Impact of High-Performance Expansion and Shrinkage-Reducing Agents on the Mechanical Properties and Shrinkage Compensation of High-Strength Concrete

Abstract

:1. Introduction

2. Experimental Protocol

2.1. Test Materials

2.2. Matching Ratio

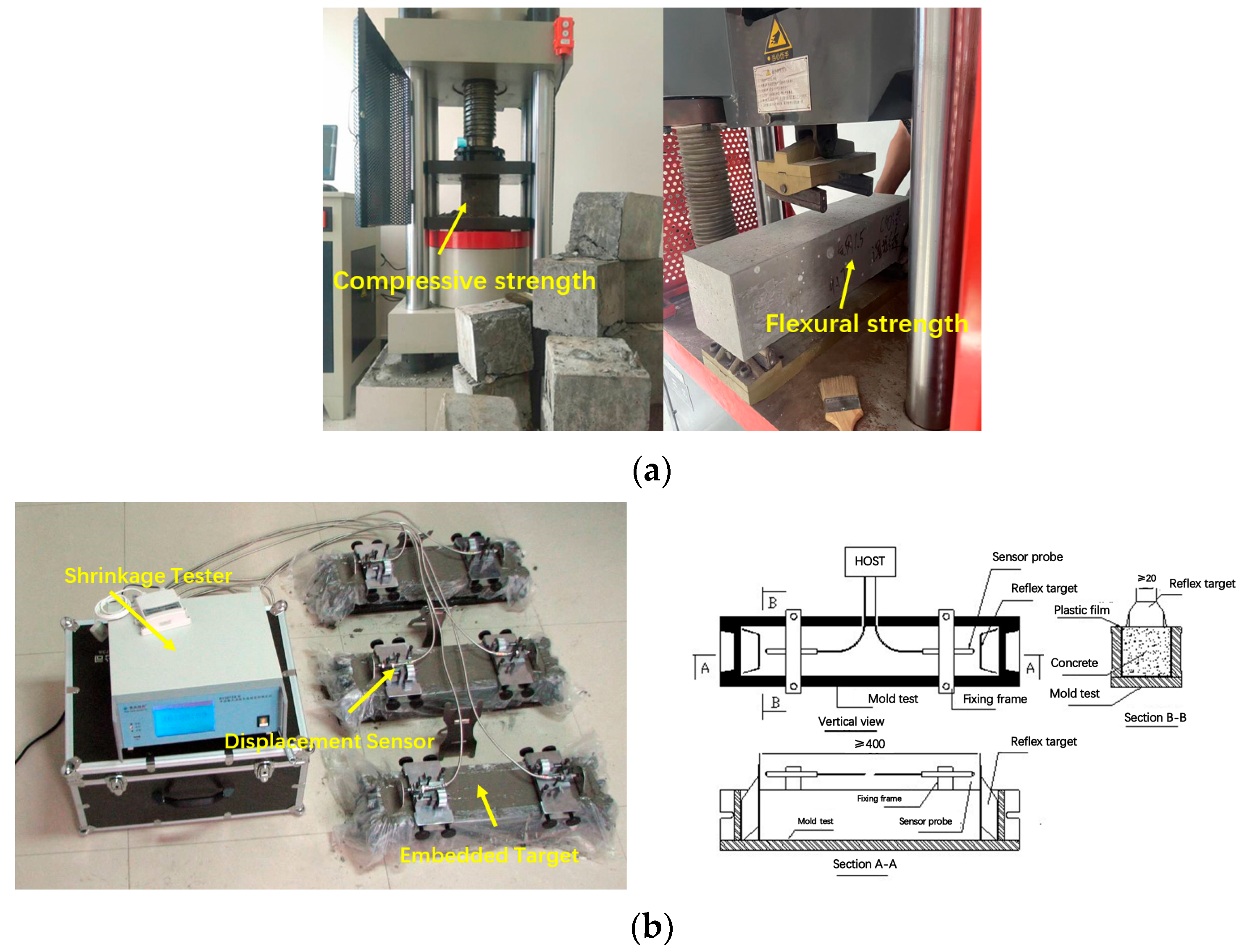

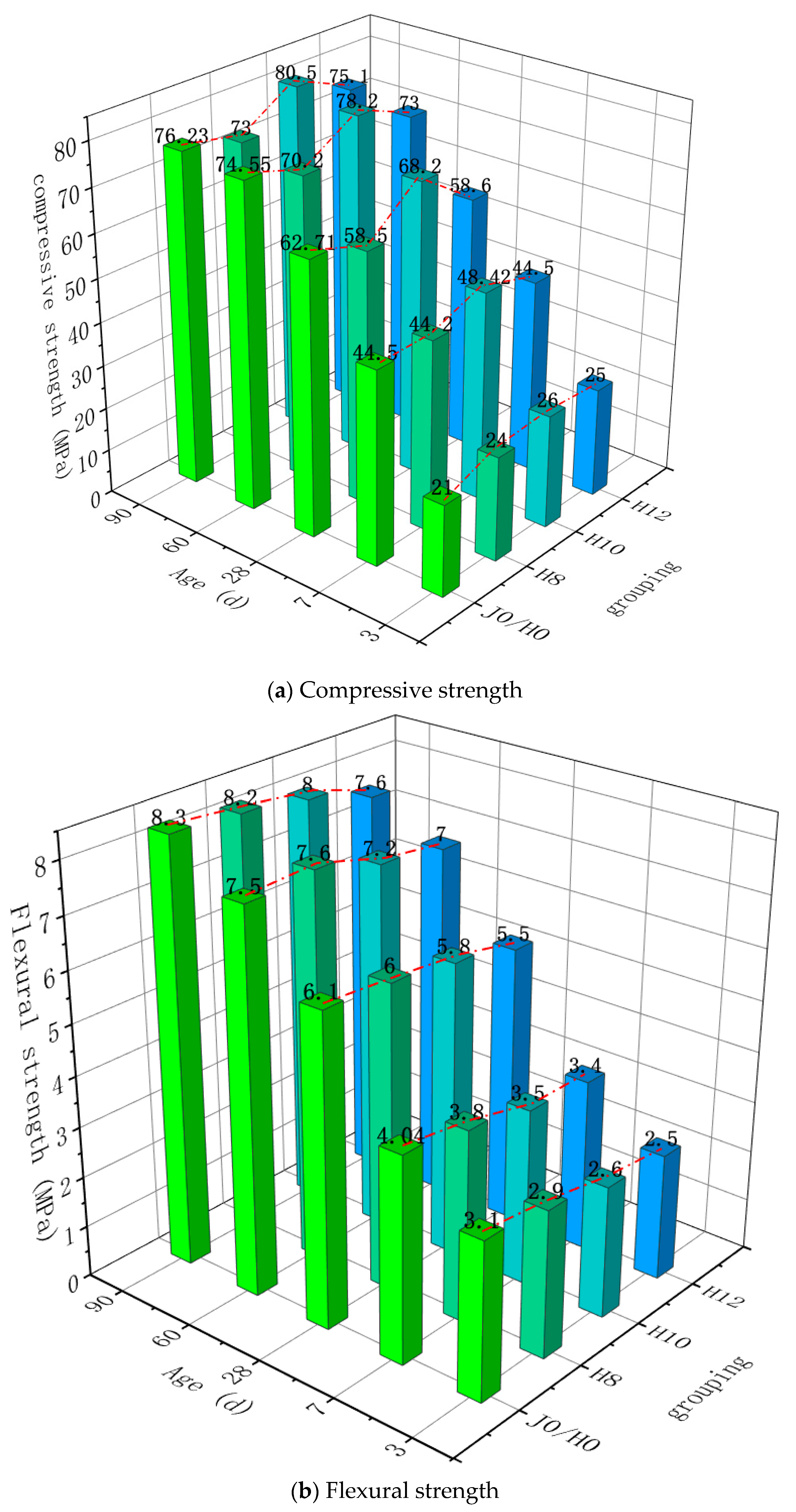

2.3. Test Method

3. Results and Analysis

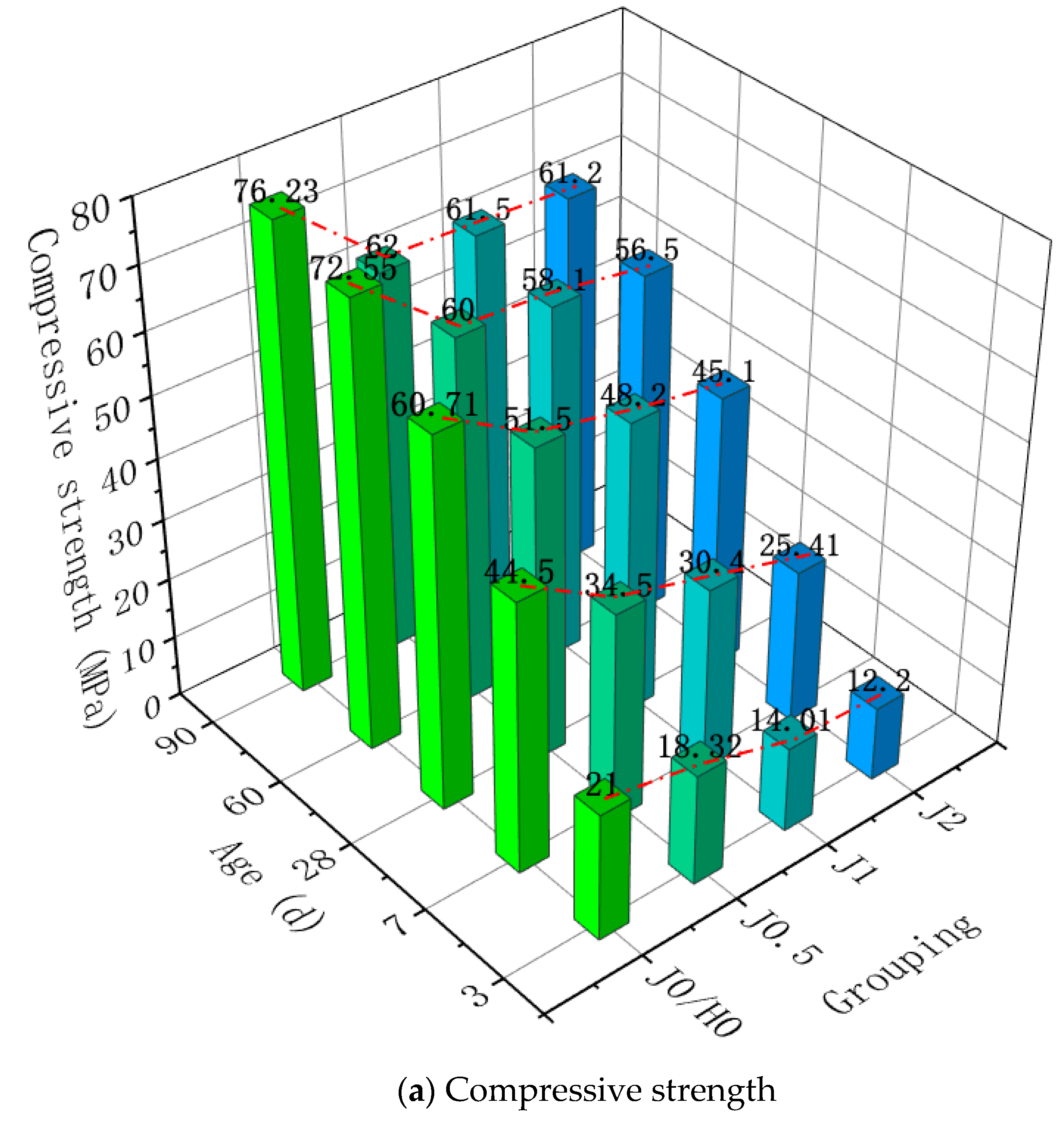

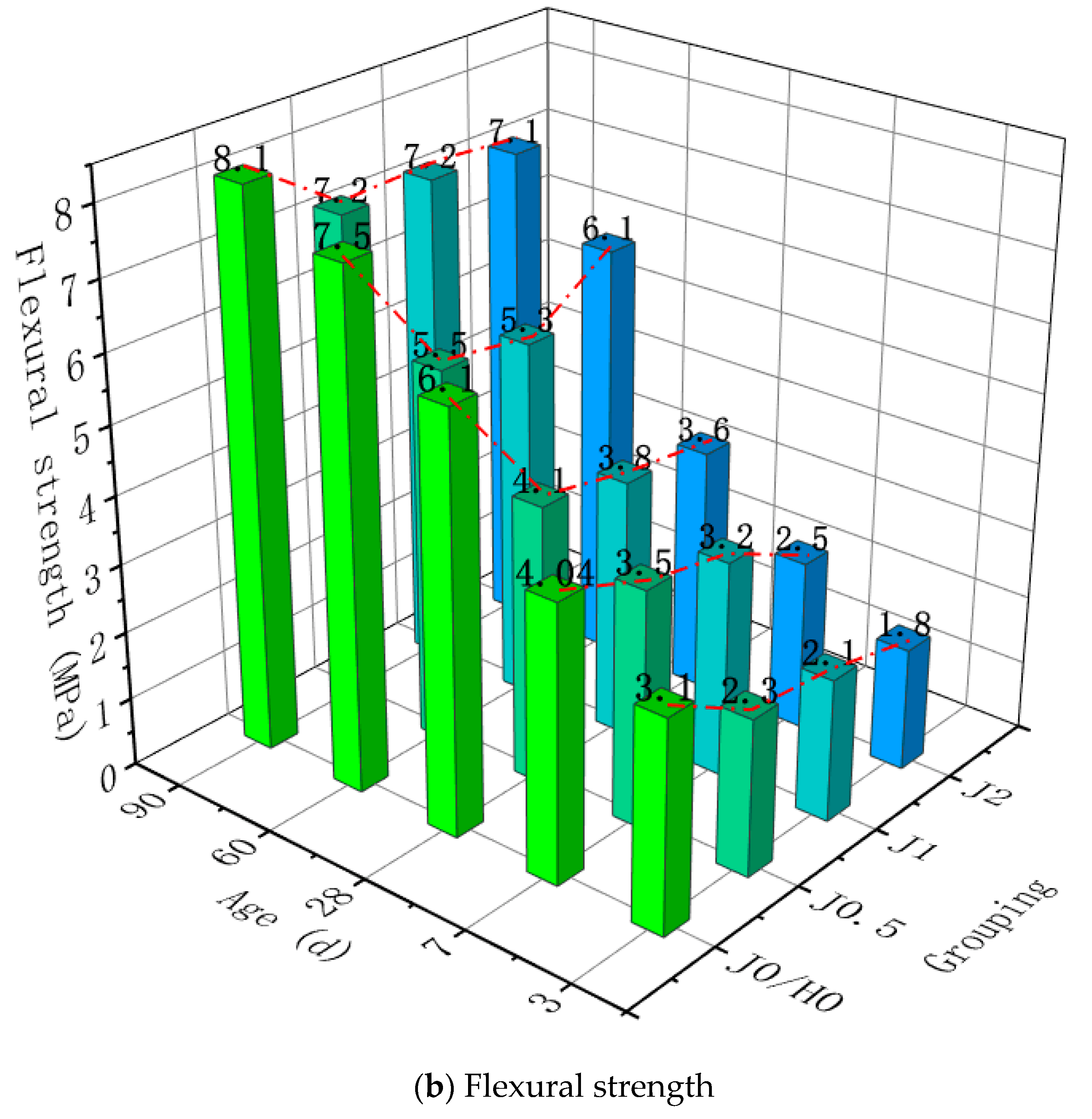

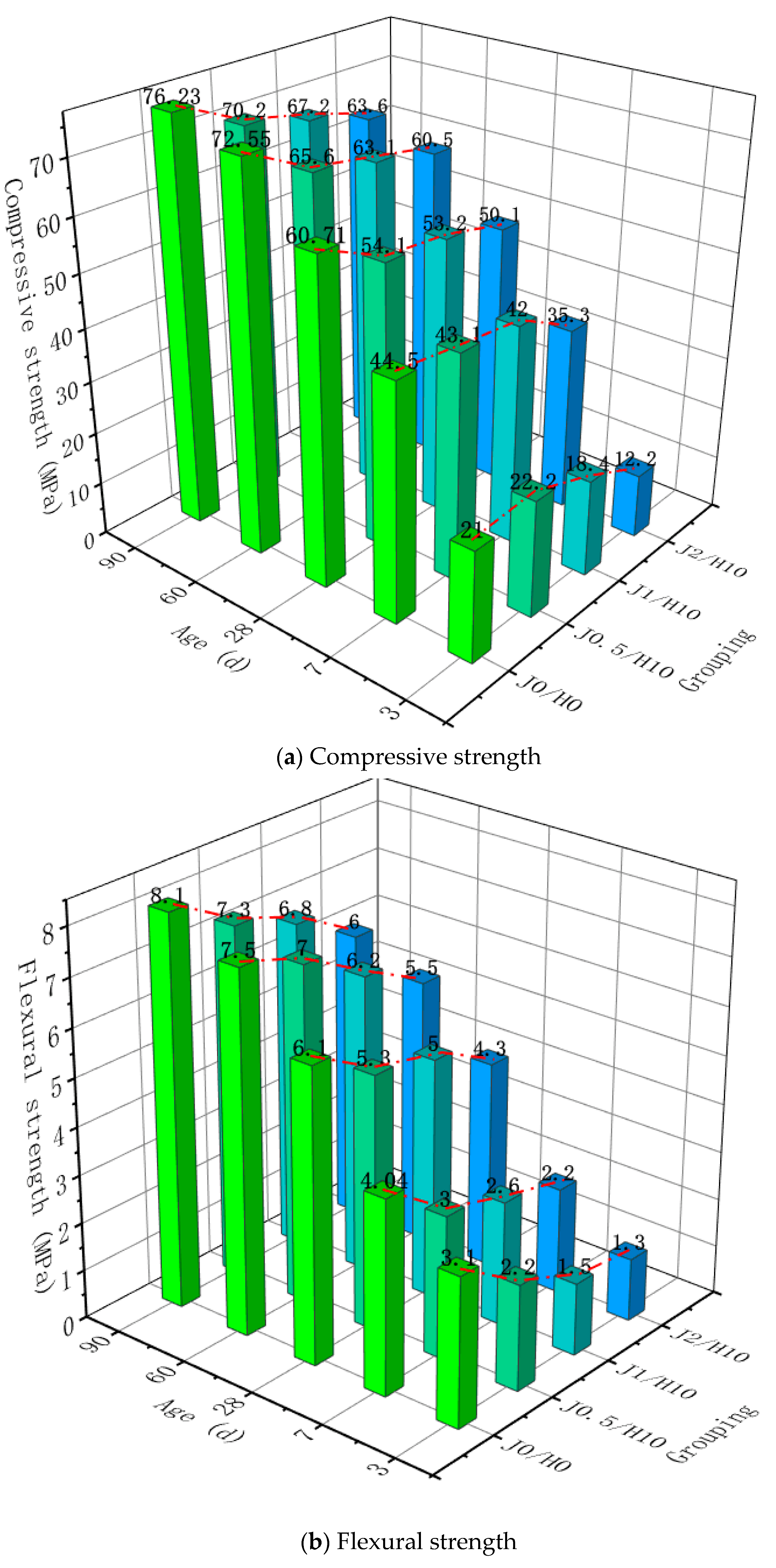

3.1. Effect of HPEA and Shrinkage Reducer on the Strength of Concrete

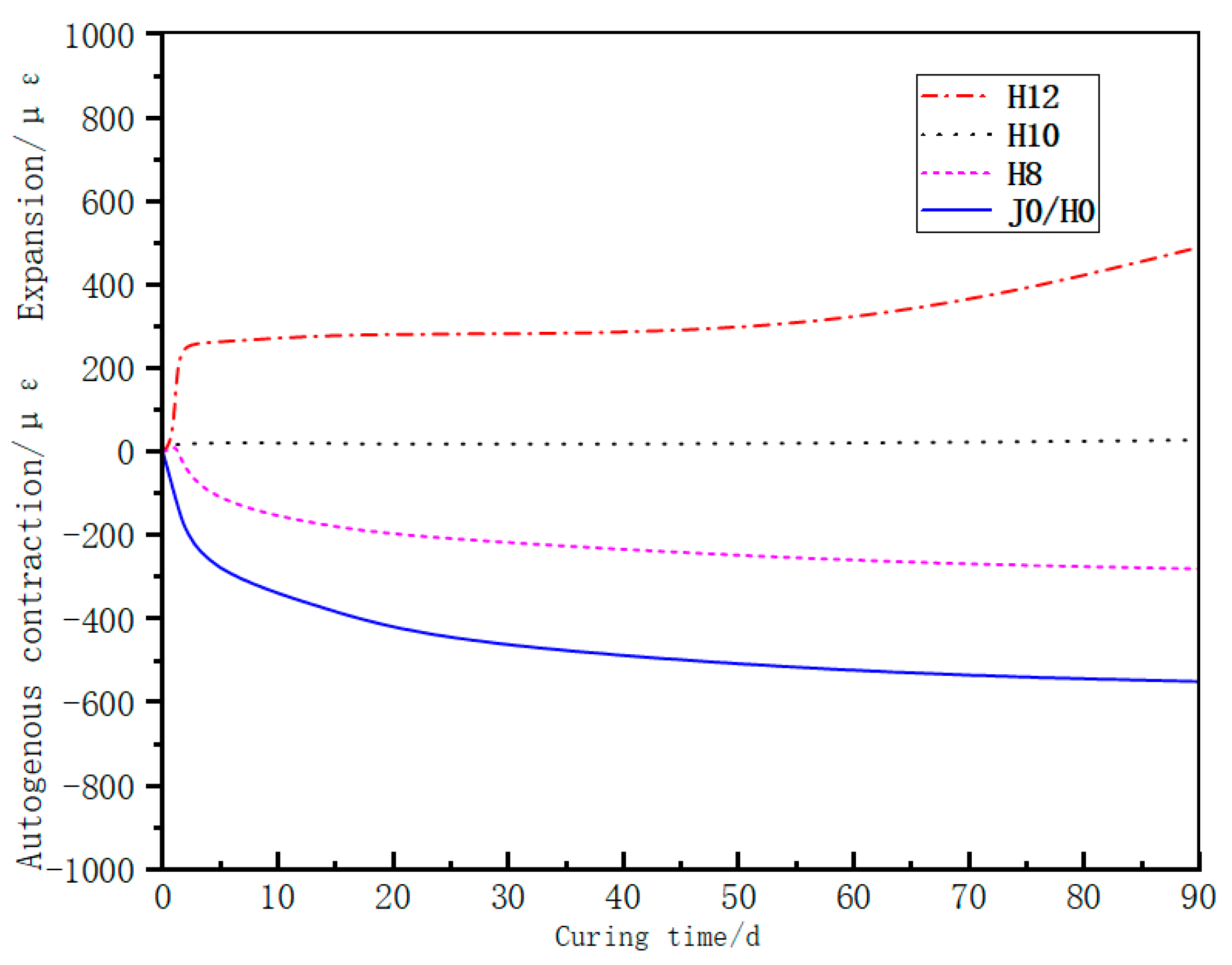

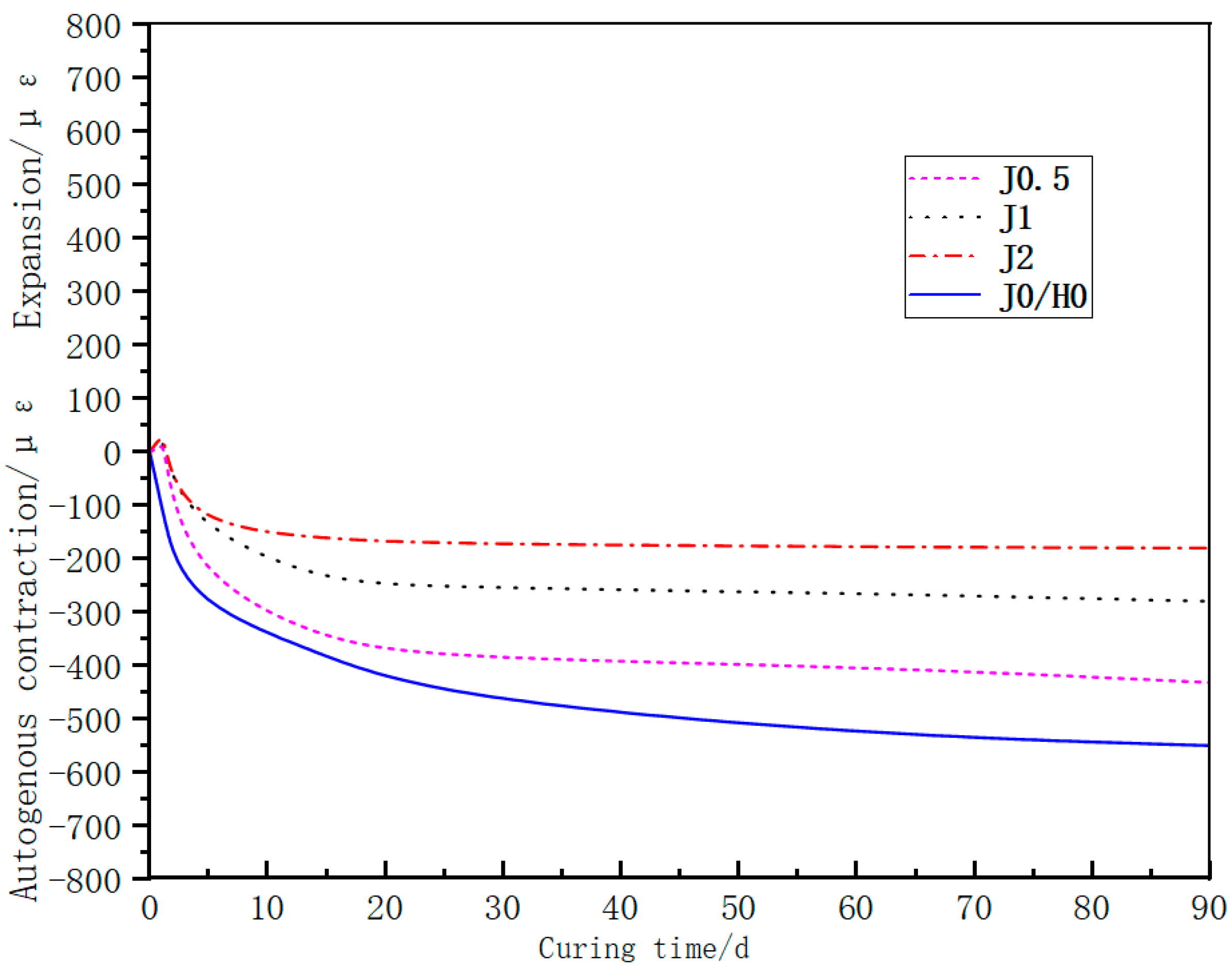

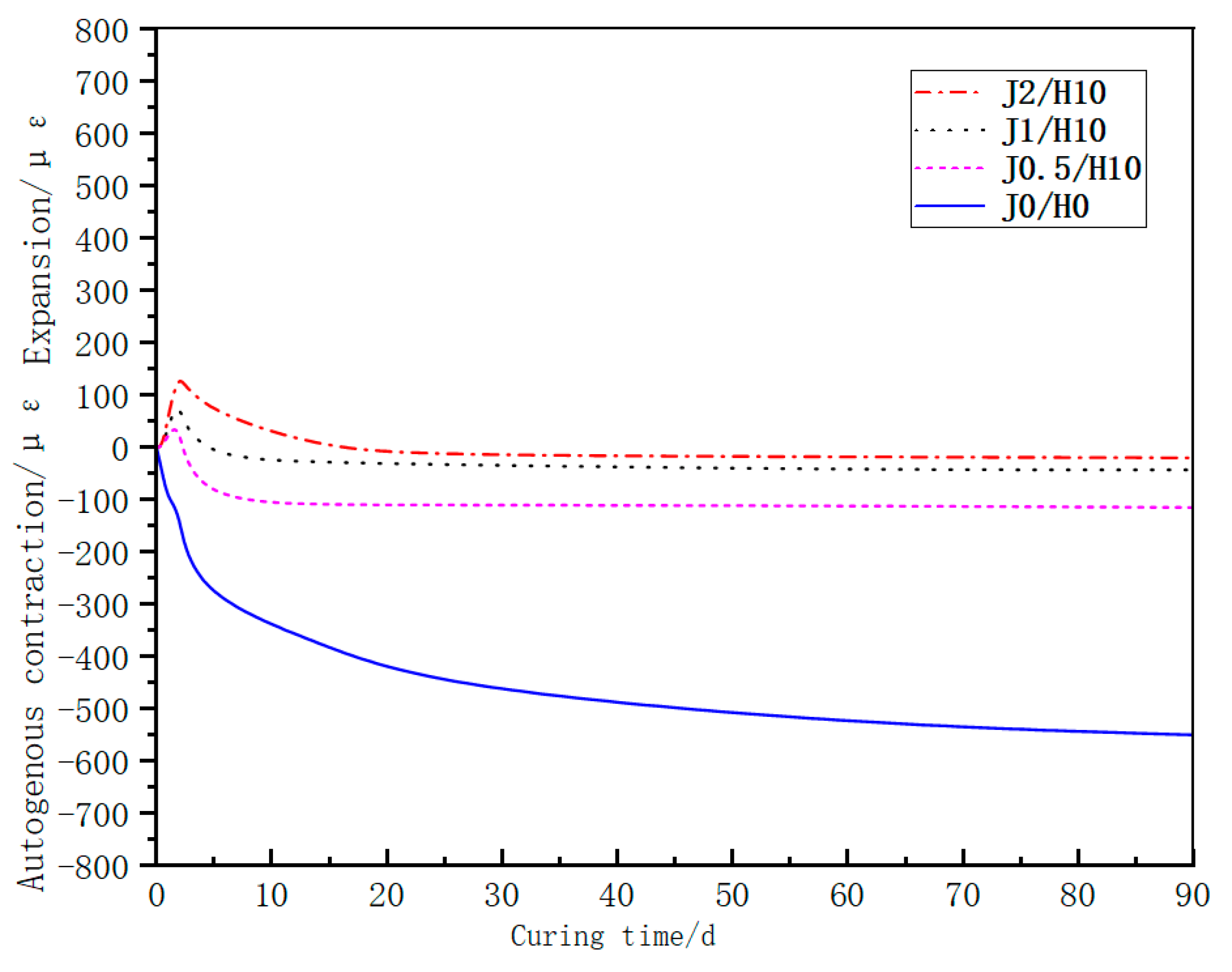

3.2. Effect of Shrinkage-Reducing Agent and HPEA on the Autogenous Shrinkage of Concrete

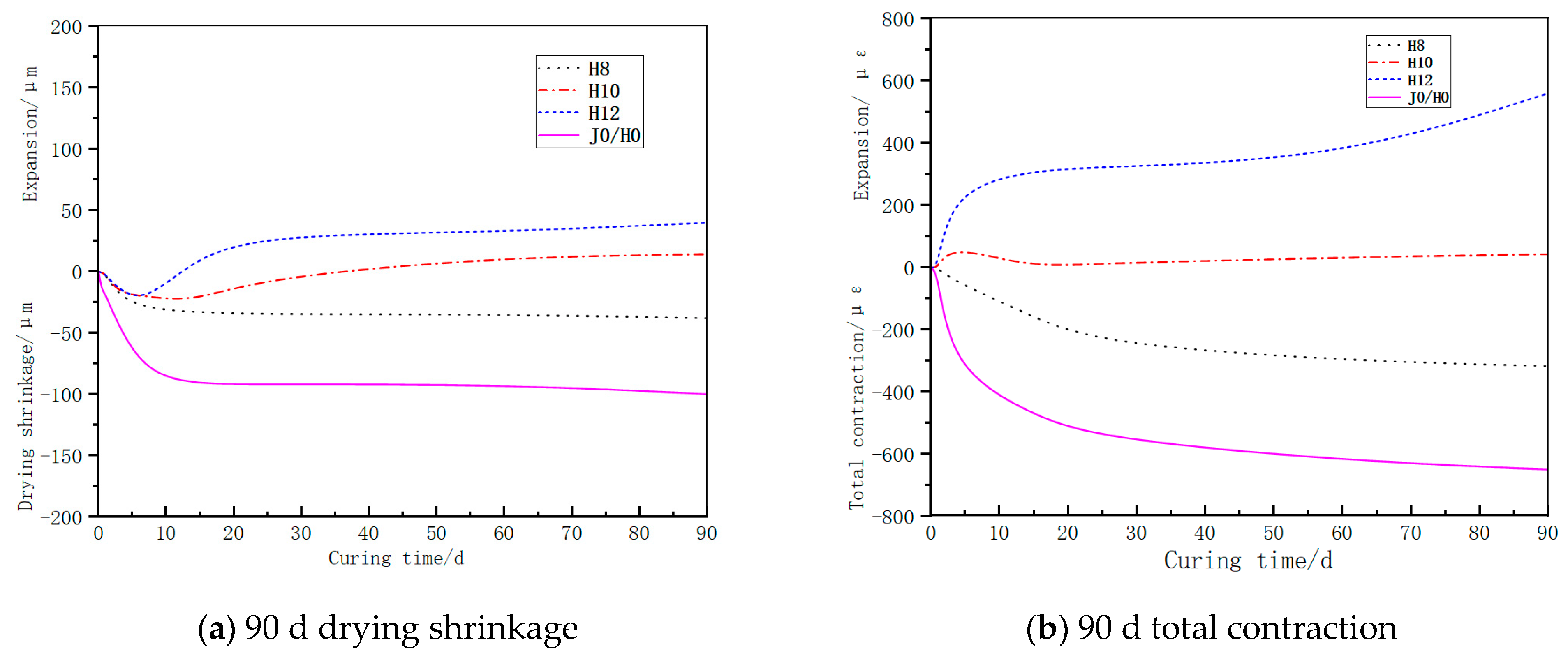

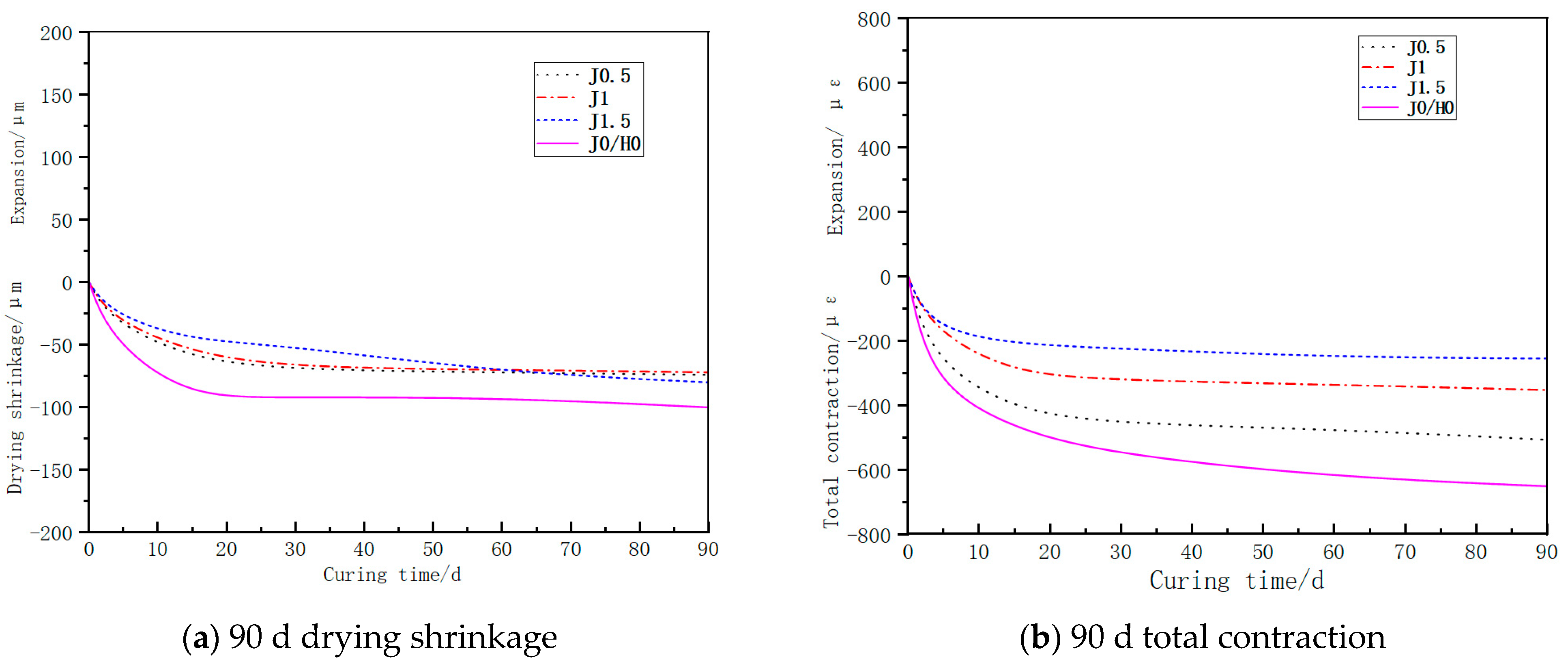

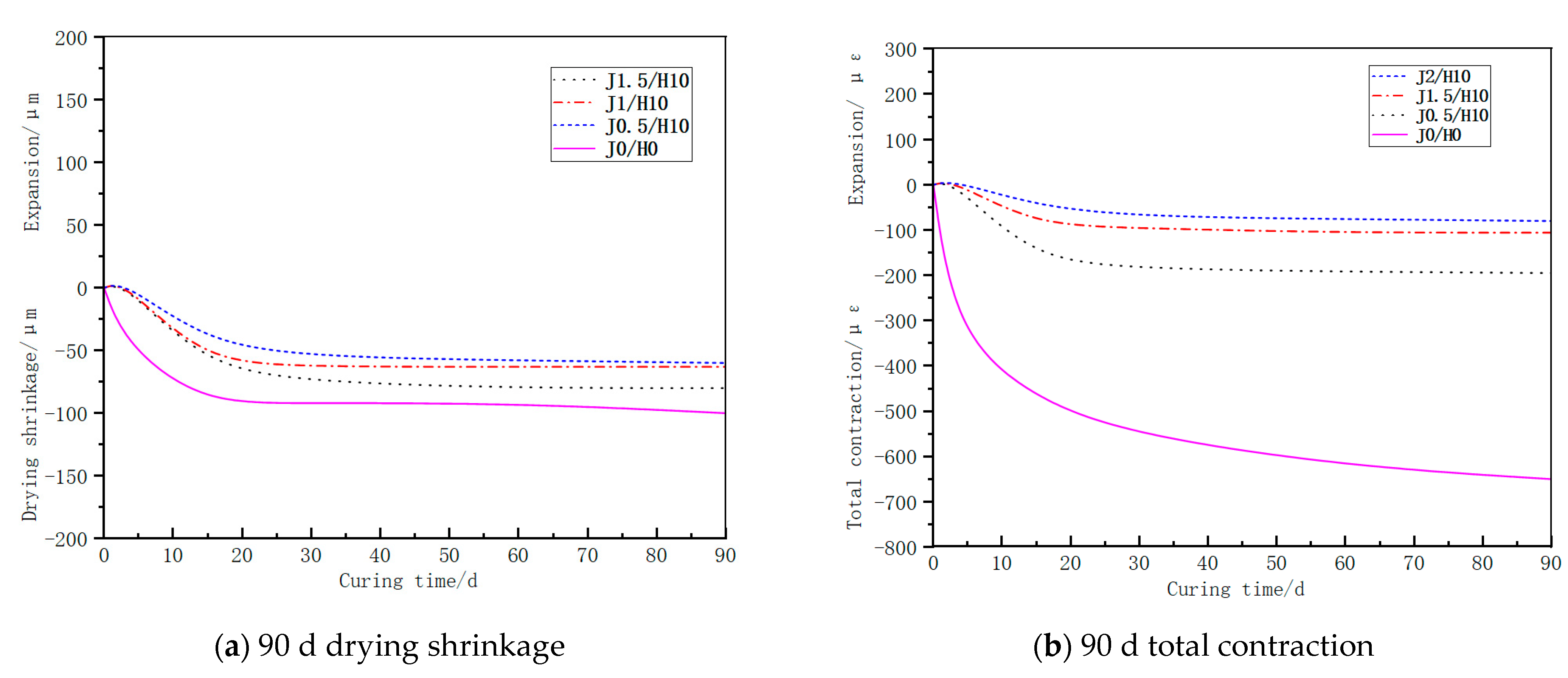

3.3. Effect of HPEA and Shrinkage Reducer on Drying and Total Shrinkage of Concrete

4. Conclusions

- (1)

- A HPEA can promote the development of early compressive strength of high-strength concrete, but it has a negative impact on the development of flexural strength. The autogenous shrinkage and dry shrinkage of high-strength concrete decrease with the increase in HPEA content. An appropriate amount of HPEA can solve the shrinkage problem of concrete, but it needs to be well controlled. The insufficient amount of HPEA can not fully compensate for the shrinkage of concrete, while the excessive amount of HPEA can delay the expansion and lead to cracking, which makes it difficult to solve the concrete crack problem by using HPEA alone.

- (2)

- A shrinkage-reducing agent will reduce the hydration rate of high-strength concrete, prolonging the curing time, and is not conducive to the development of early strength of concrete, but it has obvious advantages in reducing the drying shrinkage of concrete, with the drying shrinkage reduction of more than 20%. However, the effect of the shrinkage-reducing agent is limited, and there is still a shrinkage phenomenon when adding high dose of the shrinkage-reducing agent. Therefore, adding an expansion agent alone can not solve the crack problem of concrete.

- (3)

- The combined use of a HPEA and expansion agent shows a synergistic effect on high-strength concrete. With the increase in the content of the shrinkage-reducing agent, the strength of high-strength concrete at all ages decreases, but is still higher than that of the components added with the shrinkage-reducing agent alone. When the content of the shrinkage reducing agent is 2% and the content of the HPEA is 10%, the synergistic effect of the two admixtures is better, and the shrinkage effect of high-strength concrete is the strongest. There is still shrinkage due to an insufficient HPEA dosage, and the concrete does not get enough expansion at the early stage. In order to solve the problem of concrete shrinkage cracks, we will take the HPEA as the basis to seek other additives to carry out the research of synergy.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, S.; Zhang, Z. Summary of cracks in concrete pavement. Subgrade Eng. 2008, 2, 20–22. [Google Scholar] [CrossRef]

- Emborg, M.; Bernander, S. Assessment of Risk of Thermal Cracking in Hardening Concrete. J. Struct. Eng. 1994, 120, 2893–2912. [Google Scholar] [CrossRef]

- Bentur, A.; Kovler, K. Evaluation of early age cracking characteristics in cementitious systems. Mater. Struct. 2003, 36, 183–190. [Google Scholar] [CrossRef]

- Wei, Y.; Hansen, W. Characterizing Cracking Potential of Cementitious Mixtures Based on Shrinkage and Humidity Drop Rate. ACI Mater. J. 2013, 110, 433–440. [Google Scholar]

- Zhang, X.; Ai, J.; Hao, C. Literature Review on Crack Control of Super Long Concrete Structures. Struct. Eng. 2021, 37, 235–242. [Google Scholar] [CrossRef]

- Wang, Q.; He, Y.; Xiao, Y. Overview of crack control for high-performance concrete. Concrete 2013, 5, 119–123. [Google Scholar]

- Chen, Z.; Cui, J.; Zhu, J.; An, M.; Yu, Z. Analysis and control of cracking in reinforced concrete. Eng. Mech. 2006, 23, 86–107. [Google Scholar]

- Wu, Z.M.; Shi, C.J.; Khayat, K.H. Investigation of mechanical properties and shrinkage of ultra-high performance concrete: Influence of steel fiber content and shape. Compos. B Eng. 2019, 174, 107021. [Google Scholar] [CrossRef]

- Li, P.P.; Sluijsmans, M.; Brouwers, H.; Yu, Q.L. Functionally graded ultra-high performance cementitious composite with enhanced impact properties. Compos. B Eng. 2020, 183, 107680. [Google Scholar] [CrossRef]

- Park, S.H.; Ryu, G.S.; Koh, K.T.; Kim, D.J. Effect of shrinkage reducing agent on pullout resistance of high-strength steel fibers embedded in ultra-high-performance concrete. Cem. Concr. Compos. 2014, 49, 59–69. [Google Scholar] [CrossRef]

- Li, W.; Huang, Z.; Hu, G.; Duan, W.H.; Shah, S.P. Early-age shrinkage development of ultra-high-performance concrete under heat curing treatment. Constr. Build. Mater. 2017, 131, 767–774. [Google Scholar] [CrossRef]

- Park, J.J.; Yoo, D.Y.; Kim, S.W.; Yoo, D.-Y. Benefits of using expansive and shrinkage-reducing agents in UHPC for volume stability. Mag. Concr. Res. 2014, 66, 745–750. [Google Scholar] [CrossRef]

- Li, S.; Mo, L.; Deng, M.; Cheng, S. Mitigation on the autogenous shrinkage of ultra-high performance concrete via using MgO expansive agent. Constr. Build. Mater. 2021, 312, 125422. [Google Scholar] [CrossRef]

- Sun, W.; Chen, H.; Luo, X.; Qian, H. The effect of hybrid fibers and expansive agent on the shrinkage and permeability of high-performance concrete. Cem. Concr. Res. 2001, 31, 595–601. [Google Scholar] [CrossRef]

- Peng, L.I.; Miao, M.; Xiao-Jie, M.A. Effect of Expansive Agent on the Performance of Shrinkage-Compensated Concrete. Bull. Chin. Ceram. Soc. 2016, 259, 119768. [Google Scholar]

- Nagataki, S.; Gomi, H. Expansive admixtures (mainly ettringite). Cement Concr. Compos. 1998, 20, 163–170. [Google Scholar] [CrossRef]

- Kioumarsi, M.; Azarhomayun, F.; Haji, M.; Shekarchi, M. Effect of Shrinkage Reducing Admixture on Drying Shrinkage of Concrete with Different w/c Ratios. Materials 2020, 13, 5721. [Google Scholar] [CrossRef]

- Li, Z. Drying shrinkage prediction of paste containing meta-kaolin and ultrafine fly ash for developing ultra-high performance concrete. Mater. Today Commun. 2016, 6, 74–80. [Google Scholar] [CrossRef]

- Rajabipour, F.; Sant, G.; Weiss, J. Interactions between shrinkage reducing admixtures (SRA) and cement paste’s pore solution. Cem. Concr. Res. 2007, 38, 606–615. [Google Scholar] [CrossRef]

- Press, C. Dynamics of Surfactant Self-Assemblies; Crc Press: Boca Raton, FL, USA, 2005. [Google Scholar]

- Lura, P.; Pease, B.; Mazzotta, G.B.; Rajabipour, F.; Weiss, J. Influence of Shrinkage-Reducing Admixtures on Development of Plastic Shrinkage Cracks. Mater. J. 2007, 104, 187–194. [Google Scholar]

- Chen, M.; Zhou, M.; Wu, S.; He, Z. Effect of shrinkage-reducing admixture on hydration and shrinkage deformation of cement-based materials at early ages. Eng. J. Wuhan Univ. 2007, 40, 78–82. [Google Scholar]

- Ren, H.; Guo, L. Effect of addition of shrinkage reducing admixture on properties of concrete. J. Dalian Univ. Technol. 2013, 53, 397–402. [Google Scholar]

- Sant, G.; Lothenbach, B.; Juilland, P.; Le Saout, G.; Weiss, J.; Scrivener, K. The origin of early age expansions induced in cementitious materials containing shrinkage reducing admixtures. Cem. Concr. Res. 2010, 41, 218–229. [Google Scholar] [CrossRef]

- Demir, İ.; Sevim, Ö.; Tekin, E. The effects of shrinkage-reducing admixtures used in self-compacting concrete on its strength and durability. Constr. Build. Mater. 2018, 172, 153–165. [Google Scholar] [CrossRef]

- Marshdi, Q.S.R.; Jasim, A.H.; Obeed, H.A. Effect of Dolomite as Expansive Agent and Shrinkage Reducing Admixture in Self-Compacting Shrinkage—Compensating Concrete. J. Univ. Babylon Eng. Sci. 2018, 26, 1–8. [Google Scholar] [CrossRef]

- Liu, L.; Fang, Z.; Huang, Z.; Wu, Y. Solving shrinkage problem of ultra-high-performance concrete by a combined use of expansive agent, super absorbent polymer, and shrinkage-reducing agent. Compos. Part B Eng. 2022, 230, 109503. [Google Scholar] [CrossRef]

- Collepardi, M.; Borsoi, A.; Collepardi, S.; Olagot, J.J.O.; Troli, R. Effects of shrinkage reducing admixture in shrinkage compensating concrete under non-wet curing conditions. Cem. Concr. Compos. 2005, 27, 704–708. [Google Scholar] [CrossRef]

- Su, A.; Qin, L.; Zhang, S.; Zhang, J.; Li, Z. Effects of Shrinkage Reducing Agent and Expansive Admixture on the Volume Deformation of Ultrahigh Performance Concrete. Adv. Mater. Sci. Eng. 2017, 2017, 1–7. [Google Scholar]

- Ji, X.; Liu, M.; Xiang, F.; Rao, W.; Wang, H. Study on the Early-age Cracking Resistance of Concrete with Expansive Agent Using Temperature-stress Testing Machine. China Concr. Cem. Products 2020, 2, 14–18. [Google Scholar] [CrossRef]

- Huang, Z.; Liu, Y.; Li, C. College of Civil Engineering, Hunan University;Troop 61251 of the People′s Liberation Army. Performance Research of Ultra High Performance Concrete Incorporating HCSA Expansion Agent. Mater. Rev. 2015, 29, 116–121. [Google Scholar]

- Kong, A.; Zhou, C. Research progress of application of shrinkage-reducing admixture in cement-based materials (I)—Workability, mechanical properties and durability. Concrete 2020, 5, 73–78. [Google Scholar]

- Bentz, D.P.; Peltz, M.A.; Snyder, K.A.; Davis, J.M. VERDiCT: Viscosity Enhancers Reducing Diffusion in Concrete Technology. Concr. Int. 2009, 31, 31–36. [Google Scholar]

- He, Z.; Li, Z.J.; Chen, M.Z. Properties of shrinkage-reducing admixture-modified pastes and mortar. Mater. Struct. 2006, 39, 445–453. [Google Scholar] [CrossRef]

- GB/T 23439-2017; Concrete Expansion Agent. China National Standardization Administration: Beijing, China, 2017. (In Chinese)

- GB/T 50081-2002; China National Standard for Test Methods for Mechanical Properties of Ordinary Concrete. China National Standardization Administration: Beijing, China, 2002. (In Chinese)

- GB/T50082-2009; Chinese National Standard for Test Methods of Long-Term Performance and Durability of Ordinary Concrete. China National Standardization Administration: Beijing, China, 2009. (In Chinese)

- Oliveira, M.J.; Ribeiro, A.B.; Branco, F.G. Combined effect of expansive and shrinkage reducing admixtures to control autogenous shrinkage in self-compacting concrete. Constr. Build. Mater. 2014, 52, 267–275. [Google Scholar] [CrossRef]

- Xie, T.; Fang, C.; Mohamad Ali, M.S.; Visintin, P. Characterizations of autogenous and drying shrinkage of ultra-high performance concrete (UHPC): An experimental study. Cement Concr. Compos. 2018, 91, 156–173. [Google Scholar] [CrossRef]

- Liu, J.; Farzadnia, N.; Shi, C.; Ma, X. Effects of superabsorbent polymer on shrinkage properties of ultra-high strength concrete under drying condition. Construct. Build. Mater. 2019, 215, 799–811. [Google Scholar] [CrossRef]

- Cao, S.P.; Zhou, Q.F.; Peng, Y.L.; Li, G.X. Effects of Expansive Agent and Steel Fiber on the Properties of the Fly Ash Ceramsite Lightweight Aggregate Concrete. Appl. Mech. Mater. 2013, 357–360, 1332–1336. [Google Scholar] [CrossRef]

- Yang, L.; Shi, C.; Wu, Z. Mitigation techniques for autogenous shrinkage of ultra-high-performance concrete—A review. Compos. Part B Eng. 2019, 178, 107456. [Google Scholar] [CrossRef]

- Kong, A.; Zhou, C. Research progress of application of shrinkage-reducing admixture in cement-based materials (II)—Volume stability. Concrete 2020, 6, 79–84+89. [Google Scholar] [CrossRef]

- Jin, Y.; Wang, Z.; Wang, Z. Principle, Performance and Application of Shrinkage Compensating Concrete Prepared with Expansion Agent. Sci. Technol. Overseas Build. Mater. 1996, 17, 40–44. [Google Scholar]

- Yan, P.; Jian, H.; Tan, X. Several problems needing attention when using expansion agent to prepare shrinkage compensating concrete. J. Chin. Ceram. Soc. 2000, 28 (Suppl. 1), 42–45. [Google Scholar]

- Gong, J.; Luo, H.; Zhang, Y.; Gong, X.; Xie, Z.; Wu, W.; Dai, Y. Effect of Shrinkage Reducing Agent and HCSA Expansion Agent on Mechanical Properties and Shrinkage Properties of UHPC. Mater. Rep. 2021, 35, 8042–8048+8063. [Google Scholar]

| Composite | CaO | Al2O3 | MgO | SiO2 | Fe2O3 | SO3 | LOI |

|---|---|---|---|---|---|---|---|

| Cement | 65.1 | 3.1 | 2.8 | 23.2 | 2.6 | 1.6 | 1.6 |

| Fly ash | 6.2 | 32.6 | 0.7 | 48.5 | 8.7 | 1.2 | 2.1 |

| HPEA | 65.21 | 4.88 | 1.45 | 1.81 | 1.22 | 22.33 | 3.10 |

| Material | Physical Properties |

|---|---|

| Cement | Ordinary Portland cement (OPC, density: 3.15 g/cm3, specific surface area: 3440 cm2/g) |

| Fly ash | (Density: 2.35 g/cm3, specific surface area: 4110 cm2/g) |

| Fine aggregate | (River sand, size: 0.45 mm, density: 2.58 g/cm3, absorption: 1%) |

| Coarse aggregate | (Basalt gravel, 5~20 mm, apparent density 2.933 g/cm3) |

| Superplasticizer | Polycarboxylic-based superplasticizer (specific gravity: 1.05 ± 0.05, pH: 5.0 ± 1.5) |

| Recommended Dosage/% | Fineness | Setting Time/min | Compressive Strength/MPa | Limit Expansion Rate/% | ||||

|---|---|---|---|---|---|---|---|---|

| Specific Surface Area/(cm2/g) | 1.15 mm Sieve Residue/% | Initial Setting | Final Coagulation | 7 d | 28 d | 7 d in Water | Air 21 d | |

| 8–12 | 3300 | 0 | 185 | 280 | 25 | 46.8 | 0.048 | 0.02 |

| Groups | Slump Flow (mm) | Air | Cement | Fly Ash | Water-Reducing Agent | Sand | Gravel | Water | HPEA | Shrinkage-Reducing Agent |

|---|---|---|---|---|---|---|---|---|---|---|

| J0/H0 | 120 ± 20 | 1.7 | 432 | 108 | 5.4 | 699 | 1049 | 162 | 0 | 0 |

| J0.5 | 120 ± 20 | 1.9 | 432 | 108 | 5.4 | 708 | 1063 | 162 | 0 | 2.7 |

| J1 | 120 ± 20 | 1.9 | 432 | 108 | 5.4 | 708 | 1063 | 162 | 0 | 5.4 |

| J2 | 120 ± 20 | 1.9 | 432 | 108 | 5.4 | 708 | 1063 | 162 | 0 | 10.8 |

| H8 | 120 ± 20 | 1.8 | 389 | 108 | 5.4 | 708 | 1063 | 162 | 43.2 | 0 |

| H10 | 120 ± 20 | 1.8 | 378 | 108 | 5.4 | 708 | 1063 | 162 | 54 | 0 |

| H12 | 120 ± 20 | 1.8 | 367 | 108 | 5.4 | 708 | 1063 | 162 | 64.8 | 0 |

| J0.5/H10 | 120 ± 20 | 1.8 | 378 | 108 | 5.4 | 708 | 1063 | 162 | 54 | 2.7 |

| J1/H10 | 120 ± 20 | 1.8 | 378 | 108 | 5.4 | 708 | 1063 | 162 | 54 | 5.4 |

| J2/H10 | 120 ± 20 | 1.8 | 378 | 108 | 5.4 | 708 | 1063 | 162 | 54 | 10.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xi, Y.-F.; Lee, J.; Chen, B.-L.; Yang, B.; Yu, M.-Z.; Yan, X.-Z.; Zhu, L. Impact of High-Performance Expansion and Shrinkage-Reducing Agents on the Mechanical Properties and Shrinkage Compensation of High-Strength Concrete. Buildings 2023, 13, 717. https://doi.org/10.3390/buildings13030717

Xi Y-F, Lee J, Chen B-L, Yang B, Yu M-Z, Yan X-Z, Zhu L. Impact of High-Performance Expansion and Shrinkage-Reducing Agents on the Mechanical Properties and Shrinkage Compensation of High-Strength Concrete. Buildings. 2023; 13(3):717. https://doi.org/10.3390/buildings13030717

Chicago/Turabian StyleXi, Yun-Feng, Jin Lee, Bao-Ling Chen, Bing Yang, Miao-Zhang Yu, Xiao-Zhou Yan, and Li Zhu. 2023. "Impact of High-Performance Expansion and Shrinkage-Reducing Agents on the Mechanical Properties and Shrinkage Compensation of High-Strength Concrete" Buildings 13, no. 3: 717. https://doi.org/10.3390/buildings13030717

APA StyleXi, Y.-F., Lee, J., Chen, B.-L., Yang, B., Yu, M.-Z., Yan, X.-Z., & Zhu, L. (2023). Impact of High-Performance Expansion and Shrinkage-Reducing Agents on the Mechanical Properties and Shrinkage Compensation of High-Strength Concrete. Buildings, 13(3), 717. https://doi.org/10.3390/buildings13030717