Abstract

The rapid urbanization of developed countries and the difficulty in disposing of agricultural wastes have created opportunities for the construction industry to use agricultural wastes. A wide variety of agricultural waste materials are already in use with concrete as substitutes for cement and aggregates, as well as reinforcing materials. This study reviews the available literature published from 1935 to 2022 on agricultural wastes being used as building materials. The research utilizes a bibliographic approach based on the Scopus database. This article retrieves data employing the Scopus database and incorporates 671 articles based on the keywords, agricultural wastes used as building materials. The scientometric analysis is the second step, wherein the patterns of the obtained articles are investigated with various factors such as countries with the most publications, sources that have the most publications, most frequently appearing keywords, and articles with more relevant research works. A summary of the results obtained at various stages of the research is depicted in each phase. Detailed quantitative and qualitative discussions are also conducted to achieve the three main objectives: the summarization of quantitative data, discussion of the existing application, and identification of future research directions. These findings serve the future endeavor of agricultural waste-to-building materials’ incineration academic research. The scientometric review paves the way for academics from various nations to impart novel ideas and information and foster research collaboration.

1. Introduction

The construction industry worldwide consists of real estate and urban development that include residential and office buildings, retail properties, hotels, amusement parks, and many such establishments. Concurrently, the urban development sector comprises any subsectors such as water supply and sanitation, urban transport, schools, and healthcare that aid in city development and management [1].

The demand for and cost of building materials are increasing daily due to the shortage of raw materials [2]. Therefore, the procurement of natural resources for building materials is becoming a global issue. Furthermore, conventional building materials, such as cement, require a great deal of thermal and electrical energy. Hence, during production, it results in higher construction costs. Furthermore, the construction industry is inherently unsustainable. These observations suggest that more scientific research works are needed in developing more sustainable and environmentally friendly building materials without sacrificing or relinquishing the building quality [3].

In addition, the disposal of wastes generated from crops such as sugarcane bagasse, wheat husks, coconut shell, and rice husks is crucial in developing countries. For example, India has been reported to produce over 600 (MT) of agricultural waste in a year [4]. Moreover, as the farming system becomes more intensive, agricultural wastes are expected to be generated more because of the rising agricultural practices in the current decade [5]. The predominantly used methods for disposing of and dealing with agricultural wastes are dumping, incinerating, and composting conventionally. Unfortunately, all these methods have significant negative environmental consequences. However, new research attempts have shown that agricultural waste and its byproducts can be utilized to develop a viable and preliminary solution to the recently identified challenges, either in part or as a whole [6,7].

The use of agricultural wastes in the construction industry reduces the environmental impact of waste disposal in landfills, thereby reducing the pollution caused by conventional building materials such as cement [8]. There has been partial replacing of the sand in the production of cement blocks with agricultural crop wastes such as peanut shells, rice husks, rice straws, and coconut shells. The utilization of agricultural wastes in producing blocks has met ASTM standards for the strength and durability of the product [9,10,11,12,13,14,15,16,17]. In addition, wat and barley straw fibers stabilized the soil to produce bricks with properties facilitating the development of environmentally friendly and safe building materials [18]. Furthermore, it was demonstrated that straw bale instead of soil construction led to more environmentally friendly buildings. Materials with thermal performance and low embodied energy have been cited as the reason for this issue. It has also been concluded that the use of agricultural wastes as building materials is acceptable and can help meet the sustainability goals, and at the same time reduce pollution and other harmful effects involved [19,20].

The field of research employing agricultural wastes as building materials and their applications in construction can almost be traced back to the beginning of the 21st century. The state of agricultural wastes being economical, universally available, cost-efficient, and yet a possible building material motivated the current investigation. These agricultural wastes are utilized as building material on supplementary cementitious materials (SCMs), an alternative to recycled aggregate, and alternative building materials. The utilization of agricultural wastes in the construction industry assists environmental and sustainable development in various ways.

This article qualitatively evaluates the global trend of the literature seeking alternative agricultural wastes as building materials from 1935 to 2022. In the current study, scientometric analysis was conducted to examine the published articles that employed agricultural wastes for construction. Therefore, a systematic analysis of various studies on agricultural wastes as building materials is provided including an assessment of the current state of the research and a forecast of future trends based on the knowledge of the application of agricultural wastes as building materials.

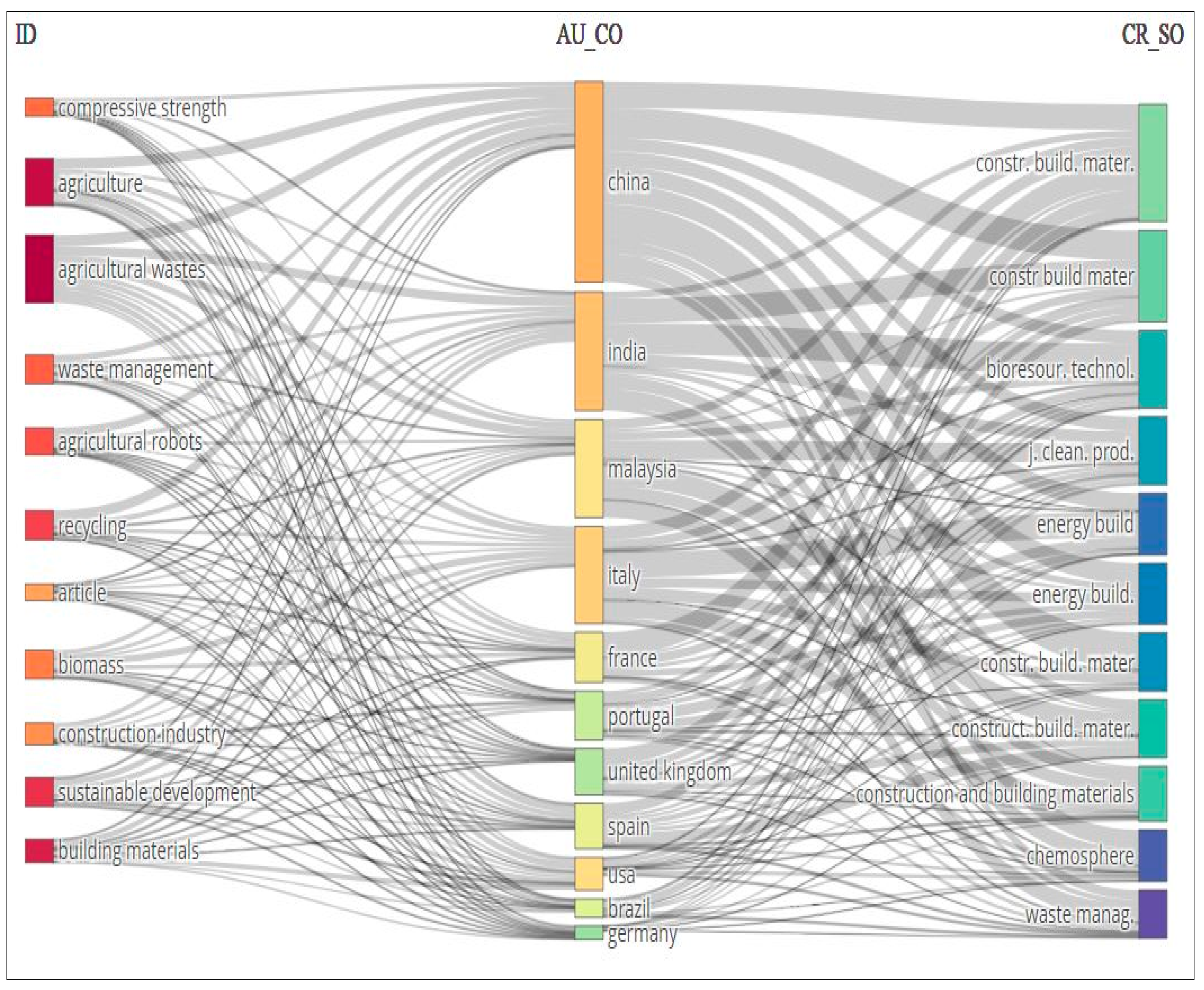

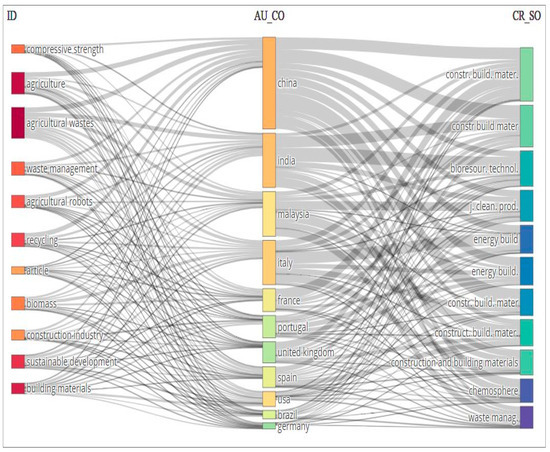

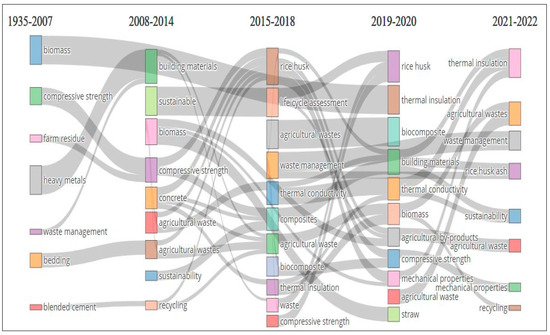

As a visual reference, this type of investigation on the performance of scientists can reveal patterns followed and improve the research in developing and mature disciplines [21,22]. In recent years, bibliometric analysis has become a popular method. The main objective of the bibliometric study is to measure the performance within a specific field or body of literature in national and international scientific and technological research [23,24,25,26]. Data from a wide range of fields, such as biology, physics, social science, and health science have been incorporated into the methodology employed in preparing this article. Even when traditional literature reviews fail to provide enough direction, bibliometric analyses play an important role in helping researchers chart a course forward [27]. Figure 1 illustrates the Sankey diagram of the country, keyword, and source of topics researched. Bibliometric analysis was conducted based on three principles: the Zipf, Bradford, and Lotka laws [28]. According to the Zipf’s law, predicting the distribution of words in a text is possible based on their frequency [29]. The Bradford’s law is a good starting point for librarians in determining the number of core journals in a given field of study [30,31]. In accordance with the Law of Scientific Productivity, formulated by Lotka, an author’s published articles, on average once in every two years in a given field, measure the scientific productivity of the author [32,33].

Figure 1.

Sankey diagram of country, keyword, and source of researched topics.

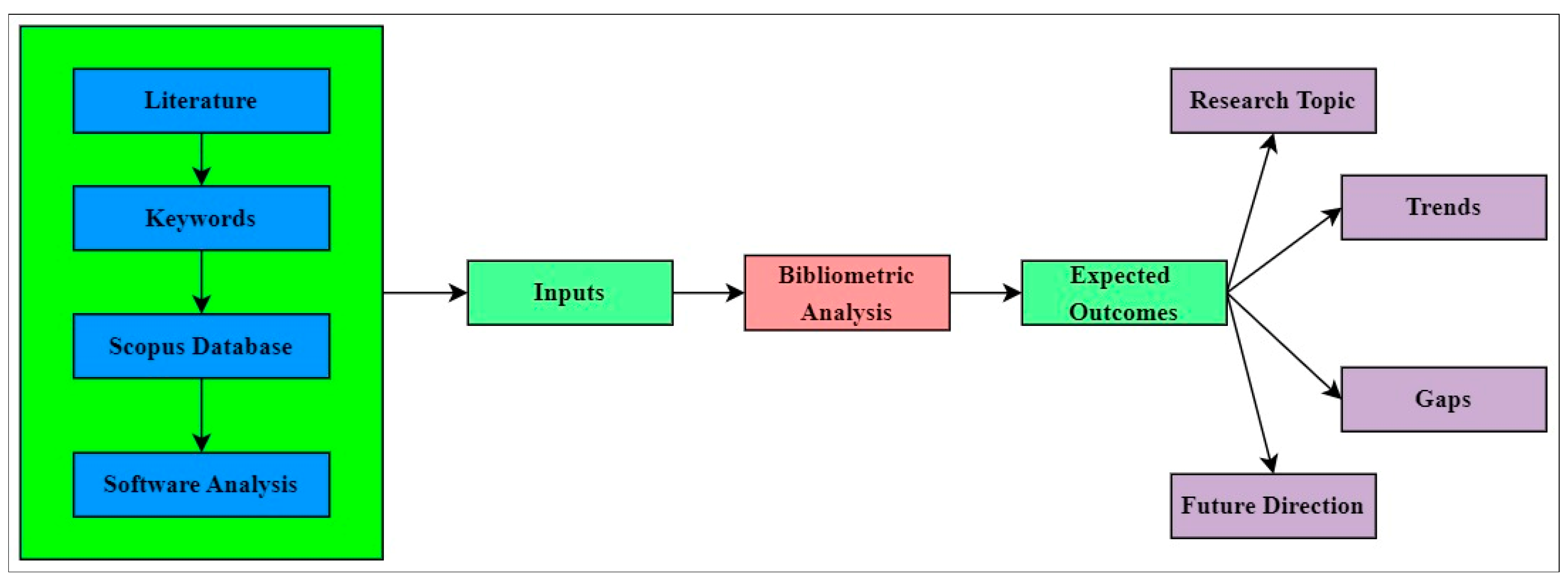

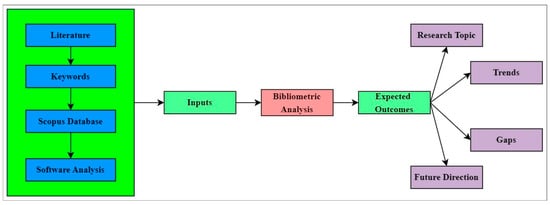

Bibliometrics is the study of the structure of documents using tools, objectives, frequency classification, ranking, and reference analysis. Although document structures are essential for all topics, they are particularly important in the field of information inspection [34]. In the concept of “sustainable alternative building material” in this article, the unique values of the documents were created through knowledge diagrams based on keywords, groups, and citations using the VOSviewer quantification feature [35]. This method was applied for validation from the year 1935 to 2022. The outcome of the bibliometric analysis is demonstrated in Figure 2.

Figure 2.

Outcome of bibliometric analysis.

VOSviewer is used to view bibliographic analysis, and to create and view graphical maps based on author sections and other important published topics. Network maps utilize various colors, shapes, and symbols to represent the relationship and its relative contribution. The number of sides represents nodes, and the thickness of the link chain represents the connectivity with the number of copies made by the researcher. Some researchers have used the VOSviewer software (version 1.6.18) to publish the bibliometric analysis results [36,37,38,39,40,41,42].

In this study, a scientometric analysis was conducted on the bibliometric data regarding the utilization of agricultural wastes as building materials. A scientometric analysis was employed to address the fundamental flaws of conventional manual reviews. More precisely, the identification of sources with the greatest number of articles, co-occurrence of keywords, author collaboration, the most cited articles, and regions actively engaged in the utilization of agricultural wastes as building materials were studied.

2. Methodology

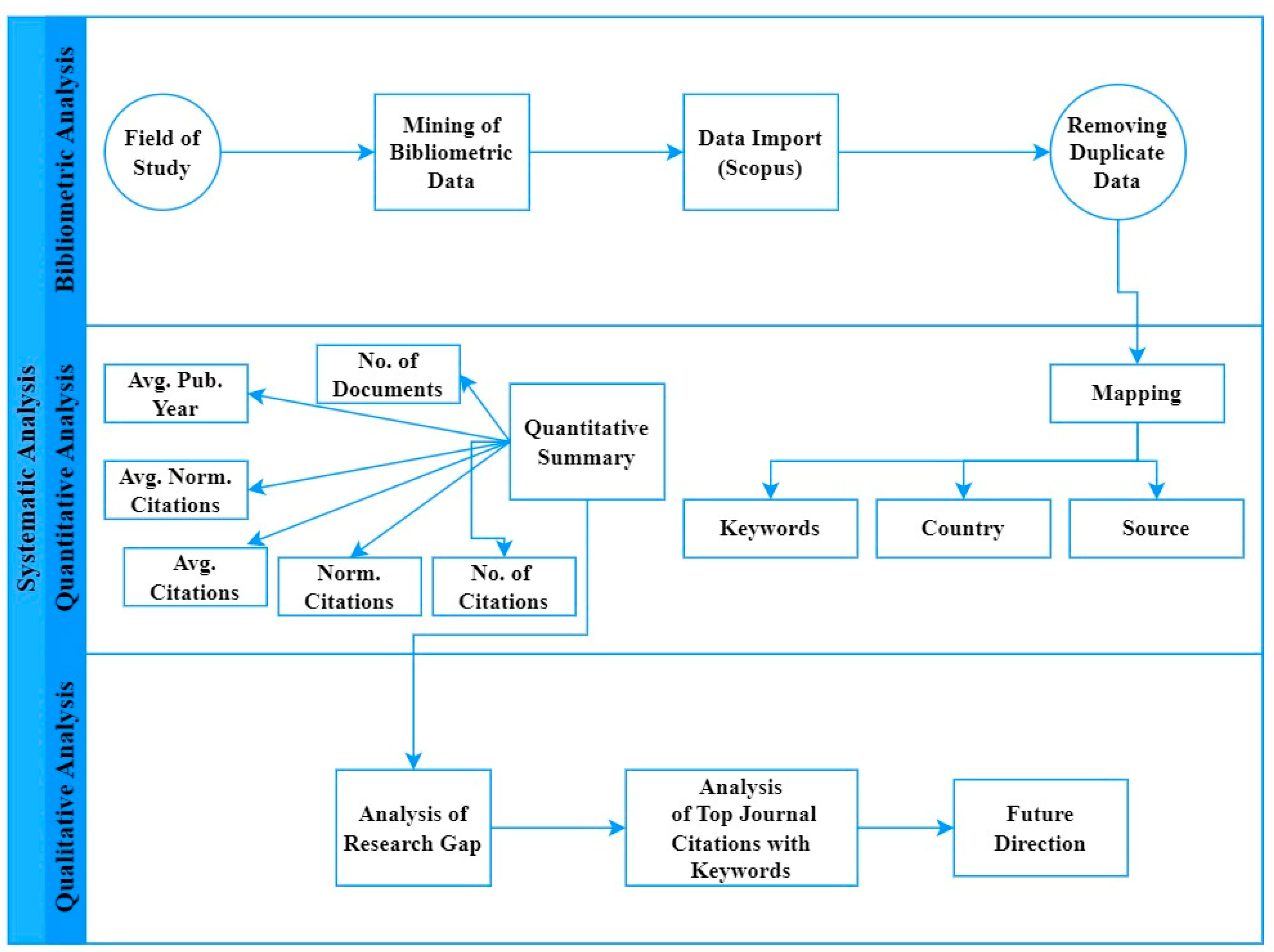

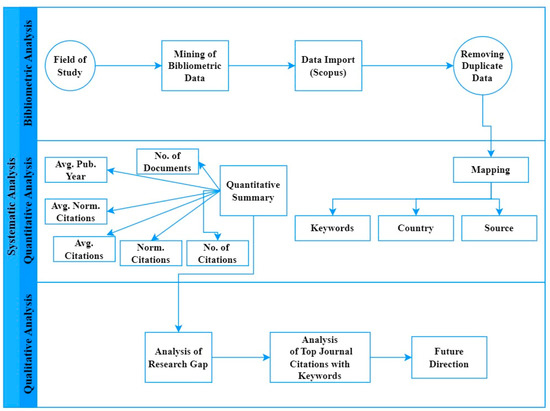

To complete the examination of this research, the researchers observed the articles on “agricultural wastes as building materials” distributed in the World Logical Diary through 2022 and considered their relevance. For the corresponding exploration, the relevant data sets were scrutinized from the Scopus database. A complete analysis was carried out with the whole content of the publications (articles, book chapters, and proceeding papers), involving investigations on “agricultural wastes used as building materials” and “agricultural wastes in the construction industry”. In this bibliometric assessment, the segments examined were articles, authors, and references. Figure 3 displays the graphical representation of the methodology of this research.

Figure 3.

Methodology of research.

Data Acquisition

In this study, the data obtained from the existing literature play a pivotal role as they determine the scientific basis of the concluded results. Therefore, the database and the search system were sensibly selected. Scopus was chosen as the bibliographic database because it is comprehensive and structured, serving as a powerful source for intensive scientific research. It is the most widely used and recognized database for bibliographic research. Between the period of 1935–2022 with the keyword “agricultural wastes used as building materials”, a total of 671 publications were retrieved from the Scopus database, including articles, conference contributions, book chapters, and books.

Table 1 lists the document publication types for the same stipulated time (1935 to 2022) and indicates the language in which the articles were published. In total, 96% of the documents were published in the English language. Regarding the publication access of the articles, 74% of the articles were published as open source.

Table 1.

Main information about data.

3. Discussion

3.1. Trends in Scientific Study on Agricultural Wastes Used as Building Materials

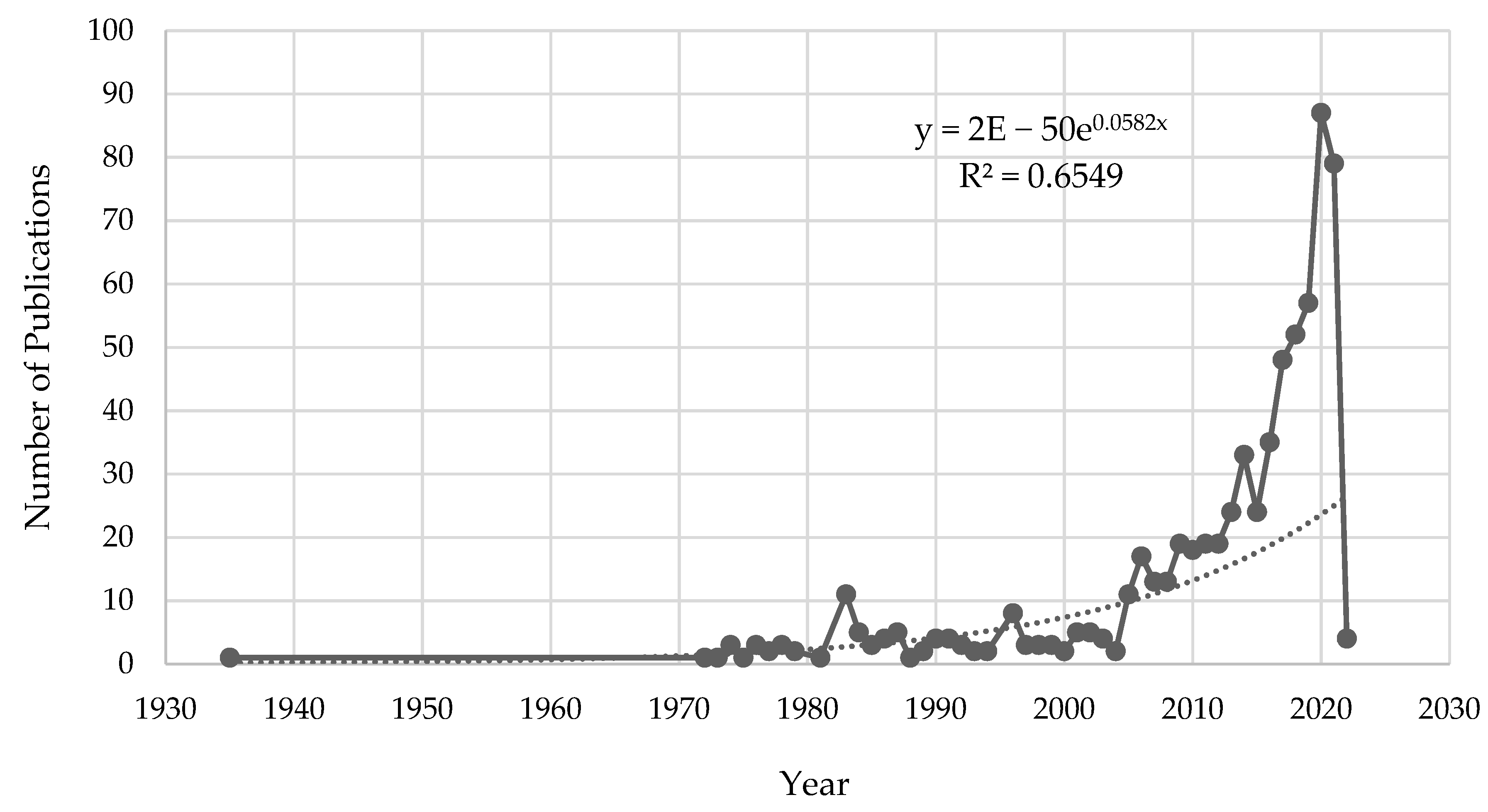

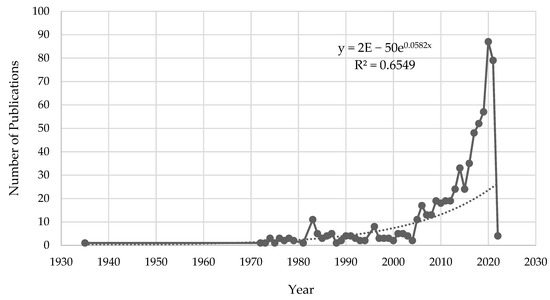

Journal trends in “agricultural wastes used as building materials” from the year 1935 to 2022 are presented and elucidated in this section. As was mentioned, 671 published articles were obtained from this period of time. The yearly publication trend is depicted in Figure 4. Since 2004, the number of articles published on the topic has increased significantly. Every decadal year, for example, 1985 and 1995, a peak in the publication trend is observed. Despite this, the number of research articles published has steadily increased over the last four decades. From 2015 to 2020, the number of publications was seen to grow exponentially.

Figure 4.

Number of publications on “agricultural wastes used as building materials”.

3.2. Analysis of Research Keywords

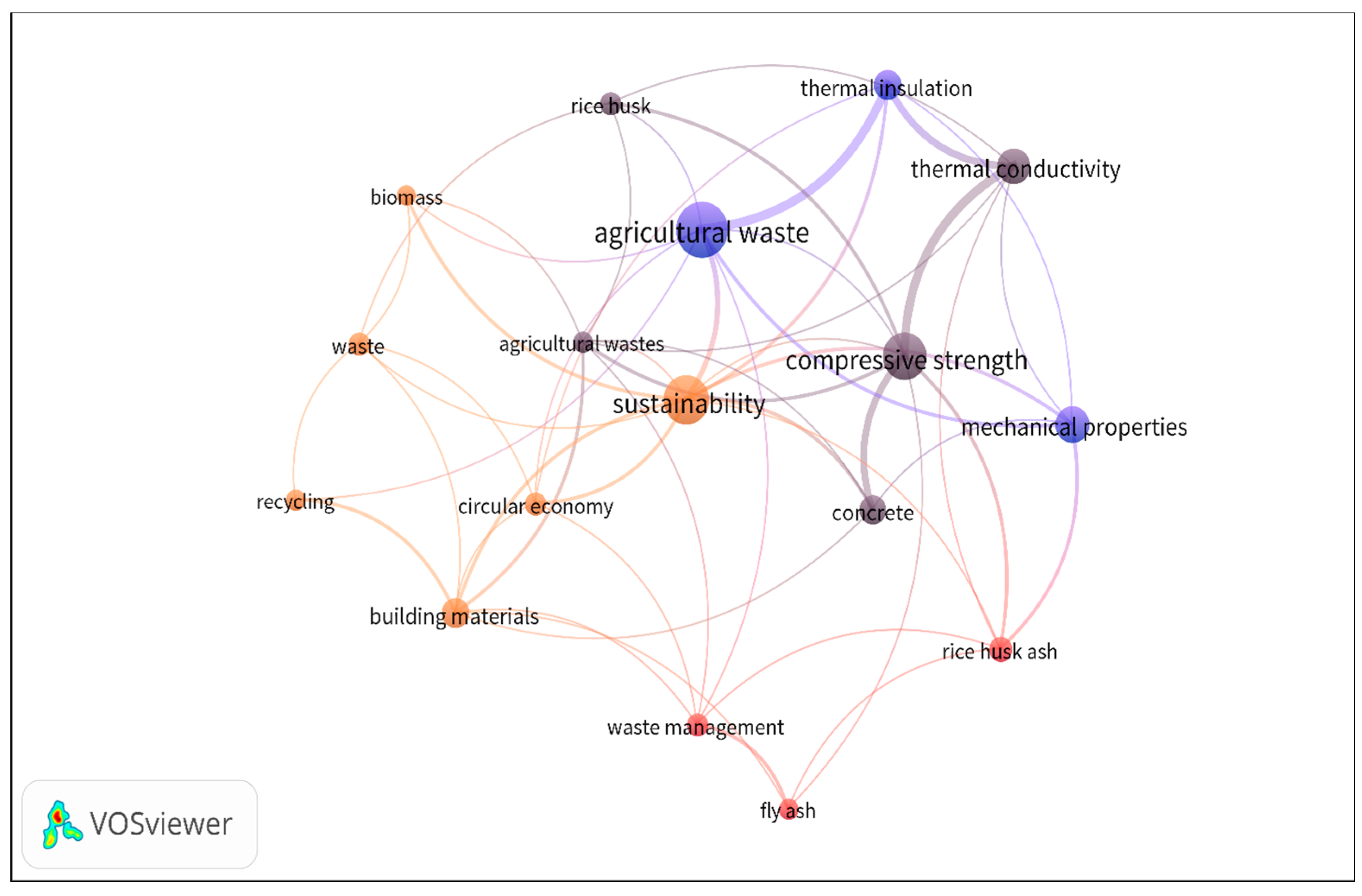

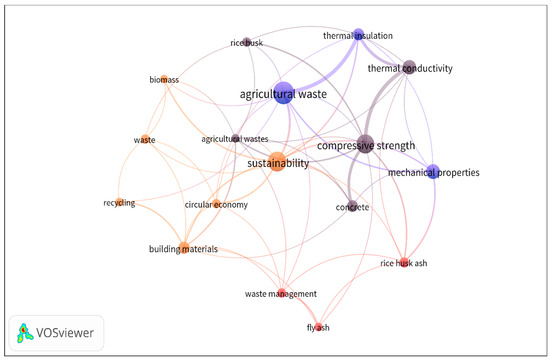

Existing studies and research topics are described regarding keywords [43]. A close relationship indicated between two or more keywords is stated as keyword co-occurrence. Author keywords and fractional counting are used to improve the quality of VOSviewer results [44]. This review started with a broader topic search to analyze the research trend of “agricultural wastes used as building materials”. The retrieved publications were examined to see the most popular keywords associated with “agricultural wastes used as building materials”. Figure 5 shows the most occurring keywords. The minimum number of co-occurrences was maintained following the default value, which was six. Maintaining this limiting condition, 35 published articles out of 671 were initially selected.

Figure 5.

Keywords.

In general, there were closer ties among the keywords in the same grouping (Figure 5). For example, studies on agricultural wastes and compressive strength have frequently been carried out in the same publication. In Figure 5, the interconnectedness of keywords is illustrated by the distances and connection lines that connect them. The most frequently studied keywords are agricultural waste, building materials, brick, and concrete. According to the visualization of the literature samples, the average year of publication (Avg. Pub. Year), the average citation (Avg. Citation), and the average normalized citation (Avg. Norm. Citation) are further summarized in Table 2. The following information was utilized for the tabulation [45].

Table 2.

Quantitative summary of influence of keywords.

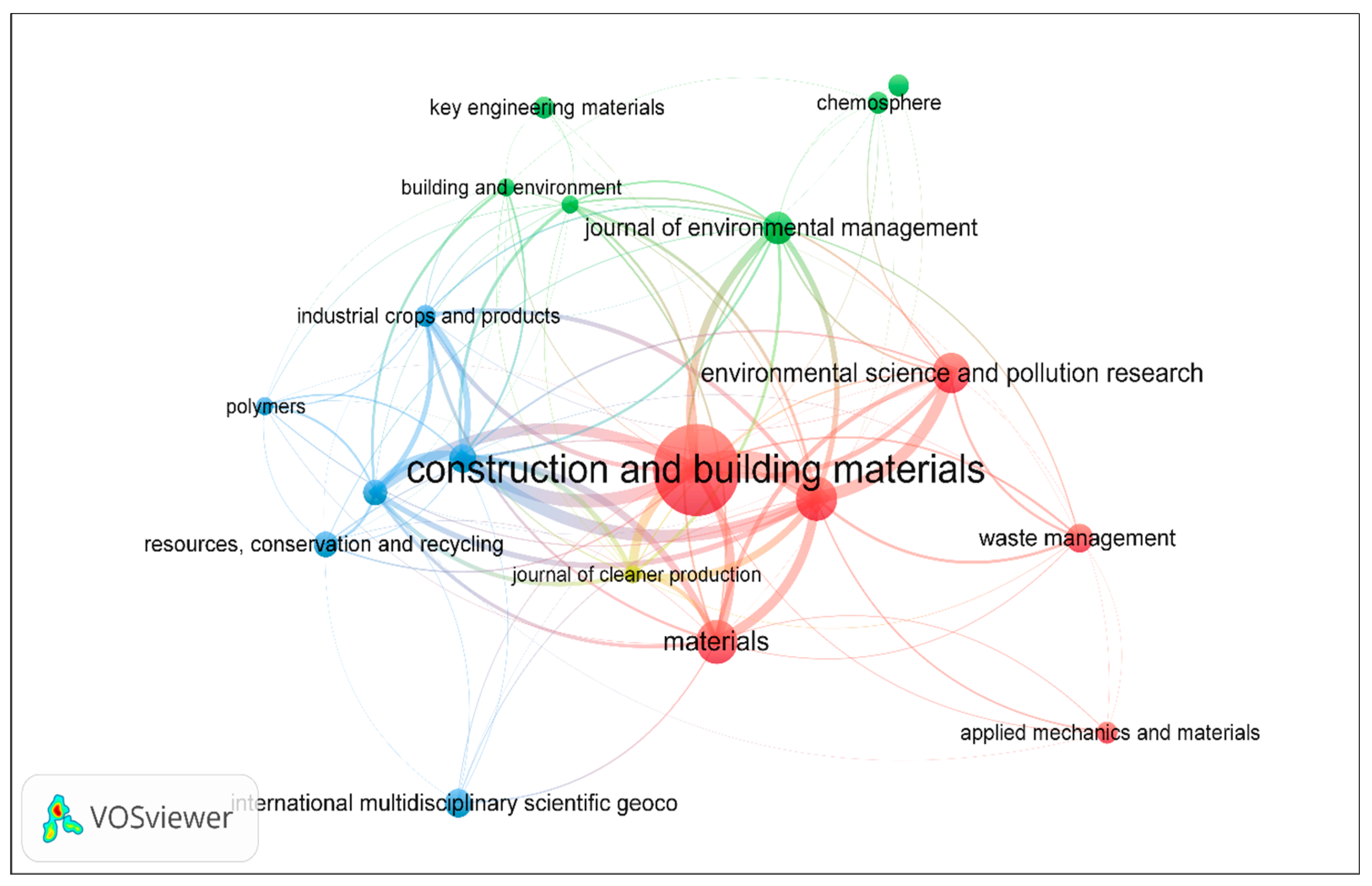

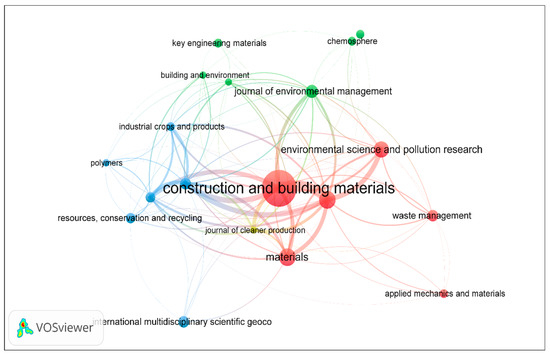

3.3. Analysis of Articles’ Sources

Analyzing the journal’s impact in the specific field helps readers obtain the best information available and quickly identify the journals that may be best for publication [46]. The journal sources were also summarized, and the annual number of published articles are discussed here too. The minimum number of articles in VOSviewer was set to 6. Among the 394 sources identified, 18 satisfied the thresholds set and were included in the composite network. The source occurrences map is illustrated in Figure 6.

Figure 6.

Source occurrences map.

- Cluster 1: Chemosphere links are identified to be 6, with total link strength of 10; Construction and Building Materials links are 14, with total link strength of 293; Journal of Environmental Management links are 12, with total link strength of 92; Key Engineering Materials links are 2, with total link strength of 2; Transactions of The Chinese Society of Agricultural Engineering links are 3, with total link strength of 3.

- Cluster 2: Applied Mechanics and Materials links are 6, with total link strength of 15; Environmental Science and Pollution Research links are 11, with total link strength of 113; Journal of Building Engineering links are 13, with total link strength of 296; Waste Management links are 7, with total link strength of 37.

- Cluster 3: Energy and Buildings links are 11, with total link strength of 202; Industrial Crops and Products links are 10, with total link strength of 96; Lecture Notes in Civil Engineering links are 7, with total link strength of 13; Sustainability (Switzerland) links are 10, with total link strength of 141.

- Cluster 4: International Multidisciplinary Scientific Geoconference Surveying Geology and Mining Ecology Management links are 7, with total link strength of 17; Materials links are 13, with total link strength of 156; Resources, Conservation and Recycling links are 8, with total link strength of 30.

Table 3 provides a quantitative summary of the impact of the sources.

Table 3.

Quantitative summary of impact of sources.

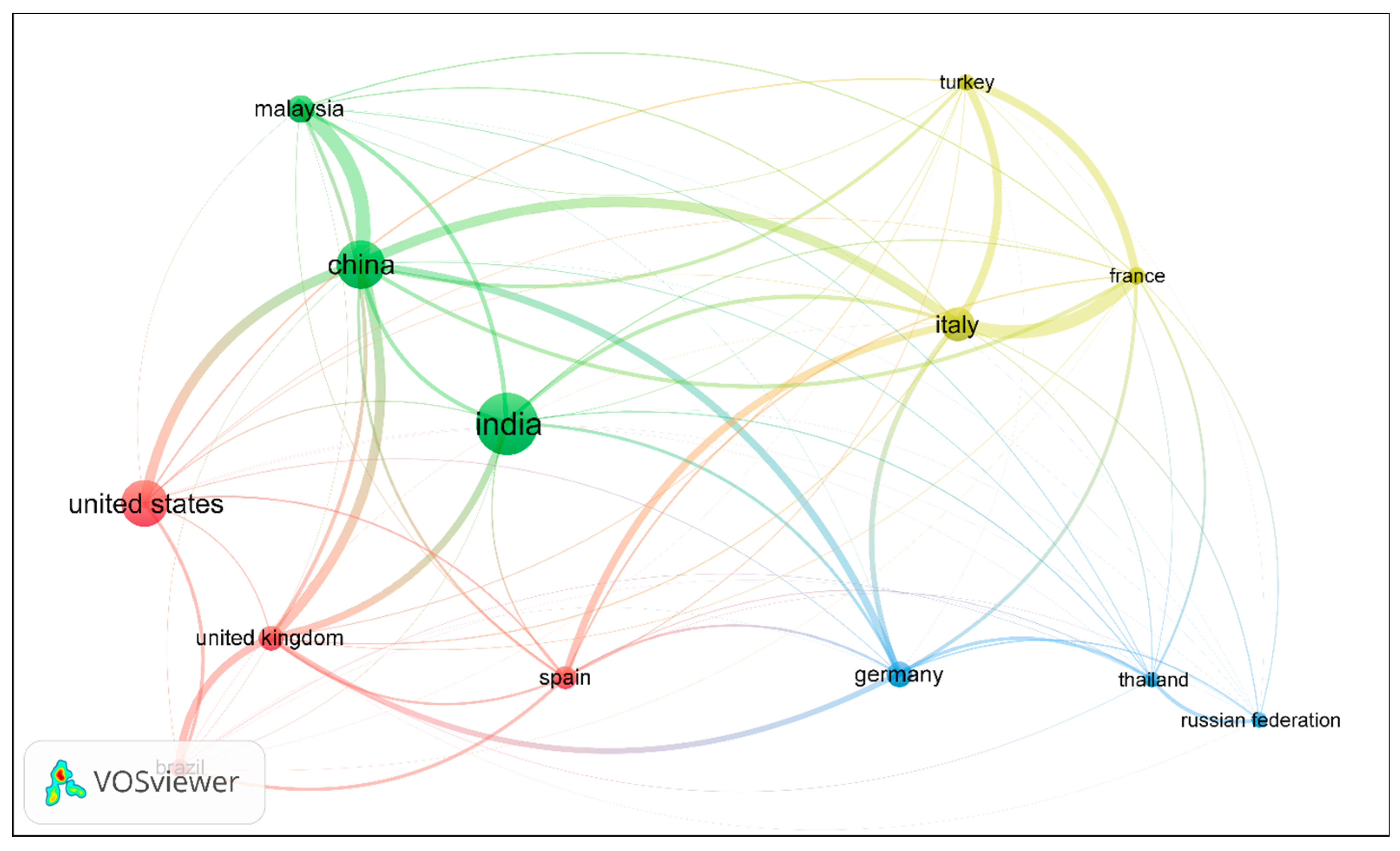

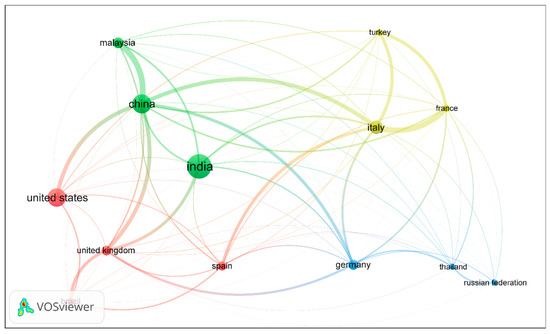

3.4. Analysis of Articles’ Regions

On a minimal count, the number of countries included per document is 20. In 102 countries, each with a threshold of 13 countries, the total strength of co-production groups with other countries was calculated and the country with the highest unlimited bandwidth was selected. Figure 7 demonstrates the collective network based on the collaboration of the countries. The four groups of elements identified from the cluster network are:

Figure 7.

Country occurrences map.

- The clustered links for Brazil, Spain, the United Kingdom, and the United States are 12 and the total link strength is 4353. This cluster collection has the most considerable number of articles (143 articles).

- The clustered links for China, India, and Malaysia are 12 and the total link strength is 5237. This cluster collection has the most considerable number of articles (176 articles).

- The clustered links for Germany, Russian Federation, and Thailand are 12 and the total link strength is 2395. This cluster collection has the most considerable number of articles (73 articles).

- The clustered links for France, Italy, and Turkey are 12 and the total link strength is 4961. This cluster collection has the most considerable number of articles (86 articles).

A quantitative summary of the impact of sources, including 13 countries, is reported in Table 4. Conclusively, India and China contributed the most research on agricultural wastes being used as building materials.

Table 4.

Quantitative summary of impact of sources.

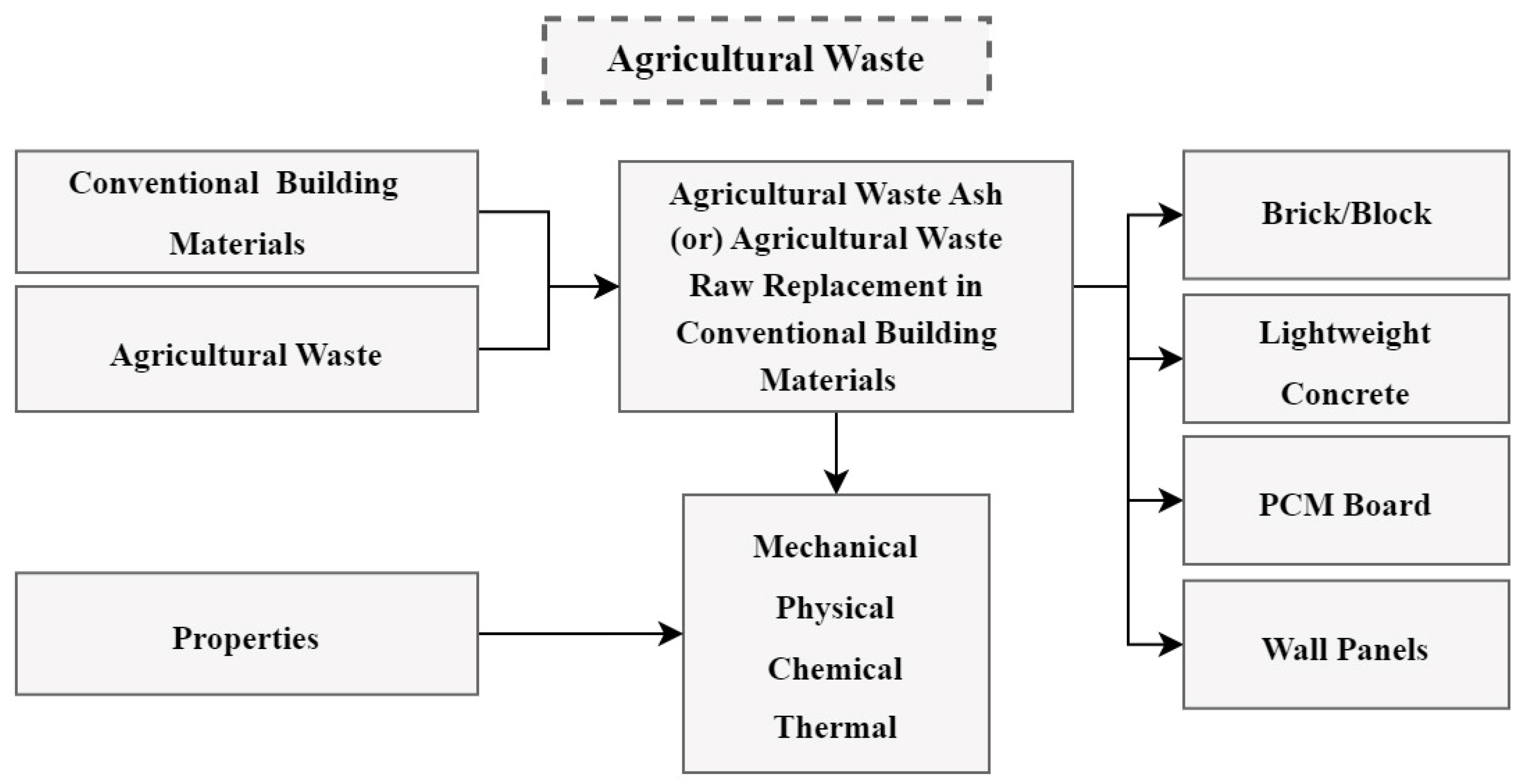

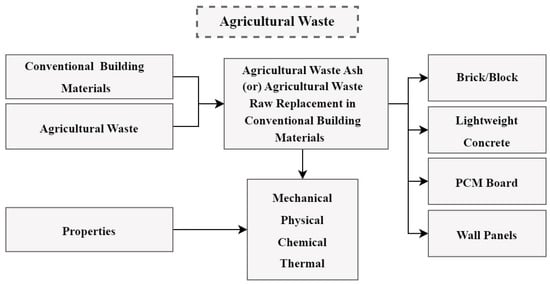

4. Description of Active Research Areas: Agricultural Wastes Used as Building Materials

Wastes generated from the primary treatment of some natural and agricultural products can be important alternatives to ecological concrete production [11]. Agricultural wastes can be applied as an alternative in sheets, bricks, proof cement, wall panels, cement panels, particle boards, and insulation panels [47]. Figure 8 shows various applications of agricultural wastes as building materials.

Figure 8.

Applications of agricultural wastes as building materials.

Many studies worldwide have validated the importance of agricultural waste in considering future uses and introducing many new types of agricultural waste that can be further used. Due to their environmental friendliness and economic viability, global and affordable agricultural wastes are considered a starting point for this investigation. Amorphous silica is abundantly present in agricultural waste ash, which makes it an excellent candidate to be utilized as a pozzolanic material [48]. When researchers used agricultural waste as an alternative for 30% cement in high-strength concrete, they demonstrated that this material proves to be a potential alternate candidate that can be employed. Despite such substitutions, agricultural waste ash cement has demonstrated excellent performance in mortar and concrete even when exposed to a hydrochloric acid solution [49].

4.1. Agricultural Wastes Used in Concrete

Emphasis is placed on using agricultural-waste-incorporated cement in concrete to increase the mechanical qualities of mixed agricultural waste concrete. It is critical to understand and interpret the cost efficiency of any new technology in a sustainable building. A study in [49] examined the economics of using agricultural-waste-incorporated cement in the production of concrete. As a result, efforts should be made to find ways to incorporate various agricultural wastes into concrete as sustainable materials. A review of all the available publications (articles, book chapters, and conference papers), as a result of searches on the terms “agricultural wastes” and “agricultural cement”, was carried out in this investigation.

Novel residues of 100:0 (blast furnace slag/sugar cane straw ash), 85:15 (85/15), 75:25 (75/25), and 67:33 (67/33) were examined as a partial replacement for the blast furnace slag to evaluate whether the ash obtained from biomass could be used as a filler in bituminous blends. After the successful treatment, most of the examined biomass ashes were assessed and found to be environmentally friendly, with the absence of hazardous particles, making them an ideal alternative for the natural fillers in bituminous mixes. The findings also revealed that the alkaline solution affected the compressive strength development, reaching more than 60 MPa after 90 days of specimen curing. Consequently, sugar cane straw ash demonstrated favorable results as it is a viable material for alkali-activated binders [50].

There is a good chance that most of the investigated biomass ashes could be used as a natural filler in bituminous mixtures because of their low organic matter and harmful fines content [51].

Employing spectroscopic methods, the interaction between sugarcane bagasse ash (SCBA) and the brick-making clay in a brick-making process was evaluated. At temperatures between 800 and 1100 °C, brick-making clay and SCBA were mixed before being hydraulically uniaxially compressed and sintered [52].

When concrete was submerged in a 5% magnesium sulphate solution for 364 days, it was subjected to various tests to determine its qualities, such as setting time, compressive strength, and expansion owing to magnesium sulphate assault. The expansion level of the concrete bar created with 30% slag powder was the same as that of the concrete bar manufactured from Portland cement Type V. Pozzolanic material palm oil fuel ash (POFA) acted as a good substitute for cement in concrete according to the obtained results [53].

Environmental concerns such as pollution and energy usage have piqued the public’s attention in recent years. The accompanying legislation has prompted the building industry to emphasize thermal insulation more. The development and implementation of bio-based insulating materials may help reduce the negative environmental impact of buildings by lowering the amount of energy utilized during the construction and operation of structures [54].

Prusty et al. [9] discussed the agricultural waste materials that can be utilized as a partial substitute for fine aggregates in concrete. It has been observed that the workability of the agricultural waste concrete, which includes groundnut shell, oyster shell, cork, rice husk ash (RHA) [55,56,57], and tobacco waste as an alternative, stood superior to that of concrete having just groundnut shell. According to the review, many significant studies are needed on all fine aggregates replacing agricultural waste materials. Nevertheless, this research provided more assurance on the utilization of concrete, which is a noteworthy discovery.

Research was done in [58] examining the durability, mechanical characteristics, global warming potential (GWP), and air pollutants of various ternary- and quaternary-RHA blended concrete mixes. As a conclusion, it was discovered that ternary and quaternary concrete mixes, including RHA and fly ash, decreased GWP while boosting durability without affecting the design strength.

Many studies have used oil palm ash in concrete, mortar, and cement paste as a pozzolanic material, either as a binder or as a filler substitute to lessen the negative environmental effect [59].

Concrete’s mechanical qualities improved when SCMs such as fly ash and silica fume were utilized in ordinary Portland cement (OPC) as a partial substitute for OPC. Consequently, RHA was examined as a potential alternative solid-phase microbe SCM. Three different diameters of RHA (600 mm, 150 mm, and 44 mm) were used in conjunction with 10% and 20% partial cement replacements. In addition to RHA-modified concrete specimens, a commonly used local Class C fly ash was also included for comparison purposes [60].

Based on various alternatives to traditional SCMs, the performance and durability of recycled aggregate concrete were assessed in [61] incorporating the available industrial byproducts, including RHA, POFA/POCP, and other industrial byproducts. The compressive strength and mass change of concrete were measured based on the effects of hydrochloric acid and magnesium sulphate (MgSO4).

The feasibility of recycled aggregate concrete was evaluated in [62] utilizing readily industrial byproducts such as RHA and POFA as alternatives to traditional SCMs. In addition, an investigation of the impact of compressive strength and microstructural analysis were carried out.

Magnesium oxysulfate cement (MOSC) is one of the new cements that has garnered significant interest in the cement industry in recent years. MOSC is a ternary cementing system composed of active MgO and a specific concentration of MgSO4 solution. Low energy consumption, low thermal conductivity, and high fire resistance are the primary advantages of MOSC [63].

In recent years, many scientists have employed MOSC to recycle industrial solid wastes, such as fly ash, which have been studied extensively. Both low- and high-calcium fly ash have promising application prospects in MOSC, with a dosage that can reach up to 50% of MgO [55,64].

To improve the utilization of forestry wastes and save MgO, composites containing locust powders with 0–25% mass of MgO were mechanically mixed and cured for 3 days and 100 days. Mechanical properties, water resistance, and microstructure of the slurry were investigated. The maximum locust dosage based on fluidity was found to be 25% [56,65].

From the Scopus database, 564 articles were retrieved with the keywords “Agricultural Waste Used in Concrete”. From the data analysis, the top 10 globally cited articles are reported in Table 5 with total citations (TC), TC per year, normalized TC (Norm. TC), and reference (Ref.).

Table 5.

Top 10 most globally cited articles.

4.2. Agricultural Wastes Used in Insulation

Building insulations are generally made from materials derived from petrochemicals (mostly polystyrene) and natural sources treated with high energy efficiency (glass and rock wool). Bringing “sustainability” into the design process of buildings prompted researchers to examine the development of thermal and acoustic insulating materials made from natural or recycled resources. In [76], the current state of the art was provided in the field of building insulation products made from natural or recycled materials.

Insulation materials made from natural fiber waste appeared to be an excellent alternative thanks to their abundant availability in the southern regions of Chile, potential low cost, minimal energy consumption during the manufacturing process, and high bio-degradation rate at the end of their lives. Moreover, the flexural and compressive stresses of expanded polystyrene block insulation were assessed and compared with conventional insulation. Furthermore, the flexural stress values were compared with the findings obtained from the conventional expanded polystyrene type IX and documented [77].

A scientific plan for bio-insulation research was presented as the conclusion, as well as recommendations for selecting suitable types of treatments, both traditional and innovative, for enhancing specific properties, the order in which properties should be tested along with a scientific presentation of research findings [78]. This research could precisely aid in the development of a more detailed understanding of the current state of bio-insulation research.

An environmentally acceptable method was developed for replacing cement with wood ash at 10, 15, 20, and 25%. In addition, styrene-butadiene polymers were added to increase strength and stiffness for modifying mortars. In all likelihood, by substituting cement with up to 10% wood ash, 1.5% banana fibers, and 0.3% styrene-butadiene polymer emulsion, the best performance could be achieved among other ingredients. Furthermore, according to the researchers, the composite material produced has excellent thermal insulation capabilities and may be employed in various cement-based applications [79].

From the Scopus database, 149 articles were retrieved using the keywords “Agricultural Wastes Used in Insulation”. From that data analysis, the top 10 globally cited articles are reported in Table 6 with total citations (TC), TC per year, normalized TC (Norm. TC), and reference (Ref.).

Table 6.

Top 10 most globally cited articles.

4.3. Agricultural Wastes Used in Thermal Insulating Materials

From the environmental point of view, insulation serves to be very energy efficient. The expected energy has the advantage that, if it is used for construction, the required operating energy can significantly be decreased. The energy saved helps reduce the causes of environmental pollution. Table 7 represents the physical properties of boards made of recycled materials manufactured from various agricultural wastes. The waste-incorporated materials are used in the construction of floors, walls, roofs, bridges, boats, and other vessels. These building insulations are easy to handle, dust-free, and non-irritating to the skin. They also provide good thermal insulation.

Table 7.

Physical properties of insulation boards from agricultural wastes [89].

4.4. Agricultural Wastes Used in Mortar

The thermal advantages of cork mortars for renderings were compared with cement-expanded polystyrene mortars, specifically in steady and unsteady situations [90]. The average thermal conductivity of the mortar was reduced by over 76%, and its density was decreased by around 30% when 70% of the dry weight of the olive stone was added to the cement lime mortar. Conclusively, based on the percentage of the olive stone added, a significant decrease in the thermal conductivity was observed compared with the reduction in the density [91,92]. From the Scopus database, 149 journals were retrieved using the keyword “Agricultural Wastes Used in Mortar”. From the data analysis, the top 10 globally cited articles are reported in Table 8 with total citations (TC), TC per year, normalized TC (Norm. TC), and reference (Ref.).

Table 8.

Top 10 most globally cited articles.

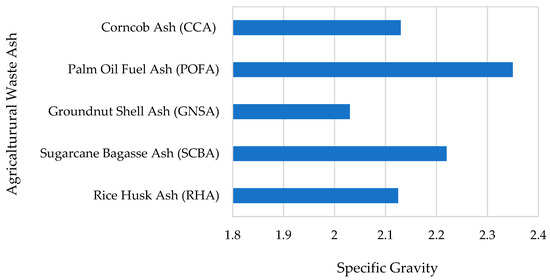

4.5. Physical and Chemical Properties of Agricultural Waste Ash

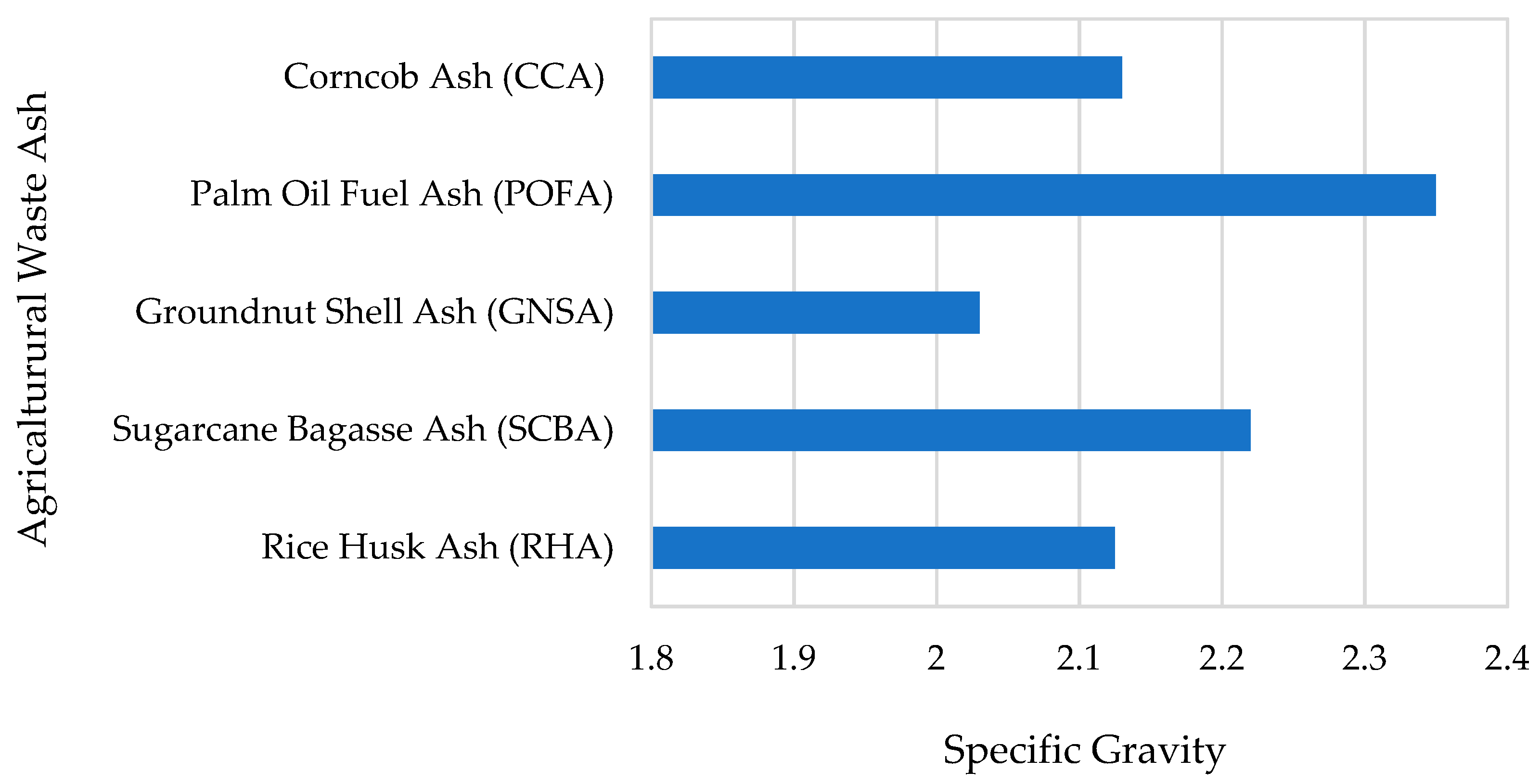

Low-density particles are used to produce low-density concrete and can be utilized in various applications including building frames. The density, specific gravity, bulk density, and fineness of agricultural waste ash vary depending on the location and the processing parameters. Figure 9 depicts the specific gravity of agricultural waste ashes such as corncob ash (CCA) [101], SCBA [102,103,104,105,106,107,108,109], groundnut shell ash (GNSA) [89,110,111,112], RHA [113,114,115,116,117,118], and POFA [119,120]. The chemical composition of the ash is directly related to the interaction percentages of SiO2, Al2O3, Fe2O3, CaO, MgO, SO3, K2O, Na2O, P2O5, MnO2, and TiO2, which are given in Table 9.

Figure 9.

Specific gravity of agricultural waste ash.

Table 9.

Chemical composition of agricultural waste ash.

4.6. Microstructural Characteristics of Agricultural Waste Ash

Microstructural analysis of agricultural waste ash is essential because it can considerably affect the performance of the agricultural waste ash blended cementitious system, particularly the mechanical properties [121,122,123,124,125]. Understanding the microstructures of various types of agricultural waste ash enables one to predict the behavior of ash–concrete blends.

In the literature, micrographs of corncob ash revealed the presence of both macro- and micropores. Crystalline and spherical CCA particles were also observed [126,127,128]. In addition, it was stated that coconut shell ash particles have an extremely irregular shape [129]. Nevertheless, some particles were discovered to be spherical. The scanning electronic microscopy micrograph of GNSA uncovered that its surface is irregular and porous [130]. POFA has highly porous particles, but when it is grounded, its porosity is significantly reduced [131]. In addition, it has been reported that RHA particles have an irregular shape, and it is evident from the structure of RHA that its pores vary in size from nanometers to micrometers. These pores contribute to an increased RHA surface area [93,132]. In its microstructure, SCBA particles include prismatic, spherical, and fibrous particles [133].

4.7. Mechanical Properties of Agricultural Waste Used in Building Materials

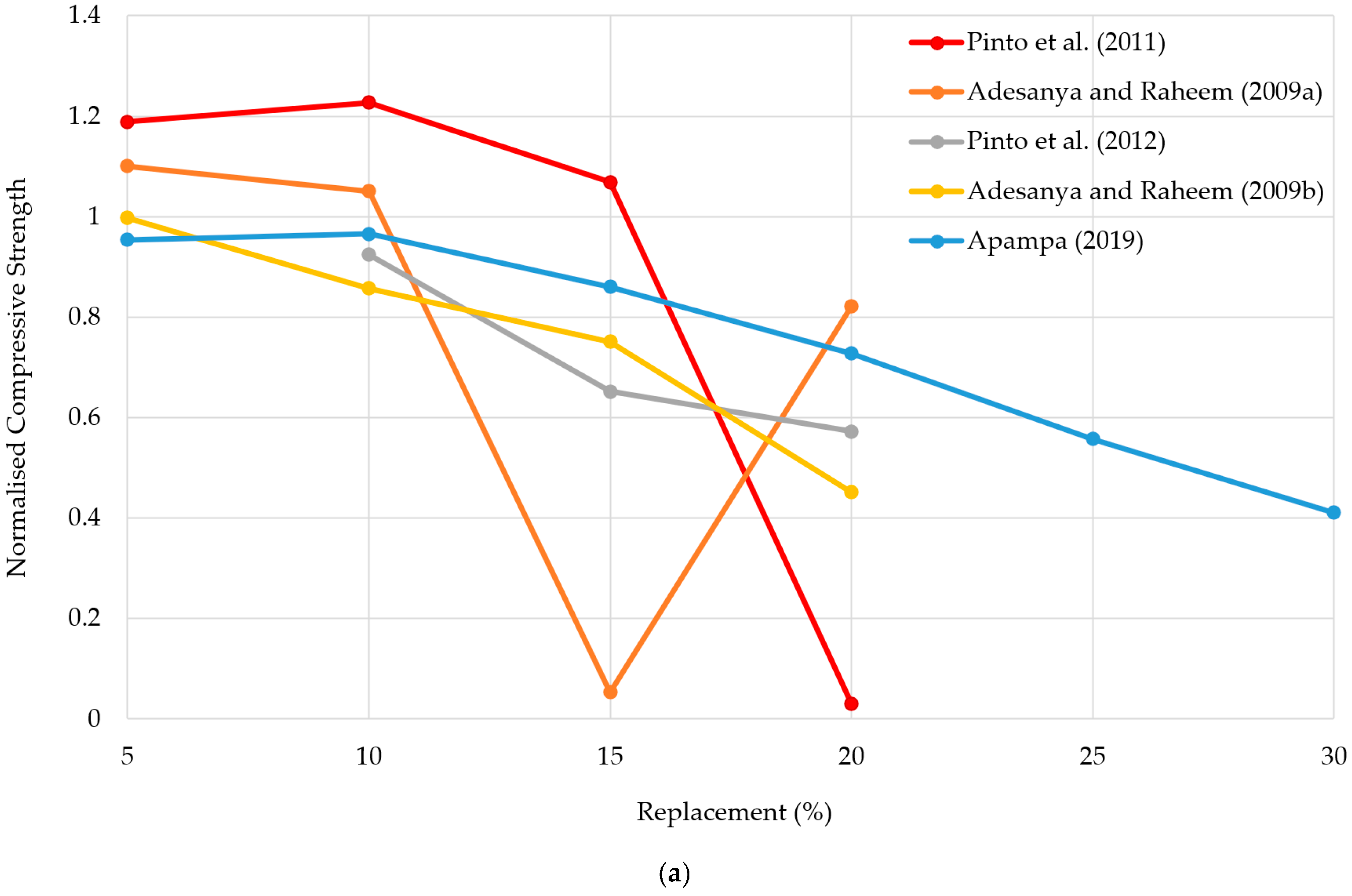

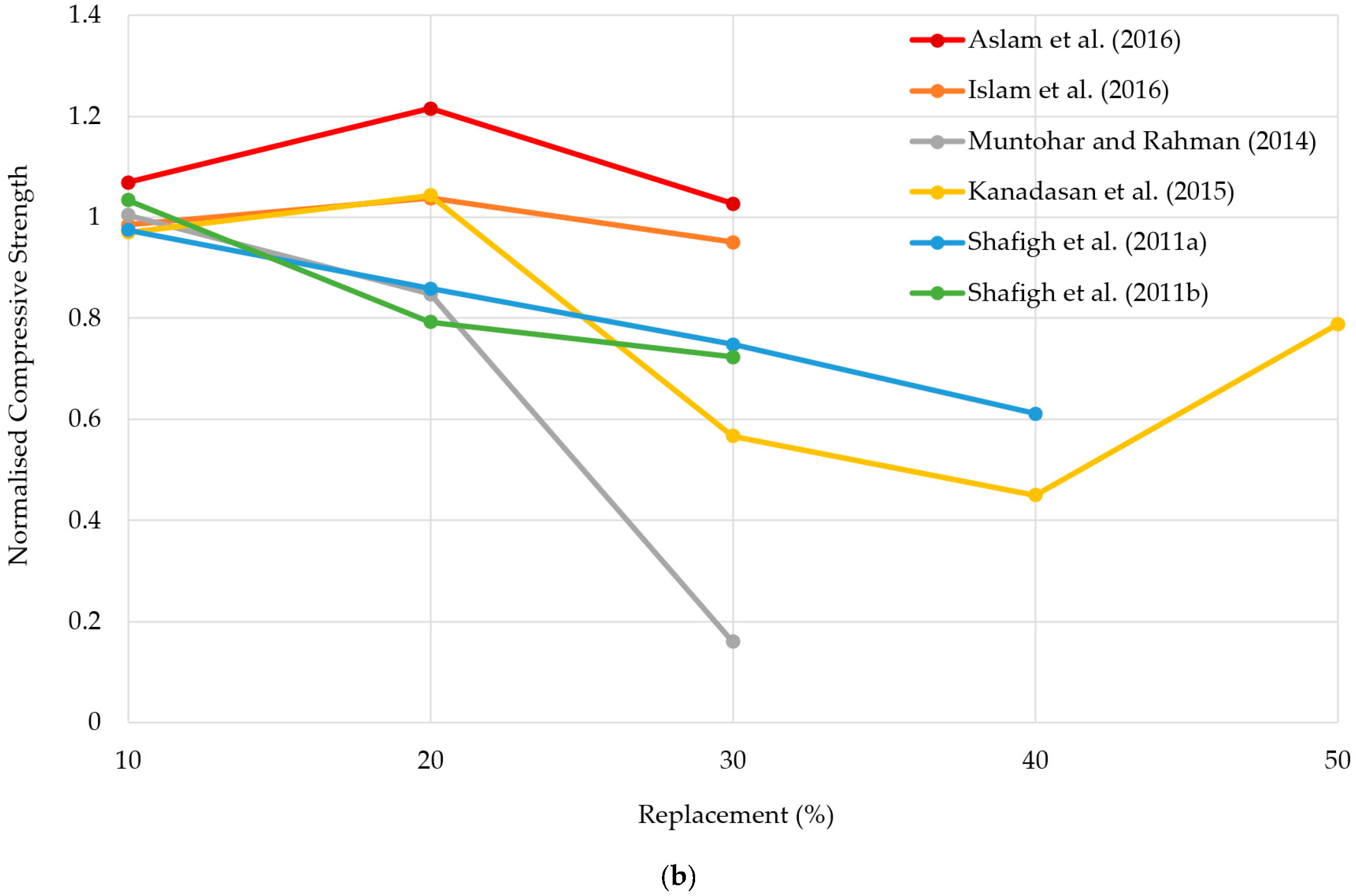

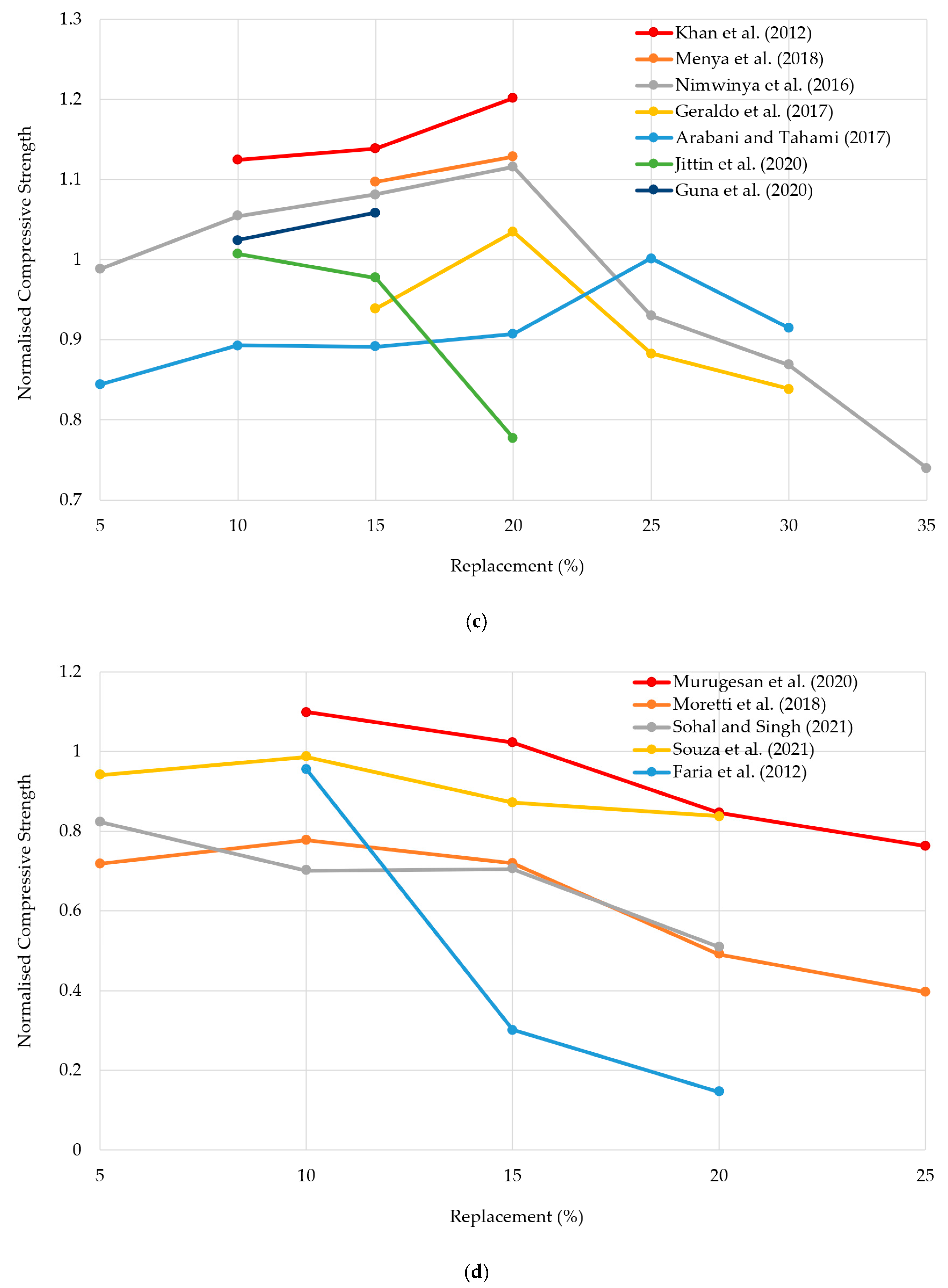

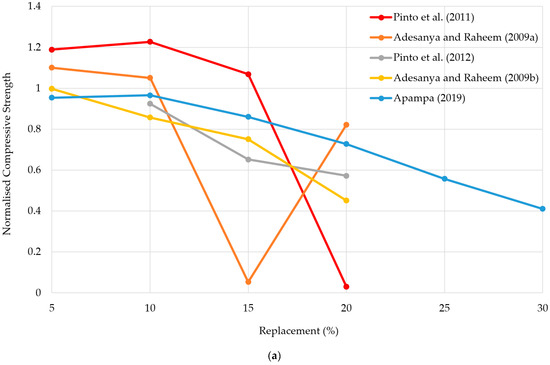

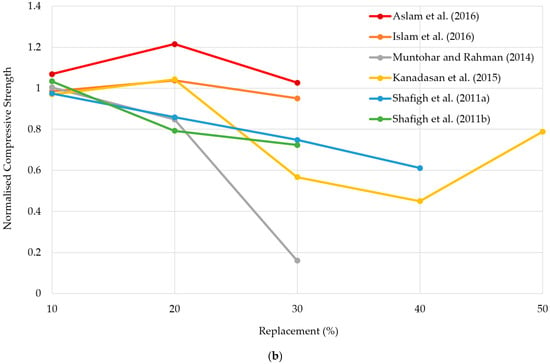

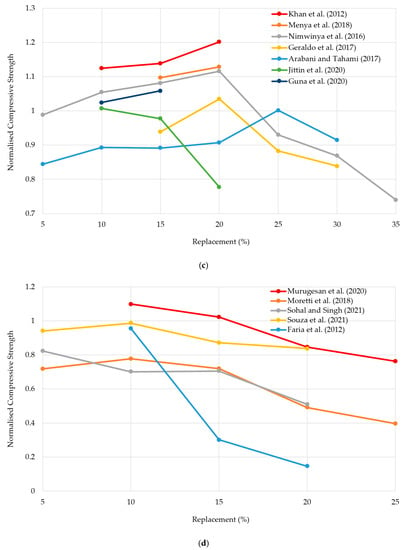

Figure 10 displays the influence of various agricultural waste ashes on the compressive strength of blended concrete after 28 days of curing. Even though the addition of agricultural waste ashes increases the compressive strength, exceeding the optimal replacement level of cement with agricultural waste ashes decreases the compressive strength of the cementitious system. RHA- and SCBA-blended concrete had a higher normalized compressive strength than concrete blended with CCA and POFA.

Figure 10.

Normalized compressive strength of agricultural waste ash in concrete; (a) CCA (Pinto et al. [134], Adesanya and Raheem [135], Pinto et al. [136], Adesanya and Raheem [137], Apampa [138]), (b) POFA (Aslam et al. [139], Islam et al. [140], Muntohar and Rahman [141], Kanadasan et al. [142], Shafigh et al. [143], Shafigh et al. [144]), (c) RHA (Khan et al. [94], Menya et al. [145], Nimwinya et al. [146], Geraldo et al. [147], Arabani and Tahami [148], Jittin et al. [149], Guna et al. [150]), (d) SCBA (Murugesan et al. [151], Moretti et al. [152], Sohal and Singh [153], Souza et al. [154], Faria et al. [155]).

The optimal replacement level of RHA and SCBA in concrete has been determined to be between 10 and 20%. The normalized compressive strengths of RHA- and SCBA-blended concrete were approximately 1.2 times that of control concrete. In addition to the 10% replacement level, 20% has been reported as the optimal replacement level for POFA in previous research works. At the optimal replacement level, the normalized compressive strengths of POFA-modified concrete ranged from 1.01 to 1.11. Normalized compressive strengths for CCA-based concrete ranged between 0.81 and 1.02 and 0.88 and 1.08 at the optimal replacement levels of 5 to 10%, respectively [156].

4.8. Research Trends and Recommendations

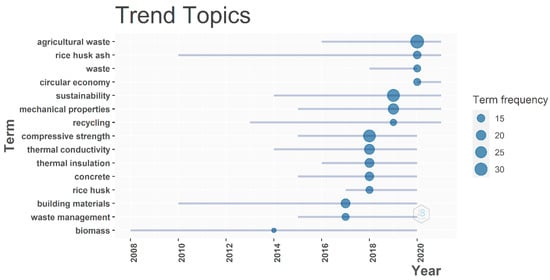

As a sustainable alternative building material, agricultural waste has led to relevant literature works over the past decades. Apart from the articles and technical documents, there have been many other publications and research attempts in this field. The most important building materials are sand, cement, concrete, insulators, and brick, as illustrated in Figure 11 based on their usage. Many research works have been carried out on replacing cement and concrete, and trending research is toward thermal insulation, brick, and aggregate. Technology acts as an important tool for sustainable construction. Thermal insulation is one of the most significant ways to decrease energy consumption. From the year 2008 to 2022, the total number of keyword entries found was 671 including concrete, wood, and steel [157].

Figure 11.

Trend of publications in agricultural waste as a building material.

In agriculture, the utilization of agricultural waste products in the building materials industry helps reduce the emissions from waste storage or incineration, avoiding the excessive accumulation of waste in sanitary landfills and improving environmental quality. There is a dearth of thermal science research on agricultural waste in concrete, cement, and brick. Several researchers have employed agricultural wastes as building materials in various fields. However, agricultural wastes such as refractory bricks have not been used as building materials in various cases.

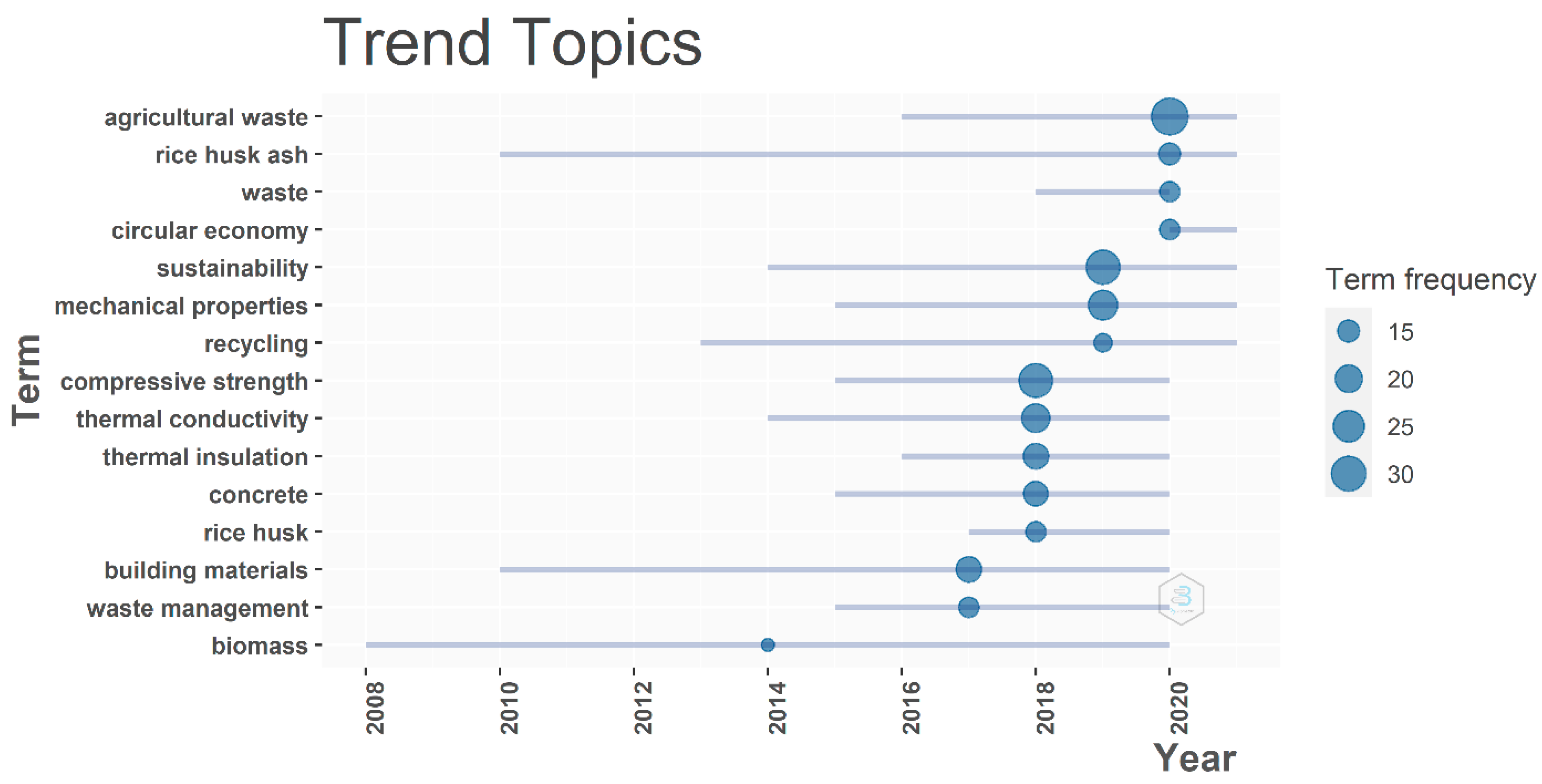

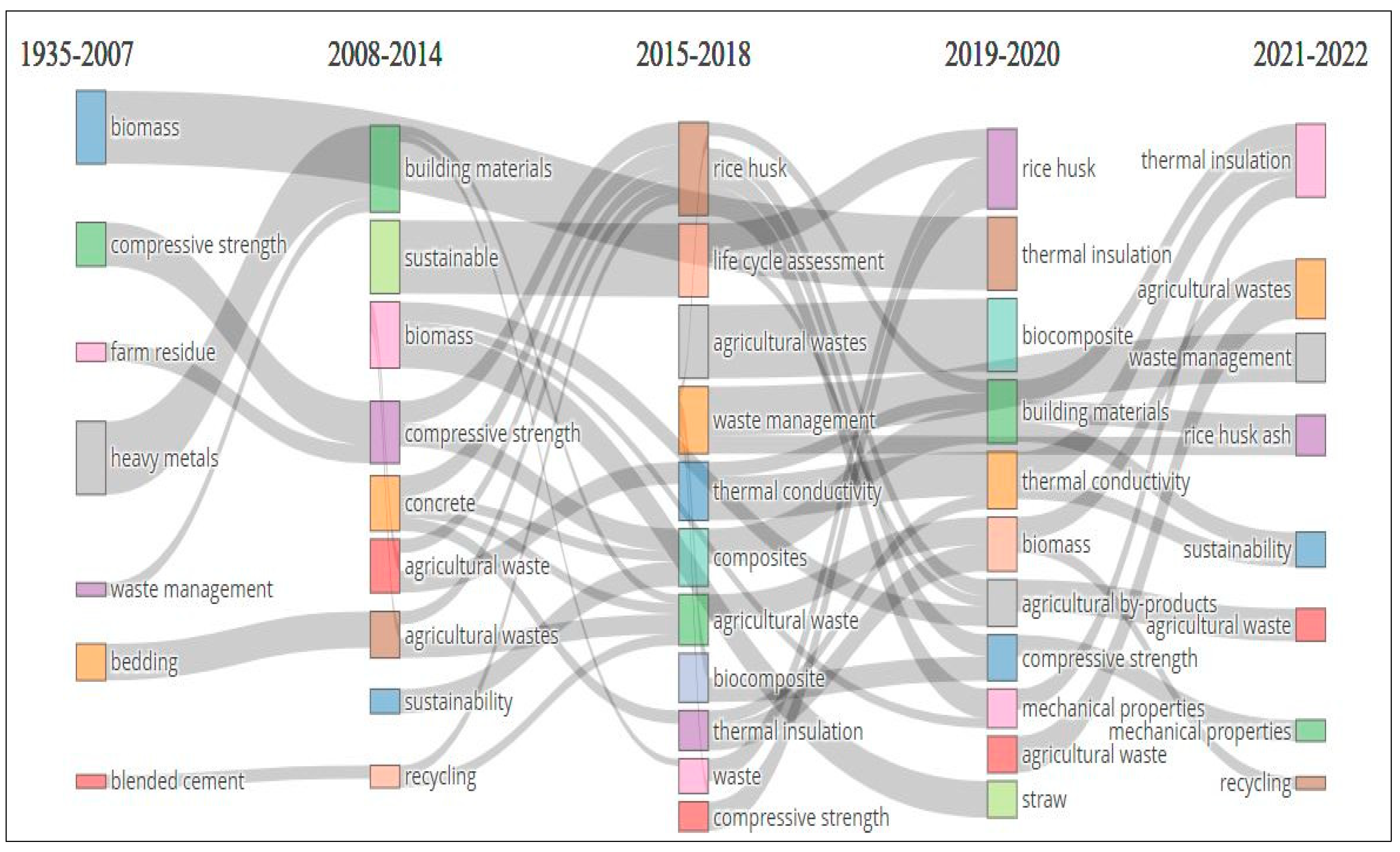

Figure 12 shows the development of keywords in this research. From 1935 to 2007, the keywords connected with future work were bedding, biomass, blended cement, compressive strength, farm residue, heavy metals, and waste management. From 2008 to 2014, keywords in the research changed to agricultural wastes, biomass, recycling, compressive strength, and building materials. The indices are weighted inclusion index: 3.71, inclusion index: 3.70, occurrences: 17, and stability index: 1.33. In 2015–2018, keywords in the research changed to agricultural waste, thermal conductivity, thermal insulation, waste management, compressive strength, waste, rice husk, straw, building materials, bio composite, and agricultural byproducts. The indices are weighted inclusion index: 4.59, inclusion index: 4.33, occurrences: 62, and stability index: 1.38. From 2019 to 2020, keywords in the research changed to agricultural waste, straw, thermal conductivity, building materials, bio composite, agricultural byproducts, mechanical properties, and thermal insulation. The indices are weighted inclusion index: 7.44, inclusion index: 6.66, occurrences: 89, and stability index: 2.94. Finally, from 2019 to 2020, the keywords in research were agricultural byproducts, agricultural waste, RHA, and waste management. The indices are the weighted inclusion index: 1.36, inclusion index: 1.45, occurrences: 13, and stability index: 0.39. These points help us understand the connection of keywords and future words for research on these keywords.

Figure 12.

Keywords for future direction.

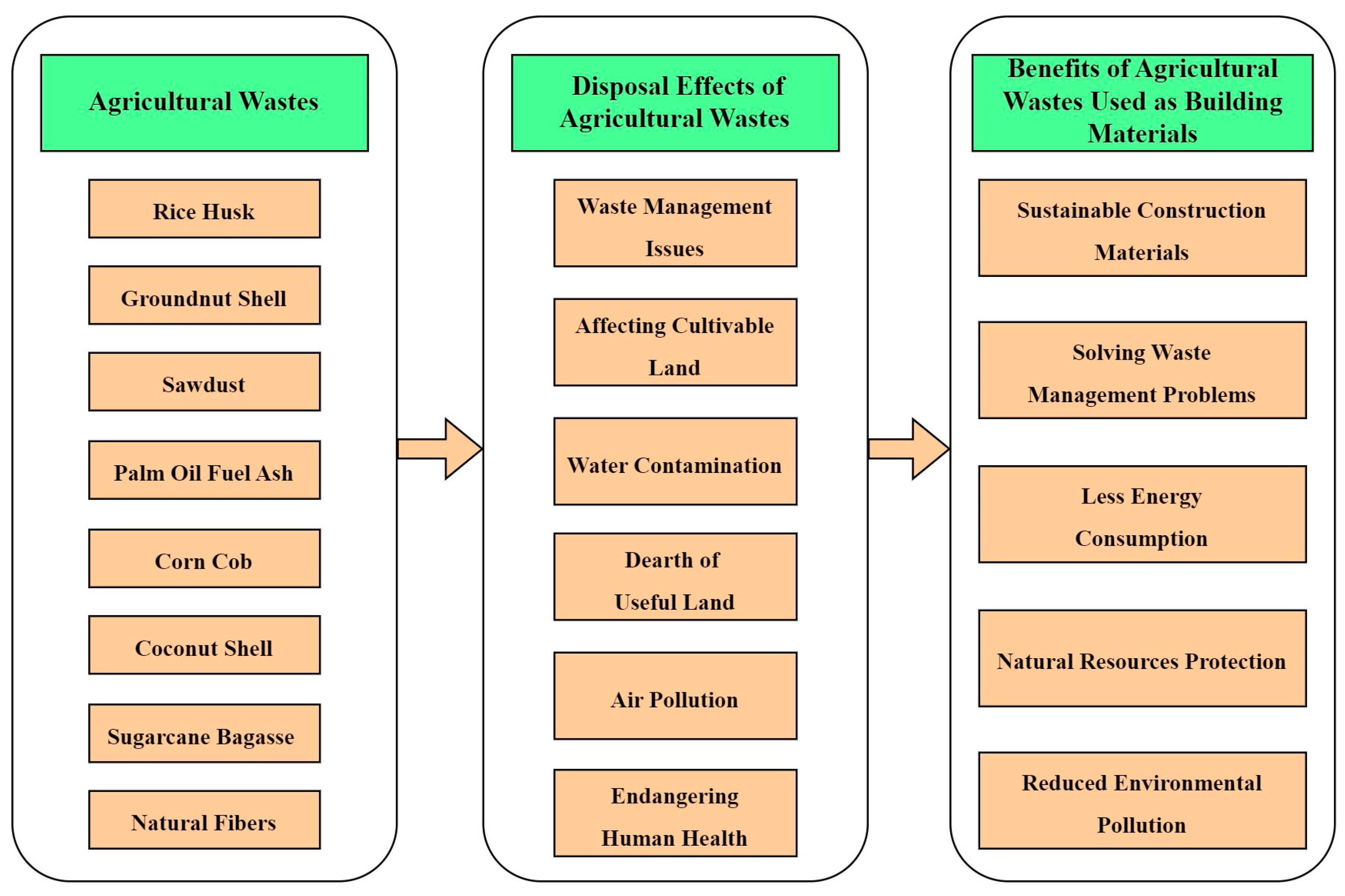

5. Discussion

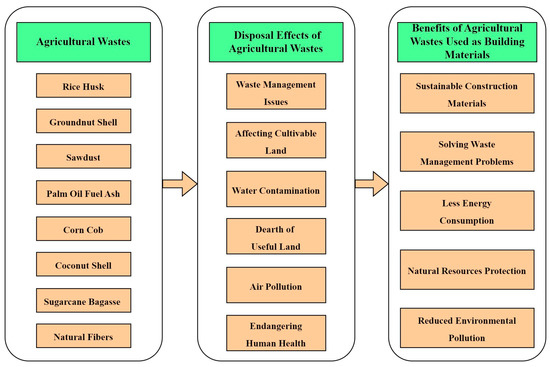

As was previously mentioned, a variety of operations and a wide range of sources result in enormous amounts of waste being generated. The challenges associated with disposing of waste products are illustrated by their hazardous and complex composition. These wastes could contaminate usable lands and cause problems for waste management authorities if they are dumped in landfills. The flowchart of generated agricultural wastes, their related disposal effects, and the benefits of them being used as building materials are demonstrated in Figure 13. Additionally, waste materials have a tendency to contaminate water when they come into contact with water bodies.

Figure 13.

Flowchart showing generated agricultural wastes, their related disposal effects, and their benefits when used as building materials.

Moreover, a number of waste products in powder form are simple to combine with air and pollute the atmosphere. If waste is dumped close to agricultural lands, this could have an impact on cultivable lands. Therefore, it is necessary to dispose of or reuse waste materials properly because not doing so puts the natural environment and human health in danger. One of the most popular building materials is concrete. Therefore, recycling waste into concrete would be a more environmentally friendly strategy. Concrete can use a variety of waste products as natural aggregate replacements, including plastic, rubber, recycled concrete aggregate, glass, ashes, and slag.

On the other hand, several agricultural wastes (RHA, etc.) contain chemical compounds that are appropriate for SCMs. As a result, these waste materials can replace cement in concrete, which is a benefit of using waste materials in concrete. Furthermore, according to the majority of researchers, adding waste materials produces composites with better strength characteristics at a lower price. In addition, waste management issues can be resolved by reducing the amount of waste that ends up in landfills, thereby preserving the environment.

Recycled aggregate concrete has comparatively weak mechanical properties due to the existence of weak bonds between the old mortar and aggregate, alongside cross cracks and fractures in the recycled aggregates developed during the recycling process. However, some improvement methods, such as adding mineral admixtures, changing the mixing process, and coating recycled aggregates with cement slurry or admixture solution, can help mitigate the strength loss caused by incorporating recycled aggregates. For the purpose of generating large quantities of recycled aggregate concrete, these processes must be further studied. Furthermore, it is important to look into the structural and material aspects of long-term durability performance.

As already mentioned, waste materials used as SCMs can possibly enhance the mechanical properties of concrete in addition to producing concrete that is more environmentally friendly. The filler effect and pozzolanic properties of SCMs enable this improvement. However, there is an optimal limit at which adding SCMs to concrete no longer improves its properties. As a result, it is still necessary to investigate how SCMs can be utilized in large quantities without losing their material properties.

6. Application

Sustainable development should be of particular importance as the global population increases, and the concrete industry should contribute to this development. Utilizing byproducts and agricultural wastes in concrete is one approach. According to the studies, many agricultural wastes, such as CCA, POFA, RHA, GNSA, etc., may be used as partial replacements or additions of aggregate or cement in concrete, mortar, and brick production. These replacements can considerably contribute to the construction industry’s cost-effectiveness, energy savings, and environmental impact reduction. Considering the current criteria for sustainable infrastructure and the associated environmental benefits, the use of agricultural wastes as aggregate or cement in concrete production can also contribute to the concrete industry’s sustainability.

7. Conclusions

This study used a three-stage holistic approach to review the articles published in the “agricultural wastes used as building materials” domain over the past decades.

- In addition to Scopus, bibliometrics was utilized to compile this review’s findings. A total of 671 publications with the keywords “agricultural wastes used as building materials”, “agricultural wastes used as a replacement of cement”, and “agricultural wastes used as a replacement of aggregate” were found and investigated.

- It was found that the journals of Building and Environment, Energy and Buildings, Journal of Cleaner Production, and Construction and Building Materials have all published research works in the field of agricultural wastes used as building materials. There was consensus that Renewable and Sustainable Energy Reviews held the most sway.

- The research communities in China, India, and Australia have all made significant contributions, and there are many active links between them. India had a considerable yearly impact.

- Qualitative analysis summarized the major areas of research on agricultural wastes used as building materials and discussed existing gaps. This comprehensive review adds knowledge to the framework and direction for future research on this topic.

- With the help of this study, researchers can identify high-impact journals or scholars, understand recent trends in research on agricultural wastes as building materials, and promote academics and related works to think creatively about incorporating new agricultural wastes as building materials.

8. Recommendations for Future Research Work

The following future studies are recommended based on the analysis performed in this research.

- Limited research works have been published on the use of agricultural wastes as fine aggregate in concrete. This allows for a thorough examination of the engineering characteristics of every agricultural-waste-based concrete mix and a comparison with conventional concrete.

- The majority of studies on concrete made from agricultural waste have primarily focused on compressive strength. All agricultural-waste-based concretes and their corresponding conventional concrete, however, could be studied for other properties such as tensile and flexural strengths, elastic modulus, and ultrasonic pulse velocity.

- Few durability studies on agricultural-waste-based concretes have been published. Therefore, future research on the durability characteristics of various agricultural waste concrete types can be conducted.

- Agricultural waste ash has been employed as fine aggregate in concrete in a number of research attempts. As a result, other raw agricultural wastes might be utilized in concrete to partially replace the fine aggregate and achieve the desired effects on the characteristics of concrete.

- Additional studies are needed to establish the strength variations and thermal properties when using these agricultural wastes as a fine aggregate replacement in concrete.

Author Contributions

Conceptualization, N.G. and A.B.; methodology, N.G., A.B. and K.L.; validation, N.G., A.B. and K.L.; formal analysis, A.B.; investigation, N.G. and A.B.; writing—original draft preparation, N.G., A.B. and K.L.; writing—review and editing, A.B.; project administration, A.B. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Datta, P. Available online: India-national-building-code-nbc-2016-vol-1.pdf (accessed on 15 March 2022).

- House of the Rising Costs: Construction Materials Surge amid Higher Demand, Supply Constraints|The Real Economy Blog. Available online: https://realeconomy.rsmus.com/house-of-the-rising-costs-construction-materials-surge-amid-higher-demand-supply-constraints/ (accessed on 20 January 2022).

- Mezher, T. Building Future Sustainable Cities: The Need for a New Mindset. Constr. Innov. 2011, 11, 136–141. [Google Scholar] [CrossRef]

- Cardoen, D.; Joshi, P.; Diels, L.; Sarma, P.M.; Pant, D. Agriculture Biomass in India: Part 1. Estimation and Characterization. Resour. Conserv. Recycl. 2015, 102, 39–48. [Google Scholar] [CrossRef]

- Vitali, F.; Parmigiani, S.; Vaccari, M.; Collivignarelli, C. Agricultural Waste as Household Fuel: Techno-Economic Assessment of a New Rice-Husk Cookstove for Developing Countries. Waste Manag. 2013, 33, 2762–2770. [Google Scholar] [CrossRef] [PubMed]

- Mortier, N.; Velghe, F.; Verstichel, S. Organic Recycling of Agricultural Waste Today: Composting and Anaerobic Digestion. Biotransformation Agric. Waste By-Prod. Food Feed Fibre Fuel Econ. 2016, 69–124. [Google Scholar] [CrossRef]

- Uçar, N.; Bakhtiari, S.; Doustkhah, E.; Yarmohammadi, M.; Pedram, M.Z.; Alyamaç, E.; Seydibeyoğlu, M.Ö. Biodegradation of Plastic-Based Waste Materials. Biodegrad. Biodeterior. Nanoscale 2022, 175–212. [Google Scholar] [CrossRef]

- Abdel-Shafy, H.I.; Mansour, M.S.M. Solid Waste Issue: Sources, Composition, Disposal, Recycling, and Valorization. Egypt. J. Pet. 2018, 27, 1275–1290. [Google Scholar] [CrossRef]

- Prusty, J.K.; Patro, S.K.; Basarkar, S.S. Concrete Using Agro-Waste as Fine Aggregate for Sustainable Built Environment—A Review. Int. J. Sustain. Built Environ. 2016, 5, 312–333. [Google Scholar] [CrossRef]

- Memon, S.A.; Javed, U.; Khushnood, R.A. Eco-Friendly Utilization of Corncob Ash as Partial Replacement of Sand in Concrete. Constr. Build. Mater. 2019, 195, 165–177. [Google Scholar] [CrossRef]

- Turgut, P.; Murat Algin, H. Limestone Dust and Wood Sawdust as Brick Material. Build Env. 2007, 42, 3399–3403. [Google Scholar] [CrossRef]

- Junaid, M.F.; Rehman, Z.U.; Kuruc, M.; Medveď, I.; Bačinskas, D.; Čurpek, J.; Čekon, M.; Ijaz, N.; Ansari, W.S. Lightweight Concrete from a Perspective of Sustainable Reuse of Waste Byproducts. Constr. Build. Mater. 2022, 319, 126061. [Google Scholar] [CrossRef]

- Modani, P.O.; Vyawahare, M.R. Utilization of Bagasse Ash as a Partial Replacement of Fine Aggregate in Concrete. Procedia. Eng. 2013, 51, 25–29. [Google Scholar] [CrossRef]

- Turgut, P. Properties of Masonry Blocks Produced with Waste Limestone Sawdust and Glass Powder. Constr. Build. Mater. 2008, 22, 1422–1427. [Google Scholar] [CrossRef]

- Kuo, W.T.; Wang, H.Y.; Shu, C.Y.; Su, D.S. Engineering Properties of Controlled Low-Strength Materials Containing Waste Oyster Shells. Constr. Build. Mater. 2013, 46, 128–133. [Google Scholar] [CrossRef]

- Costi de Castrillo, M.; Ioannou, I.; Philokyprou, M. Reproduction of Traditional Adobes Using Varying Percentage Contents of Straw and Sawdust. Constr. Build. Mater. 2021, 294, 123516. [Google Scholar] [CrossRef]

- Sathiparan, N.; de Zoysa, H.T.S.M. The Effects of Using Agricultural Waste as Partial Substitute for Sand in Cement Blocks. J. Build. Eng. 2018, 19, 216–227. [Google Scholar] [CrossRef]

- Laborel-Préneron, A.; Aubert, J.-E.; Magniont, C.; Maillard, P.; Poirier, C. Effect of Plant Aggregates on Mechanical Properties of Earth Bricks. J. Mater. Civ. Eng. 2017, 29, 04017244. [Google Scholar] [CrossRef]

- Parisi, F.; Asprone, D.; Fenu, L.; Prota, A. Experimental Characterization of Italian Composite Adobe Bricks Reinforced with Straw Fibers. Compos. Struct. 2015, 122, 300–307. [Google Scholar] [CrossRef]

- Li, J.; Lu, J.; Li, X.; Ren, T.; Cong, R.; Zhou, L. Dynamics of Potassium Release and Adsorption on Rice Straw Residue. PLoS ONE 2014, 9, e90440. [Google Scholar] [CrossRef]

- Young, J.; Chi, R. Intercultural Relations: A Bibliometric Survey. Int. J. Intercult. Relat. 2013, 37, 133–145. [Google Scholar] [CrossRef]

- Bornmann, L.; Daniel, H. What Do Citation Counts Measure? A Review of Studies on Citing Behavior. J. Doc. 2008, 64, 45–80. [Google Scholar] [CrossRef]

- Ganbat, T.; Chong, H.Y.; Liao, P.C.; Wu, Y.D. A Bibliometric Review on Risk Management and Building Information Modeling for International Construction. Adv. Civ. Eng. 2018, 2018, 8351679. [Google Scholar] [CrossRef]

- Chan, L.K.; Wu, M.L. A Systematic Approach to Quality Function Deployment with a Full Illustrative Example. Omega 2005, 33, 119–139. [Google Scholar] [CrossRef]

- Huang, J.; Mao, L.X.; Liu, H.C.; Song, M.S. Quality Function Deployment Improvement: A Bibliometric Analysis and Literature Review. Qual. Quant 2021, 1–20. [Google Scholar] [CrossRef]

- Chen, C. CiteSpace II: Detecting and Visualizing Emerging Trends and Transient Patterns in Scientific Literature. J. Am. Soc. Inform. Sci. Technol. 2006, 57, 359–377. [Google Scholar] [CrossRef]

- Japec, L.; Kreuter, F.; Berg, M.; Biemer, P.; Decker, P.; Lampe, C.; Lane, J.; O’Neil, C.; Usher, A. Big Data in Survey Research: Aapor Task Force Report. Public Opin. Q 2015, 79, 839–880. [Google Scholar] [CrossRef]

- Bailón-Moreno, R.; Jurado-Alameda, E.; Ruiz-Baños, R.; Courtial, J.P. Bibliometric Laws: Empirical Flaws of Fit. Scientometrics 2005, 63, 209–229. [Google Scholar] [CrossRef]

- The Meaning-Frequency Law in Zipfian Optimization Models of Communication. Available online: https://www.researchgate.net/publication/266147458_The_meaning-frequency_law_in_Zipfian_optimization_models_of_communication (accessed on 20 January 2022).

- Garfield, E. Citation Analysis as a Tool in Journal Evaluation. Science 1972, 178, 471–479. [Google Scholar] [CrossRef]

- Agarwal, A.; Durairajanayagam, D.; Tatagari, S.; Esteves, S.C.; Harlev, A.; Henkel, R.; Roychoudhury, S.; Homa, S.; Puchalt, N.G.; Ramasamy, R.; et al. Bibliometrics: Tracking Research Impact by Selecting the Appropriate Metrics. Asian J. 2016, 18, 296. [Google Scholar] [CrossRef]

- Yair, G.; Gueta, N.; Davidovitch, N. The Law of Limited Excellence: Publication Productivity of Israel Prize Laureates in the Life and Exact Sciences. Scientometrics 2017, 113, 299–311. [Google Scholar] [CrossRef]

- Kyvik, S. Productivity Differences, Fields of Learning, and Lotka’s Law. Scientometrics 1989, 15, 205–214. [Google Scholar] [CrossRef]

- van den Eynde, J.; Franchi, T.; Foo, Y.C.; Mills, B.; Ali, S.; Doulamis, I.P.; Gewillig, M.; Budts, W.; Danford, D.A.; Kutty, S. The 100 Most Influential Articles in Congenital Heart Disease in 2000–2020: A Bibliometric Analysis. Int. J. Cardiol. Congenit. Heart Dis. 2021, 4, 100156. [Google Scholar] [CrossRef]

- Li, Y.; Rong, Y.; Ahmad, U.M.; Wang, X.; Zuo, J.; Mao, G. A Comprehensive Review on Green Buildings Research: Bibliometric Analysis during 1998–2018. Environ. Sci. Pollut. Res. 2021, 28, 46196–46214. [Google Scholar] [CrossRef]

- Katinas, V.; Marčiukaitis, M.; Perednis, E.; Dzenajavičienė, E.F. Analysis of Biodegradable Waste Use for Energy Generation in Lithuania. Renew. Sustain. Energy Rev. 2019, 101, 559–567. [Google Scholar] [CrossRef]

- Vlachokostas, C.; Michailidou, A.V.; Achillas, C. Multi-Criteria Decision Analysis towards Promoting Waste-to-Energy Management Strategies: A Critical Review. Renew. Sustain. Energy Rev. 2021, 138, 110563. [Google Scholar] [CrossRef]

- Li, C.Z.; Lai, X.; Xiao, B.; Tam, V.W.Y.; Guo, S.; Zhao, Y. A Holistic Review on Life Cycle Energy of Buildings: An Analysis from 2009 to 2019. Renew. Sustain. Energy Rev. 2020, 134, 110372. [Google Scholar] [CrossRef]

- Marvuglia, A.; Havinga, L.; Heidrich, O.; Fonseca, J.; Gaitani, N.; Reckien, D. Advances and Challenges in Assessing Urban Sustainability: An Advanced Bibliometric Review. Renew. Sustain. Energy Rev. 2020, 124, 109788. [Google Scholar] [CrossRef]

- Zhang, Y.; Pu, S.; Lv, X.; Gao, Y.; Ge, L. Global Trends and Prospects in Microplastics Research: A Bibliometric Analysis. J. Hazard Mater. 2020, 400, 123110. [Google Scholar] [CrossRef] [PubMed]

- Kumar, S.; Skariah Thomas, B.; Gupta, V.; Basu, P.; Shrivastava, S. Sandstone Wastes as Aggregate and Its Usefulness in Cement Concrete—A Comprehensive Review. Renew. Sustain. Energy Rev. 2018, 81, 1147–1153. [Google Scholar] [CrossRef]

- Hire, S.; Sandbhor, S.; Ruikar, K. Bibliometric Survey for Adoption of Building Information Modeling (BIM) in Construction Industry– A Safety Perspective. Arch. Comput. Methods Eng. 2021, 29, 679–693. [Google Scholar] [CrossRef]

- Su, H.N.; Lee, P.C. Mapping Knowledge Structure by Keyword Co-Occurrence: A First Look at Journal Papers in Technology Foresight. Scientometrics 2010, 85, 65–79. [Google Scholar] [CrossRef]

- van Eck, N.J.; Waltman, L. Visualizing Bibliometric Networks. In Measuring Scholarly Impact; Springer: Cham, Switzerland, 2014; pp. 285–320. [Google Scholar] [CrossRef]

- Jin, R.; Zou, P.X.W.; Piroozfar, P.; Wood, H.; Yang, Y.; Yan, L.; Han, Y. A Science Mapping Approach Based Review of Construction Safety Research. Saf. Sci. 2019, 113, 285–297. [Google Scholar] [CrossRef]

- Jin, R.; Yuan, H.; Chen, Q. Science Mapping Approach to Assisting the Review of Construction and Demolition Waste Management Research Published between 2009 and 2018. Resour. Conserv. Recycl. 2019, 140, 175–188. [Google Scholar] [CrossRef]

- Jhatial, A.A.; Goh, W.I.; Mohamad, N.; Mo, K.H.; Sohu, S. Incorporation of Palm Oil Fuel Ash and Egg Shell Powder as Supplementary Cementitious Materials in Sustainable Foamed Concrete. Teh. Vjesn. 2020, 27, 1394–1402. [Google Scholar] [CrossRef]

- Permatasari, N.; Sucahya, T.N.; Nandiyanto, A.B.D. Review: Agricultural Wastes as a Source of Silica Material. Indones. J. Sci. Technol. 2016, 1, 82–106. [Google Scholar] [CrossRef]

- He, J.; Kawasaki, S.; Achal, V. The Utilization of Agricultural Waste as Agro-Cement in Concrete: A Review. Sustainability 2020, 12, 6971. [Google Scholar] [CrossRef]

- Moraes, J.C.B.; Tashima, M.M.; Akasaki, J.L.; Melges, J.L.P.; Monzó, J.; Borrachero, M.V.; Soriano, L.; Payá, J. Effect of Sugar Cane Straw Ash (SCSA) as Solid Precursor and the Alkaline Activator Composition on Alkali-Activated Binders Based on Blast Furnace Slag (BFS). Constr. Build. Mater. 2017, 144, 214–224. [Google Scholar] [CrossRef]

- Melotti, R.; Santagata, E.; Bassani, M.; Salvo, M.; Rizzo, S. A Preliminary Investigation into the Physical and Chemical Properties of Biomass Ashes Used as Aggregate Fillers for Bituminous Mixtures. Waste Manag. 2013, 33, 1906–1917. [Google Scholar] [CrossRef]

- Viruthagiri, G.; Sathiya Priya, S.; Shanmugam, N.; Balaji, A.; Balamurugan, K.; Gopinathan, E. Spectroscopic Investigation on the Production of Clay Bricks with SCBA Waste. Spectrochim. Acta A Mol. Biomol. Spectrosc. 2015, 149, 468–475. [Google Scholar] [CrossRef]

- Tangchirapat, W.; Saeting, T.; Jaturapitakkul, C.; Kiattikomol, K.; Siripanichgorn, A. Use of Waste Ash from Palm Oil Industry in Concrete. Waste Manag. 2007, 27, 81–88. [Google Scholar] [CrossRef]

- Liuzzi, S.; Sanarica, S.; Stefanizzi, P. Use of Agro-Wastes in Building Materials in the Mediterranean Area: A Review. Energy Procedia 2017, 126, 242–249. [Google Scholar] [CrossRef]

- Nie, Y.; Lu, J.; Liu, Z.; Meng, D.; He, Z.; Shi, J. Mechanical, Water Resistance and Environmental Benefits of Magnesium Oxychloride Cement Incorporating Rice Husk Ash. Sci. Total Environ. 2022, 849, 157871. [Google Scholar] [CrossRef]

- He, Z.; Han, X.; Zhang, Y.; Zhang, Z.; Shi, J.; Gencel, O. Development of a New Magnesium Oxychloride Cement Board by Recycling of Waste Wood, Rice Husk Ash and Flue Gas Desulfurization Gypsum. J. Build. Eng. 2022, 61, 105206. [Google Scholar] [CrossRef]

- He, Z.H.; Du, S.G.; He, L.L. Compressive Strengths of High Volume Fly Ash Concrete Containing Rice Husk Ash. J. Adv. Microsc. Res. 2016, 11, 72–76. [Google Scholar] [CrossRef]

- Gursel, A.P.; Maryman, H.; Ostertag, C. A Life-Cycle Approach to Environmental, Mechanical, and Durability Properties of “Green” Concrete Mixes with Rice Husk Ash. J. Clean. Prod. 2016, 112, 823–836. [Google Scholar] [CrossRef]

- Al-Mulali, M.Z.; Awang, H.; Abdul Khalil, H.P.S.; Aljoumaily, Z.S. The Incorporation of Oil Palm Ash in Concrete as a Means of Recycling: A Review. Cem. Concr. Compos. 2015, 55, 129–138. [Google Scholar] [CrossRef]

- Ahsan, M.B.; Hossain, Z. Supplemental Use of Rice Husk Ash (RHA) as a Cementitious Material in Concrete Industry. Constr. Build. Mater. 2018, 178, 1–9. [Google Scholar] [CrossRef]

- Alnahhal, M.F.; Alengaram, U.J.; Jumaat, M.Z.; Alsubari, B.; Alqedra, M.A.; Mo, K.H. Effect of Aggressive Chemicals on Durability and Microstructure Properties of Concrete Containing Crushed New Concrete Aggregate and Non-Traditional Supplementary Cementitious Materials. Constr. Build. Mater. 2018, 163, 482–495. [Google Scholar] [CrossRef]

- Chopperla, S.T.; Yamuna, V.; Bahurudeen, A.; Santhanam, M.; Gopinath, A. Durability of Concrete with Agro-Waste: A Local Approach to Sustainability. Green Mater. 2019, 7, 84–96. [Google Scholar] [CrossRef]

- Zeng, X.; Yu, H.; Wu, C. An Overview of Study on Basic Magnesium Sulfate Cement and Concrete in China (2012–2019). KSCE J. Civ. Eng. 2019, 23, 4445–4453. [Google Scholar] [CrossRef]

- Zhang, N.; Yu, H.; Gong, W.; Liu, T.; Wang, N.; Tan, Y.; Wu, C. Effects of Low- and High-Calcium Fly Ash on the Water Resistance of Magnesium Oxysulfate Cement. Constr. Build. Mater. 2020, 230, 116951. [Google Scholar] [CrossRef]

- Qiu, Y.; Sun, Q.; Feng, K.; Luo, A.; Wu, X.; Ba, M. Experimental Study on the Preparation of Magnesium Oxysulfate Cement-Based Composites Using Waste Locust Powders to Replace Non-Renewable Magnesium Oxide. Constr. Build. Mater. 2023, 366, 130129. [Google Scholar] [CrossRef]

- Ganesan, K.; Rajagopal, K.; Thangavel, K. Evaluation of Bagasse Ash as Supplementary Cementitious Material. Cem. Concr. Compos. 2007, 29, 515–524. [Google Scholar] [CrossRef]

- Rodríguez De Sensale, G. Strength Development of Concrete with Rice-Husk Ash. Cem. Concr. Compos. 2006, 28, 158–160. [Google Scholar] [CrossRef]

- Zhang, M.H.; Lastra, R.; Malhotra, V.M. Rice-Husk Ash Paste and Concrete: Some Aspects of Hydration and the Microstructure of the Interfacial Zone between the Aggregate and Paste. Cem. Concr. Res. 1996, 26, 963–977. [Google Scholar] [CrossRef]

- Aprianti, E.; Shafigh, P.; Bahri, S.; Farahani, J.N. Supplementary Cementitious Materials Origin from Agricultural Wastes—A Review. Constr. Build. Mater. 2015, 74, 176–187. [Google Scholar] [CrossRef]

- van Tuan, N.; Ye, G.; van Breugel, K.; Fraaij, A.L.A.; Bui, D.D. The Study of Using Rice Husk Ash to Produce Ultra High Performance Concrete. Constr. Build. Mater. 2011, 25, 2030–2035. [Google Scholar] [CrossRef]

- Aprianti, S.E. A Huge Number of Artificial Waste Material Can Be Supplementary Cementitious Material (SCM) for Concrete Production—A Review Part II. J. Clean. Prod. 2017, 142, 4178–4194. [Google Scholar] [CrossRef]

- Loh, Y.R.; Sujan, D.; Rahman, M.E.; Das, C.A. Sugarcane Bagasse—The Future Composite Material: A Literature Review. Resour. Conserv. Recycl. 2013, 75, 14–22. [Google Scholar] [CrossRef]

- Mannan, M.A.; Ganapathy, C. Concrete from an Agricultural Waste-Oil Palm Shell (OPS). Build Env. 2004, 39, 441–448. [Google Scholar] [CrossRef]

- Al-Khalaf, M.N.; Yousif, H.A. Use of Rice Husk Ash in Concrete. Int. J. Cem. Compos. Lightweight Concr. 1984, 6, 241–248. [Google Scholar] [CrossRef]

- Tay, J. Ash from OilPalm Waste as a Concrete Material. J. Mater. Civ. Eng. 1990, 2, 94–105. [Google Scholar] [CrossRef]

- Asdrubali, F.; D’Alessandro, F.; Schiavoni, S. A Review of Unconventional Sustainable Building Insulation Materials. Sustain. Mater. Technol. 2015, 4, 1–17. [Google Scholar] [CrossRef]

- Rojas, C.; Cea, M.; Iriarte, A.; Valdés, G.; Navia, R.; Cárdenas-R, J.P. Thermal Insulation Materials Based on Agricultural Residual Wheat Straw and Corn Husk Biomass, for Application in Sustainable Buildings. Sustain. Mater. Technol. 2019, 20, e00102. [Google Scholar] [CrossRef]

- Liu, L.F.; Li, H.Q.; Lazzaretto, A.; Manente, G.; Tong, C.Y.; Liu, Q.B.; Li, N.P. The Development History and Prospects of Biomass-Based Insulation Materials for Buildings. Renew. Sustain. Energy Rev. 2017, 69, 912–932. [Google Scholar] [CrossRef]

- Akinyemi, B.A.; Dai, C. Development of Banana Fibers and Wood Bottom Ash Modified Cement Mortars. Constr. Build. Mater. 2020, 241, 118041. [Google Scholar] [CrossRef]

- Pode, R. Potential Applications of Rice Husk Ash Waste from Rice Husk Biomass Power Plant. Renew. Sustain. Energy Rev. 2016, 53, 1468–1485. [Google Scholar] [CrossRef]

- Konta, J. Clay and Man: Clay Raw Materials in the Service of Man. Appl. Clay Sci. 1995, 10, 275–335. [Google Scholar] [CrossRef]

- Khedari, J.; Charoenvai, S.; Hirunlabh, J. New Insulating Particleboards from Durian Peel and Coconut Coir. Build Env. 2003, 38, 435–441. [Google Scholar] [CrossRef]

- Demir, I. Effect of Organic Residues Addition on the Technological Properties of Clay Bricks. Waste Manag. 2008, 28, 622–627. [Google Scholar] [CrossRef]

- Demir, I.; Baspinar, M.S.; Orhan, M. Utilization of Kraft Pulp Production Residues in Clay Brick Production. Build Environ. 2005, 40, 1533–1537. [Google Scholar] [CrossRef]

- Sampathrajan, A.; Vijayaraghavan, N.C.; Swaminathan, K.R. Mechanical and Thermal Properties of Particle Boards Made from Farm Residues. Bioresour. Technol. 1992, 40, 249–251. [Google Scholar] [CrossRef]

- Yang, H.S.; Kim, D.J.; Lee, Y.K.; Kim, H.J.; Jeon, J.Y.; Kang, C.W. Possibility of Using Waste Tire Composites Reinforced with Rice Straw as Construction Materials. Bioresour. Technol. 2004, 95, 61–65. [Google Scholar] [CrossRef] [PubMed]

- Shiralipour, A.; McConnell, D.B.; Smith, W.H. Physical and Chemical Properties of Soils as Affected by Municipal Solid Waste Compost Application. Biomass Bioenergy 1992, 3, 261–266. [Google Scholar] [CrossRef]

- Pinto, J.; Cruz, D.; Paiva, A.; Pereira, S.; Tavares, P.; Fernandes, L.; Varum, H. Characterization of Corn Cob as a Possible Raw Building Material. Constr. Build. Mater. 2012, 34, 28–33. [Google Scholar] [CrossRef]

- Madurwar, M.V.; Ralegaonkar, R.V.; Mandavgane, S.A. Application of Agro-Waste for Sustainable Construction Materials: A Review. Constr. Build. Mater. 2013, 38, 872–878. [Google Scholar] [CrossRef]

- Brás, A.; Leal, M.; Faria, P. Cement-Cork Mortars for Thermal Bridges Correction. Comparison with Cement-EPS Mortars Performance. Constr. Build. Mater. 2013, 49, 315–327. [Google Scholar] [CrossRef]

- Barreca, F.; Fichera, C.R. Use of Olive Stone as an Additive in Cement Lime Mortar to Improve Thermal Insulation. Energy Build. 2013, 62, 507–513. [Google Scholar] [CrossRef]

- Banu, S.S.; Kartikeyan, J.; Jayabalan, P. Influence of Using Agro-Waste as a Partial Replacement in Cement on the Compressive Strength of Concrete—A Statistical Approach. Constr. Build. Mater. 2020, 250, 118746. [Google Scholar] [CrossRef]

- Mohseni, E.; Naseri, F.; Amjadi, R.; Khotbehsara, M.M.; Ranjbar, M.M. Retracted: Microstructure and Durability Properties of Cement Mortars Containing Nano-TiO2 and Rice Husk Ash. Constr. Build. Mater. 2016, 114, 656–664. [Google Scholar] [CrossRef]

- Khan, R.; Jabbar, A.; Ahmad, I.; Khan, W.; Khan, A.N.; Mirza, J. Reduction in Environmental Problems Using Rice-Husk Ash in Concrete. Constr. Build. Mater. 2012, 30, 360–365. [Google Scholar] [CrossRef]

- Huseien, G.F.; Mirza, J.; Ismail, M.; Hussin, M.W. Influence of Different Curing Temperatures and Alkali Activators on Properties of GBFS Geopolymer Mortars Containing Fly Ash and Palm-Oil Fuel Ash. Constr. Build. Mater. 2016, 125, 1229–1240. [Google Scholar] [CrossRef]

- Boateng, A.A.; Skeete, D.A. Incineration of Rice Hull for Use as a Cementitious Material: The Guyana Experience. Cem. Concr. Res. 1990, 20, 795–802. [Google Scholar] [CrossRef]

- Lertwattanaruk, P.; Suntijitto, A. Properties of Natural Fiber Cement Materials Containing Coconut Coir and Oil Palm Fibers for Residential Building Applications. Constr. Build. Mater. 2015, 94, 664–669. [Google Scholar] [CrossRef]

- James, J.; Subba Rao, M. Reactivity of Rice Husk Ash. Cem. Concr. Res. 1986, 16, 296–302. [Google Scholar] [CrossRef]

- Mohseni, E.; Khotbehsara, M.M.; Naseri, F.; Monazami, M.; Sarker, P. RETRACTED: Polypropylene Fiber Reinforced Cement Mortars Containing Rice Husk Ash and Nano-Alumina. Constr. Build. Mater. 2016, 111, 429–439. [Google Scholar] [CrossRef]

- Pereira, A.; Akasaki, J.L.; Melges, J.L.P.; Tashima, M.M.; Soriano, L.; Borrachero, M.V.; Monzó, J.; Payá, J. Mechanical and Durability Properties of Alkali-Activated Mortar Based on Sugarcane Bagasse Ash and Blast Furnace Slag. Ceram. Int. 2015, 41, 13012–13024. [Google Scholar] [CrossRef]

- Adesanya, D.A.; Raheem, A.A. A Study of the Permeability and Acid Attack of Corn Cob Ash Blended Cements. Constr. Build. Mater. 2010, 24, 403–409. [Google Scholar] [CrossRef]

- Praveenkumar, S.; Sankarasubramanian, G.; Sindhu, S. Strength, Permeability and Microstructure Characterization of Pulverized Bagasse Ash in Cement Mortars. Constr. Build. Mater. 2020, 238, 117691. [Google Scholar] [CrossRef]

- Arif, E.; Clark, M.W.; Lake, N. Sugar Cane Bagasse Ash from a High Efficiency Co-Generation Boiler: Applications in Cement and Mortar Production. Constr. Build. Mater. 2016, 128, 287–297. [Google Scholar] [CrossRef]

- Bahurudeen, A.; Kanraj, D.; Gokul Dev, V.; Santhanam, M. Performance Evaluation of Sugarcane Bagasse Ash Blended Cement in Concrete. Cem. Concr. Compos. 2015, 59, 77–88. [Google Scholar] [CrossRef]

- Berenguer, R.A.; Capraro, A.P.B.; de Medeiros, M.H.F.; Carneiro, A.M.P.; de Oliveira, R.A. Sugar Cane Bagasse Ash as a Partial Substitute of Portland Cement: Effect on Mechanical Properties and Emission of Carbon Dioxide. J. Environ. Chem. Eng. 2020, 8, 103655. [Google Scholar] [CrossRef]

- Jagadesh, P.; Ramachandramurthy, A.; Murugesan, R. Evaluation of Mechanical Properties of Sugar Cane Bagasse Ash Concrete. Constr. Build. Mater. 2018, 176, 608–617. [Google Scholar] [CrossRef]

- Moraes, J.C.B.; Akasaki, J.L.; Melges, J.L.P.; Monzó, J.; Borrachero, M.V.; Soriano, L.; Payá, J.; Tashima, M.M. Assessment of Sugar Cane Straw Ash (SCSA) as Pozzolanic Material in Blended Portland Cement: Microstructural Characterization of Pastes and Mechanical Strength of Mortars. Constr. Build. Mater. 2015, 94, 670–677. [Google Scholar] [CrossRef]

- Setayesh Gar, P.; Suresh, N.; Bindiganavile, V. Sugar Cane Bagasse Ash as a Pozzolanic Admixture in Concrete for Resistance to Sustained Elevated Temperatures. Constr. Build. Mater. 2017, 153, 929–936. [Google Scholar] [CrossRef]

- Singh, N.B.; Singh, V.D.; Rai, S. Hydration of Bagasse Ash-Blended Portland Cement. Cem. Concr. Res. 2000, 30, 1485–1488. [Google Scholar] [CrossRef]

- Claudiu, A.; Cobirzan, N. Use of Agricultural Products and Waste in the Building Materials Industry. ProEnvironment/ProMediu 2013, 6, 472–478. [Google Scholar]

- Reddy, M.V.S.; Sasi, K.; Ashalatha, K.; Madhuri, M. Groundnut Shell Ash as Partial Replacement of Cement in Concrete. Res. J. Sci. Technol. 2017, 9, 313. [Google Scholar] [CrossRef]

- Duque-Acevedo, M.; Belmonte-Ureña, L.J.; Cortés-García, F.J.; Camacho-Ferre, F. Agricultural Waste: Review of the Evolution, Approaches and Perspectives on Alternative Uses. Glob. Ecol. Conserv. 2020, 22, e00902. [Google Scholar] [CrossRef]

- Roselló, J.; Soriano, L.; Santamarina, M.P.; Akasaki, J.L.; Monzó, J.; Payá, J. Rice Straw AshA Potential Pozzolanic Supplementary Material for Cementing Systems. Ind. Crops. Prod. 2017, 103, 39–50. [Google Scholar] [CrossRef]

- Rodríguez de Sensale, G.; Rodríguez Viacava, I. A Study on Blended Portland Cements Containing Residual Rice Husk Ash and Limestone Filler. Constr. Build. Mater. 2018, 166, 873–888. [Google Scholar] [CrossRef]

- Ambedkar, B.; Alex, J.; Dhanalakshmi, J. Enhancement of Mechanical Properties and Durability of the Cement Concrete by RHA as Cement Replacement: Experiments and Modeling. Constr. Build. Mater. 2017, 148, 167–175. [Google Scholar] [CrossRef]

- Chao-Lung, H.; Anh-Tuan, B.L.; Chun-Tsun, C. Effect of Rice Husk Ash on the Strength and Durability Characteristics of Concrete. Constr. Build. Mater. 2011, 25, 3768–3772. [Google Scholar] [CrossRef]

- Ganesan, K.; Rajagopal, K.; Thangavel, K. Rice Husk Ash Blended Cement: Assessment of Optimal Level of Replacement for Strength and Permeability Properties of Concrete. Constr. Build. Mater. 2008, 22, 1675–1683. [Google Scholar] [CrossRef]

- Huang, H.; Gao, X.; Wang, H.; Ye, H. Influence of Rice Husk Ash on Strength and Permeability of Ultra-High Performance Concrete. Constr. Build. Mater. 2017, 149, 621–628. [Google Scholar] [CrossRef]

- Tangchirapat, W.; Jaturapitakkul, C.; Chindaprasirt, P. Use of Palm Oil Fuel Ash as a Supplementary Cementitious Material for Producing High-Strength Concrete. Constr. Build. Mater. 2009, 23, 2641–2646. [Google Scholar] [CrossRef]

- Wi, K.; Lee, H.S.; Lim, S.; Song, H.; Hussin, M.W.; Ismail, M.A. Use of an Agricultural By-Product, Nano Sized Palm Oil Fuel Ash as a Supplementary Cementitious Material. Constr. Build. Mater. 2018, 183, 139–149. [Google Scholar] [CrossRef]

- Zuo, S.; Yuan, Q.; Huang, T.; Zhang, K.; Shi, J.; Tan, Y. Microstructural Changes of Young Cement Paste Due to Moisture Transfer at Low Air Pressures. Cem. Concr. Res. 2023, 164, 107061. [Google Scholar] [CrossRef]

- He, Z.H.; Qian, C.X.; Du, S.G. Hydration and Microstructure of Cement Pastes Containing Limestone Powder and Rice Husk Ash. Nanosci. Nanotechnol. Lett. 2016, 8, 140–147. [Google Scholar] [CrossRef]

- Zhan, P.M.; Zhang, X.X.; He, Z.H.; Shi, J.Y.; Gencel, O.; Yen, N.T.H.; Wang, G.C. Strength, Microstructure and Nanomechanical Properties of Recycled Aggregate Concrete Containing Waste Glass Powder and Steel Slag Powder. J. Clean. Prod. 2022, 341, 130892. [Google Scholar] [CrossRef]

- He, Z.; Qian, C.; Du, S.; Huang, M.; Xia, M. Nanoindentation Characteristics of Cement Paste and Interfacial Transition Zone in Mortar with Rice Husk Ash. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2017, 32, 417–421. [Google Scholar] [CrossRef]

- He, Z.H.; Shen, M.L.; Shi, J.Y.; Yalçınkaya, Ç.; Du, S.G.; Yuan, Q. Recycling Coral Waste into Eco-Friendly UHPC: Mechanical Strength, Microstructure, and Environmental Benefits. Sci. Total Environ. 2022, 836, 155424. [Google Scholar] [CrossRef]

- Memon, S.A.; Khan, M.K. Ash Blended Cement Composites: Eco-Friendly and Sustainable Option for Utilization of Corncob Ash. J. Clean. Prod. 2018, 175, 442–455. [Google Scholar] [CrossRef]

- Oyebisi, S.; Ede, A.; Olutoge, F.; Ogbiye, S. Evaluation of Reactivity Indexes and Durability Properties of Slag-Based Geopolymer Concrete Incorporating Corn Cob Ash. Constr. Build. Mater. 2020, 258, 119604. [Google Scholar] [CrossRef]

- Shakouri, M.; Exstrom, C.L.; Ramanathan, S.; Suraneni, P. Hydration, Strength, and Durability of Cementitious Materials Incorporating Untreated Corn Cob Ash. Constr. Build. Mater. 2020, 243, 118171. [Google Scholar] [CrossRef]

- Madakson, P.; Yawas, D. Characterization of Coconut Shell Ash for Potential Utilization in Metal Matrix Composites for Automotive Applications. Int. J. Eng. Sci. Technol. 2012, 4, 1190–1198. [Google Scholar]

- Trivedi, N.S.; Mandavgane, S.A. Utilization of an Agro Waste, Groundnut Shell Ash, for Removal of 2,4-Dichlorophenoxyacetic Acid. In Recent Advances in Chemical Engineering; Springer: Singapore, 2016; pp. 165–173. [Google Scholar] [CrossRef]

- Nagaratnam, B.H.; Mannan, M.A.; Rahman, M.E.; Mirasa, A.K.; Richardson, A.; Nabinejad, O. Strength and Microstructural Characteristics of Palm Oil Fuel Ash and Fly Ash as Binary and Ternary Blends in Self-Compacting Concrete. Constr. Build. Mater. 2019, 202, 103–120. [Google Scholar] [CrossRef]

- Xu, W.; Lo, T.Y.; Memon, S.A. Microstructure and Reactivity of Rich Husk Ash. Constr. Build. Mater. 2012, 29, 541–547. [Google Scholar] [CrossRef]

- Castaldelli, V.N.; Moraes, J.C.B.; Akasaki, J.L.; Melges, J.L.P.; Monzó, J.; Borrachero, M.V.; Soriano, L.; Payá, J.; Tashima, M.M. Study of the Binary System Fly Ash/Sugarcane Bagasse Ash (FA/SCBA) in SiO2/K2O Alkali-Activated Binders. Fuel 2016, 174, 307–316. [Google Scholar] [CrossRef]

- Pinto, J.; Paiva, A.; Varum, H.; Costa, A.; Cruz, D.; Pereira, S.; Fernandes, L.; Tavares, P.; Agarwal, J. Corn’s Cob as a Potential Ecological Thermal Insulation Material. Energy Build. 2011, 43, 1985–1990. [Google Scholar] [CrossRef]

- Adesanya, D.A.; Raheem, A.A. Development of Corn Cob Ash Blended Cement. Constr. Build. Mater. 2009a, 23, 347–352. [Google Scholar] [CrossRef]

- Pinto, J.; Vieira, B.; Pereira, H.; Jacinto, C.; Vilela, P.; Paiva, A.; Pereira, S.; Cunha, V.M.C.F.; Varum, H. Corn Cob Lightweight Concrete for Non-Structural Applications. Constr. Build. Mater. 2012, 34, 346–351. [Google Scholar] [CrossRef]

- Adesanya, D.A.; Raheem, A.A. A Study of the Workability and Compressive Strength Characteristics of Corn Cob Ash Blended Cement Concrete. Constr. Build. Mater. 2009b, 23, 311–317. [Google Scholar] [CrossRef]

- Apampa, O.A. Environmental Benefits of Corn Cob Ash in Lateritic Soil Cement Stabilization for Road Works. Afr. J. Sci. Technol. Innov. Dev. 2019, 11, 427–431. [Google Scholar] [CrossRef]

- Aslam, M.; Shafigh, P.; Jumaat, M.Z. Oil-Palm by-Products as Lightweight Aggregate in Concrete Mixture: A Review. J. Clean. Prod. 2016, 126, 56–73. [Google Scholar] [CrossRef]

- Islam, M.M.U.; Mo, K.H.; Alengaram, U.J.; Jumaat, M.Z. Mechanical and Fresh Properties of Sustainable Oil Palm Shell Lightweight Concrete Incorporating Palm Oil Fuel Ash. J. Clean. Prod. 2016, 115, 307–314. [Google Scholar] [CrossRef]

- Muntohar, A.S.; Rahman, M.E. Lightweight Masonry Block from Oil Palm Kernel Shell. Constr. Build. Mater. 2014, 54, 477–484. [Google Scholar] [CrossRef]

- Kanadasan, J.; Fauzi, A.F.A.; Razak, H.A.; Selliah, P.; Subramaniam, V.; Yusoff, S. Feasibility Studies of Palm Oil Mill Waste Aggregates for the Construction Industry. Materials 2015, 8, 6508–6530. [Google Scholar] [CrossRef]

- Shafigh, P.; Jumaat, M.Z.; Mahmud, H.B.; Alengaram, U.J. A New Method of Producing High Strength Oil Palm Shell Lightweight Concrete. Mater. Des. 2011a, 32, 4839–4843. [Google Scholar] [CrossRef]

- Shafigh, P.; Jumaat, M.Z.; Mahmud, H. Oil Palm Shell as a Lightweight Aggregate for Production High Strength Lightweight Concrete. Constr. Build. Mater. 2011b, 25, 1848–1853. [Google Scholar] [CrossRef]

- Menya, E.; Olupot, P.W.; Storz, H.; Lubwama, M.; Kiros, Y. Production and Performance of Activated Carbon from Rice Husks for Removal of Natural Organic Matter from Water: A Review. Chem. Eng. Res. Des. 2018, 129, 271–296. [Google Scholar] [CrossRef]

- Nimwinya, E.; Arjharn, W.; Horpibulsuk, S.; Phoo-Ngernkham, T.; Poowancum, A. A Sustainable Calcined Water Treatment Sludge and Rice Husk Ash Geopolymer. J. Clean. Prod. 2016, 119, 128–134. [Google Scholar] [CrossRef]

- Geraldo, R.H.; Fernandes, L.F.R.; Camarini, G. Water Treatment Sludge and Rice Husk Ash to Sustainable Geopolymer Production. J. Clean. Prod. 2017, 149, 146–155. [Google Scholar] [CrossRef]

- Arabani, M.; Tahami, S.A. Assessment of Mechanical Properties of Rice Husk Ash Modified Asphalt Mixture. Constr. Build. Mater. 2017, 149, 350–358. [Google Scholar] [CrossRef]

- Jittin, V.; Bahurudeen, A.; Ajinkya, S.D. Utilisation of Rice Husk Ash for Cleaner Production of Different Construction Products. J. Clean. Prod. 2020, 263, 121578. [Google Scholar] [CrossRef]

- Guna, V.; Ilangovan, M.; Rather, M.H.; Giridharan, B.V.; Prajwal, B.; Vamshi Krishna, K.; Venkatesh, K.; Reddy, N. Groundnut Shell/Rice Husk Agro-Waste Reinforced Polypropylene Hybrid Biocomposites. J. Build. Eng. 2020, 27, 100991. [Google Scholar] [CrossRef]

- Murugesan, T.; Vidjeapriya, R.; Bahurudeen, A. Sugarcane Bagasse Ash-Blended Concrete for Effective Resource Utilization Between Sugar and Construction Industries. Sugar Tech. 2020, 22, 858–869. [Google Scholar] [CrossRef]

- Moretti, J.P.; Nunes, S.; Sales, A. Self-Compacting Concrete Incorporating Sugarcane Bagasse Ash. Constr. Build. Mater. 2018, 172, 635–649. [Google Scholar] [CrossRef]

- Sohal, K.S.; Singh, R. Sustainable Use of Sugarcane Bagasse Ash in Concrete Production. Lect. Notes Civ. Eng. 2021, 113, 397–407. [Google Scholar] [CrossRef]

- Souza, N.S.L.D.; Anjos, M.A.S.D.; Sá, M. das V.V.A. de; Farias, E.C. de; Souza, M.M. de; Branco, F.G.; Pereira, A. Evaluation of Sugarcane Bagasse Ash for Lightweight Aggregates Production. Constr. Build. Mater. 2021, 271, 121604. [Google Scholar] [CrossRef]

- Faria, K.C.P.; Gurgel, R.F.; Holanda, J.N.F. Recycling of Sugarcane Bagasse Ash Waste in the Production of Clay Bricks. J Env. Manag. 2012, 101, 7–12. [Google Scholar] [CrossRef]

- Charitha, V.; Athira, V.S.; Jittin, V.; Bahurudeen, A.; Nanthagopalan, P. Use of Different Agro-Waste Ashes in Concrete for Effective Upcycling of Locally Available Resources. Constr. Build. Mater. 2021, 285, 122851. [Google Scholar] [CrossRef]

- Geng, S.; Wang, Y.; Zuo, J.; Zhou, Z.; Du, H.; Mao, G. Building Life Cycle Assessment Research: A Review by Bibliometric Analysis. Renew. Sustain. Energy Rev. 2017, 76, 176–184. [Google Scholar] [CrossRef]