1. Introduction

China has the most expressways in the world, with a total mileage of 150,000 km in 2020, according to statistics from the Ministry of Transport [

1,

2,

3]. The evolution process of China’s expressway mileage from 2010 to 2020 is shown in

Figure 1. As asphalt composite concrete pavement has the advantages of a short construction period, smoothness, comfort, low noise, and convenient maintenance. Asphalt composite concrete pavement structure accounts for more than 90 percent of the expressway that has been opened to traffic in China. Therefore, a large amount of asphalt composite concrete material is required every year in China [

4,

5,

6]. Asphalt composite concrete pavement is the main part of the expressway, therefore, its characteristics have important impacts on the safety, comfort, and durability during the expressway service process [

7,

8].

A typical viscoelastic composite material, asphalt composite concrete is a three-phase system made up of an asphalt binder, a mineral mixture, and air. In order to investigate the effects of temperature, loading stress level, modifiers, additives, etc., on the viscoelastic properties of asphalt composite concrete, various viscoelastic mechanical behavior models are currently combined with viscoelastic basic elements such as dampers and springs [

9,

10,

11,

12,

13,

14]. These tests are based on the uniaxial compression creep test, triaxial compression creep test, and small beam bend test for creep [

15,

16,

17]. Numerous constitutive models based on viscoelastic mechanics have been proposed in order to investigate the viscoelastic deformation properties of asphalt composite concrete, most notably the simple Kelvin model and Maxwell model, the three-element Vendepoel model and Lethersich model, the four-element Burgers model, and the generalized Kelvin model and Maxwell model with more elements [

18,

19,

20,

21]. Additionally, Gao et al. [

19] proposed a five-element model with eight parameters, which can better describe the creep deformation characteristics of plain asphalt mixtures and fiber-reinforced asphalt mixtures. The fitting results obtained from the model are consistent with the data from measurements, and the rheological time it predicts is accurate. To characterize the creep deformation trend of rubber particles and diatomite asphalt mixture, Liang et al. [

20] proposed a modified Burgers model. This model is obviously superior to the Burgers model, and its fitting results at the later stages of creep deformation are more in line with actual experimental findings. According to Ni [

22], the mechanical properties of asphalt composite concrete are closely related to loading time and ambient temperature, and the effects of loading time and ambient temperature should be considered concurrently in the mechanical analysis of asphalt pavement structure; the structural mechanical response of asphalt pavement with multi-layer viscoelastic properties can be calculated using the elastic viscoelastic correspondence principle.

Fiber is added to asphalt composite concrete to considerably increase the overall mechanical performance and durability of asphalt composite concrete pavement, hence extending its useful life and addressing the issue of early damage [

23]. The research on the viscoelastic properties of fiber-reinforced asphalt composite concrete has drawn increasing attention worldwide due to the fact that the inclusion of fiber can greatly improve the road performance of asphalt composite concrete [

24,

25,

26,

27]. Through the compression creep test of polyester fiber-reinforced asphalt composite concrete, Guo and Guo [

28] investigated the impact of fiber length on the viscoelastic performance of asphalt composite concrete in the creep loading stage under different fiber amounts. They then established a viscoelastic mechanical behavior model of fiber-reinforced asphalt composite concrete taking the influence of fiber amount into consideration. Through a pull-out test, Liang [

29] examined the impact of fiber length on the performance of asphalt composite concrete. Rheological testing and microscopic examination of the fiber asphalt matrix material were carried out by Chen and Lin [

30]. The findings demonstrate that the distribution of fiber in asphalt is random in three dimensions, which has a positive influence on bonding and greatly raises the viscosity ratio between fiber-reinforced asphalt composite concrete and regular asphalt composite concrete. Through the Marshall test, static triaxial test, and dynamic triaxial test, Bueno et al. [

31] investigated the effects of fiber amount and length on the mechanical properties of fiber-reinforced cold-mixed asphalt composite concrete. According to the findings, the fiber output is between 0.10 and 0.25 percent, and the 40 mm fiber exhibits good reinforcement properties. Chen [

32] analyzed the influence of the fiber on the pavement performance, expatiated the strengthening mechanism of the fiber asphalt composite concrete pavement with the theory of composite materials and the interfacial chemistry through the tests of the six fibers and three gradations, the asphalt mixture of different combination. Zhou [

33] studied the fatigue damage behavior of asphalt mixture and the fatigue failure of asphalt pavement and predicted the fatigue life of AC overlay on existing PCC pavement based on the theory and method of fatigue damage mechanics. Chen [

34] paved the corn stalk fiber and basalt fiber SMA-13 mixture indoor test road, carried out the production mix ratio design and summarized the corn stalk fiber and basalt fiber asphalt mixture road construction technology. Then, based on the full-scale accelerated loading test, the rutting depth of the corn stalk fiber and basalt fiber SMA-13 surface layer structure and the lignin fiber SMA-13 surface layer structure were analyzed. The research results showed that the corn stalk fiber and basalt fiber SMA-13 surface layer structure has a longer service life [

35,

36,

37]. Nevertheless, there are still a lot of issues in the current research that need to be resolved, including the effects of fiber aspect ratio on the parameters of the viscoelastic mechanical behavior model and the viscoelastic properties of asphalt composite concrete, as well as the effects of fiber-volume-fraction and aspect ratio on the parameters of the viscoelastic mechanical behavior model and the viscoelastic properties of asphalt composite concrete after unloading. How to apply a parameter to accurately depict the impact of fiber-volume-fraction and aspect ratio on the viscoelastic mechanical characteristics of asphalt composite concrete is another important consideration.

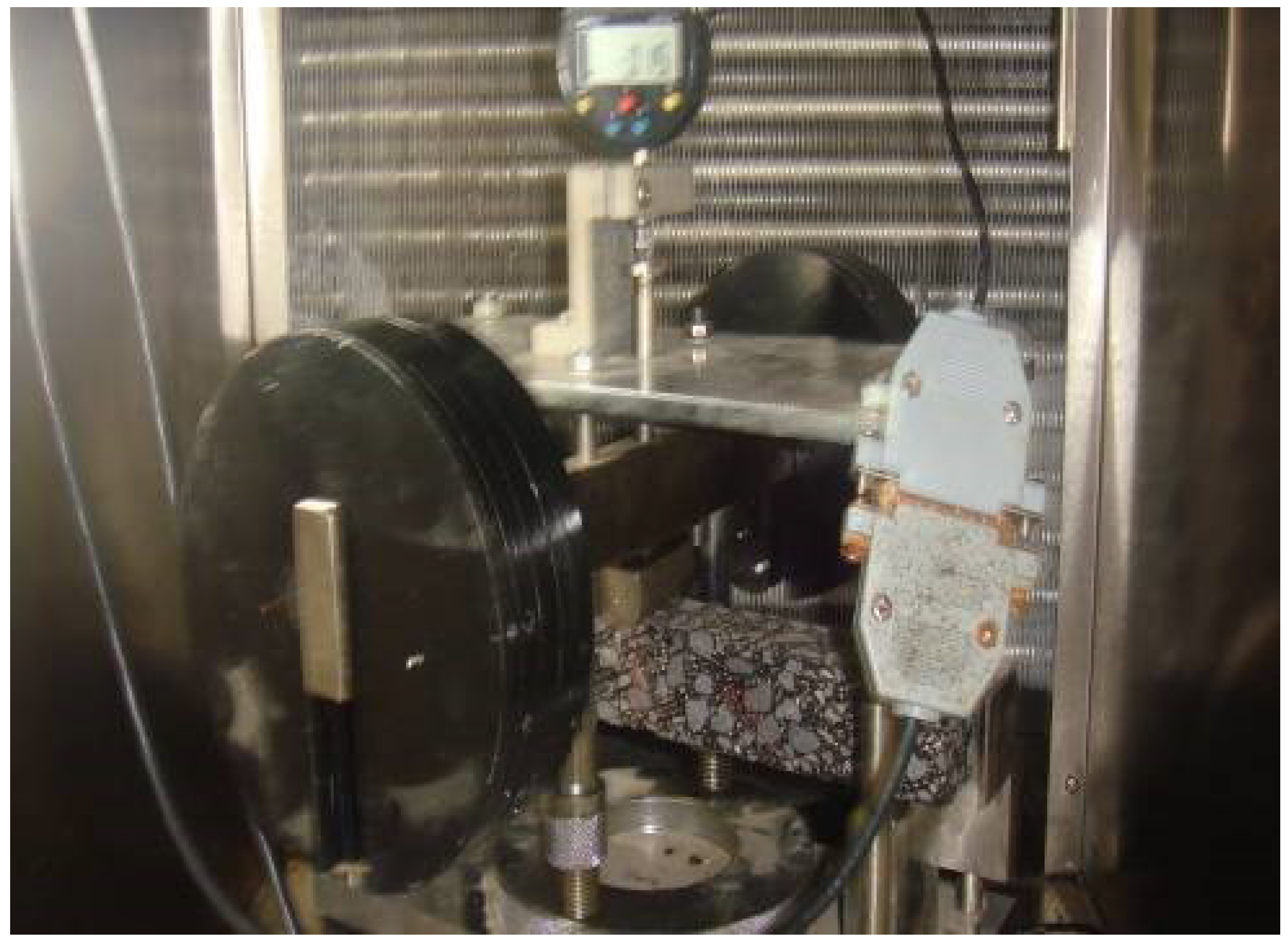

In this study, the ideal asphalt content was established using the conventional Marshall test method, and the tiny beam bend test for creeps was then conducted using the variables fiber volume percent Vf and length–diameter-ratio Ra. The effects of Vf and Ra on the parameters of the viscoelastic mechanical behavior model and the viscoelastic characteristics of asphalt composite concrete throughout the creep loading and unloading stages were carefully investigated using Burger’s model as a foundation. To fully portray the impact of Vf and Ra, fiber amount characteristic parameters λf were used. Last but not least, a viscoelastic mechanical behavior model of fiber-reinforced asphalt composite concrete was created and a viscoelastic analysis was performed.

3. Results

3.1. Effects of Vf on the Parameters of Equation (1) Model

Equation (1) model is composed of the Maxwell model and Kelven model in series. In this model, the elastic element

E1 produces instantaneous elastic deformation that can be recovered immediately after unloading. The resistance of fiber-reinforced asphalt composite concrete to elastic deformation increases with the value. The viscous element

η1 causes permanent deformation in the viscous flow that is irreversible after unloading. The permanent deformation caused by the same load at the same moment decreases as the value increases. The expansion of viscous deformation occurs more slowly and the depth of rutting in fiber-reinforced asphalt composite concrete pavement decreases with increasing relaxation time

η1/

E1. Under the influence of

E2, the deformation produced in the viscoelastic composite element

η2 and

E2 will recover gradually. The deformation of fiber-reinforced asphalt composite concrete material develops more slowly and is more resistant to deformation the longer the delay time

η2/

E2.

Table 2 displays the model parameters for Equation (1) for fiber-reinforced asphalt composite concrete with various fiber-volume-fractions. It is clear that as the fiber-volume-fraction rises,

E1 first rises and then falls. The greatest value is attained when the fiber-volume-fraction is 0.35 percent. The elastic deformation resistance to the transient load of fiber-reinforced asphalt composite concrete is now very strong. Fiber can only improve the elasticity of asphalt composite concrete when the fiber volume percent is adequate, as evidenced by the fact that when the fiber-volume-fraction reaches 0.69 percent, the value of fiber-reinforced asphalt composite concrete

E1 is lower than that of matrix asphalt composite concrete. As the fiber-volume-fraction rises, the value of

η1 first rises and then falls. The greatest value, which is more than twice the value of the matrix asphalt composite concrete, is attained when the fiber-volume-fraction is 0.35 percent. The fiber-reinforced asphalt composite concrete’s

η1 is smaller than the matrix asphalt composite concrete when the fiber-volume-fraction exceeds 0.69 percent.

As a result, fibers with the right volume fraction have positive effects on viscosity. The fiber exhibits a good viscosity-increasing effect at a volume percentage of 0.35 percent. At the moment, asphalt composite concrete with fiber reinforcement has a decent resistance to permanent deformation, and too much fiber lowers that resistance. The relaxation time η1/E1 and delay time η2/E2 of fiber-reinforced asphalt composite concrete first increase and then decrease with the increase in fiber-volume-fraction. When the fiber-volume-fraction is 0.35 percent, the relaxation time η1/E1 and delay time η2/E2 both reach the maximum value. As a result, adding the right quantity of fiber can increase asphalt composite concrete’s resistance to rutting. The fiber has a better impact on the rutting resistance of asphalt composite concrete when the fiber volume ratio is 0.35 percent. E1, η1, η1/E1, and η2/E2 increase first and then decrease with the increase in fiber-volume-fraction. When the fiber-volume-fraction is 0.35 percent, the maximum value appears. The best volume fraction of polyester fiber to play the best role in reinforcing is 0.35 percent at the moment because fiber-reinforced asphalt composite concrete has strong resistance to elastic deformation, viscous flow deformation, and rutting deformation.

3.2. Effects of Vf on the Parameters of Equation (2) Model

When the small beam bend test for the creep piece enters the accelerated creep stage, remove the load, collect the mid-span deflection of the beam test piece within 30 min after unloading, convert the deflection into strain, apply Origin 8.5 software to fit the test data and model parameters, and obtain the Equation (2) model parameters of asphalt composite concrete with different fiber-volume-fraction, as shown in

Table 3. It can be seen that the same parameter values of the Equation (2) model and Equation (1) model are quite different. It is shown that the

E2 and

η2 value of Equation (1) model parameters greatly increases compared with the loading stage, and the delay time

η2/

E2 also increases, but

η1 significantly decreases.

This is so because the rapid creep stage of asphalt composite concrete is the creep failure stage. Dislocations and slides between the interior aggregates occur when asphalt composite concrete beams are bent, resulting in material damage and decreased performance. The mechanical model parameters obtained in the creep loading stage cannot be used to characterize the actual deformation characteristics of fiber-reinforced asphalt composite concrete after unloading because the actual permanent deformation represented by the model parameters in the unloading stage is greater than the theoretical permanent deformation represented by the model parameters in the loading stage, and the rate of actual deformation recovery also becomes slow.

Table 3 also shows that, in comparison to the creep loading stage, there is less of a correlation between the test data in the creep unloading stage and the model in Equation (2). This suggests that the Burgers model is more accurate at describing the viscoelastic deformation properties of asphalt composite concrete during the loading process.

3.3. Effects of Ra on the Parameters of Equation (1) Model

Table 4 displays the model parameters that were produced using Equation (1) model and Origin 8.5 software fitting the test data of fiber-reinforced asphalt composite concrete creep loading stage with various fiber length–diameter-ratios. It is clear that as the fiber length-to-diameter ratio rises, the elastic modulus of elastic element

E1 in the model initially rises and then falls. The greatest value is attained at a fiber length–diameter-ratio of 324, and the fiber exhibits good elastic reinforcement. With an increase in the fiber length–diameter-ratio, the value of the model parameter

η1 first rises and subsequently falls. The greatest value is reached for a fiber length–diameter-ratio of 324. The value is raised by nearly two times when compared to the base asphalt composite concrete. The viscosity-increasing impact of the fiber is currently better, and fiber-reinforced asphalt composite concrete is more resistant to permanent deformation.

With an increase in the fiber length–diameter-ratio, the relaxation time η1/E1 first rises and subsequently falls. The greatest value is seen when the fiber length–diameter-ratio reaches 324. The fiber-reinforced asphalt composite concrete currently offers greater resistance to rutting deformation. With an increase in the fiber length–diameter-ratio, the delay time η2/E2 first rises and subsequently falls. The highest delay time is reached at a fiber length–diameter-ratio of 324, and the fiber-reinforced asphalt composite concrete exhibits good resistance to long-term deformation. As can be observed, fiber-reinforced asphalt composite concrete is more resistant to elastic deformation, rutting deformation, and viscous flow deformation. The ideal fiber length-to-diameter ratio is 324.

3.4. Effects of Ra on the Parameters of Equation (2) Model

Table 5 displays the model parameters that were produced using Equation (2) model and Origin 8.5 software fitting the test data of fiber-reinforced asphalt composite concrete creep unloading stage with various fiber length–diameter-ratios. The values of the same model parameters have significantly altered in the two distinct stages of creep loading and creep unloading, as can be seen. The equation for the creep unloading stage (2), the actual permanent deformation of fiber-reinforced asphalt composite concrete with different fiber aspect ratios, as represented by the model parameters in the unloading stage, is greater than the theoretical permanent deformation, as represented by the model parameters in the creep loading stage. This is because the

E2 and

η2 values of the model parameters in the loading stage have a large increase, the delay time

η2/

E2 has a small increase, but

η1 has a large decrease. When compared to theoretical creep deformation, which is described by model parameters in the loading stage, actual creep deformation, as measured by unloading stage characteristics, recovers more slowly. At the unloading stage, there is less correlation between experimental data and the fiber-reinforced asphalt composite concrete model with various aspect ratios than there is at the loading stage.

3.5. Establishment of Constitutive Equation of Fiber-Reinforced Asphalt Composite Concrete

In summary, the length–diameter-ratio and fiber-volume-fraction have a significant impact on the viscoelastic characteristics of asphalt composite concrete. Using the models in Equations (1) and (2), the viscoelastic constitutive equations of fiber-reinforced asphalt composite concrete are developed for the creep loading stage and the unloading stage, respectively. The characteristic parameter of fiber amount λf = Vf × Ra is used to reflect the comprehensive influence of Vf and Ra. Equation (1) model parameters all have the change rule of first increasing and then decreasing with the increase in fiber amount characteristic parameters. The relationship between model parameters and fiber amount characteristic parameters of nonlinear fitting Equation (1) can be expressed as:

By substituting Equations (3)~(6) into Equation (2), the creep equation of fiber-reinforced asphalt composite concrete characterized by the Burgers model considering the influence of λf can be obtained:

The derivative of Equation (7) with respect to time can be used to obtain the differential constitutive equation of fiber-reinforced asphalt composite concrete described by the Burgers model taking into account the influence of λf:

Equation (2) model parameters all have the change rule of first increasing and then decreasing with λf. The relationship between the model parameters and λf of nonlinear fitting Equation (2) can be expressed as:

By substituting Equations (3)~(7) into Equation (2), the creep equation of fiber-reinforced asphalt composite concrete characterized by the Burgers model considering the influence of fiber amount characteristic parameters can be obtained:

The derivative Equation (13) can be used to generate the differential constitutive equation of fiber-reinforced asphalt composite concrete described by the Burgers model taking into account the influence of fiber amount characteristic parameters over time:

4. Discussion

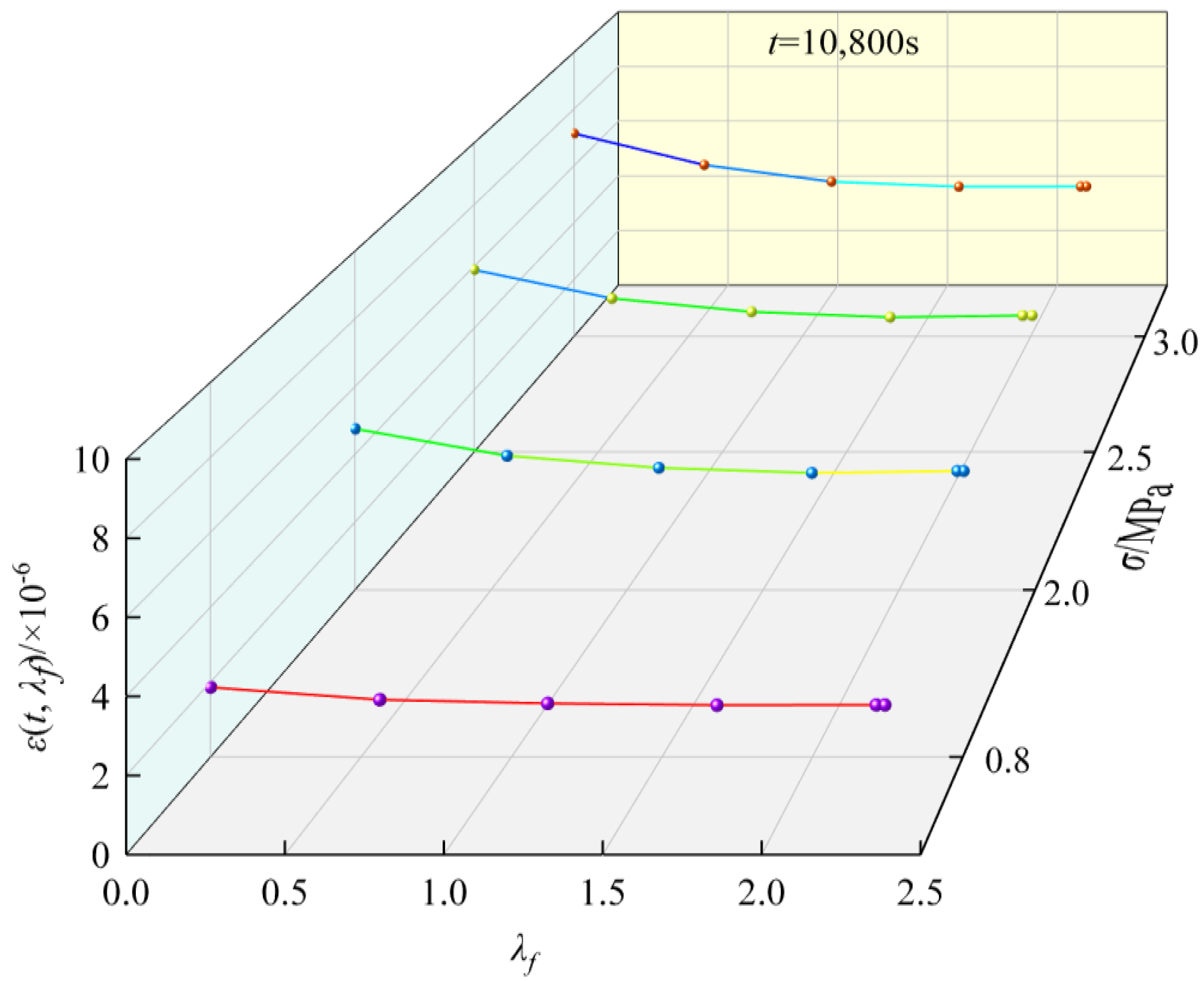

The relationship between the creep strain at the loading stage and the characteristic parameters of fiber amount obtained from Equation (7) is shown in

Figure 4. As can be observed, the creep strain drops first and then increases with the increase in fiber amount characteristic parameters, regardless of the same loading time, different stress levels, or the same loading stress, with different loading times. The lowest value is attained when the fiber amount characteristic parameter is around 1.68. The fiber-reinforced asphalt composite concrete now exhibits good resistance to creep deformation. The creep strain of fiber-reinforced asphalt composite concrete increases with increasing tension and loading duration.

Figure 5 depicts the link between the creep rate during the loading stage and the characteristic fiber amount values determined from Equation (8). The smallest value of the creep rate is reached when the fiber amount characteristic parameter is 1.68; the higher the stress, the higher the creep rate. As can be seen, the creep rate first reduces and then increases as the fiber amount characteristic parameter increases. Additionally, Equation (8) demonstrates that as loading time increases, the creep rate decreases.

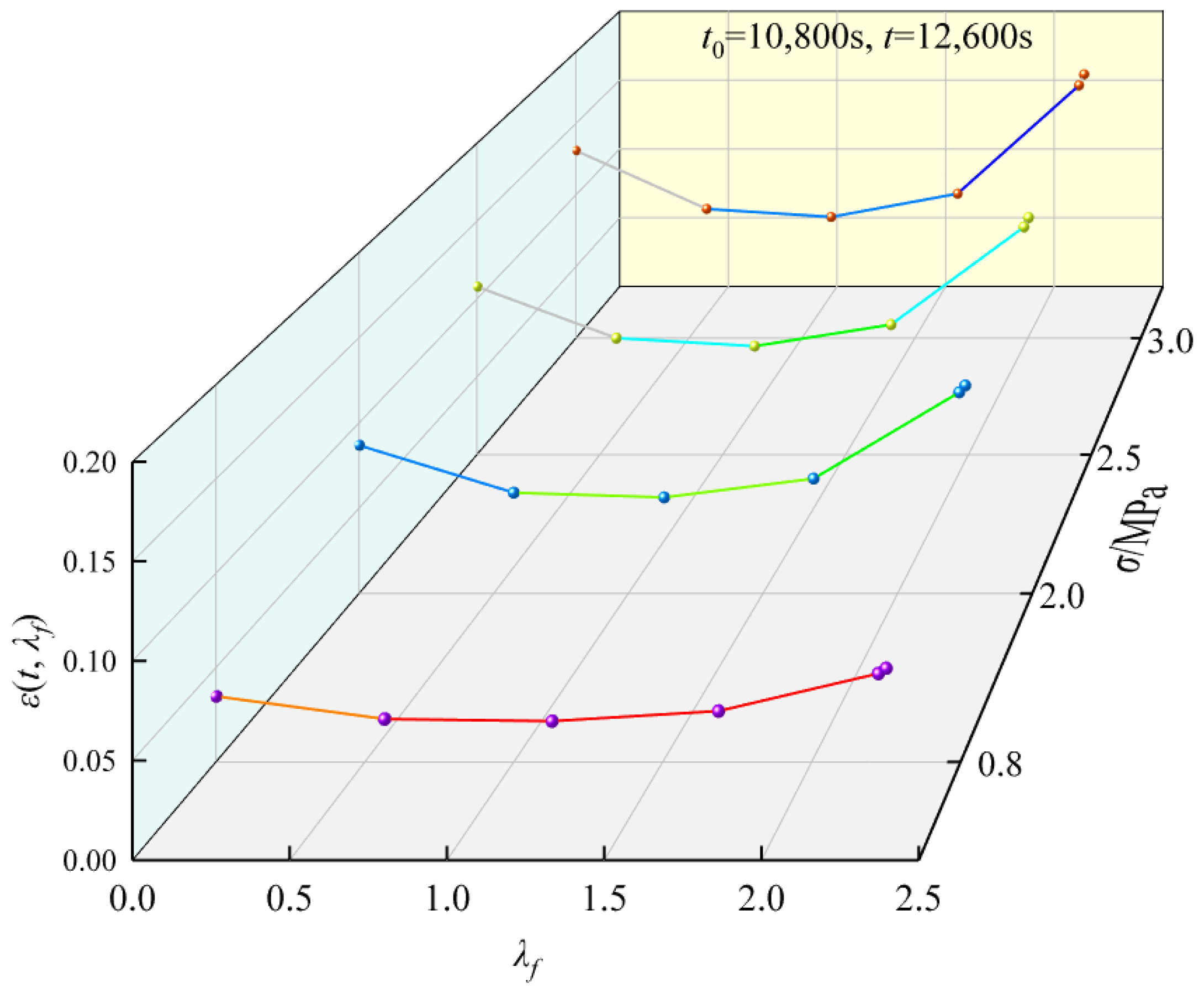

The relationship between the creep strain of fiber-reinforced asphalt composite concrete after unloading and the characteristic parameters of fiber amount obtained from Equation (12) is shown in

Figure 6. It is evident that the residual creep deformation following unloading increases with increasing loading tension. As the characteristic parameter for fiber amount increases, the residual creep deformation first drops and subsequently increases. The minimal residual creep deformation of fiber-reinforced asphalt composite concrete has a fiber amount characteristic parameter value of around 1.13 for the same loading and unloading period and varied loading stress circumstances. Currently, fiber-reinforced asphalt composite concrete has a superior capacity for self-healing creep deformation. Additionally, Equation (12) demonstrates that damage to the fiber-reinforced asphalt composite concrete material and residual creep deformation after unloading increase with the length of the creep loading time.

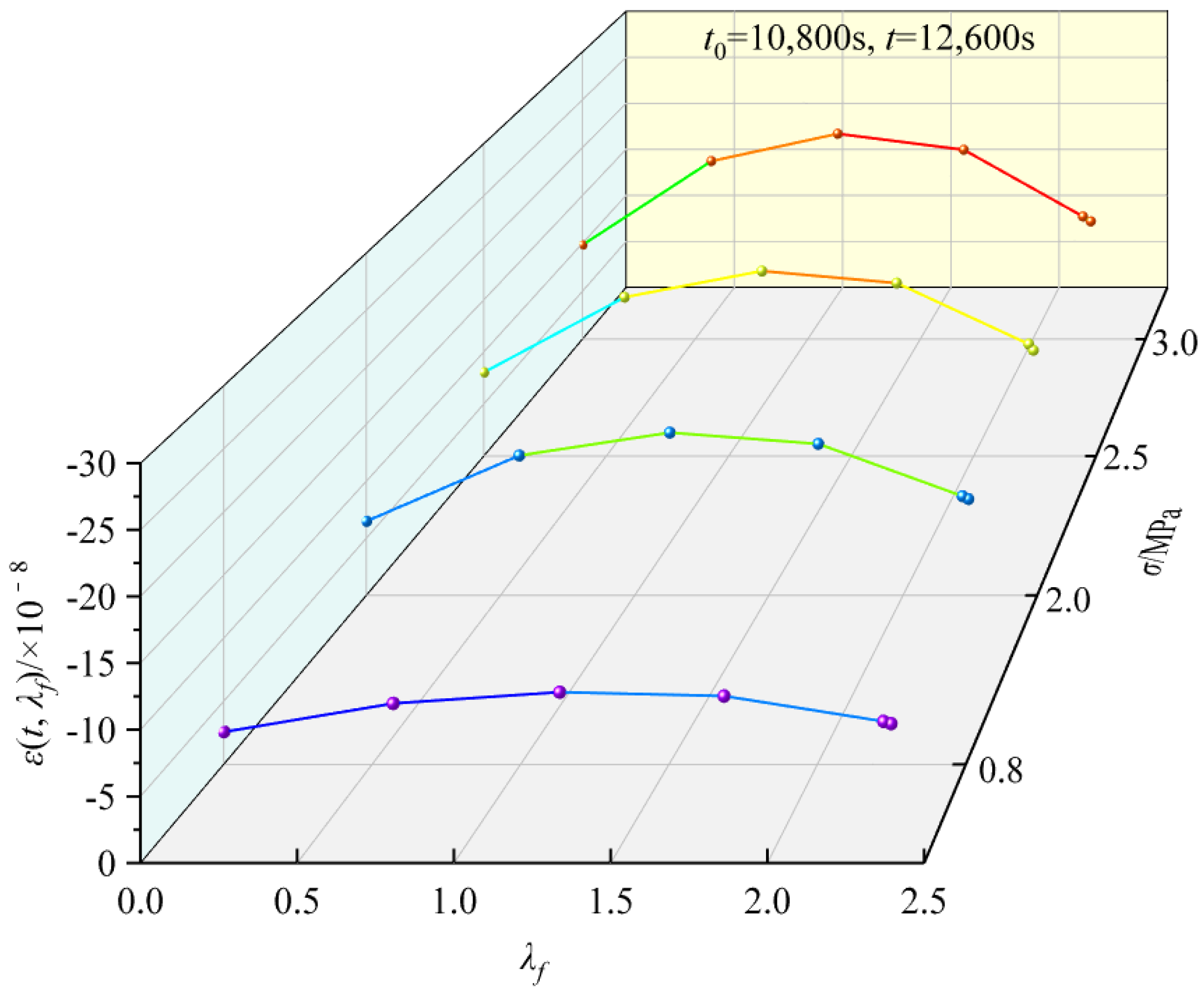

Figure 7 depicts the link between the fiber-reinforced asphalt composite concrete’s post-unloading creep rate and the typical fiber amount characteristics derived from Equation (13). As can be seen, the greater the loading stress, the faster the creep deformation recovers due to the inertia of the immediate recovery of elastic deformation after unloading. With an increase in fiber amount characteristic characteristics, the creep deformation recovery rate first rises and subsequently falls. When the creep deformation recovery rate is at its highest, the fiber amount characteristic characteristics of fiber-reinforced asphalt composite concrete are around 1.13 under the same loading and unloading times and under various loading stress circumstances. Currently, fiber-reinforced asphalt composite concrete has a good capacity for self-healing deformation. Additionally, according to Equation (13), creep load damage to fiber-reinforced asphalt composite concrete increases with loading time and decreases with creep deformation recovery rate.

5. Conclusions and Limitations

Based on the creep test of polyester fiber-reinforced asphalt composite concrete, this paper draws the following conclusions.

According to the results of the fiber-reinforced asphalt composite concrete’s creep tests, the position of the creep deformation time relationship curve, the creep rate, the position of the creep compliance time curve, and the instantaneous modulus of resilience following unloading are all lowest when the fiber-volume-fraction is 0.35 percent and the length–diameter-ratio is 324. Currently, fiber-reinforced asphalt composite concrete has strong resilience to elastic deformation after unloading as well as good resistance to creep deformation.

The Burgers model has a strong connection with the test results of fiber-reinforced asphalt composite concrete during the creep loading and unloading stages. This model has a flaw in that it describes the permanent deformation of asphalt composite concrete as a linear function that is inversely related to viscosity and proportionate to time. The model is still unable to accurately depict the deformation characteristics of asphalt composite concrete during the whole loading and unloading operation due to the relationship between viscosity and the increment of permanent deformation.

With an increase in the fiber-volume-fraction and length–diameter-ratio, the model parameters of the Burgers model in the creep loading stage and unloading stage change according to a predetermined pattern. Fiber-reinforced asphalt composite concrete offers superior resistance to elastic deformation, viscous flow deformation, and rutting deformation when the fiber-volume-fraction is 0.35 and the length–diameter-ratio is 324.

The material performance of fiber-reinforced asphalt composite concrete is harmed by creep loading damage. The numerical values of the identical model parameters in the creep loading stage and the creep unloading stage change significantly in the viscoelastic model that represents the creep deformation properties of fiber-reinforced asphalt composite concrete. The deformation features of the unloading process can be more accurately reflected by the Burgers model.

The distinctive fiber amount metrics can fully capture the impact of fiber-volume-fraction and aspect ratio. Burgers model’s description of the differential constitutive equation of fiber-reinforced asphalt composite concrete under creep loading, which accounts for the influence of fiber amount’s characteristic parameters, may be described by Equation (8). Equation (13) can be used to define the differential constitutive equations of fiber-reinforced asphalt composite concrete in the creep unloading stage as described by the Burgers model while taking the influence of fiber amount characteristic factors into consideration. Theoretical investigation demonstrates that polyester fiber-reinforced asphalt composite concrete has greater deformation resistance and deformation self-healing ability when the characteristic parameter value of polyester fiber amount is 1.13.

In this paper, the applicability of the conclusions drawn from polyester fiber asphalt composite concrete to other types of soft fiber asphalt concrete needs further study. The relationship between the macroscopic mechanical properties and the microstructure of fiber-reinforced asphalt concrete deserves further study. The influence of fiber type and cooling rate on TSRST test parameters of fiber asphalt concrete still needs further study.