.5 and PR-4/AF-2.5 specimens was found to be 109.26% and 273.93% higher, respectively, than that of the CC specimens. However, upon failure, the ultimate stiffness of the AF-2.5 and PR-4/AF-2.5 specimens was only 91.89% and 150.23% higher than the stiffness of CC specimens. This suggests that the rate of stiffness degradation was greater in the AF-2.5 and PR-4/AF-2.5 specimens due to their higher load carrying capacity during the initial stages of loading [

45]. Furthermore, the crack length and crack width were found to be the highest for CC at the failure stage, indicating that CC is also more susceptible to crack propagation at the failure stage. From

Table 9, it is concluded from the comparison of parameters for different beam specimens that PR-4/AF-2.5 has the highest load carrying capacity and stiffness at both the initial crack and failure stages, while CC is the most flexible at both stages [

46,

47,

48,

49]. Additionally, CC is more susceptible to cracking and crack propagation at both stages, while PR-4/AF-2.5 is less susceptible to cracking and more resistant to crack propagation at both stages.

The ductility ratio is an essential factor in determining the ability of concrete structures to withstand external loads and forces without failure. It refers to the material’s capacity to undergo inelastic deformation before failure and is calculated by taking the ratio of the ultimate load to the yield load of the specimens. According to

Figure 6, the CC, AF-2.5, and PR-4/AF-2.5 specimens had yield loads of 97.2, 87.1, and 89.3 MPa, respectively, and ductility values of 1.222, 1.569, and 1.767, respectively. A higher ductility ratio implies that the material can undergo more deformation before failure, while a lower ratio suggests that the material is more brittle and may fail abruptly. As PR-4/AF-2.5 exhibited a higher ductility ratio than the other specimens, it may be suitable for constructing seismic-resistant reinforced concrete (RC) elements.

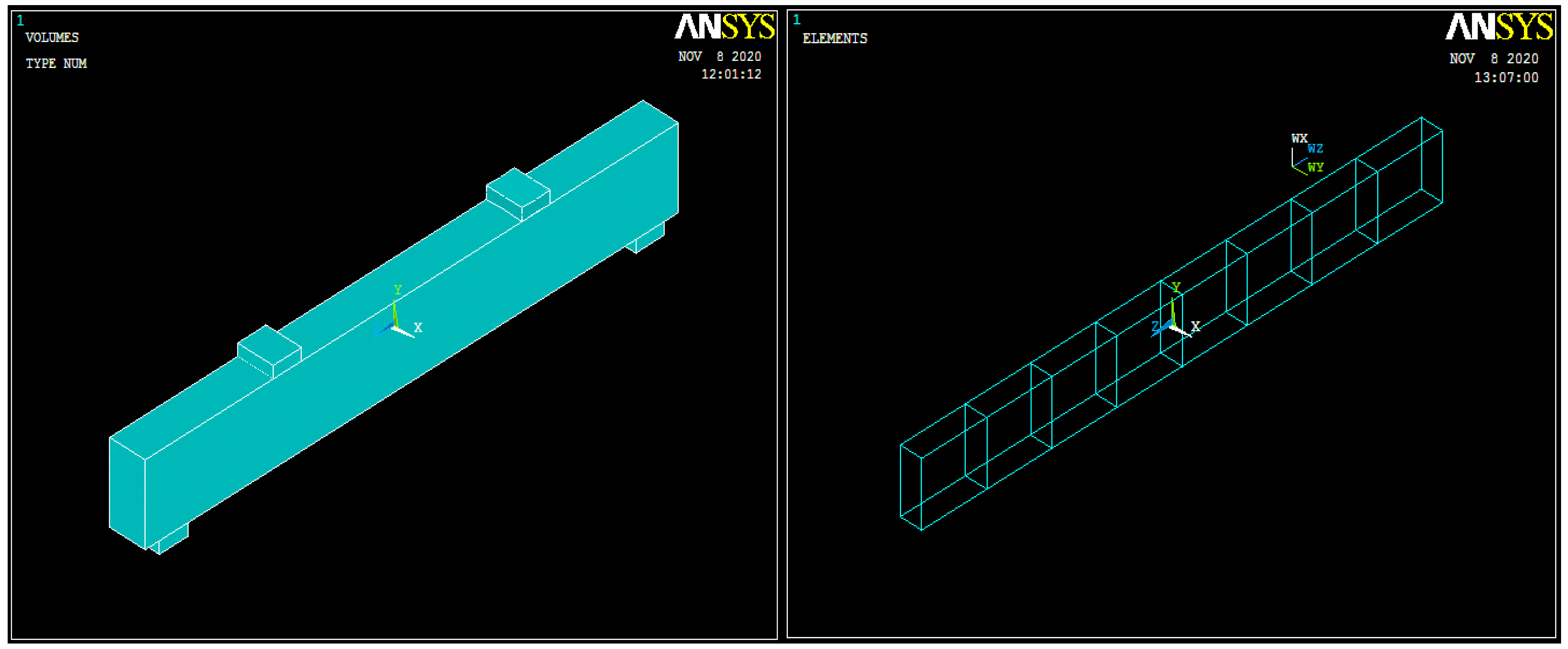

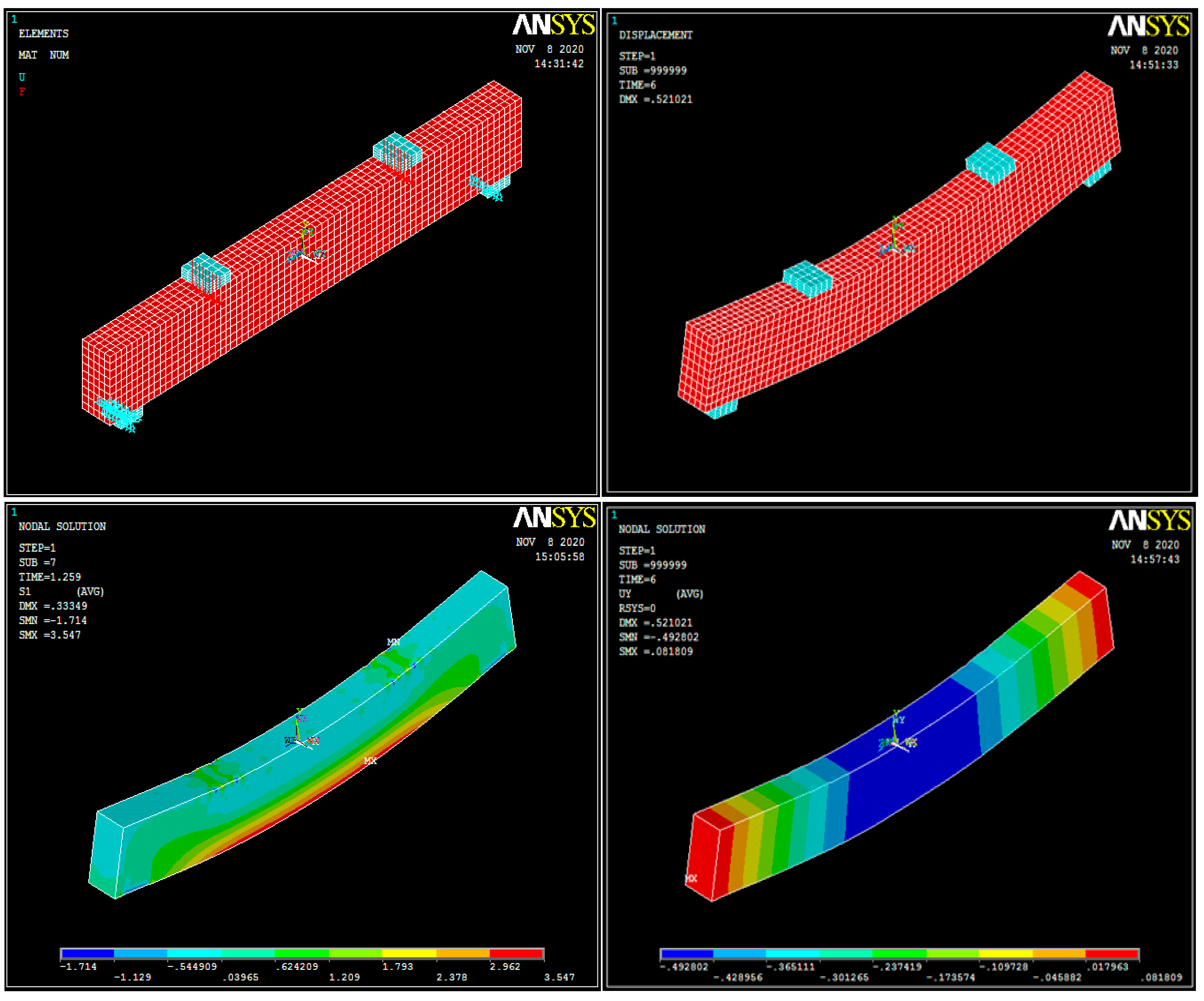

4.4. Numerical Investigation

Finite element analysis (FEA) using ANSYS software was performed on RC beams, which were produced with M50-grade concrete with optimal addition of AF and PR. Nonlinear analysis was carried out to determine the structural properties of the beams and the predicted results were compared with the experimental results. It is a technique of numerical analysis that provides approximate solutions to various technical problems and has been used extensively in engineering and industrial research applications [

50,

51,

52,

53]. This analysis involves the use of mathematical models and computer simulations to predict the performance of RC beams in terms of strength, deformation, and failure modes. Additionally, numerical analysis can provide insights into the behavior of RC beams that cannot be observed through experimental testing alone, leading to a better understanding of their structural behavior and the potential for more efficient and cost-effective designs.

In the numerical analysis of RC beams using ANSYS, the modeling techniques involve creating the beam’s geometry, generating a mesh to discretize the domain, modeling the material properties of concrete and reinforcing steel, and applying appropriate boundary conditions. Accurate representation of the geometry, mesh density, material properties, and boundary conditions is crucial for obtaining reliable results. Material assignment in ANSYS can be completed through direct assignment by manually inputting material properties, utilizing material libraries provided by ANSYS, or transferring material properties through mapping techniques. Accurately defining the material properties of concrete and reinforcing steel is essential for obtaining accurate simulation results. Processing the output data involves techniques such as visualizing results through contour plots, animations, and stress distributions, extracting key parameters such as bending moments, shear forces, deflections, and crack patterns, comparing results with experimental data or design code provisions, and performing parametric studies to understand the influence of input parameters on the beam’s response.

From ANSYS element library, different elements were used to represent different materials utilized in the modelling of RC beams. SOLID65 is a 3D eight-node solid element used to model the concrete portion of the beam [

54,

55,

56,

57,

58,

59,

60]. It is a general-purpose element that can account for nonlinear material behavior and damage, such as cracking and crushing of concrete under compression. It is a higher-order element with more nodes than some of the other solid elements in ANSYS, which is commonly used for the analysis of complex solid structures. SOLID65 is preferrable in ANSYS for concrete structures due to its accurate stress and strain predictions, better convergence, wide applicability, and large deformation capability. LINK8 is a 3D two-node element used to model the reinforcing steel bars in the beam (

Figure 7), a truss element that can account for the tensile behavior of the steel reinforcement. SOLID45 is a 3D eight-node solid element used to model the steel plates and bolts in a steel–concrete composite beam [

61,

62,

63,

64,

65,

66,

67,

68]. It is a general-purpose element that can account for material nonlinearity and damage, such as yielding of the steel plates under tension or shear. The geometry of the beam is defined by creating nodes at key locations along the beam and connecting them with solid and link elements. A constitutive model is a mathematical relationship between stress and strain, describing the material behavior under external loads. It determines how the material responds to different loads, including static, dynamic, and thermal loads. The constitutive model provides the basis for developing and validating numerical algorithms to solve structural problems using FEA. The selection of an appropriate constitutive model is critical for obtaining accurate results from FEA. The model should be based on the material properties and loading conditions of the structure being analyzed. An incorrect constitutive model selection can result in erroneous results and wrong conclusions. Therefore, the necessary information on the constitutive model, including material properties such as modulus of elasticity, Poisson’s ratio, yield strength, ultimate strength, and fatigue properties of concrete, reinforcing steel, and steel plates, are specified in

Table 11.

The loading and boundary conditions are defined regarding the RC beam model and then the FEA is performed to determine the stress and deformation response of the beam under the modelled loading conditions, and the observed results were compared with the experimental results from the previous stages of the investigation.

From

Table 12, it is observed that the experimental and numerical results are generally consistent with each other. The experimental values are slightly lower for load carrying capacity, stiffness, and crack length, and slightly higher for deflection and crack width compared to the numerical values [

69,

70,

71,

72,

73,

74,

75]. This may be due to uncertainties in experimental measurements or variations in the material properties of different samples. However, the differences between the experimental and numerical results are relatively small and do not significantly affect the overall conclusions of the study. The results of the study suggest that aramid-fiber- and polyurethane-resin-reinforced high-strength concrete may be suitable for various applications, such as building structures that require high strength and durability, precast concrete manufacturing, and other construction applications.

In terms of the load carrying capacity and stiffness characteristics, the PR-4/AF-2.5 and AF-2.5 specimens had higher values compared to the CC specimen for both experimental and numerical results. When comparing the experimental results with the numerical results for the CC, AF-2.5, and PR-4/AF-2.5 specimens in terms of their load at initial crack (ICL) and load at failure (UL), there was a difference observed. The numerical results for ICL were 5.66%, 10.14%, and 5.91% higher than the experimental results for the CC, AF-2.5, and PR-4/AF-2.5 specimens, respectively. Similarly, the UL carrying capacity for the same specimens showed a higher numerical value, with a difference of 9.11%, 11.98%, and 8.64% higher than their experimental results, respectively. These trends indicate a slight discrepancy between the experimental and numerical results, which could be due to various factors, such as the assumptions made in the numerical model or the experimental setup. In terms of the crack length and width, the PR-4/AF-2.5 and AF-2.5 specimens had lower values compared to the CC specimen for both experimental and numerical results. This indicates that the AF-2.5 and PR-4/AF-2.5 specimens had less crack propagation compared to the CC specimen. The numerical results were almost matches and consistently higher than the experimental results, with merely zero standard deviation. The differences between the experimental and numerical results are relatively small and do not significantly affect the study’s overall conclusions.

Based on the strength, durability, and structural properties, it is concluded that the addition of PR and AF can significantly influence the properties of M50-grade concrete, such as strength, ductility, and durability, without increasing the cementitious content and using the optimum dosage of 2.5% AF and 4% of PR.

5. Conclusions

The following are the major conclusions from the detailed experimental investigation on M50-grade HSC mixes created with varying percentages of AF and PR. It is concluded that the production of HSC is possible with the addition of the optimum dosage of AF without compromising the workability properties of concrete while adding the PR.

It is possible to produce M50-grade concrete mixes without increasing the cement and supplementary cementitious materials in a concrete mix. The inclusion of AF improves the viscosity of the HSC mixes, thereby reducing the slump values, making the concrete more difficult to work with.

At 28 days of curing, AF-2.5 mixes show an increase in FS by 28.73% and SPTS by 31.1%. However, the effect on CS may show a comparatively notable significant improvement of 28.71% compared to the CC mixes, which show 78.18 MPa with a YM of 45.28 GPa. The addition of PR up to 4% in HSC mixes shows notable results, which show CS of 42.15%, SPTS of 50%, and FS of 34.18% compared to the CC mixes. It regulates the permeation of water and the volume of voids, thereby improving the CSH gel formation in concrete and adding AF.

In the sulfuric acid attack test, CC and optimized concrete specimens show losses in CS by 15.39% and 11.72%, respectively, at 90 days of immersion in an acid solution. When the CC and optimized concrete specimens (PR-4/AF-2.5) are exposed to hydrochloric acid for 90 days, it shows losses in CS by 9.81% and 5.50%, respectively. In the sulfate attack test, CC and optimized concrete specimens (PR-4/AF-2.5) show losses in CS by 10.49% and 8.20%, respectively, at 90 days of immersion in a sulfate solution. The specimens made with optimized ingredients (PR-4/AF-2.5) also show excellent resistance against water absorption, absorbing 23.69% less water content than the CC specimens for the same period of immersion (90 days).

PR-4/AF-2.5 has the highest load-carrying capacity and stiffness at both the initial crack and failure stages, while CC is the most flexible. Additionally, CC is more susceptible to cracking and crack propagation at both stages, while PR-4/AF-2.5 is less susceptible to cracking and more resistant to crack propagation at both stages.

The differences between the experimental and numerical results are relatively small and do not significantly affect the study’s overall conclusions.

Based on the strength, durability, and structural properties, it is concluded that the addition of PR and AF can significantly influence the properties of M50-grade concrete, such as strength, ductility, and durability, without increasing the cementitious content and using the optimum dosage of 2.5% AF and 4% of PR.

The potential shortcomings of HSC made with AF and PR include high cost, limited availability of aramid fibers, different material properties compared to traditional concrete, uncertain long-term durability, and the need for specialized knowledge and design considerations. Further research is needed to optimize the reinforcement dosage and configuration, evaluate durability, and assess cost-effectiveness. The future scope for this investigation includes conducting research on the long-term durability and sustainability of HSC with the addition of AF and PR, exploring different types and amounts of supplementary cementitious materials, investigating the feasibility of using recycled materials, exploring the use of HSC in different types of structures, and conducting cost–benefit analyses to determine the economic viability of using AF and PR in HSC.