The Impact of High-Alkali Biofuel Fly Ash on the Sustainability Parameters of Concrete

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

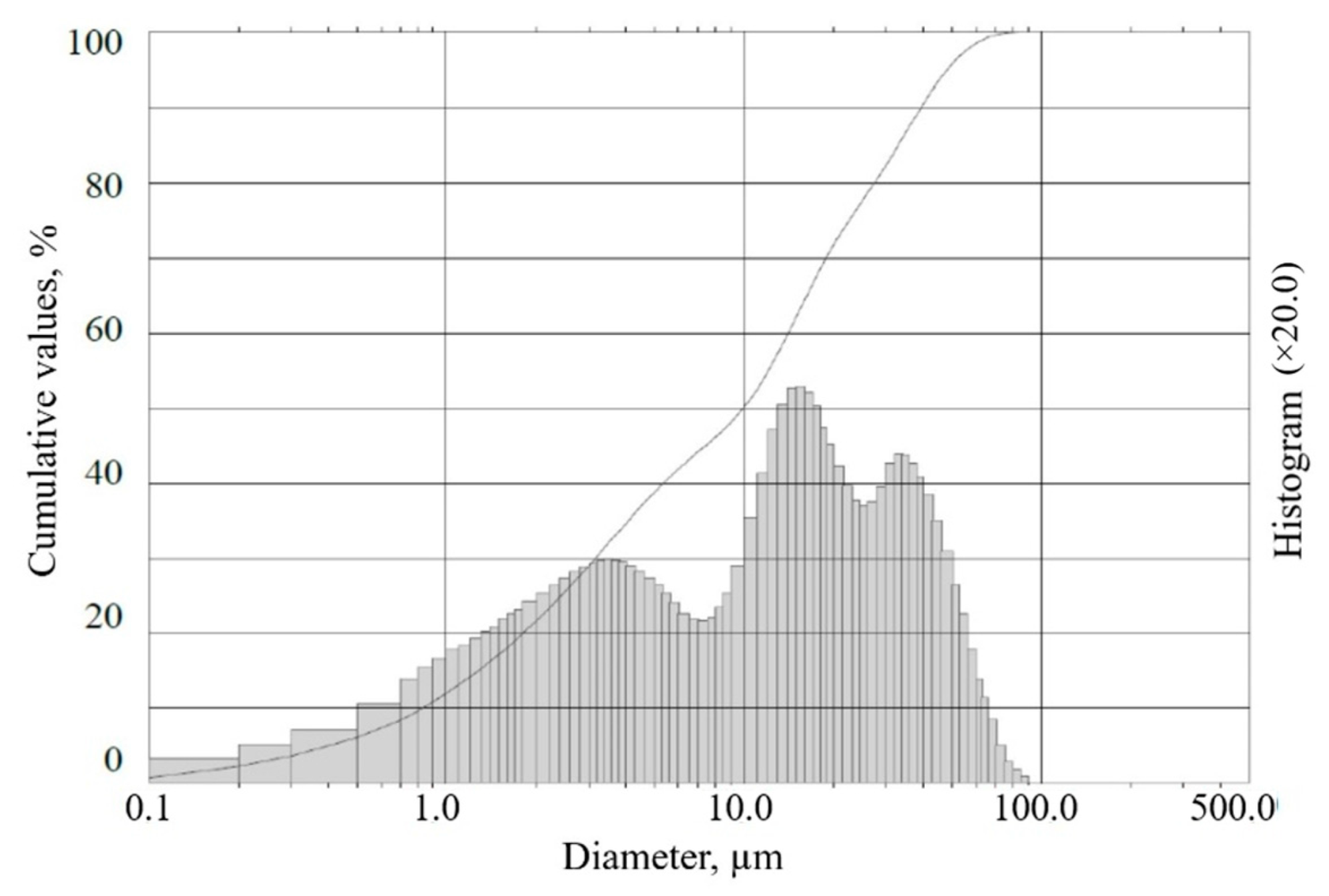

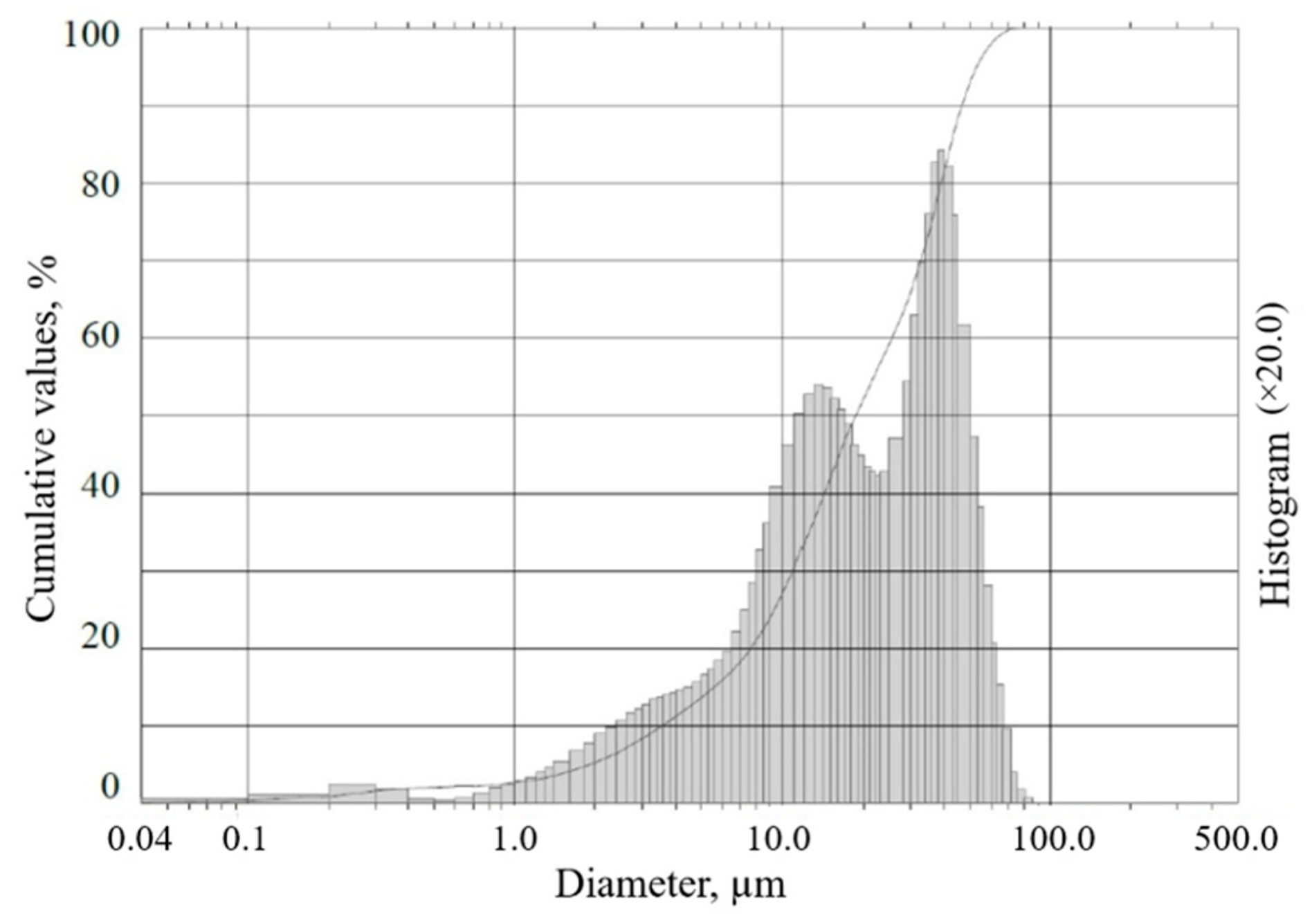

3.1. Parameters of BFA

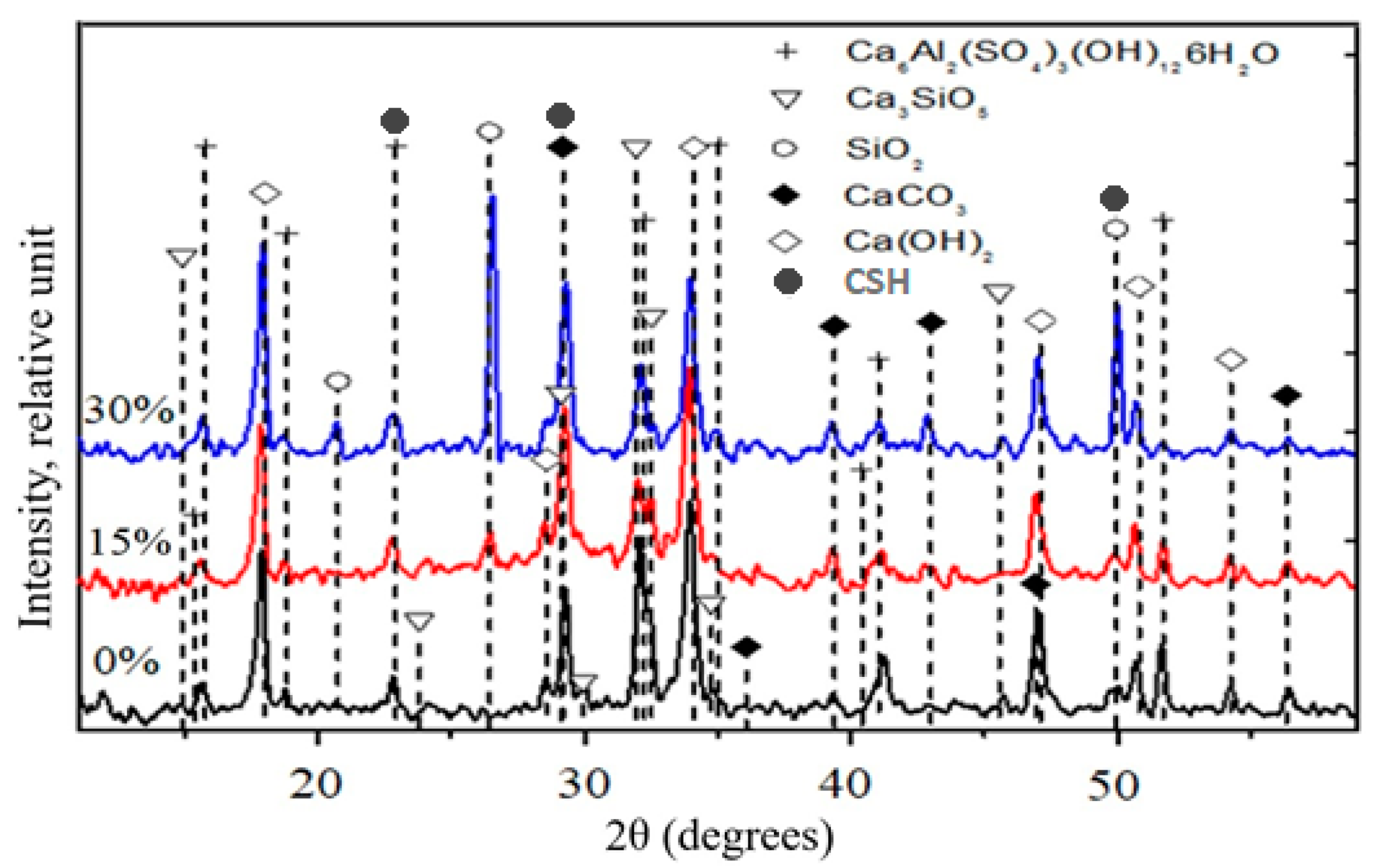

3.2. X-ray of BFA Modified Hardened Cement Paste

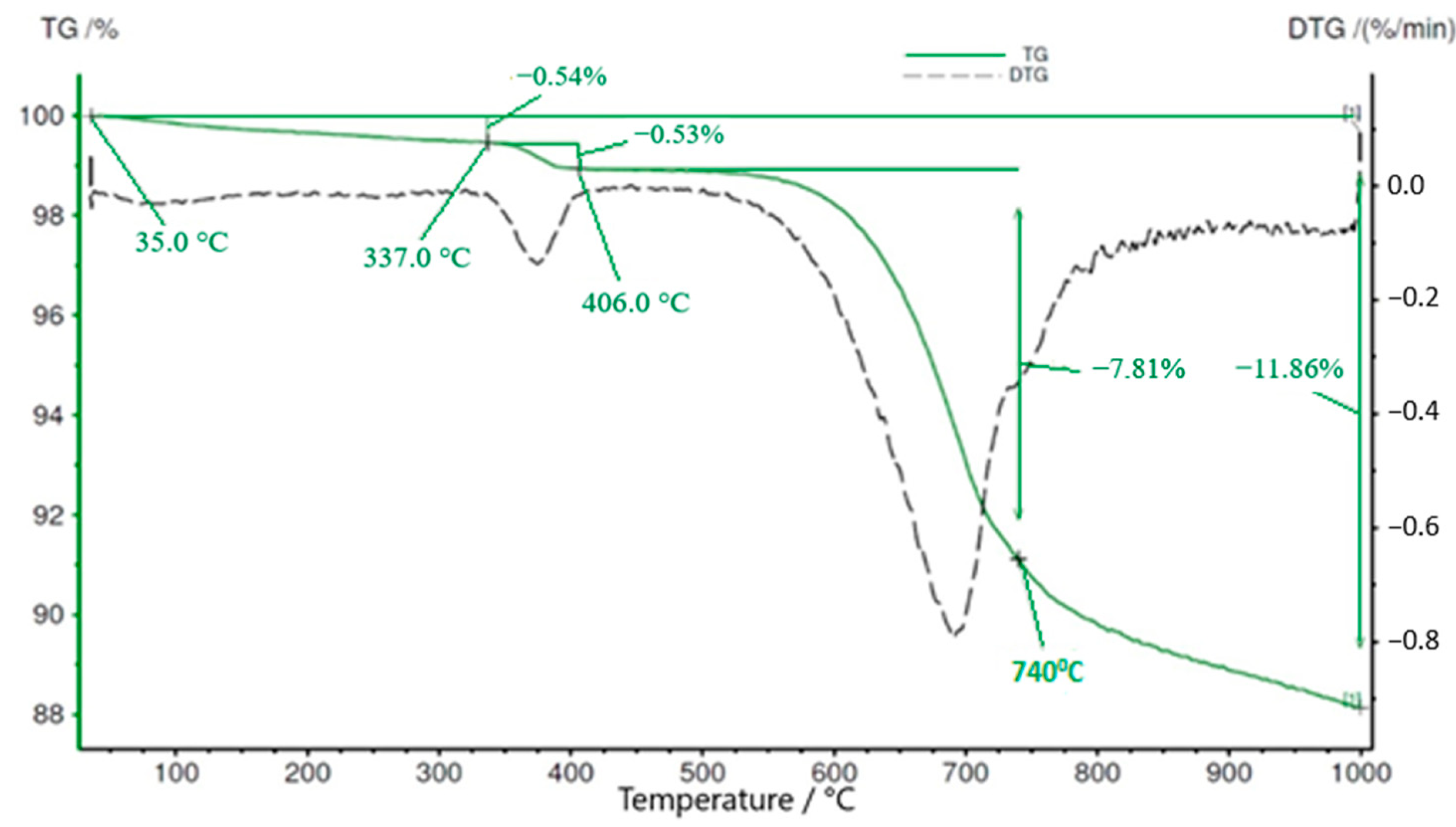

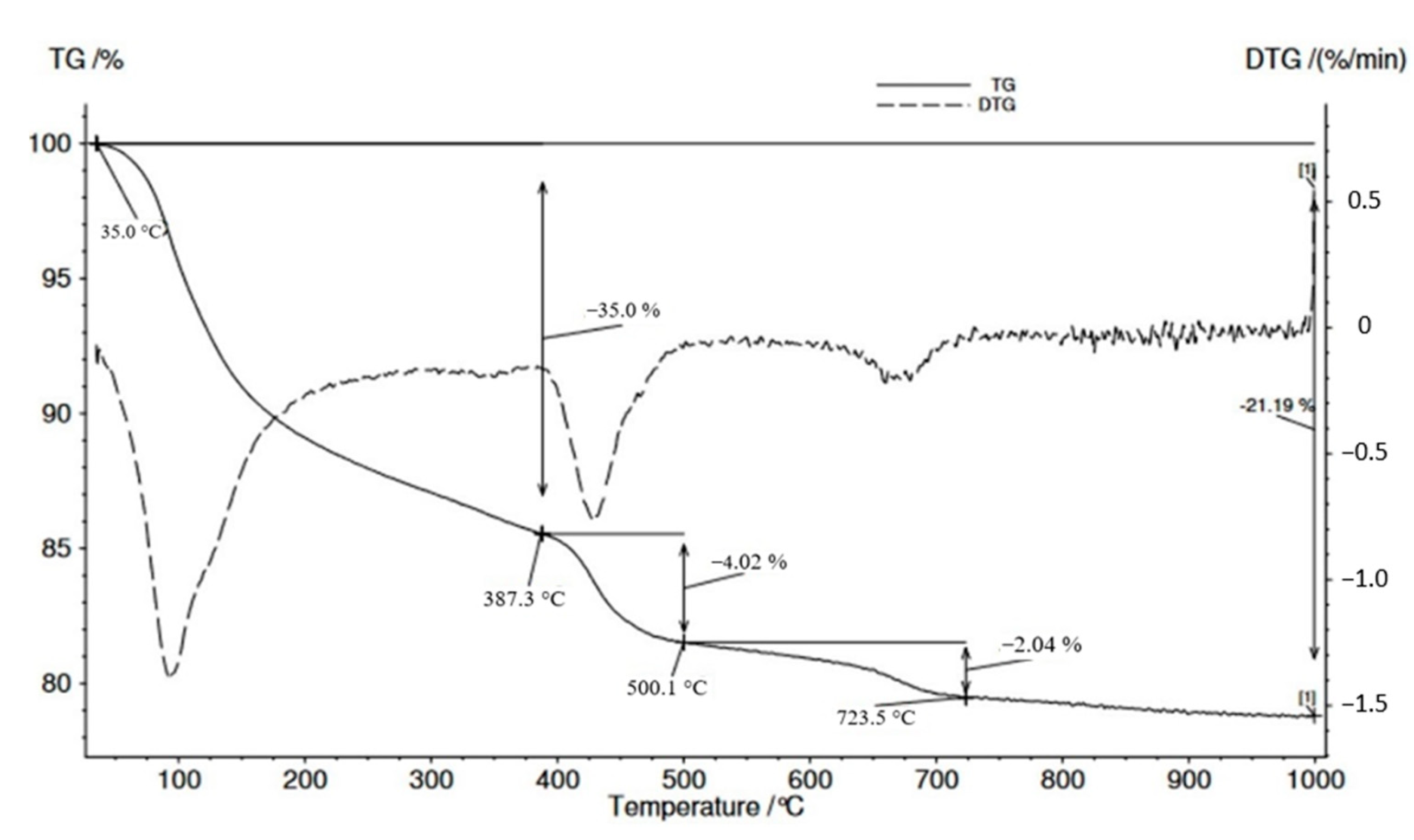

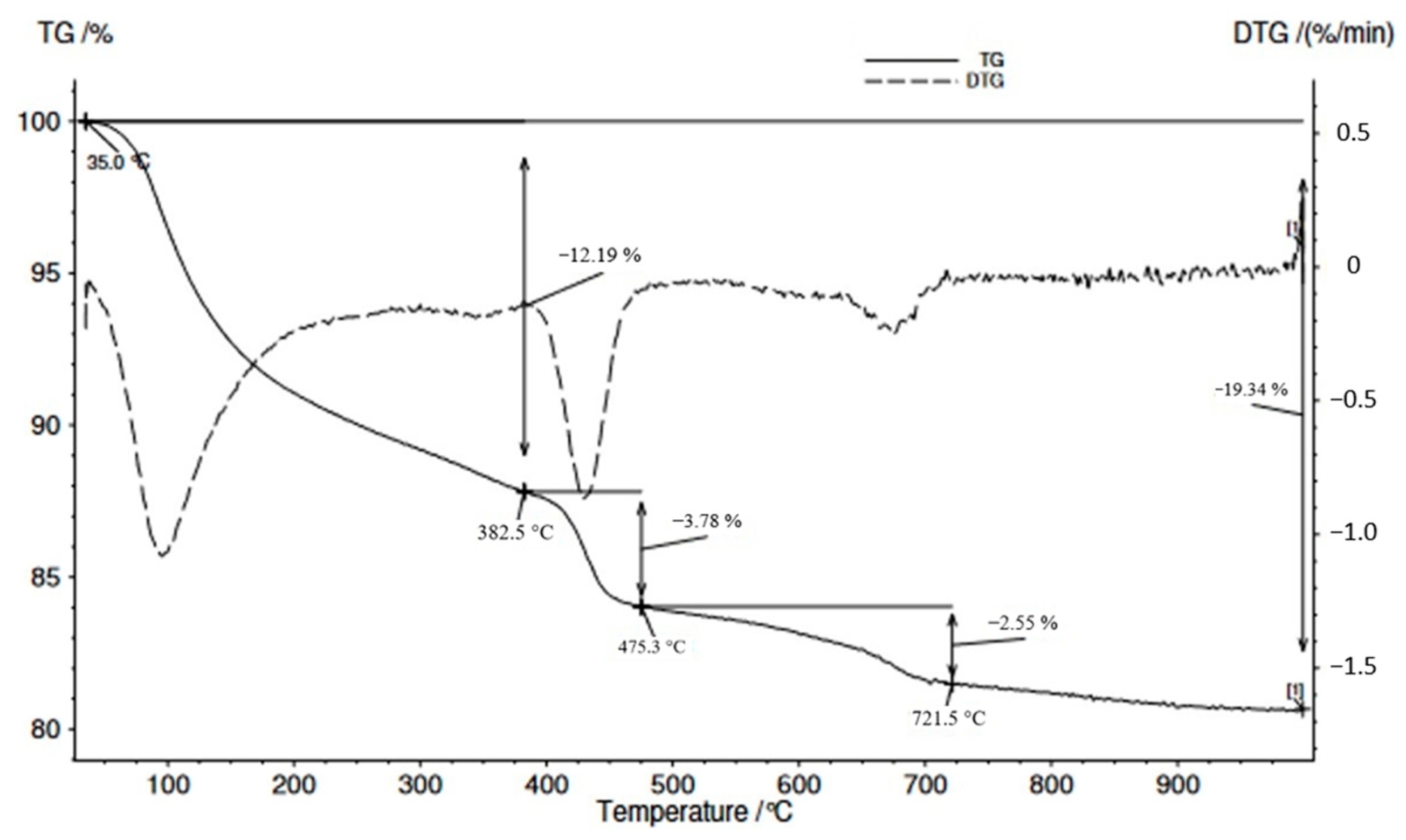

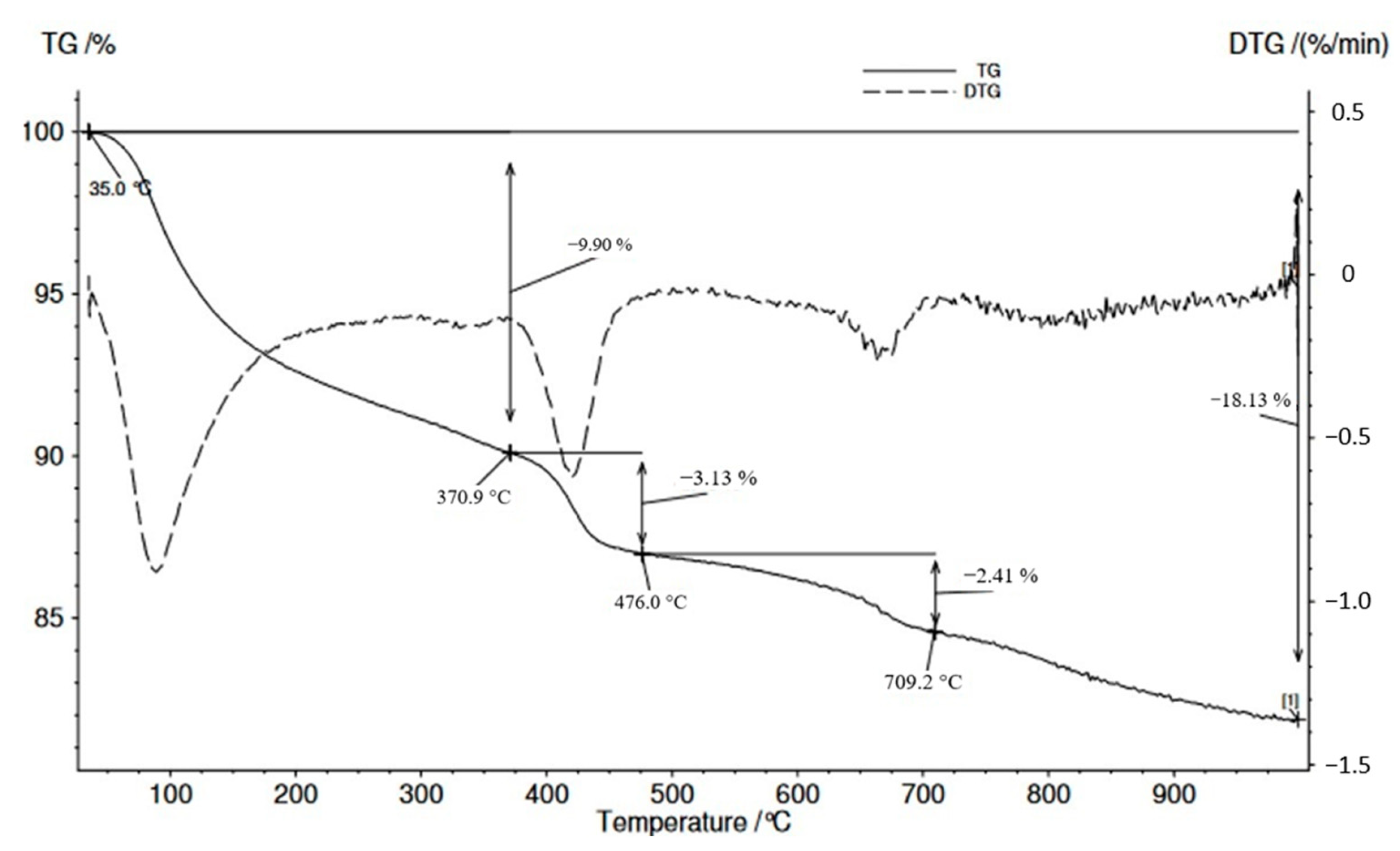

3.3. Thermogravimetric Analysis of BFA-Modified Hardened Cement Paste

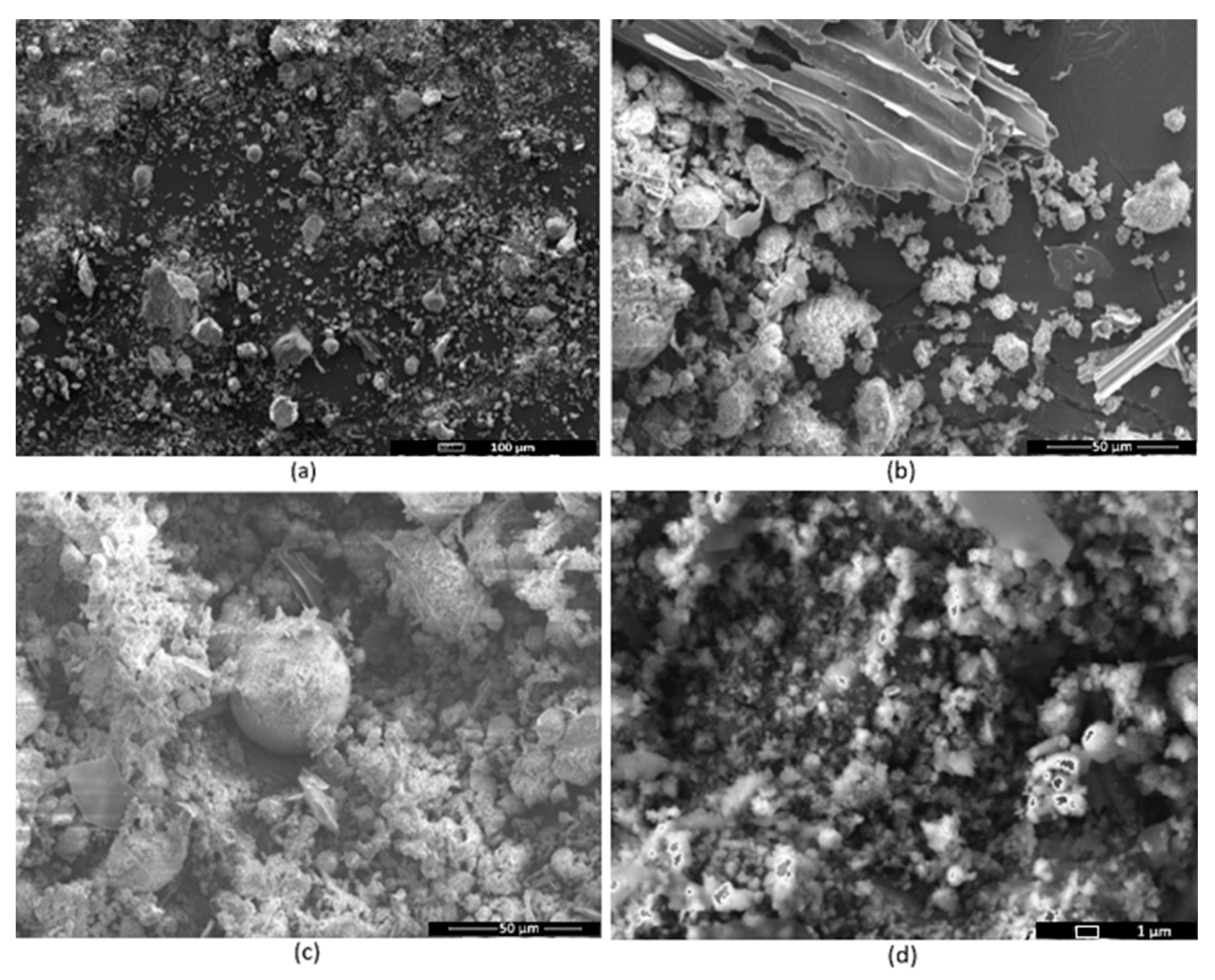

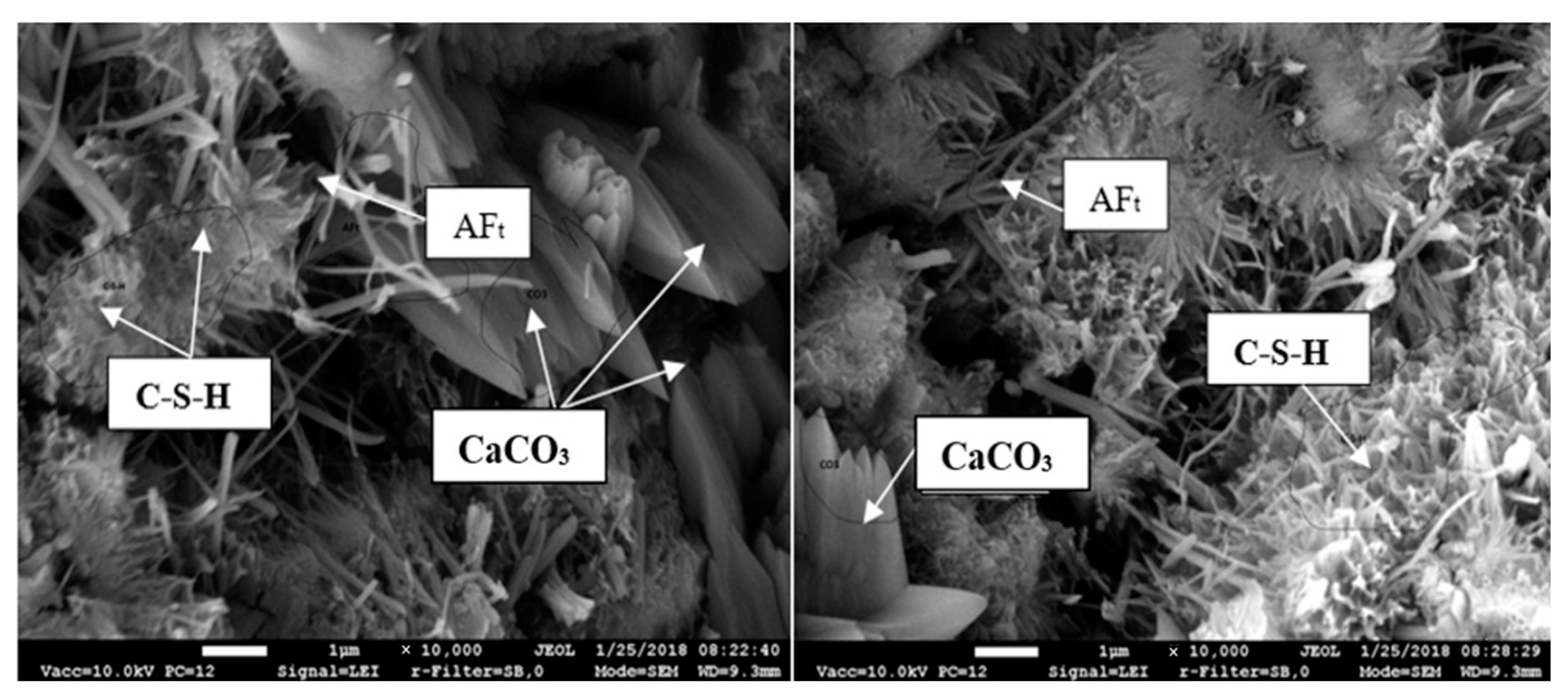

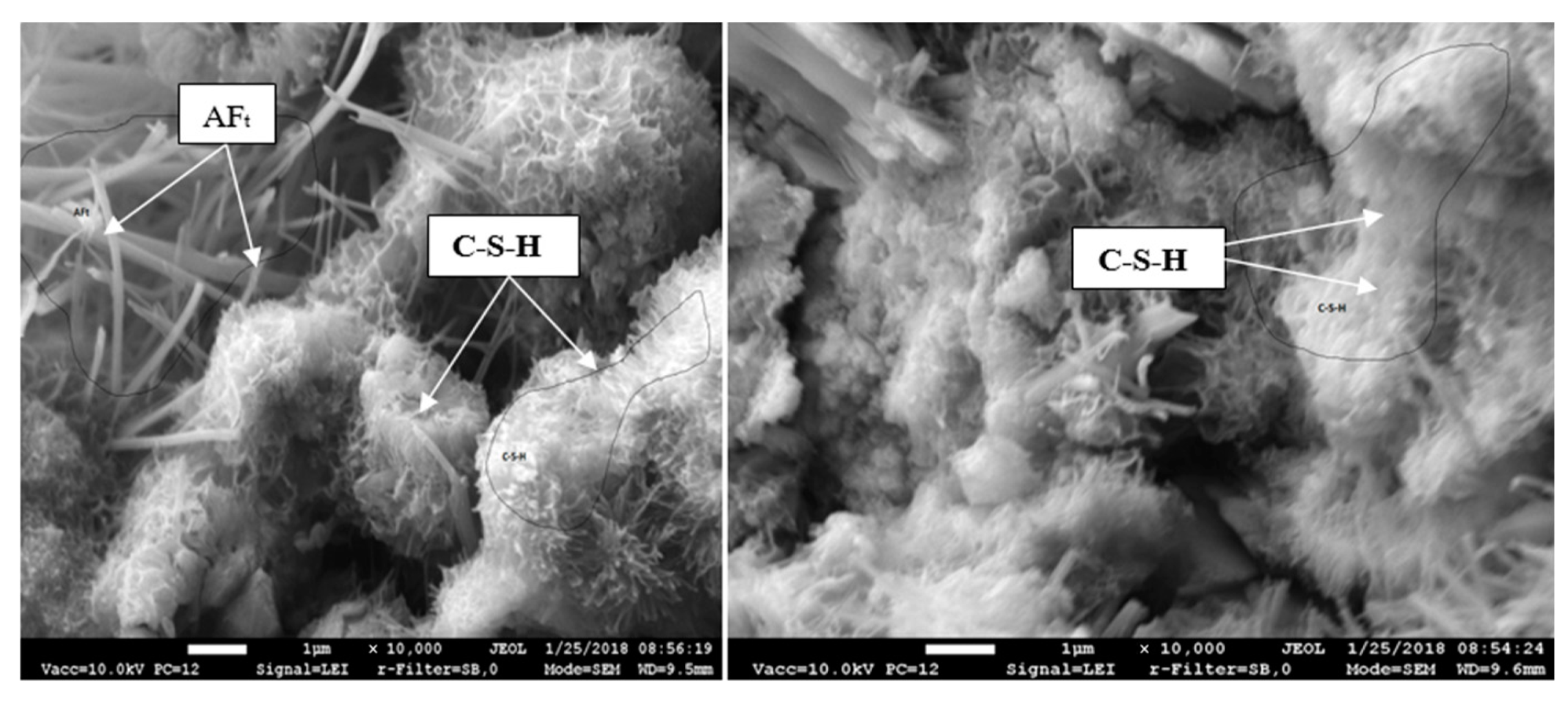

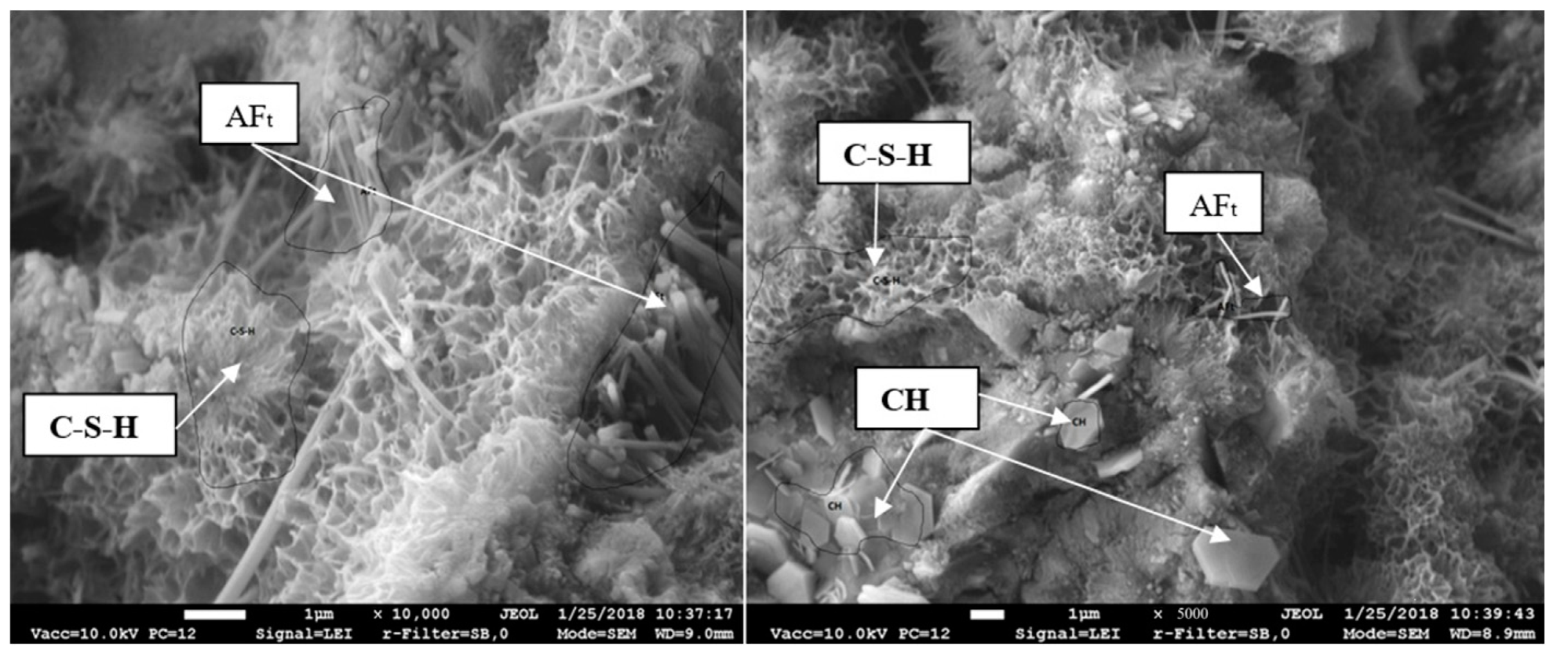

3.4. SEM Analysis of BFA-Modified Hardened Cement Paste

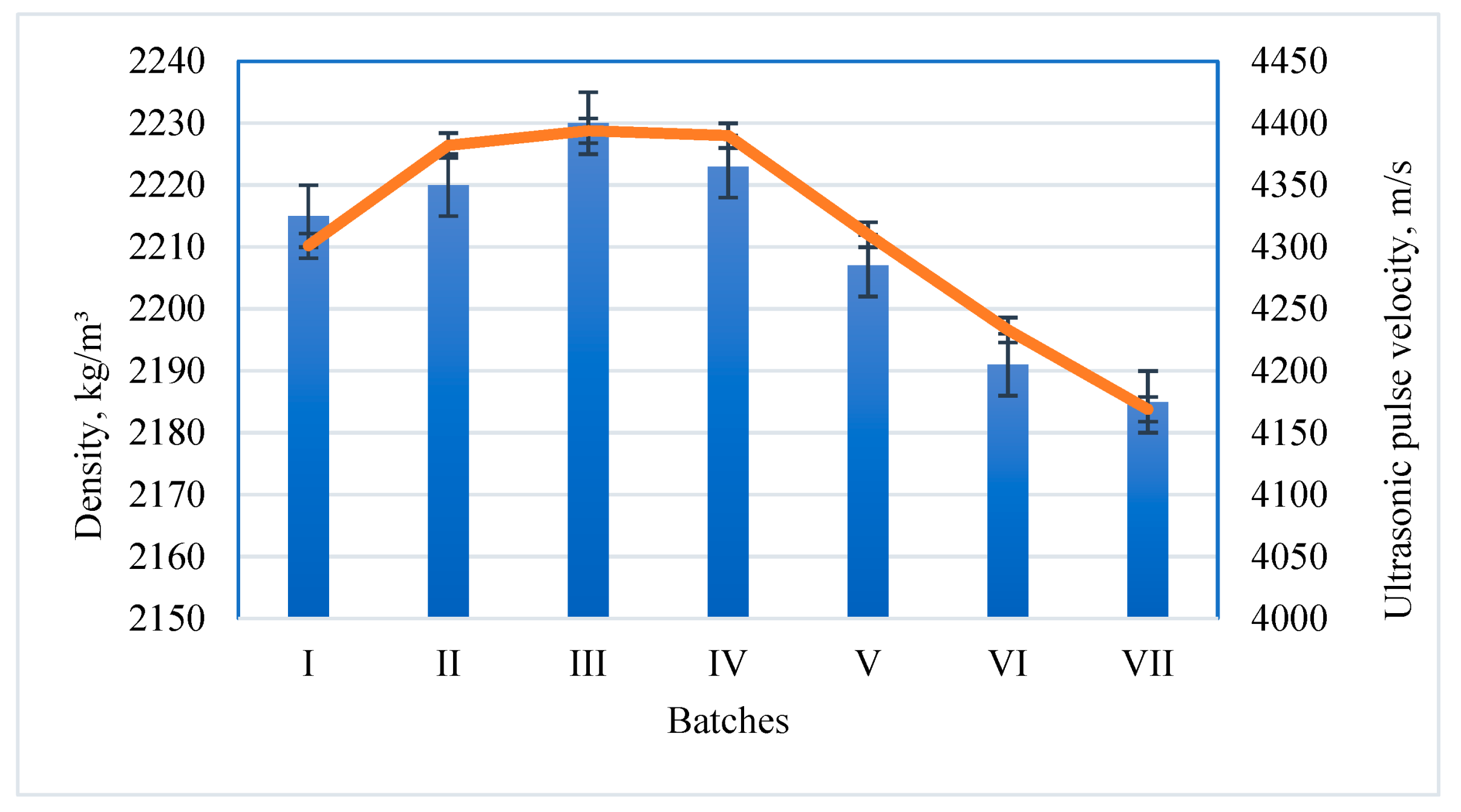

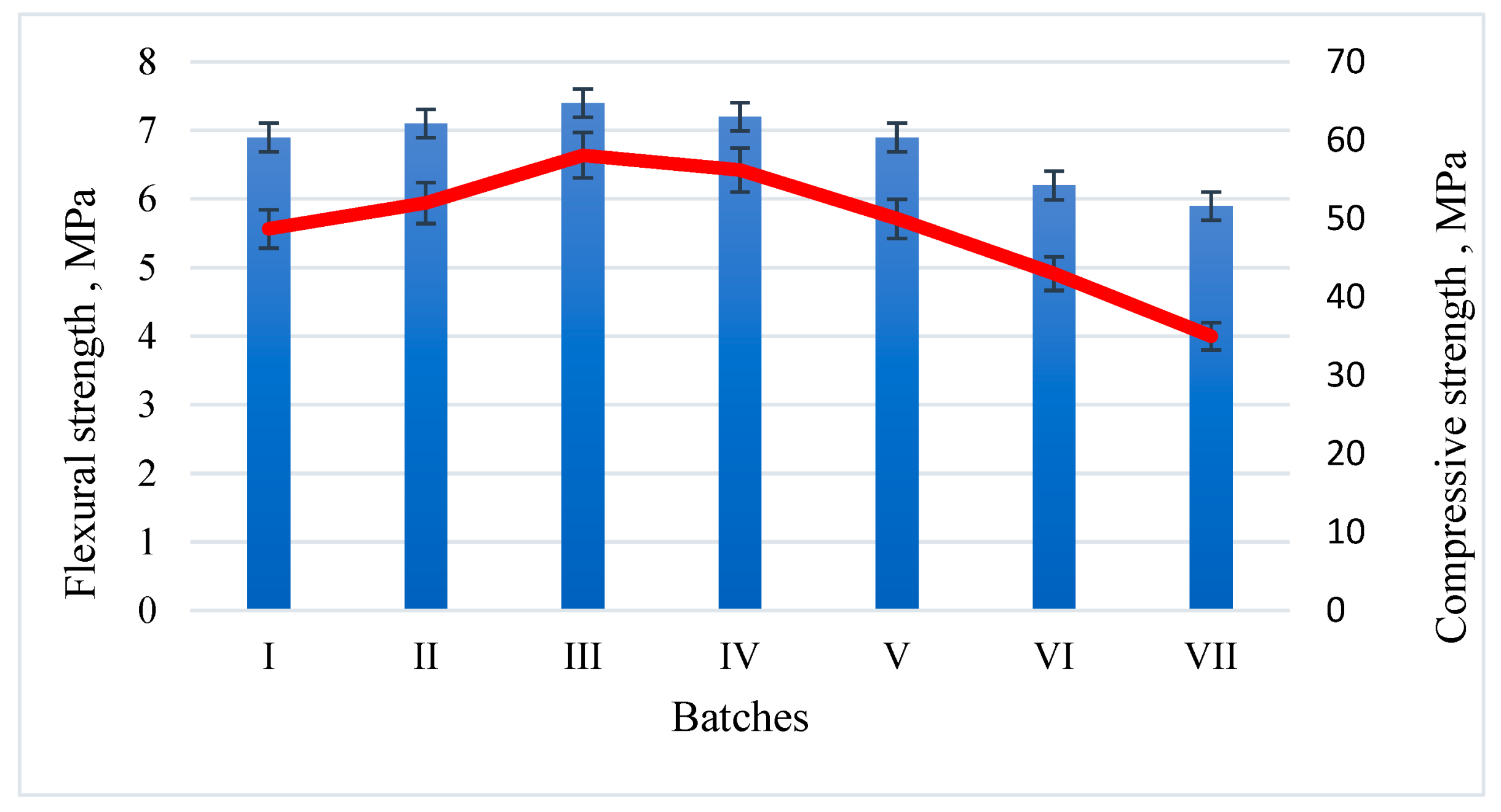

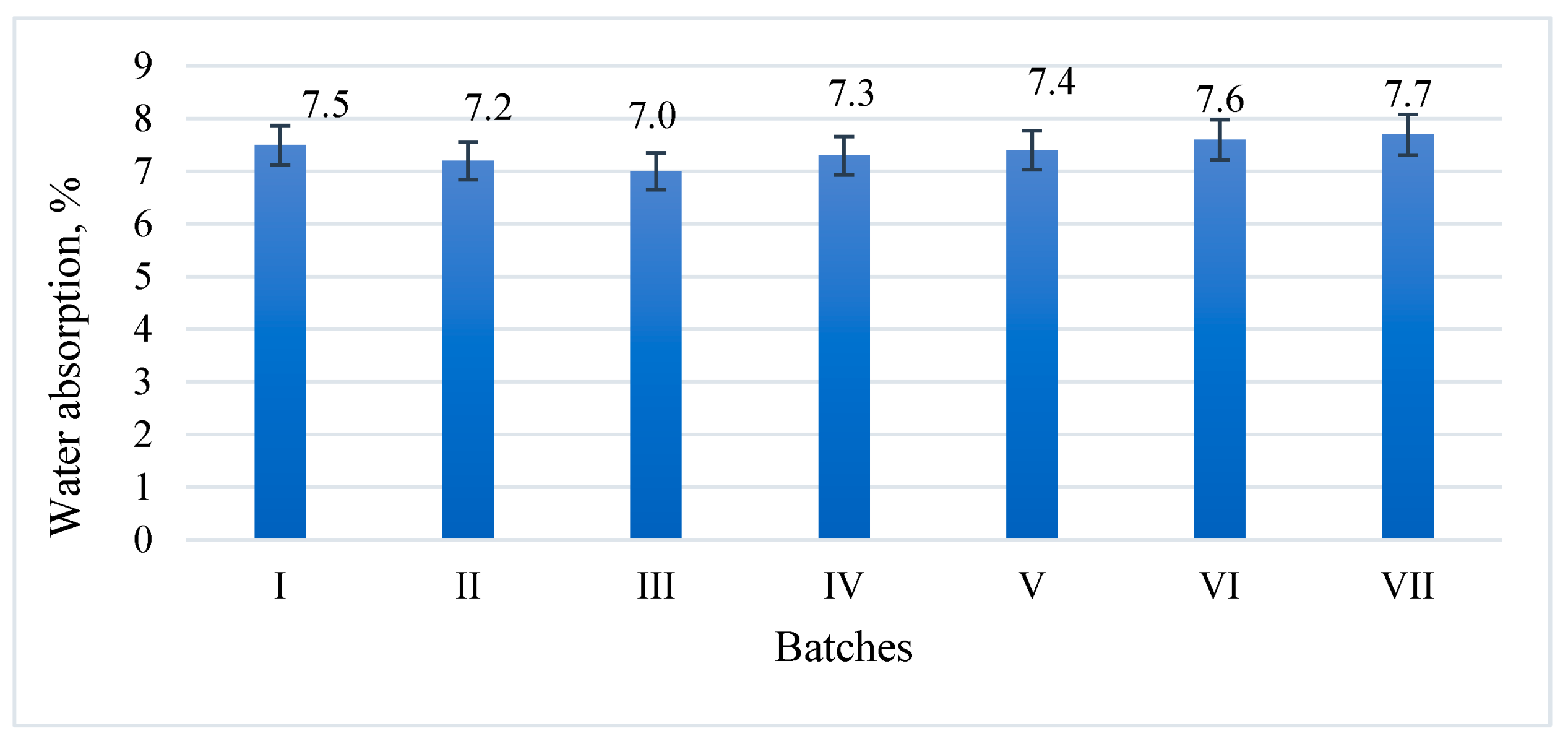

3.5. Properties of Concrete

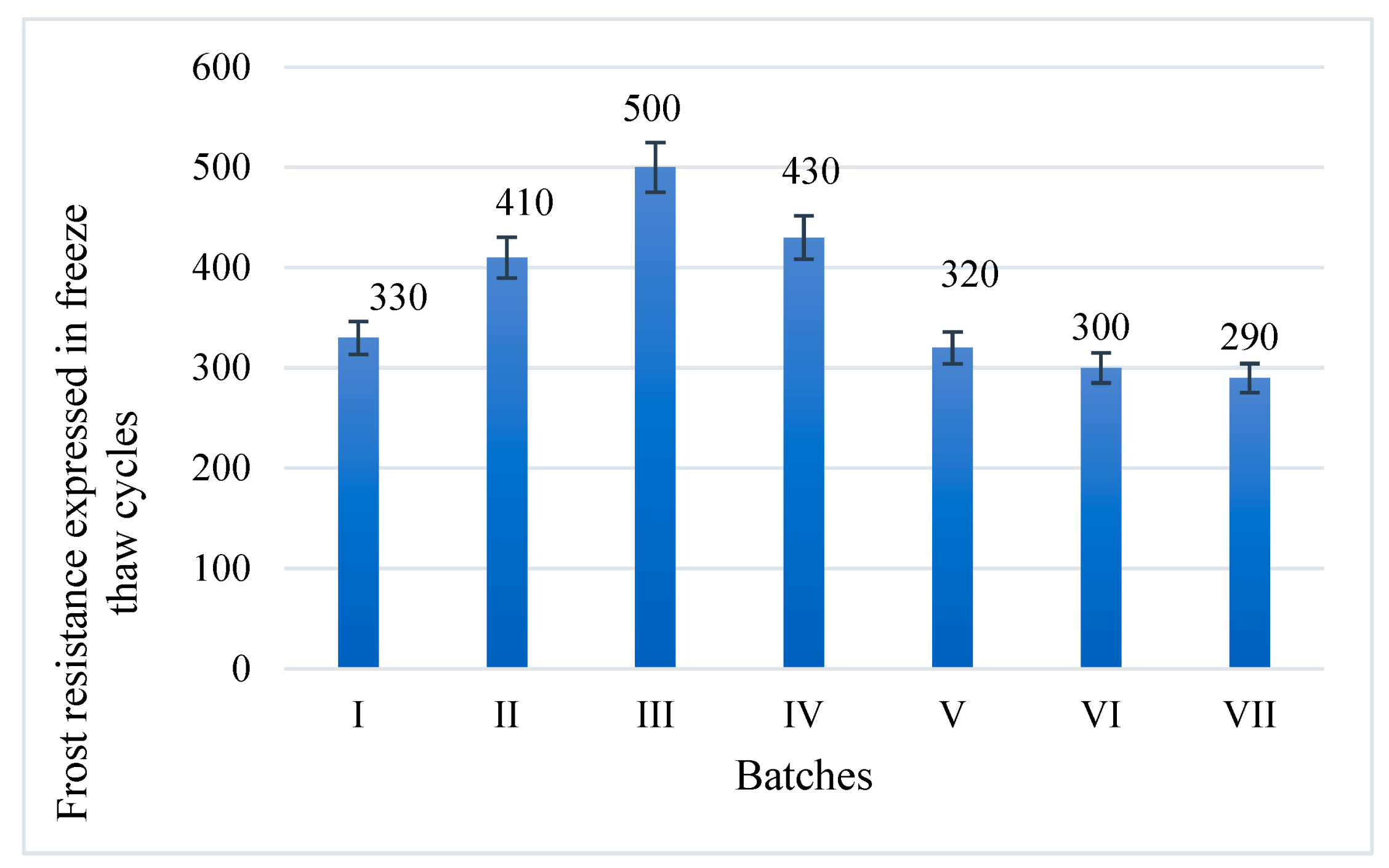

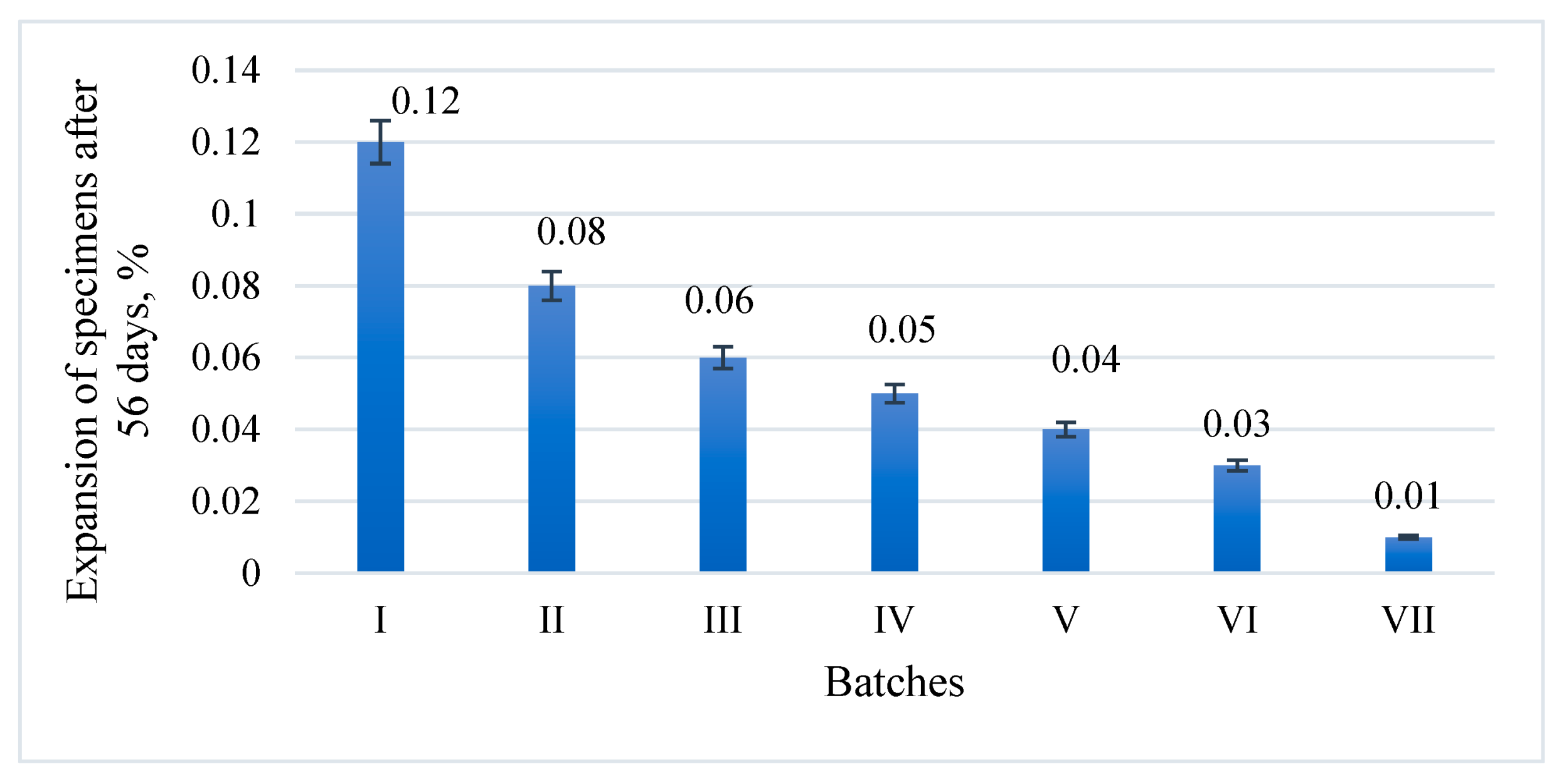

3.6. Durability Analysis

3.7. Analysis and Forecast of Sustainability of Concrete Samples Modified with BFA

4. Conclusions

- The chemical analysis and fineness tests of BFA revealed that SiO2, CaO, and K2O are the main chemical components of BFA. SO3, P2O5, and MgO are present in lower amounts, and the amounts of other components are not significant. BFA has an average particle size of 23 μm. The pozzolanic activity of BFA was found to be 350 mg of CaO/g ash.

- With a significant increase in the SiO2/CaO ratio (from 0.32 to 0.51) due to cement substitution with up to 30% of BFA, the crystallisation of portlandite and ettringite decreased. The decrease in ettringite can be influenced by the Al2O3 amount in the cement matrix. With the increase in cement substitution with BFA up to 30%, the Al2O3/SiO2 ratio decreased from 0.294 to 1.88.

- The pozzolanic nature of BFA and its numerous alkaline compounds ensured the crystallisation of CSHs in the cement matrix. BFA decreases the formation of ettringite, but when the SiO2/CaO ratio varies between 0.32 and 0.41 and the Na2O + K2O/CaO ratio varies between 0.032 and 0.043, it promotes CSH formation to a certain extent. The replacement of 15% of cement with BFA decreased CSH formation by only 12%, whereas the replacement of 30% of cement with BFA decreased formation by up to 31%, compared to the control specimen. Through the replacement of up to 30% of the cement portion with BFA, the Na2O + K2O/CaO ratio increased up to threefold (from 0.02 to 0.067) and maintained sufficient formation of calcium silicate hydrates (CSHs).

- When there was extra alkalinity, namely, the Na2O + K2O/CaO ratio in the cement matrix was not higher than 0.043, and the SiO2/CaO ratio varied in the range of 0.32–0.41, the concrete had a better structure, the highest density, better closed porosity, higher compressive strength, and can resists the highest number of freeze thaw cycles. Compared to the control samples, the compressive strength increased by up to 19.3% and the calculated number of freeze and thaw cycles increased to 51.5 and by 30% when 10–15% of cement was replaced with BFA.

- It was found that expansion of the samples decreased with a higher amount of BFA in the mix. The lowest expansion of hardened mortar of 0.01% was observed after 56 days of storage of the samples in a 1 M NaOH solution at 80° C, when up to 30% of cement was substituted with BFA. The obtained results allow us to conclude that the substitution of cement with BFA suppresses the damaging ASR effect in sustainable concrete. High-alkali BFA has a beneficial effect on the development of new cementitious materials.Several recommendations, based on the conducted research, may be presented to manufacturers:

- -

Smaller BFA particles are more involved in the cement hydration process;- -

Higher-alkali-content BFA, due to the fact that hydration products fill concrete pores, has a positive effect on concrete’s resistance to freeze–thaw cycles and ASR;- -

The possibility of increasing the amount of alkali in the different types of BFA may be considered in future research.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Chaunsali, P.; Uvegi, H.; Osmundsen, R.; Laracy, M.; Poinot, T.; Ochsendorf, J.; Olivetti, E. Mineralogical and Microstructural Characterization of Biomass Ash Binder. Cem. Concr. Compos. 2018, 89, 41–51. [Google Scholar] [CrossRef]

- International Energy Agency (IEA). Key World Energy Statistics 2016; IEA: Paris, France, 2016. [Google Scholar] [CrossRef]

- Scurlock, J.M.O.; Hall, D.O. The Contribution of Biomass to Global Energy Use (1987). Biomass 1990, 21, 75–81. [Google Scholar] [CrossRef]

- Odzijewicz, J.I.; Wołejko, E.; Wydro, U.; Wasil, M.; Jabłońska-Trypuć, A. Utilization of Ashes from Biomass Combustion. Energies 2022, 15, 9653. [Google Scholar] [CrossRef]

- Wang, S.; Baxter, L. Comprehensive study of biomass fly ash in concrete: Strength, microscopy, kinetics and durability. Fuel Process. Technol. 2007, 88, 1165–1170. [Google Scholar] [CrossRef]

- Rajamma, R.; Ball, R.J.; Tarelho, L.A.; Allen, G.C.; Labrincha, J.A.; Ferreira, V.M. Characterisation and use of biomass fly ash in cement-based materials. J. Hazard. Mater. 2009, 172, 1049–1060. [Google Scholar] [CrossRef]

- Liu, Z.; Deng, P.; Zhang, Z. Application of silica-rich biomass ash solid waste in geopolymer preparation: A review. Constr. Build. Mater. 2022, 356, 129142. [Google Scholar] [CrossRef]

- Tamanna, K.; Raman, S.N.; Jamil, M.; Hamid, R. Review Utilization of wood waste ash in construction technology: A review. Constr. Build. Mater. 2020, 237, 117654. [Google Scholar] [CrossRef]

- Xiao, R.; Chen, X.; Wang, F.; Yu, G. The Physicochemical Properties of Different Biomass Ashes at Different Ashing Temperature. Renew. Energy 2011, 36, 244–249. [Google Scholar] [CrossRef]

- Esteves, T.C.; Rajamma, R.; Soares, D.; Silva, A.S.; Ferreira, V.M.; Labrincha, J.A. Use of biomass fly ash for mitigation of alkali-silica reaction of cement mortars. Constr. Build. Mater. 2012, 26, 687–693. [Google Scholar] [CrossRef]

- Gabrijel, I.; Jelčić Rukavina, M.; Štirmer, N. Influence of Wood Fly Ash on Concrete Properties through Filling Effect Mechanism. Materials 2021, 14, 7164. [Google Scholar] [CrossRef]

- Ukrainczyk, N.; Vrbos, N.; Koenders, E.A.B. Reuse of Woody Biomass Ash Waste in Cementitious Materials. Chem. Biochem. Eng. Q. 2016, 30, 137–148. [Google Scholar] [CrossRef]

- Wang, S.; Miller, A.; Llamazos, E.; Fonseca, F.; Baxter, L. Biomass fly ash in concrete: Mixture proportioning and mechanical properties. Fuel 2008, 87, 365–371. [Google Scholar] [CrossRef]

- Maschio, S.; Tonello, G.; Piani, L.; Furlani, E. Fly and bottom ashes from biomass combustion as cement replacing components in mortars production: Rheological behaviour of the pastes and materials compression strength. Chemosphere 2011, 85, 666–671. [Google Scholar] [CrossRef] [PubMed]

- Rissanen, J.; Ohenoja, K.; Kinnunen, P.; Illikainen, M. Partial Replacement of Portland-Composite Cement by Fluidized Bed Combustion Fly Ash. J. Mater. Civ. Eng. 2017, 29, 04017061. [Google Scholar] [CrossRef]

- Rajamma, R.; Senff, L.; Ribeiro, M.; Labrincha, J.; Ball, R.; Allen, G.; Ferreira, V. Biomass fly ash effect on fresh and hardened state properties of cement based materials. Compos. Part B Eng. 2015, 77, 1–9. [Google Scholar] [CrossRef]

- Berra, M.; Mangialardi, T.; Paolini, A.E. Reuse of woody biomass fly ash in cement-based materials. Constr. Build. Mater. 2015, 76, 286–296. [Google Scholar] [CrossRef]

- Lazik, P.R.; Bošnjak, J.; Cetin, E.; Kücük, A. Application of wood ash as a substitute for fly ash and investigation of concrete properties. Otto. Graf. J. 2020, 19, 103–118. [Google Scholar]

- Tulashie, S.K.; Dapaah, S.; Mensah, D.; Appiah, N. Palm fiber ash as a supplementary cementitious material for the production of mortar prism. Innov. Infrastruct Solut. 2021, 7, 3. [Google Scholar] [CrossRef]

- Carević, I.; Štirmer, N.; Serdar, M.; Ukrainczyk, N. Effect of Wood Biomass Ash Storage on the Properties of Cement Composites. Materials 2021, 14, 1632. [Google Scholar] [CrossRef]

- Udoeyo, F.F.; Inyang, H.; Young, D.T.; Oparadu, E.E. Potential of Wood Waste Ash as an Additive in Concrete. J. Mater. Civ. Eng. 2006, 18, 605–611. [Google Scholar] [CrossRef]

- Ban, C.C.; Ramli, M. The Implementation of Wood Waste Ash as a Partial Cement Replacement Material in the Production of Structural Grade Concrete and Mortar: An Overview. Resour. Conserv. Recycl. 2011, 55, 669–685. [Google Scholar] [CrossRef]

- Szcześniak, A.; Zychowicz, J.; Stolarski, A. Assessment of the Influence of Fly Ash Additive on the Tightness of Concrete with Furnace Cement CEM IIIA 32,5N. Bull. Mil. Univ. Technol. 2017, 66, 153–164. [Google Scholar] [CrossRef]

- Wang, S.; Miller, A.; Llamazos, E.; Baxter, L.; Fonseca, F. Durability of Biomass Fly Ash Concrete: Freezing and Thawing and Rapid Chloride Permeability Tests. Fuel 2008, 87, 359–364. [Google Scholar] [CrossRef]

- Teixeira, E.R.; Camões, A.; Branco, F.; Aguiar, J.; Fangueiro, R. Recycling of biomass and coal fly ash as cement replacement material and its effect on hydration and carbonation of concrete. Waste Manag. 2019, 94, 39–48. [Google Scholar] [CrossRef] [PubMed]

- Demis, S.; Tapali, J.G.; Papadakis, V.G. An Investigation of the Effectiveness of the Utilization of Biomass Ashes as Pozzolanic Materials. Constr. Build. Mater. 2014, 68, 291–300. [Google Scholar] [CrossRef]

- Romero, E.; Quirantes, M.; Nogales, R. Characterization of Biomass Ashes Produced at Different Temperatures from Olive-Oil-Industry and Greenhouse Vegetable Wastes. Fuel 2017, 208, 1–9. [Google Scholar] [CrossRef]

- Rutkowska, G.; Wiśniewski, K.; Chalecki, M.; Górecka, M.; Miłosek, K. Influence of Fly-Ashes on Properties of Ordinary Concretes. Ann. Wars. Univ. Life Sci. SGGW Land Reclam. 2016, 48, 79–94. [Google Scholar] [CrossRef]

- Popławski, J.; Lelusz, M. Utility assessment of biomass fly-ash for production of concrete products. Czas. Technol. 2017, 2017, 129–142. [Google Scholar] [CrossRef]

- Thomas, M. Optimizing the Use of Fly Ash in Concrete; Portland Cement Association: Skokie, IL, USA, 2007; p. 5420. [Google Scholar]

- Jaworska, B.; Stańczak, D.; Tarańska, J.; Jaworski, J. The Influence of Cement Substitution by Biomass Fly Ash on the Polymer–Cement Composites Properties. Materials 2021, 14, 3079. [Google Scholar] [CrossRef]

- Pera, J.; Ambroise, J. Influence of different polymers on the properties of cementitious matrices. In Proceedings of the 10th International Congress on Polymers in Concrete—ICPIC’01, Honolulu, HI, USA, 21–24 May 2001. [Google Scholar]

- Šantek Bajto, J.; Štirmer, N.; Cerković, S.; Carević, I.; Kostanić Jurić, K. Pilot Scale Production of Precast Concrete Elements with Wood Biomass Ash. Materials 2021, 14, 6578. [Google Scholar] [CrossRef]

- Carević, I.; Baričević, A.; Štirmer, N.; Šantek Bajto, J. Correlation between physical and chemical properties of wood biomass ash and cement composites performances. Constr. Build. Mater. 2020, 256, 119450. [Google Scholar] [CrossRef]

- Teker Ercan, E.E.; Andreas, L.; Cwirzen, A.; Habermehl-Cwirzen, K. Wood Ash as Sustainable Alternative Raw Material for the Production of Concrete—A Review. Materials 2023, 16, 2557. [Google Scholar] [CrossRef] [PubMed]

- Tarelho, L.A.C.; Teixeira, E.R.; Silva, D.F.R.; Modolo, R.C.E.; Labrincha, J.A.; Rocha, F. Characteristics of distinct ash flows in a biomass thermal power plant with bubbling fluidised bed combustor. Energy 2015, 90, 387–402. [Google Scholar] [CrossRef]

- LST EN 197-1:2011; Cement—Part 1: Composition, Specifications and Conformity Criteria for Common Cements. The National Standards Authority of Ireland (NSAI): Dublin, Ireland, 2011.

- Lothenbach, B.; Scrivener, K.; Hooton, R.D. Supplementary cementitious materials. Cem. Concr. Res. 2011, 41, 1244–1256. [Google Scholar] [CrossRef]

- LST EN 12620:2003+A1:2008; Aggregates for Concrete. Lithuanian Standards Board: Vilnius, Lithuania, 2008.

- LST EN 12350-5:2019; Testing Fresh Concrete—Part 5: Flow Table Test. Lithuanian Standards Board: Vilnius, Lithuania, 2019.

- LST EN 12390-7:2019; Testing Hardened Concrete—Part 7: Density of Hardened Concrete. Lithuanian Standards Board: Vilnius, Lithuania, 2019.

- LST EN 12390-3:2019; Testing Hardened Concrete—Part 3: Compressive Strength of Test Specimens. Lithuanian Standards Board: Vilnius, Lithuania, 2019.

- LST EN 12390-5:2019; Testing Hardened Concrete—Part 5: Flexural Strength of Test Specimens. Lithuanian Standards Board: Vilnius, Lithuania, 2019.

- LST EN 12504-4; Testing concrete—Part 4: Determination of Ultrasonic Pulse Velocity. Lithuanian Standards Board: Vilnius, Lithuania, 2019.

- Scheikin, A.E.; Dopschic, L.M. Cement Concrete with High Frost Resistance; Stroyizdat: Leningrad, Russia, 1989. [Google Scholar]

- Cabrera, M.; Galvin, A.P.; Agrela, F.; Carvajal, M.D.; Ayuso, J. Characterisation and technical feasibility of using biomass bottom ash for civil infrastructures. Constr. Build. Mater. 2014, 58, 234–244. [Google Scholar] [CrossRef]

- Fořt, J.; Šál, J.; Ševčík, R.; Doleželová, M.; Keppert, M.; Miloš, J.; Záleská, M.; Stehel, V.; Černý, R. Biomass fly ash as an alternative to coal fly ash in blended cements: Functional aspects. Constr. Build. Mater. 2021, 271, 121544. [Google Scholar] [CrossRef]

- Rissanen, J.; Giosué, C.; Ohenoja, K.; Kinnunen, P.; Marcellini, M.; Letizia Ruello, M.; Tittarelli, F.; Illikainen, M. The effect of peat and wood fly ash on the porosity of mortar. Constr. Build. Mater. 2019, 223, 421–430. [Google Scholar] [CrossRef]

- Quarcioni, V.A.; Chotoli, F.F.; Coelho, A.C.V.; Cintotto, M.A. Indirect and direct Chapelle’s method for the determination of lime consumption in pozzolanic materials. IBRACON Struct. Mater. 2015, 8, 1–7. [Google Scholar] [CrossRef]

- Mitchell, L.D.; Margeson, J.C. The effects of solvents on CSH as determined by thermal analysis. J. Therm. Anal. Calorim. 2006, 86, 591–594. [Google Scholar] [CrossRef]

- Berodier, E.; Scrivener, K. Understanding the Filler Effect on the Nucleation and Growth of C–S–H. J. Am. Ceram. Soc. 2014, 97, 3764–3773. [Google Scholar] [CrossRef]

- Shehata, M.H.; Thomas, M.D. Use of ternary blends containing silica fume and fly ash to suppress expansion due to alkali–silica reaction in concrete. Cem. Concr. Res. 2002, 32, 341–349. [Google Scholar] [CrossRef]

- Aquino, W.; Lange, D.A.; Olek, J. The influence of metakaolin and silica fume on the chemistry of alkali–silica reaction products. Cem. Concr. Compos. 2001, 23, 485–493. [Google Scholar] [CrossRef]

- Karim, M.R.; Zain, M.F.M.; Jamil, M.; Lai, F.C. Fabrication of a non-cement binder using slag, palm oil fuel ash and rice husk ash with sodium hydroxide. Constr. Build. Mater. 2013, 49, 894–902. [Google Scholar] [CrossRef]

- Jaturapitakkul, C.; Tangpagasit, J.; Songmue, S.; Kiattikomol, K. Filler effect and pozzolanic reaction of ground palm oil fuel ash. Constr. Build. Mater. 2011, 25, 4287–4293. [Google Scholar] [CrossRef]

- Kaminskas, R.; Barauskas, I.; Kubiliute, R.; Monstvilaite, D. The effect of the pozzolanic activity of different micro-fillers on portland cement hydration. Ceram. Silikáty 2020, 64, 145–154. [Google Scholar] [CrossRef]

- Thomas, H.F.W. Cement Chemistry, 2nd ed.; Thomas Telford Publishing: London, UK, 1997. [Google Scholar]

- Jiahui, P.; Jianxin, Z.; Jindong, Q. The mechanism of the formation and transformation of ettringite. J. Wuhan Univ. Technol. Mat. Sci. Edit. 2006, 21, 158–161. [Google Scholar] [CrossRef]

- Prince, W.; Espagne, M.; Aitcin, P.C. Ettringite formation: A crucial step in cement superplasticizer compatibility. Cem. Concr. Res. 2003, 33, 635–641. [Google Scholar] [CrossRef]

- Palou, M.T.; Kuzielova, E.; Novotny, R.; Šoukal, F.; Žemlička, M. Blended cements consisting of Portland cement–slag–silica fume–metakaolin system. J. Therm. Anal. Calorim. 2016, 125, 1025–1034. [Google Scholar] [CrossRef]

- Wang, Y.; Shui, Z.; Wang, L.; Gao, X.; Huang, Y.; Song, Q.; Liu, K. Alumina-rich pozzolan modification on Portland-limestone cement concrete: Hydration kinetics, formation of hydrates and long-term performance evolution. Constr. Build. Mater. 2020, 258, 119712. [Google Scholar] [CrossRef]

- Pocius, E.; Nagrockienė, D.; Pundienė, I. The influence of concrete sludge from residual concrete on fresh and hardened cement paste properties. Materials 2023, 16, 2531. [Google Scholar] [CrossRef]

- Shin, S.M.; Ho, C.S.; Song, Y.S.; Lin, J.P. Kinetics of the Reaction of Ca(OH)2 with CO2 at Low Temperature. Ind. Eng. Chem. Res. 1999, 38, 1316–1322. [Google Scholar] [CrossRef]

- Elinwa, A.U.; Mahmood, Y.A. Ash from timber waste as cement replacement material. Cem. Concr. Compos. 2002, 24, 219–222. [Google Scholar] [CrossRef]

- Elinwa, A.U.; Ejeh, S.P. Effects of incorporation of sawdust incineration fly ash in cement pastes and mortars. J. Asian Archit. Build. Eng. 2004, 3, 1–7. [Google Scholar] [CrossRef]

- Vaičiukynienė, D.; Balevičius, G.; Vaičiukynas, V.; Kantautas, A.; Jakevičius, L. Synergic effect between two pozzolans: Clinoptilolite and silica gel by-product in a ternary blend of a Portland cement system. Const. Build. Mater. 2022, 344, 128155. [Google Scholar] [CrossRef]

- Schöler, A.; Lothenbach, B.; Winnefeld, F.; Haha, M.B.; Zajac, M.; Ludwig, H.M. Early hydration of SCMblended Portland cements: A pore solution and isothermal calorimetry study. Cem. Concr. Res. 2017, 93, 71–82. [Google Scholar] [CrossRef]

- Johnson, A.; Catalan, L.; Kinrade, S. Characterization and evaluation of fly-ash from co-combustion of lignite and wood pellets for use as cement admixture. Fuel 2010, 89, 3042–3050. [Google Scholar] [CrossRef]

- Feng, C.; Roels, S.; Janssen, H. Towards a more representative assessment of frost damage to porous building materials. Build. Environ. 2019, 164, 106343. [Google Scholar] [CrossRef]

- Koroth, S.R. Evaluation and Improvement of Frost Durability of Clay Bricks; Concordia University: Montreal, QC, Canada, 1997. [Google Scholar]

- Liu, L.; Wang, X.; Zhou, J.; Chu, H.; Shen, D.; Chen, H.; Qin, S. Investigation of pore structure and mechanical property of cement paste subjected to the coupled action of freezing/thawing and calcium leaching. Cem. Concr. Res. 2018, 109, 133–146. [Google Scholar] [CrossRef]

- Omran, A.; Soliman, N.; Xie, A.; Davidenko, T.; Tagnit-Hamou, A. Field trials with concrete incorporating biomass-fly ash. Const. Build. Mater. 2018, 186, 660–669. [Google Scholar] [CrossRef]

- Zhu, H.; Zhai, M.; Liang, G.; Li, H.; Wu, Q.; Zhang, C.; Hua, S. Experimental study on the freezing resistance and microstructure of alkali-activated slag in the presence of rice husk ash. J. Build. Eng. 2021, 38, 102173. [Google Scholar] [CrossRef]

- Teixeira, E.R.; Camões, A.; Branco, F.G. Valorisation of wood fly ash on concrete. Resour. Conserv. Recycl. 2019, 145, 292–310. [Google Scholar] [CrossRef]

- Nagrockienė, D.; Daugėla, A. Investigation into the properties of concrete modified with biomass combustion fly ash. Constr. Build. Mater. 2018, 174, 369–375. [Google Scholar] [CrossRef]

- Wang, S. Cofired biomass fly ashes in mortar: Reduction of Alkali Silica Reaction (ASR) expansion, pore solution chemistry and the effects on compressive strength. Constr. Build. Mater. 2015, 82, 123–132. [Google Scholar] [CrossRef]

| Properties | BFA |

|---|---|

| Particle density, kg/m3 | 2757 |

| Bulk density, kg/m3 | 829 |

| Chemical Composition of BFA, Mass % | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| SiO2 | Al2O3 | Fe2O3 | CaO | K2O | SO3 | Na2O | P2O5 | MgO | MnO2 | Cl |

| 41.93 | 2.70 | 1.91 | 30.3 | 8.43 | 4.95 | 0.49 | 4.75 | 3.6 | 0.59 | 0.38 |

| Chemical composition of Portland cement, mass % | ||||||||||

| 21.76 | 6.12 | 3.37 | 63.5 | 1.0 | 0.8 | 0.3 | - | 3.15 | - | - |

| Composition Designation | CEM I, % | BFA Content, % Cement | SiO2/CaO | Na2O + K2O/CaO | Al2O3/SiO2 | Sand, % | BFA, % | V/R |

|---|---|---|---|---|---|---|---|---|

| I | 30.77 | 0 | 0.320 | 0.020 | 0.294 | 69.23 | 0 | 0.47 |

| II | 29.23 | 5 | 0.353 | 0.027 | 0.276 | 69.23 | 1.54 | 0.47 |

| III | 27.69 | 10 | 0.380 | 0.034 | 0.259 | 69.23 | 3.08 | 0.47 |

| IV | 26.15 | 15 | 0.409 | 0.043 | 0.241 | 69.23 | 4.62 | 0.47 |

| V | 24.62 | 20 | 0.440 | 0.050 | 0.223 | 69.23 | 6.15 | 0.47 |

| VI | 23.08 | 25 | 0.471 | 0.058 | 0.206 | 69.23 | 7.69 | 0.47 |

| VII | 21.54 | 30 | 0.506 | 0.066 | 0.188 | 69.23 | 9.23 | 0.47 |

| Sample Designation | Weight Loss, %, in the Temperature Range Up to the Following Values | Cement Content in Composition, % | ||||

|---|---|---|---|---|---|---|

| 150 °C | 200 °C | 500 °C | 750 °C | 1000 °C | ||

| I | 9.1 | 11.7 | 4.02 | 2.04 | 21.19 | 100 |

| IV | 7.0 | 10.3 | 3.78 | 2.55 | 19.34 | 85 |

| VII | 5.8 | 8.1 | 3.13 | 2.41 | 18.13 | 70 |

| Batches | I | II | III | IV | V | VI | VII |

|---|---|---|---|---|---|---|---|

| Slump flow, mm | 171 | 170 | 169 | 166 | 165 | 140 | 130 |

| Batches | I | II | III | IV | V | VI | VI |

|---|---|---|---|---|---|---|---|

| Frost resistance criterion | 2.10 | 2.48 | 3.07 | 2.69 | 2.11 | 1.98 | 1.80 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nagrockienė, D.; Pundienė, I.; Kanapeckienė, L.; Jarmolajeva, E. The Impact of High-Alkali Biofuel Fly Ash on the Sustainability Parameters of Concrete. Buildings 2023, 13, 3015. https://doi.org/10.3390/buildings13123015

Nagrockienė D, Pundienė I, Kanapeckienė L, Jarmolajeva E. The Impact of High-Alkali Biofuel Fly Ash on the Sustainability Parameters of Concrete. Buildings. 2023; 13(12):3015. https://doi.org/10.3390/buildings13123015

Chicago/Turabian StyleNagrockienė, Džigita, Ina Pundienė, Loreta Kanapeckienė, and Ela Jarmolajeva. 2023. "The Impact of High-Alkali Biofuel Fly Ash on the Sustainability Parameters of Concrete" Buildings 13, no. 12: 3015. https://doi.org/10.3390/buildings13123015

APA StyleNagrockienė, D., Pundienė, I., Kanapeckienė, L., & Jarmolajeva, E. (2023). The Impact of High-Alkali Biofuel Fly Ash on the Sustainability Parameters of Concrete. Buildings, 13(12), 3015. https://doi.org/10.3390/buildings13123015