Fatigue Test and Unified Fatigue Life Calculation of Q460C Steel Notched Plates

Abstract

1. Introduction

2. The Problem of Fatigue Life Calculation Currently

3. Ellipsoidal Fracture Model and Unified Crack Growth Approach

3.1. Ellipsoidal Fracture Model of Structural Steel

3.2. Unified Crack Growth Approach of Structural Steel

- (1)

- The fatigue fracture area, A, of structural steel and its connections is the sum of fatigue crack initiation and stable propagation area, Af (including initial defect effect), and fatigue crack instability propagation area, An (tensile fracture area under the nominal maximum stress), i.e., A = Af + An.

- (2)

- The ellipsoidal fracture model of structural steel, originally proposed by the second author [16], is used as the cracking criterion of the crack tip during fatigue crack instability propagation, and can be expressed as Equation (3).

- (3)

- Assuming that the fatigue crack starts at the initial crack or defect and propagates radially to the periphery, the functions between fatigue crack initiation and stable propagation length, af, and fatigue crack initiation and stable propagation area, Af, are obtained. See Section 5.1 for the calculation process.

- (4)

- Since the fatigue crack growth accelerates with the number of load cycles, N, it is assumed that the fatigue crack initiation and stable growth rate, vc, is a monotonically increasing power function of the number of load cycles, N, as shown in Equation (5).

- (5)

- As Equation (7) suggests, a fatigue life calculation model that uniformly calculates the fatigue crack initiation and stable propagation life is obtained by integrating the fatigue crack growth rate equation.

4. Fatigue Tests on Q460C Steel Notched Plates

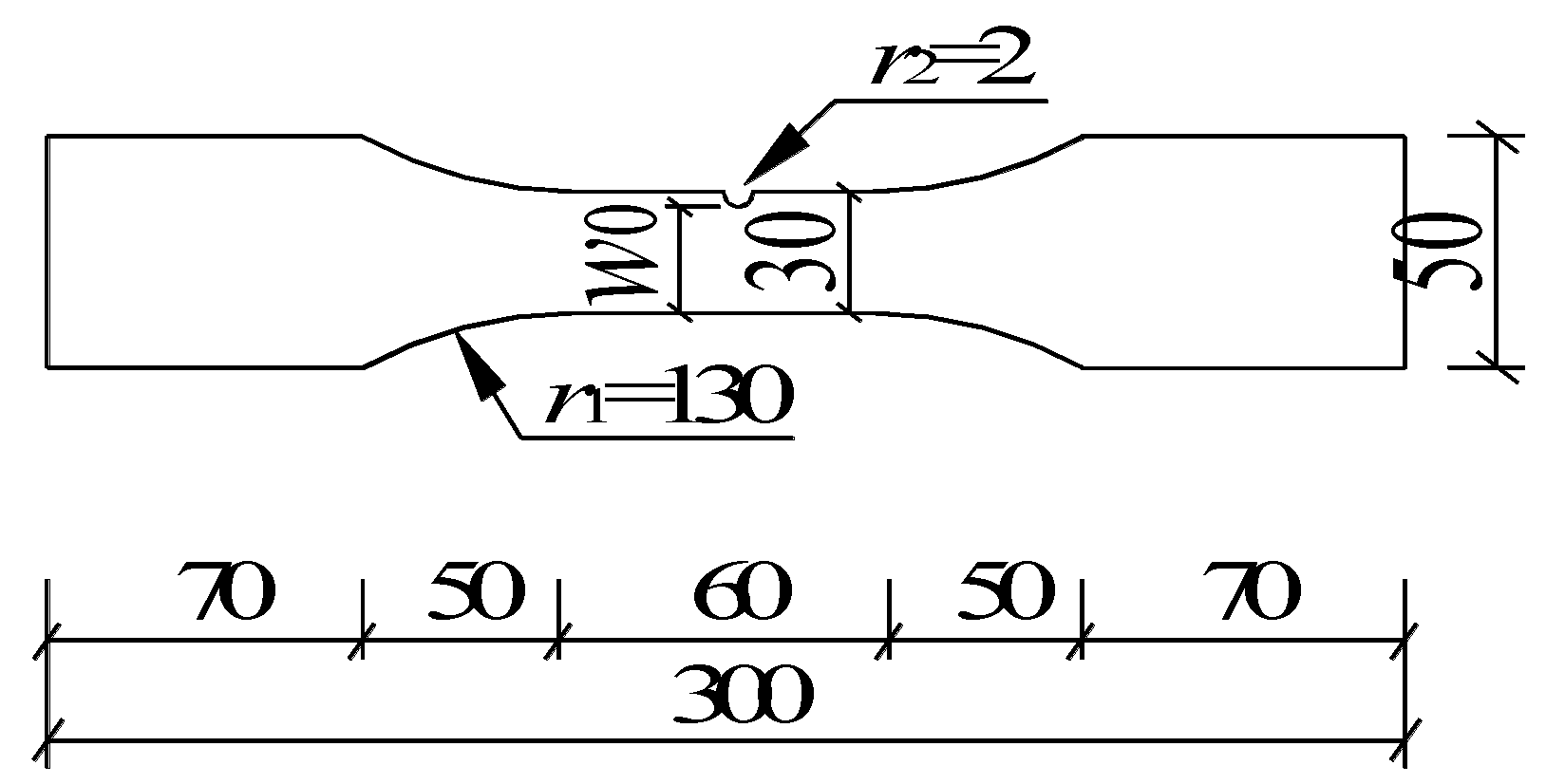

Specimen Design

5. Calculation of Fatigue Crack Initiation and Stable Propagation Length

5.1. Theoretical Estimation of Fatigue Crack Initiation and Stable Propagation Length

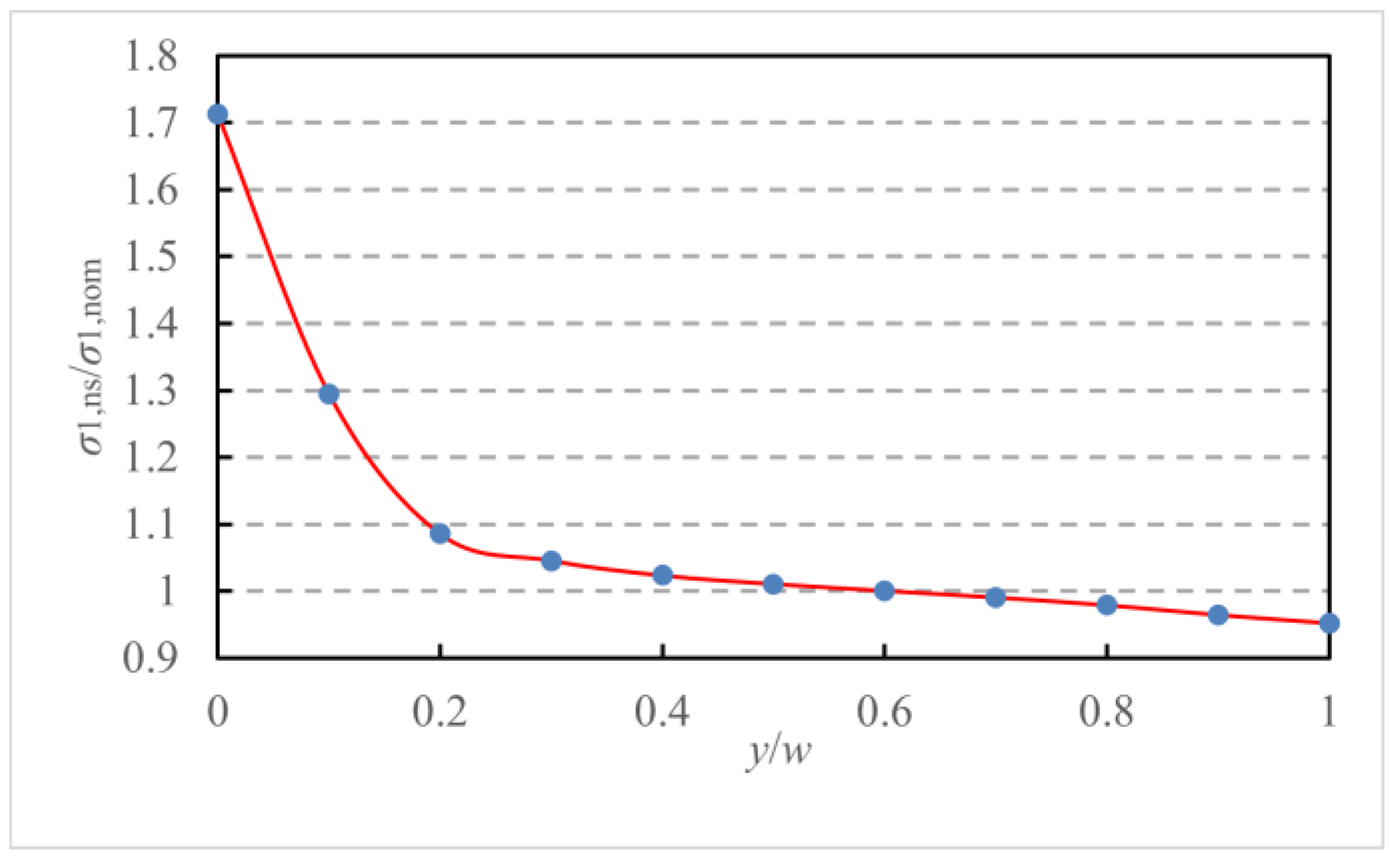

5.2. Numerical Calculation of Fatigue Crack Initiation and Stable Propagation Length

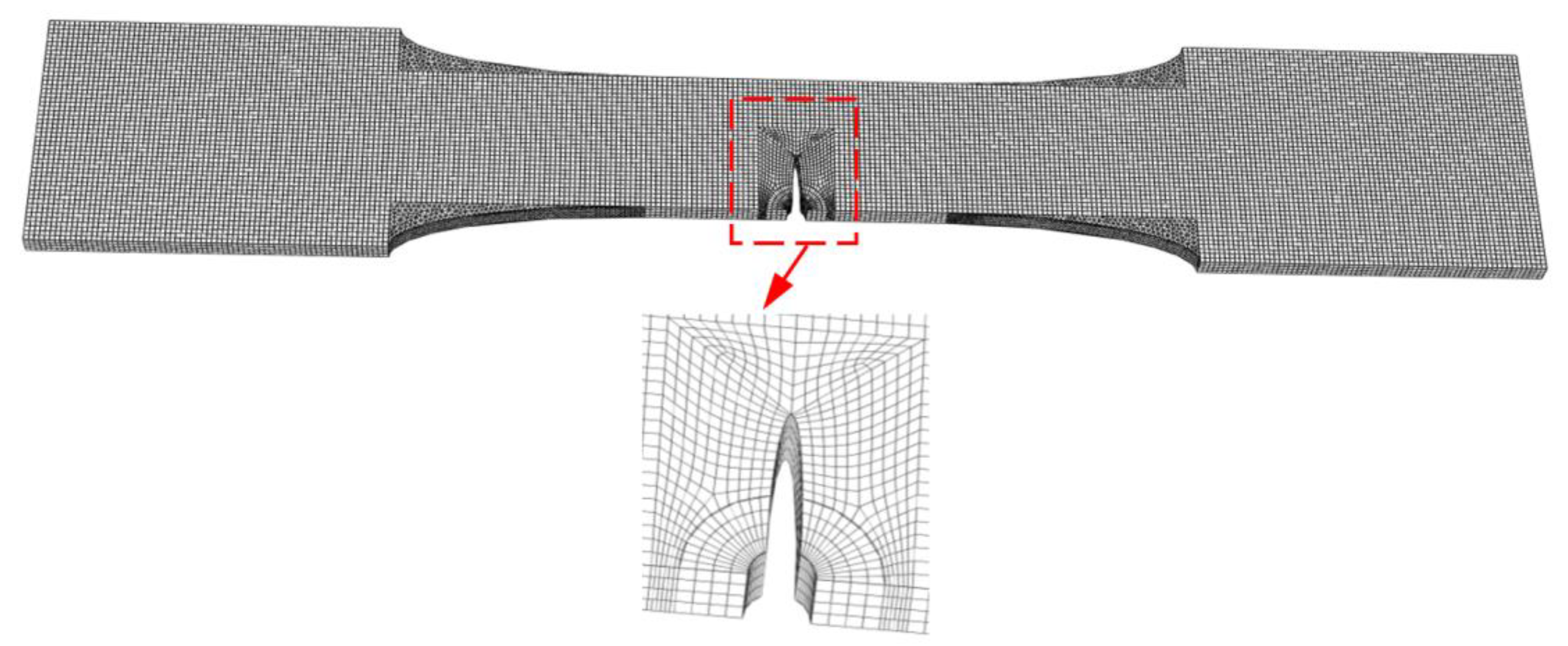

5.2.1. Implementation of the Ellipsoidal Yield Model in ANSYS

- (1)

- Use FORTRAN language to create or modify the programming code for the ellipsoidal yield model and the flow rule subroutines;

- (2)

- Run “anscust.bat” to compile the new code and generate the new “ANSYS.EXE”;

- (3)

- Use ANSYS Parametric Design Language to plant the new code into the ANSYS program.

5.2.2. Flow Rule and Hardening Law

5.2.3. Material Parameters

5.2.4. Geometric Model, Boundary Conditions, and Fatigue Load

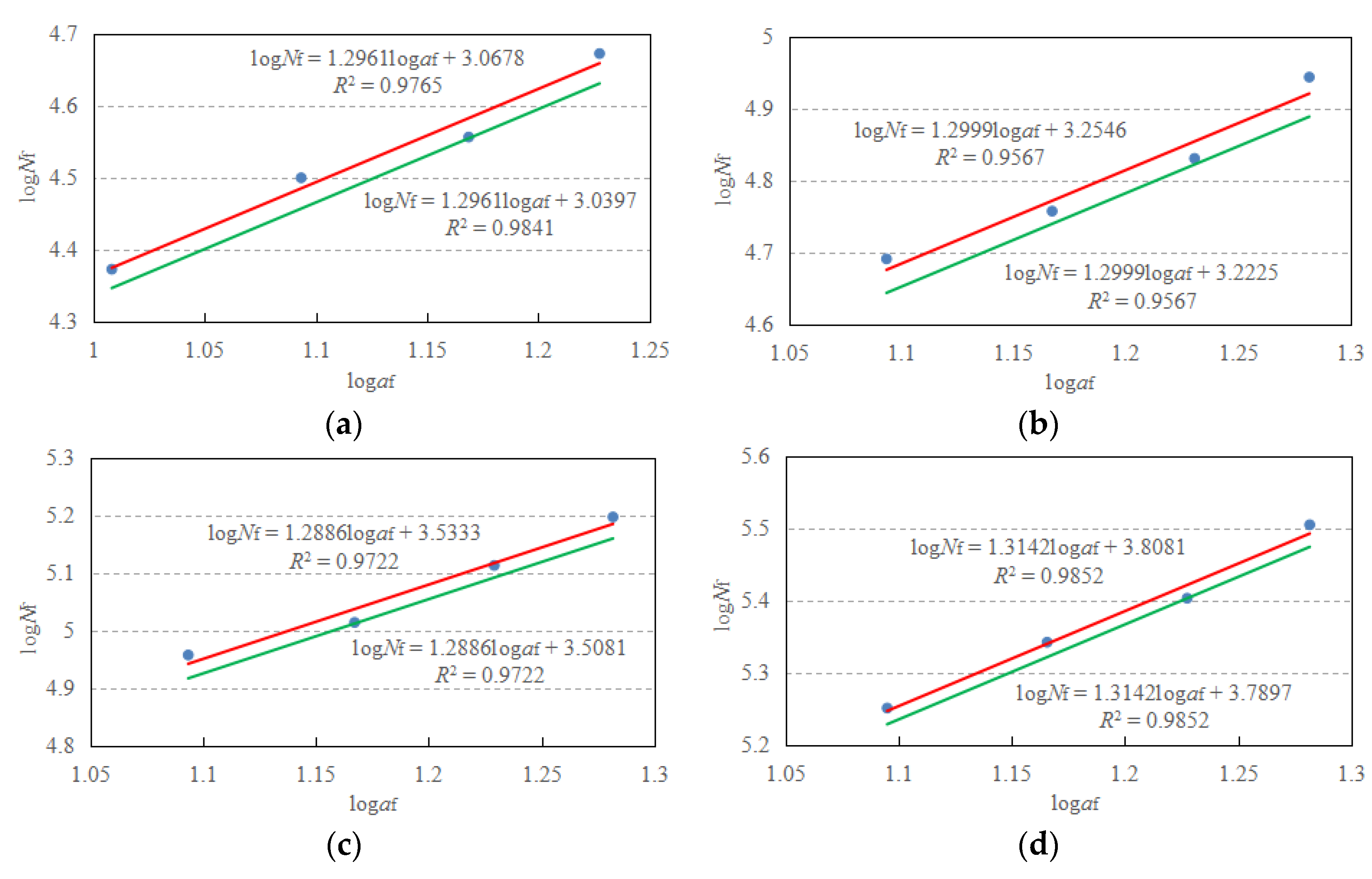

6. Fatigue Life Calculation of Q460C Steel Notched Plates

7. Conclusions

- A crack initiates at the edge of the notch, propagates along the width of the plate at the notched section to the un-notched edge of the plate, and penetrates through the thickness of the plate. Fracture occurs at the notched section when the fatigue crack penetrates the width of the notched section.

- The relative stress amplitude, Δσ/fy, rather than the relative converted stress amplitude, Δσc/fy, is the stress parameter that affects the fatigue life of the notched plates.

- The fatigue life of the Q460C steel notched plates increases with decreases in the relative stress amplitude, Δσ/fy, and the relative nominal maximum stress, σmax/fy. The effect of the relative stress amplitude, Δσ/fy, on the fatigue life of the Q460C steel notched plate is larger than that of the relative nominal maximum stress, σmax/fy.

- The fatigue life predictions determined using the fatigue life formula specified in China’s current code are conservative for specimens with a high stress amplitude (i.e., Δσ ≥ 0.5fy), while they are unsafe for those with a low stress amplitude (i.e., Δσ = 0.4fy), with the calculation errors ranging from −17.1% to +84.9%.

- The fatigue life predictions determined using the modified Gerber ruler are unsafe for the specimens with a high nominal maximum stress (i.e., σmax ≥ 0.7fy), while they are conservative for those with a low maximum stress (i.e., σmax < 0.7fy), with the calculation error being from −66.8% to +276.3%.

- The effects of the relative stress amplitude, Δσ/fy, and the relative nominal maximum stress, σmax/fy, on the fatigue life of the Q460C steel notched plates are considered by means of the unified crack growth approach, which provides prediction errors ranging from −12.9% to +3.5%. The fatigue life predictions by the unified crack growth approach are shown to be more accurate, yet generally on the safe side, compared to those predicted according to the method set out in China’s current code.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chen, S.F.; Gu, Q. Steel Structures (Volume Ⅰ): Basic Theory of Steel Structures; Architecture Industrial Press: Beijing, China, 2003. [Google Scholar]

- Souto, C.D.S.; Gomes, V.M.G.; Figueiredo, M.; Correia, J.; Lesiuk, G.; Fernandes, A.; De Jesus, A. Fatigue behaviour of thin-walled cold roll-formed steel sections. Int. J. Fatigue 2021, 149, 106299. [Google Scholar] [CrossRef]

- Božić, Ž.; Schmauder, S.; Wolf, H. The effect of residual stresses on fatigue crack propagation in welded stiffened panels. Eng. Fail. Anal. 2018, 84, 346–357. [Google Scholar] [CrossRef]

- Cheng, B.; Huang, F.H.; Duan, Y.H.; Chen, M.-T. Fatigue performance of bird-beak SHS gap K-joints under brace in-plane force. J. Struct. Eng. 2021, 147, 04021167. [Google Scholar] [CrossRef]

- Braun, M.; Scheffer, R.; Fricke, W.; Ehlers, S. Fatigue strength of fillet-welded joints at subzero temperatures. Fatigue Fract. Eng. Mat. Struct. 2020, 43, 403–416. [Google Scholar] [CrossRef]

- Sedmak, A.; Hemer, A.; Sedmak, S.A.; Milović, L.; Grbović, A.; Čabrilo, A.; Kljajin, M. Fatigue strength of hot-dip galvanized S960 cut edges and longitudinalwelds. Int. J. Fatigue 2021, 150, 106298. [Google Scholar] [CrossRef]

- Lahtinen, T.; Vilaça, P.; Infante, V. Fatigue behavior of MAG welds of thermo-mechanically processed 700MC ultra high strength steel. Int. J. Fatigue 2019, 126, 62–71. [Google Scholar] [CrossRef]

- Guo, H.C.; Wan, J.H.; Liu, Y.H.; Hao, J. Experimental study on fatigue performance of high strength steels welded joints. Thin Wall. Struct. 2018, 131, 45–54. [Google Scholar] [CrossRef]

- Liu, M.; Luo, S.J.; Shen, Y.; Lin, X.Z. Corrosion fatigue crack propagation behavior of S135 high-strength drill pipe steel in H2 S environment. Eng. Fail. Anal. 2019, 97, 493–505. [Google Scholar] [CrossRef]

- Jie, Z.Y.; Li, Y.D.; Wei, X.; Zhuge, P. Fatigue life assessment of inclined welded joints in steel bridges subjected to combined normal and shear stresses. Adv. Steel Constr. 2018, 14, 620–633. [Google Scholar]

- Zong, L.; Shi, G.; Wang, Y.Q.; Li, Z.-X.; Ding, Y. Experimental and numerical investigation on fatigue performance of non-load-carrying fillet welded joints. J. Constr. Steel Res. 2017, 130, 193–201. [Google Scholar] [CrossRef]

- Cicero, S.; Garcia, T.; Alvarez, J.A.; Klimpel, A.; Bannister, A.; Martín-Meizoso, A. Fatigue behavior and BS7608 fatigue classes of steels with thermally cut hole. J. Constr. Steel Res. 2017, 128, 74–83. [Google Scholar] [CrossRef]

- Neuber, H. Theory of stress concentration for shear-strained prismatic bodies with arbitrary nonlinear stress-strain law. J. App. Mech. 1961, 28, 544–550. [Google Scholar] [CrossRef]

- Paris, P.C.; Erdogan, F. A critical analysis of crack growth laws. J. Bas. Eng. 1963, 85D, 528–534. [Google Scholar] [CrossRef]

- Wang, W.Z. Fatigue failure model of Q345 steel round bars. J. Harb. Inst. Technol. 2019, 51, 58–64. [Google Scholar]

- Wang, W.Z. Crack criterion and fracture tests of structural steel. Eng. Mech. 2008, 25, 27–31. [Google Scholar]

- Standard for Design of Steel Structures. GB50017-2017; Architecture Industrial Press of China; Ministry of Housing and Urban-Rural Development, and Inspection and Quarantine of the People’s Republic of China: Beijing, China, 2017.

- Metallic Materials-Fatigue Testing-Axial-Force-Controlled Method. GB/T 3075-2008; Inspection and Quarantine, and Standardization Administration of the People’s Republic of China: Beijing, China, 2008.

- Metallic Materials-Tensile Testing at Ambient Temperature. GB/T 228-2010; Inspection and Quarantine, and Standardization Administration of the People’s Republic of China: Beijing, China, 2010.

- Wang, W.Z.; Qian, X.D.; Su, R.Q.; Wang, X. Tensile tests and analyses of notched specimens fabricated from high strength steels using a generalized yield model. Fatigue Fract. Eng. Mat. Struct. 2010, 33, 310–319. [Google Scholar] [CrossRef]

| Specimen No. | w0 (mm) | t (mm) | A (mm2) | σmax/fy | σmin/fy | Δσc/fy | Δσ/fy |

| A1 | 28.1 | 4.1 | 115.21 | 0.70 | 0.29 | 0.50 | 0.41 |

| A2 | 28.3 | 4.1 | 116.03 | 0.60 | 0.14 | 0.50 | 0.46 |

| A3 | 28.2 | 4.1 | 115.62 | 0.50 | 0.00 | 0.50 | 0.50 |

| A4 | 28.1 | 4.1 | 115.21 | 0.40 | −0.14 | 0.50 | 0.54 |

| Specimen No. | w0 (mm) | t (mm) | A (mm2) | σmax/fy | σmin/fy | Δσ/fy | |

| B1 | 28.1 | 4.1 | 115.21 | 0.80 | 0.10 | 0.70 | |

| B2 | 28.2 | 4.0 | 112.80 | 0.70 | 0.00 | 0.70 | |

| B3 | 28.3 | 4.1 | 116.03 | 0.60 | −0.10 | 0.70 | |

| B4 | 28.1 | 4.1 | 115.21 | 0.50 | −0.20 | 0.70 | |

| B5 | 28.2 | 4.0 | 112.80 | 0.70 | 0.10 | 0.60 | |

| B6 | 28.1 | 4.1 | 115.21 | 0.60 | 0.00 | 0.60 | |

| B7 | 28.2 | 4.0 | 112.80 | 0.50 | −0.10 | 0.60 | |

| B8 | 28.1 | 4.0 | 112.40 | 0.40 | −0.20 | 0.60 | |

| B9 | 28.2 | 4.0 | 112.80 | 0.70 | 0.20 | 0.50 | |

| B10 | 28.1 | 4.1 | 115.21 | 0.60 | 0.10 | 0.50 | |

| B11 | 28.1 | 4.0 | 112.40 | 0.50 | 0.00 | 0.50 | |

| B12 | 28.2 | 4.1 | 115.62 | 0.40 | −0.10 | 0.50 | |

| B13 | 28.2 | 4.1 | 115.62 | 0.70 | 0.30 | 0.40 | |

| B14 | 28.1 | 4.1 | 115.21 | 0.60 | 0.20 | 0.40 | |

| B15 | 28.1 | 4.1 | 115.21 | 0.50 | 0.10 | 0.40 | |

| B16 | 28.1 | 4.0 | 112.40 | 0.40 | 0.00 | 0.40 |

| Yield Strength, fy | Ultimate Strength, fu | Yield Strain, εy | Ultimate Strain, εu | E | μ |

|---|---|---|---|---|---|

| (MPa) | (MPa) | (%) | (%) | (GPa) | |

| 540.8 | 629.0 | 0.032 | 14.0 | 202.6 | 0.28 |

| Specimen No. | Δσc/fy | Δσ/fy | Nf,t (cycles) | Nf,s (cycles) | es-t (%) | ΔσG,SC/fy | Nf,G (cycles) | eG-t (%) |

| A1 | 0.50 | 0.41 | 171,400 | 142,130 | −17.1 | 0.26 | 260,794 | +52.2 |

| A2 | 0.50 | 0.46 | 135,700 | 142,130 | +4.7 | 0.34 | 121,193 | −10.7 |

| A3 | 0.50 | 0.50 | 129,700 | 142,130 | +9.6 | 0.41 | 68,850 | −43.7 |

| A4 | 0.50 | 0.54 | 113,600 | 142,130 | +25.1 | 0.48 | 43,192 | −62.0 |

| Specimen No. | Δσ/fy | σmax/fy | Nf,t (cycles) | Nf,s (cycles) | es-t (%) | ΔσG,SC/fy | Nf,G (cycles) | eG-t (%) |

| B1 | 0.70 | 0.80 | 24,700 | 45,670 | +84.9 | 0.37 | 92,952 | +276.3 |

| B2 | 0.70 | 0.70 | 31,600 | 51,798 | +63.9 | 0.45 | 52,403 | +65.8 |

| B3 | 0.70 | 0.60 | 36,000 | 59,071 | +64.1 | 0.51 | 34,392 | −4.5 |

| B4 | 0.70 | 0.50 | 44,900 | 67,773 | +50.9 | 0.57 | 25,091 | −44.1 |

| B5 | 0.60 | 0.70 | 49,100 | 71,052 | +44.7 | 0.38 | 83,214 | +69.5 |

| B6 | 0.60 | 0.60 | 57,200 | 82,251 | +43.8 | 0.44 | 54,613 | −4.5 |

| B7 | 0.60 | 0.50 | 67,700 | 95,934 | +41.7 | 0.49 | 39,844 | −41.1 |

| B8 | 0.60 | 0.40 | 87,800 | 112,828 | +28.5 | 0.53 | 31,487 | −64.1 |

| B9 | 0.50 | 0.70 | 90,700 | 101,165 | +11.5 | 0.32 | 143,794 | +58.5 |

| B10 | 0.50 | 0.60 | 103,300 | 119,335 | +15.5 | 0.37 | 94,371 | −8.6 |

| B11 | 0.50 | 0.50 | 129,700 | 142,130 | +9.6 | 0.41 | 68,850 | −46.9 |

| B12 | 0.50 | 0.40 | 157,400 | 171,121 | +8.7 | 0.44 | 544,09 | −65.4 |

| B13 | 0.40 | 0.70 | 178,300 | 151,011 | −15.3 | 0.26 | 280,847 | +57.5 |

| B14 | 0.40 | 0.60 | 219,900 | 182,525 | −17.0 | 0.29 | 184,319 | −16.2 |

| B15 | 0.40 | 0.50 | 253,000 | 223,455 | −11.7 | 0.33 | 134,472 | −46.8 |

| B16 | 0.40 | 0.40 | 319,700 | 277,598 | −13.1 | 0.35 | 106,268 | −66.8 |

| Specimen No. | An (mm2) | Af (mm2) | af,c (mm) | η | ξ (10−3) | s | ξ0.95 (10−3) | Nf,c (cycles) | ec-t (%) |

|---|---|---|---|---|---|---|---|---|---|

| B1 | 73.83 | 41.79 | 10.2 | 0.772 | 4.30 | 0.017 | 4.52 | 23,056 | −6.7 |

| B2 | 62.80 | 49.60 | 12.4 | 0.772 | 4.30 | 0.017 | 4.52 | 29,746 | −5.9 |

| B3 | 55.57 | 60.46 | 14.7 | 0.772 | 4.30 | 0.017 | 4.52 | 37,265 | +3.5 |

| B4 | 45.98 | 69.23 | 16.9 | 0.772 | 4.30 | 0.017 | 4.52 | 44,438 | −1.0 |

| B5 | 64.37 | 50.84 | 12.4 | 0.769 | 3.14 | 0.019 | 3.32 | 47,163 | −3.9 |

| B6 | 54.02 | 58.78 | 14.7 | 0.769 | 3.14 | 0.019 | 3.32 | 58,813 | +2.8 |

| B7 | 46.31 | 69.72 | 17.0 | 0.769 | 3.14 | 0.019 | 3.32 | 71,110 | −1.9 |

| B8 | 36.78 | 78.43 | 19.1 | 0.769 | 3.14 | 0.019 | 3.32 | 82,858 | −5.6 |

| B9 | 63.02 | 49.78 | 12.4 | 0.776 | 1.81 | 0.015 | 1.89 | 81,349 | −10.3 |

| B10 | 55.17 | 60.04 | 14.6 | 0.776 | 1.81 | 0.015 | 1.89 | 101,443 | −1.8 |

| B11 | 45.98 | 69.23 | 16.9 | 0.776 | 1.81 | 0.015 | 1.89 | 122,091 | −5.9 |

| B12 | 36.78 | 78.43 | 19.1 | 0.776 | 1.81 | 0.015 | 1.89 | 142,919 | −9.2 |

| B13 | 64.37 | 50.84 | 12.4 | 0.761 | 1.27 | 0.011 | 1.31 | 159,265 | −10.7 |

| B14 | 54.02 | 58.78 | 14.7 | 0.761 | 1.27 | 0.011 | 1.31 | 196,779 | −10.5 |

| B15 | 46.14 | 69.48 | 16.9 | 0.761 | 1.27 | 0.011 | 1.31 | 236,831 | −6.4 |

| B16 | 35.89 | 76.51 | 19.1 | 0.761 | 1.27 | 0.011 | 1.31 | 278,516 | −12.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lv, F.; Wang, W.; Zhao, W. Fatigue Test and Unified Fatigue Life Calculation of Q460C Steel Notched Plates. Buildings 2023, 13, 697. https://doi.org/10.3390/buildings13030697

Lv F, Wang W, Zhao W. Fatigue Test and Unified Fatigue Life Calculation of Q460C Steel Notched Plates. Buildings. 2023; 13(3):697. https://doi.org/10.3390/buildings13030697

Chicago/Turabian StyleLv, Fengjun, Wanzhen Wang, and Wei Zhao. 2023. "Fatigue Test and Unified Fatigue Life Calculation of Q460C Steel Notched Plates" Buildings 13, no. 3: 697. https://doi.org/10.3390/buildings13030697

APA StyleLv, F., Wang, W., & Zhao, W. (2023). Fatigue Test and Unified Fatigue Life Calculation of Q460C Steel Notched Plates. Buildings, 13(3), 697. https://doi.org/10.3390/buildings13030697