Abstract

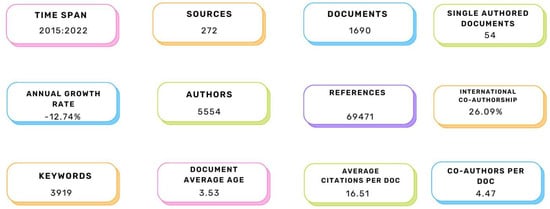

Natural-fibre-reinforced composites (NFRCs) are revolutionising the way materials are used for various purposes, and they have enriched applications from aerospace to concrete. In tandem with these works, sustainable materials that are eco-friendly and possess strength and endurance are rapidly replacing conventional materials. Recent decades have shown that many exuberant, curious-minded researchers are working on this particular domain, creating numerous materials for a variety of applications. What exactly is being performed in the laboratory is not being carried out in the field and duly disseminated. The major constraint is knowledge sharing and bottlenecks involved in assessing that research. Scientometrics is a field providing access to the consolidated research landscape report on a particular topic informing research on what work is being performed, how it is performed, who performs it, and what is the future scope. In this work, we analyse the research works, trends, and challenges related to NFRCs for engineering applications. It is found that research works, and the utilisation related to NFRCs, have soared in the last two decades, which proves to be a promising area to work upon. We use the Scopus database for the analysis, and scientometric analysis is carried over with biblioshiny. We find that there is a decreasing trend in publications (−12.74%/year); 272 sources are involved with 1690 documents published containing 5554 authors with 54 single-authored documents. There are 3919 keywords involved with 16.51 average citations received for the documents published. This work can be used to understand the research trend and also to take up newer research.

1. Introduction

The ability of people to live in peace and harmony on Earth for an extended period of time is referred to as sustainability. There are many different definitions of sustainability, and they have changed over time and with the literature and context. Three dimensions (or pillars) are frequently used to describe sustainability: environmental, economic, and social. Three pillars—economic, environmental, and social, also known colloquially as profits, planet, and people, respectively—are frequently used to describe sustainability. In that breakdown, the idea of “economic sustainability” focuses on protecting natural resources, including both renewable and exhaustible inputs, that offer physical inputs for economic development. NFRC filaments have attracted a lot of attention on the market, particularly to the development of concrete, plastics, composites, etc. However, concrete is the most widely utilised building material globally, and its consumption has improved in a variety of sectors since approximately the Roman period. This trend is primarily attributable to the material’s superior strength, durability, and convenience in comparison to other building materials [1,2,3,4]. Because of its poor tensile strength, low resistance to cracking, and poor propensity for mechanical damage, its implementation is severely constrained. Generally, fibre-reinforced concrete is evaluated as a means of compensating for concrete’s fragility [5]. Since biblical times [6], fragile composites have been reinforced with fibre. To increase the tensile strength of concrete, synthetic fibres, glass fibres, steel fibres, polyvinyl alcohol fibres [7,8], and natural fibres have been utilised [9]. Steel fibre is the most commonly employed of these [6,10]. However, rust is an issue with steel fibres, which restricts their consumption [11]. Many studies show that synthetic fibres are the best way to address this problem, despite the fact that their production is both expensive and energy-intensive. In such situations, natural fibres are typically considered a viable solution for the production of fibre-reinforced concrete. Independent natural fibres are disseminated indiscriminately throughout the matrix, and concrete’s microscopic dimensions are discontinuous. There are environmental, socioeconomic, energy, and resource conservation advantages to using natural fibre [12].

Moreover, natural fibres are generally categorised according to their source: animal, mineral, and plant [13]. In particular, organic fibres are preferred. Plant fibre is the most desirable type of fibre because it contains cellulose, whereas animal fibre is predominantly protein-rich, and mineral fibre is related to health. The report by Pickering et al. [13] notwithstanding, plant fibre is stronger and sturdier than animal fibre. Researchers have noted that utilising plant fibres in concrete formulations has the potential to considerably enhance the characteristics and efficiency of concrete [10]. Furthermore, due to their low densities [14], cellulose-based plant fibres may be employed as a reinforcement material in concrete because of their outstanding tensile strength and distinctive morphology. To improve the distinctive strength of concrete, the possibility of combining different fibres, including nylon fibre, jute fibre, human hair fibre, coir fibre, sisal fibre, and hemp fibre, was explored [15]. According to studies [15,16], natural fibres improve the mechanical properties of concrete, including its compressive strength, tensile strength, susceptibility to fracture and destruction, and deformability. Natural fibre has the additional benefit of consuming minimal energy to be transformed into fibre [17]. Synthetic fibres are often used to enhance the tensile strength of concrete due to their advantageous properties. These synthetic filaments, such as acrylic and steel, are, however, expensive. Therefore, synthetic fibres increase the total construction costs. Furthermore, natural fibres are a less costly, ecologically sustainable, and long-lasting way to boost concrete’s tensile strength [15]. The largest challenges, however, remain to be uneven printing, clogging, and the uneven distribution of the fibre matrix. Natural fibres such as hemp, kenaf, flax, and jute can be used as reinforcing agents in additive manufacturing (AM). These sources contain a variety of polymers that each have unique characteristics and behaviours. The best practices or methods offer long-lasting consistency and performance in terms of increased fibre-matrix bonding with a stronger fibre matrix, according to research. In actuality, the majority of problems relate to researching raw materials and composites based on NFRPCs in order to build an environmentally acceptable product or method.

Natural-fibre-reinforced polymer composites (NFRCs) are attracting more attention because of their high specific strength, low density, and biocompatibility [18]. Many material and processing-related issues must be resolved in order to ensure long-term stability and performance. Balla et al. [19] examined the use of several additive manufacturing (AM) techniques in the processing of polymer composites, as well as the serious issues connected to the processing of NFRCs and AM. Additive manufacturing is a potent technique for producing components with complex shapes out of a variety of materials (AM). Finding ways to deal with errors while preserving the calibre and consistency of the output is one of the toughest challenges. This system is constructed using a customised online image acquisition system and an image-diagnosis-based feedback quality control technique for a standard AM process called fused filament fabrication [20]. Additive manufacturing (AM) has expanded quickly since it was initially introduced as a result of its many advantages. The work of Landes and Letcher [21] focuses on an additively made composite material that is a more eco-friendly substitute for conventional composites. The strength of bamboo-filled PLA was found to be comparable to those of several bamboo-fibre-reinforced polymers made using more traditional methods. Wang et al. investigated liquid-powder and hybrid liquid–solid AM printing processes as well as AM composites [22]. Natural-fibre-reinforced composites can be printed using fused deposition modelling (FDM), one of the fastest-growing additive manufacturing (AM) technologies (NFRC). The review by Rajendran et al. [23] summarises the most recent NFRC-AM extraction techniques. Discussions covered fibre treatments, creating composites, and compatibilisers. The mechanical properties of printed parts are impacted by printing factors. Natural-fibre-reinforced polymer composite filaments have garnered a lot of attention on the market. Uneven printing, clogging, and uneven fibre matrix dispersion remain the main problems, nevertheless. Kenaf fibres are also one of the most-often-utilised reinforcements in polymer composites. KF/PLA composite filaments have certain problems with market adoption as well as long-term viability [24].

As composite reinforcing fillers for polymer-based filaments are generated using the fused deposition modelling (FDM) method, natural fibres are gaining popularity. It was suggested to use a novel technique to enhance the mechanical capabilities of biocomposites. Comparable to continuous glass fibre/PolyAmide (PA)-printed composites, these composites’ tensile characteristics were also found there [25]. The common manufacturing procedures for PLA composites reinforced with natural fibres were covered by Zhu and Wu [25,26], including injection moulding, extrusion moulding, hot pressing moulding, hot pressing moulding, and 3D printing moulding. The advantages and disadvantages of various procedures were explored by the authors. Hygromorphic biocomposites are a brand-new way to use natural fibre to make self-bending objects that react to moisture gradients [27].

Natural-fibre-reinforced composites based on flax fibre can be printed and are extremely clear, according to Jiang et al. More than 90% of light can pass through the produced composites, and their tensile performance is on par with that of composites manufactured from synthetic fibres [28]. Zhang [29] developed a method for printing continuous-flax-fibre-reinforced plastic components using a five-axis three-dimensional (3D) printer (CFFRP). The compressive strength and modulus of the 3D-printed CFFRP specimens increased by 29% and 522%, respectively, in comparison to the planar slicing method. The mechanical characterisation of 3D-printed biomaterials was the subject of Rahman et al.’s research [30]. Reinforcements made of natural fibre have been added to the 3D-printed pieces to improve their mechanical properties. The samples were mechanically described using fractography and tensile testing. The biomass produced by the oil palm industry has been identified as a possible source of green materials. Investigating the utilisation of EFB fibre in additive manufacturing materials is the goal of this project. Regarding shore hardness and thermal conductivity, it might be comparable to PLA or ABS [31]. The swelling of natural fibres is typically a drawback when considering structural applications of biocomposites [32]. However, the development of hygromorph biocomposites relies heavily on this approach (HBC). Frulex et al. investigated the matrix stiffness and hydroexpansion of 3D-printed continuous-flax-fibre-reinforced biocomposites [33]. Water absorption, hydroexpansion, and HBC elastic characteristics are all decreased by matrix stiffness.

Blown-up filament fibres from soybean hulls can be used in 3D printing to create thermoplastic copolyester (TPC) composites (FFF). To comprehend their influence on the mechanical and microstructural characteristics of the composite, the hulls underwent physical and chemical treatment. Soybean hull-fibre thermoplastic copolyester (TPC) composite parts were evaluated by Ball et al. [34]. Both in the printed form and after spending 168 h submerged in deionised water, the composites’ elastic modulus was 803 MPa higher than that of pure TPC. The use of pinecone fibres as reinforcement in acrylonitrile butadiene styrene in the study by Costa et al. [35] offers an additional method of reducing solid waste. It advances the concept of green composites (ABS). There is a limited amount of landfill space, so it is critical to find uses for these products. Post-consumer textile waste and polyethylene terephthalate (PET) water bottles could cooperate thanks to surface modifications. White denim fabric’s cellulose fibres were broken down by the water and given new applications. As a result, it has been demonstrated that a technique for recycling waste materials for 3D printing is feasible [36]. Due to their excellent performance and durability, fibre composites have seen highly robust development in recent years. An extensive overview of the mechanical testing and performance analysis of polymer–fibre composites produced by additive manufacturing, namely fused deposition modelling, is provided in this work by Shanmugam et al. [37] (FDM).

One of the most innovative industrial technologies is 3D printing. One of the most affordable and popular 3D printing processes is FDM. The most widely used type of filament for printing is PLA. Pure PLA is rigid, has a low tensile strength, and is not very flexible. Composites can be made by combining PLA with a variety of natural fibres [38]. According to Regalla [39], the tensile strength, fracture initiation, and propagation behaviour of polymer matrix composite layered shell structures produced by additive manufacturing (AM) have been examined. In various modes and directly in filament form utilising a filament extruder, tests on reinforced polymer matrix composites produced by additive manufacturing (AM) were conducted. The development of macroscopic fracture depends on internal faults such as voids and lack-of-fusion (LOF) sites.

A versatile aliphatic linear thermoplastic polymer made from renewable resources such as wheat, corn, rice, and sweet potatoes is called polylactic acid (also known as polylactide) (PLA). PLA can be 3D-printed, uses less energy, and emits fewer greenhouse gases during production. A study by Rajeshkumar et al. [40] investigates the effects of various natural fibres on PLA-based natural-fibre-reinforced composites. This work will help researchers and academics better understand PLA-based bio-composites.

2. Scientometric Investigations

Scopus is the citation database owned by Elsevier LLC and it is widely used for scientometrics studies. Because of Scopus’ large coverage of a wide range of themes, breadth of coverage, high frequency of citations, and accessibility of numerous analysis tools [41,42,43,44], it was utilised to assess the national and worldwide state of additively made NFRPC research. Scopus is the largest database of scholarly literature that has undergone peer review, with about 80 million indexed entries. It has also developed a reputation as a trustworthy and thorough bibliometric resource for academic research. There are few research papers published involving scientometrics research for Civil Engineering purposes [45,46,47,48]. The academic community has used it extensively as a source of scientometric data [49,50,51]. To retrieve the scientometric data on sustainable material development using NFRCs, a three-level keyword search was applied to the Scopus database focusing on the period of 2014–2022. It was observed that publications in this research area started only from the year 2014 onwards. Level 1 includes natural-fibre-related keywords (“Natural fiber”), level 2 includes material-related keywords ((material)), and level 3 considers composite-related keywords ((“Natural Fibers”) OR (“Fibers”)). Thus, the set of these keywords identifies the possible combination of research topics studied on additively manufactured NFRPCs. The search was conducted in January 2023. The following search query was entered in the search field of the Scopus database to retrieve the scientometric data on additively manufactured NFRPCs:

(TITLE-ABS-KEY (“natural fiber”) AND TITLE-ABS-KEY (material)) AND PUBYEAR > 2014 AND (LIMIT-TO (SUBJAREA, “MATE”)) AND (LIMIT-TO (DOCTYPE, “ar”)) AND (LIMIT-TO (EXACTKEYWORD, “Natural Fibers”) OR LIMIT-TO (EXACTKEYWORD, “Fibers”) OR LIMIT-TO (EXACTKEYWORD, “Fiber Reinforced Plastics”) OR LIMIT-TO (EXACTKEYWORD, “Composites”)) AND (LIMIT-TO (LANGUAGE, “English”)) AND (EXCLUDE (EXACTKEYWORD, “Scanning Electron Microscopy”))

3. Results and Discussion

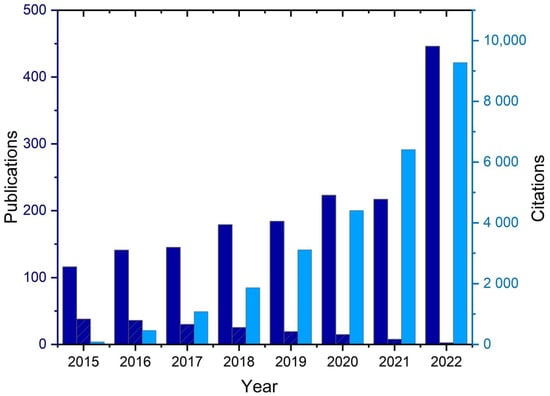

A variety of visualisation methods were used to retrieve information that was helpful from the 1690 generated documents. Authors were helped in the process of data visualisation by tools such as VOS viewer (version 1.6.15), OriginPro 2022b (64-bit), and Biblioshiny (version 4.1.1) [52]. The correlations in co-citations, co-authorship, and bibliographic coupling were also identified using these techniques. Figure 1 displays yearly publications and citations for research on additively produced NFRPCs. The year of 2015 saw the initial publication of this subject. Some articles received citations up until 2016. The productivity of additively made NFRPC research has increased since 2020, and a sharp increase was observed in 2021–2022. The most publications were published in 2022. (5736).

Figure 1.

Number of publications and their corresponding citations in the field of additively manufactured NFRPCs.

3.1. Publishing and Citation Trends

The NFRPC’s annual publication and citation trends are depicted in Figure 2. The h-index, total publications, number of cited publications, total citations, mean citations per publication (TC/TP), and mean citations per cited publication (TC/NCP) are also included (h). A total of 702 publications (or 78% of all publications) and 16,955 citations (or 92.3% of all received citations) were produced between 2021 and January 2023, respectively. The largest number of documents (N = 446) and citations (N = 9272) were found in the year 2022. Research on naturally reinforced polymer composites made additively is expanding rapidly over time, according to publication patterns. The average number of citations for each cited publication (TC/NCP) in the years 2021 and 2022 was 29.44 and 20.78, respectively. Table 1 shows the data related to number of publications vs. the citation trend based on article level and mean citations per year.

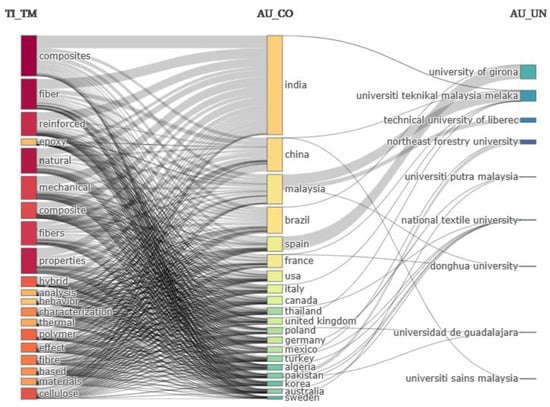

Figure 2.

Keywords coupled with countries and affiliations.

Table 1.

Citation trend and mean citations received.

These findings imply that, despite the modest progress of additively made NFRPC research, it has become significant in terms of publications in 2021. The use of the material including conventional plastics, which are primarily non-biodegradable, has begun to decline in the industry. Instead, bio-composites, which rely on a polymer matrix that may be either carbon-neutral or biodegradable, are starting to gain popularity. This is mainly because synthetic polymers have a seriously detrimental effect on the environment. Natural-fibre-reinforced composites (NFRPCs) were developed by researchers to encourage plastic recycling and reduce plastic production. The focus of research so far has been on NFRPC processing techniques that do not actually differ all that much from processing conventional plastics. Similar techniques to those used to process and form conventional plastics, such as extrusion, compression moulding, and injection moulding, are used to process and create NFRPCs. One of the main reasons for the increase in research on additively manufactured NFRPCs may be the growing recognition of AM technology among academics and industry as one of the most important factors in the development of the fourth industrial revolution.

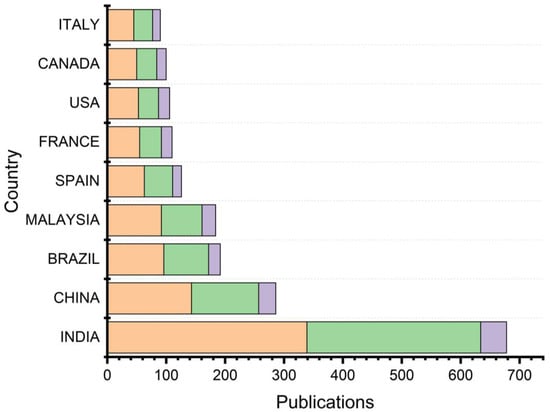

3.2. Leading Countries

These findings imply that, despite the modest progress of additively made NFRPC research, it has become significant in terms of publications in 2021. A total of 19 nations submitted research articles on additively produced NFRPCs between 2015 and 2022. In terms of publications and citations in the field of additively made NFRPC, the following countries dominate: India (431), China (170), Brazil (122), Malaysia (115), Spain (78), France (69), the United States (68), Canada (68), and Italy (57). India has the most citations (4142), as seen in Figure 3, followed by China. Brazil, on the other hand, trails India in terms of the number of citations produced from just two papers (3997). We can infer that a lot of researchers read and used their publications because citations are the most significant quality indicator. India, China, and Brazil are the top three contributors, accounting for 68.0% of all additively manufactured NFRPC articles published worldwide, highlighting the three nations’ outstanding research prowess in this field. Figure 2 shows the keywords coupled with countries involved in the research and the top institutions contributing to the research. Figure 3 provides information about the top countries publishing a higher number of papers per year in that India, China, and Brazil top the chart. Various colours in the graph indicate the publications, publications arising from single-country authorship, and publications arising from multiple-country authorship. If a country produces a higher number of multiple-country-authorship papers, it indicates the level of collaborative research they undertake.

Figure 3.

Scopus publications by country (the three colours indicate Publications, Publications among single-country authors, and Publications with other country collaborations).

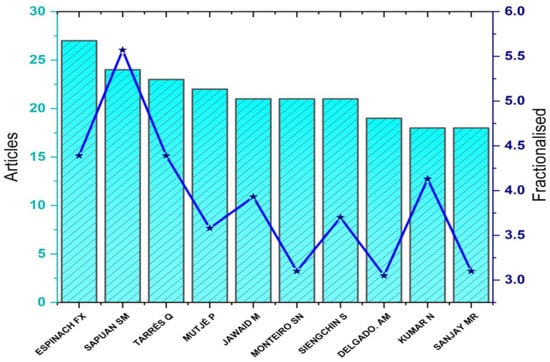

3.3. Most Productive Authors

The most productive authors in the field of additively manufactured NFRPCs are shown in Figure 4 with the y axis on left side showing the number of articles published and that on the right side showing fractionalised count. When counting a publication with many authors, each author’s contribution is given the same weight regardless of how many authors were involved in the project. With fractional counting, each co-author receives a proportional share of credit for a joint publication, up to a maximum of one [53]. Each publication, thus, carries the same total weight in the case of fractional counting. The authors are as follows: Espinach FX, affiliated with Universitat de Girona, Spain; Sapuan SM, affiliated with Universiti Putra Malaysia, Serdang, Malaysia. However, the authors with the highest citation impact are as follows: Espinach FX, affiliated with Universitat de Girona, Spain; Sapuan SM, affiliated with Universiti Putra Malaysia, Serdang, Malaysia. These two authors published only 51 documents in the field of additively manufactured NFRPCs but have 9272 citations with a significant citation impact of 98.5. The three authors—Tarees Q and Mutje P, affiliated with the University de Girona, Girona, Spain; Jawaid M, affiliated with Universiti Putra Malaysia, Serdang, Malaysia—have a citation impact of 86.3. The contributions made by several other authors—Monteiro SN, affiliated with Instituto Militar de Engenharia, Rio de Janeiro, Brazil; Siengchin S, affiliated with King Mongkut’s University of Technology North Bangkok, Thailand; Delgadd-Aguilar M, affiliated with Universitat de Girona, Girona, Spain; Kumar N PTU, affiliated with the Department of Mechanical Engineering, Jalandhar, India; Sanjay MR, affiliated with King Mongkut’s University of Technology North Bangkok, Bangkok, Thailand—indicate that the research on the additive manufacturing of NFRPCs has a lot of scope for future investigations.

Figure 4.

Scopus publications by the top ten authors in the field of additively manufactured NFRPCs.

Table 2 shows the authors’ local impact with reference to their h index, g- index, total citations (TCs), and number of publications (NP) and also the year they started the publication in this domain: Publication starting year (PSY). Jawaid M has the highest h index, which shows that his articles (16 out of 21) have more than 16 citations, followed by Monteiro SN and Sanjay MR sharing an h index of 15. An individual’s M-Index can be calculated by dividing their H-index by the number of years they have been in the field. The G-Index comprises the most-cited papers from the top G journals. These data show that the authors’ productivity is one parameter to look upon while understanding a particular area of research.

Table 2.

Author’s local impact.

3.4. Analysis of the Overall Growth Trend

The primary findings of the scientometric analysis in terms of sources, documents, publications’ annual growth rate, and numerous other indices pertaining to authors, keywords, and documents are summarised in Figure 5 below. A −12.74% yearly growth rate suggests that there will be plenty of room for NFRPC additive manufacturing research in the future. An indication of the interest of potential researchers in the topic is the average number of citations per document, which is 16.51.

Figure 5.

Summary of the main results of the scientometric analysis.

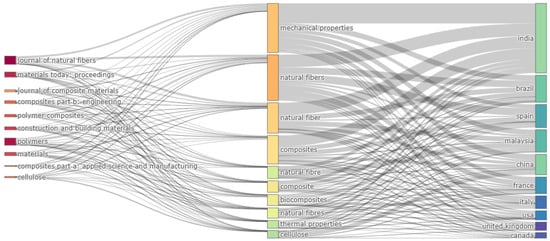

3.5. Three-Factor Analysis (Countries, Sources and Keywords)

The three-field plot gives an insight into the countries with the highest scientific production and the major sources related to natural fibre composites and the connected keywords. In addition, it shows the relationship between them. The plot was created using Biblioshiny. In Figure 6, it is possible to see how the keywords mechanical properties, natural fibers/fibres, composites, and biocomposites are strongly connected to India, Brazil, Spain, Malaysia, and China. Moreover, the major sources for these topics are the Journal of Natural Fibers, Materials Today: Proceedings, Polymers, Journal of Composite Materials, Composites Part B: Engineering, and Materials. In particular, the Journal of Natural Fibers and Polymers are strongly connected to the topics of mechanical properties and natural fibers/fibres, whereas Materials Today: Proceedings broadly covers all the keywords. Table 3 shows the sources and their citation impact with reference to the number of years studied.

Figure 6.

Three-field plot showing the relationship between sources, keywords, and countries.

Table 3.

Sources and their citation impact.

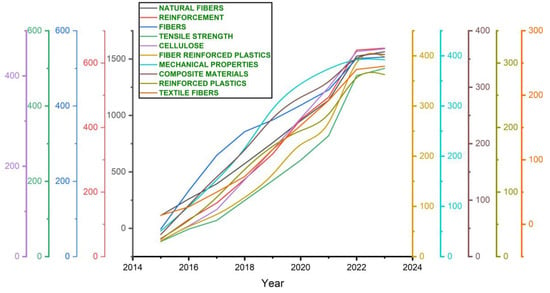

3.6. Word Dynamics

Figure 7 shows how keywords have evolved between 2015 and 2022. The evolution of the top ten terms used by the authors is depicted in the graph. It is clear that Cellulose will be the most popular keyword in 2022, followed by Composite Materials, demonstrating how scientific production is increasingly focusing on the investigation of these themes. All other pertinent keywords, such as Fiber Reinforced Plastics, Fibers, Mechanical Properties, Natural Fibers, Reinforced Plastics, Reinforcement, Tensile Strength, and Textile fibers, are also on the rise. After the introduction of Cellulose, these keywords have grown quickly, and the graph below illustrates how this has increased interest in the research and creation of additively manufactured NFRPCs.

Figure 7.

The evolution of the top ten keywords.

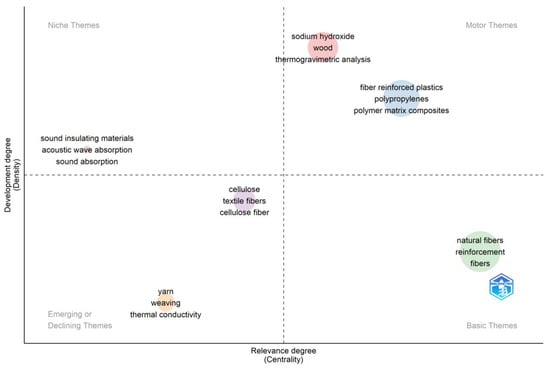

3.7. Thematic Mapping

As seen in Figure 8, thematic mapping enables the depiction of four distinct topic typologies. The keywords field is utilised by the thematic map. Themes are categorised in this two-dimensional graph according to their density and centrality. The centrality, which is a gauge of a theme’s importance or relevance, is represented by the X-axis. On the Y-axis, the density that indicates the stage of development of a theme is shown. The themes are classified and placed in four quadrants (Figure 6) that are discussed below.

Figure 8.

Thematic mapping of keywords.

- Motor themes are found in the upper-right quadrant (Q1). These are high-density and high-centrality themes, which means they are important and well developed. “Fiber reinforced plastics”, “polypropylenes”, “polymer matrix composites”, “sodium hydroxide”, “wood”, and “thermogravimetric analysis” are the main themes in this analysis. This quadrant’s themes are well evolved and extensively researched, making them ideal for comprehensive literature reviews and scientometric studies.

- Basic themes are in the lower-right quadrant (Q2). Due to its high centrality and low density, this quadrant contains important, but insufficiently developed, themes. “Natural fibres”, “reinforcement”, and “fibers” are the main themes in this quadrant, indicating lot of scope for further research in these areas.

- Emerging or disappearing themes are shown in the lower-left quadrant (Q3). Future research would be appropriate for these new and underdeveloped topics. Here, the terms “cellulose”, “textile fibers”, “cellulose fiber”, “cellulose fiber”, “yarn”, “weaving”, and “thermal conductivity” are obvious.

- Very specialised/niche themes are located in the upper-left quadrant (Q4). This area has a high density and low centrality. The themes, “sound insulating materials”, “acoustic wave absorption”, and “sound absorption”, represent the good development of research in the specified areas but remain isolated due to a low level of centrality.

The study used the authors’ keywords and criteria, which are Minimum Cluster Frequency (per thousand documents) (5) and Number of Words (250).

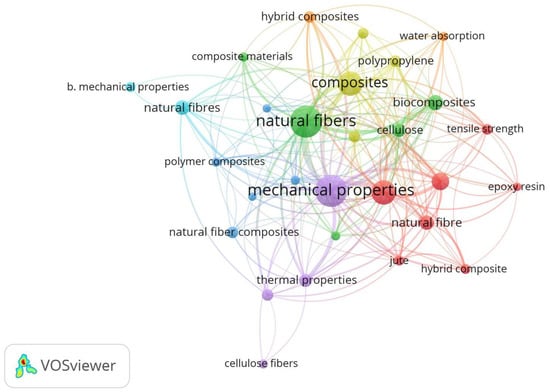

4. Co-Occurrence of Keywords

On the basis of bibliographic data retrieved from the Scopus database, a co-occurrence keywords analysis was conducted using both authors’ keywords and index keywords. The map consists of circle-associated labels. The dimensions of both are dictated by the item’s weight, and some of them could not be presented to prevent overlap. Each item is shown with a colour that corresponds to the cluster to which it belongs. By default, the software generates clusters, which represent a collection of closely linked nodes. Specifically, the VOS mapping approach is used to construct maps, where VOS stands for “visualisation of similarities”. The VOS mapping technique is based on the idea that objects should be positioned according to how similar they are, with objects that are more similar being placed closer together and those that are less similar being placed further away. Figure 9 shows a map of co-occurring keywords. The map has 18 keywords that are linked together by 125 links and has a total link strength of 502 links. On the map, there may be four clusters visible. There are 19 keywords in the red cluster (cluster 1), followed by 3 in the green cluster (cluster 2), 24 in the blue cluster (cluster 3), and 3 in the purple cluster (cluster 4), which is the smallest.

Figure 9.

Co-occurrence of keywords.

5. Summary and Conclusions

The goal of this study was to provide a thorough overview of additively made NFRPC research using scientometric analysis. Through annual research productivity, publication, and citation patterns, the study was able to identify publication trends, significant countries, sources, authors, and studies that have significantly contributed to the field of additively manufactured NFRPC research. Only 50 papers in total were extracted from the Scopus database for the years 2015 to 2023 and analysed using the R-studio bibliometric programme Biblioshiny (version 4.1.1) and VOS viewer (version 1.6.15). Based on the current state of the research, the paper makes informative suggestions for further study in the area of additively made NFRPC. The first article on NFRPCs produced using additive manufacturing appeared in 2015, and during the subsequent three years, the research has grown dramatically. Of the 19 countries that have published research publications on the subject of additively made NFRPC, India (431) and China (170) have produced the most documents. A nation may not always be more influential if it is more productive. In terms of citation productivity, France is second behind India with 86 citations from just two works. The top three contributors, India, China, and Brazil, account for 68.0% of all NFRPC pieces that are additively made globally, highlighting their tremendous research expertise in this area. Based on the quantity of documents, the Journal of Natural Fibers and Polymers emerged as the top journals contributing to the discussion of additively made NFRPCs. According to Citescore, “Composites Part B: Engineering” had the most impact, followed by “Acta Biomaterialia” (15.8) and “Polymers” (5.8). “Materials Today: Proceedings” received a Citescore of 2.3 for 2021. The journal “Composites Part B: Engineering” is a good choice to have a high impact for their articles as scientometric analysis is a tool that researchers can use to choose journals for potential publication of their works. To increase the likelihood of publishing acceptance, “Materials Today: Proceedings” and “Polymers” may also be selected based on their productivity.

Scientists can use the application of scientometric analysis as a great tool to help them better understand the research themes and research gaps. It provides guidance for upcoming research projects. The study makes use of a method known as “thematic mapping” of Biblioshiny to achieve this objective. The following research topics were found: fibre-reinforced plastics, polypropylenes, polymer matrix composites, sodium hydroxide, wood, and thermogravimetric analysis are the main motor topics. Themes that are emerging or declining include “cellulose”, “textile fibers”, “cellulose fiber”, “cellulose fiber”, “yarn”, “weaving”, and “thermal conductivity”. The niche themes include “sound insulating materials”, “acoustic wave absorption”, and “sound absorption”. The study found that there is plenty of room for future research in the area of creating biocomposites employing reinforced plastics and natural-fibre-reinforced composites based on thematic mapping.

Limitations and Recommendations

This work was performed with Scopus as the source database; there are other databases including Web of Science, Lens.org, Dimensions, and Pubmed, and every database has its own indexing method, protocols, and search query execution system. Careful consideration should be given to decide the selection and usage of databases as it influences the results. The search was conducted during January 2023 and care should be noted that the databases are updated regularly, and a search performed during later stages will provide updated results. We wish research could be performed by using other databases and for a larger period of time with a greater number of sources studied. In addition, artificial intelligence applications in sustainable material development are not well understood or studied, which can also be undertaken with a scientometric perspective.

Author Contributions

Conceptualization, G.R. and V.M.; methodology, V.M.; software, G.R. and V.M.; validation, S.C., K.S. and A.S.; formal analysis, G.R. and N.B.; investigation, G.R. and V.M.; resources, N.B.; data curation, N.B.; writing—original draft preparation, G.R., V.M. and N.B.; writing—review and editing, G.R., V.M., A.S. and N.B.; visualization, S.C.; supervision, V.M.; project administration, G.R., S.C., K.S. and A.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

All data used in this study are available on request from authors.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Naganna, S.R.; Jayakesh, K.; Anand, V.R. Nano-TiO2 particles: A photocatalytic admixture to amp up the performance efficiency of cementitious composites. Sādhanā 2020, 45, 280. [Google Scholar] [CrossRef]

- Ramesh, B.M.; Vongole, R.M.; Nagraj, Y.; Naganna, S.R.; Sreedhara, B.M.; Mailar, G.; Ramesh, P.S.; Yaseen, Z.M. Valorization of incinerator bottom ash for the production of resource-efficient eco-friendly concrete: Performance and toxicological characterization. Archit. Struct. Constr. 2021, 1, 65–78. [Google Scholar] [CrossRef]

- Katman, H.Y.B.; Khai, W.J.; Bheel, N.; Kırgız, M.S.; Kumar, A.; Benjeddou, O. Fabrication and characterization of cement-based hybrid concrete containing coir fiber for advancing concrete construction. Buildings 2022, 12, 1450. [Google Scholar] [CrossRef]

- Bheel, N. Basalt fibre-reinforced concrete: Review of fresh and mechanical properties. J. Build. Pathol. Rehabil. 2021, 6, 12. [Google Scholar] [CrossRef]

- Boulekbache, B.; Hamrat, M.; Chemrouk, M.; Amziane, S. Flexural behaviour of steel fibre-reinforced concrete under cyclic loading. Constr. Build. Mater. 2016, 126, 253–262. [Google Scholar] [CrossRef]

- Brandt, A.M. Fibre reinforced cement-based (FRC) composites after over 40 years of development in building and civil engineering. Compos. Struct. 2008, 86, 3–9. [Google Scholar] [CrossRef]

- Wang, L.; He, T.; Zhou, Y.; Tang, S.; Tan, J.; Liu, Z.; Su, J. The influence of fiber type and length on the cracking resistance, durability and pore structure of face slab concrete. Constr. Build. Mater. 2021, 282, 122706. [Google Scholar] [CrossRef]

- Wang, L.; Guo, F.; Yang, H.; Wang, Y.A.N.; Tang, S. Comparison of fly ash, PVA fiber, MgO and shrinkage-reducing admixture on the frost resistance of face slab concrete via pore structural and fractal analysis. Fractals 2021, 29, 2140002. [Google Scholar] [CrossRef]

- Bheel, N.; Awoyera, P.; Aluko, O.; Mahro, S.; Viloria, A.; Sierra, C.A.S. Sustainable composite development: Novel use of human hair as fiber in concrete. Case Stud. Constr. Mater. 2020, 13, e00412. [Google Scholar] [CrossRef]

- Islam, M.S.; Alam, S. Principal Component and Multiple Regression Analysis for Steel Fiber Reinforced Concrete (SFRC) Beams. Int. J. Concr. Struct. Mater. 2013, 7, 303–317. [Google Scholar] [CrossRef]

- Bahekar, P.V.; Gadve, S.S.; Bahekar, P.V.; Gadve, S.S. Advances in Concrete Construction. Adv. Concr. Constr. 2019, 8, 247. [Google Scholar]

- Onuaguluchi, O.; Banthia, N. Plant-based natural fibre reinforced cement composites: A review. Cem. Concr. Compos. 2016, 68, 96–108. [Google Scholar] [CrossRef]

- Pickering, K.L.; Efendy, M.G.A.; Le, T.M. A review of recent developments in natural fibre composites and their mechanical performance. Compos. Part A Appl. Sci. Manuf. 2016, 83, 98–112. [Google Scholar] [CrossRef]

- Raj, A.; Sathyan, D.; Mini, K.M.; Raj, A.; Sathyan, D.; Mini, K.M. Advances in Concrete Construction. Adv. Concr. Constr. 2021, 11, 151. [Google Scholar]

- Yan, L.; Chouw, N.; Huang, L.; Kasal, B. Effect of alkali treatment on microstructure and mechanical properties of coir fibres, coir fibre reinforced-polymer composites and reinforced-cementitious composites. Constr. Build. Mater. 2016, 112, 168–182. [Google Scholar] [CrossRef]

- Zakaria, M.; Ahmed, M.; Hoque, M.M.; Hannan, A. Effect of jute yarn on the mechanical behavior of concrete composites. Springerplus 2015, 4, 731. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Wang, L.; Wang, X. Compressive and flexural properties of hemp fiber reinforced concrete. Fibers Polym. 2004, 5, 187–197. [Google Scholar] [CrossRef]

- Ganguly, A.; Shankar, S.; Das, A.; Shukla, M.; Swaroop, C.; Bhardwaj, T. Natural fibre reinforced composites: A review based on additive manufacturing routes and biodegradability perspective. Mater. Today Proc. 2022, 62, 131–135. [Google Scholar] [CrossRef]

- Balla, V.K.; Kate, K.H.; Satyavolu, J.; Singh, P.; Tadimeti, J.G.D. Additive manufacturing of natural fiber reinforced polymer composites: Processing and prospects. Compos. Part B Eng. 2019, 174, 106956. [Google Scholar] [CrossRef]

- Liu, C.; Law, A.C.C.; Roberson, D.; Kong, Z.J. Image analysis-based closed loop quality control for additive manufacturing with fused filament fabrication. J. Manuf. Syst. 2019, 51, 75–86. [Google Scholar] [CrossRef]

- Landes, S.; Letcher, T. Mechanical Strength of Bamboo Filled PLA Composite Material in Fused Filament Fabrication. J. Compos. Sci. 2020, 4, 159. [Google Scholar] [CrossRef]

- Wang, Y.; Zhou, Y.; Lin, L.; Corker, J.; Fan, M. Overview of 3D additive manufacturing (AM) and corresponding AM composites. Compos. Part A Appl. Sci. Manuf. 2020, 139, 106114. [Google Scholar] [CrossRef]

- Rajendran Royan, N.R.; Leong, J.S.; Chan, W.N.; Tan, J.R.; Shamsuddin, Z.S.B. Current State and Challenges of Natural Fibre-Reinforced Polymer Composites as Feeder in FDM-Based 3D Printing. Polymers 2021, 13, 2289. [Google Scholar] [CrossRef] [PubMed]

- Lee, C.H.; Padzil, F.N.B.M.; Lee, S.H.; Ainun, Z.M.A.; Abdullah, L.C. Potential for Natural Fiber Reinforcement in PLA Polymer Filaments for Fused Deposition Modeling (FDM) Additive Manufacturing: A Review. Polymers 2021, 13, 1407. [Google Scholar] [CrossRef] [PubMed]

- Le Duigou, A.; Castro, M.; Bevan, R.; Martin, N. 3D printing of wood fibre biocomposites: From mechanical to actuation functionality. Mater. Des. 2016, 96, 106–114. [Google Scholar] [CrossRef]

- Zhu, Z.H.; Wu, H.W. Review on the Preparation Processes of Natural Fiber Reinforced PLA Composites. In Proceedings of the MEACM 2020: Mechanical Engineering and Applied Composite Materials; Mechanisms and Machine Chience Series; Springer: Berlin/Heidelberg, Germany, 2021; pp. 277–281. [Google Scholar] [CrossRef]

- Le Duigou, A.; Barbé, A.; Guillou, E.; Castro, M. 3D printing of continuous flax fibre reinforced biocomposites for structural applications. Mater. Des. 2019, 180, 107884. [Google Scholar] [CrossRef]

- Jiang, Y.; Yarin, A.L.; Pan, Y. Printable highly transparent natural fiber composites. Mater. Lett. 2020, 277, 128290. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, D.; Huang, T.; Hu, Q.; Lammer, H. 3D Printing Method of Spatial Curved Surface by Continuous Natural Fiber Reinforced Composite. IOP Conf. Ser. Mater. Sci. Eng. 2020, 782, 022059. [Google Scholar] [CrossRef]

- Rahman, N.A.A.; Anuar, H.; Ali, F.; Suhr, J. Poly(Lactic) Acid Reinforced with Alkaline Lignin Biocomposites Prepared by Thermal Extrusion for Sustainable 3D Printing Process. J. Phys. Conf. Ser. 2021, 2129, 012003. [Google Scholar] [CrossRef]

- Darsani, A.B.; Bin Marwah, O.M.F.; Sa’ude, N.B.; Hassan, S.B. Potential Behaviour of Oil Palm Empty Fruit Bunch Fibre Reinforced with Polypropelene For 3D Printing Filament Material. Int. J. Eng. Trends Technol. 2021, 69, 194–197. [Google Scholar] [CrossRef]

- Le Duigou, A.; Correa, D.; Ueda, M.; Matsuzaki, R.; Castro, M. A review of 3D and 4D printing of natural fibre biocomposites. Mater. Des. 2020, 194, 108911. [Google Scholar] [CrossRef]

- Fruleux, T.; Castro, M.; Sauleau, P.; Matsuzaki, R.; Le Duigou, A. Matrix stiffness: A key parameter to control hydro-elasticity and morphing of 3D printed biocomposite. Compos. Part A Appl. Sci. Manuf. 2022, 156, 106882. [Google Scholar] [CrossRef]

- Balla, V.K.; Tadimeti, J.G.D.; Kate, K.H.; Satyavolu, J. 3D printing of modified soybean hull fiber/polymer composites. Mater. Chem. Phys. 2020, 254, 123452. [Google Scholar] [CrossRef]

- Costa, I.L.; Pereira, P.H.; Claro, A.M.; do Amaral, N.C.; da Silva Barud, H.; Ribeiro, R.B.; Mulinari, D.R. 3D-printing pen from valorization of pine cone residues as reinforcement in acrylonitrile butadiene styrene (ABS): Microstructure and thermal properties. J. Thermoplast. Compos. Mater. 2021, 36, 089270572110127. [Google Scholar] [CrossRef]

- Carrete, I.A.; Quiñonez, P.A.; Bermudez, D.; Roberson, D.A. Incorporating Textile-Derived Cellulose Fibers for the Strengthening of Recycled Polyethylene Terephthalate for 3D Printing Feedstock Materials. J. Polym. Environ. 2020, 29, 662–671. [Google Scholar] [CrossRef]

- Shanmugam, V.; Rajendran, D.J.J.; Babu, K.; Rajendran, S.; Veerasimman, A.; Marimuthu, U.; Singh, S.; Das, O.; Neisiany, R.E.; Hedenqvist, M.S.; et al. The mechanical testing and performance analysis of polymer-fibre composites prepared through the additive manufacturing. Polym. Test. 2021, 93, 106925. [Google Scholar] [CrossRef]

- Deb, D.; Jafferson, J.M. Natural fibers reinforced FDM 3D printing filaments. Mater. Today Proc. 2021, 46, 1308–1318. [Google Scholar] [CrossRef]

- Regalla, S.P.; Karwa, S.S.; Rajesh, S.; Shyam, P.V.; Shrivastava, P.N. Strength and fracture behaviour of polymer matrix composite layered structures made by additive manufacturing. Mater. Today Proc. 2020, 28, 1030–1038. [Google Scholar] [CrossRef]

- Rajeshkumar, G.; Arvindh Seshadri, S.; Devnani, G.L.; Sanjay, M.R.; Siengchin, S.; Prakash Maran, J.; Al-Dhabi, N.A.; Karuppiah, P.; Mariadhas, V.A.; Sivarajasekar, N.; et al. Environment friendly, renewable and sustainable poly lactic acid (PLA) based natural fiber reinforced composites—A comprehensive review. J. Clean. Prod. 2021, 310, 127483. [Google Scholar] [CrossRef]

- Bosman, J.; Mourik, I.V.; Rasch, M.; Sieverts, E.; Verhoeff, H. Scopus Reviewed and Compared: The Coverage and Functionality of the Citation Database Scopus, including Comparisons with Web of Science and Google Scholar. Utrecht University Repository. 2006. Available online: https://www.researchgate.net/publication/27700433_Scopus_Reviewed_and_Compared_The_coverage_and_Functionality_of_the_Citation_Database_Scopus_Including_Comparisons_with_Web_of_Science_and_Google_Scholar (accessed on 14 January 2023).

- Bar-Ilan, J. Citations to the “Introduction to informetrics” indexed by WOS, Scopus and Google Scholar. Scientometrics 2010, 82, 495–506. [Google Scholar] [CrossRef]

- Klyosov, A.A. Wood-Plastic Composites; John Wiley & Sons: Hoboken, NJ, USA, 2007. [Google Scholar]

- Ganasen, N.; Bahrami, A.; Loganathan, K. A scientometric analysis review on agricultural wastes used as building materials. Buildings 2023, 13, 426. [Google Scholar] [CrossRef]

- Li, C.Z.; Li, S.; Li, X.; Wu, H.; Xiao, B.; Tam, V.W.Y.; Asiedu-Kwakyewa, C. A scientometric review of management of prefabricated construction from 2011–2021. Buildings 2022, 12, 1515. [Google Scholar] [CrossRef]

- Peng, W.; Haron, N.A.; Alias, A.H.; Law, T.H. Leadership in construction: A scientometric review. Buildings 2022, 12, 1825. [Google Scholar] [CrossRef]

- Rashidi, A.; Tamošaitienė, J.; Ravanshadnia, M.; Sarvari, H. A scientometric analysis of construction bidding research activities. Buildings 2023, 13, 220. [Google Scholar] [CrossRef]

- Xu, H.; Chang, R.; Pan, M.; Li, H.; Liu, S.; Webber, R.J.; Zuo, J.; Dong, N. Application of artificial neural networks in construction management: A scientometric review. Buildings 2022, 12, 952. [Google Scholar] [CrossRef]

- Gul, S.; Rehman, S.U.; Ashiq, M.; Khattak, A. Mapping the Scientific Literature on COVID-19 and Mental Health. Psychiatr. Danub. 2020, 32, 463–471. [Google Scholar] [CrossRef] [PubMed]

- Jabali, K.A.; Ashiq, M.; Ahmad, S.; Rehman, S.U. A Bibliometric Analysis of Research Productivity on Diabetes Modeling and Artificial Pancreas 2001 to 2020. Libr. Philos. Pract. 2020, 1–19. Available online: https://digitalcommons.unl.edu/libphilprac/4305/ (accessed on 11 December 2020).

- Baas, J.; Schotten, M.; Plume, A.; Côté, G.; Karimi, R. Scopus as a curated, high-quality bibliometric data source for academic research in quantitative science studies. Quant. Sci. Stud. 2020, 1, 377–386. [Google Scholar] [CrossRef]

- Aria, M.; Cuccurullo, C. bibliometrix: An R-tool for comprehensive science mapping analysis. J. Informetr. 2017, 11, 959–975. [Google Scholar] [CrossRef]

- Perianes-Rodriguez, A.; Waltman, L.; van Eck, N.J. Constructing bibliometric networks: A comparison between full and fractional counting. J. Informetr. 2016, 10, 1178–1195. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).