Abstract

A large amount of industrial solid waste is generated from industrial activities worldwide. One such waste is marble waste, a waste generated from quarries which is generated in larger amount which needs attention. It is proved that this waste has a significant impact both on the people health and on the environment. Hence, research works are directed towards addressing usage of waste marble power, the aim of this experimental investigation is to study the usability of sand obtained by crushing marble waste (MWS) on the mixing of lightweight concrete based on expanded perlite aggregate (EPA). First, the mechanical, chemical, and physical properties of marble waste sand and expanded perlite aggregate were determined after which different mixtures of concrete are prepared by varying the percentage of EPA (0, 20, 40, 60, 80, and 100%), in order to find the optimum mixture focussing on obtaining best hydraulic properties. Also, in this work, the thermal and acoustic properties (thermal conductivity, thermal diffusivity, specific heat capacity and sound reduction index at different frequencies) of the tested concrete samples were investigated. Results shows that it is possible to obtain thermal and acoustic insulation lightweight concrete by using sand obtained by crushing marble wastes. Also, addition of more than 20% of EPA aggregate in concrete, develops a thermal insulating lightweight concrete which possess capacity to store heat and produce better thermal performance. Concrete blend with a percentage of more than of 20% of EPA aggregate can be placed in the category of acoustic insulation lightweight concrete. In summary, cement based on MWs and EPA provides better workability and energy saving qualities, which are economical and environmentally beneficial and may result in decreased construction budget and improve a long-term raw materials sustainability.

1. Introduction

Recycling industrial solid waste has recently become an important and effective way to address ecological and economic constraints worldwide [1,2,3,4,5]. As it is known, solid wastes are considered as an inevitable problem which human race is facing in recent decade [6]. Recently, bountiful research works done indicates that the main solution of this problem is to recycling these wastes in order, first, to meet the deficit between production/consumption ratio and, second, to protect the surround environment [7]. Many local and international regulations have emphasized the need to examine waste recycling and land filling methods to minimize its negative impacts. A review of the literature done by authors indicates that many investigations have focused on solid waste to reach more environmental efficiency and applicable materials and also solutions for utilizing them in productive way is discussed. The huge increase in the popularity of using environmentally friendly, low-cost and dangerous materials in the productivity of building materials has led to the need for a deep investigation of how to achieve this on a large scale by harnessing the environment as well as preserving the materials and confirming the requirements within acceptable limits according to cement and concrete specs [8]. Many waste materials were found to have potential usage in addition as binder, filler, reinforcing agent in construction materials. One of solid wastes studied in detail is marble wastes generated from marble cutting and polishing industries. The main method of reuse of marble wastes is its incorporating in concrete as a replacement of natural aggregates or supplementary cementitious material [9,10,11]. Results obtained by various researchers show an increase in the compressive strength of cement/concrete at different ages. Additionally, others results show that incorporating marble aggregate on concrete develops a significant decrease in its workability and durability [12,13]. Alternatively, results of previous research have indicated that the addition of marble aggregates on concrete as a substitution of raw aggregates improved both compressive, tensile and flexural strengths and on the Young’s modulus [14].

Additionally, the addition/replacement of marble powder remarkably improves the durability of concrete or self-compacting concrete when it is added to the cementitious matrix as hydraulic additives [15]. Also, results indicate that the carbonation resistance is not affected by adding marble powder on mix. The reuse of marble powder as a mineral filler, on self-compacting concrete, has sonically improved its mechanical properties both in the fresh state and in the late setting [16]. Alternatively, several research’s demonstrate the efficiency of using common aggregate in a granular matrix to obtain insulating lightweight concrete [17] and fire—resistant concrete [18,19]. The recycling of marble waste is an area of potential for engineers to explore and utilize, as the volume of accumulated waste is around 200 million tons annually worldwide [20,21]. It is very evident that only very less companies recycle marble waste, that too for a specific purpose. It is obligatory to enhance integrated and sustainable solutions for managing marble waste to preserve material resources such as minerals and ores. Increasing the resource productivity and improving the reuse and recycling of materials in a way that reduces the depletion of raw resources, preserves the environment and contributes to achieving development and environmental sustainability goals [22,23,24,25]. The operation includes the collection, transportation, sorting and recycling of waste emitted from quarries and demolition construction works, benefiting from building materials, recycling and reusing them at the project site to reduce transportation costs, disposal of waste, preserve natural resources and benefit in a manner that achieves the requirements of the leadership system in energy and environmental designs. Hence it is very evident that utilization of marble waste for construction material development purpose, in particular to unstudied area is need of the hour, keeping this in mind, this work is designed.

The main purpose of this study is to investigate of the reuse of marble waste as a sand added to EPA aggregate concrete to produce an insulation lightweight concrete with prime focus on developing thermal insulation characteristics. The first part of this paper consists of investigates the physical and chemical properties of sand obtained by crushing marble wastes (MWs) and Expanded Perlite Aggregates (EPA). The second part consists of studies related to the physical, thermal and acoustic properties of different concrete mixtures prepared by varying the percentage of EPA aggregate as a substitution of the MWS sand dosage.

2. Materials and Methods

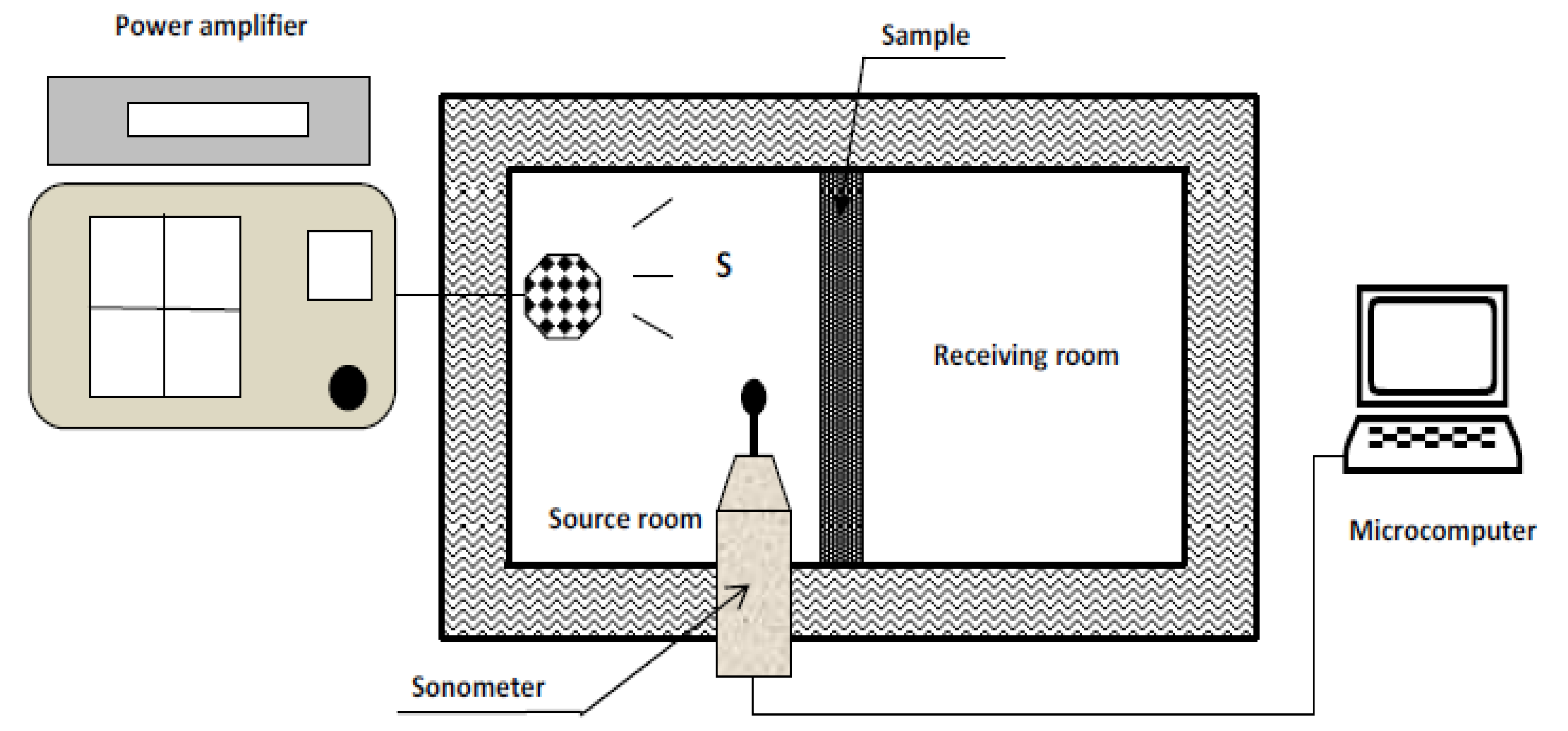

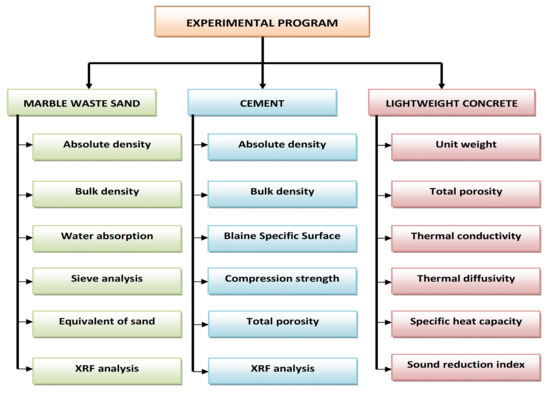

2.1. Experimental Flowchart

In the current lab program, study is done to understand the usability of powder (sand) obtained by crushing marble wastes to prepare a thermal and acoustic insulate lightweight concrete. The flow chart of this experimental program is shown in Figure 1.

Figure 1.

Flow chart of the experimental program.

2.2. Materials

2.2.1. Expanded Perlite Aggregate (EPA)

Expanded Perlite Aggregate (EPA) generally contains 70% to 80% of silicon dioxide and from 12% to 16% of alumina. Physical and mechanical properties of used materials; CEM I 42.5 MPa, marble waste sand samples and EPA are tabulated in Table 1.

Table 1.

Physical and mechanical properties of materials.

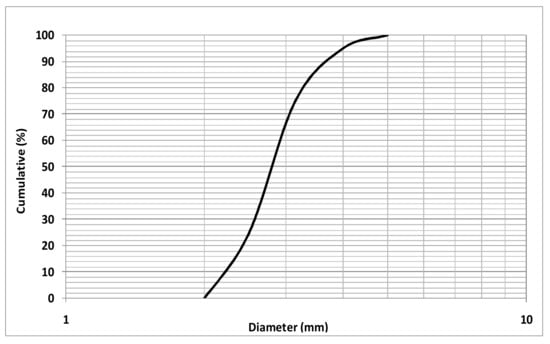

A sieve analysis was carried out on Expanded Perlite Aggregates (EPA) sample according to the requirements of the standard elsewhere [26]. The curve of the grain size distribution of the Expanded Perlite Aggregates (EPA) is shown in Figure 2.

Figure 2.

Particle size distribution curve of Expanded Perlite Aggregates (EPA).

2.2.2. Marble Waste Sand “MWS”

Marble waste used in this work is obtained by crushing to small sizes as possible by using a hammer as shown visually in Figure 3. crushed pieces of marble were grained in the jaw crusher machine. Marble powder is then prepared by sieving it on 63-µm mesh till reach fine particle size.

Figure 3.

Preparation of Marble Wastes Sand “MWS”.

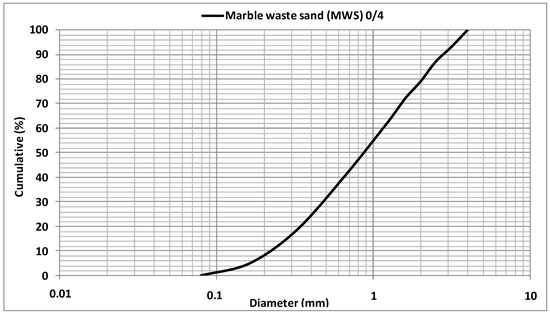

A sieve analysis was carried out on the MWS sample according to the requirements of the standard elsewhere [26]. The curve of the grain size distribution of the marble waste sand MWS is shown in Figure 4.

Figure 4.

Particle size distribution curve of marble waste sand MWS.

Detailed XRF analysis done for cement and ultrafine marble waste is shown in Table 2. Results show that the used MWS mainly composed of calcite (CaCO3) for about 94.20% which confirms that it is too rich in calcite. In addition to this MWS does not contains any organic matter.

Table 2.

XRF analysis of cement CEM I 42.5, and marble waste (MWS).

2.2.3. Cement

2.2.4. Superplasticizer

To improve the workability of the lightweight concrete, a superplasticizer (SP) was used. The SP/cement ratio was established with a Marsh cone test in accordance with the standard NF P18-507 [28]. The result shows that this ratio is equal to 1%.

2.3. Methods

2.3.1. Preparation and Testing Methods

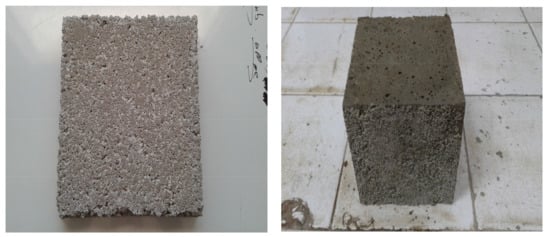

During this experimental investigation, specimens’ plate and cubic shapes were prepared by varying EPA proportion to percentages in the range of 0% to 60% by substituting the sand volume as shown in Figure 5. Cubic specimens with dimensions of 100 × 100 × 100 mm were used to calculate unit weight and also for total porosity measurement tests. A 270 × 270 × 40 mm plate specimen was used for 36 thermal conductivity and thermal diffusivity measurements. Finally, a plate specimen with dimensions of 700 × 700 × 50 mm was used to determine the sound reduction index [29,30]. All experimental tests were carried out at the age of 28 days of curing done in ambient temperature. The composition of the different mixtures of the lightweight concrete with EPA and MWS are presented in Table 3. LC0, LC10, LC20, LC30, LC40, LC50 and LC60 respectively, are the mixtures with adding 0%, 10%, 20%, 30%, 40%, 50% and 60% of EPA, respectively. Water/cement ratio (W/C) is varied from 0.33 to 0.60 taken account of total porosity of the blends [30]. In addition, as mentioned in Table 3, a percent of 1.0% of super-plasticizer was added to the blends to improve its workability in order to enhance specimens casting.

Figure 5.

Plate and cubic concrete specimens.

Table 3.

Mix composition of proposed lightweight concrete blends (As Addition).

Since the aggregate of EPA are very sensitive and very brittle, a specific mixing process was used as following:

- Mix sand and cement until homogenization.

- Water mixing with the SP.

- Add water with SP and mix at automatic mixer.

- Add EPA aggregate until complete homogenization.

- Oiling inside portion of the mould.

- Casting the mold and allowing it for 24 h before demoulding.

2.3.2. Unit Weight and Total Porosity Measurements

The unit weight and total porosity of the different lightweight concrete mixtures were measured using cubic samples with dimensions of 100 × 100 × 100 mm this according to the requirements of the standard NF ISO-5017 [31] Based on three different weightings, first, the dried sample was weighted (m1), after that, the sample is weighted after eliminating the air, using a desiccator, and saturated in a water tank for 72 h: denoted (m2). Third, the saturated sample is wiped superficially to remove surface water: denoted (m3). Finally, the sample total porosity is given as follow:

2.3.3. Thermal Conductivity Measurement

The thermal conductivity is defined as the amount of heat which is transferred in one unit time through a material of one surface unit and one unit of thickness, when the two opposite faces differ by one unit of temperature. The specimen thermal conductivities of all lightweight concretes were measured using the boxes method by using plate samples with a dimension of 270 × 270 × 40 mm. This test was carried out according to the requirements of the standard NF EN ISO 8990 [32]. The experimental thermal conductivity was determined using the following equation

where:

- ▪ U is the electric tension in V;

- ▪ S is the plate sample section in m2;

- ▪ T1, T2, TB and Ta are the temperatures measured using platinum temperature sensors in K; R is the heater in Ω; and C is the overall heat transfer coefficient.

2.3.4. Thermal Diffusivity Measurement

Thermal diffusivity is defined as the heat propagation speed by conduction in a material. It is totally related to both the thermal capacity and the thermal conductivity of the material. A thermal diffusivity measurement test consists measure the response of the transient thermal of the material due to a temperature change. Noticed that good diffuser material of thermal energy is a material with a high thermal diffusivity. In the contrary, a material with low thermal diffusivity is considerate as a much slower diffusing thermal energy material. In the same thermal conductivity test, the thermal diffusivity measurement was carried out on plate specimens with dimensions of 270 × 40 mm using the Box method. The principle of the method consists of emitting a heat flux, for a few seconds using the lamp, on one face of the sample. Thermal diffusivity was determined from the temperature variation in the non-irradiated surface of the sample. The value of the thermal diffusivity of each specimen of lightweight concrete is determined using the approximate expressions of Degiovanni model [33] as follows:

where:

- ▪ e is the specimen thickness

- ▪ t1/3, t1/2, t2/3, and t5/6 are respectively the partial times for 1/3, 1/2, 2/3 and 5/6 of the maximum value of the temperature [33]. Finally, the thermal diffusivity of the sample is given by an average of the three values [33]:

2.3.5. Specific Heat Capacity Measurement

Generally, the specific heat capacity (Cp) of a material is defined as the required heat amount that is able to raise the temperature by one degree of the material mass unity. It is noticed that a material with more heat energy must increase the substance temperature with high specific heat capacity than when using a material with a low specific heat capacity. The value of the specific heat capacity of a material depends on both its thermal diffusivity, thermal conductivity and on its unit weight. This value is given by the following expression:

where:

- ▪ ρ is the unit weight in kg/m3

- ▪ λexp is the thermal conductivity in W/m.K

- ▪ αexp is the experimental thermal diffusivity in m2/s

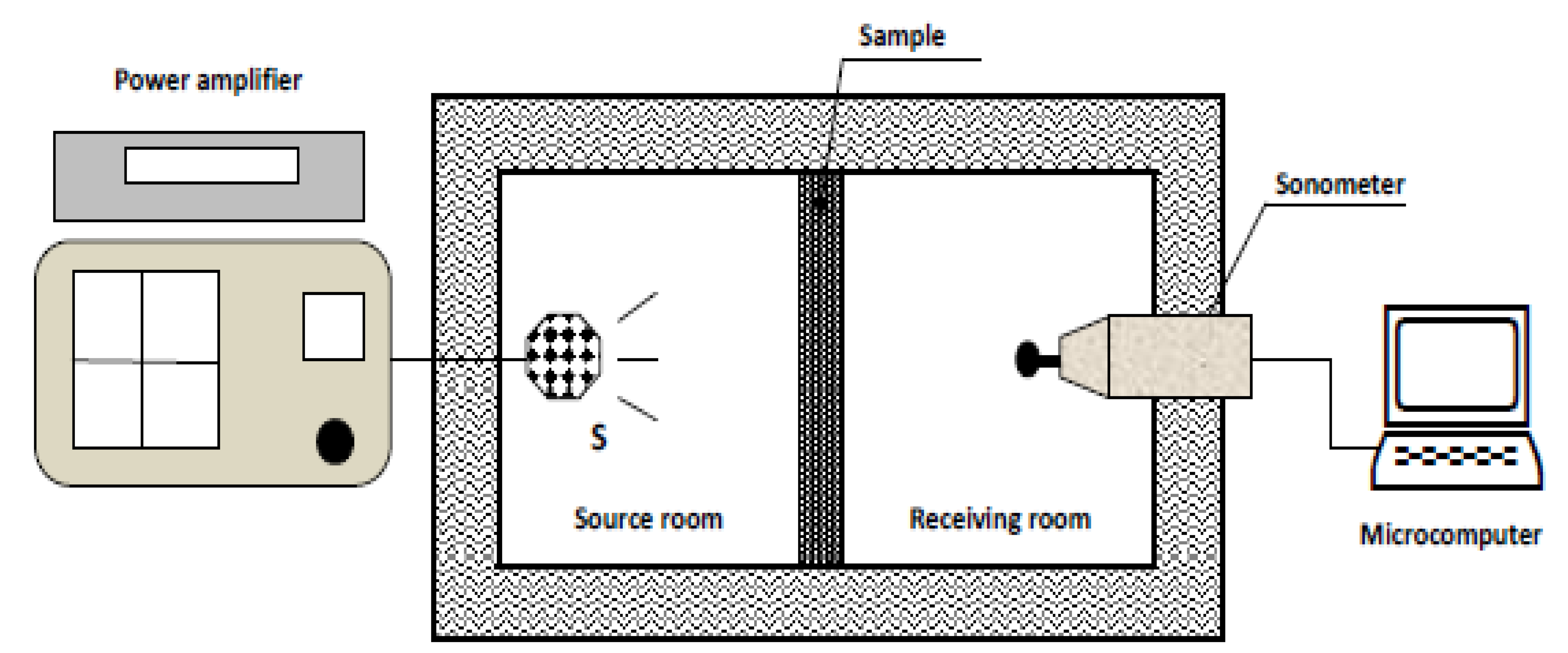

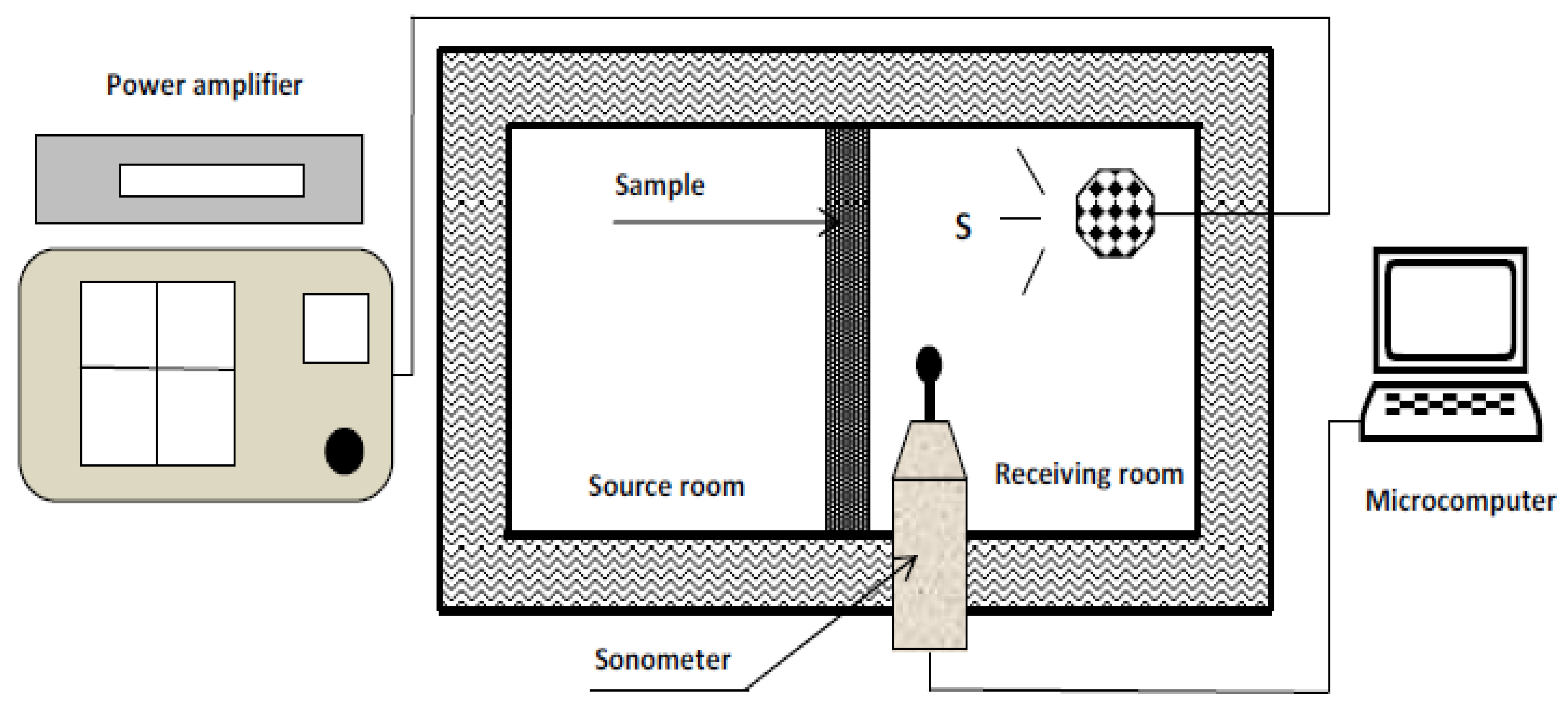

2.3.6. Sound Reduction Index Measurement

Generally, the sound reduction index “RW” qualifies the acoustic protection qualities of a material for a different set of standardized noises. Also, it is noticed that when the sound reduction index is high, the material sound insulation is high. The sound reduction index measurement process is presented in Table 4. Also, it is evident that the reverberation time Tr is frequently stated as a single value, if measured as a wide band signal (20 Hz to 20 kHz). In this study, the sonometer measures the reverberation time for a signal to drop by 30 dB. The reverberation time for a signal to drop by 60 dB was determined by multiplying the value of the reverberation time by 2 to decrease it by 30 dB. The sound reduction index is determined, plate specimens with a dimensions 700 × 700 × 50 mm, according to the specs of both standards ISO 16283 [34] and ISO 140 [35] using the following expression:

where:

Table 4.

Sound reduction index measuring process.

- ▪ Tr is the reverberation time in seconds in the receiving room

- ▪ S is the section of the plate specimen

- ▪ D is the level difference given as follow:where: L1 and L2, are the average sound pressure levels, in dB, in the source room and in the receiving room, respectively.

The reverberation time in the receiving room is calculated in seconds using Sabine’s formula with the following equation:

where:

- ▪ V is the receiving room volume in m3

- ▪ A is the equivalent absorption area in m2

3. Results and Discussions

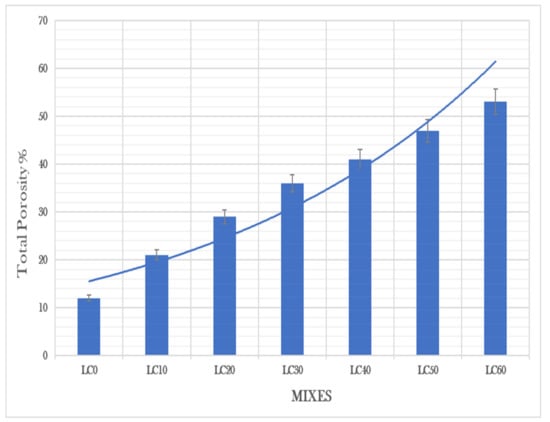

3.1. Effects of EPA Dosage on Total Porosity of the Lightweight Concrete

The results of total porosity test measurement of the different lightweight concrete specimens are shown in Figure 6. The results show that total porosity of lightweight concrete increased when increasing the percentage of EPA aggregate. As an example, total porosity increases from 12% for the concrete without EPA (LC0) to 53% for a concrete with 60% of EPA (LC60). This increase in porosity is due to the grain shape difference between that of EPA aggregate and that of MWS sand. Noticed that the EPA grain shape is spherical and in the contrary the MWS grain shape is angular. Indeed, the granular arrangement of concrete with high percentage of EPA gives a concrete with high void percentage and thereafter a high porosity. Finally, we can conclude that the substitution of MWS sand by EPA aggregate affects remarkably the concrete porosity.

Figure 6.

Effect of EPA aggregate dosage on total porosity of concrete specimens.

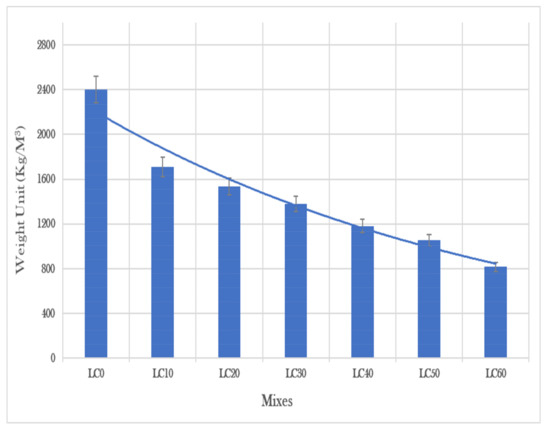

3.2. Effects of EPA Dosage on the Unit Weight of the Lightweight Concrete

The results of the unit weight measurement are presented in Figure 7. The presented results show that the unit weight of lightweight concrete specimen decreases with an increase in EPA dosage. Indeed, the unit weight decreased from 1835 kg/m3 for concrete specimens with 0% EPA (LC0) to 815 kg/m3 for a concrete specimen containing a percentage of 60% of EPA (LC60). This is due, first, to the low density of EPA which is about 70 kg/m3 compared to then of marble wastes aggregate (2650 kg/m3). Additionally, results presented in Figure 6 and Figure 7, shows that the unit weight decreases when the total porosity increases. Thus, with reference to the results obtained, the concrete with a percentage of EPA aggregate higher than 20% (LC30, LC40, LC50 and LC60) can be classified as lightweight concrete because their unit weights are lower than 1500 kg/m3. Additionally, their unit weights are found to be higher than 1500 kg/m3, the concrete with a percentage of 10 % and 20% of EPA (LC10) and (LC20) are classified as normal concrete.

Figure 7.

Effect of EPA aggregate dosage on the unit weight of concrete specimens.

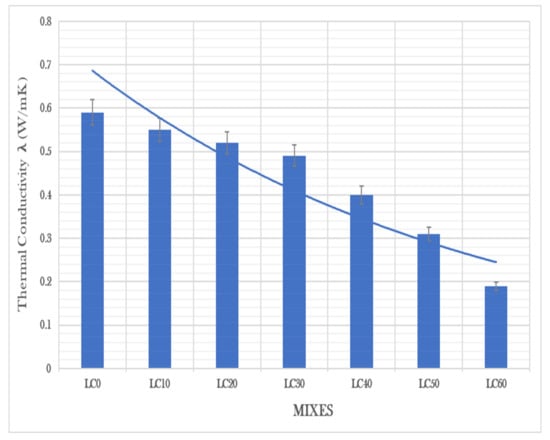

3.3. Effects of EPA Dosage on the Thermal Conductivity of the Lightweight Concrete

The results of thermal conductivity measurements of the different concretes are presented in Figure 8, in the dry state, as a function of SWM percentage. The obtained results show that the substitution of EPA aggregate in the granular matrix has a considerable influence on the thermal conductivity of the tested concrete. Indeed, the thermal conductivity of concrete specimen decreases when increasing the EPA aggregate percentage. Noticed that the thermal conductivity decreases from 0.59 W/mK for concrete specimens with 0% EPA (LC0) to 0.19 W/mK for the concrete specimens containing a percentage 60% of EPA (LC60). This result was due to the main causes. The first is the insulating property of the EPA aggregate, which has a very low thermal conductivity of about 0.040 W/m.K. The second cause is that when the EPA percentage increases, the porosity increases and after that, the thermal conductivity decreases because of the very low thermal conductivity of the air content at about 0.02 W/mK [25]. Another conclusion is that the thermal conductivities of tested concrete are strongly affected by the used aggregates and especially by their thermal conductivities, which are 0.04 W/mK and 2.9 W/mK [36] for EPA aggregate and MWS sand, respectively.

Figure 8.

Effect of EPA aggregate dosage on the thermal conductivity of concrete specimens.

In addition, results presented in Figure 7 and Figure 8, it shows that it decreases with the decreasing unit weight of the concrete specimen. For example, thermal conductivity and unit weight of concrete LC20 are 0.52 W/m.K and 1535 kg/m3, respectively and they are equal 0.19 W/m.K and 815 kg/m3, respectively for the concrete LC60 containing 60% of EPA aggregate. Finally, the concrete mixtures can be classified into two categories: The category of thermal insulation lightweight concrete for a percentage of 30, 40, 50 and 60% of EPA with a thermal 0.19 W/mK ≤ λ ≤ 0.49 W/mK. The category of non insulation normal concrete for a percentage 0%, 10% and 20% with a thermal conductivity higher then 0.50 W/mK.

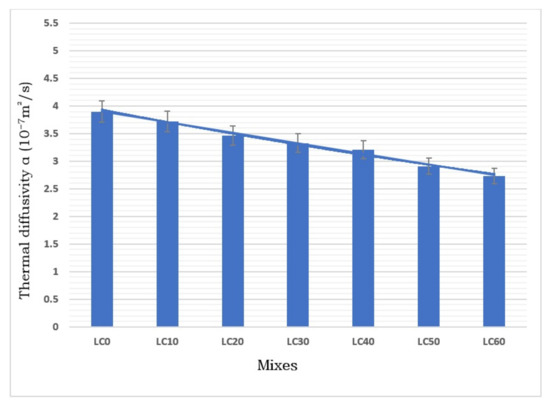

3.4. Effects of EPA Dosage on the Thermal Diffusivity of the Lightweight Concrete

Figure 9, presents the results of thermal diffusivity measurements of the seven concrete mixtures. The substitution of MWS sand by EPA aggregate in the granular matrix had a remarkable influence on the thermal diffusivity of the tested concrete. Results show that thermal diffusivity decreases with the increasing EPA aggregate percentage of addition. For example, thermal diffusivity range from 3.95 × 10−7 m2/s for concrete without EPA aggregate (LC0) to 2.65 × 10−7 m2/s when substited the MWS sand with 60% EPA aggregate (LC60). As a conclusion, thermal diffusivity of concrete depends on the thermal characteristics of the EPA aggregate and MWS sand because cement, water and SP dosage are maintained constant. Additionally, the results presented in Figure 8 and Figure 9, show that the reduction in thermal conductivity conducts a reduction in thermal diffusivity. Indeed, thermal diffusivity and conductivity are proportional. This is due the decrease of specimen unit weight. For example, the concrete LC30 containing 30% EPA aggregate produced 6% reduction in thermal conductivity and 16% reduction in thermal diffusivity compared to those of the specimens without EPA aggregate.

Figure 9.

Effect of EPA aggregate dosage on the thermal diffusivity of concrete specimens.

Also, the air entrainment has a remarkable contribution in the reduction of the thermal diffusivity of the different tested mixtures. For example, thermal diffusivity decreases from 3.47 × 10−7 m2/s for concrete with 20% EPA (LC20) with a total porosity of 29% to 2.97 × 10−7 m2/s for concrete with 50% EPA (LC50) with a total porosity of 47%. Finally, the decrease in thermal diffusivity improves the thermal insulation of the tested lightweight concrete. This improvement can be explained by the obtained rate at which heat travels by conduction through the body. Indeed, if thermal diffusivity is low, more heating across the thickness of material is becoming mandatory.

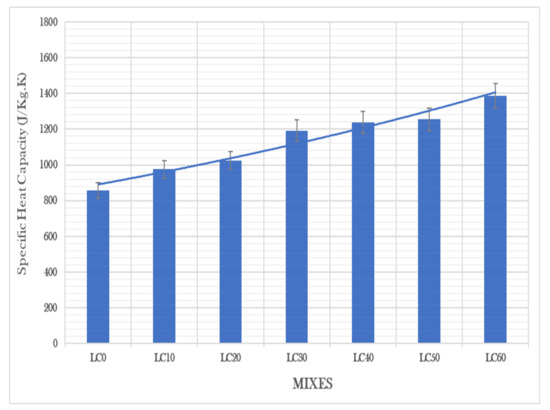

3.5. Effects of EPA Dosage on the Specific Heat Capacity of the Lightweight Concrete

The influence of EPA aggregate dosage on the specific heat capacity of the tested mixtures is presented in Figure 10. The illustrated results shows that the specific heat capacity of the different tested concretes increases when increasing the EPA aggregate percentage. According to the results presented in Table 4, the specific heat capacity increases from 858 J/kg.K, for the reference concrete without EPA aggregate (LC0), to 1297 J/kg.K for the concrete containing 60% of EPA and 40% of MWS (LC60). This may be attributed to:

Figure 10.

Effect of EPA aggregate dosage on specific heat capacity of concrete specimens.

The low heat capacity of marble sand (798 J/kg.C) compared to then of EPA aggregate.

The increase of porosity, caused by adding EPA aggregate, tends to decrease the thermal conductivity of lightweight concrete. This reduction increases with the increase in the mass fraction of EPA aggregate and the decrease of MWS sand. This can be explained by that the thermal conduction in a porous material result from the thermal properties of the solid phase and the interconnected pores, knowing that the granular skeleton conductivity is greater than that of the air [37].

Finally, it is noticed that in a more porous material, the conduction surface of the solid decreases with the increasing air content. However, the heat flux is proportional to the conduction surface. It requires more energy and higher specific heat to increase the temperature of a more porous concrete.

Results also shows that the specific heat capacity and the thermal resistance varied in the opposite direction. As an example, the adding 40% of EPA aggregate to the concrete mixture gives an increase for about 44% in specific capacity and a reduction for about 32% in thermal conductivity [36]. Finally, we can conclude that adding more than 30% of EPA aggregate gives a thermal insulating lightweight concrete that can be considerate as a material capacity to store heat and produce better thermal performance.

3.6. Effects of EPA Dosage on the Sound Reduction Index of the Lightweight Concrete

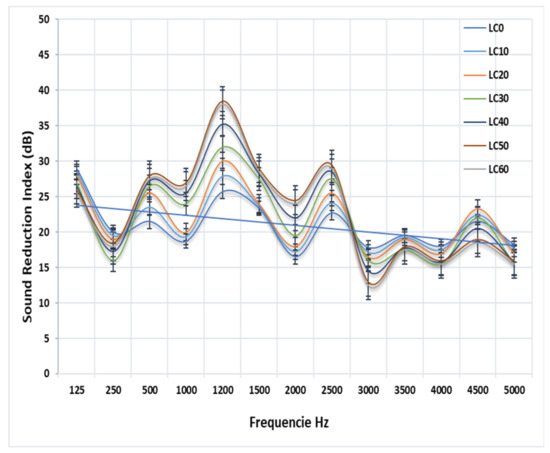

In this section the results of the effects of substitute MWS sand by EPA aggregate on the sound reduction index of concrete are presented and discussed. Figure 11 illustrates the sound reduction index variation with different frequencies, varied from 125 Hz to 5000 Hz, for the seven tested concrete specimens LC0, LC10, LC20, LC30, LC50 and LC60. Noticed the principle of the used method consists of the frequency value of airborne sound insulation converted into a single number. This obtained value characterizes the acoustical performance of the concrete specimen.

Figure 11.

Effect of EPA aggregate dosage on sound reduction index of concrete specimens.

Then, all obtained data were compared to the reference values offered by the standard ISO 717-1 [38] within the frequency range of 125 Hz to 5000 Hz [34,39]. According to the results presented in Figure 8, the EPA aggregate dosage as a replacement of MWS sand has a remarkable effect on the sound reduction index of concrete specimen. As an example, for the frequency of 1500 Hz, the substitution of 50% of MWS sand by EPA aggregate conduct to an increase in the sound reduction index for about 26% and it conducts to reduction for about 11% for the frequency of 5000 Hz. This result is logical since the sound reduction index of a material always increases with its mass. The results also indicate that the sound reduction index of the concrete specimen’s decreases compared to the reference concrete (LC0) for the frequency range from 3000 to 5000 Hz. As a conclusion, the insulation lightweight concretes are found to be useful in conditions with low frequencies. Finally, the comparison of the obtained results of the sound reduction index of the different tested concretes specimens with that of other lightweight concretes types shows that the specimens LC30, LC40, LC50, and LC60 can be placed in the category of acoustic insulation lightweight concrete and this according to the requirements of the standard ASTM C 332 [40].

4. Conclusions

Solid waste recycling is the main challenge nowadays. Reaching sustainability in raw material resources are the sustainable development goals of industry, innovation and infrastructure. The current practical investigation based on Vision 2050, to reduce raw material consumption and carbon dioxide emissions in concrete manufacturing. This work presented the results of an experimental investigation of the possibility reusing of fines (marble waste powder) to obtain both thermal and acoustic lightweight concrete. It is found that the total porosity of concrete specimens increased with the increasing percentage of EPA aggregate. The unit weight of concrete specimens dropped with the increase in EPA dosage. The tested concrete specimens are of two categories: The category of thermal insulating lightweight concrete for a percentage of higher than 20% of EPA and the other category of non-insulation normal concrete for a percentage lower than 20% of EPA aggregate. Furthermore; addition of EPA aggregate on concrete decreases thermal diffusivity, which improves the thermal insulation of the lightweight concrete. Also, addition of more than 20% of EPA aggregate in concrete, gives a thermal insulating lightweight concrete which posses capacity to store heat and produce better thermal performance. We conclude that; concrete blend with a percentage of more than of 20% of EPA aggregate can be placed in the category of acoustic insulation lightweight concrete.

Author Contributions

Data curation, O.B. and M.A.A.; Formal analysis, O.B. and G.R.; Investigation, O.B., M.A.A. and G.R.; Methodology, O.B., M.A.A. and G.R.; Resources, O.B. and G.R.; Writing original draft, M.A.A. All authors have read and agreed to the published version of the manuscript.

Funding

The authors extend their appreciation to the Deputyship for Research & Innovation, Ministry of Education in Saudi Arabia for funding this research work through the project number (IF2/PSAU/2022/01/22684).

Data Availability Statement

No data, models or code were generated or used during the study.

Conflicts of Interest

The authors declare no conflict of interest.

References

- El-Kattan, I.M.; Abdelzaher, M.A.; Farghali, A.A. Positive impact of ultra fine-ceramic waste on the physico-mechanical features and microstructure of white cement pastes composites. J. Mater. Res. Technol. 2020, 9, 9395–9402. [Google Scholar] [CrossRef]

- Kherbache, S.; Bouzidi, N.; Bouzidi, M.A.; Moussaceb, K.; Tahakourt, A.K. The behavior of the concretes and mortars reinforced by metallic fibers wastes as substitution of cement. J. Mater. Environ. Sci. 2016, 7, 18–29. [Google Scholar]

- Vardhan, K.; Siddique, R.; Goyal, S. Influence of marble waste as partial replacement of fine aggregates on strength and drying shrinkage of concrete. Constr. Build. Mater. 2019, 228, 116730. [Google Scholar] [CrossRef]

- Saleh, H.; Al-Kahlidi, M.M.A.; Abulridha, H.A.; Banoon, S.R.; Abdelzaher, M.A. Current situation and future prospects for plastic waste in maysan governorate: Effects and treatment during the COVID-19 pandemic. Egypt. J. Chem. 2021, 64, 4449–4460. [Google Scholar] [CrossRef]

- Kore, S.D.; Vyas, A.K.; Kabeer KI, S.A. A brief review on sustainable utilisation of marble waste in concrete. Int. J. Sustain. Eng. 2020, 13, 264–279. [Google Scholar] [CrossRef]

- Chaid, R.; Jauberthie, R.; Zeghiche, J.; Kherchi, F. Impact de la poudre de marbre conjuguée au calcaire du CEM II sur la durabilité du béton. Eur. J. Environ. Civ. Eng. 2011, 15, 427–445. [Google Scholar] [CrossRef]

- Hebhoub, H.; Aoun, H.; Belachia, M.; Houari, H.; Ghorbel, E. Use of waste marble aggregates in concrete. Constr. Build. Mater. 2011, 25, 1167–1171. [Google Scholar] [CrossRef]

- Kumaraswamy, J.; Kumar, V.; Purushotham, G. A review on mechanical and wear properties of ASTM a 494 M grade nickel-based alloy metal matrix composites. Mater. Today Proc. 2021, 37, 2027–2032. [Google Scholar] [CrossRef]

- Lasfar, S.; Moualli, F.I.; Latrach, A.; Chergui, M.; Choukir, A.; Diab, A. Resistance of two different types of concrete pipes used in sewer systems under sulfuric acid and sodium sulfate attacks. J. Mater. Environ. Sci. 2015, 6, 3002–3014. [Google Scholar]

- Tantawy, M.A.; El-Roudi, A.M.; Abdalla, E.M.; Abdelzaher, M.A. Fire resistance of sewage sludge ash blended cement pastes. J. Eng. 2013, 2013. [Google Scholar] [CrossRef]

- Lothenbach, B.; Scrivener, K.; Hooton, R.D. Supplementary cementitious materials. Cem. Concr. Res. 2011, 41, 1244–1256. [Google Scholar] [CrossRef]

- Kore, S.D.; Vyas, A.K. Impact of marble waste as coarse aggregate on properties of lean cement concrete. Case Stud. Constr. Mater. 2016, 4, 85–92. [Google Scholar] [CrossRef]

- Andre, A.; de Brito, J.; Rosa, A.; Pedro, D. Durability performance of concrete incorporating coarse aggregates from marble industry waste. J. Clean. Prod. 2014, 65, 389–396. [Google Scholar] [CrossRef]

- Talah, A.; Kharchi, F.; Chaid, R. Influence of marble powder on high performance concrete behavior. Procedia Eng. 2015, 114, 685–690. [Google Scholar] [CrossRef]

- Ulubeyli, G.C.; Bilir, T.; Artir, R. Durability properties of concrete produced by marble waste as aggregate or mineral additives. Procedia Eng. 2016, 161, 543–548. [Google Scholar] [CrossRef]

- Gesoğlu, M.; Güneyisi, E.; Kocabağ, M.E.; Bayram, V.; Mermerdaş, K. Fresh and hardened characteristics of self compacting concretes made with combined use of marble powder, limestone filler, and fly ash. Constr. Build. Mater. 2012, 37, 160–170. [Google Scholar] [CrossRef]

- Jedidi, M.; Benjeddou, O.; Soussi, C. Effect of expanded perlite aggregate dosage on properties of lightweight concrete. Jordan J. Civ. Eng. 2015, 9, 278–291. [Google Scholar] [CrossRef]

- Topçu, İ.B.; Işıkdağ, B. Manufacture of high heat conductivity resistant clay bricks containing perlite. Build. Environ. 2007, 42, 3540–3546. [Google Scholar] [CrossRef]

- Alyousef, R.; Benjeddou, O.; Soussi, C.; Khadimallah, M.A.; Jedidi, M. Experimental study of new insulation lightweight concrete block floor based on perlite aggregate, natural sand, and sand obtained from marble waste. Adv. Mater. Sci. Eng. 2019, 2019. [Google Scholar] [CrossRef]

- Gencel, O.; Bayraktar, O.Y.; Kaplan, G.; Arslan, O.; Nodehi, M.; Benli, A.; Gholampour, A.; Ozbakkaloglu, T. Lightweight foam concrete containing expanded perlite and glass sand: Physico-mechanical, durability, and insulation properties. Constr. Build. Mater. 2022, 320, 126187. [Google Scholar] [CrossRef]

- Abdelzaher, M.A. Experiential investigation on the effect of heavy fuel oil substitution by high sulfur petcoke on the physico-mechanical features and microstructure of white cement composites. Eng. Res. Express 2021, 3, 015028. [Google Scholar] [CrossRef]

- Bakshi, P.; Pappu, A.; Patidar, R.; Gupta, M.K.; Thakur, V.K. Transforming marble waste into high-performance, water-resistant, and thermally insulative hybrid polymer composites for environmental sustainability. Polymers 2020, 12, 1781. [Google Scholar] [CrossRef] [PubMed]

- Abdelzaher, M.A.; Shehata, N. Hydration and synergistic features of nanosilica-blended high alkaline white cement pastes composites. Appl. Nanosci. 2022, 12, 1731–1746. [Google Scholar] [CrossRef]

- Bakshi, P.; Pappu, A.; Bharti, D.K.; Patidar, R.; Gupta, M.K. Sustainable development of particulate reinforced composites by recycling marble waste for advanced construction applications: Ultra-low water absorption, remarkable thermal and mechanical behaviour. Waste Biomass Valorization 2021, 12, 6449–6464. [Google Scholar] [CrossRef]

- Khan, A.; Patidar, R.; Pappu, A. Marble waste characterization and reinforcement in low density polyethylene composites via injection moulding: Towards improved mechanical strength and thermal conductivity. Constr. Build. Mater. 2021, 269, 121229. [Google Scholar] [CrossRef]

- Abdelzaher, M.A. Performance and hydration characteristic of dark white evolution (DWE) cement composites blended with clay brick powder. Egypt. J. Chem. 2022, 65, 419–427. [Google Scholar] [CrossRef]

- EN 197-1; Cement–Part 1: Composition, Specifications and Conformity Criteria for Common Cements. AFNOR: Saint-Denis, France, 2000.

- NF P18-507; Additions for Concrete. Water Retention. Method for Measurement of Fluidity by Flowing with the Cone de Marsh. AFNOR: Saint-Denis, France, 1992.

- Lendvai, L.; Singh, T.; Fekete, G.; Patnaik, A.; Dogossy, G. Utilization of waste marble dust in poly (lactic acid)-based biocomposites: Mechanical, thermal and wear properties. J. Polym. Environ. 2021, 29, 2952–2963. [Google Scholar] [CrossRef]

- Rey, E.; Jongmans, D.; Gotteland, P.; Garambois, S. Characterisation of soils with stony inclusions using geoelectrical measurements. J. Appl. Geophys. 2006, 58, 188–201. [Google Scholar] [CrossRef]

- NF ISO 5017; Dense Shaped Refractory Products—Determination of Bulk Density, Apparent Porosity and True Porosity—Produits Réfractaires Façonnés Denses. AFNOR: Saint-Denis, France, 2013.

- NF EN ISO 8990; Thermal Insulation-Determination of Steady-State Thermal Transmission Properties-Calibrated and Guarded Hot Box. AFNOR: Saint-Denis, France, 1996.

- Jannot, Y.; Degiovanni, A. Thermal Properties: Measurement of Materials; Wiley editions: Hoboken, NJ, USA, 2018. [Google Scholar]

- ISO 16283-1; Acoustics: Field Measurement of Sound Insulation in Buildings and of Building Elements, Part 1: Airborne Sound Insulation. AFNOR: Saint-Denis, France, 2014.

- ISO 140-4; Acoustics: Measurement of Sound Insulation in Buildings and of Building Elements, Part 4: Field. AFNOR: Saint-Denis, France, 1998.

- Alyousef, R.; Jedidi, M.; Khadimallah, M.A.; Benjeddou, O.; Soussi, C. The Study of New Insulating Lightweight Concrete with Expanded Perlite Aggregate and Sand from Marble Waste. Adv. Mater. Sci. Eng. 2019, 2019, 8160461. [Google Scholar]

- Stephan, K.; Laesecke, A. The thermal conductivity of fluid air. J. Phys. Chem.Ref. Data 1985, 14, 227–234. [Google Scholar] [CrossRef]

- ISO 717-1; Acoustics: Rating of Sound Insulation in Buildings and of Building Elements, Part 1: Airborne Sound Insulation. AFNOR: Saint-Denis, France, 2013.

- Shawkey, M.A.; Abdelzaher, M.A.; Mahmoud, H.M.; Rashad, M.M. Monitoring of acoustic emission behaviour during early-age cement paste hydration. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2021; Volume 1046, p. 012020. [Google Scholar]

- ASTM C 332; Standard Specification for Lightweight Aggregates for Insulating Concrete. ASTM: West Conshohocken, PA, USA, 1999.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).