Cyclic Behavior of Different Connections in Precast Concrete Shear Walls: Experimental and Analytical Investigations

Abstract

1. Introduction

2. Experimental Program

2.1. Test Matrix

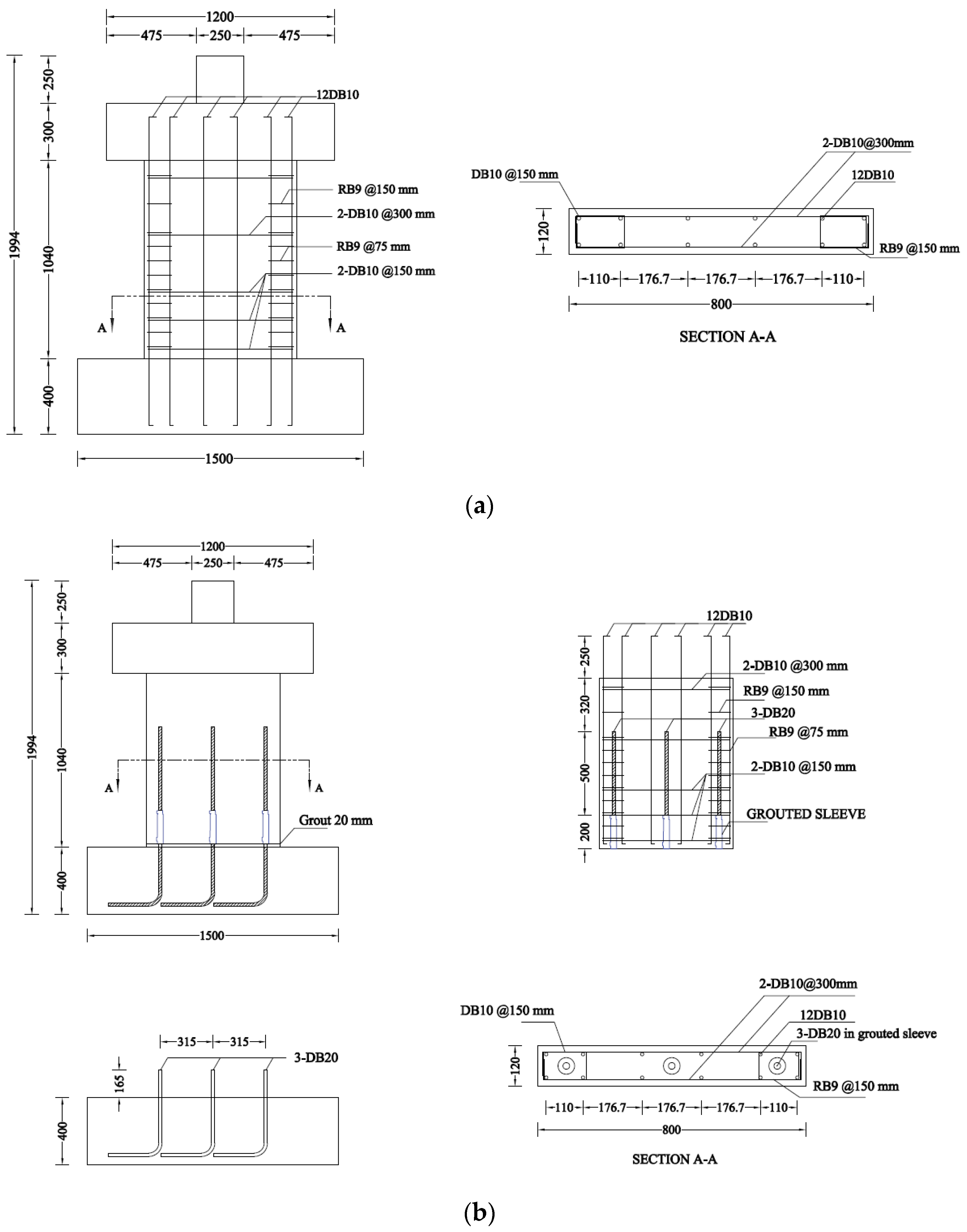

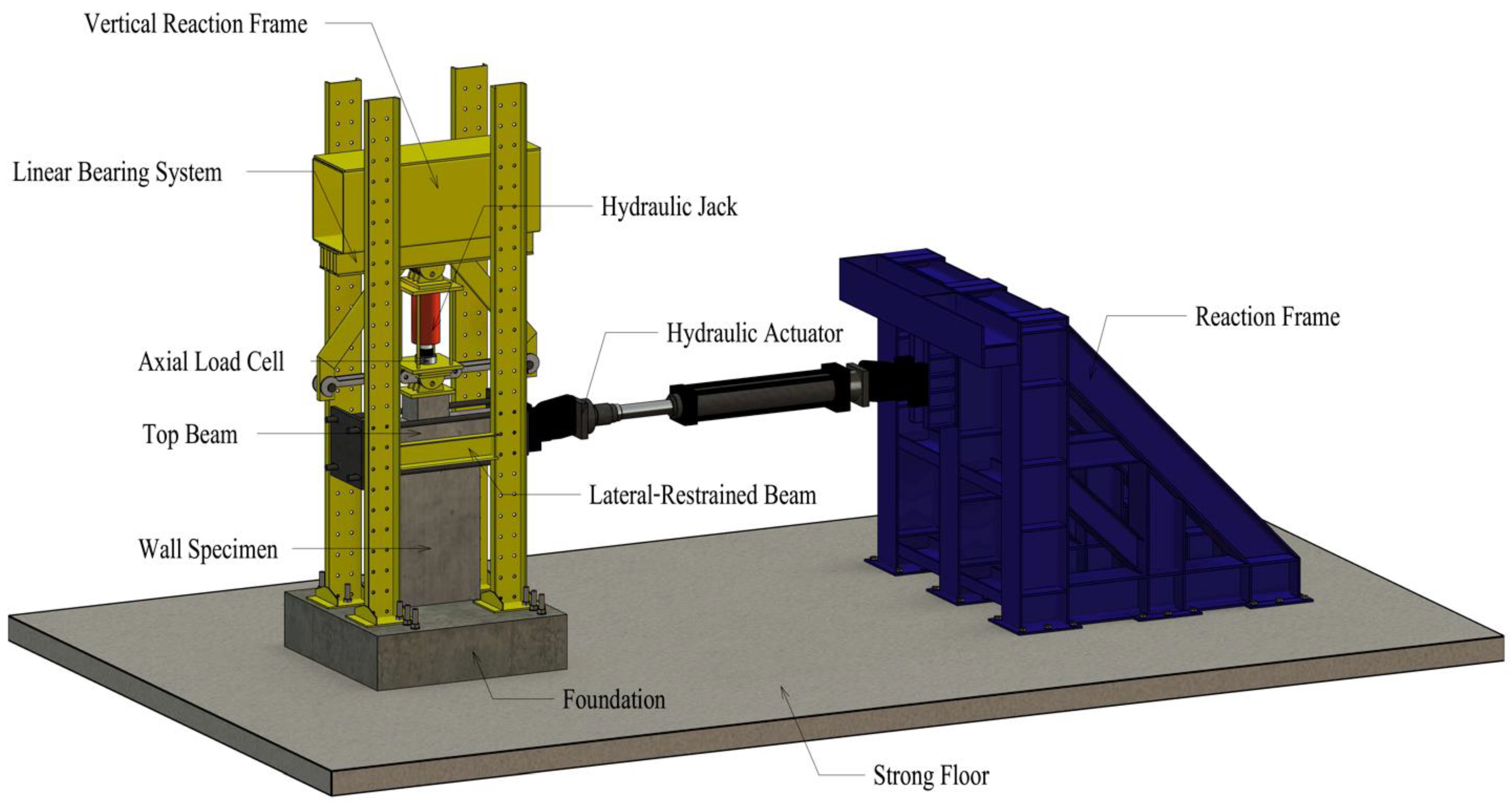

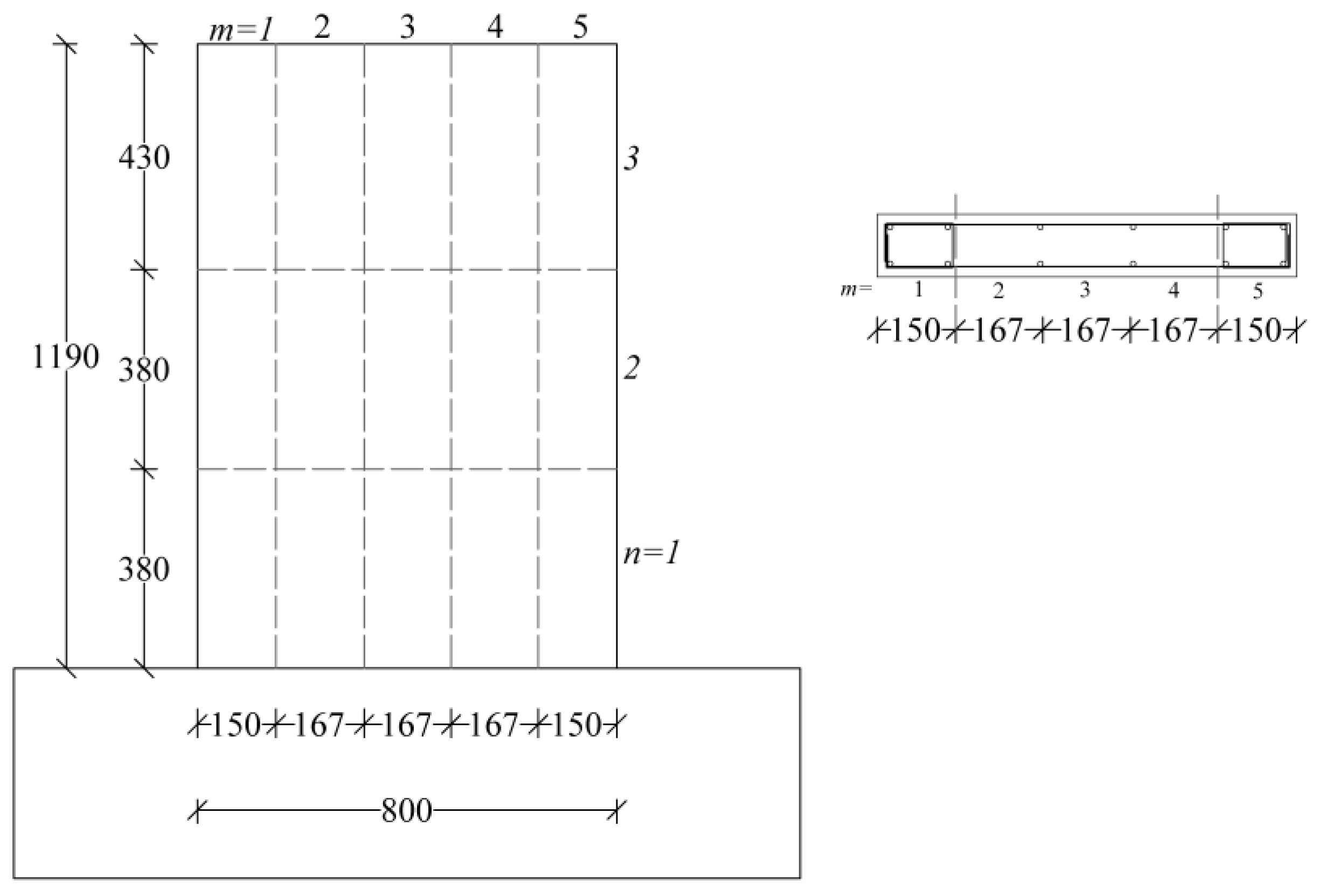

2.2. Specimen Details

2.3. Construction Procedure

2.4. Material Properties

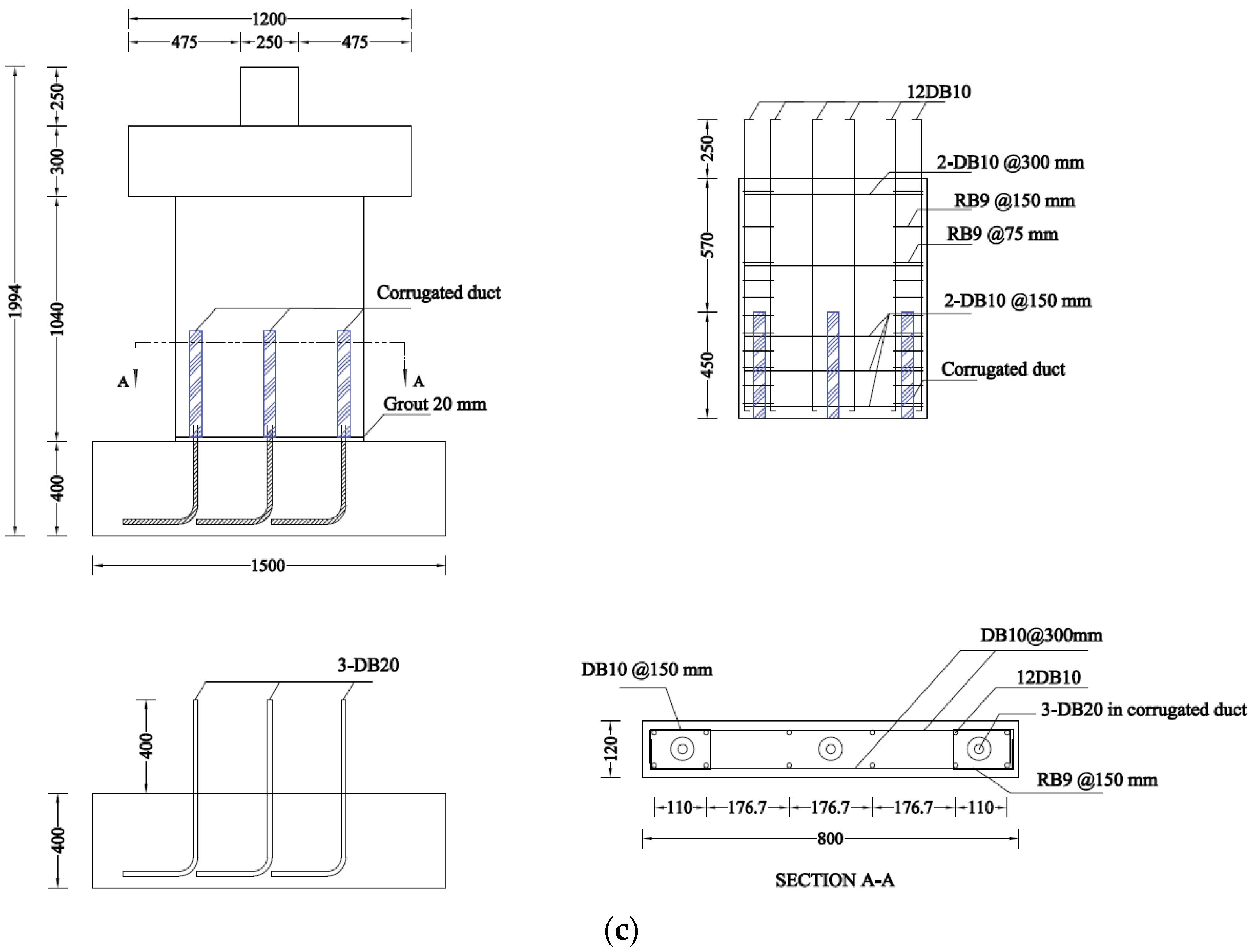

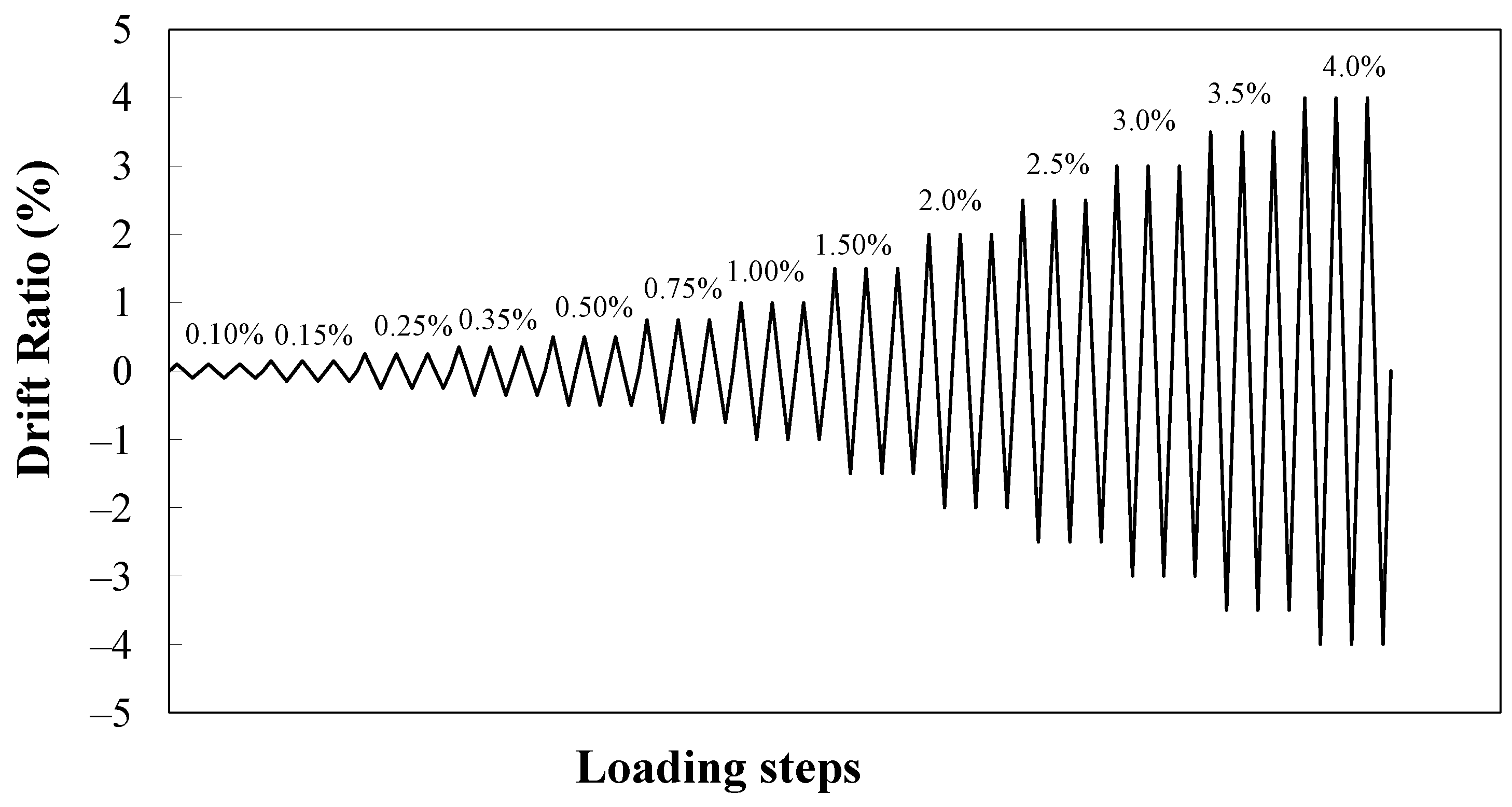

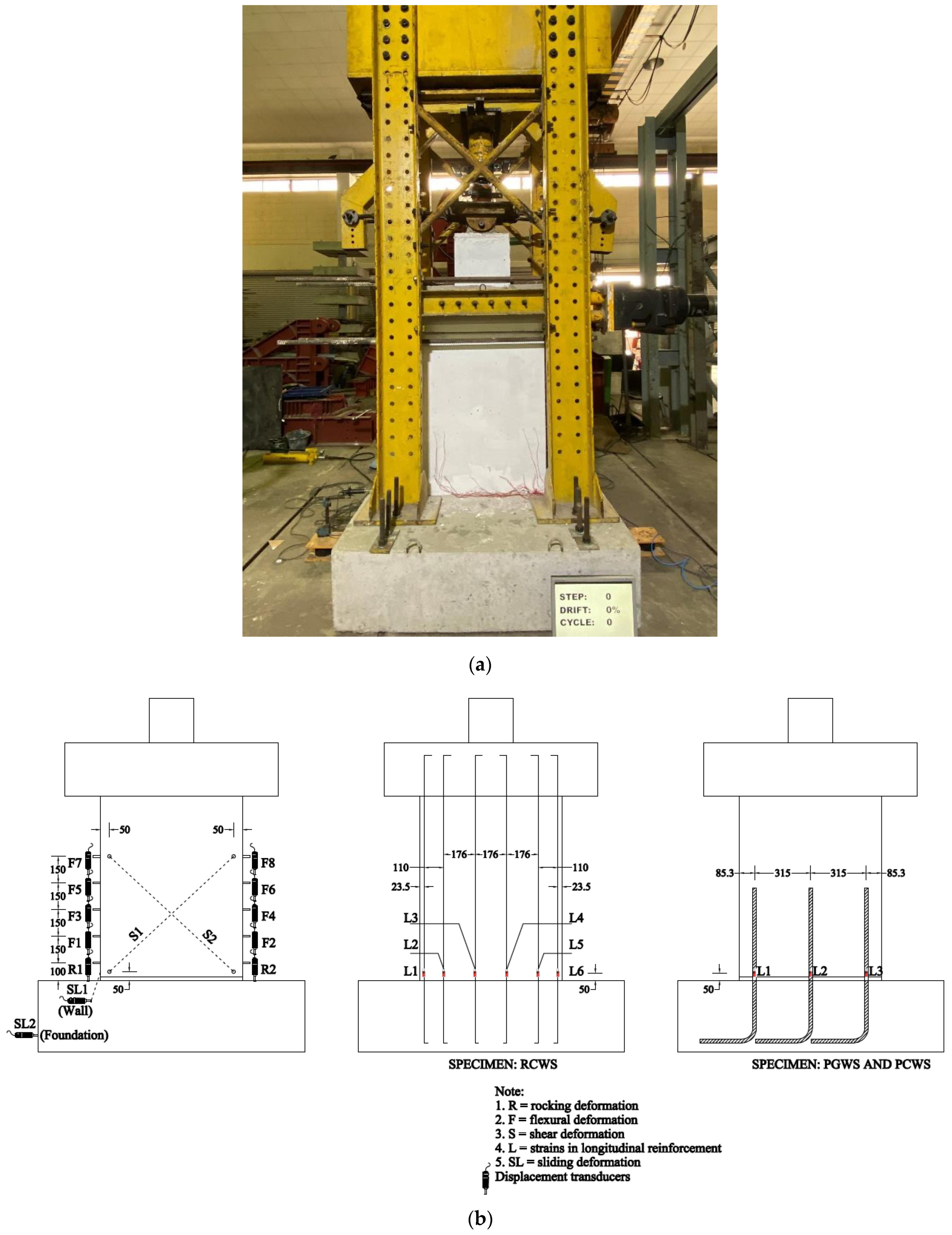

2.5. Test Setup

3. Experimental Results

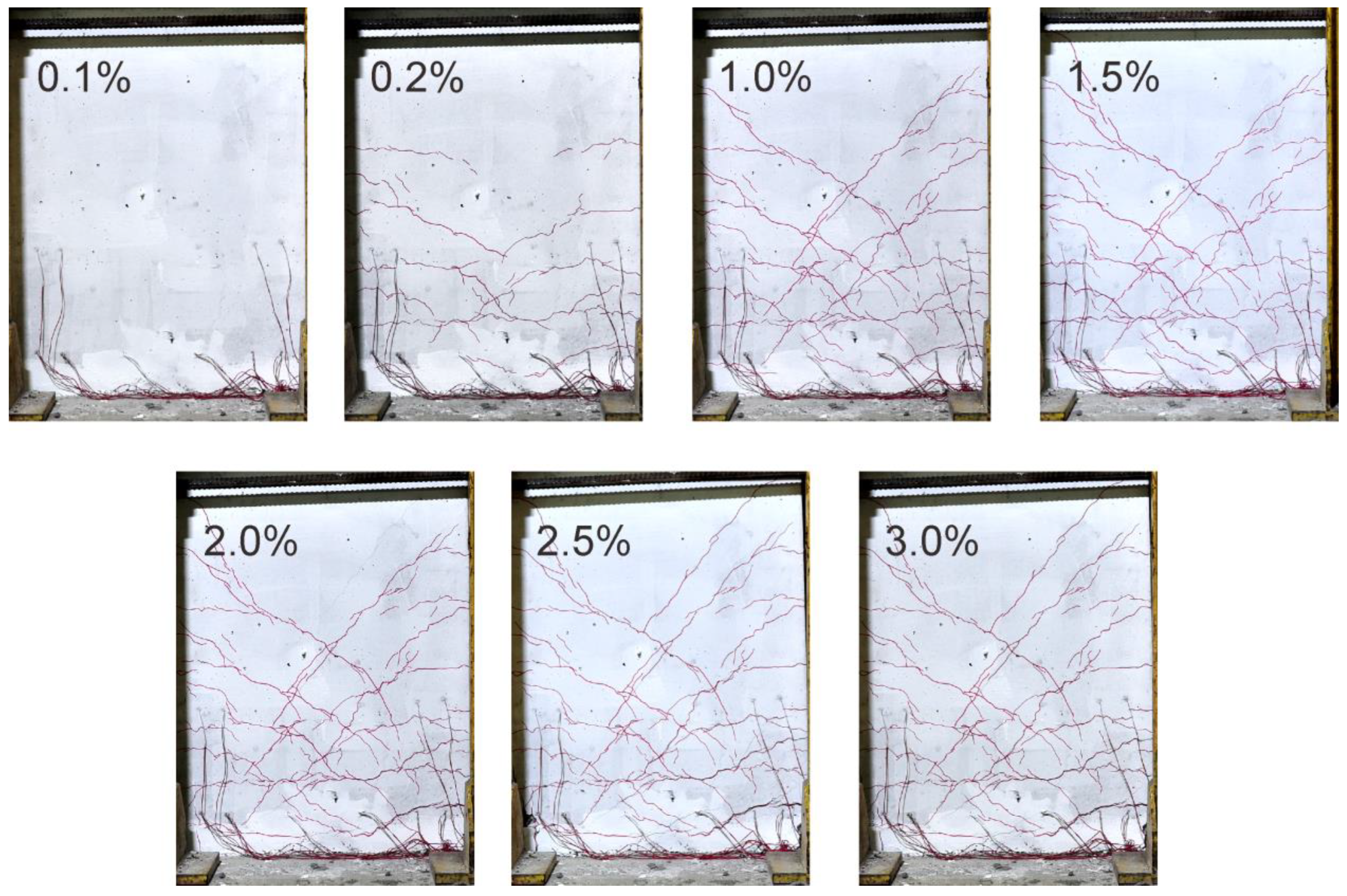

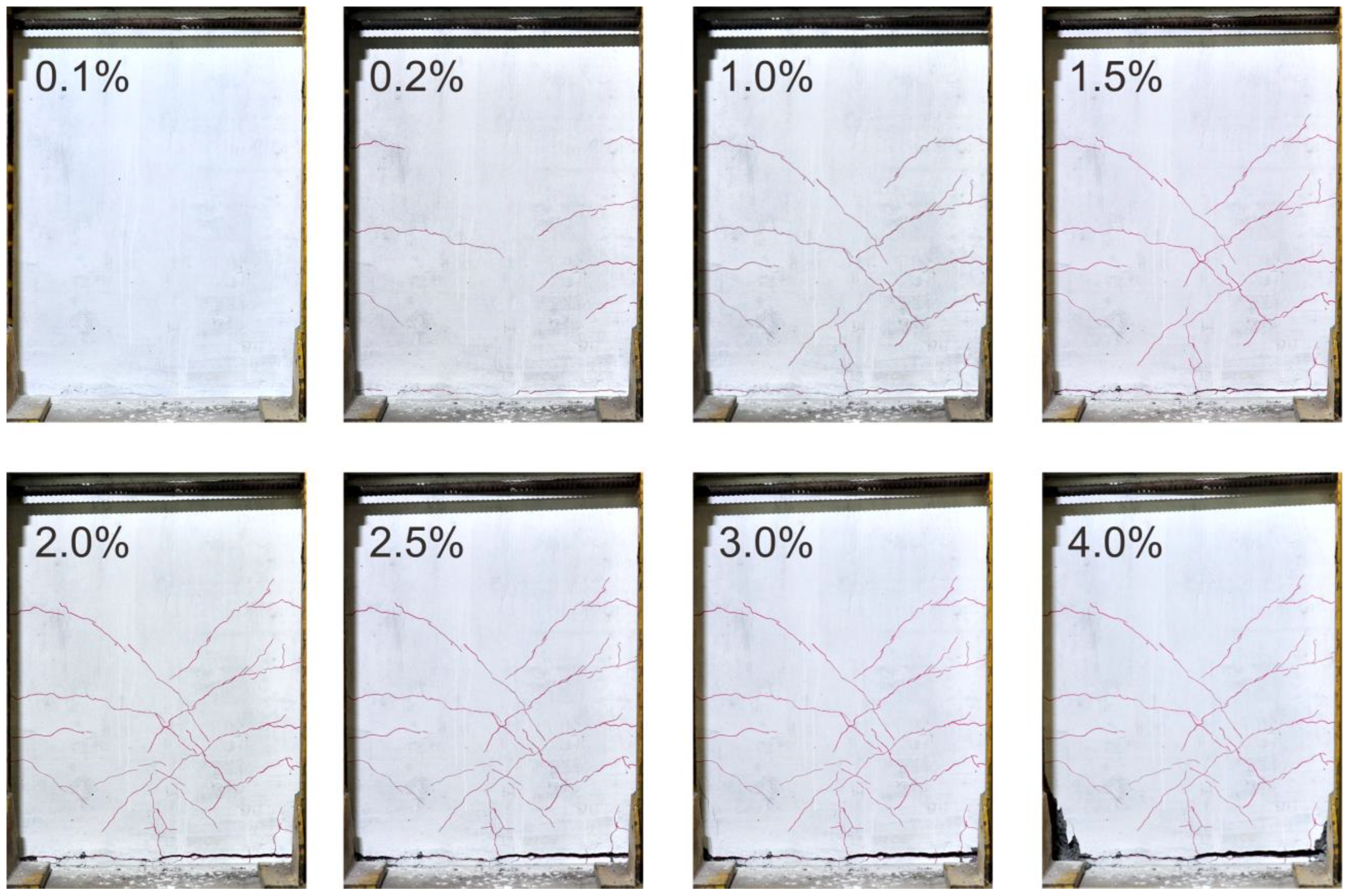

3.1. Crack Patterns and Failure Modes

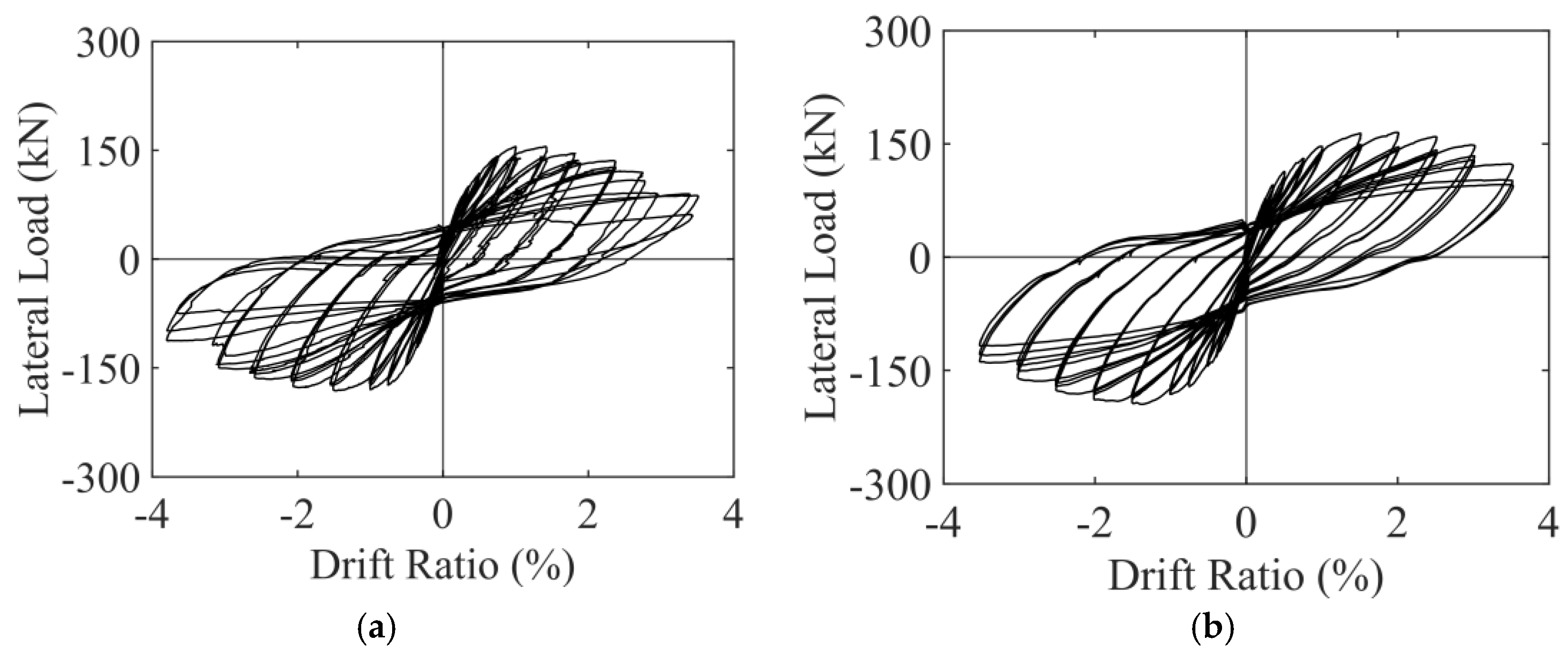

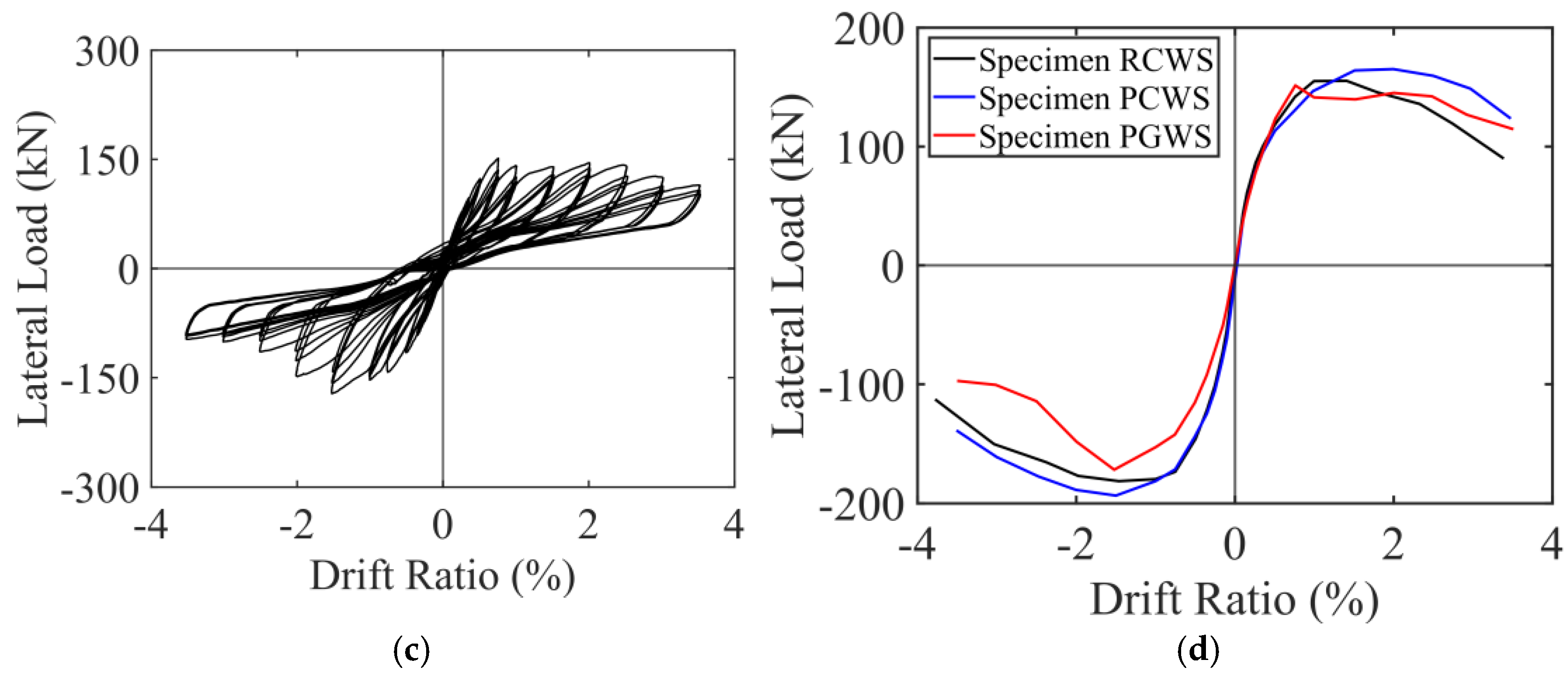

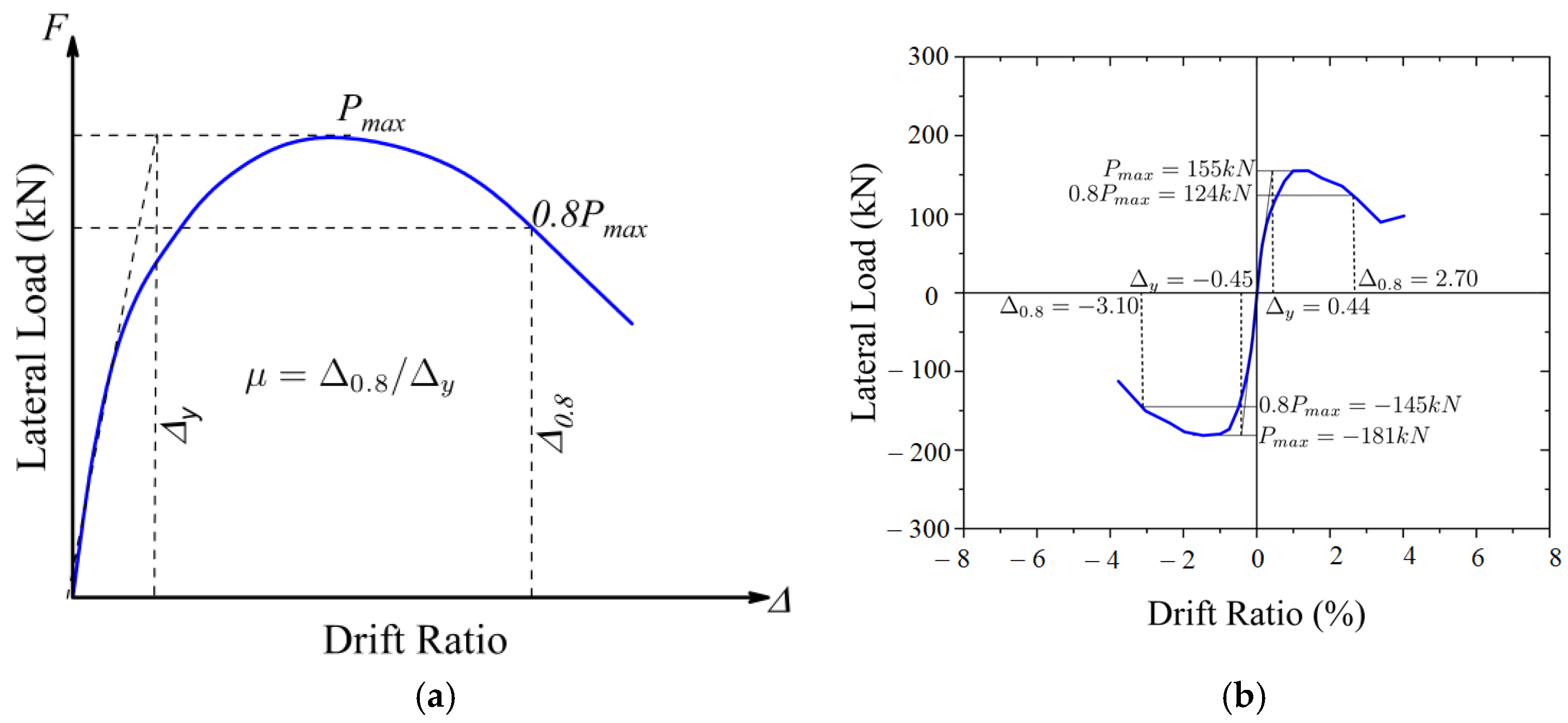

3.2. Hysteretic Response and Ductility of Shear Walls

3.3. Lateral Deformation Components

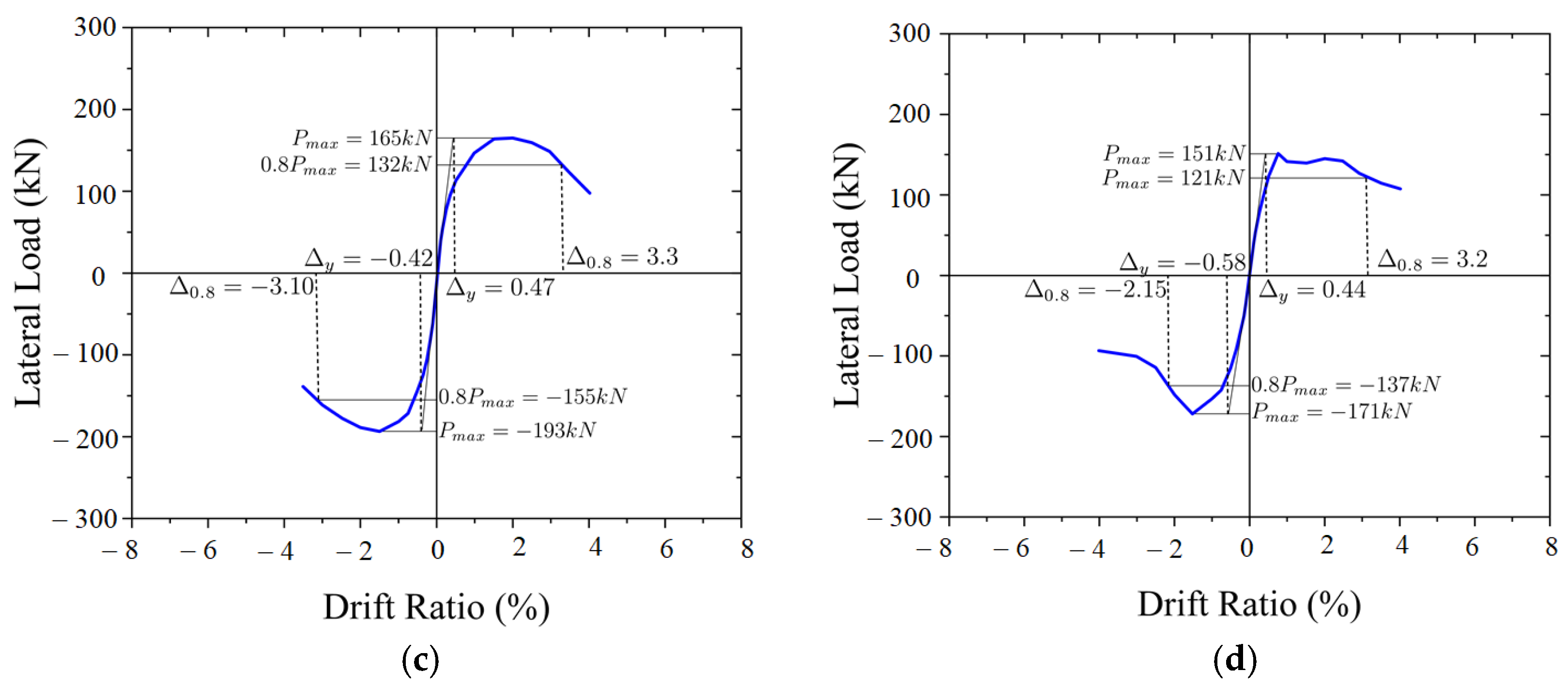

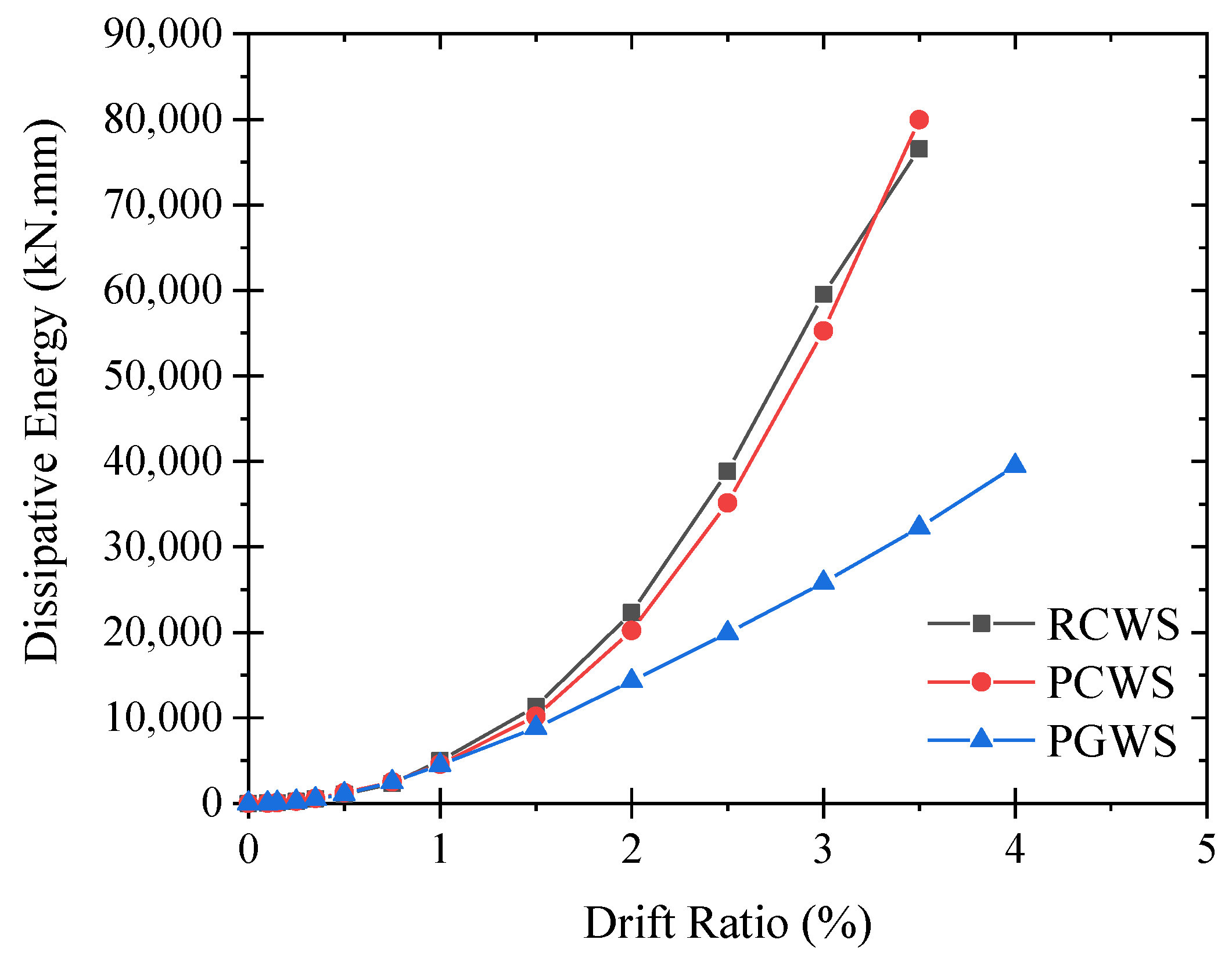

3.4. Energy Dissipation

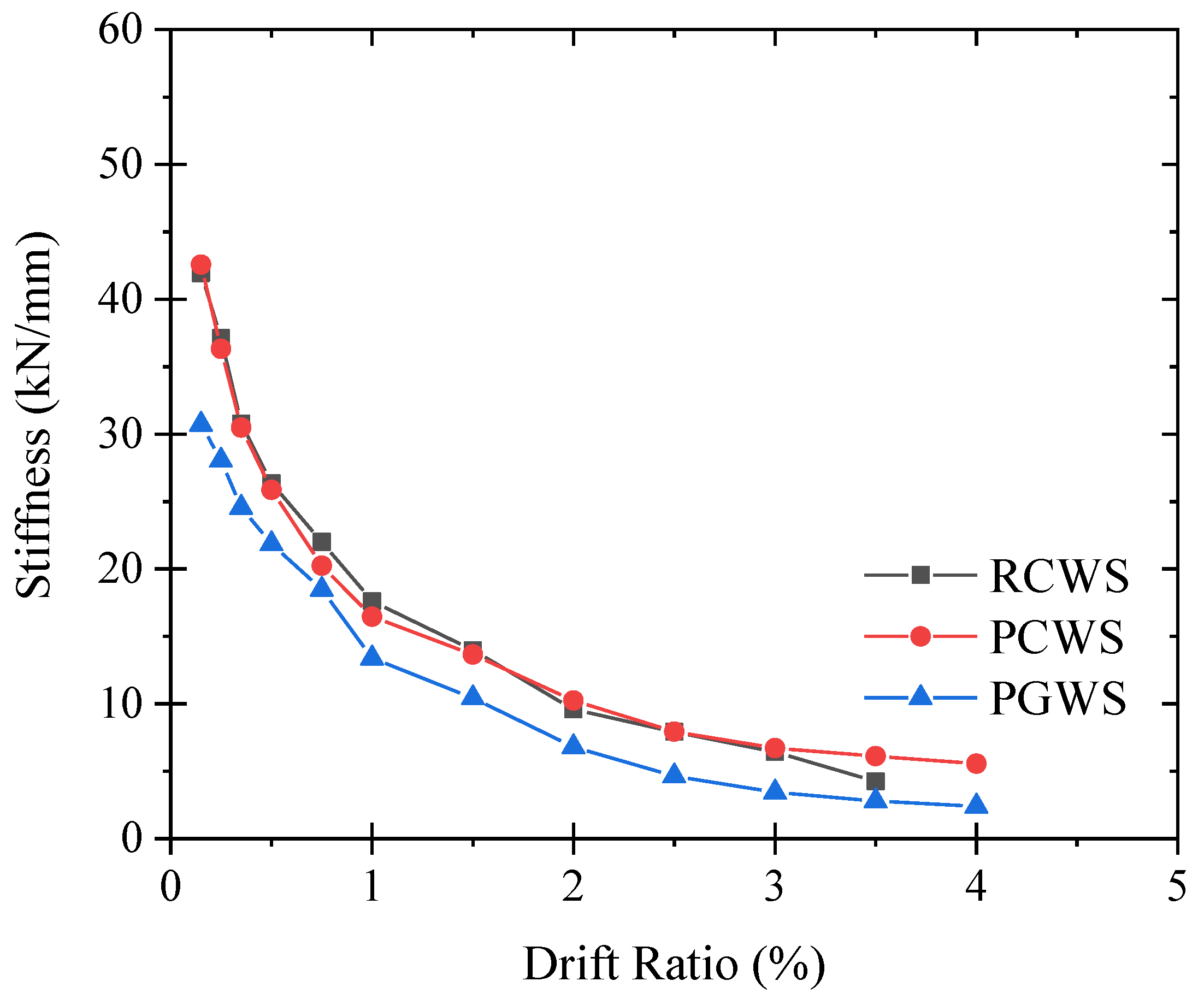

3.5. Secant Stiffness Degradation

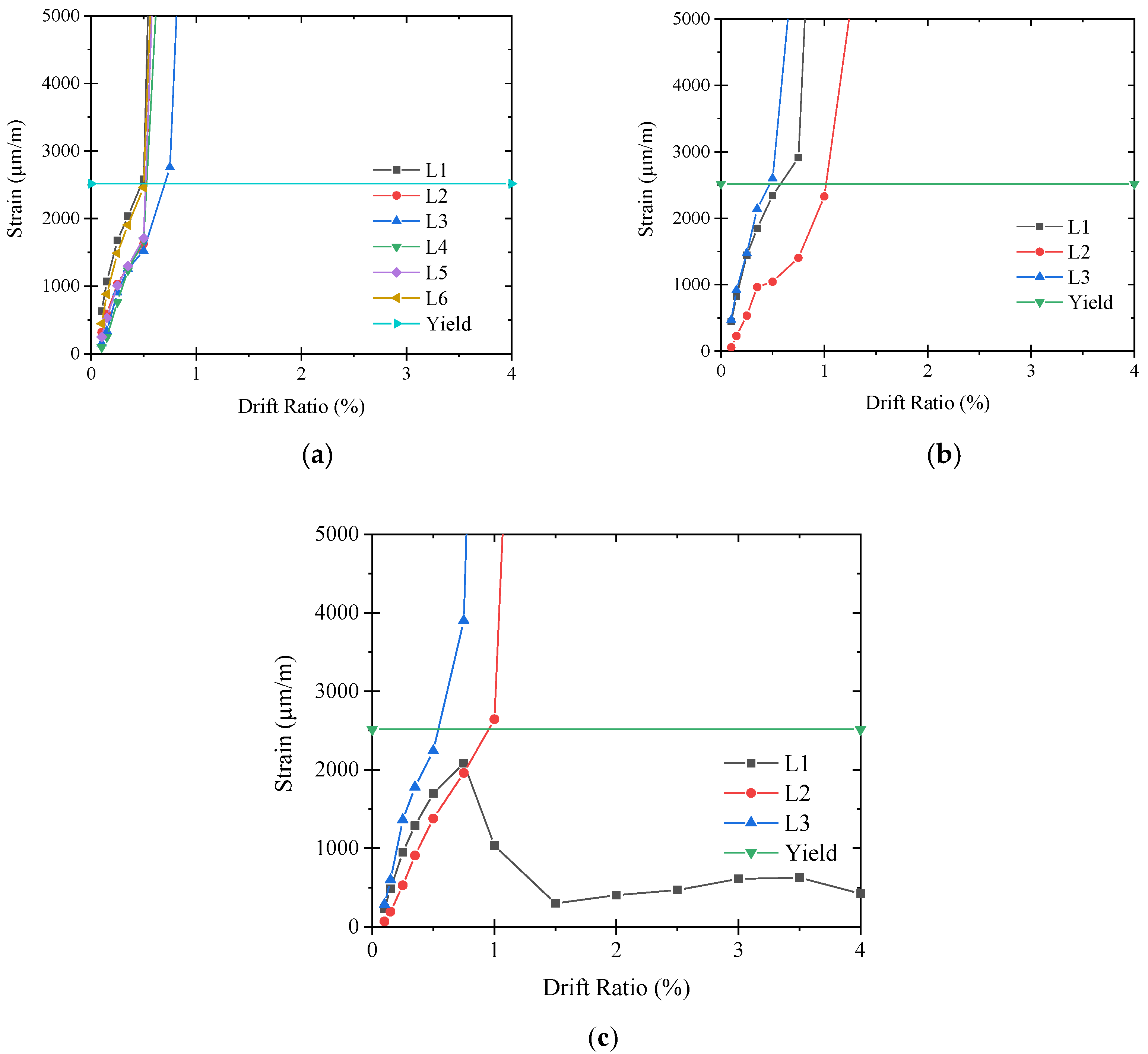

3.6. Strains of Longitudinal Reinforcement

4. Numerical Simulations

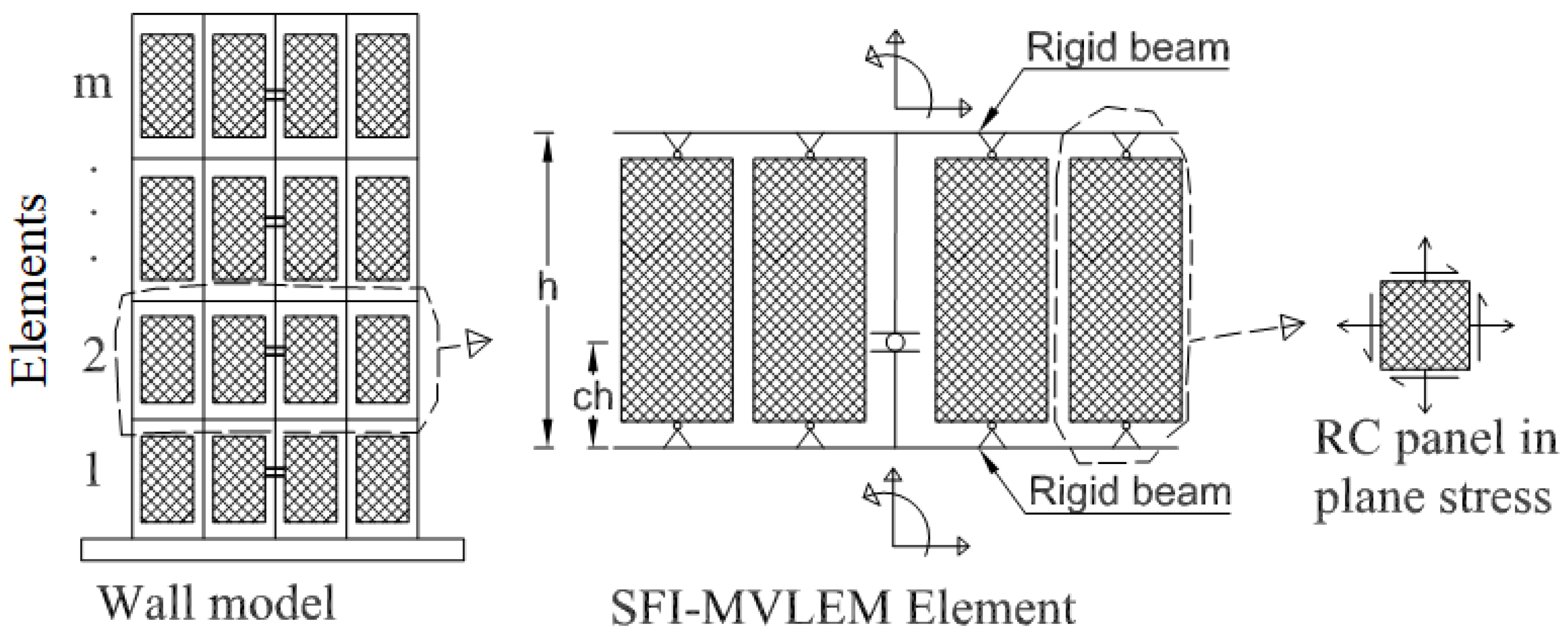

4.1. Element and Panel Discretization

4.2. Material Constitutive Relations

4.3. Comparison of Predicted vs. Experimental Hysteretic Response

5. Discussions

6. Conclusions

- The crack patterns and ultimate failure modes of the specimens RCWS and PCWS were close to each other, whereas the failure of the specimen PGWS was characterized by a wide crack at the wall-footing junction. Further, the number of flexure and shear cracks in specimen PGWS was lower than the corresponding number in specimens RCWS and PGWS, suggesting that the mode of failure in the specimen PGWS was mainly controlled by rocking.

- The hysteretic load-deflection behavior of the specimens RCWS and PCWS was identical in terms of initial stiffness, ductility, peak load, pinching, and energy dissipation. On the contrary, the hysteretic response of the specimen PGWS exhibited extensive pinching in both directions, which can be attributed to the rocking behavior. It was observed that the contribution of rocking to the total lateral deformation of the specimen PGWS was predominantly high as compared to the corresponding contributions in the specimens RCWS and PCWS. As a result, the total dissipated energy by the specimen PGWS was significantly low compared to the corresponding values of other specimens. Different deformation components were extracted, and it was found that the contribution of rocking to the total lateral deformation of specimen PGWS was up to 70%.

- For drift ratios below 1%, all specimens exhibited a gradual evolution of dissipated energy. The cumulative energy dissipation among the specimens was similar within this range. However, above a 1% drift ratio, the specimen PGWS deviated from the dissipated energy trend observed in the specimen RCWS (representing a cast-in-place shear wall). This can be attributed to the extensive pinched hysteretic response caused by the rocking mechanism in the specimen PGWS. In contrast, the specimen PCWS demonstrated a higher total dissipated energy of 87.6 kN-m compared to the specimen RCWS, which recorded a value of 76.6 kN-m.

- The secant slope vs. drift ratio response of all the specimens was identical. Strain gages attached to the longitudinal bars suggested that all longitudinal bars in the specimens RCWS and PCWS yielded, whereas one longitudinal bar in the splice sleeve of the specimen PGWS could not achieve yielding. This suggests that the splice sleeve connection at the corresponding had failed prior to attaining yielding. This can be attributed to the grout defect that has been encountered in previous studies. Thus, corrugated duct splices not only provide an excellent alternative to grouted sleeve splices’ connections but also eliminate the risks associated with grout defects.

- Nonlinear fiber-based modeling in OpenSees was performed using SFI-MVLEM elements. The nonlinear modeling was limited to specimens RCWS and PCWS, and a single model was created that was representative of both specimens. The predicted hysteretic response of the OpenSees model was in close agreement with the experimental response.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Singhal, S.; Chourasia, A.; Chellappa, S.; Parashar, J. Precast reinforced concrete shear walls: State of the art review. Struct. Concr. 2019, 20, 886–898. [Google Scholar] [CrossRef]

- Elliott, K. Precast Concrete Structures; CRC Press: Boca Raton, FL, USA, 2019; Available online: https://books.google.com/books?hl=en&lr=&id=cjH3DwAAQBAJ&oi=fnd&pg=PP1&ots=49pcPigwZk&sig=Bh94D_d4NmItAz9AoyTnderTyc4 (accessed on 26 August 2022).

- Perez, F.J.; Pessiki, S.; Sause, R. Experimental Lateral Load Response of Unbonded Post-Tensioned Precast Concrete Walls. ACI Struct J. 2013, 110, 1045–1056. [Google Scholar] [CrossRef]

- Pimanmas, A.; Yooprasertchai, E.; Wiwatrojanagul, P. Cyclic loading test of precast concrete load-bearing walls designed for gravitational loading. Mag. Concr. Res. 2021, 73, 595–607. [Google Scholar] [CrossRef]

- Yooprasertchai, E.; Warnitchai, P. Seismic performance of precast hybrid moment-resisting frame/rocking wall systems. Mag. Concr. Res. 2018, 70, 1118–1134. [Google Scholar] [CrossRef]

- Yooprasertchai, E.; Hadiwijaya, I.J.; Warnitchai, P. Seismic performance of precast concrete rocking walls with buckling restrained braces. Mag. Concr. Res. 2016, 68, 462–476. [Google Scholar] [CrossRef]

- Guo, T.; Zhang, G.; Chen, C. Experimental Study on Self-Centering Concrete Wall with Distributed Friction Devices. J. Earthq. Eng. 2014, 18, 214–230. [Google Scholar] [CrossRef]

- Gu, Q.; Dong, G.; Wang, X.; Jiang, H.; Peng, S. Research on pseudo-static cyclic tests of precast concrete shear walls with vertical rebar lapping in grout-filled constrained hole. Eng Struct. 2019, 189, 396–410. [Google Scholar] [CrossRef]

- ACI. ACI 318-19: Building Code Requirements for Structural Concrete and Commentary; ACI: Farmington Hills, MI, USA, 2019; Available online: https://www.concrete.org/store/productdetail.aspx?ItemID=318U19&Language=English (accessed on 27 December 2021).

- Haber, Z.B.; Saiidi, M.S.; Sanders, D.H. Seismic Performance of Precast Columns with Mechanically Spliced Column-Footing Connections. ACI Struct. J. 2014, 111, 639–650. [Google Scholar] [CrossRef]

- Ameli, M.J.; Parks, J.E.; Brown, D.N.; Pantelides, C.P. Seismic evaluation of grouted splice sleeve connections for reinforced precast concrete column-to-cap beam joints in accelerated bridge construction. PCI J. 2015, 60, 80–103. [Google Scholar] [CrossRef]

- Ameli, M.J.; Brown, D.N.; Parks, J.E.; Pantelides, C.P. Seismic Column-to-Footing Connections Using Grouted Splice Sleeves. ACI Struct. J. 2016, 113, 1021–1030. [Google Scholar] [CrossRef]

- Belleri, A.; Riva, P. Seismic performance and retrofit of precast concrete grouted sleeve connections. PCI J. 2012, 57, 97–109. [Google Scholar] [CrossRef]

- Peng, Y.Y.; Qian, J.R.; Wang, Y.H. Cyclic performance of precast concrete shear walls with a mortar–sleeve connection for longitudinal steel bars. Mater. Struct. 2016, 49, 2455–2469. [Google Scholar] [CrossRef]

- Soudki, K.A.; Rizkalla, S.H.; LeBlanc, B. Horizontal connections for precast concrete shear walls subjected to cyclic deformations part 1: Mild steel connections. PCI J. 1995, 40, 78–96. [Google Scholar] [CrossRef]

- Xiao, S.; Wang, Z.; Li, X.; Harries, K.A.; Xu, Q.; Gao, R. Study of effects of sleeve grouting defects on the seismic performance of precast concrete shear walls. Eng. Struct. 2021, 236, 111833. [Google Scholar] [CrossRef]

- Xue, W.; Huang, Q.; Niu, P. Reversed cyclic tests on precast concrete shear walls with grouted corrugated metallic duct connections. Eng. Struct. 2022, 256, 113948. [Google Scholar] [CrossRef]

- Zhang, W.; Wang, J.; Zhang, J.; Cao, Y.; Qin, P.; Yi, W. Experimental study on post-fire performance of half grouted sleeve connection with construction defect. Constr. Build. Mater. 2020, 244, 118165. [Google Scholar] [CrossRef]

- Popa, V.; Papurcu, A.; Cotofana, D.; Pascu, R. Experimental testing on emulative connections for precast columns using grouted corrugated steel sleeves. Bull. Earthq. Eng. 2015, 13, 2429–2447. [Google Scholar] [CrossRef]

- Fan, J.J.; Feng, D.C.; Wu, G.; Hou, S.; Lu, Y. Experimental study of prefabricated RC column-foundation assemblies with two different connection methods and using large-diameter reinforcing bars. Eng. Struct. 2020, 205, 110075. [Google Scholar] [CrossRef]

- Zhi, Q.; Kang, L.; Jia, L.; Xiong, J.; Guo, Z. Seismic performance of precast shear walls prestressed via post-tensioned high strength bars placed inside grouted corrugated pipes. Eng. Struct. 2021, 237, 112153. [Google Scholar] [CrossRef]

- Hamidian, M.R.; Shafigh, P. Post-peak Behaviour of Composite Column Using a Ductile Lightweight Aggregate Concrete. Int. J. Concr. Struct. Mater. 2021, 15, 16. [Google Scholar] [CrossRef]

- McKenna, F. OpenSees: A Framework for Earthquake Engineering Simulation. Comput. Sci. Eng. 2011, 13, 58–66. [Google Scholar] [CrossRef]

- Kolozvari, K.; Orakcal, K.; Wallace, J.W. Modeling of Cyclic Shear-Flexure Interaction in Reinforced Concrete Structural Walls. I: Theory. J. Struct. Eng. 2014, 141, 04014135. [Google Scholar] [CrossRef]

- Kolozvari, K.; Tran, T.A.; Orakcal, K.; Wallace, J.W. Modeling of Cyclic Shear-Flexure Interaction in Reinforced Concrete Structural Walls. II: Experimental Validation. J. Struct. Eng. 2014, 141, 04014136. [Google Scholar] [CrossRef]

- Kolozvari, K.; Orackal, K.; Wallace, J. Shear-Flexure Interaction Modeling for Reinforced Concrete Structural Walls and Columns under Reversed Cyclic Loading; Pacific Earthquake Engineering Research Center, University of California: Berkeley, CA, USA, 2015. [Google Scholar]

- Orakcal, K.; Ulugtekin, D. Constitutive Modeling of Reinforced Concrete Panel Behavior under Cyclic Loading. In Proceedings of the 15th World Conference on Earthquake Engineering, Lisbon, Portugal, 24–28 September 2012. [Google Scholar]

- Mander, J.B.; Priestley, M.J.N.; Park, R. Observed Stress Strain Behavior of Confined Concrete. J. Struct. Eng. 1988, 114, 1827–1849. [Google Scholar] [CrossRef]

- Chang, G.A.; Mander, J.B. Seismic Energy Based Fatigue Damage Analysis of Bridge Columns: Part 1—Evaluation of Seismic Capacity; NCEER Technical Rep. No. NCEER-94; US National Center for Earthquake Engineering Research: Alachua, FL, USA, 1994. [Google Scholar]

- Menegotto, M.; Pinto, P.E. Method of analysis for cyclically loaded RC plane frames including changes in geometry and non-elastic behavior of elements under combined normal force and bending. In Proceedings of the IABSE Symposium on Resistance and Ultimate Deformability of Structures Acted on by Well Defined Repeated Loads, Lisbon, Portugal; 1973; pp. 15–22. Available online: https://www.e-periodica.ch/cntmng?pid=bse-re-001:1973:13::9 (accessed on 4 September 2022).

- Fllippou, F.E.; Popov, E.P.; Bertero, V.V. Effects of Bond Deterioration on Hysteretic Behavior of Reinforced Concrete Joints. 1983. Available online: https://nehrpsearch.nist.gov/static/files/NSF/PB84192020.pdf (accessed on 4 September 2022).

| Type of Wall | Designation | Height (mm) | Length (mm) | Width (mm) |

|---|---|---|---|---|

| Cast-in-situ wall | RCWS | 1190 | 800 | 120 |

| PC wall with corrugated duct splices | PGWS | 1190 | 800 | 120 |

| PC wall with grouted sleeve splices | PCWS | 1190 | 800 | 120 |

| RCWS | PCWS | PGWS | ||||

|---|---|---|---|---|---|---|

| Concrete Cylinder Strength (MPa) | Footing | Wall | Footing | Wall | Footing | Wall |

| 34.13 | 32.68 | 34.13 | 32.68 | 34.13 | 32.68 | |

| Axial load (kN) | 150 | 150 | 150 | |||

| Grout (50 × 50 × 50 mm) (MPa) | - | 97.58 | 97.58 | |||

| Bar Type | Yield Strength (MPa) | Tensile Strength (MPa) |

|---|---|---|

| RB9 | 311.49 | 466.72 |

| DB10 | 412.19 | 620.36 |

| DB12 | 509.45 | 617.58 |

| DB20 | 502.74 | 646.38 |

| ID | Direction | Dissipated Energy (kN-m) | |||||

|---|---|---|---|---|---|---|---|

| PCWS | Push | 165 | 132 | 3.3 | 0.53 | 6.23 | 87.6 |

| Pull | 193 | 155 | 3.1 | 0.42 | 7.38 | ||

| RCWS | Push | 155 | 124 | 2.7 | 0.44 | 6.14 | 76.6 |

| Pull | 181 | 145 | 3.1 | 0.45 | 6.89 | ||

| PGWS | Push | 151 | 121 | 3.1 | 0.44 | 7.04 | 39.5 |

| Pull | 171 | 137 | 2.15 | 0.58 | 3.71 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yooprasertchai, E.; Wiwatrojanagul, P.; Saingam, P.; Khan, K. Cyclic Behavior of Different Connections in Precast Concrete Shear Walls: Experimental and Analytical Investigations. Buildings 2023, 13, 1433. https://doi.org/10.3390/buildings13061433

Yooprasertchai E, Wiwatrojanagul P, Saingam P, Khan K. Cyclic Behavior of Different Connections in Precast Concrete Shear Walls: Experimental and Analytical Investigations. Buildings. 2023; 13(6):1433. https://doi.org/10.3390/buildings13061433

Chicago/Turabian StyleYooprasertchai, Ekkachai, Pongsak Wiwatrojanagul, Panumas Saingam, and Kaffayatullah Khan. 2023. "Cyclic Behavior of Different Connections in Precast Concrete Shear Walls: Experimental and Analytical Investigations" Buildings 13, no. 6: 1433. https://doi.org/10.3390/buildings13061433

APA StyleYooprasertchai, E., Wiwatrojanagul, P., Saingam, P., & Khan, K. (2023). Cyclic Behavior of Different Connections in Precast Concrete Shear Walls: Experimental and Analytical Investigations. Buildings, 13(6), 1433. https://doi.org/10.3390/buildings13061433