The Effect of Preload Loss on the Mechanical Properties of Grid Structure Connected with Bolted-Ball Joints

Abstract

1. Introduction

2. The Numerical Simulation of the Plane Grid with a Bolt-Ball Joint Connection

2.1. The Modeling of Plane Truss

2.2. The Preload Setting

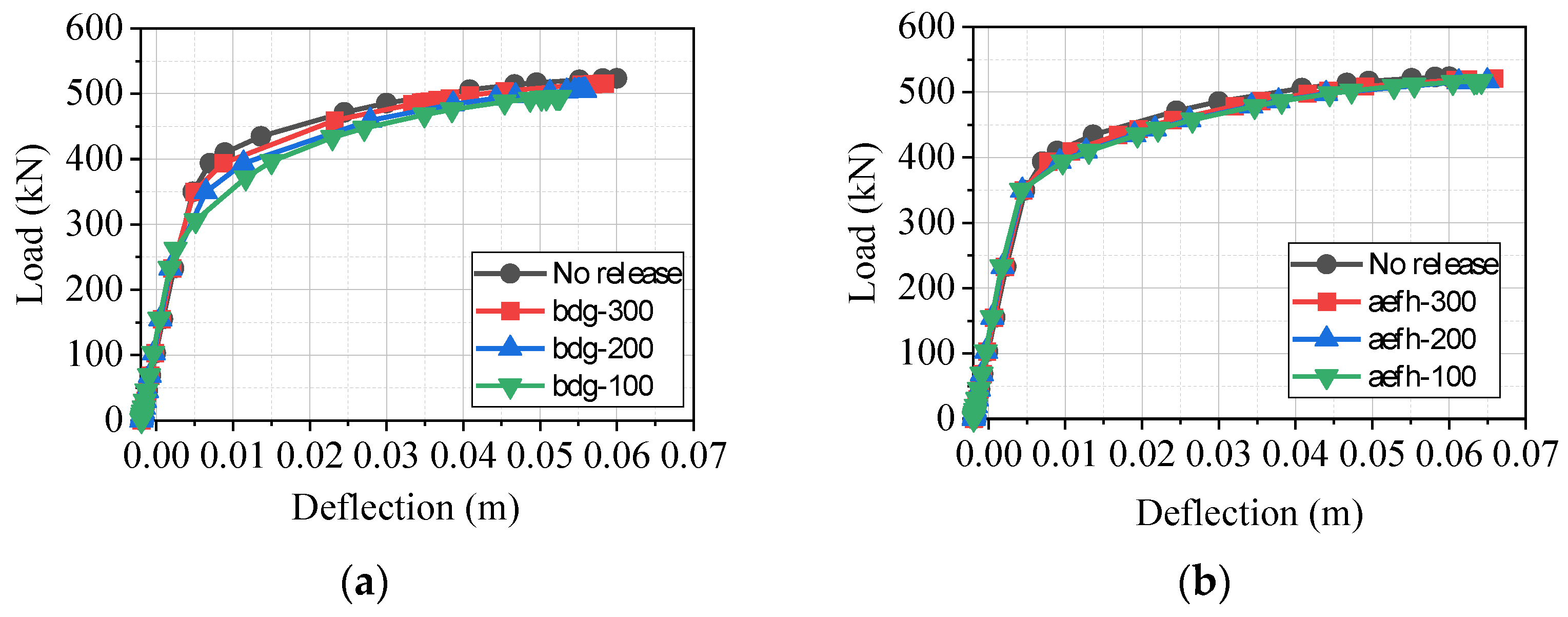

2.3. Discussion of Results

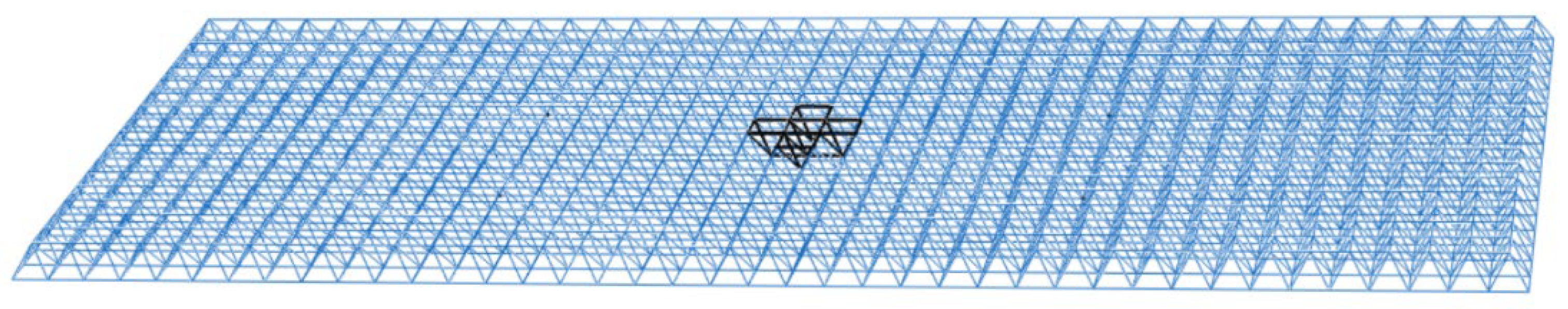

3. Numerical Simulation of a Grid with Bolt-Ball Joint Connection

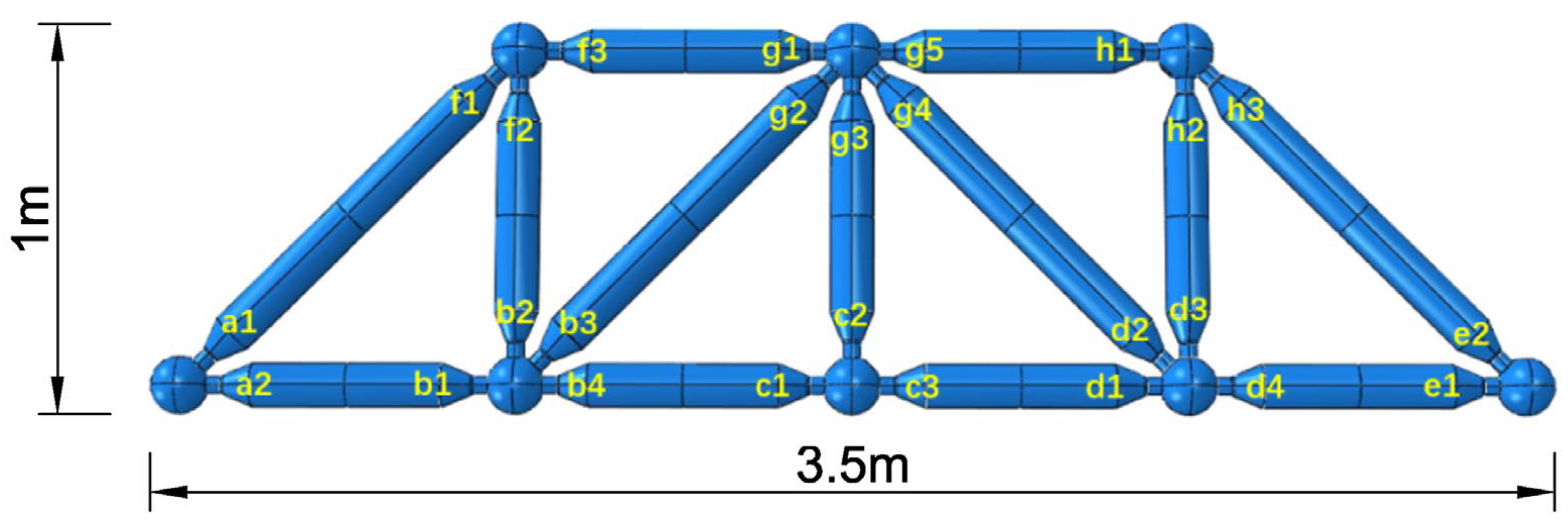

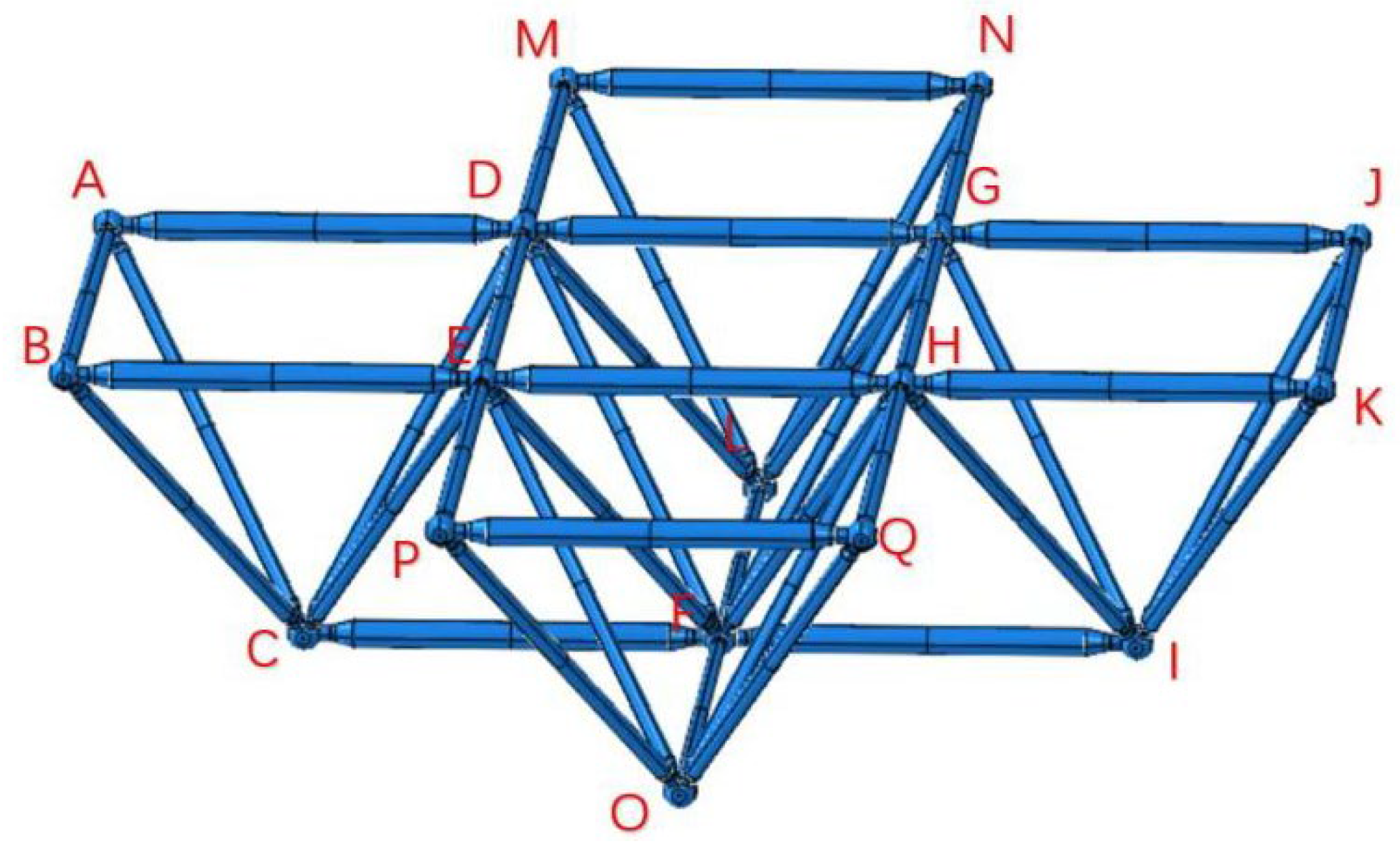

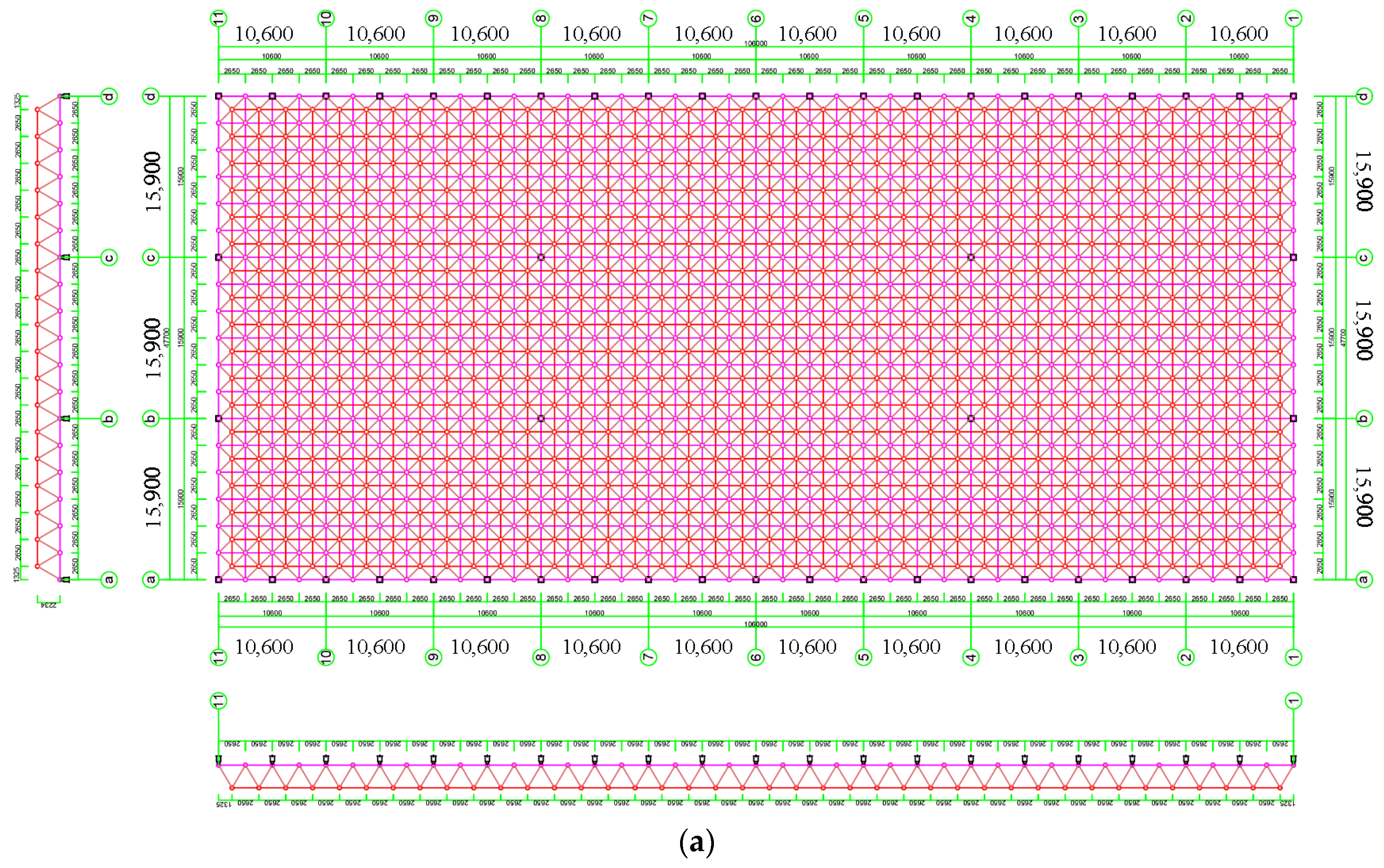

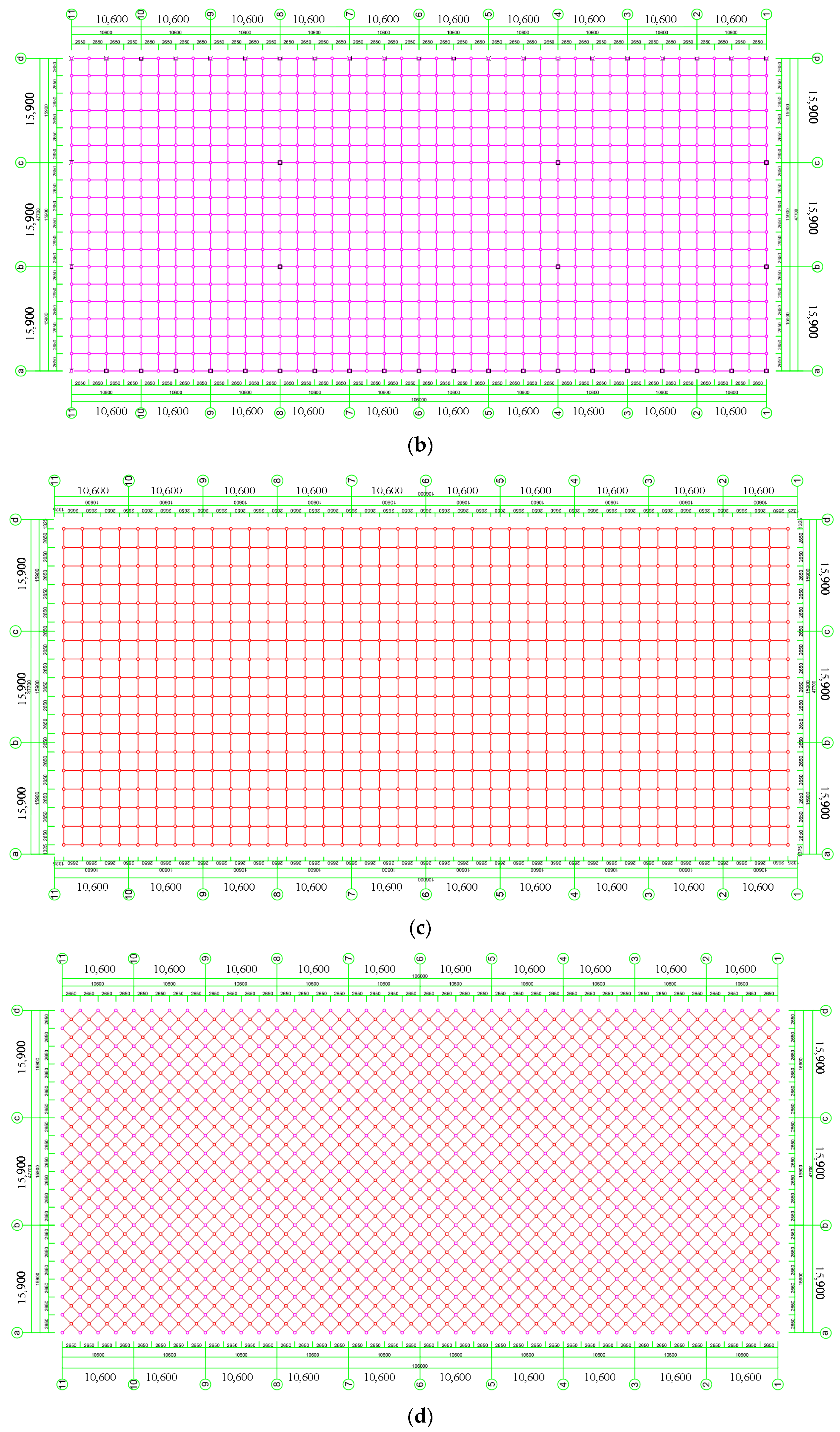

3.1. Modeling of the Grid Structure

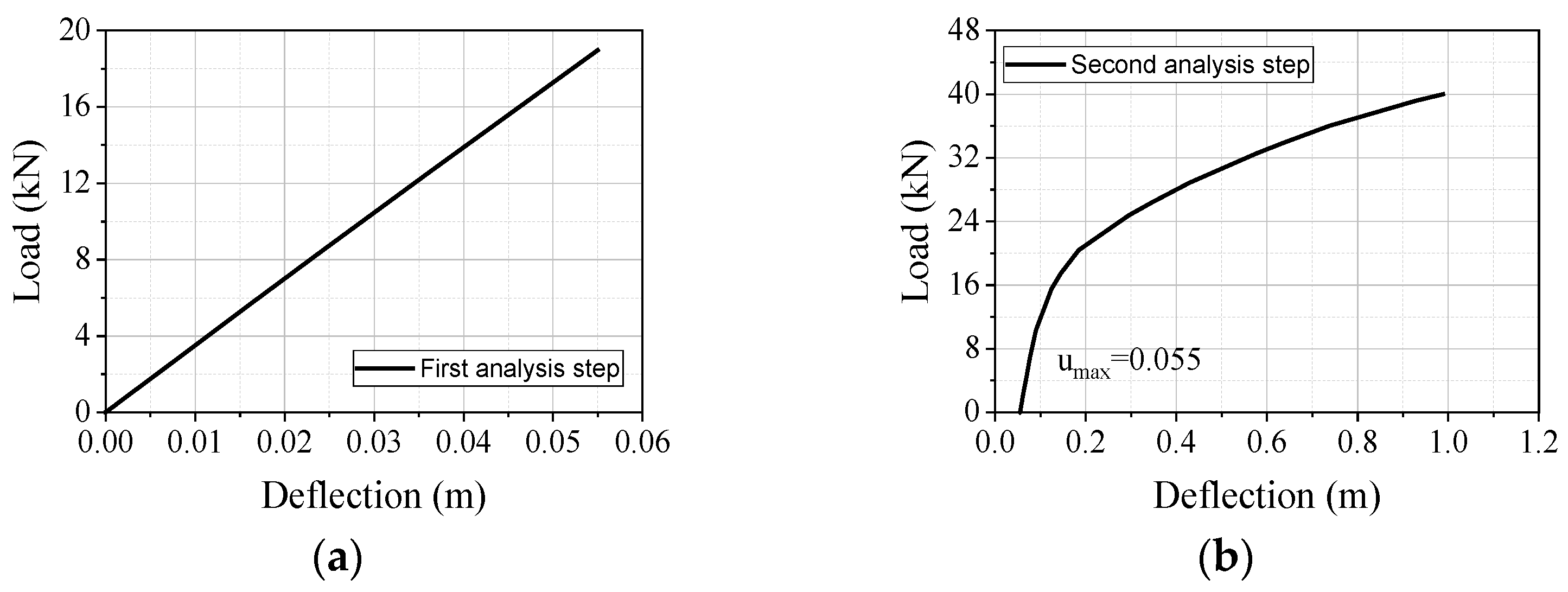

3.2. Load Adding

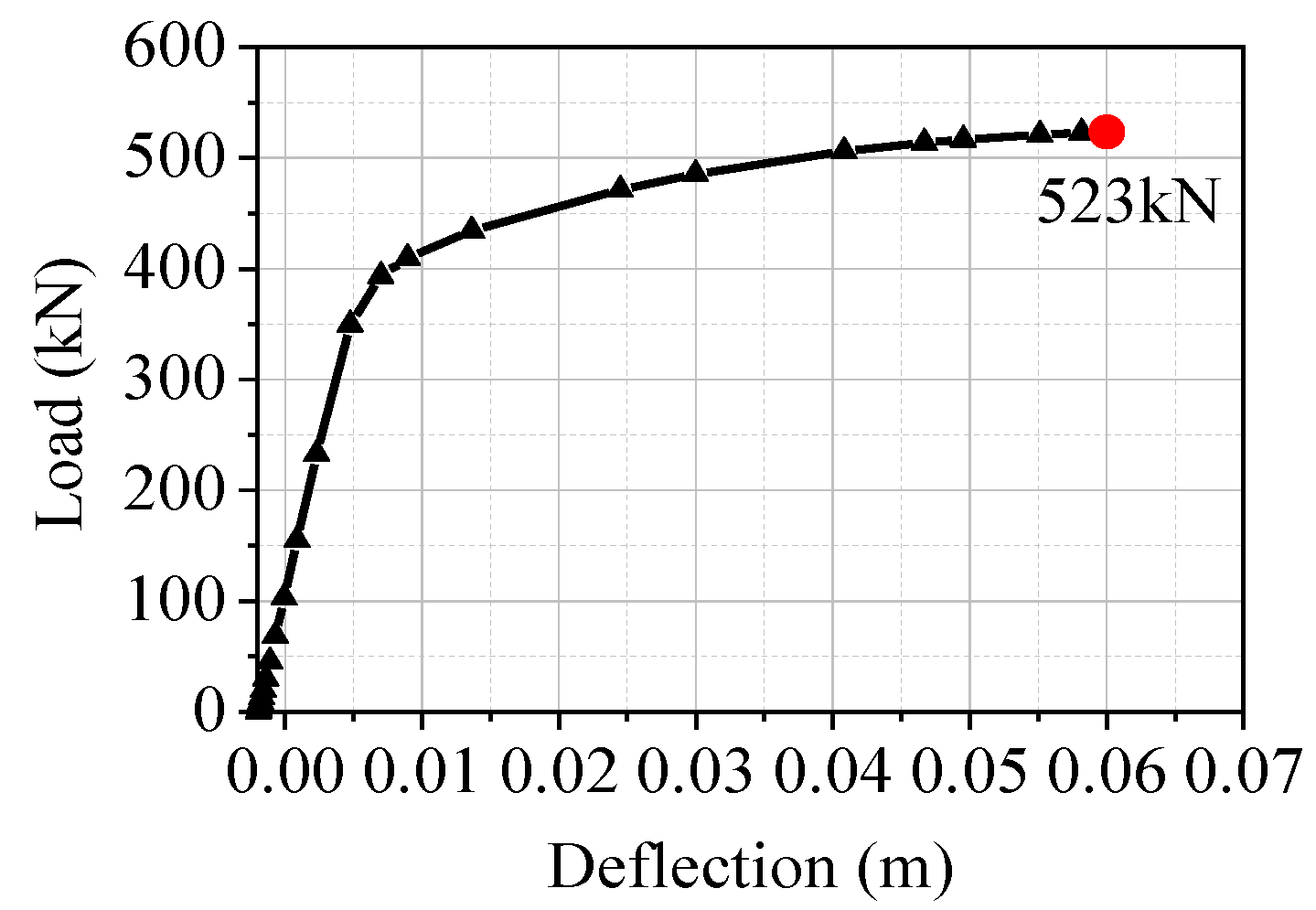

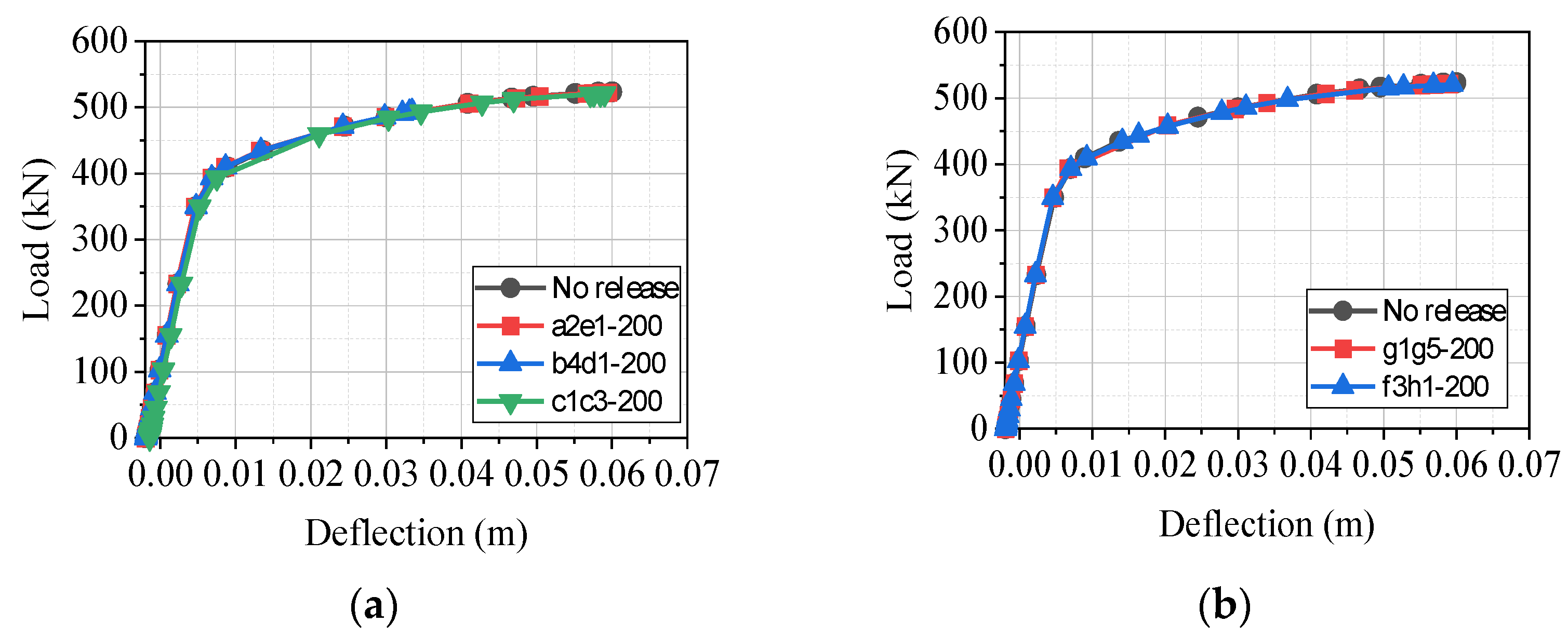

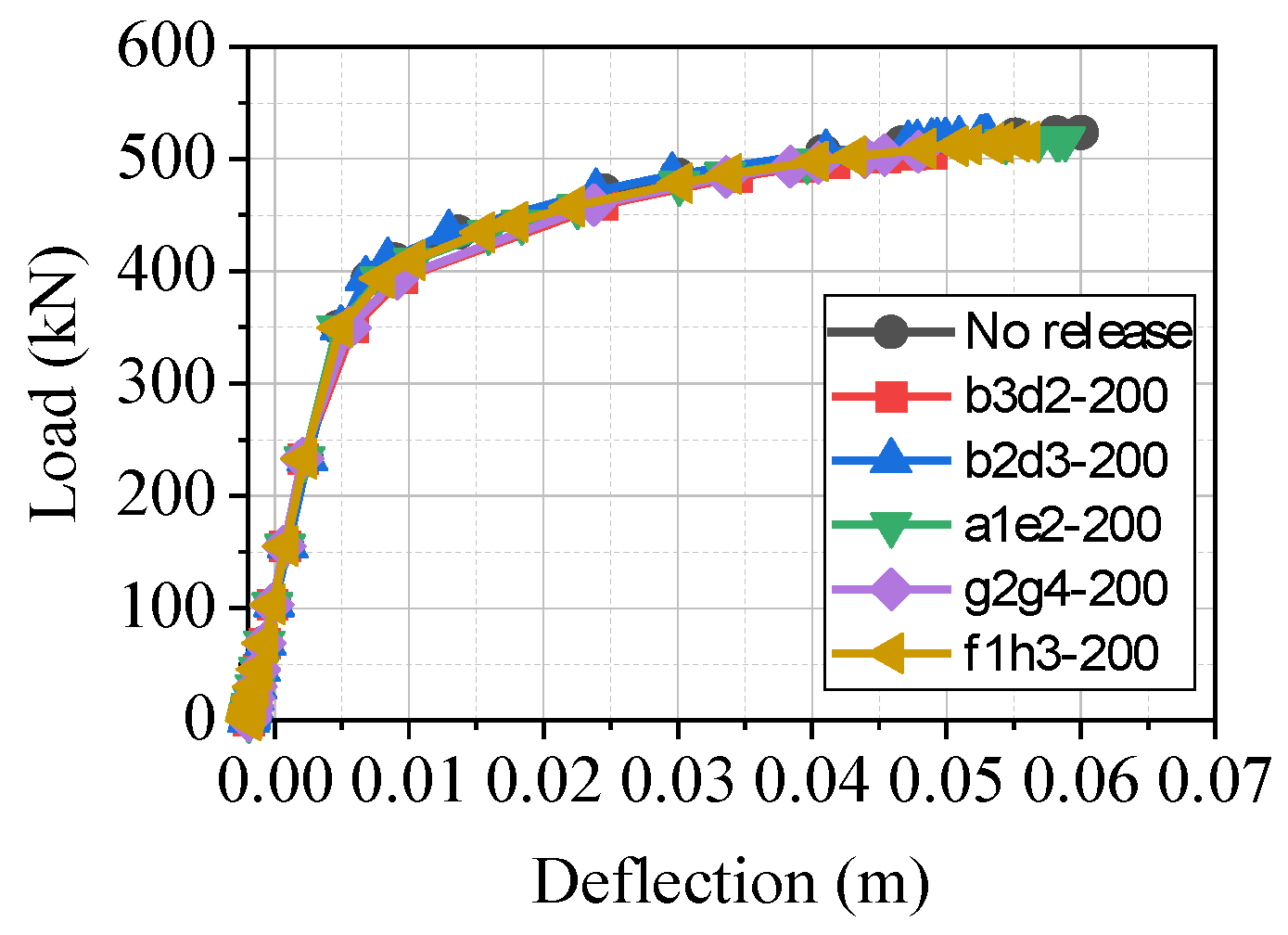

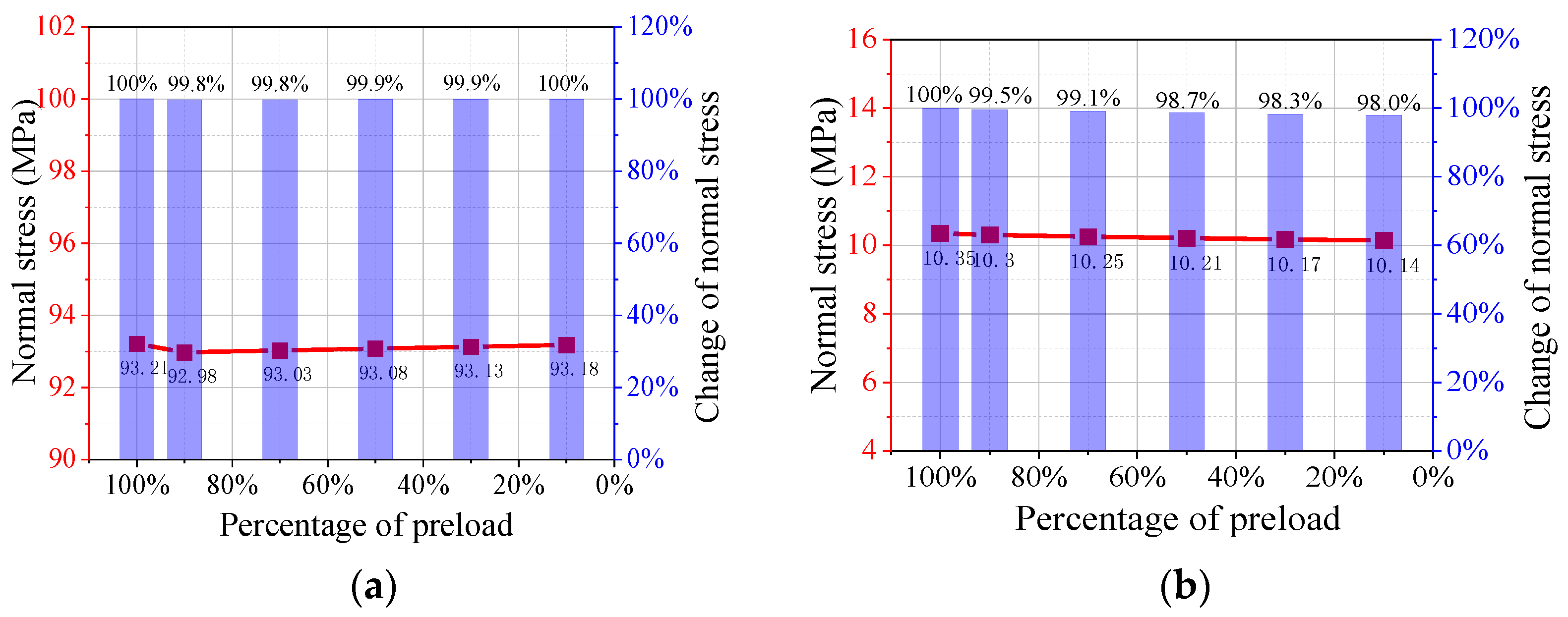

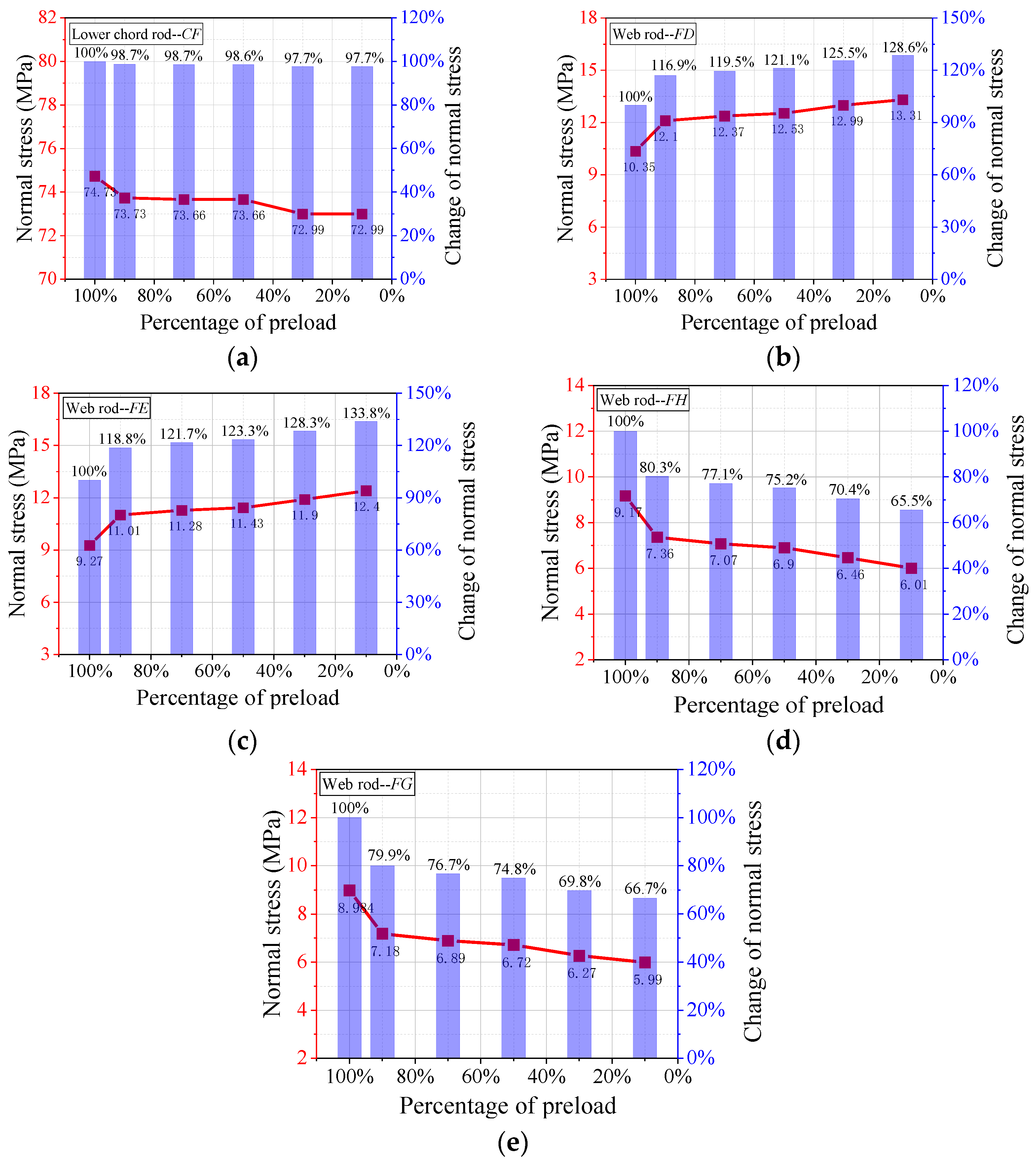

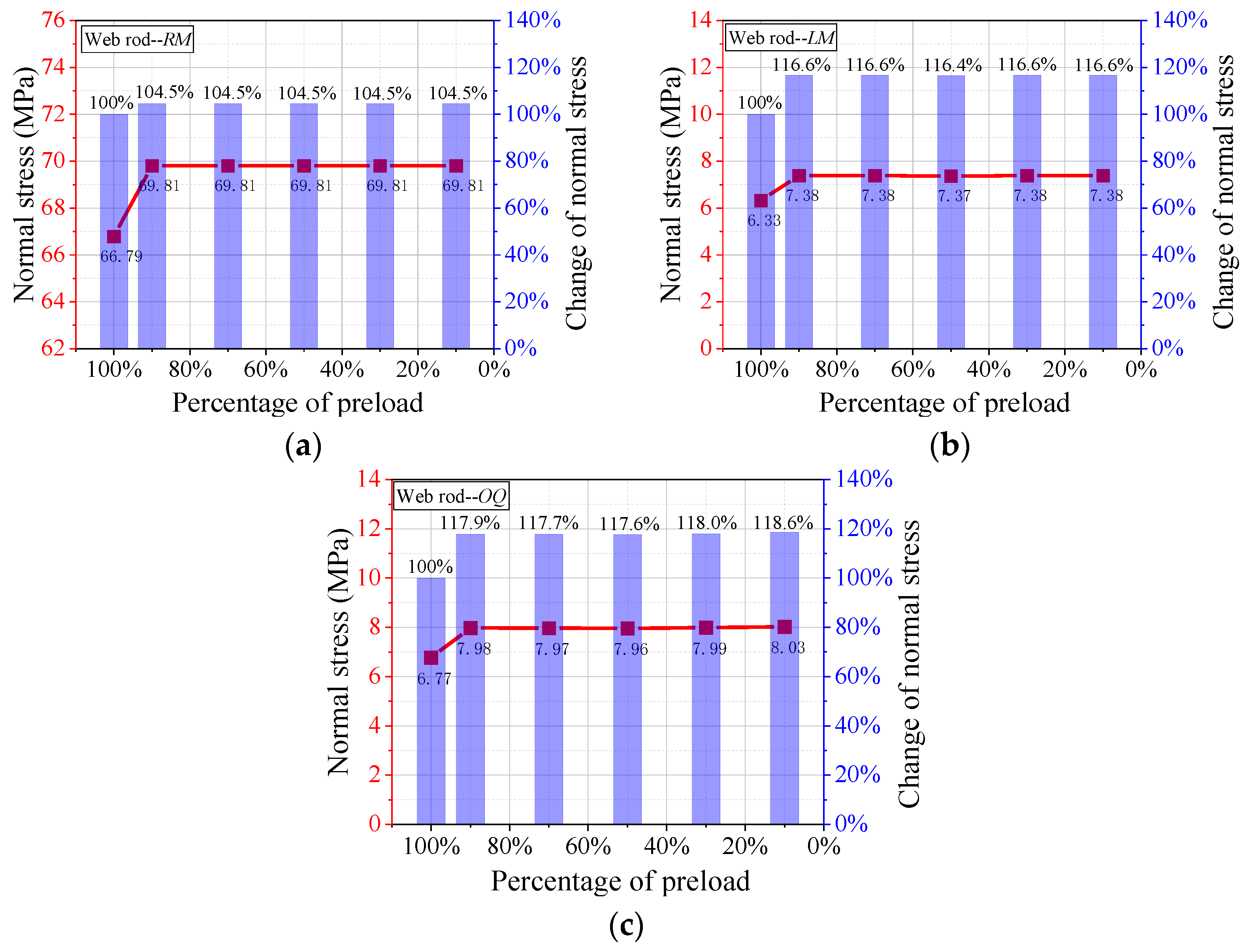

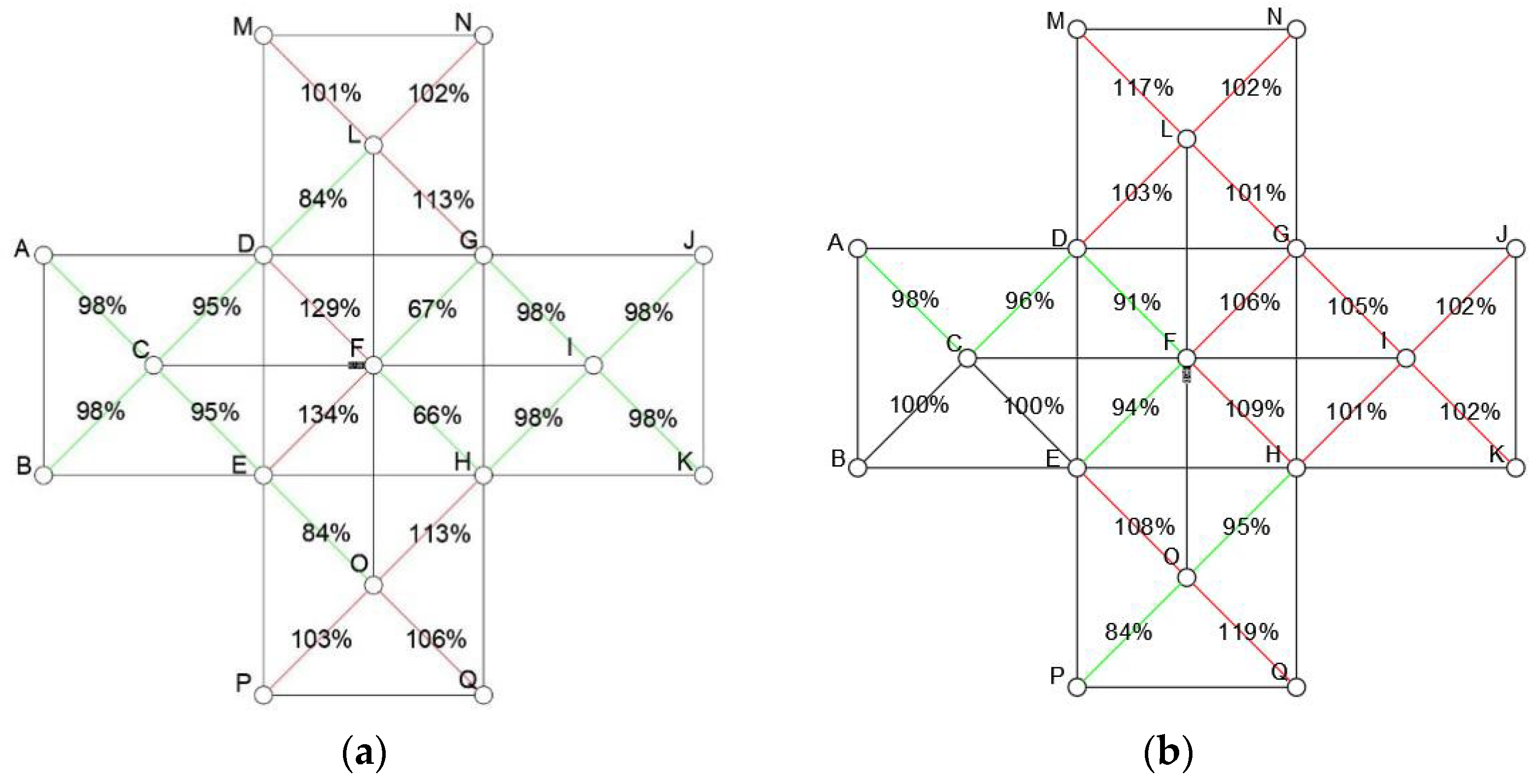

3.3. Discussion of Results

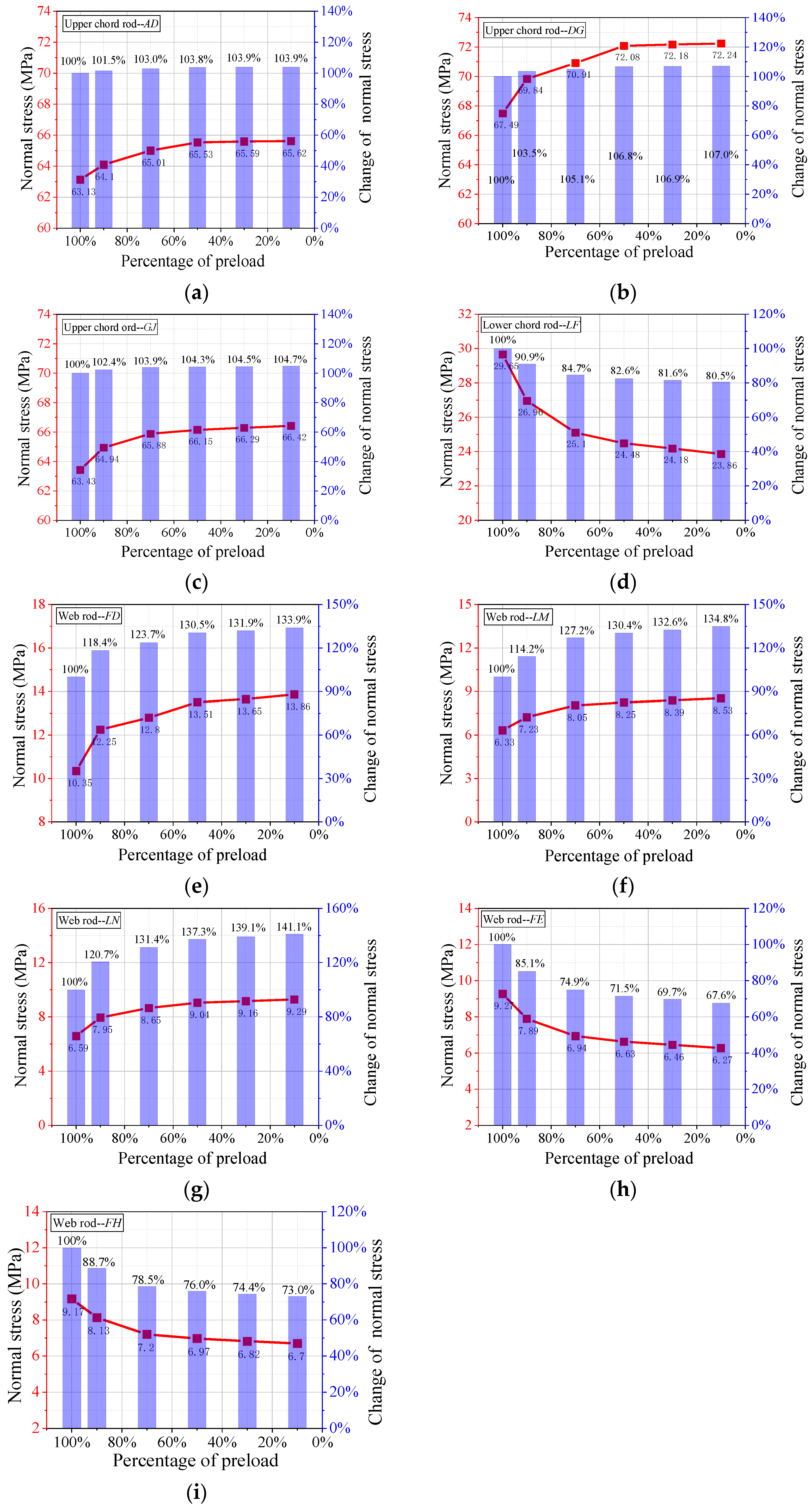

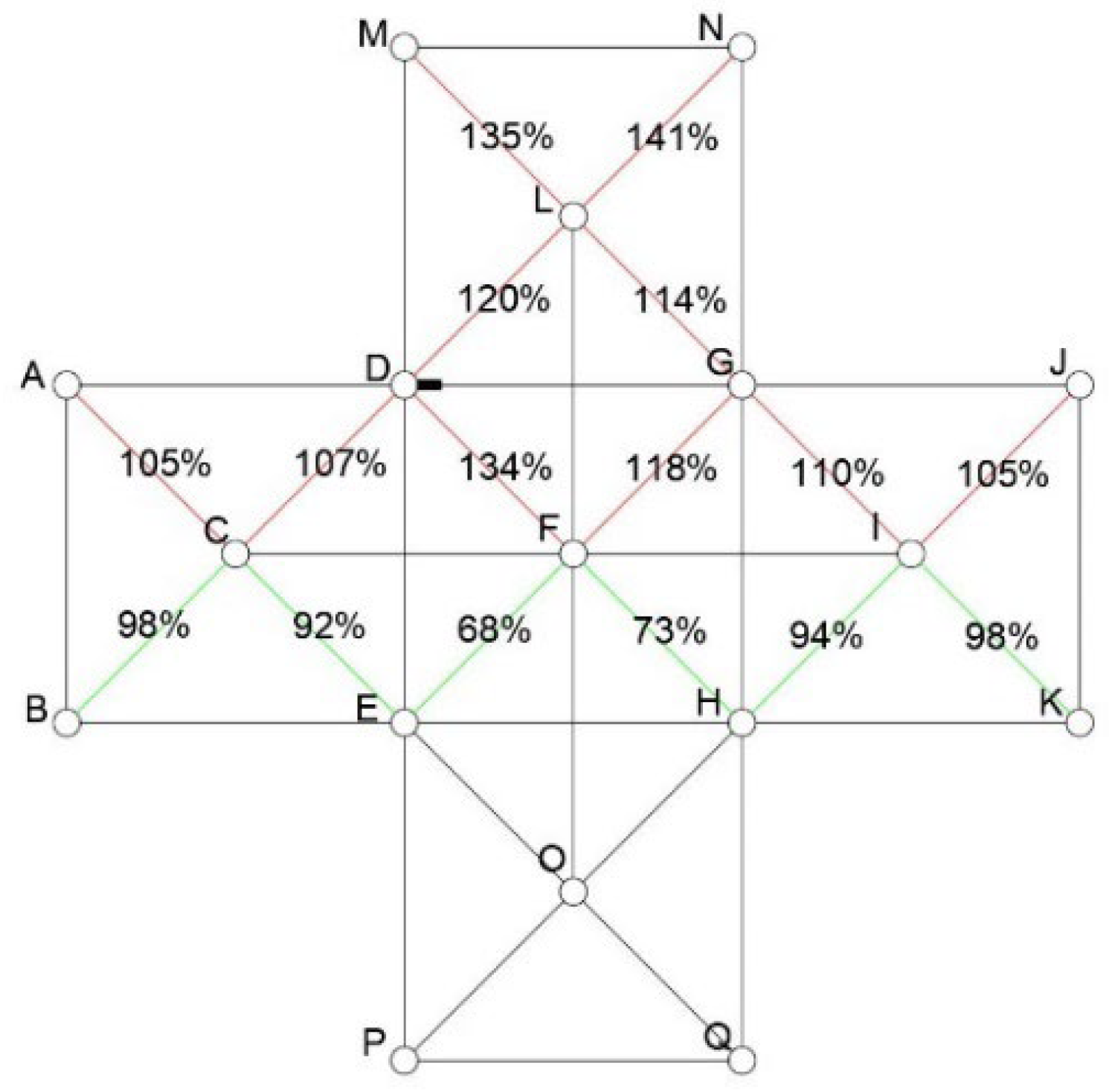

3.4. The Analysis of the Local Rod Simulation Results

4. Conclusions

- 1.

- The release of the preload of the outer web rod is less effective on the overall stiffness and bearing capacity of the structure compared to that of the inner web rod. The release of the preload of the outer web rod results in a reduction of the overall stiffness and bearing capacity by 1.5% at most, while the release of the preload of the inner web rod results in a reduction of overall stiffness and bearing capacity by 5.4% at most.

- 2.

- The magnitude of the preload significantly affects the stiffness of the bolt-ball joint and the bearing capacity in a small range of rotation.

- 3.

- Relaxing the preload of an upper chord or a lower chord rod has little effect on the whole structure while relaxing the preload of a web rod will reduce the overall stiffness and bearing capacity by approximately 3% at most.

- 4.

- The preload of the rod in the larger span direction plays an important role, however, the preload of the upper chord has a greater impact, while the preload of the web rod and the upper chord in the smaller span direction has no significant effect on the normal stress in the surrounding rods.

- 5.

- The rod with a release preload has little effect on the overall deflection of the structure because the middle five inverted quadrangular pyramid grids are only a small part in comparison to the whole grid structure. Therefore, the influence of the preload release of more rods on the structure needs further research.

- 6.

- The preload state of the lower chord in the width direction changes rapidly when it is 90–100%, and the normal stress of the surrounding rod does not change when it is less than 90%. Therefore, it is necessary to pay attention to the preload of the lower chord in the direction of a smaller span.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Shang, H.; Ma, K.J.; Wei, Y.H.; Lu, Y. Experimental Studies on Shear Resistance Performances for the Shear key of H Shape Steel Spatial Grid Roofs. Lat. Am. J. Solids Struct. 2019, 16, 1–17. [Google Scholar] [CrossRef]

- Fan, Z.; Yang, S.; Luan, H. Research progress and practice of design of spatial structure joints. J. Build. Struct. 2011, 32, 1–15. [Google Scholar]

- Mousavi, A.A.; Zhang, C.; Masri, S.F.; Gholipour, G. Structural damage localization and quantification based on a CEEMDAN Hilbert transform neural network approach: A model steel truss bridge case study. Sensors 2020, 20, 1271. [Google Scholar] [CrossRef] [PubMed]

- Colombi, P. The ponding problem on flat steel roof grids. J. Constr. Steel Res. 2006, 62, 647–655. [Google Scholar] [CrossRef]

- Piroglu, F.; Ozakgul, K. Partial collapses experienced for a steel space truss roof structure induced by ice ponds. Eng. Fail. Anal. 2016, 60, 155–165. [Google Scholar] [CrossRef]

- Wu, Q.; Wang, H.; Qian, H.; Han, K.; Fan, F. Effect of insufficient screwing depth of bolt on mechanical behavior of bolt-ball joint and stability of single-layer reticulated shell. Eng. Struct. 2020, 213, 110590. [Google Scholar] [CrossRef]

- Wang, X.; Weng, K.; Liu, H.; Zhang, Y.; Chen, Z. Experimental study on the mechanical property of visual bolt-ball joint system. Adv. Struct. Eng. 2013, 16, 1749–1761. [Google Scholar] [CrossRef]

- Fan, F.; Ma, H.; Chen, G.; Shen, S. Experimental study of semi-rigid joint systems subjected to bending with and without axial force. J. Constr. Steel Res. 2012, 68, 126–137. [Google Scholar] [CrossRef]

- Yeum, C.; Dyke, S.J. Vision-based automated crack detection for bridge inspection. Comput. Aided Civ. Infrastruct. Eng. 2015, 30, 759–770. [Google Scholar] [CrossRef]

- Munawar, H.S.; Ullah, F.; Shahzad, D.; Heravi, A.; Qayyum, S.; Akram, J. Civil infrastructure damage and corrosion detection: An application of machine learning. Buildings 2022, 12, 156. [Google Scholar] [CrossRef]

- Thai, H.T. Machine learning for structural engineering: A state-of-the-art review. Structures 2022, 38, 448–491. [Google Scholar] [CrossRef]

- Sangirardi, M.; Altomare, V.; Santis, S.D.; Felice, G.d. Detecting damage evolution of masonry structures through computer-vision-based monitoring methods. Buildings 2022, 12, 831. [Google Scholar] [CrossRef]

- Lin, Y.; Nie, Z.; Ma, H. Structural damage detection with automatic feature-extraction through deep learning. Comput. Aided Civ. Infrastruct. Eng. 2017, 32, 1025–1046. [Google Scholar] [CrossRef]

- Xu, J.; Wang, S.; Bai, J.; Li, Y.; Quan, X. Study on durability and piezoresistivity of cement-based piezoelectric materials mixed with carbon fiber and iron tailings under salt-freezing erosion. Buildings 2022, 12, 1150. [Google Scholar] [CrossRef]

- Lucena, R.L.; Dos Santos, J. Structural health monitoring using time reversal and cracked rod spectral element. Mech. Syst. Signal Process. 2016, 79, 86–98. [Google Scholar] [CrossRef]

- Zagrai, A.; Giurgiutiu, V. Electro-mechanical impedance method for crack detection in thin plates. J. Intell. Mater. Syst. Struct. 2001, 12, 709–718. [Google Scholar] [CrossRef]

- Zhu, R.; Li, F.; Zhang, D.; Tao, J. Effect of joint stiffness on deformation of a novel hybrid frp-aluminum space truss system. J. Struct. Eng. 2019, 145, 04019123. [Google Scholar] [CrossRef]

- Xu, J.; Feng, D.; Mangalathu, S.; Jeon, J. Data-driven rapid damage evaluation for life-cycle seismic assessment of regional reinforced concrete bridges. Earthq. Eng. Struct. Dyn. 2022, 51, 2730–2751. [Google Scholar] [CrossRef]

- Saka, T.; Heki, K. The Effect of Joints on the Strength of Space Trusses. In Proceedings of the 3rd International Conference on Space Structure, Guildford, UK, 11–14 September 1984; pp. 417–422. [Google Scholar]

- Ei-sheikh, A.L. Numerical analysis of space trusses with flexible member-end joints. Int. J. Space Struct. 1992, 8, 189–197. [Google Scholar] [CrossRef]

- Wang, F.; Wang, X.; Zhang, W. Analysis of the influence of joint stiffness stability performance of single -layer reticulated shell. Steel Constr. 2015, 8, 43–45. [Google Scholar]

- Gomes, V.; Rodrigues, M.; Correia, J. Monotonic and fracture behaviours of bolted connections with distinct bolt preloads and surface treatments. Fract. Struct. Integr. 2019, 48, 304–317. [Google Scholar] [CrossRef]

- GB/T 16939-2016; High Strength Bolts for Joints of Space Grid Structures. China National Standardization Administration Committee: Beijing, China, 2016. (In Chinese)

- Dong, J. Monitoring The Connection State of Bolted Spherical Joint in Space Structures Based on Time Reversal Method; Qingdao University of Technology: Qingdao, China, 2019. [Google Scholar]

- JB/T 6040-2011; Construction Machinery. Test Methods of Tightening Torque for Bolts. China Tianjin Engineering Machinery Research Institute: Beijing, China, 2011. (In Chinese)

- GB 50017-2017; Design Standard for Steel Structures. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2017. (In Chinese)

| Load (kN) | Bolt Ball (mm2) | Sealing Plate (mm2) |

|---|---|---|

| 2.5 | 197.6 | 167.5 |

| 5 | 258.0 | 237.0 |

| 7.5 | 293.1 | 270.3 |

| 10 | 313.6 | 293.6 |

| 12.5 | 323.8 | 306.3 |

| 15 | 326.7 | 319.4 |

| 17.5 | 328.7 | 324.1 |

| 20 | 330.6 | 328.6 |

| Situation | Effect | Conclusions |

|---|---|---|

| Releasing upper and lower chord rods | No significant effect | 1. In this plane truss, the upper chord rods are mainly under compression and the lower chord rods are mainly under tension, while the web rods in the middle bear the bending resistance. 2. Releasing the outer web rods has less significant effect compared to releasing the inner web rods. |

| Releasing outer web rods | Reduces overall stiffness and capacity | |

| Releasing inner web rods | Reduces overall stiffness and capacity, with a more significant impact |

| Rods | AD | DG | GJ | BE | EH | HK | MN | PQ |

|---|---|---|---|---|---|---|---|---|

| Normal stress | −63.13 | −67.49 | −63.43 | −64.09 | −68.32 | −63.99 | −66.79 | −68.96 |

| Rods | AB | MD | DE | EP | NG | GH | HQ | JK |

| Normal stress | −102.10 | −108.60 | −93.21 | −113.50 | −109.20 | −93.25 | −110.50 | −102.40 |

| Rods | CA | CD | CB | CE | FD | FE | FH | FG | IG | IH |

|---|---|---|---|---|---|---|---|---|---|---|

| Normal stress | 41.78 | −29.33 | 40.98 | −29.47 | 10.35 | 9.27 | 9.17 | 8.98 | −28.33 | −29.33 |

| Rods | IJ | IK | LM | LN | LD | LG | OE | OH | OP | OQ |

| Normal stress | 41.09 | 40.86 | 6.33 | −6.59 | 15.52 | 15.62 | 15.78 | 16.18 | −7.58 | 6.77 |

| Percentage of Preload | AD | DG | GJ | BE | EH | HK | MN | PQ |

|---|---|---|---|---|---|---|---|---|

| AB | MD | DE | EP | NG | GH | HQ | JK | |

| 100% | −63.13 | −67.49 | −63.43 | −64.09 | −68.32 | −63.99 | −66.79 | −68.96 |

| −102.10 | −108.60 | −93.21 | −113.50 | −109.20 | −93.25 | −110.50 | −102.40 | |

| 90% | −64.10 | −69.84 | −64.94 | −63.97 | −67.82 | −63.74 | −66.35 | −68.87 |

| 102% | 103% | 102% | 100% | 99% | 100% | 99% | 100% | |

| −101.80 | −107.90 | −93.53 | −113.20 | −108.90 | −92.47 | −110.2 | −102.00 | |

| 100% | 99% | 100% | 100% | 100% | 99% | 100% | 100% | |

| 70% | −65.01 | −70.91 | −65.88 | −63.80 | −67.44 | −63.56 | −66.04 | −68.78 |

| 103% | 105% | 104% | 100% | 99% | 99% | 99% | 100% | |

| −101.90 | −108.00 | −93.24 | −113.20 | −108.80 | −92.26 | −110.20 | −102.10 | |

| 100% | 99% | 100% | 100% | 100% | 99% | 100% | 100% | |

| 50% | −65.53 | −72.08 | −66.15 | −63.75 | −67.32 | −63.51 | −65.95 | −68.76 |

| 104% | 107% | 104% | 99% | 99% | 99% | 99% | 100% | |

| −102.00 | −108.20 | −92.87 | −113.20 | −108.80 | −92.27 | −110.20 | −102.10 | |

| 100% | 100% | 100% | 100% | 100% | 99% | 100% | 100% | |

| 30% | −65.59 | −72.18 | −66.29 | −63.74 | −67.26 | −63.48 | −65.90 | −68.75 |

| 104% | 107% | 105% | 100% | 98% | 99% | 99% | 100% | |

| −102.00 | −108.20 | −92.91 | −113.20 | −108.80 | −92.26 | −110.20 | −102.10 | |

| 100% | 100% | 100% | 100% | 100% | 100% | 100% | 100% | |

| 10% | −65.62 | −72.24 | −66.42 | −63.74 | −67.21 | −63.45 | −65.86 | −68.74 |

| 104% | 107% | 105% | 99% | 98% | 99% | 99% | 100% | |

| −102.10 | −108.20 | −93.06 | −113.20 | −108.80 | −92.24 | −110.20 | −102.10 | |

| 100% | 100% | 100% | 100% | 100% | 99% | 100% | 100% |

| Percentage of Preload | CA | CD | CB | CE | FD | FE | FH | FG | IG | IH |

|---|---|---|---|---|---|---|---|---|---|---|

| IJ | IK | LM | LN | LD | LG | OE | OH | OP | OQ | |

| 100% | 41.78 | −29.33 | 40.98 | −29.47 | 10.35 | 9.27 | 9.17 | 8.99 | −28.33 | −29.33 |

| 41.09 | 40.86 | 6.326 | −6.59 | 15.52 | 15.62 | 15.78 | 16.18 | −7.58 | 6.77 | |

| 90% | 42.77 | −30.01 | −40.63 | −28.31 | 12.25 | 7.885 | 8.126 | 9.63 | −29.64 | −28.56 |

| 102% | 102% | 99% | 96% | 118% | 85% | 89% | 107% | 105% | 97% | |

| 41.99 | 40.62 | −7.23 | −7.95 | 17.11 | 16.76 | 15.74 | 16.24 | −7.61 | 6.84 | |

| 102% | 99% | 114% | 121% | 110% | 107% | 100% | 100% | 100% | 101% | |

| 70% | 43.5 | −31.14 | 40.43 | −27.65 | 12.8 | 6.94 | 7.20 | 10.26 | −30.6 | −27.92 |

| 104% | 106% | 99% | 94% | 124% | 75% | 79% | 114% | 108% | 95% | |

| 42.75 | 40.33 | −8.05 | −8.65 | 17.69 | 17.35 | 15.75 | 16.26 | −7.64 | 6.82 | |

| 104% | 99% | 127% | 131% | 114% | 111% | 100% | 100% | 101% | 101% | |

| 50% | 43.65 | −30.94 | 40.32 | −27.46 | 13.51 | 6.63 | 6.97 | 10.38 | −30.94 | −27.73 |

| 105% | 106% | 98% | 93% | 131% | 72% | 76% | 116% | 109% | 95% | |

| 42.98 | 40.25 | −8.25 | −9.038 | 18.21 | 17.54 | 15.77 | 16.26 | −7.65 | 6.82 | |

| 105% | 99% | 130% | 137% | 117% | 112% | 100% | 101% | 101% | 101% | |

| 30% | 43.78 | −31.13 | 40.31 | −27.33 | 13.65 | 6.46 | 6.82 | 10.47 | −31.07 | −27.63 |

| 105% | 106% | 98% | 93% | 132% | 70% | 74% | 117% | 110% | 94% | |

| 43.09 | 40.21 | −8.39 | −9.157 | 18.34 | 17.64 | 15.76 | 16.27 | −7.65 | 6.82 | |

| 105% | 98% | 133% | 139% | 118% | 113% | 100% | 101% | 101% | 100% | |

| 10% | 43.93 | −31.31 | 40.32 | −27.17 | 13.86 | 6.27 | 6.70 | 10.56 | −31.18 | −27.56 |

| 105% | 107% | 98% | 92% | 134% | 68% | 73% | 118% | 110% | 94% | |

| 43.19 | 40.17 | −8.53 | −9.29 | 18.54 | 17.75 | 15.75 | 16.29 | −7.65 | 6.83 | |

| 105% | 98% | 135% | 141% | 120% | 114% | 100% | 101% | 101% | 101% |

| Percentage of Preload | CF | FI | LF | FO |

|---|---|---|---|---|

| 100% | 74.73 | 74.89 | 29.65 | 30.07 |

| 90% | 74.72 | 74.99 | 26.96 | 30.29 |

| 100% | 100% | 91% | 101% | |

| 70% | 74.79 | 75.06 | 25.10 | 30.57 |

| 100% | 100% | 85% | 102% | |

| 50% | 74.75 | 75.11 | 24.48 | 30.66 |

| 100% | 100% | 83% | 102% | |

| 30% | 74.76 | 75.12 | 24.18 | 30.72 |

| 100% | 100% | 82% | 102% | |

| 10% | 74.76 | 75.12 | 23.86 | 30.78 |

| 100% | 100% | 81% | 102% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pan, Z.; Wang, H.; Yang, Y.; Li, W.; Shang, J.; Gu, Z. The Effect of Preload Loss on the Mechanical Properties of Grid Structure Connected with Bolted-Ball Joints. Buildings 2023, 13, 1178. https://doi.org/10.3390/buildings13051178

Pan Z, Wang H, Yang Y, Li W, Shang J, Gu Z. The Effect of Preload Loss on the Mechanical Properties of Grid Structure Connected with Bolted-Ball Joints. Buildings. 2023; 13(5):1178. https://doi.org/10.3390/buildings13051178

Chicago/Turabian StylePan, Zuanfeng, Hao Wang, Yichao Yang, Wendi Li, Jiaqi Shang, and Zhengyu Gu. 2023. "The Effect of Preload Loss on the Mechanical Properties of Grid Structure Connected with Bolted-Ball Joints" Buildings 13, no. 5: 1178. https://doi.org/10.3390/buildings13051178

APA StylePan, Z., Wang, H., Yang, Y., Li, W., Shang, J., & Gu, Z. (2023). The Effect of Preload Loss on the Mechanical Properties of Grid Structure Connected with Bolted-Ball Joints. Buildings, 13(5), 1178. https://doi.org/10.3390/buildings13051178