Abstract

Expansive soils in the field are typically exposed to cyclic wetting and drying due to climatic fluctuations and subjected to a variety of stress conditions in nature or when used as compacted layers for the construction of hydraulic barriers or waste disposal facilities. The hysteric behavior of the soil-water characteristic curve (SWCC) is a key parameter for understanding, modeling, and interpreting the unsaturated behavior of these soils under such conditions. This study investigates the effect of stress states on the hysteresis behavior of soil-water characteristic curves (SWCCs) for compacted highly expansive clay over a range of matric suction between 0 and 1500 kPa. Two test series were performed, the first test series investigated the effect of stress states on the hysteresis of SWCCs during a single drying-wetting (DW) cycle. The second test series studied the combined effect of stress applied and multiple drying-wetting cycles on the SWCC hysteresis. For the sake of comparison, the overall SWCC hysteresis due to drying-wetting cycles was quantified using the average degree of hysteresis in terms of volumetric water content (ADHθ). Furthermore, contributors to the observed hysteresis were defined using two newly proposed measures; namely, average degree hysteresis in terms of gravimetric water content (ADHw) and in terms of volume change (ADHe*). The outcomes of this study indicate that consideration of stress states on the hysteresis of SWCC for expansive clay is of great importance. The results show a dual trend for the variation of ADHθ with applied vertical stress. Furthermore, multiple DW cycles induced a significant reduction in the hysteresis (ADHθ) under low- and high-stress states up to a certain level of DW cycles, then, no further changes in the hysteresis trend were detected. It was also found that hysteresis loops under a low-stress state were concentric in shape while hysteresis loops for specimens under a high-stress state were non-concentric, with a downward shift in hysteresis loops with the increase in DW cycles.

1. Introduction

Expansive soil is used as compacted layers or liners as construction material for several geotechnical and geoenvironmental projects, such as backfills, subgrades, clay barriers, and buffers for radioactive waste disposal (i.e., [1,2,3,4,5,6]). These layers typically exist in an unsaturated state where the water and air inside soil pores interact with each other. The soil-water characteristic curve (SWCC) is a measure of the amount of water stored inside soil pores at any given soil suction. Several studies have shown the correlation between SWCC and unsaturated soil hydro-mechanical properties such as shear strength, permeability, infiltration, and volume change [7,8,9]. Hence, a full understanding of the factors that affect the SWCC is needed. From the technical literature, several factors affecting the SWCC have been identified including soil types, soil structure, particle-size distribution (PSD), fine percent, initial water content, initial dry density, drying-wetting cycles, stress history, and stress states [10,11,12,13,14].

In the field, soils are typically subjected to cyclic wetting and drying due to soil–atmosphere interaction producing SWCCs with different trends for the wetting and the drying paths. Early research observed that soil holds more water during drying than during wetting. This phenomenon is known as hysteresis [7,15]. The hysteresis loops (defined as the area between each pair of drying and wetting) produced in SWCCs were studied by several researchers and their observance was attributed to one or more of the following factors: (i) plastic deformation of the soil during desorption/absorption, (ii) air entrapped during the drying process decreases water storage in the wetting path, (iii) the geometric non-uniformity of the individual pores, which induce the “inkbottle effect”, (v) the contact angle effect, which affects the radius of curvature of the meniscus and in turn affects the value of suction [7,15,16]. These phenomena are mainly dominant in the low suction range where the capillary effect is dominant. In the case of expansive soil, elastic and plastic deformations (volume changes) associated with drying and wetting add more complexity to the hysteretic behavior of these soils by changing the volume of soil pores [17,18].

Several studies investigated the hydraulic hysteresis between drying and wetting SWCC for non-expansive soils [17,19,20,21,22,23]. Soils with appreciable clay content were observed to have a more visible hysteretic behavior than clayey silt soils. In addition, the SWCC hysteresis (the difference between drying and wetting branch) was high under low suction value and vice versa [24]. On the other hand, studies investigating the SWCC hysteresis of expansive soils are limited [13,18,25]. These studies reported that, besides hydraulic hysteresis, volume changes also affect the hysteresis observed between drying and wetting paths for expansive soils. Jayanth et al. [26] reported that expansive soil with active clay minerals exhibits higher hysteresis than other soils.

The drying-wetting hysteresis and possible effects on strength, and hydraulic conductivity have been studied for residual soil; the results have been interpreted in light of microstructure changes and reveal development of small pores to cracks up to certain levels of drying-wetting cycles [27,28,29].

Recently, several researchers investigated the effect of applied stress on SWCC hysteresis of non-expansive soils [12,30,31,32]. Ng and Leung [19] studied the effect of stress on the hysteresis of SWCC of compacted decomposed silty clay using stress-controlled soil columns under normal vertical stresses of 0, 40, and 80 kPa. Test results revealed that the hysteresis loops area decreased with the increase of applied stress. This reduction in the hysteresis loops was attributed to the reduction in the void ratio. Similar behavior was reported by Tse [30] for decomposed granite under different stresses (0, 20, 53, and 80 kPa) and by Li and Liu [12] for loess and volcanic soils (vertical stress 0, 40, and 80 kPa) within matric suction range (from zero to 400 kPa). Conversely, Goh et al. [32] reported different SWCC hysteresis phenomena for sand-kaolinite mixtures subjected to drying and wetting over a range of suction between 0 and 500 kPa and under 0 and 50 kPa confining isotropic pressure. Test results indicate that the hysteresis loops area under 50 kPa confining pressure was higher than hysteresis under zero confining pressure. Furthermore, Ng and Pang [33] reported that the hysteresis behavior of SWCC for undisturbed volcanic soil from Hong Kong appears to be independent of the applied stress within the considered range of matric suction. In the same context, Ng et al. [34] investigated the hysteresis of SWCC under different stress levels for colluvium and decomposed soils using the instantaneous profile method. The results indicate that hydraulic hysteretic loops were observed within depths less than 1.85 m, after which the hysteresis diminished and no significant hysteretic loops were detected up to 3.0 m. Hence, there is a non-consensus regarding the SWCC hysteresis behavior under different stresses. The role of pore size distribution and pore structure on the hysteresis of drying-wetting has been studied under low stresses between 0–50 kPa by Ng et al., (2023) [35], and irregularity of pore shape enhanced the hysteresis phenomena.

For expansive soils, studies regarding the hysteresis of stress-dependent SWCC are scarce. The only study identified was that conducted by Zhang et al. [18] where the hysteresis of SWCCs for expansive soil (obtained from ZaoYang, Hubei Province in Central China) was evaluated under applied stresses of zero and 50 kPa. Hysteresis of SWCC was measured for a range of matric suction between 0 and 200 kPa using the modified one-dimensional stress-controlled volumetric pressure plate extractor developed by Ng and Pang [33]. The results revealed that the increase in vertical stresses resulted in hysteresis being less significant. Zhang et al. [18] attributed the observed behavior to applied stress restraining expansive soil’s volumetric change (expansion-shrinkage); therefore, the reduction in inter-aggregate and intra-aggregate pores, in turn, led to reduction in hysteresis loops.

Further categorization of the technical literature revealed that most studies related to the hysteresis of SWCC were carried out under a single drying-wetting cycle [20,21,22,23,36,37]. There are a limited number of studies that were carried out under several drying-wetting cycles for non-expansive soils [12,32,35,38]. Experimental procedures involved imposing two to three cycles of drying and wetting within a range of suction between 0 to 800 kPa. These studies revealed that the hysteresis loops area decreased with the increase in drying-wetting cycles. Combining multiple drying and wetting cycles with applied confining pressure of 0 and 50 kPa, Goh et al. [32] reported a decrease in hysteresis loops with increased drying-wetting cycles.

For expansive soils, investigation of the SWCC hysteresis under multiple drying-wetting cycles is scarce. Lin and Cerato [17] conducted drying-wetting SWCC on two expansive soils under no stress and the results inferred a difference in hysteresis of SWCC between primary (first) and secondary drying-wetting cycles. Therefore, it is worth noting that there is a need to investigate the SWCC hysteresis of expansive soil under the combined effect of multiple drying and wetting cycles and applied stress.

To this end, this study investigates the effect of stress states on the SWCC hysteresis behavior of compacted natural expansive clay subjected to single or multiple drying-wetting (DW) cycles. SWCC was determined for specimens that were laterally confined (one-dimensional condition) and subjected to vertical stresses ranging between 7 and 300 kPa. The relative contribution of applied vertical stress and DW cycles on the drying and wetting branches of SWCC and its hysteresis was highlighted. Furthermore, changes in volume and gravimetric water content during DW cycles were measured and sources of SWCC hysteresis behavior were discussed.

2. Experimental Study

The following sections provide details of the clay material used, specimen preparation procedure, equipment used, test plan, and test procedure.

2.1. Soil Used and Geotechnical Characterization

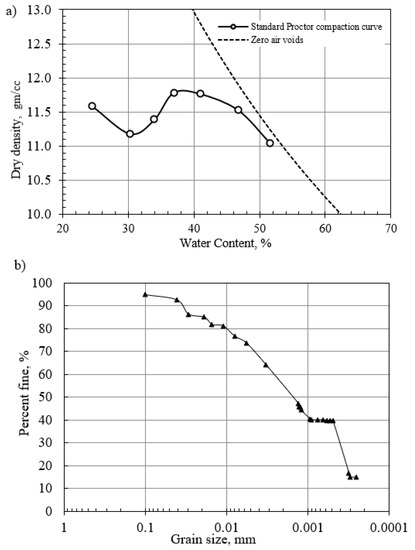

The material used in this study was collected from the eastern province of Saudi Arabia, specifically from Al-Qatif City (latitude 26°56′ N and longitude 50°01′ E). A test pit was excavated to a depth of 1.5–3.0 m below the ground surface. The natural clay was transported to the laboratory, pulverized, and sieved using a 425 µm opening sieve to obtain clay powder. Standard Proctor compaction test performed on studied clay in accordance with ASTM D698 [39] revealed that the maximum dry unit weight and optimum moisture content were 11.78 kN/m3 and 38%, respectively, as shown in Figure 1a. A summary of the geotechnical properties of this clay is shown in Table 1. Figure 1b presented the gradation curve for this clay, the clay portion estimated to be around 57%. Based on characterization results, Al-Qatif clay is classified as clay with high plasticity (CH) and has high to very high swell potential. Mineralogical characterization of this clay using the X-Ray diffraction technique conducted by Al-Mahbashi [40] and Al-Mahbashi et al. [41] revealed that the dominant clay minerals are montmorillonite and palygorskite (attapulgite). Rafi [42] reported that the percentages of montmorillonite and palygorskite in this clay reach up to 23% and 33%, respectively; considerable content of such minerals interpret the high swell potential of this clay. This clay spreads in wide areas and compacted layers have wide applications in liner projects or disposal facilities as a sealing material. It may be exposed to different drying-wetting cycles, and besides variations in its moisture content, this clay may have sustained different levels of field stresses.

Figure 1.

(a) Standard compaction curve and (b) gradation curve of Al-Qatif expansive clay.

Table 1.

Geotechnical characteristics of Al-Qatif clay.

2.2. Specimen Preparation and Pre-Conditioning

The specimens were prepared by mixing sieved soil with a pre-determined amount of distilled water equivalent to optimum moisture content as per the compaction curve (Figure 1a). The mixture was stored in a humid environment for 24 h to moisture homogenize. Subsequently, soil specimens were statically compacted to maximum dry unit weight in a test ring with dimensions of 50 mm diameter and 20 mm high.

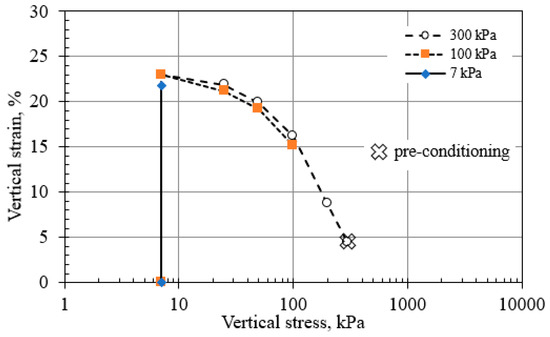

The starting point for the determination of the SWCCs of expansive clay subjected to DW cycles is full saturation condition. Therefore, initially compacted specimens were pre-conditioned by saturation followed by loading to target vertical stress (Figure 2). Saturation was achieved by fully inundating the ring-confined specimens in an odometer cell under initial vertical stress of 7 kPa and maintained till full swell was attained (not less than 24 h). After attaining full swell, the vertical stress on specimens were incrementally increased to target vertical stress (in the case of 100 and 300 kPa; see Figure 2) and was maintained to equilibrate. After pre-conditioning, specimens were expeditiously transferred to the SWCC testing device for DW cycle application as detailed below.

Figure 2.

Saturation process of used samples.

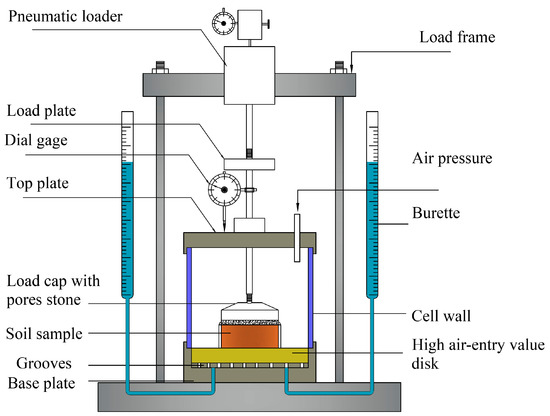

2.3. SWCC Testing Device

In this study, SWCC determination under DW paths was carried out using a GCTS Fredlund SWC-150 device. This device works on the principles of axis-translation technique (as per ASTM D 6836 [50]) and has the capability of simultaneously applying suction and vertical stress on ring-confined specimens. The main components of this device are the pressure cell, control panel, and load frame. The schematic diagram of Fredlund SWC-150 device is shown in Figure 3. The pressure cell is provided with a high air entry value (HAEV) ceramic disk to separate water and air phases during suction application and allow only water to pass through it from or to (drying or wetting) soil specimens. Vertical stress was applied on test specimens using a pneumatic loader controlled with a pressure regulator and dial gauge, and was attached to a loading frame (Figure 3). The loading ram transferred the load from the pneumatic loader to the loading plate (connected to the top plate of device cell) which in turn transferred this load to the specimens inside cell pressure. More details regarding the operation of the device are provided by Pham et al. [51], Al-Mahbashi et al. [52], and Elkady et al. [53].

Figure 3.

Schematic diagram of SWC-150 device.

2.4. Drying-Wetting Cycles and Test Plan

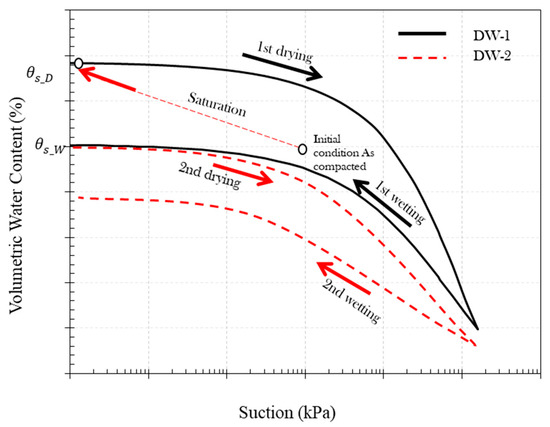

A schematic diagram showing the drying and wetting cycles applied on test specimens is shown in Figure 4. As illustrated in Figure 4, the starting point for specimens subjected to DW cycles is at full saturation (details regarding specimen saturation and pre-conditioning were provided in Section 2.2). After specimen pre-conditioning, drying progressed by applying matric suction in increments between 10 kPa and 1500 kPa. At the end of the drying suction range (i.e., 1500 kPa), the wetting branch of the SWCC was evaluated by reducing matric suction in decrements of matric suction all the way back to zero. For multiple DW cycles, the aforementioned procedure was repeated to obtain successive DW cycles. In this study, the experimental program involved two test series described as follows:

Figure 4.

Schematic of drying-wetting cyclic.

H1 Series: specimens were subjected to a single drying-wetting cycle under a range of vertical stress of 7, 100, and 300 kPa (with 300 kPa approximately equivalent to the swelling pressure of the expansive clay considered in this study). For the convenience of reference, these specimens were labeled as S7, S100, and S300, respectively. This series focused mainly on assessing the effect of vertical stress on SWCC hysteresis.

H2 Series: This test series explored the combined effect of vertical stress and DW cycles on the hysteresis of SWCC. Specimens were exposed to multiple DW cycles under two levels of vertical stresses of 7 kPa and 300 kPa simulating low- and high-stress conditions, respectively. For convenience of reference, these specimens were labeled M7 and M300, respectively. DW cycles were continued until hysteresis reached an equilibrium state (i.e., no appreciable changes in SWCC hysteresis as a result of DW cycles were observed).

2.5. SWCC Testing Procedures

The pre-conditioned saturated specimens (Section 2.2) were transferred to the pressure cell and placed in close contact with the HAEV ceramic disk and selected vertical stress was applied. Matric suction was applied on the specimens in increments or decrements to obtain drying-wetting curves of SWCC (following the test plan in Section 2.4), respectively. During each matric suction increment or decrement, water outflow (during drying) or inflow (during wetting) was monitored using graduated burettes (Figure 3) and equilibrium was considered when no change in water level reading for 24 h was observed. At the end of each increment/decrement, the cell was dismantled and the weight of the specimen was recorded expeditiously to obtain specimen weight for gravimetric water content calculations. Vertical deformations due to vertical stress and suction application were monitored using a dial gauge connected to the loading arm, as shown in Figure 3. To obtain a full picture of specimen volume change, radial strains developed due to lateral shrinkage of specimens were recorded after each suction increment or decrement. During low matric suction levels (<100 kPa), radial strains were observed to be small and unevenly distributed; therefore, radial strains were recorded using an image processing technique [40,54]. As applied matric suction increased, radial shrinkage becomes appreciable to the extent that the specimens are separated from the confining ring. For this case, radial strains were measured using a caliper.

3. Results and Discussion

Experimental results obtained from this study on the hysteresis of SWCC during DW cycles and under different stress states for highly expansive clay are presented in the following sections.

3.1. Effect of Vertical Stress on the Hysteresis of SWCC

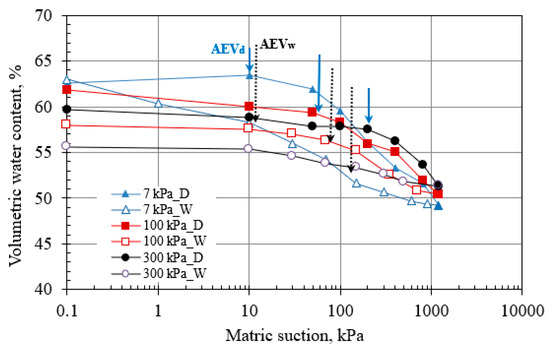

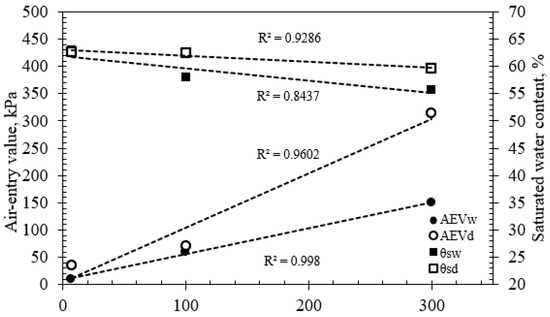

This section discusses the results of test series H1, which focused on the effect of vertical stress on the hysteretic behavior of SWCCs of expansive clay under a single drying and wetting cycle. The SWCCs were plotted as a relationship between volumetric water content and matric suction as shown in Figure 5. It was observed that the applied vertical stress had a significant effect on the features of the drying and wetting branches of the SWCCs. For the drying SWCC, the increase in vertical stress resulted in an increase in air entry value (AEVd) and a decrease in saturated volumetric water content at the beginning of drying (θsd). The increase in AEVd signifies a delay in the initiation of desaturation. Quantitatively, the AEVd under low stress (i.e., 7 kPa) was observed to be 10 kPa and increased to about 50 and 200 kPa under applied stress of 100 and 300, respectively. Similar behavior of increase in AEVd with an increase in vertical stress was reported by Vanapalli et al. [55], Rassam and Williams [56], and Lee et al. [57]. The increase in AEVd was attributed to the reduction in specimen pore volume due to applied vertical stress and, consequently, more suction was needed to desaturate. For the wetting SWCC, it was observed that vertical stress has a notable effect on the air expulsion value (AEVw) and the difference between saturated volumetric water content for the drying and wetting curves (i.e., at zero suction). The AEVw is defined as the suction value marking the transition from an unsaturated state to a saturated state during wetting [36]. Figure 6 provides a summary of the variation in saturated volumetric water content (θsd for the drying curve and θsw for wetting curve) and AEV (AEVd for the drying curve and AEVw for the wetting curve) with applied vertical stresses. From Figure 6, saturated volumetric water contents for the drying and wetting curves are observed to decrease in linear trend with an increase in stress. Furthermore, the θsw was consistently less than θsd. One exception is for S7 where there is no notable difference between saturated water content for drying and wetting path. Similar behavior was observed in Zhang et al. [18]. With respect to AEV, AEVd was greater in value than AEVw with values showing a linear increase with the increase in vertical stress (Figure 6).

Figure 5.

Effect of vertical stress on the hysteresis of SWCC during drying-wetting.

Figure 6.

Variation in main characters of SWCC during drying-wetting with applied stresses.

Another characteristic of the drying and wetting SWCC is the observance of hysteresis. In this study, the hysteretic behavior of drying-wetting SWCC was quantitatively expressed using the average degree of hysteresis (ADHθ) defined as follows [13]:

where; is the volumetric water content on the drying curve; is the volumetric water content on the wetting curve for the same value of matric suction; and n is the number of data points at which SWCC hysteresis is evaluated. Values of ADHθ for drying and wetting SWCC under different applied vertical stress are summarized in Table 2. The results show a dual-trend for the variation of ADHθ with applied vertical stress. ADHθ decreased by about 40% with an increase in applied stress from 7 to 100 kPa. On the other hand, an increase in applied stress from 100 kPa to 300 kPa resulted in a 52% increase in ADHθ.

Table 2.

Hysteresis criterion in drying-wetting SWCC under different stress states.

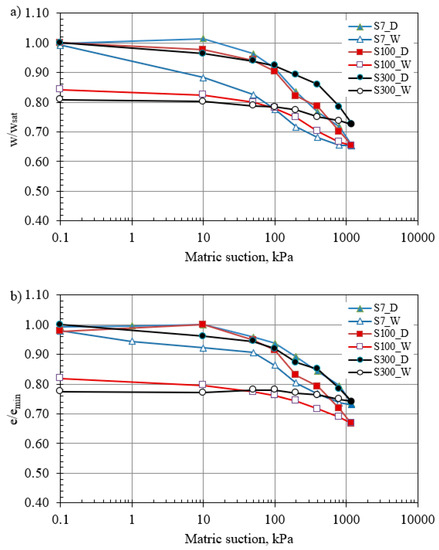

To interpret the observed dual-trend of hysteresis behavior, sources of SWCC hysteresis are identified and quantified. Based on technical literature, sources of SWCC hysteresis can be categorized into two main types: (i) those related to the amount of water expelled from or taken into the specimen (due to entrapped air and inkbottle effect) and (ii) those related to irrecoverable volume changes during drying and wetting (due to swelling and shrinkage). To visualize these sources, test results are represented as plots for normalized gravimetric water content (w/wsat) versus suction and normalized void ratio (e/emax) versus suction as shown in Figure 7a,b. The terms w and e represent the gravimetric water content and the void ratio at any value of suction along the drying or wetting path of SWCC, while wsat and emax is the saturated gravimetric water content and maximum void ratio for specimen at the start of drying curve, respectively. Broadly speaking, Figure 7a shows a hysteresis in gravimetric water content due to drying and wetting. In other words, the amount of water intake during wetting is less than the amount of water expelled during drying at different suction levels. Similarly, hysteresis behavior was observed from the normalized void ratio-suction plot (Figure 7b) indicating irrecoverable volume changes during drying and wetting. Considering the effect of applied vertical stress, Figure 7a,b show that applied vertical stress resulted in different magnitudes of hysteresis for normalized gravimetric water content and void ratio (volume). From Figure 7b, it is observed that, at the end of the drying, S7 experienced less volumetric shrinkage than S100. As wetting progresses back to zero suction, S7 recovered the majority of its volume (void ratio) under low stress while S100 showed irrecoverable volume change due to the partial restraint to swelling under the applied vertical stress. This restraint induced notable volume change hysteresis. For S300, the test specimen underwent less volumetric shrinkage strains during drying than S100 (Figure 7b) and when wetting back to zero suction, applied stress restrained specimen swelling, which in turn induced slightly lower hysteresis in volume change for S300 as compared to S100.

Figure 7.

Normalized SWCC hysteresis under considered stresses in terms of (a) gravimetric water content and (b) void ratio.

To quantify the aforementioned sources of SWCC hysteresis for the expansive clay considered in this study, two additional measures were identified. First, is the average degree of hysteresis in terms of gravimetric water content (ADHw), which is a measure of the difference between the drying and wetting curves plotted as gravimetric water content. Second, is the average degree of hysteresis in terms of void ratio (ADHe), which is a measure of the magnitude of irrecoverable volume change that takes place as a result of drying and wetting. The mathematical formulae for these terms are as follows:

where:

- id = gravimetric water content in the drying path

- = gravimetric water content in the wetting path

- eid = void ratio in the drying path

- eiw = void ratio in the wetting path

- n = number of points at which hysteresis is computed

For the sake of mathematical compatibility between ADHw and ADHe, ADHe* was proposed and defined as follows:

- Gs = specific gravity of soil

- γw = unit weight of water

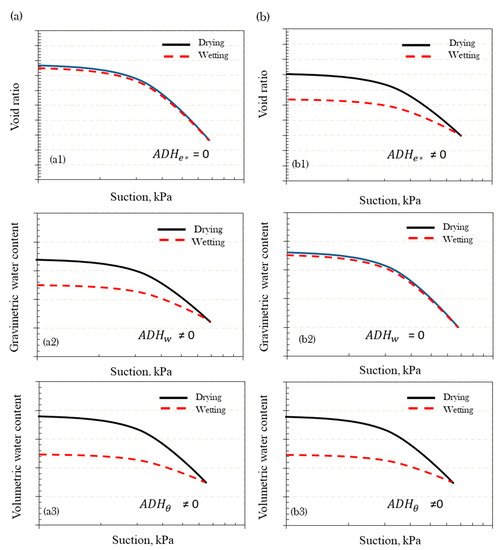

To demonstrate the benefits of adopting ADHw and ADHe* in interpreting the sources of SWCC hysteresis and its connection to ADHθ, two hypothetical cases are illustrated in Figure 8a,b. The first hypothetical case considers that a specimen undergoes elastic deformation due to drying and wetting as shown in Figure 8(a1), while gravimetric water content hysteresis exists (Figure 8(a2)). For this case, ADHe* will be computed to be zero, while ADHw has a value. This indicates that SWCC hysteresis (quantified by ADHθ) as shown in Figure 8(a3) is only attributed to the gravimetric water content hysteresis. In addition, any increase in ADHw value (i.e., an increase in gravimetric water content hysteresis) will result in a higher value in ADHθ. The second hypothetical case (Figure 8b) assumes volume change hysteresis (ADHe* ≠ 0) as shown in Figure 8(b1) with no gravimetric water content hysteresis (ADHw = 0) as shown in Figure 8(b2). For this case, SWCC hysteresis in ADHθ (Figure 8(b3)) is mainly attributed to volume change hysteresis, and any increase in ADHe* is accompanied by a reduction in ADHθ. This inversely proportional relationship between ADHe* and ADHθ is due to the mathematical nature of the ADHθ. From Equation (1), volumetric water content is defined as volume of water (Vw)/total volume of soil (VT); hence, for constant water content, any increase in total volume will result in a reduction in volumetric water content and consequently reduction in ADHθ.

Figure 8.

Sketch of hysteresis taken place during DW SWCC (a) assumption 1 and (b) assumption 2.

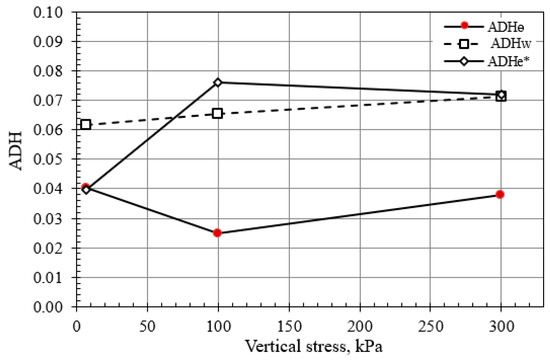

Now referring to the case in this study, Figure 9 shows the variation of ADHθ, ADHw and ADHe* with applied vertical stress. The expansive clay considered was observed to experience significant hysteresis in volume changes in addition to gravimetric water content (Figure 7b). For S7, the specimen shows a higher ADHw value than ADHe* indicating that gravimetric water content hysteresis is the dominant component in the SWCC hysteresis (ADHθ) at this level of stress. Under applied vertical stress of 100 kPa, a significant increase in volume change hysteresis ADHe* (about 92%) and a slight increase in ADHw (5%) were observed in comparison to S7. This shift in ADH values indicates a shift in the role of volume change hysteresis and gravimetric water content hysteresis on SWCC hysteresis. In other words, the increase in ADHw with an increase in stress from 7 to 100 kPa is relatively small and could induce a marginal increase in ADHθ; however, the significant increase in ADHe* resulted in a significant reduction in ADHθ (Figure 9). Therefore, ADHe* seems to control the SWCC hysteresis (ADHθ) at this stress level. For the S300 specimen, ADHw and ADHe* are comparable. The increase in stress from 100 to 300 kPa induced a slight increase in ADHw (i.e., 8%) and a notable decrease (i.e., 5.5%) in ADHe* resulted in an observable increase in ADHθ as shown in Figure 9.

Figure 9.

Summary of normalized ADH under considered stresses.

3.2. Effect of Multiple Drying-Wetting Cycles on Hysteresis of SWCC under Low-Stress State

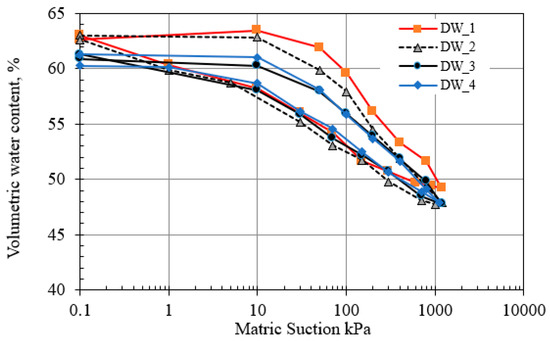

This section provides detailed analyses of experimental results derived from test series H2. Specifically, this section discusses the effect of multiple DW cycles on the hysteresis of SWCC evaluated under low vertical stress of 7 kPa (i.e., M7). As shown in Figure 10, DW applications were terminated after four cycles as no appreciable difference in SWCC hysteresis was observed beyond the third DW cycle (Section 2).

Figure 10.

Effect of multi-drying-wetting cycles in the hysteresis of SWCC under low stress, 7 kPa.

Visual examination of Figure 10 indicates that DW cycles have a considerable effect on the drying curves of SWCCs. Variation of air entry value during drying (AEVd) with DW cycles presented in Table 3 indicate that AEVd decreased with an increase in DW cycles with negligible difference in AEVd values observed beyond the third cycle. For the wetting branches of SWCC, it is observed that wetting curves fall along a single path; hence, indicating that DW cycles have a marginal effect on the wetting branches of SWCC. Consequently, air expulsion values (AEVw) for wetting branches of the SWCC showed no significant change in value due to DW cycles (Table 3). In conclusion, the effect of multiple DW cycles is more pronounced on the drying SWCC curves than wetting curves. After the second DW cycle, drying curves tend to coincide with each other indicating a diminishing effect of DW cycles on hysteresis. Similar behavior was reported by Goh et al. [32].

Table 3.

Hysteresis criterion in SWCC during multiple drying-wetting under low stress, 7 kPa.

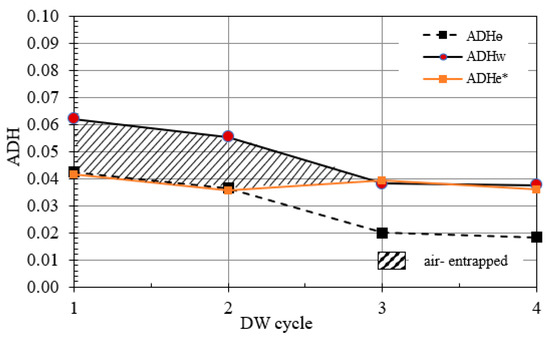

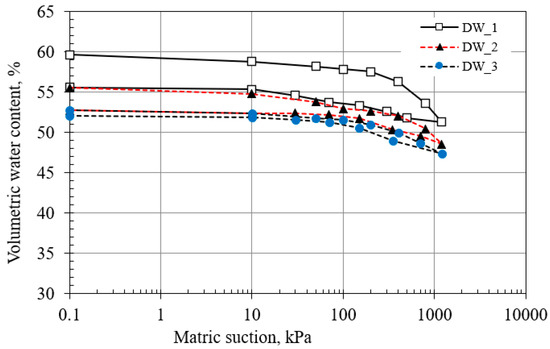

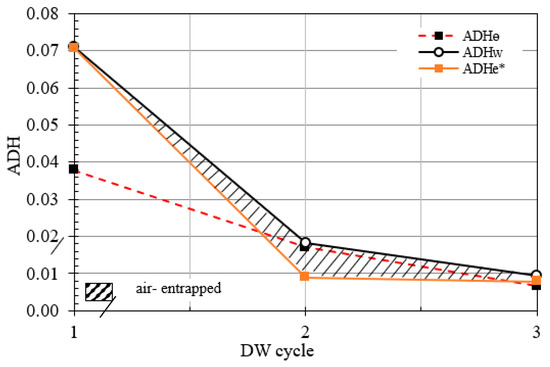

The effect of multiple DW cycles on the hysteresis of SWCCs presented in Figure 10 was quantified using the parameter ADHθ (Equation (1)). Values of ADHθ as DW cycles progress are presented in Table 3. These values imply a notable reduction in ADHθ with an increase in DW cycles up to the third cycle, after which, only a slight reduction in ADHθ was observed. In other words, the SWCC hysteresis behavior under an applied vertical stress of 7 kPa tends to reach an equilibrium state after three DW cycles. To identify the main sources of observed hysteresis, plots for the variation of gravimetric water content and volume with suction during multiple DW cycles are shown in Figure 11a,b. These figures reveal that both hystereses in gravimetric water content and specimen volume contribute to the overall SWCC hysteresis. Using ADHw and ADHe* parameters (Equations (2) and (4)), the relative contribution of gravimetric water content and volume change hysteresis on SWCC hysteresis can be further visualized. The variation of ADHw and ADHe* as a function of DW cycles is illustrated in Figure 12. The trendlines for ADHw and ADHe* signify a reduction in gravimetric water hysteresis with an increase in DW cycles up to the third DW cycle, while volume change hysteresis undergoes insignificant change. Beyond the third DW cycle, negligible changes in ADHw and ADHe* were observed. These trends denote that ADHw (i.e., gravimetric water content hysteresis) is the dominant contributor to SWCC hysteresis. Consequently, due to the directly proportional relationship, ADHθ follows a similar trendline as ADHw. Moreover, it is worth noting that the difference between ADHw and ADHe* trendlines (hatched area in Figure 12) represent the accumulation of entrapped air inside specimen pores. This accumulation in entrapped air was observed to fade away by the third cycle indicating that DW cycles have led to air bubbles being expelled from specimen pores and ADHw comes to be close to ADHe*.

Figure 11.

Hysteresis in SWCC during multi-drying-wetting cycles under low stress, 7 kPa in terms of (a) volumetric strains and (b) gravimetric water content.

Figure 12.

Variation ADH during drying-wetting cycles under low stress 7 kPa.

3.3. Effect of Multi-Drying-Wetting Cycles on the Hysteresis of Stress-Dependent SWCC (High-Stress State, 300 kPa)

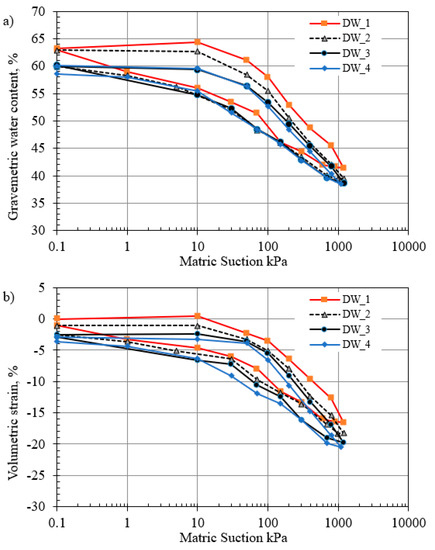

This section provides a detailed analysis of the effect of multiple drying-wetting cycles on drying and wetting paths and the hysteresis of SWCC under high stress of 300 kPa (i.e., M300). The plot of volumetric water content versus matric suction for all DW cycles was presented in Figure 13.

Figure 13.

Effect of multi-drying-wetting cycles in the hysteresis of SWCC under high stress, 300 kPa.

In comparison with the M7 (Figure 10), it is evident that applying a high vertical stress of 300 kPa resulted in a significant shift in the cyclic SWCC hysteresis trends. In particular, Figure 10 shows that M7 hysteresis loops are concentric with the first cycle enveloping the subsequent cycles. Under high applied stress of 300 kPa (Figure 13), the M300 hysteresis loops show a downward shift in its position with an increase in DW cycles indicating the change in the range of volumetric water content. As DW cycles continue, M300 SWCC hysteresis was observed to diminish after three DW cycles.

Looking at the individual drying and wetting branches of SWCCs, the shape of drying branches converges towards a single form with an increase in DW cycle. Similar observations were noted for wetting branches. The values of air entry value AEVd and air expulsion value AEVw along with DW cycles were presented in Table 4. AEVd show a slight increase with an increase in DW cycles, while AEVw was approximately constant.

Table 4.

Hysteresis criterion in SWCC during multiple drying-wetting under high stress, 300 kPa.

With respect to M300 SWCC hysteresis, computed ADHθ values (Table 4) were observed to decrease with an increase in DW cycles reaching a minimum value of 0.067. This decreasing ADHθ trend implies a reduction in SWCC hysteresis with DW cycles. Furthermore, the minimum value of 0.067 implies that the SWCC hysteresis behavior almost diminishes by the end of the third DW cycle. This is diminishing trend is consistent with that noted earlier in Figure 13. Comparing ADHθ values for M300 with that for M7, it is evident that high stress accelerates the diminishing of the SWCC hysteresis with multiple DW cycles.

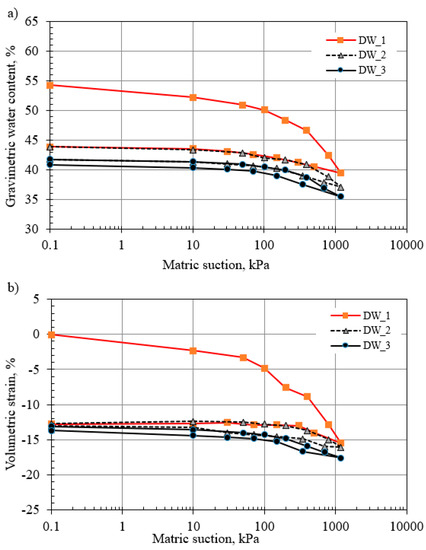

This behavior could be interpreted by looking into the sources of hysteresis in SWCC (water content and volume changes) as discussed earlier (Section 3.2 and Section 3.3). For this purpose, the SWCC in Figure 13 were re-plotted in terms of gravimetric water content and volumetric strains as shown in Figure 14a,b. Figure 14a,b showed significant hysteresis in terms of gravimetric water content and volume changes with DW cycles. Measures of gravimetric water content and volumetric hysteresis (i.e., ADHw and ADHe*) were plotted in comparison with ADHθ in Figure 15. From Figure 15, it is clear that, after the first DW cycle, the hysteresis in terms of ADHw and ADHe* values are numerically equal. This implies that the amount of change in specimen volume is equivalent to the amount of change in gravimetric water content. In other words, the specimen is considered to be fully saturated after the first cycle with virtually no entrapped air in the specimen. Comparing ADHw with ADHe* for M300 after the first DW cycle, it can be construed that the applied vertical stress plays a significant role in reducing the entrapped air. After the second DW cycle, ADHθ trendline showed an appreciable reduction in value. Referring to hypothetical cases presented in Figure 8, this reduction in ADHθ can be attributed to either a decrease in ADHw or an increase in ADHe*. Because both ADHw and ADHe* decrease at the end of the second DW cycle, it is inferred that ADHw had a more dominant effect on overall SWCC hysteresis (ADHθ). Furthermore, it is observed that ADHw is slightly higher than ADHe* indicating that air is entrapped in the specimen at the end of the second DW cycle (hatched area in Figure 15). As DW cycle proceeds, Figure 15 indicates that, after the third DW cycle, volume change hysteresis reached equilibrium denoted by a constant ADHe* value between the second and third DW cycle. Simultaneously, ADHw slightly decreased by the application of the third DW cycle causing a further decrease in ADHθ. For the aforementioned discussion, it can be deduced that gravimetric water content hysteresis (ADHw) plays a more significant role in SWCC hysteresis under high applied stress.

Figure 14.

Hysteresis in SWCC during multi-DW cycles under high stress, 300 kPa in term of (a) gravimetric water content and (b) volumetric strains.

Figure 15.

Variation ADH during drying-wetting cycles under high stress 300 kPa.

4. Summary and Conclusions

This study was conducted to investigate the hysteretic behavior of SWCCs for highly expansive clay during DW cycles under different stress states. The study was carried out on compacted-saturated specimens through two test series; in the first series (H1), the hysteresis of SWCCs during a single DW cycle was studied under three stress states (i.e., 7, 100, and 300 kPa). The second test series (H2) highlighted the effect of multi DW cycles on the hysteresis of SWCC under a low-stress state (i.e., 7 kPa) and a high-stress state (i.e., 300 kPa), and test specimens for this series were exposed to four and three DW cycles, respectively. In light of the experimental achievements of this study, the following conclusions can be drawn:

- Stress states had significant effects on SWCC hysteresis of expansive clay subjected to a single DW cycle. Air entry value AEVd and air expulsion value AEVw showed a significant increase of ten and fifteen times, respectively, with the increase in applied stress up to 300 kPa.

- The hysteresis phenomena were interpreted in light of observed gravimetric water content and volume change hysteresis that the specimen underwent during DW. Two measures were defined, namely, average degree of hysteresis in terms of gravimetric water content (ADHw) and in terms of void ratio (ADHe*). These have proven to clearly quantify the relative contribution of each hysteresis component to the overall SWCC hysteresis.

- Multiple DW cycles had a pronounced effect on the SWCCs hysteresis. Combined with vertical stress, different trends for hysteresis loops were observed. Specifically, hysteresis loops for M7 specimens were concentric in shape, while hysteresis loops for M300 were non-concentric with a downward shift in hysteresis loops with the increase in DW cycles.

- The values of air entry value AEVd were slightly increased with the increase in DW cycles, while air expulsion value AEVw was approximately constant and appeared to be independent of the number of DW cycles.

- In terms of ADHθ, the hysteresis was observed to decrease with an increase in DW cycles with the effect of DW diminishing after the third DW cycle.

Author Contributions

Conceptualization, A.M.A.-M.; methodology, A.M.A.-M.; software, A.M.A.-M.; validation, A.M.A.-M.; formal analysis, A.M.A.-M. and T.E.; investigation, A.M.A.-M.; resources, A.M.A.-M. and M.A.-S.; data curation, A.M.A.-M.; writing—original draft preparation, A.M.A.-M. and T.E.; writing—review and editing, A.M.A.-M. and T.E.; visualization, A.M.A.-M.; supervision, T.E. and M.A.-S.; project administration, A.M.A.-M.; funding acquisition, M.A.-S. All authors have read and agreed to the published version of the manuscript.

Funding

The authors are grateful to the Deanship of Scientific Research, King Saud University, for funding this research through the Vice Deanship of Scientific Research Chairs, Research Chair of Bugshan Research Chair in Expansive Soils.

Data Availability Statement

All data related to this study is presented in a tabular or graphic format within this document. Further clarifications are welcomed by the corresponding author.

Acknowledgments

The authors extend their appreciation to the Deanship of Scientific Research, King Saud University, for funding this research through the Vice Deanship of Scientific Research Chairs, Research Chair of Bugshan Research Chair in Expansive Soils.

Conflicts of Interest

The authors declare that they have no conflict of interest.

References

- Fattah, M.Y.; Salman, F.A.; Nareeman, B.J. A treatment of expansive soil using different additives. Acta Montan. Slovaca 2010, 15, 290–297. [Google Scholar]

- Zhang, M.; Zhang, H.; Cui, S.; Jia, L.; Zhou, L.; Chen, H. Engineering properties of GMZ bentonite-sand as buffer/backfilling material for high-level waste disposal. Eur. J. Environ. Civ. Eng. 2012, 16, 1216–1237. [Google Scholar] [CrossRef]

- Nowamooz, H.; Jahangir, E.; Masrouri, F.; Tisot, J.P. Effective stress in swelling soils during wetting drying cycles. Eng. Geol. 2016, 210, 33e44. [Google Scholar] [CrossRef]

- Vilarrasa, V.; Rutqvist, J.; Martin, L.; Birkholzer, J. Use of a dual-structure constitutive model for predicting the long-term behavior of an expansive clay buffer in a nuclear waste repository. Int. J. GeoMech. 2016, 16, 1e13. [Google Scholar] [CrossRef]

- Al-Mahbashi, A.M.; Dafalla, M.; Shaker, A.; Al-Shamrani, M.A. Sustainable and Stable Clay Sand Liners over Time. Sustainability 2021, 13, 7840. [Google Scholar] [CrossRef]

- Al-Mahbashi, A.M.; Dafalla, M. Impact of placement and field conditions on hydraulic conductivity and lifetime of liners. J. King Saud Univ. Sci. 2021, 33, 101410. [Google Scholar] [CrossRef]

- Fredlund, D.G.; Rahardjo, H. Soil Mechanics for Unsaturated Soils; John Wiley and Sons: New York, NY, USA, 1993. [Google Scholar]

- Erzin, Y.; Erol, O. Swell pressure prediction by suction methods. Eng. Geol. 2007, 92, 133–145. [Google Scholar] [CrossRef]

- Fredlund, D.G.; Rahardjo, H.; Fredlund, M.D. Unsaturated Soil Mechanics in Engineering Practice; John Wiley and Sons Inc.: New York, NY, USA, 2012. [Google Scholar]

- Malaya, C. Critical review on the parameters influencing soil-water characteristic curve. J. Irrig. Drain. Eng. ASCE 2012, 138, 55–62. [Google Scholar] [CrossRef]

- Bashir, R.; Sharma, J.; Stefaniak, H. Effect of hysteresis of soil-water characteristic curves on infiltration under different climatic conditions. Can. Geotech. J. 2015, 53, 273–284. [Google Scholar] [CrossRef]

- Li, J.; Liu, F.Y. A research of affect factor on hysteresis behavior for Soil-Water Characteristic Curve. Unsaturated Soil Mechanics-from Theory to Practice. In Proceedings of the 6th Asia Pacific Conference on Unsaturated Soils, Guilin, China, 23–26 October 2015; p. 361. [Google Scholar]

- Al-Mahbashi, A.M.; Elkady, T.Y.; Al-Shamrani, M.A. Hysteresis soil-water characteristic curves of highly expansive clay. Eur. J. Environ. Civ. Eng. 2018, 22, 1041–1059. [Google Scholar] [CrossRef]

- Zhang, J.; Niu, G.; Li, X.; Sun, D. Hydro-mechanical behavior of expansive soils with different dry densities over a wide suction range. Acta Geotech. 2020, 15, 265–278. [Google Scholar] [CrossRef]

- Hillel, D.; Mottes, J. Effect of plate impedance, wetting method and aging on soil moisture retention. Soil Sci. 1966, 102, 135–140. [Google Scholar] [CrossRef]

- Bear, J. Hydraulics of Groundwater; McGraw-Hill: New York, NY, USA, 1979; p. 567. [Google Scholar]

- Lin, B.; Cerato, A.B. Hysteretic soil water characteristics and cyclic swell–shrink paths of compacted expansive soils. Bull. Eng. Geol. Environ. 2013, 72, 61–70. [Google Scholar] [CrossRef]

- Zhang, R.; Zheng, J.L.; Ng, C.W.W. Experimental study on stress-dependent soil water characteristic curve of a recompacted expansive soil. In Applied Mechanics and Materials; Trans Tech Publications: Stafa-Zurich, Switzerland, 2013; Volume 256, pp. 283–286. [Google Scholar]

- Ng, C.; Leung, A. Measurements of Drying and Wetting Permeability Functions Using a New Stress-Controllable Soil Column. J. Geotech. Geoenvironmental Eng. 2012, 138, 58–68. [Google Scholar] [CrossRef]

- Benchouk, A.; Derfouf, M.; Abou-Bekr, N.; Taibi, S. Behavior of some clays on drying and wetting paths. Arab. J. Geosci. 2013, 6, 4565–4573. [Google Scholar] [CrossRef]

- Salager, S.; Nuth, M.; Ferrari, A.; Laloui, L. Investigation into water retention behaviour of deformable soils. Can. Geotech. J. 2013, 50, 200–208. [Google Scholar] [CrossRef]

- Oh, S.; Lu, N. Uniqueness of the suction stress characteristic curve under different confining stress conditions. Vadose Zone J. 2014, 13, 1–10. [Google Scholar] [CrossRef]

- Ghavam-Nasiri, A.; El-Zein, A.; Airey, D.; Rowe, R.K. Water retention of geosynthetics clay liners: Dependence on void ratio and temperature. Geotext. Geomembr. 2019, 47, 255–268. [Google Scholar] [CrossRef]

- Ebrahimi-Birang, E.; Fredlund, D.G.; Samarasekera, L. Hysteresis of the soil water characteristic curve in the high suction range. Proc. Ott. Geo. Conf. 2007, 1061–1068. [Google Scholar]

- Lima, A.; Romero, E.; Piña, Y.; Gens, A.; Li, X. Water retention properties of two deep belgian clay formations. In Unsaturated Soils: Research and Applications; Springer: Berlin/Heidelberg, Germany, 2012; pp. 179–184. [Google Scholar]

- Jayanth, S.; Iyer, K.; Singh, D.N. Influence of drying and wetting cycles on SWCCs of fine-grained soils. J. Test. Eval. 2012, 40, 376–386. [Google Scholar] [CrossRef]

- An, R.; Zhang, X.; Kong, L.; Liu, X.; Chen, C. Drying-wetting impacts on granite residual soil: A multi-scale study from macroscopic to microscopic investigations. Bull. Eng. Geol. Environ. 2022, 81, 447. [Google Scholar] [CrossRef]

- An, R.; Kong, L.; Zhang, X.; Li, C. Effects of dry-wet cycles on three-dimensional pore structure and permeability characteristics of granite residual soil using X-ray micro computed tomography. J. Rock Mech. Geotech. Eng. 2022, 14, 851–860. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, X.; Chen, C.; Xu, Y.; Liu, H. Evolution of disintegration properties of granite residual soil with microstructure alteration due to wetting and drying cycles. Bull. Eng. Geol. Environ. 2022, 81, 93. [Google Scholar] [CrossRef]

- Tse, M.K. Influence of Stress States on Soil-Water Characteristics, Conjunctive Surface-Subsurface Flow Modelling and Stability Analysis. PhD Thesis, Hong Kong University of Science and Technology, Hong Kong, China, 2007. [Google Scholar]

- Guan, G.S.; Rahardjo, H.; Choon, L.E. Shear strength equations for unsaturated soil under drying and wetting. J. Geotech. Geoenvironmental Eng. 2010, 136, 594–606. [Google Scholar] [CrossRef]

- Goh, S.G.; Rahardjo, H.; Leong, E.C. Shear strength of unsaturated soils under multiple drying-wetting cycles. J. Geotech. Geoenvironmental Eng. 2014, 140, 06013001. [Google Scholar] [CrossRef]

- Ng, C.W.; Pang, Y.W. Influence of stress state on soil-water characteristics and slope stability. J. Geotech. Geoenvironmental Eng. 2000, 126, 157–166. [Google Scholar] [CrossRef]

- Ng, C.W.; Wong, H.N.; Tse, Y.M.; Pappin, J.W.; Sun, H.W.; Millis, S.W.; Leung, A.K. A field study of stress-dependent soil–water characteristic curves and permeability of a saprolitic slope in Hong Kong. Geotechnique 2011, 61, 511–521. [Google Scholar] [CrossRef]

- Ng, C.W.W.; Peprah-Manu, D.; Zhou, C. Effects of pore structure on the hysteretic water retention behaviour of silty sand at different stresses. Acta Geotech. 2023. [Google Scholar] [CrossRef]

- Likos, W.J.; Lu, N.; Godt, J.W. Hysteresis and uncertainty in soil water-retention curve parameters. J. Geotech. Geoenvironmental Eng. 2014, 140, 04013050. [Google Scholar] [CrossRef]

- Raghuram, A.S.S.; Basha, B.M.; Moghal, A.A.B. Effect of Fines Content on the Hysteretic Behavior of Water-Retention Characteristic Curves of Reconstituted Soils. J. Mater. Civ. Eng. 2020, 32, 04020057. [Google Scholar] [CrossRef]

- Mijares, R.G.; Khire, M.V. Soil water characteristic curves of compacted clay subjected to multiple wetting and drying cycles. In Proceedings of the GeoFlorida 2010: Advances in analysis, modeling and design, West Palm Beach, FA, USA, 20–24 February 2010; pp. 400–409. [Google Scholar]

- ASTM D698; Standard Test Methods for Laboratory Compaction Characteristics of Soil Using Standard Effort (12400 ft-lbf = ft3 (600 kN-m/m3)). ASTM D698-12e2. ASTM: West Conshohocken, PA, USA, 2012.

- Al-Mahbashi, A.M. Soil Water Characteristic Curves of Treated and Untreated Highly Expansive Soil Subjected to Different Stresses. Master’s Thesis, Department of civil engineering, University of King Saud, Riyadh, Saudi Arabia, 2014. [Google Scholar]

- Al-Mahbashi, A.M.; Al-Shamrani, M.A.; Dafalla, M.; Basu, D. Effect of Temperature on Hysteretic Behavior of Water Retention Capacity for Clay–Sand Liners. Indian Geotech. J. 2021, 51, 924–934. [Google Scholar] [CrossRef]

- Rafi, A. Engineering Properties and Mineralogical Composition of Expansive Clays in Al-Qatif Area. Ph.D. Thesis, King Fahd University of Petroleum & Minerals, Dhahran, Saudi Arabia, 1988. [Google Scholar]

- ASTM D854; Standard Test Methods for Specific Gravity of Soil Solids by Water Pycnometer. ASTM International: West Conshohocken, PA, USA, 2014.

- ASTM D943; Standard Test Methods for Shrinkage Factors of Cohesive Soils by the Water Submersion method. ASTM International: West Conshohocken, PA, USA, 2018.

- ASTM D4318; Standard Test Methods for Liquid Limit, Plastic Limit, and Plasticity Index of Soils. ASTM: West Conshohocken, PA, USA, 2017.

- ASTM D2487; Standard Practice for Classification of Soils for Engineering Purpose (United Soil Classification System). ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM D4546; Standard Test Methods for One-Dimensional Swell or Collapse of Cohesive Soils. ASTM D4546-14e1. ASTM: West Conshohocken, PA, USA, 2014.

- ASTM D 2435; Standard Test Methods for One-Dimensional Consolidation Properties of Soils Using Incremental Loading, Vol. 4.08. D-18 Committee on Soils and Rocks. ASTM: West Conshohocken, PA, USA, 2003.

- ASTM D422; Standard Test Method for Particle-Size Analysis of Soils, Committee on Soils and Rocks. ASTM International: West Conshohocken, PA, USA, 2007.

- ASTM D6836; Standard Test Methods for Determination of the Soil Water Characteristic Curve for Desorption Using a Hanging Column, Pressure Extractor, Chilled Mirror Hygrometer, And/or Centrifuge. ASTM D6836. ASTM: West Conshohocken, PA, USA, 2016.

- Pham, Q.H.; Fredlund, D.G.; Padilla, J.M. Use of the GCTS apparatus for the measurement of soil-water characteristic curves. In Proceedings of the 57th Canadian Geotechnical Conference, Quebec City, QC, Canada, 24–27 October 2004; pp. 24–27. [Google Scholar]

- Al-Mahbashi, A.M.; Elkady, T.Y.; Alrefeai, T.O. Soil water characteristic curve and improvement in lime treated expansive soil. Geomech. Eng. 2015, 8, 687–706. [Google Scholar] [CrossRef]

- Elkady, T.Y.; Al-Mahbashi, A.M.; Al-Refeai, T.O. Stress-Dependent Soil-Water Characteristic Curves of Lime-Treated Expansive Clay. J. Mater. Civ. Eng. 2015, 27, 04014127. [Google Scholar] [CrossRef]

- Elkady, T.Y.; Al-Mahbashi, A.M. Effect of vertical stress on the soil water characteristic curve of highly expansive soils. In Unsaturated Soils: Research and Applications, Proceedings of the Second European Conference on Unsaturated Soils, E-UNSAT 2012, Napoli, Italy, 20–22 June 2012; pp. 165–172. Springer: Berlin/Heidelberg, Germany, 2012. [Google Scholar]

- Vanapalli, S.K.; Fredlund, D.G.; Pufahl, D.E.; Clifton, A.W. Model for the prediction of shear strength with respect to soil suction. Can. Geotech. J. 1996, 33, 379–392. [Google Scholar] [CrossRef]

- Rassam, D.W.; Williams, D.J. A relationship describing the shear strength of unsaturated soils. Can. Geotech. J. 1999, 36, 363–368. [Google Scholar] [CrossRef]

- Lee, I.M.; Sung, S.G.; Cho, G.C. Effect of stress state on the unsaturated shear strength of a weathered granite. Can. Geotech. J. 2005, 42, 624–631. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).