Mind-Mapping Assessment of Reuse Potential of Glulam: An Experimental Study

Abstract

1. Introduction

2. Materials and Methods

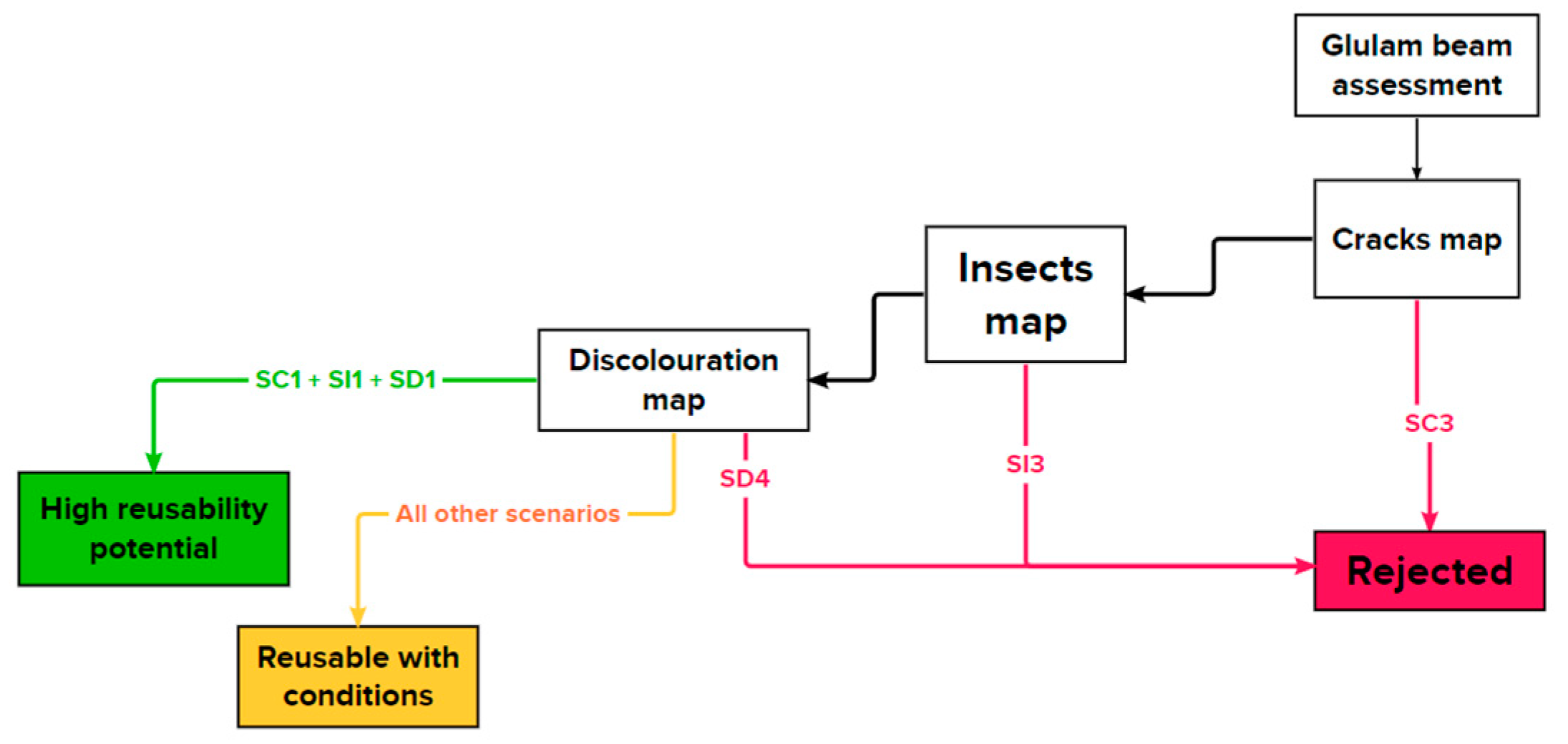

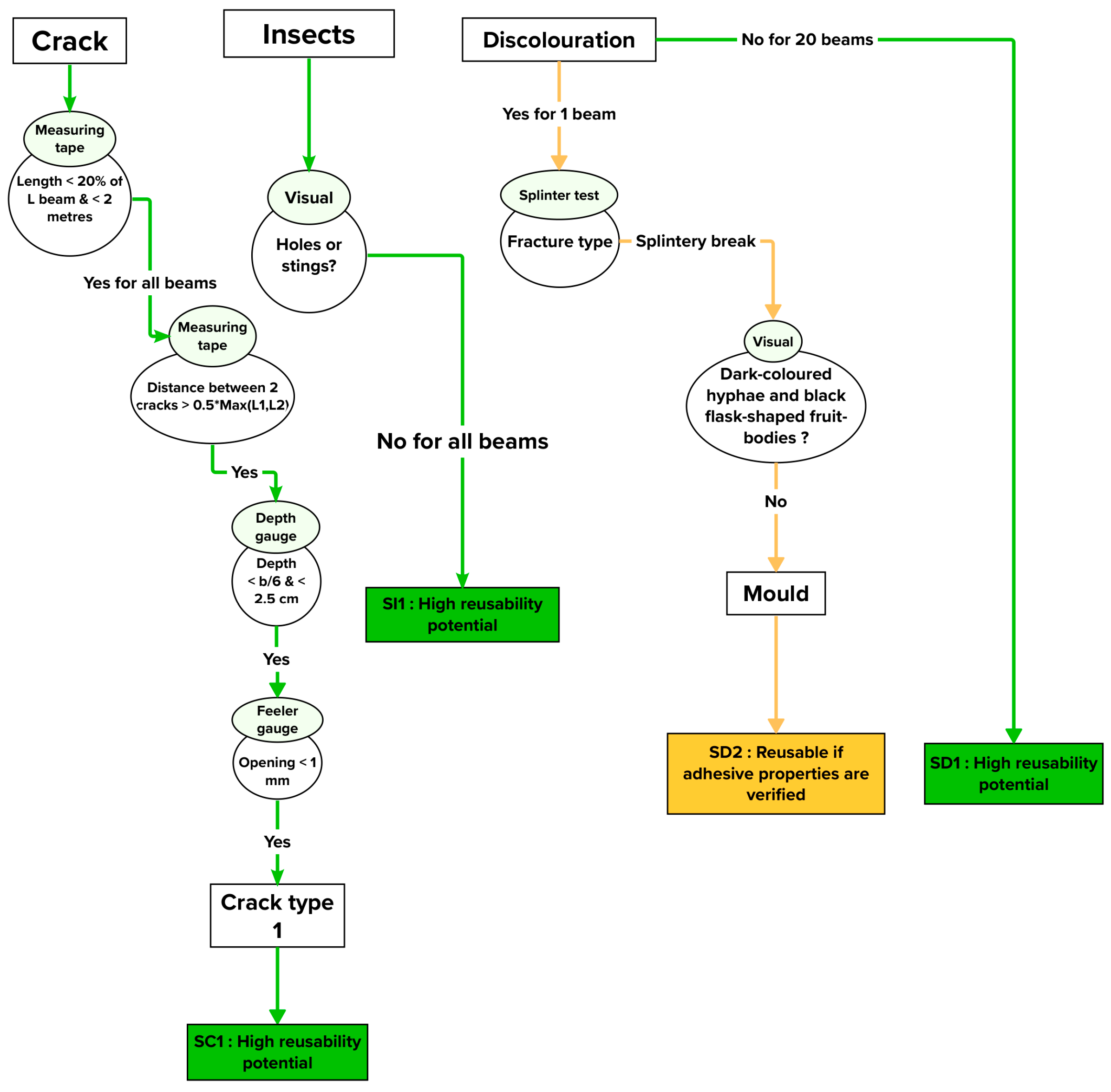

2.1. Mind Map Approach Development

2.1.1. Cracks and Delamination

- -

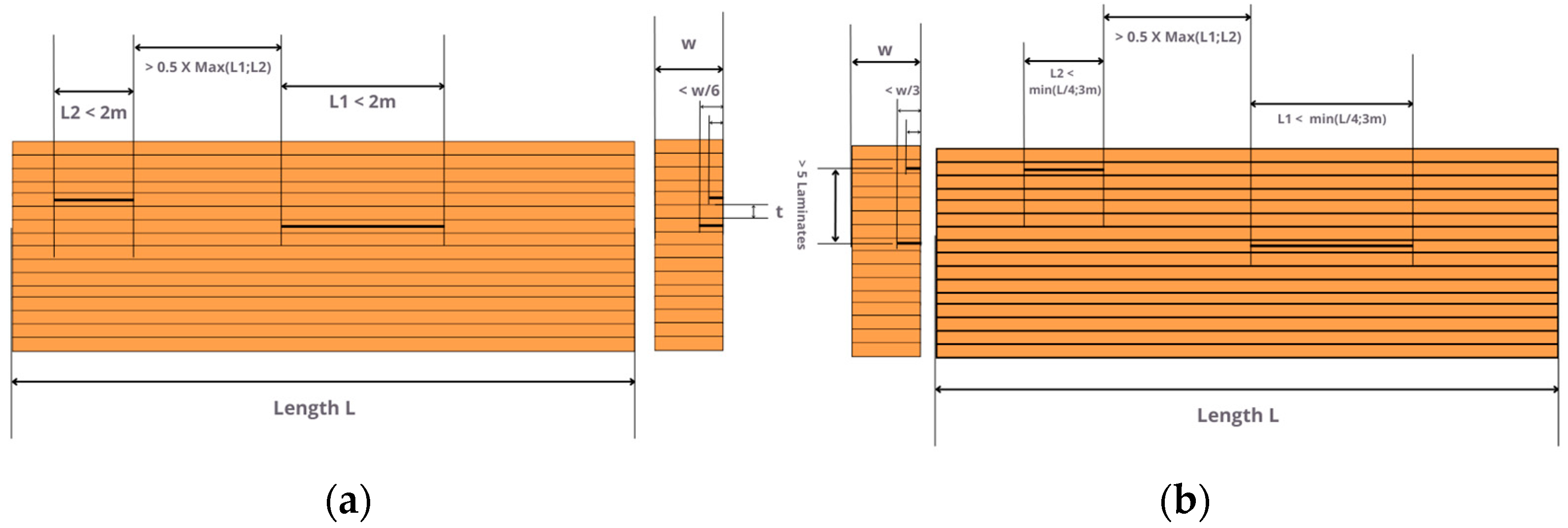

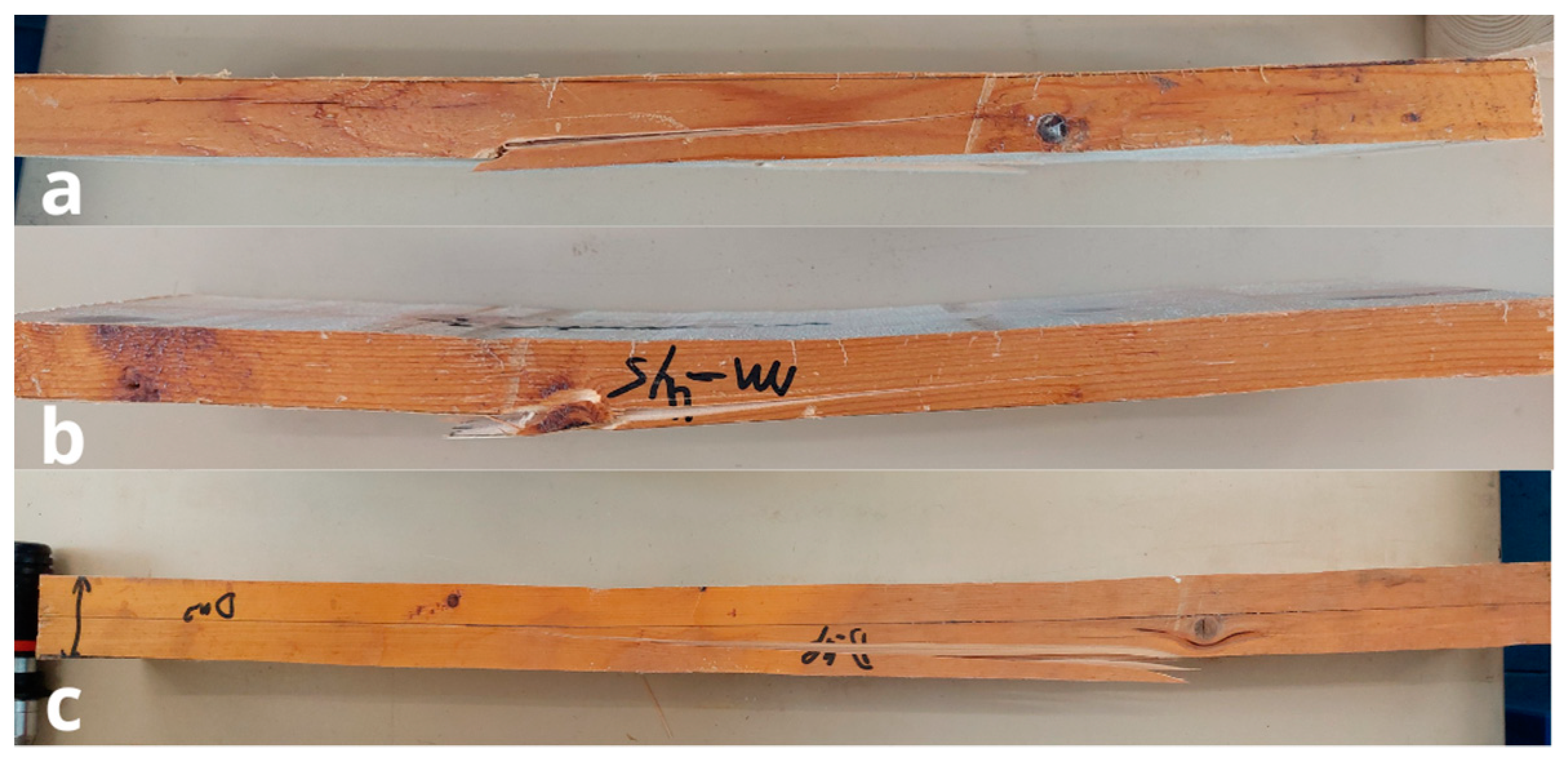

- Minor cracks with controllable locations. Minor cracks are defined as having limited impact and are distinguished by a depth that does not exceed 1/6 of the width “b” of the pieces. The maximum opening is 2.5 cm, with a length of around 2 m that does not exceed 20% of the length of the beam. These cracks can manifest in both the wood and bonding planes. In cases in which minor cracks are present on both sides of the beam, facing each other or in adjacent areas, their maximum depths should not exceed b/12. Minor cracks that are a few centimetres in length, a few millimetres in depth, and evenly spread over the entire height of the beam on both faces do not necessitate structural repairs. Cracks that are found on the edges of beams or posts and are within the width “b”, with the same attributes as the previous category, are also regarded as minor and can be treated similarly. It should be noted that the distance between any two cracks should be greater than half the length of the longer of the two cracks. Cracks of this type are referred to in Figure 2 as SC1 and are illustrated in Figure 1a;

- -

- Significant/insignificant cracks with the potential to worsen over time. Cracks falling under this category exhibit larger dimensions compared to the previous category and are oriented parallel to the bonding planes. The crack length is restricted to less than 1/4 of the beam’s length, with individual limitations of 3 m. The openings of these cracks should be less than 5 mm during dry periods, with a limit of 9 mm otherwise. The depth of the cracks must not exceed b/3, and in cases of multiple cracks, they should be separated by at least 5 elementary laminates. However, this category does not include cracks in assembly zones or at the notch. In instances in which significant or insignificant cracks are present on both sides of the beam, facing each other or in adjacent areas, the maximum depths of the cracks should not surpass b/6. Figure 2 designates cracks of this nature as SC2. It is essential to note that cracks in this category are anticipated to evolve and should be closely monitored over time. Overall, a comprehensive analysis of the crack’s origin and manufacturing conditions should be undertaken in order to limit its evolution. SC2 can be seen in Figure 1b;

- -

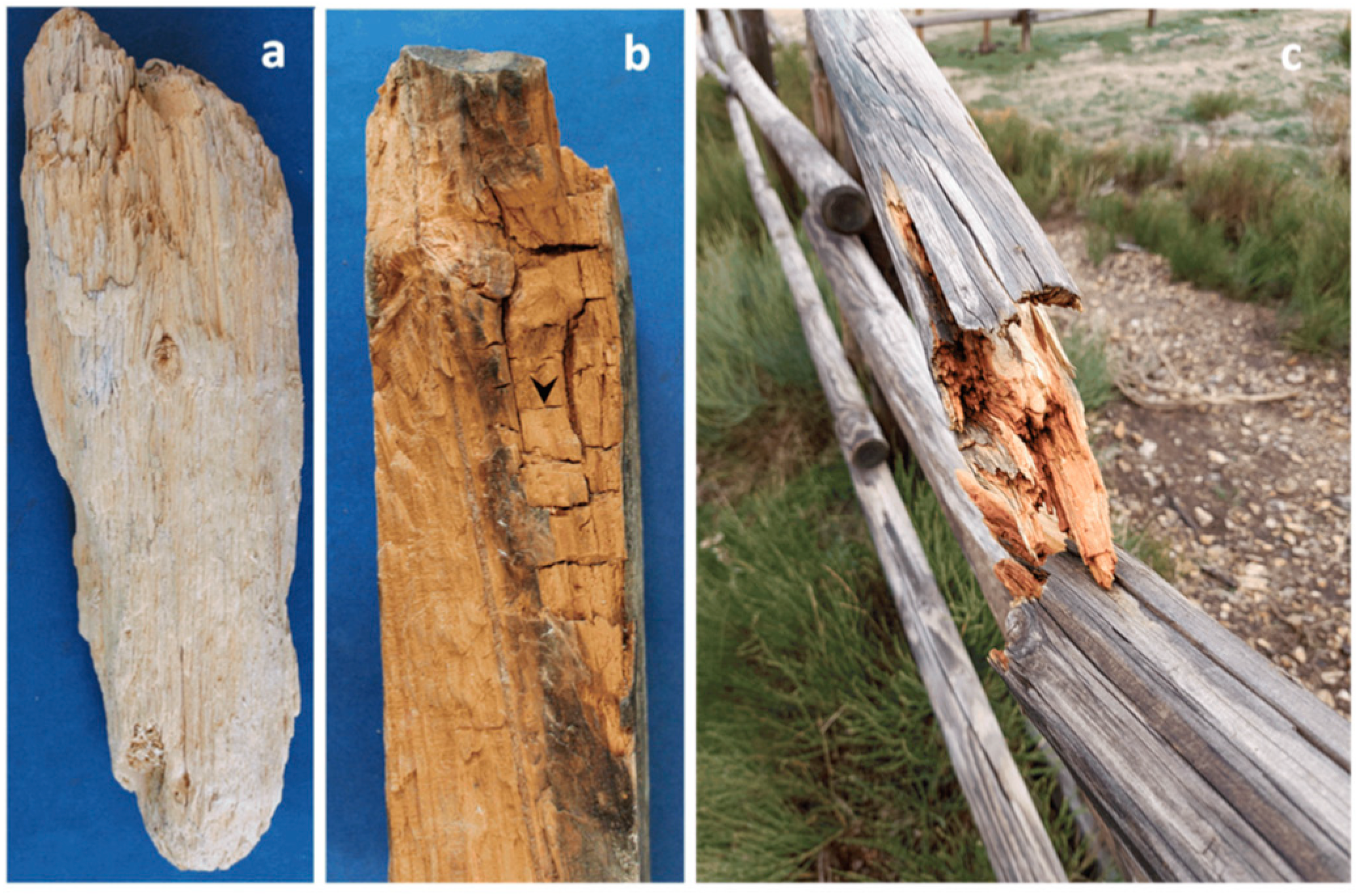

- Wider or through cracks. This category includes cracks that surpass the criteria of the previous classifications or ones that are caused by transverse tensile stress that extends over a considerable length. Additionally, this category includes cracks that propagate across multiple laminae. In Figure 2, these types of cracks are labelled as SC3.

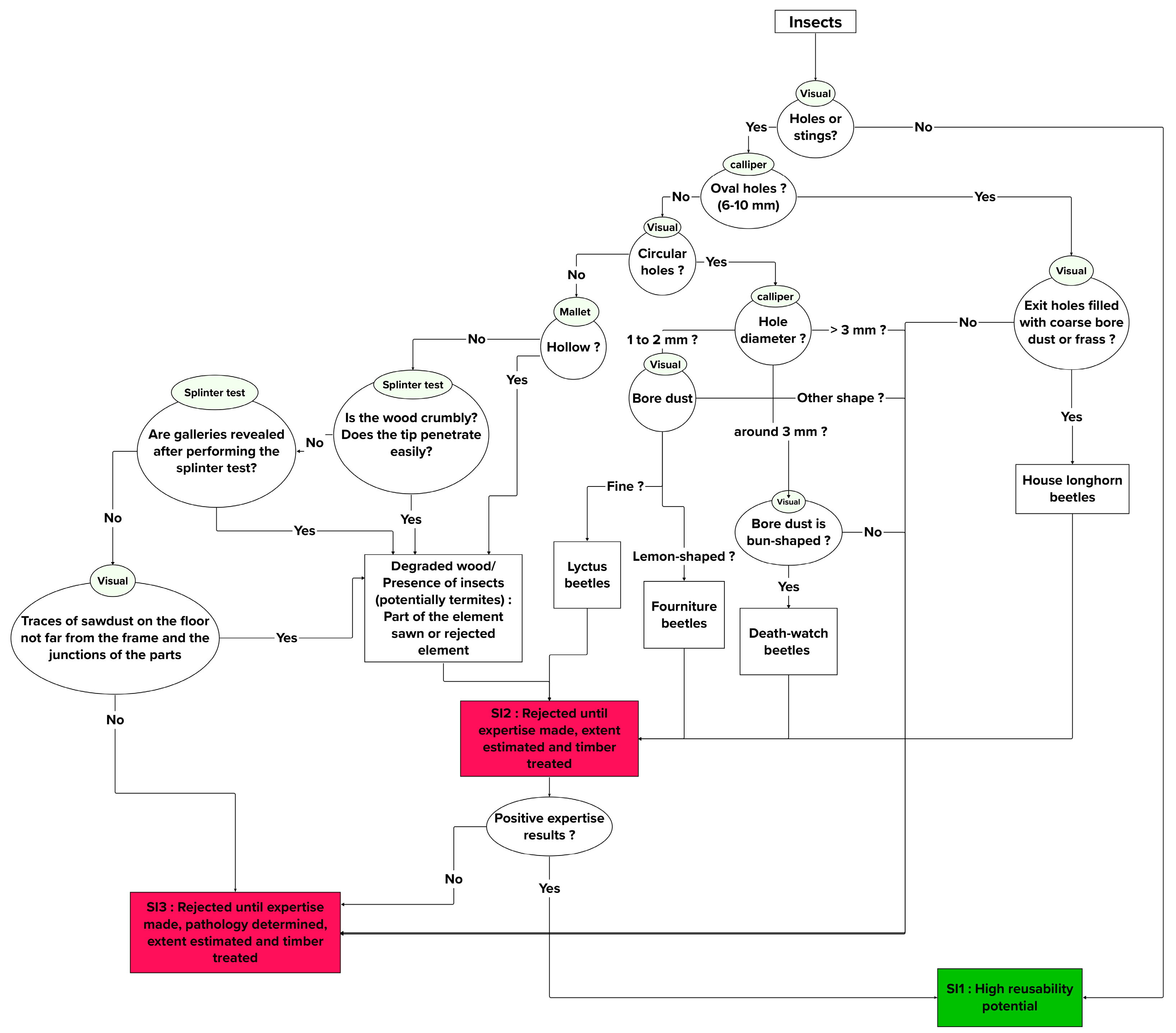

2.1.2. Insects

2.1.3. Discolouration

2.2. Case Study

2.3. Experimental Protocol

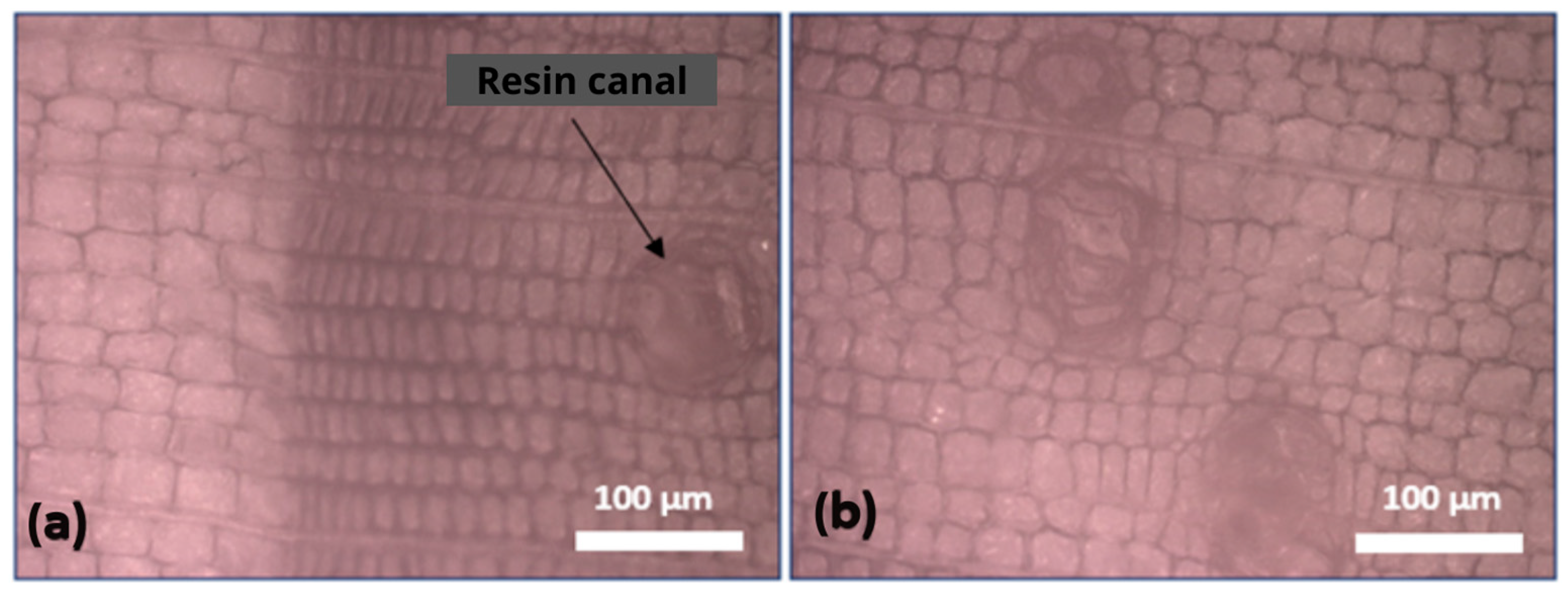

2.3.1. The Microstructural Observation

2.3.2. Density

2.3.3. Fourier Transform Infrared Spectroscopy (FTIR)

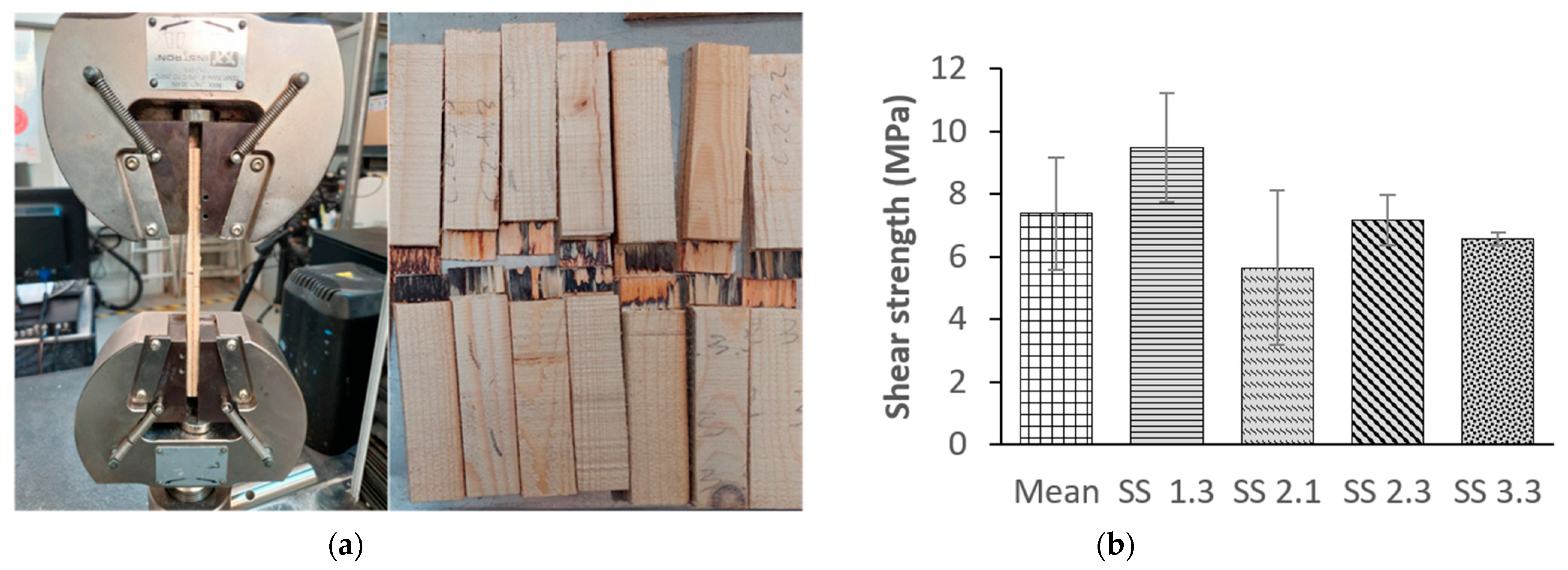

2.3.4. Shear Tests

2.3.5. Bending Tests

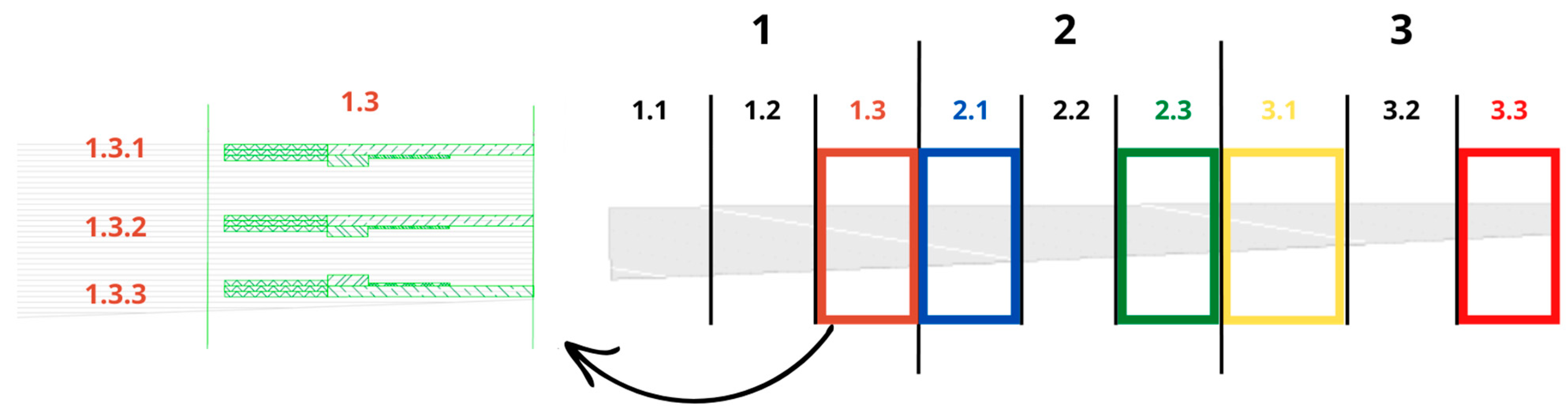

2.3.6. Sampling

3. Results and Discussion

3.1. Mind Map Application

| Lot Number | Designation | Number of Pieces | Observations | Mind Map Results |

|---|---|---|---|---|

| 1 | External portals | 6 | Five visually sound glulam beams with some greyish water infiltration stains–discolouration (Figure 10a) One beam with a mouldy zone (Figure 10b) No major cracks No major delamination No insect holes | 5 beams → SD1+SC1+SI1 → reusable; 1 beam → SC1+SD2+SI1 → reusable if adhesive mechanical properties are verified. |

| 2 | Internal portals | 4 | Visually sound glulam beams No major cracks No major delamination No insect holes No significant discolouration | 4 beams → SD1+SC1+SI1 → reusable |

| 3 | Internal portals | 4 | Visually sound glulam beams No major cracks No major delamination No insect holes No significant discolouration | 4 beams → SD1+SC1+SI1 → reusable |

| 4 | External portals | 7 | Visually sound glulam beams with some greyish water infiltration stains No major cracks No major delamination No insect holes | 7 beams → SD1+SC1+SI1 → reusable |

3.2. Experimental Results

3.2.1. Wood Species

3.2.2. Density

3.2.3. Adhesive Type

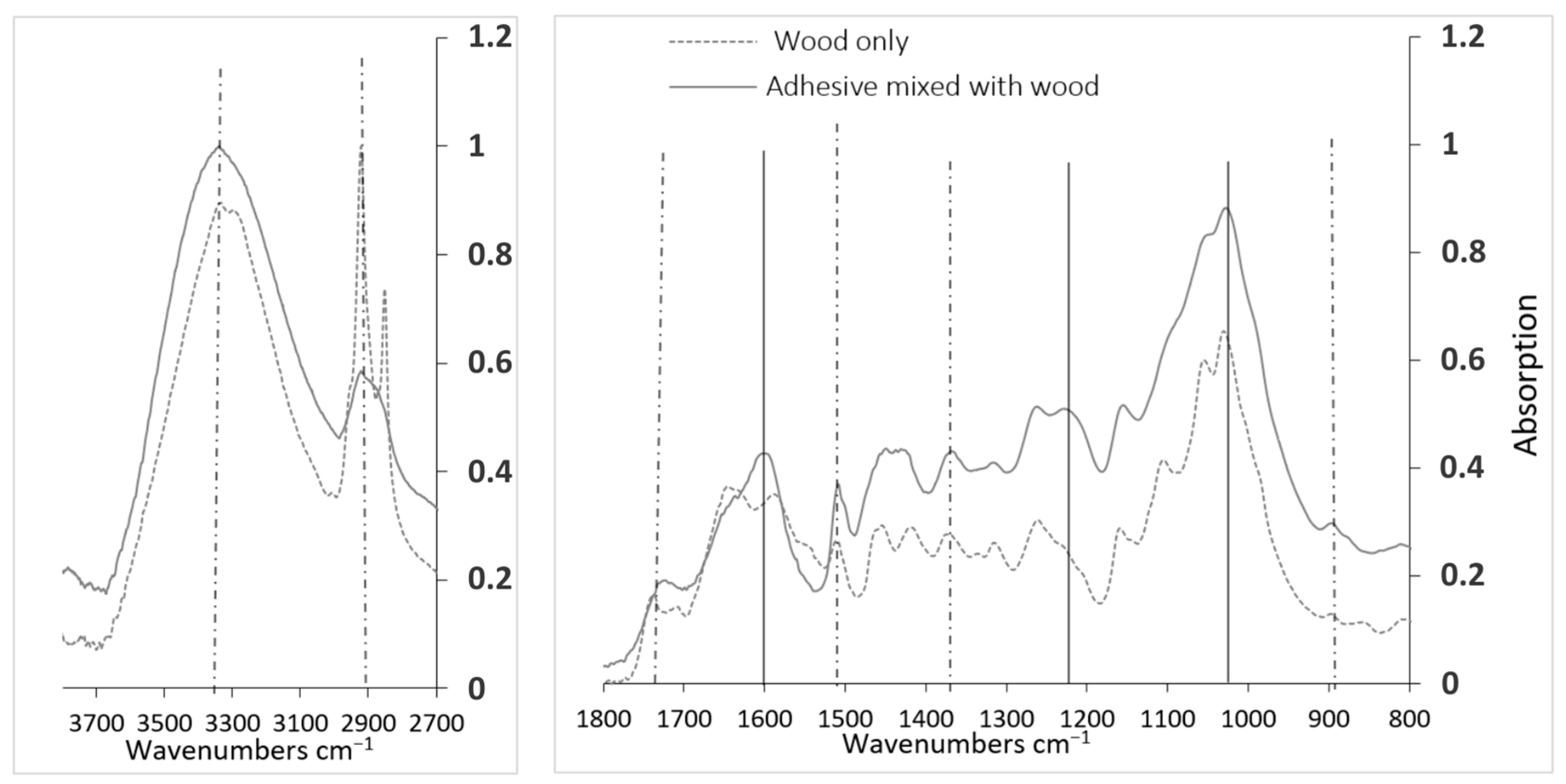

- An absorption band of 3650–3000 cm−1, which is attributed to O-H stretching vibrations, indicating the presence of hydroxyl groups in the wood components, such as cellulose, hemicellulose, and lignin;

- A peak detected at approximately 2900 cm−1, which is due to the asymmetric and symmetric C-H stretching of lignin, hemicellulose, and pectin;

- A peak centred at 1740 cm−1, which corresponds to C=O stretching vibrations of the carboxyl and acetyl groups in hemicellulose;

- A band at 1510 cm−1, which is due to the C=C stretching of the aromatic ring in lignin;

- A band at 1372 cm−1, which is linked to CH bending in both cellulose and hemicellulose;

- A peak centred at 897 cm−1, which represents the C-H vibrational mode in cellulose.

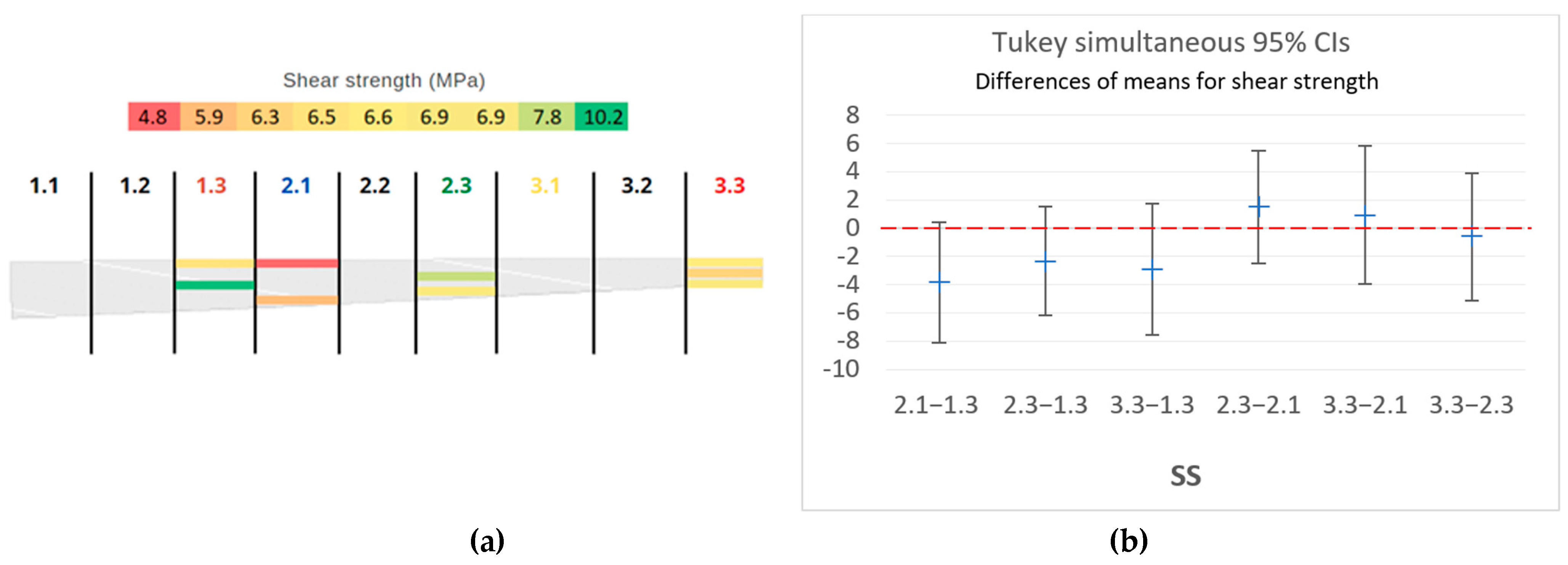

3.2.4. Shear Strength of the Adhesive–Wood Bond

3.2.5. Bending Test Results and Strength Class

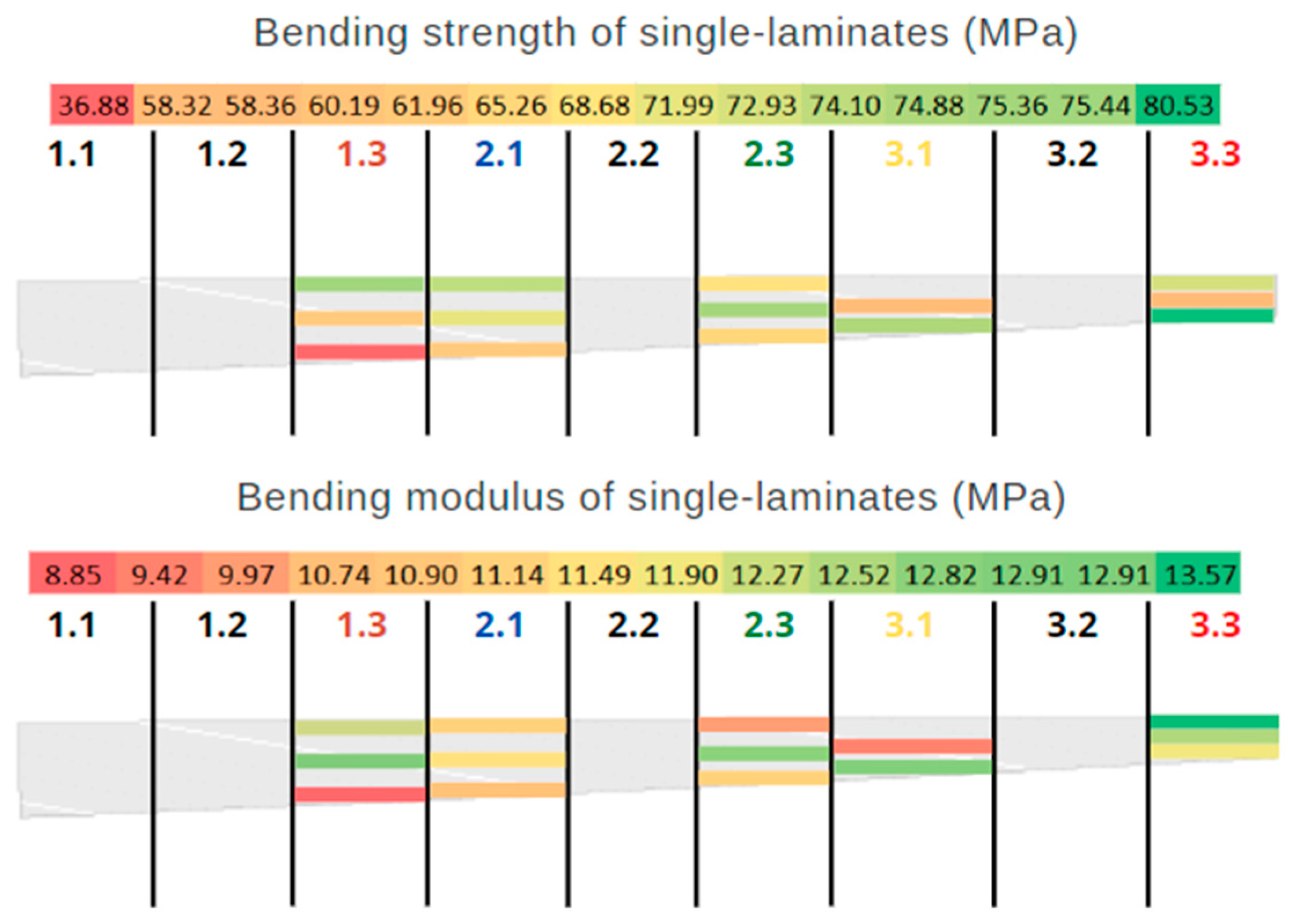

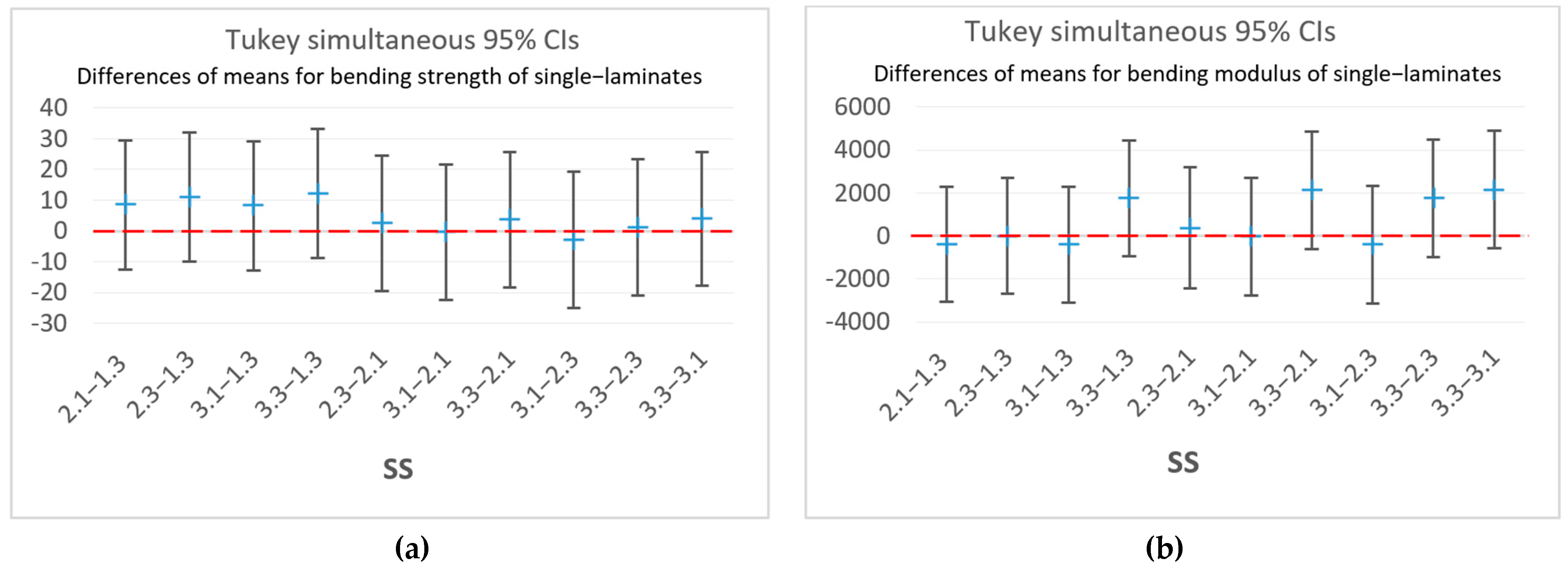

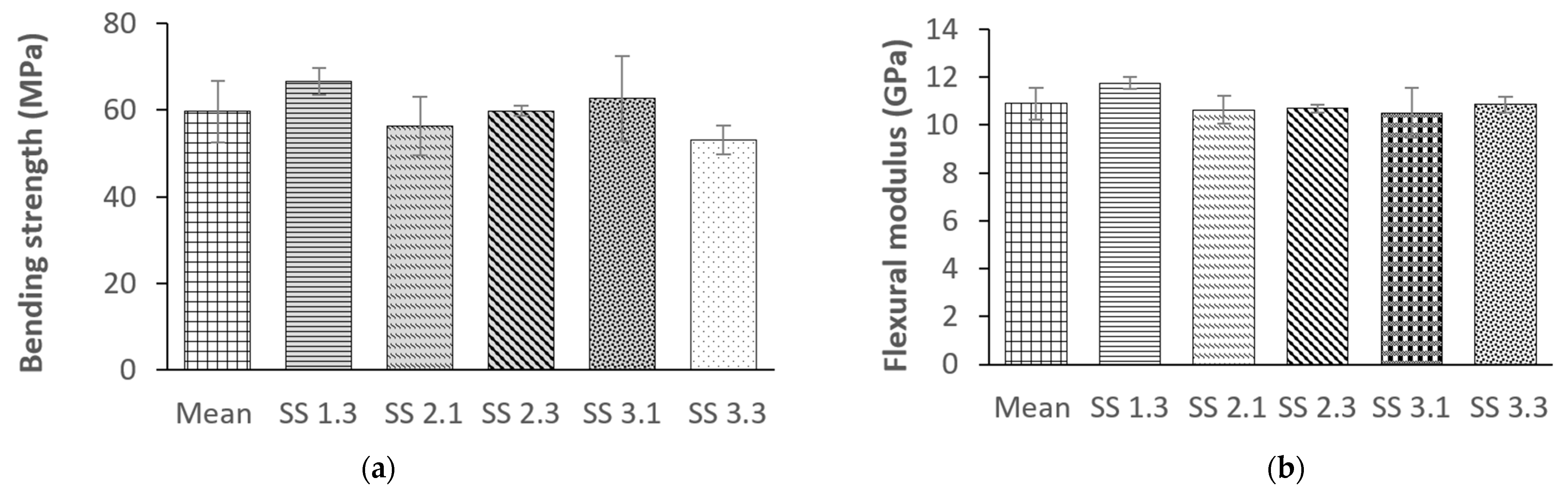

Single Laminates

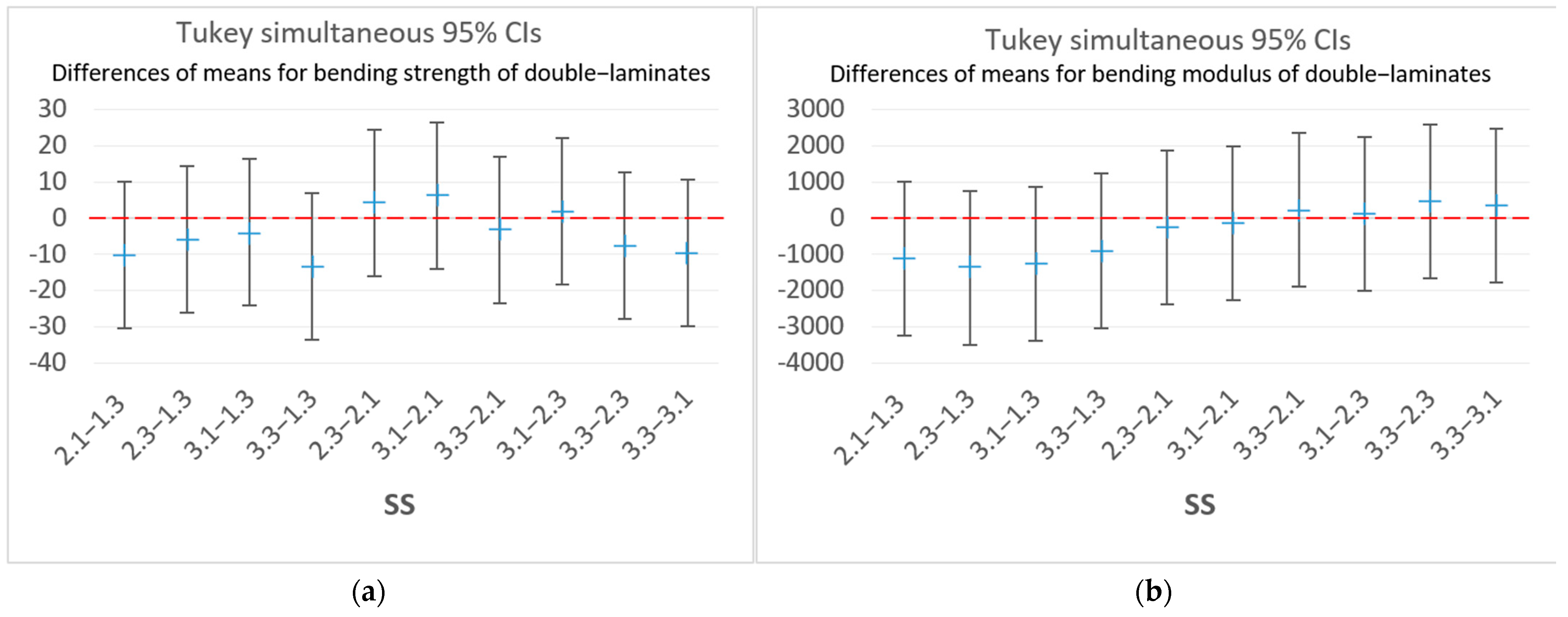

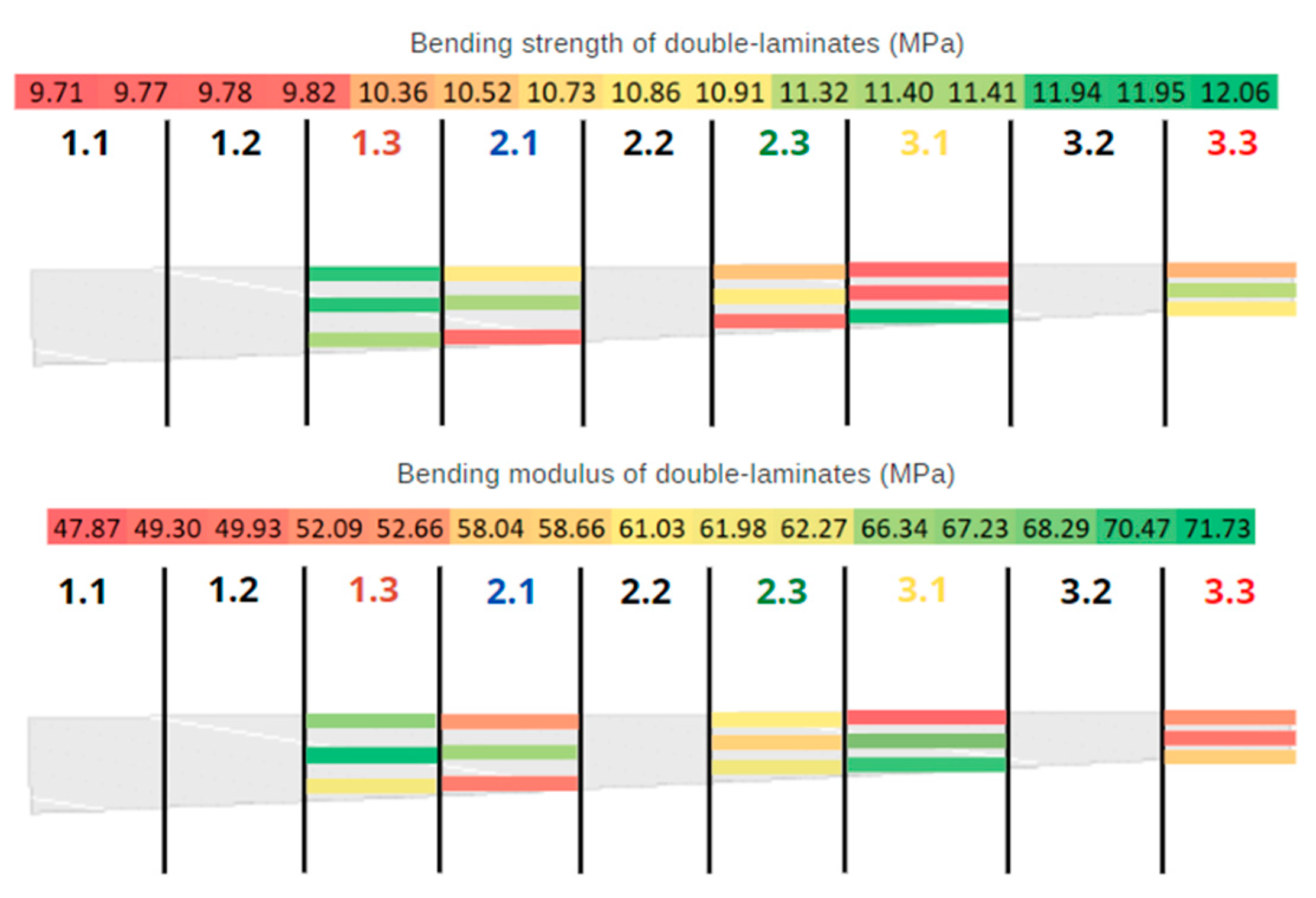

Double Laminates

4. Conclusions

- The wood species was spruce, and its density was 420 ± 45 kg/m3 in the dry state;

- The glue used in the glulam was melamine–urea–formaldehyde;

- The shear strength of the glue was 7.37 ± 1.79 MPa, which is below the threshold allowed by the current standard;

- For the single laminates, the mean bending strength was 65.85 ± 4.72 MPa, with 11.56 ± 0.80 GPa for the bending modulus, which were obtained after the calculations of the fifth percentile and using the scaling factor class C16;

- For the double laminates, the mean bending strength was 59.79 ± 23.01 MPa, with a mean bending modulus of 10.62 ± 4.07 GPa;

- The observed water infiltration (mould) on the beam had a strong influence on the properties of the glue, but not on the mechanical properties of the wood. This shows that the discolouration mind map conclusion was effective and led to the detection of this anomaly;

- The values for the double laminates were lower than those for the single laminates, but still in the same range;

- The comparison between the classes obtained from the Young’s modulus and bending strength indicated that the former was lower, leading to its adoption as the grading criterion for the GLT. This observation suggests that, for GLT reuse, emphasising the measurement of the modulus may be sufficient;

- The glued laminated timber was of class GL20H, and this class corresponds to laminations of class C16;

- During the different characterisations, no insect indications were found, which confirms the conclusion of the insect mind map;

- Note that this method will be supported by NDT for internal defects in future works.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Haeusler, L.; Guyot, M. Waste Key Figures: The Essentials 2020; ADEME: Angers, France, 2020. (In French) [Google Scholar]

- Minunno, R.; O’Grady, T.; Morrison, G.M.; Gruner, R.L. Exploring environmental benefits of reuse and recycle practices: A circular economy case study of a modular building. Resour. Conserv. Recycl. 2020, 160, 104855. [Google Scholar] [CrossRef]

- Viola, J.; Thomas, S. Re-Use of Building Components (RE-USE) Potential for Systematic Re-Use of Building Components in a Regional Context and Realisation of a Pilot Project; BBSR: Bonn, Germany, 2021. (In German) [Google Scholar]

- Ministry of Ecological Transition. Circular Economy; Ministry of Ecological Transition: Paris, France, 2020. [Google Scholar]

- Poncelet, F.; Vrijders, J.J. Technical Framework for Re-Used Materials: How Can the Technical Performance of Re-Used Materials Be Justified? CSTC: Brussels, Belgium, 2021; 47p. (In French) [Google Scholar]

- Grubeša, I.N.; Teni, M.; Krstić, H.; Vračević, M. Influence of freeze/thaw cycles on mechanical and thermal properties of masonry wall and masonry wall materials. Energies 2019, 12, 1464. [Google Scholar] [CrossRef]

- Reuse Toolkit: Material Sheets. Available online: https://vb.nweurope.eu/projects/project-search/fcrbe-facilitating-the-circulation-of-reclaimed-building-elements-in-northwestern-europe/news/reuse-toolkit-material-sheets/ (accessed on 16 April 2022).

- European Commission Proposal for a Regulation Laying down Harmonised Conditions for the Marketing of Construction Products, Amending Regulation (EU) 2019/1020 and Repealing Regulation (EU) 305/2011. Available online: https://ec.europa.eu/docsroom/documents/49315 (accessed on 30 August 2022).

- Wei, P.; Wang, B.J.; Li, H.; Wang, L.; Peng, S.; Zhang, L. A comparative study of compression behaviors of cross-laminated timber and glued-laminated timber columns. Constr. Build. Mater. 2019, 222, 86–95. [Google Scholar] [CrossRef]

- Vardanyan, E.R., Akimov, P., Khalvashi, M., Eghiazar, Eds.; Contemporary Problems of Architecture and Construction. In Proceedings of the 12th International Conference on Contemporary Problems of Architecture and Construction (ICCPAC 2020), Saint Petersburg, Russia, 25–26 November 2020; CRC Press: London, UK, 2021. ISBN 978-1-00-317642-8. [Google Scholar]

- Dietsch, P.; Tannert, T. Assessing the integrity of glued-laminated timber elements. Constr. Build. Mater. 2015, 101, 1259–1270. [Google Scholar] [CrossRef]

- Berg, S.; Sandberg, D.; Ekevad, M.; Vaziri, M. Crack influence on load-bearing capacity of glued laminated timber using extended finite element modelling. Wood Mater. Sci. Eng. 2015, 10, 335–343. [Google Scholar] [CrossRef]

- Frese, M.; Blaß, H.J. Damage Analysis of Wooden Hall Supporting Structures; KIT Scientific Publishing: Karlsruhe, Germany, 2010; ISBN 978-3-86644-590-1. (In German) [Google Scholar]

- Jiang, J.; Du, J.; Li, H.; Mei, C.; Gong, X. Hydrophobicity improvement on wood for a better application of this bio-based material. Coatings 2022, 12, 1465. [Google Scholar] [CrossRef]

- Jiang, J.; Cao, J.; Mei, C. Microstructure, hydrophobicity and thermal stability of wood treated by silica/montmorillonite nanoparticle-stabilized pickering emulsion (I). Wood Sci. Technol. 2022, 56, 111–121. [Google Scholar] [CrossRef]

- Nziengui, P. Wood Cracking in a Variable Climate under Long-Term Loads: Applications to European and Gabonese Wood Species. Ph.D. Thesis, University of Clermont Auvergne, Clermont-Ferrand, France, 2019. (In French). [Google Scholar]

- Gaff, M.; Kubovský, I.; Sikora, A.; Kačíková, D.; Li, H.; Kubovský, M.; Kačík, F. Impact of thermal modification on color and chemical changes of African padauk, merbau, mahogany, and iroko wood species. Rev. Adv. Mater. Sci. 2023, 62, 20220277. [Google Scholar] [CrossRef]

- Ayanleye, S.; Udele, K.; Nasir, V.; Zhang, X.; Militz, H. Durability and protection of mass timber structures: A review. J. Build. Eng. 2022, 46, 103731. [Google Scholar] [CrossRef]

- Groenier, J.S.; Lebow, S. Preservative-Treated Wood and Alternative Products in the Forest Service; Forest Service, Technology & Development Program: Missoula, MT, USA, 2006; 44p. [Google Scholar]

- Gaspar, F.; Cruz, H.; Gomes, A. Modeling the influence of delamination on the mechanical performance of straight glued laminated timber beams. Constr. Build. Mater. 2015, 98, 447–455. [Google Scholar] [CrossRef]

- Martín, J.A.; López, R. Biological deterioration and natural durability of wood in Europe. Forests 2023, 14, 283. [Google Scholar] [CrossRef]

- Verbist, M.; Branco, J.M.; Nunes, L. Characterization of the mechanical performance in compression perpendicular to the grain of insect-deteriorated timber. Buildings 2020, 10, 14. [Google Scholar] [CrossRef]

- Creffield, J.W. Wood Destroying Insects: Wood Borers and Termites; Csiro Publishing: Clayton, Australia, 1996; ISBN 978-0-643-10291-0. [Google Scholar]

- Desch, H.E.; Dinwoodie, J.M. Timber Structure, Properties, Conversion and Use; Macmillan Education: London, UK, 1996; ISBN 978-0-333-60905-7. [Google Scholar]

- Feci, E.; Mannucci, M.; Palanti, S. Diagnostic evaluation of insect attack on existing timber structures: A review of some case studies. Adv. Mater. Res. 2013, 778, 1020–1027. [Google Scholar] [CrossRef]

- Kim, G.-H.; Barnes, H.M.; Lyon, D.E. Effect of decay on the mechanical properties of full-sized lumber. Holzforschung 1994, 48, 145–149. [Google Scholar] [CrossRef]

- Brischke, C.; Welzbacher, C.R.; Huckfeldt, T. Influence of fungal decay by different basidiomycetes on the structural integrity of Norway spruce wood. Holz. Roh. Werkst. 2008, 66, 433–438. [Google Scholar] [CrossRef]

- Witomski, P.; Olek, W.; Bonarski, J.T. Changes in strength of Scots pine wood (Pinus silvestris L.) decayed by brown rot (Coniophora puteana) and white rot (Trametes versicolor). Constr. Build. Mater. 2016, 102, 162–166. [Google Scholar] [CrossRef]

- Gelbrich, J. Bacterial Wood Degradation: A Study of Chemical Changes in Wood and Growth Conditions of Bacteria; Sierke Verlag: Göttingen, Germany, 2009. [Google Scholar]

- Dietsch, P.; Koehler, J. Assessment of timber structures. In Report of the COST Action E55 “Modelling of the Performance of Timber Structures”; Shaker Verlag: Aachen, Germany, 2010. [Google Scholar]

- Technical Notes on Laminated Wood N°1—Cracks (In French). SNBL 2016. Available online: https://www.glulam.org/wp-content/uploads/SNBL-Note-N°1-Fissures-février-2016.pdf.pdf (accessed on 25 August 2022).

- NF EN 14081-1+A1; Timber Structures. Strength Graded Structural Timber with Rectangular Cross Section: General Requirements. NF: Paris, France, 2019.

- Findlay, W.P.K. Timber Pests and Disease; Pergamon Press: Oxford, UK, 1967; pp. 19–31. [Google Scholar] [CrossRef]

- Moore, H.B. Wood-Inhabiting Insects in Houses: Their Identification, Biology, Prevention and Control; Department of Agriculture, Forest Service: Asheville, NC, USA, 1979. [Google Scholar]

- Ridout, B. Timber decay in buildings: The conservation approach to treatment. APT Bull. J. Preserv. Technol. 2001, 32, 58–60. [Google Scholar] [CrossRef]

- Domone, P.; Illston, J. (Eds.) Construction Materials: Their Nature and Behaviour, 4th ed.; CRC Press: London, UK, 2018. [Google Scholar] [CrossRef]

- Råberg, U.; Edlund, M.-L.; Terziev, N.; Land, C.J. Testing and evaluation of natural durability of wood in above ground conditions in Europe—An overview. J. Wood Sci. 2005, 51, 429–440. [Google Scholar] [CrossRef]

- Dimou, V.; Kaziolas, D.N.; Zygomalas, I.; Avtzis, N. Influence of biotic factors on the mechanical properties of wood—Taking into account the time of harvesting. Wood Mater. Sci. Eng. 2017, 12, 140–148. [Google Scholar] [CrossRef]

- Reeb, J.E.; Milota, M.R. WDK Association Moisture Content by the Oven-Dry Method for Industrial Testing; Western Dry Kiln Association: Portland, OR, USA, 1999. [Google Scholar]

- NF EN 302-1; Adhesives for Load-Bearing Timber Structures—Test Methods—Part 1: Determination of Longitudinal Tensile Shear Strength. NF: Paris, France, 2023.

- NF EN 408+A1; Timber Structures—Structural Timber and Glued Laminated Timber—Determination of Some Physical and Mechanical Properties. NF: Paris, France, 2012.

- NF EN 14358; Timber Structures—Calculation and Verification of Characteristic Values. NF: Paris, France, 2016.

- NF EN 338; Structural Timber—Strength Classes. NF: Paris, France, 2016.

- NF EN 14080; Timber Structures—Glued Laminated Timber and Glued Solid Timber—Requirements. NF: Paris, France, 2013.

- Anatomy of Wood (In French). Available online: http://www.fun-mooc.fr/fr/cours/anatomie-du-bois/ (accessed on 22 August 2022).

- Cufar, K.; Balzano, A.; Krže, L.; Merela, M. Wood identification using non-destructive confocal laser scanning microscopy. Les/Wood 2019, 68, 19–29. [Google Scholar] [CrossRef][Green Version]

- Gryc, V.; Horáček, P. Variability in density of spruce (Picea abies [L.] Karst.) wood with the presence of reaction wood. J. For. Sci. 2007, 53, 129–137. [Google Scholar] [CrossRef]

- Spruce (In French). Available online: https://preferezlesboisdefrance.fr/essence/epicea/ (accessed on 22 August 2022).

- Cavallaro, G.; Gallitto, A.A.; Lisuzzo, L.; Lazzara, G. Comparative study of historical woods from XIX century by thermogravimetry coupled with FTIR spectroscopy. Cellulose 2019, 26, 8853–8865. [Google Scholar] [CrossRef]

- Nouri, M.; Griballah, I.; Tahlaiti, M.; Grondin, F.; Beaugrand, J. Plant extraction and physicochemical characterizations of untreated and pretreated diss fibers (Ampelodesmos Mauritanicus). J. Nat. Fibers 2021, 18, 1083–1093. [Google Scholar] [CrossRef]

- Liu, M.; Thirumalai RV, K.; Wu, Y.; Wan, H. Characterization of the crystalline regions of cured urea formaldehyde resin. RSC Adv. 2017, 7, 49536–49541. [Google Scholar] [CrossRef]

- Glulam Handbook; Syndicat National du Bois Lamellé (SNBL): Paris, France, 2013.

- Wang, X.A.; Björnberg, J.; Hagman, O.; Ahmed, S.A.; Wan, H.; Niemz, P. Effect of low temperatures on the block shear strength of Norway spruce Glulam joints. BioResources 2016, 11, 9638–9648. [Google Scholar] [CrossRef]

- Tran, V.D. Characterisation and Numerical Modelling of Reconstituted Solid Wood Beams Made from a Local Hardwood Species. Ph.D. Thesis, University of Lorraine, Nancy, France, 2014. (In French). [Google Scholar]

- Grecchi, M. Building Renovation: How to Retrofit and Reuse Existing Buildings to Save Energy and Respond to New Needs; SpringerBriefs in Applied Sciences and Technology; Springer International Publishing: Cham, Switzerland, 2022; ISBN 978-3-030-89835-9. [Google Scholar]

- Komán, S.; Sandor, F.; Jozsef, A.; Taschner, R. Effect of knots on the bending strength and the modulus of elasticity of wood. Wood Res. 2013, 58, 617–626. [Google Scholar]

- Blank, L. Bending resistance and deformation capacity of fibre reinforced Glulam beams. ETH Zur. 2018, 376, 1–238. [Google Scholar]

| Fungus Type | General Aspect and Mycelium with Hypha Characteristics | Fruit Body Characteristics |

|---|---|---|

| Serpula lacrymans (brown cubical rot) | In high humidity: white, fluffy, cottony clusters; in dry condition: grey-white colour with vibrant yellow or lilac patches. | Soft, fleshy layers with white edges. |

| Fibroporia vaillantii (brown cubical rot) | White and soft. | Shaped like a plate, dotted with tiny pores, and white in colour. |

| Coniophora puteana (brown cubical rot) | The wood becomes highly fragile and can be crumbled by hand; virtually indistinguishable from Serpula attack. | Infrequently observed slim plates of an olive-green hue. |

| Paxillus panuoides (brown cubical rot) | Mycelium has a fibrous texture, appearing yellow or purple. | Bell-shaped and muted yellow with pronounced gills underneath. |

| Amyloporia xantha (brown cubical rot) | - | Slim plate featuring tiny pores; of a yellow hue and with a lemony scent when fresh. |

| Lentinus lepideus (brown cubical rot) | - | Woody, brown fungus. |

| Phellinus contiguous (white rot) | Wood fractures into fibrous strings; fungus mycelium is soft, fluffy, and light brown. | Dark brown. |

| Donkioporia expansa (white rot) | Hyphae are fibrous and of a white hue. | Thick, leathery layers or shelves with a buff hue, featuring darker-brown pores. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yahmi, A.; Nouri, M.; Tahlaiti, M.; Khelidj, A.; Raffin, C.; Place, N. Mind-Mapping Assessment of Reuse Potential of Glulam: An Experimental Study. Buildings 2023, 13, 2929. https://doi.org/10.3390/buildings13122929

Yahmi A, Nouri M, Tahlaiti M, Khelidj A, Raffin C, Place N. Mind-Mapping Assessment of Reuse Potential of Glulam: An Experimental Study. Buildings. 2023; 13(12):2929. https://doi.org/10.3390/buildings13122929

Chicago/Turabian StyleYahmi, Aghiless, Mustapha Nouri, Mahfoud Tahlaiti, Abdelhafid Khelidj, Charlène Raffin, and Nicolas Place. 2023. "Mind-Mapping Assessment of Reuse Potential of Glulam: An Experimental Study" Buildings 13, no. 12: 2929. https://doi.org/10.3390/buildings13122929

APA StyleYahmi, A., Nouri, M., Tahlaiti, M., Khelidj, A., Raffin, C., & Place, N. (2023). Mind-Mapping Assessment of Reuse Potential of Glulam: An Experimental Study. Buildings, 13(12), 2929. https://doi.org/10.3390/buildings13122929