Surface Modification of Steel Slag Aggregate for Engineering Application in Asphalt Mixture

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Surface Pretreatment of SSA

- To prepare the pretreatment agent, epoxy resin was solved in ethanol solution at a ratio of 3:10 by weight. Then, silane coupling agent (10 wt %), anhydrous ethanol (10 wt %), m-Xylylenediamine (14 wt %), methyldiethanolamine (8 wt %) and liquid silicone rubber (8 wt %) were added.

- To pretreat the surface of SSA, it was immersed at 20 °C for 24 h in the agent which was prepared at the step (1).

- Finally, PSSA were placed in an oven at 25 °C for 24 h which made agent to be fully cured.

2.3. Mixture Design

2.4. Test Methods

2.4.1. Physical and Chemical Characterization of SSA

- (a)

- Morphological test

- (b)

- Mineral composition analysis

- (c)

- Swelling test

2.4.2. Bitumen-Aggregate Adhesion Analysis

- (a)

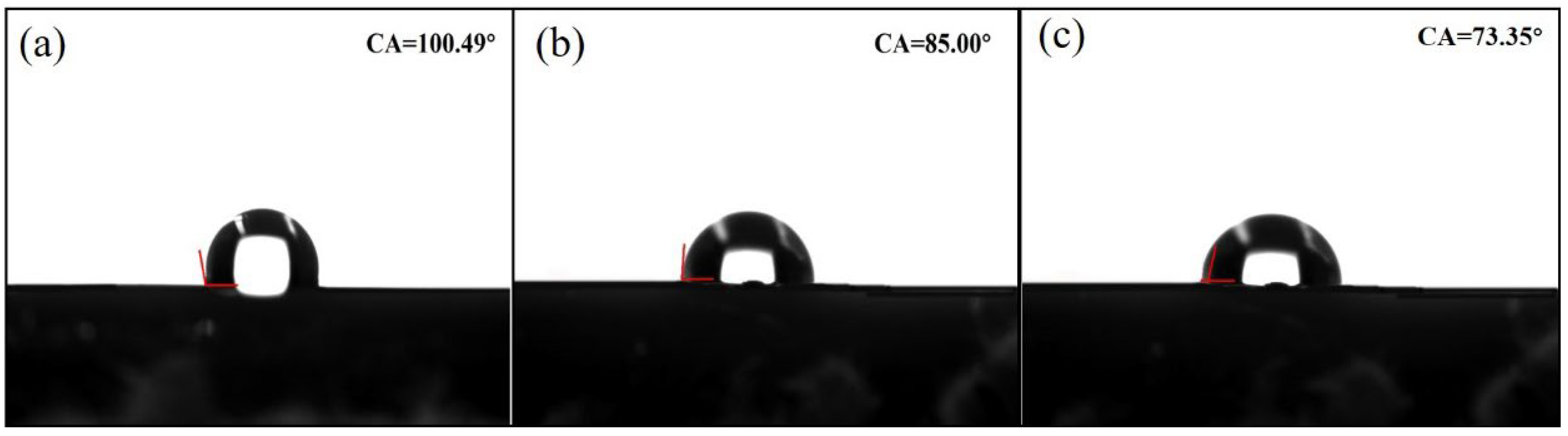

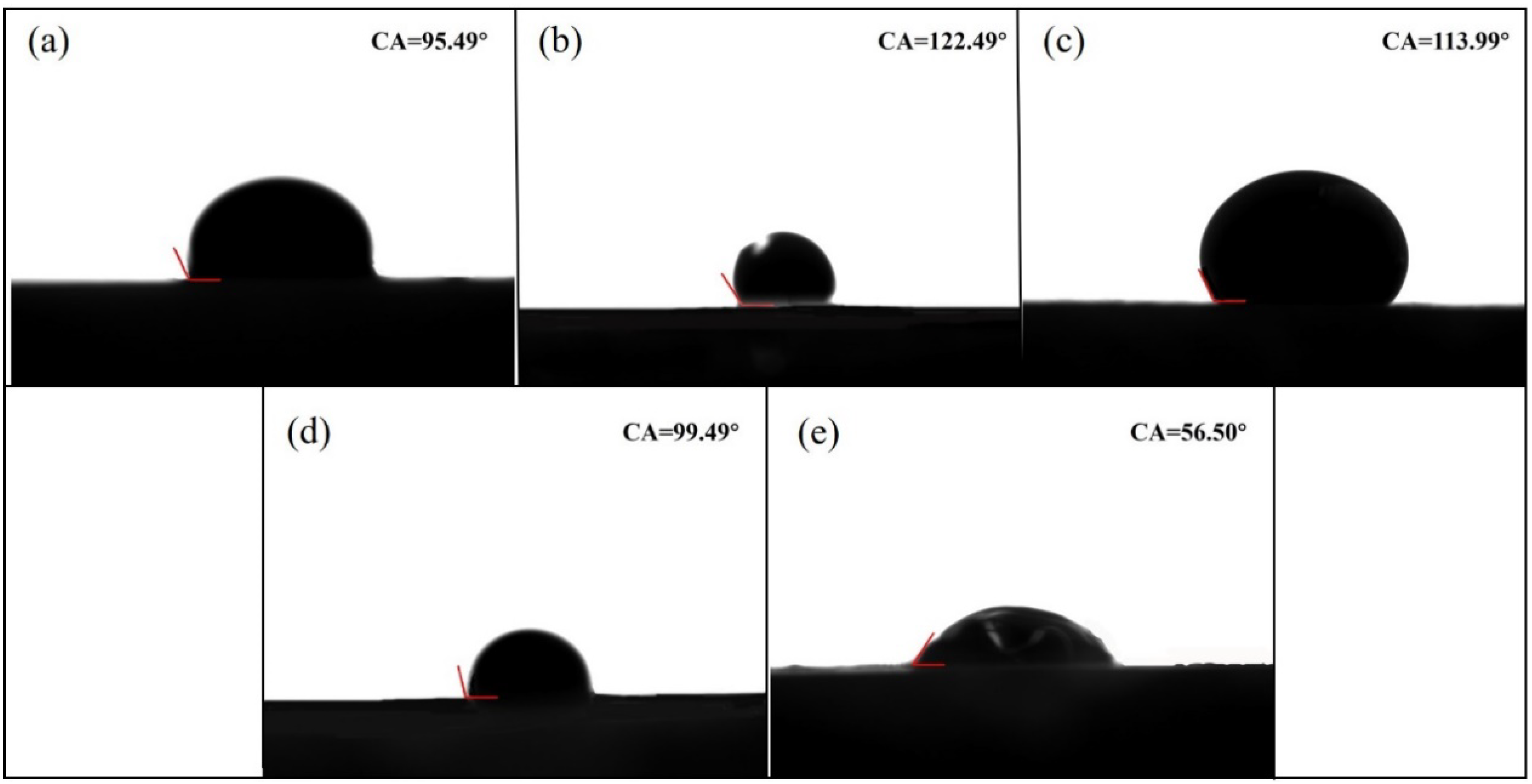

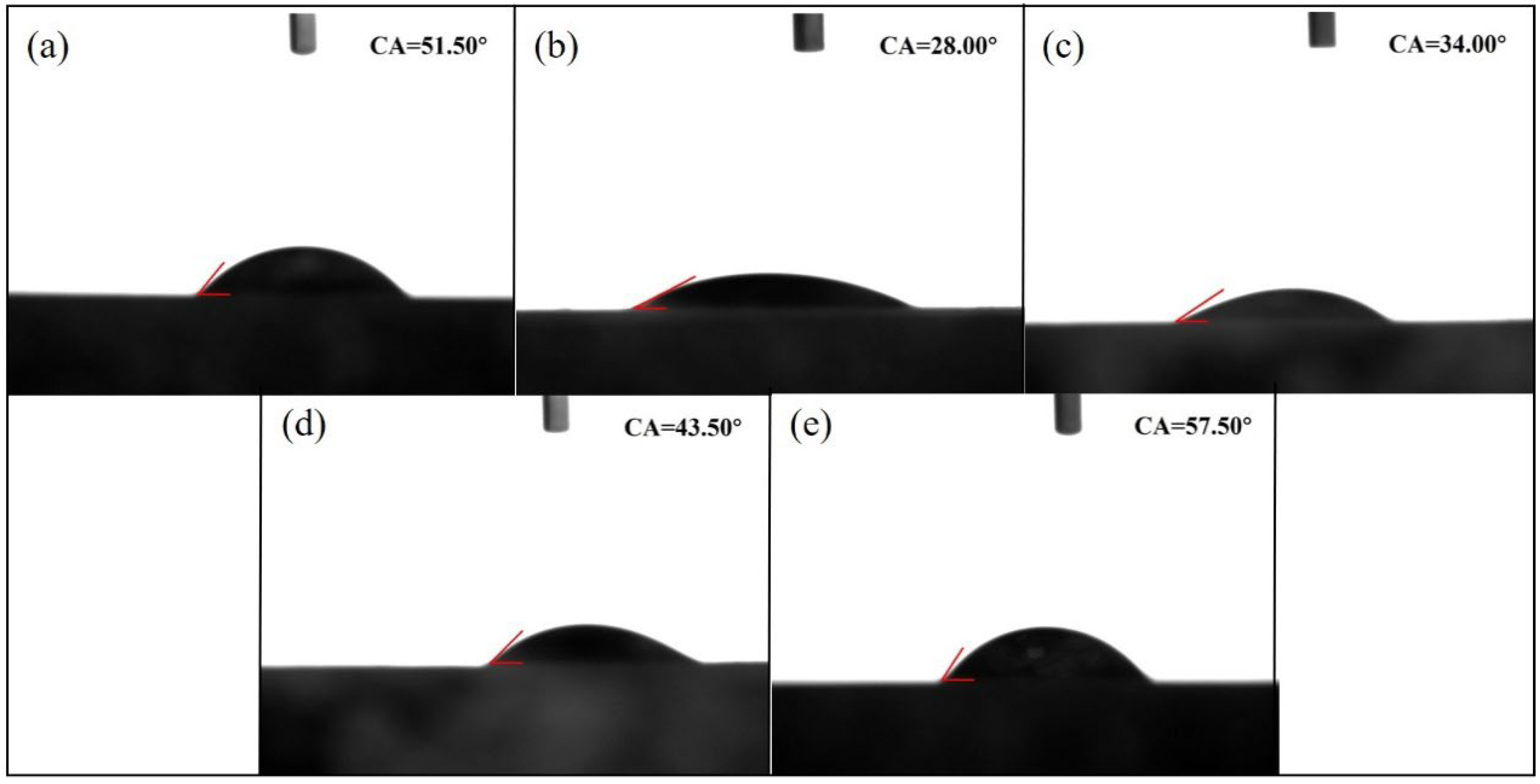

- Contact angle test

- (b)

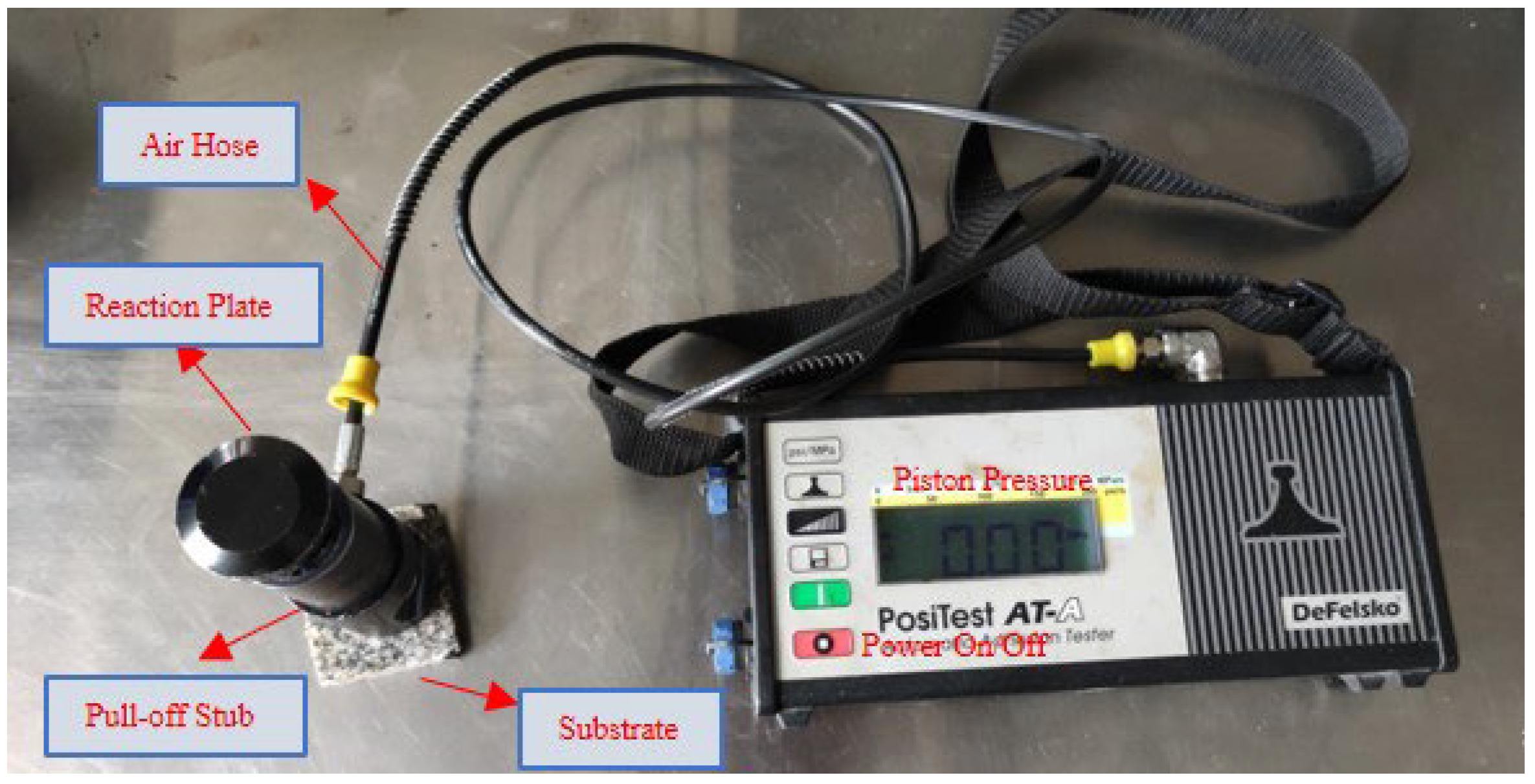

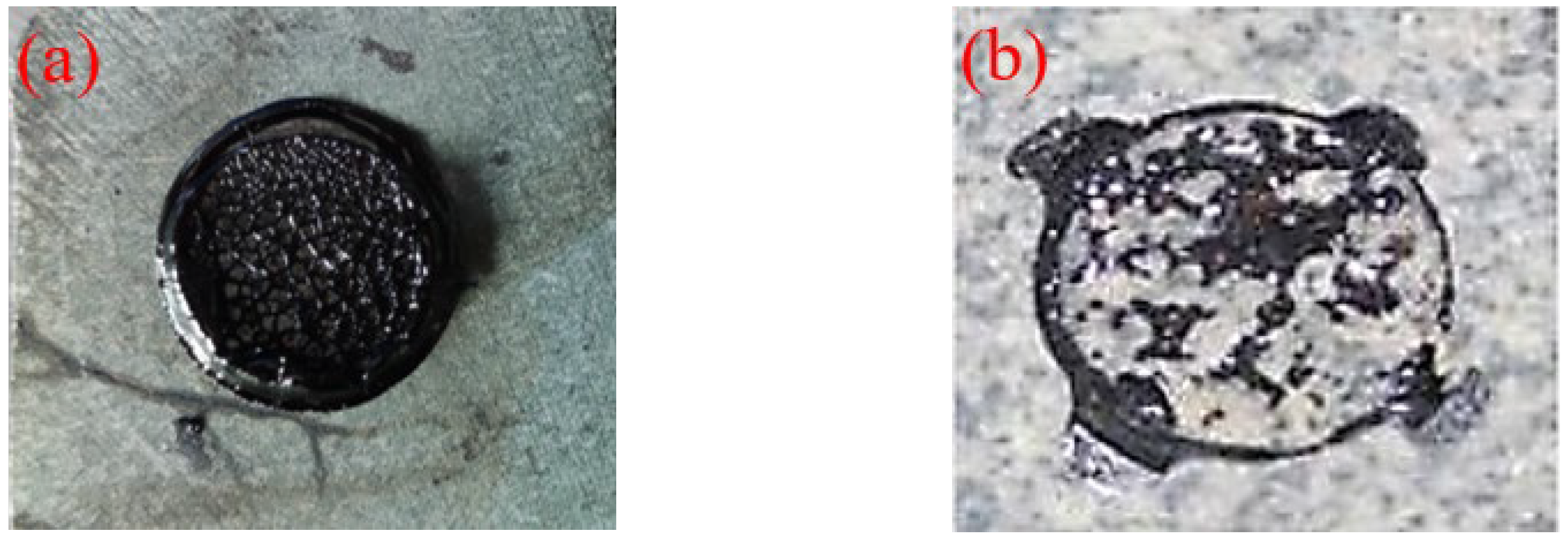

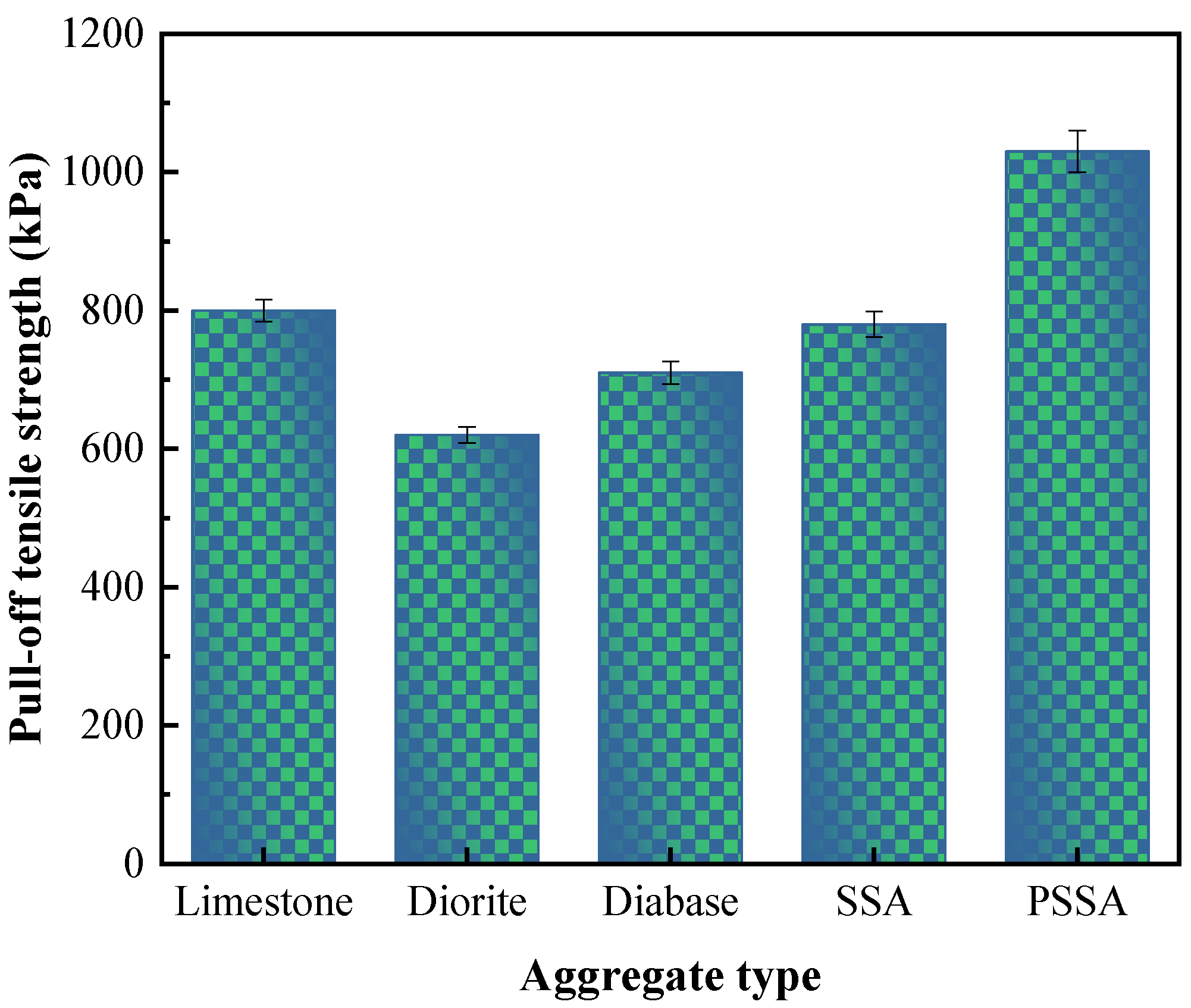

- Binder Bond Strength (BBS) test

2.4.3. The Performance Evaluation of Asphalt Mixture

3. Results and Discussion

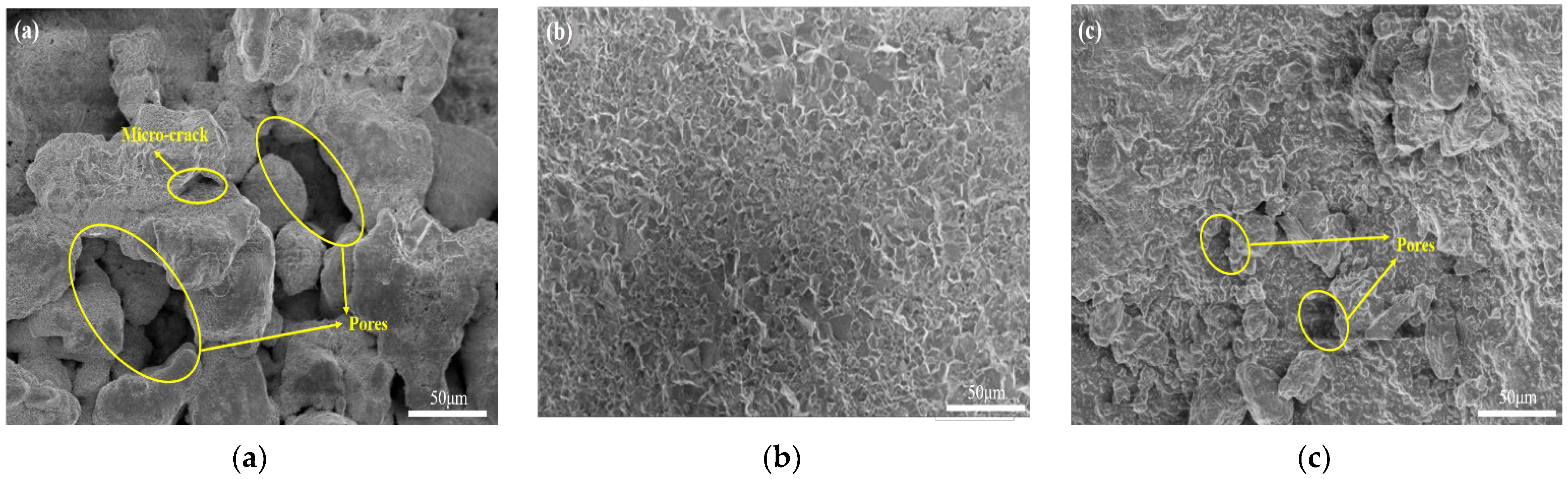

3.1. Surface Structure and Pore Changes of SSA

3.2. Chemical Composition of SSA

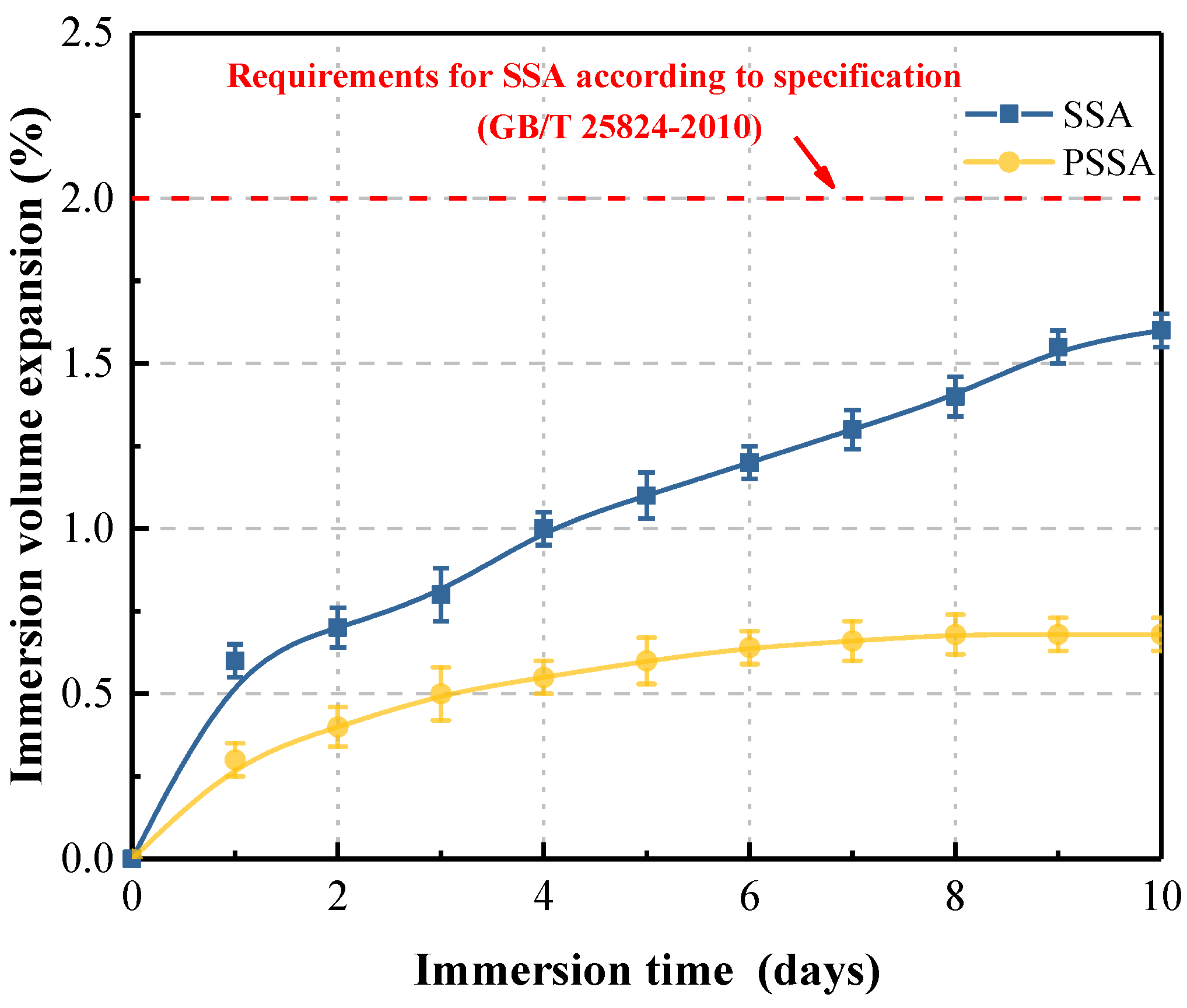

3.3. Swelling Properties of SSA

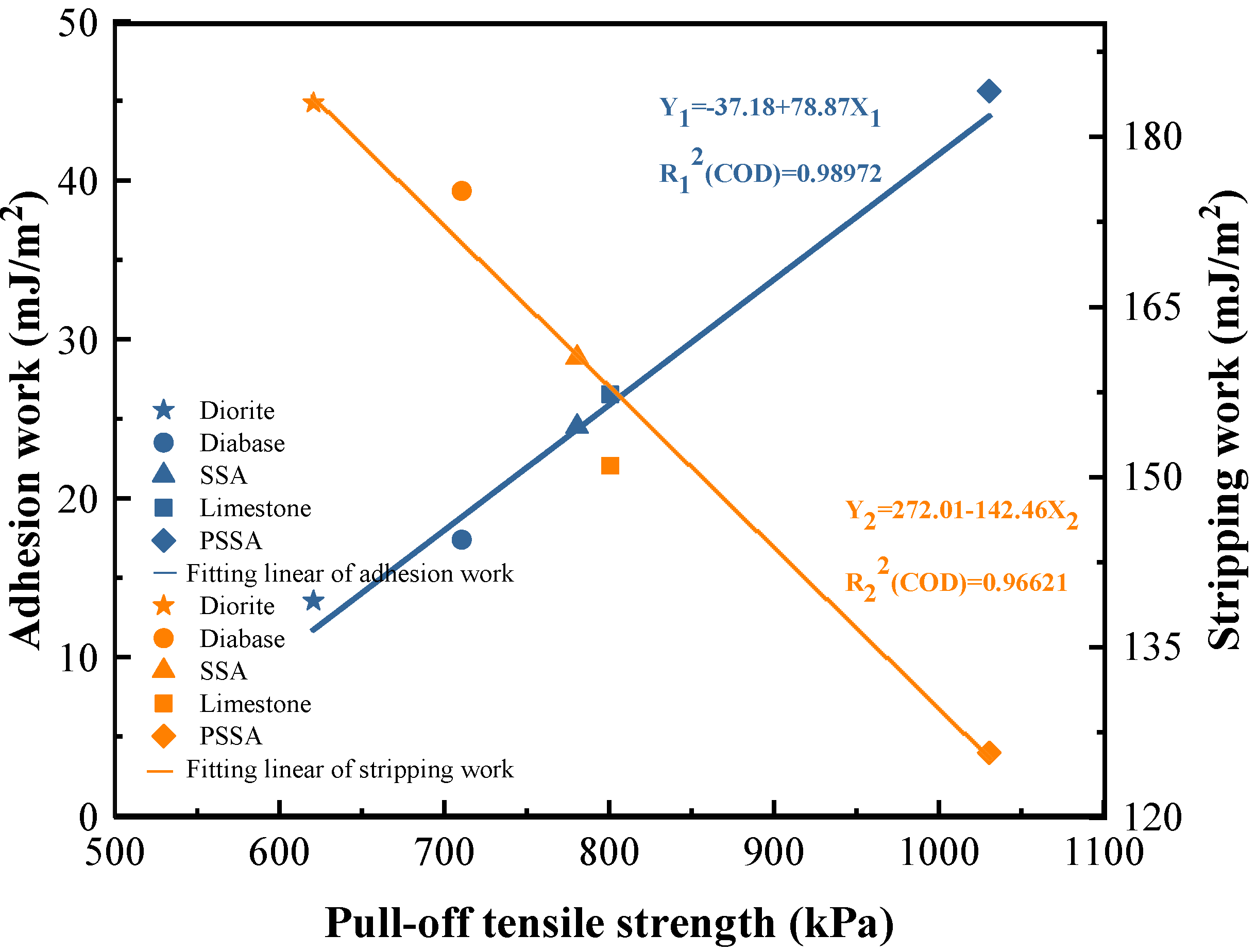

3.4. Adhesion and Stripping Work

3.5. Binder Bond Strength

3.6. Pavement Performance of Asphalt Mixture

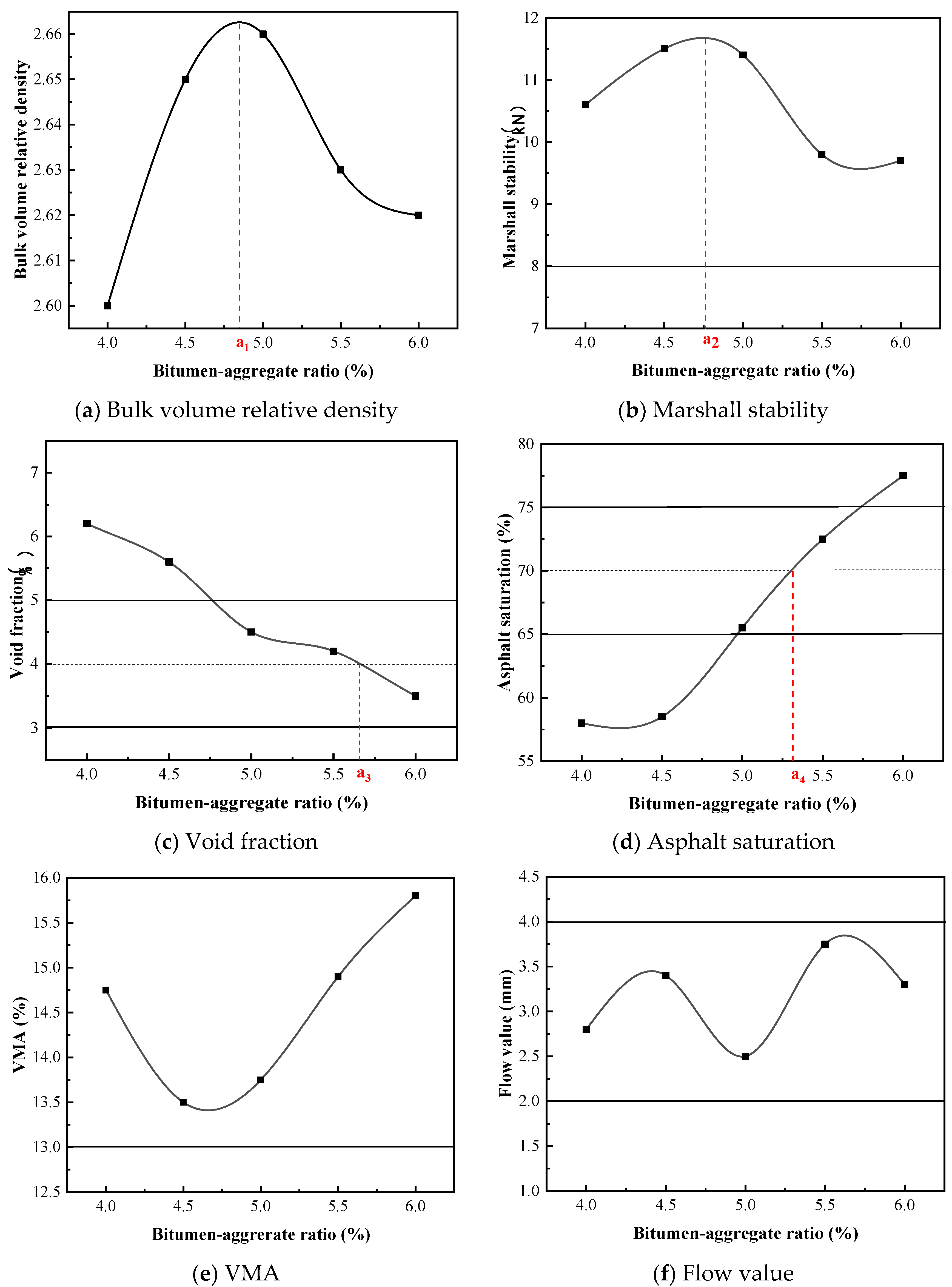

3.6.1. Standard Marshall Test

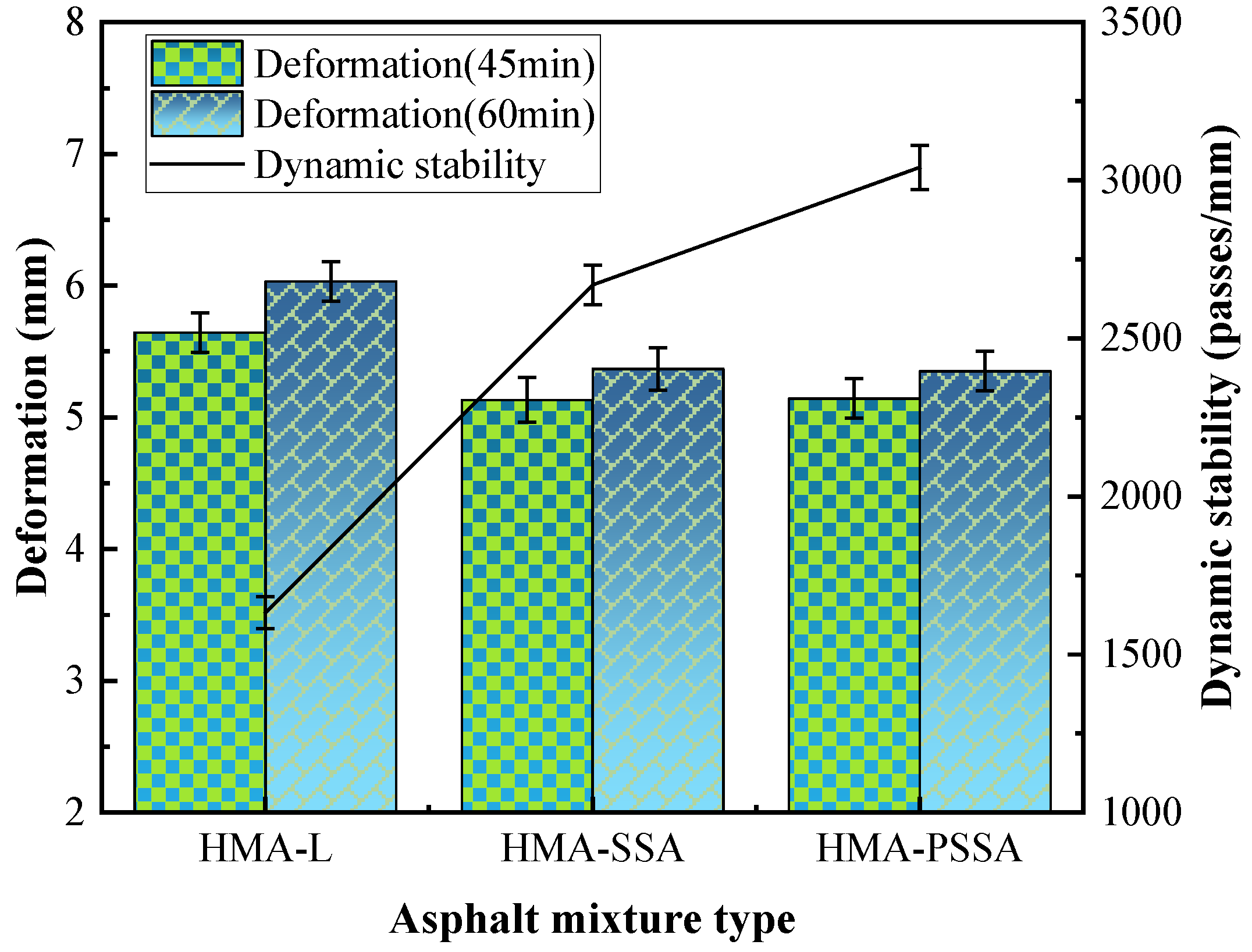

3.6.2. Wheel-Tracking Rutting Test

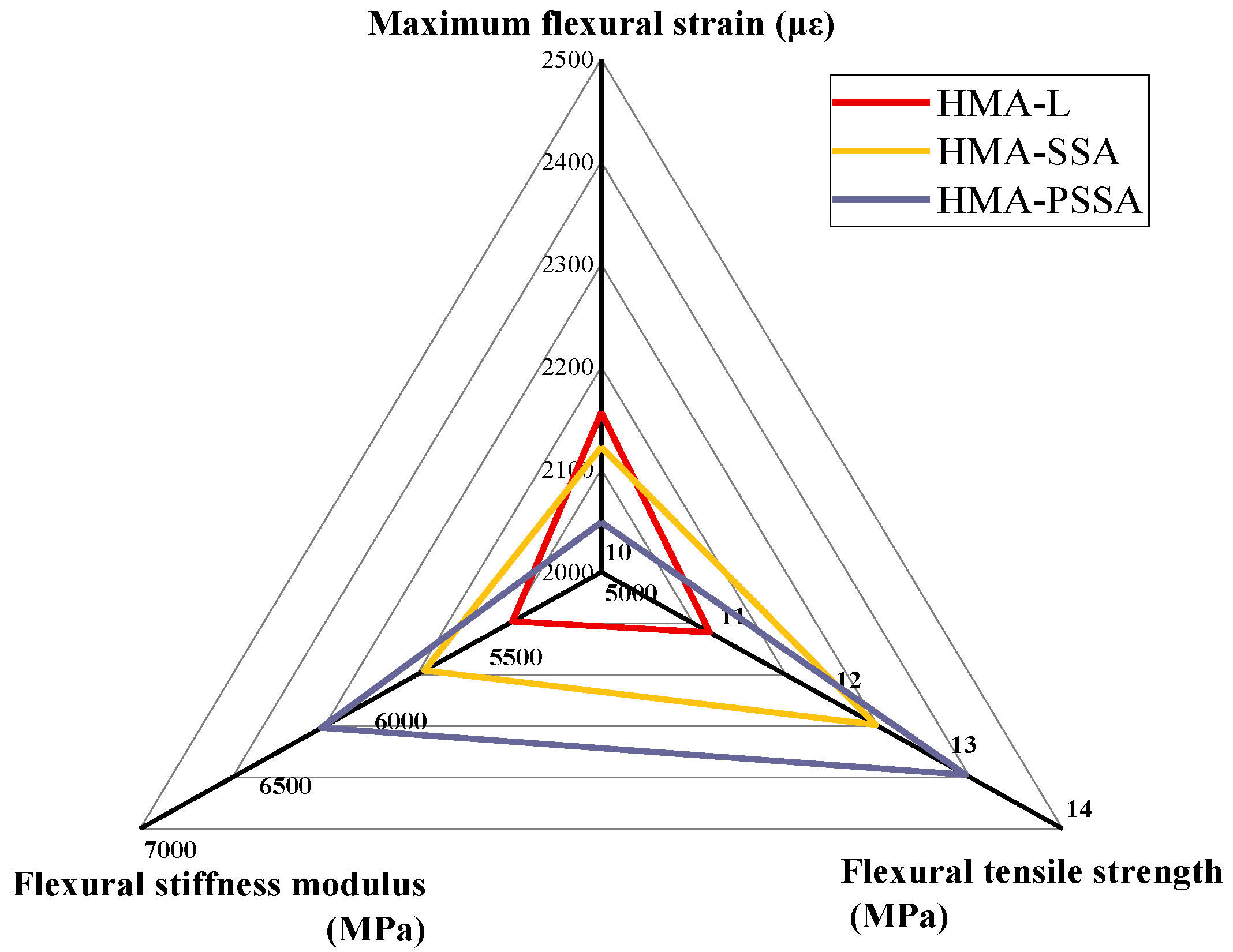

3.6.3. Low-Temperature Bending Creep Test

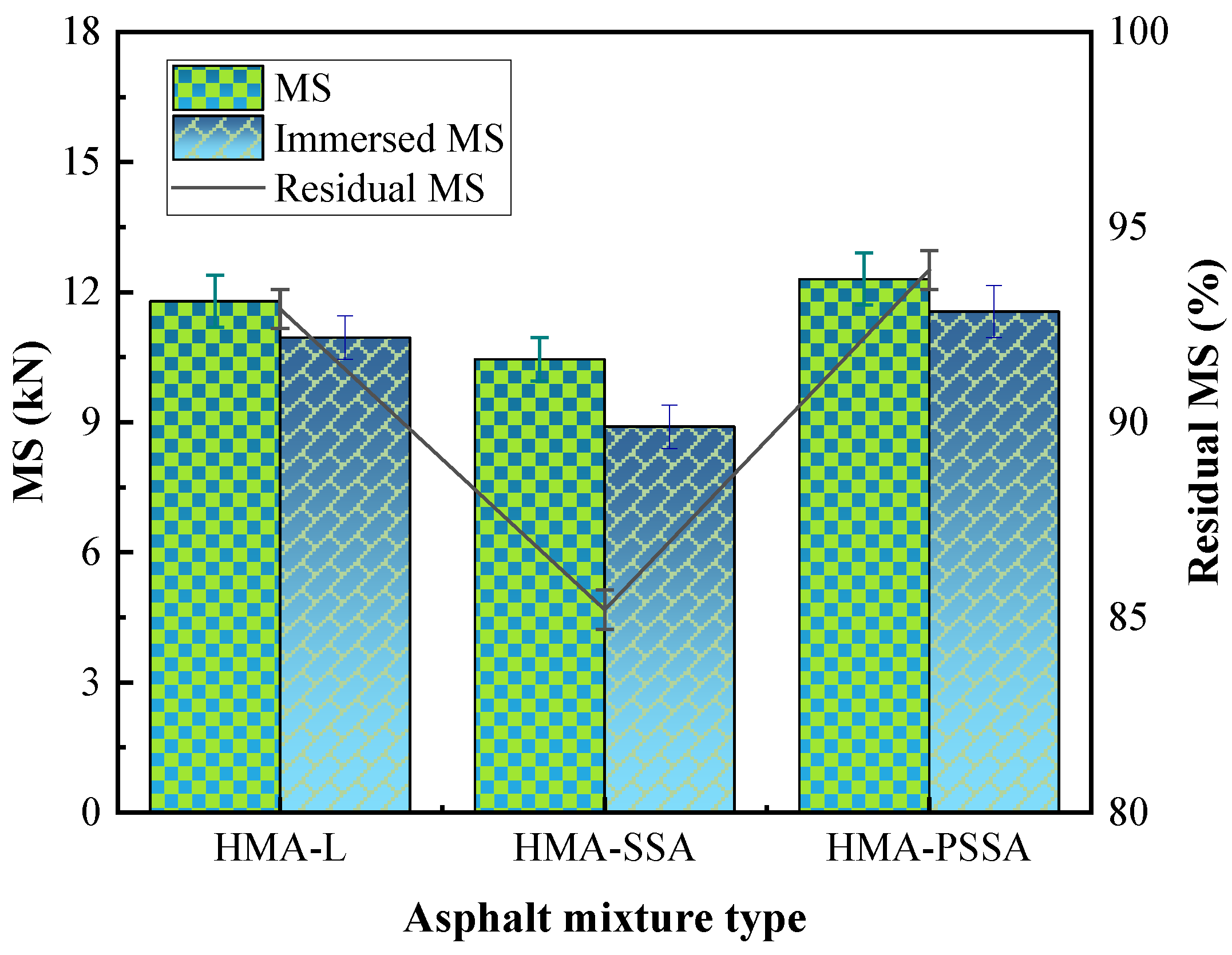

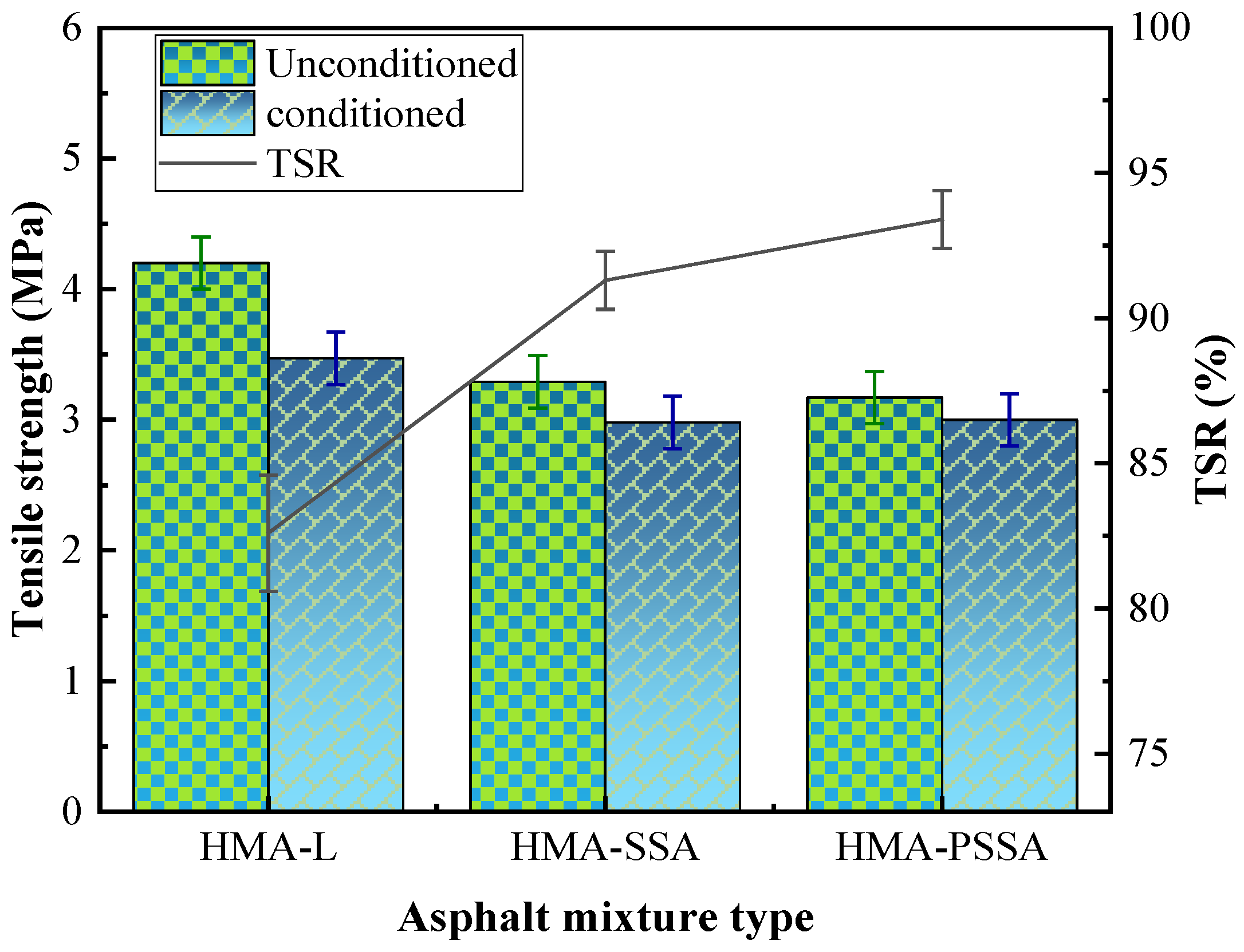

3.6.4. Immersion Marshall Test and Freeze-Thaw Splitting Test

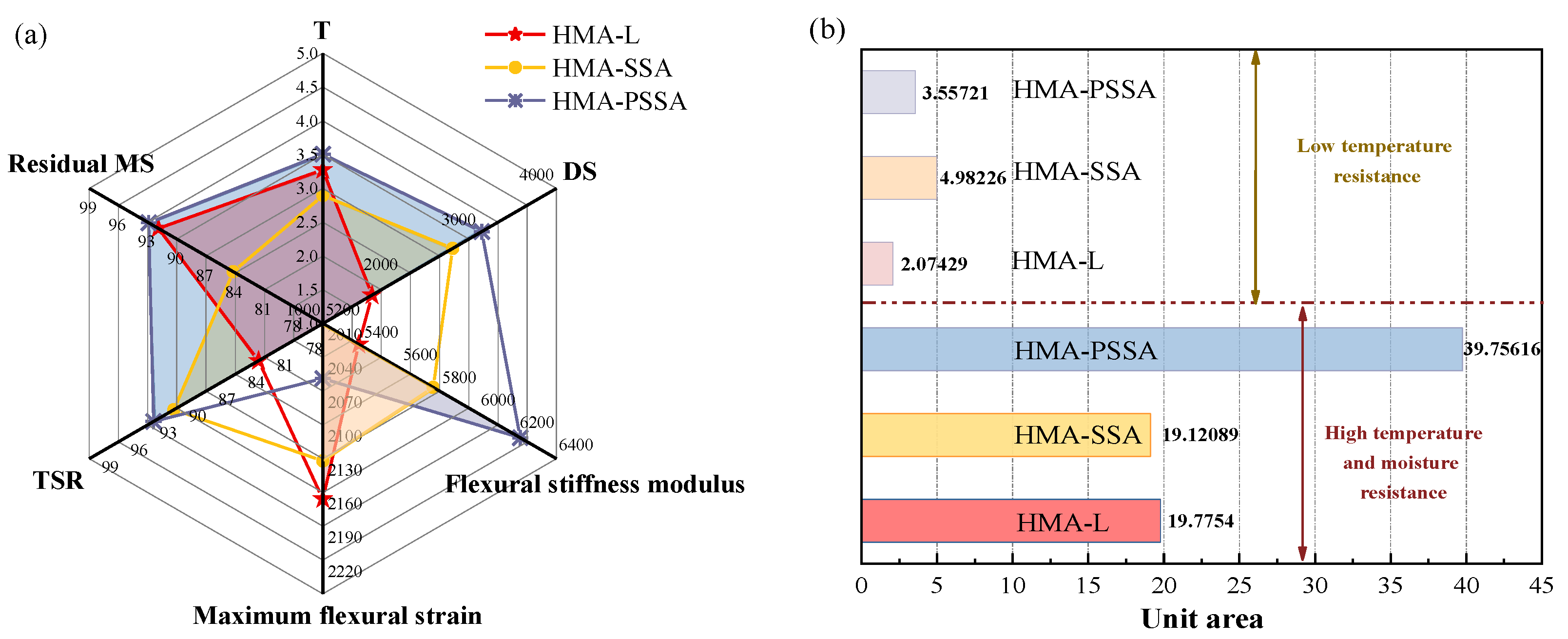

3.6.5. Comprehensive Performance Analysis

4. Conclusions

- The SEM results showed that the surface of SSA was rough, and there were micro-pores with a diameter of 100 µm and micro-cracks with a length of 20 µm. After surface treatment, PSSA still owned retained the rough surface structure and pores with size about 40 µm. PSSA have the better microstructure than SSA.

- After the surface pretreatment of SSA, the adhesion of PSSA and bitumen was better than that of limestone and SSA. In addition, the BBS test results also confirmed this phenomenon and the correlation between pull-off tensile strength, adhesion work and stripping work were determined.

- HMA-PSSA presented good Marshall stability and dynamic stability due to high adhesion of PSSA to bitumen. However, the low temperature performance of HMA-PSSA is not satisfactory, but it meets the corresponding requirements.

- HMA-PSSA showed less moisture sensitivity than HMA-L and HMA-SSA in both immersion Marshall test and freeze-thaw splitting test. This explains that HMA-PSSA has better moisture damage resistance than HMA-L and HMA-SSA.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Proctor, D.M.; Fehling, K.A.; Shay, E.C.; Wittenborn, J.L.; Green, J.J.; Avent, C.; Bigham, R.D.; Connolly, M.; Lee, B.; Shepker, T.O. Physical and chemical characteristics of blast furnace, basic oxygen furnace, and electric arc furnace steel industry slags. Environ. Sci. Technol. 2000, 34, 1576–1582. [Google Scholar] [CrossRef]

- October, M. Global Steel Markets to 2026—Hit by COVID-19 Outbreak, Steel Industry & Demand Speedily Returning to Normalcy. 2021. Available online: https://www.globenewswire.com/news-release/2021/10/06/2309315/0/en/Global-Steel-Markets-to-2026-Hit-by-COVID-19-Outbreak-Steel-Industry-Demand-Speedily-Returning-to-Normalcy.html (accessed on 25 October 2022).

- Le, K.; Hui, L.D.; Hao, Z.; Wan, L.M. Systematic research on the application of steel slag resources under the background of big data. Complexity 2018, 2018, 6703908. [Google Scholar] [CrossRef]

- Ma, L.; Xu, D.; Wang, S.; Gu, X. Expansion inhibition of steel slag in asphalt mixture by a surface water isolation structure. Road Mater. Pavement Des. 2019, 21, 2215–2229. [Google Scholar] [CrossRef]

- Guo, J.; Bao, Y.; Min, W. Steel slag in China: Treatment, recycling, and management. Waste Manag. 2018, 78, 318–330. [Google Scholar] [CrossRef] [PubMed]

- Ahmedzade, P.; Sengoz, B. Evaluation of steel slag coarse aggregate in hot mix asphalt concrete. J. Hazard. Mater. 2009, 165, 300–305. [Google Scholar] [CrossRef]

- Liu, J.; Wang, Z.; Guo, H.; Yan, F. Thermal transfer characteristics of asphalt mixtures containing hot poured steel slag through microwave heating. J. Clean. Prod. 2021, 308, 127225. [Google Scholar] [CrossRef]

- Asi, I.M. Evaluating skid resistance of different asphalt concrete mixes. Build. Environ. 2007, 42, 325–329. [Google Scholar] [CrossRef]

- Wu, S.; Xue, Y.; Ye, Q.; Chen, Y. Utilization of steel slag as aggregates for stone mastic asphalt (SMA) mixtures. Build. Environ. 2007, 42, 2580–2585. [Google Scholar] [CrossRef]

- Xue, Y.; Wu, S.; Hou, H.; Jin, Z. Experimental investigation of basic oxygen furnace slag used as aggregate in asphalt mixture. J. Hazard. Mater. 2006, 138, 261–268. [Google Scholar] [CrossRef]

- Cui, P.; Wu, S.; Xiao, Y.; Hu, R.; Yang, T. Environmental performance and functional analysis of chip seals with recycled basic oxygen furnace slag as aggregate. J. Hazard. Mater. 2020, 405, 124441. [Google Scholar] [CrossRef]

- Oluwasola, E.A.; Hainin, R.; Maniruzzaman, M.; Aziz, A. Evaluation of rutting potential and skid resistance of hot mix asphalt incorporating electric arc furnace steel slag and copper mine tailing. Indian J. Eng. Mater. Sci. 2015, 22, 550–558. [Google Scholar]

- Liapisa, I.; Likoydisb, S. Use of electric arc furnace slag in thin, skid-resistant surfacing. Procedia Soc. Behav. Sci. 2011, 48, 907–918. [Google Scholar] [CrossRef]

- Hainin, M.R.; Rusbintardjo, G.; Hameed, M.; Hassan, N.A.; Yusoff, N.M. Utilisation of Steel Slag as an Aggregate Replacement in Porous Asphalt Mixtures. J. Teknol. 2014, 69. [Google Scholar] [CrossRef]

- Sorlini, S.; Sanzeni, A.; Rondi, L. Reuse of steel slag in bituminous paving mixtures. J. Hazard. Mater. 2012, 209–210, 84–91. [Google Scholar] [CrossRef]

- Ziari, H.; Nowbakht, S.; Rezaei, S.; Mahboob, A. Laboratory Investigation of Fatigue Characteristics of Asphalt Mixtures with Steel Slag Aggregates. Adv. Mater. Sci. Eng. 2015, 2015, 623245. [Google Scholar] [CrossRef]

- Kavussi, A.; Jalili, Q.M.; Hassani, A. Fatigue behavior analysis of asphalt mixes containing electric arc furnace (EAF) steel slag. J. Rehabil. Civ. Eng. 2015, 3, 74–86. [Google Scholar] [CrossRef]

- Fwa, T.F.; Yoong, C.C.; Than, T.N.; See, S.L. Development of Environmentally Sustainable Pavement Mix. Int. J. Pavement Res. Technol. 2013, 6, 440–446. [Google Scholar] [CrossRef]

- Wang, G.; Wang, Y.; Gao, Z. Use of steel slag as a granular material: Volume expansion prediction and usability criteria. J. Hazard. Mater. 2010, 184, 555–560. [Google Scholar] [CrossRef]

- Thmson, M. Why is types hydrated lime special? In Proceedings of the International Building Lime Symposium, Orlando, FL, USA, 9–11 March 2005.

- Oluwasola, E.A.; Hainin, R.; Maniruzzaman, M.; Aziz, A. Evaluation of asphalt mixtures incorporating electric arc furnace steel slag and copper mine tailings for road construction. Transp. Geotech. 2015, 2, 47–55. [Google Scholar] [CrossRef]

- Hesami, S.; Ameri, M.; Goli, H.; Akbari, A. Laboratory investigation of moisture susceptibility of warm-mix asphalt mixtures containing steel slag aggregates. Int. J. Pavement Eng. 2015, 16, 745–759. [Google Scholar] [CrossRef]

- Coomarasamy, A.; Walzak, T. Effects of moisture on surface chemistry of steel slags and steel slag-asphalt paving mixes. Transp. Res. Rec. 1995, 1492, 85–95. [Google Scholar]

- Chen, Z.; Xie, J.; Xiao, Y.; Chen, J.; Wu, S. Characteristics of bonding behavior between basic oxygen furnace slag and asphalt binder. Constr. Build. Mater. 2014, 64, 60–66. [Google Scholar] [CrossRef]

- Kłonica, M.; Kuczmaszewski, J. Determining the value of surface free energy on the basis of the contact angle. Adv. Sci. Technol. Res. J. 2017, 11, 66–74. [Google Scholar] [CrossRef][Green Version]

- Qazizadeh, M.J.; Farhad, H.; Kavussi, A.; Sadeghi, A. Evaluating the Fatigue Behavior of Asphalt Mixtures Containing Electric Arc Furnace and Basic Oxygen Furnace Slags Using Surface Free Energy Estimation. J. Clean. Prod. 2018, 188, 355–361. [Google Scholar] [CrossRef]

- Zhang, J.; Apeagyei, A.K.; Airey, G.D.; Grenfell, J.R.A. Influence of aggregate mineralogical composition on water resistance of aggregate-bitumen adhesion. Int. J. Adhes. Adhes. 2015, 62, 45–54. [Google Scholar] [CrossRef]

- Aguiar-Moya, J.P.; Baldi-Sevilla, A.; Salazar-Delgado, J.; Pacheco-Fallas, J.F.; Loria-Salazar, L.; Reyes-Lizcano, F.; Cely-Leal, N. Adhesive properties of asphalts and aggregates in tropical climates. Int. J. Pavement Eng. 2016, 19, 738–747. [Google Scholar] [CrossRef]

- Chen, Z.; Wu, S.; Xiao, Y.; Zeng, W.; Yi, M.; Wan, J. Effect of hydration and silicone resin on Basic Oxygen Furnace slag and its asphalt mixture. J. Clean. Prod. 2016, 112, 392–400. [Google Scholar] [CrossRef]

- Zhu, J.; Wu, S.; Zhong, J.; Wang, D. Investigation of asphalt mixture containing demolition waste obtained from earthquake-damaged buildings. Constr. Build. Mater. 2012, 29, 466–475. [Google Scholar] [CrossRef]

- Aguiar-Moya, J.P.; Salazar-Delgado, J.; Baldi-Sevilla, A.; Leiva-Villacorta, F.; Loria-Salazar, L. Effect of Aging on Adhesion Properties of Asphalt Mixtures with the Use of Bitumen Bond Strength and Surface Energy Measurement Tests. Transp. Res. Rec. J. Transp. Res. Board. 2015, 2505, 57–65. [Google Scholar] [CrossRef]

- Bhasin, A.; Masad, E.; Little, D.; Lytton, R. Limits on Adhesive Bond Energy for Improved Resistance of Hot-Mix Asphalt to Moisture Damage. Transp. Res. Rec. J. Transp. Res. Board. 2006, 1970, 3–13. [Google Scholar] [CrossRef]

- Howson, J.; Masad, E.; Bhasin, A.; Little, D.; Lytton, R. Comprehensive analysis of surface free energy of asphalts and aggregates and the effects of changes in pH. Constr. Build. Mater. 2011, 25, 2554–2564. [Google Scholar] [CrossRef]

- Guo, J.; Bao, Y.; Min, W. Study on the adhesion property between asphalt binder and aggregate: A state-of-the-art review. Constr. Build. Mater. 2020, 256, 119474. [Google Scholar] [CrossRef]

- Skaf, M.; Manso, J.M.; Aragón, Á.; Fuente-Alonso, J.A.; Ortega-López, V. EAF slag in asphalt mixes: A brief review of its possible re-use. Resour. Conserv. Recycl. 2017, 120, 176–185. [Google Scholar] [CrossRef]

- Su, Z.; Muhammad, Y.; Sahibzada, M.; Li, J.; Zhang, L. Preparation and properties of aminated graphene fiber incorporated modified asphalt. Constr. Build. Mater. 2019, 229, 116836. [Google Scholar] [CrossRef]

- Guo, C.; Han, S.; Han, R. Evaluation of asphalt-aggregate adhesion using surface free energy theory. Appl. Mech. Mater. 2014, 686, 51–56. [Google Scholar] [CrossRef]

- Shafabakhsh, G.H.; Faramarzi, M.; Sadeghnejad, M. Use of Surface Free Energy method to evaluate the moisture susceptibility of sulfur extended asphalts modified with antistripping agents. Constr. Build. Mater. 2015, 98, 456–464. [Google Scholar] [CrossRef]

- Moraes, R.; Velasquez, R.; Bahia, H. Using bond strength and surface energy to estimate moisture resistance of asphalt-aggregate systems. Constr. Build. Mater. 2017, 130, 156–170. [Google Scholar] [CrossRef]

- Pasetto, M.; Baldo, N. Influence of the aggregate skeleton design method on the permanent deformation resistance of stone mastic asphalt. Mater. Res. Innov. 2015, 18, S3-96–S3-101. [Google Scholar] [CrossRef]

- Wu, S.; Xue, Y.; Ye, Q.; Chen, Y. Performance Evaluation of Asphalt Mixes Containing Steel Slag Aggregate as a Measure to Resist Studded Tire Wear. J. Mater. Civ. Eng. 2016, 28. [Google Scholar] [CrossRef]

- Ameri, M.; Hesami, S.; Goli, H. Laboratory evaluation of warm mix asphalt mixtures containing electric arc furnace (EAF) steel slag. Constr. Build. Mater. 2013, 49, 611–617. [Google Scholar] [CrossRef]

| Property | Unit | Value | Requirement | Test Method |

|---|---|---|---|---|

| Penetration (25 °C, 100 g, 5 s) | 0.1 mm | 68 | 60~80 | T0604-2011 |

| Penetration index (PI) | - | −0.6 | −1.5~+1.0 | T0604-2011 |

| Softening point | °C | 46.0 | ≥45 | T0606-2011 |

| Ductility (10 °C) | cm | 31 | ≥20 | T0605-2011 |

| Ductility (15 °C) | cm | >100 | ≥100 | T0605-2011 |

| Wax content | % | 1.8 | ≤2.2 | T0615-2011 |

| Flashing point | °C | 310 | ≥260 | T0611-2011 |

| Dynamic viscosity (60 °C) | Pa·s | 200 | ≥160 | T0620-2000 |

| Density | g/cm3 | 1.045 | - | T0603-2011 |

| RTFOT—mass loss | % | −0.25 | ≤±0.8 | T0610-2011 |

| RTFOT—Residual Penetration (25 °C) | % | 68 | ≥61 | T0604-2011 |

| RTFOT—Ductility (10 °C) | % | 7 | ≥6 | T0605-2011 |

| Property | SSA (Coarse) | PSSA (Coarse) | Limestone Aggregate (Coarse) | Limestone Aggregate (Fine) | Requirement | Test Method |

|---|---|---|---|---|---|---|

| Apparent density (g/cm3) | 3.482 | 3.525 | 2.727 | 2.699 | ≥2.60 | T0304-2005 |

| Water absorption (%) | 1.88 | 1.04 | 0.68 | - | ≤2 | T0304-2005 |

| Crush value (%) | 14.8 | 13.5 | 16.6 | - | ≤26 | T0316-2005 |

| Abrasion value (%) | 8.0 | 7.2 | 22.3 | - | ≤28 | T0317-2005 |

| Flakiness and elongation (%) | 2.2 | 2.2 | 7.5 | - | ≤12 | T0312-2005 |

| Sand equivalent (%) | - | - | - | 75 | ≥60 | T0334-2005 |

| Chemical Composition | Mass Fraction (%) |

|---|---|

| Anhydrous ethanol | 30~50 |

| Epoxy resin | 10~20 |

| Silane coupling agent | 5~10 |

| M-Xylylenediamine | 5~10 |

| Methyldiethanolamine | 3~5 |

| Liquid silicone rubber | 3~5 |

| Components | Content/wt% |

|---|---|

| CaO | 35.79 |

| Fe2O3 | 20.31 |

| SiO2 | 20.04 |

| MgO | 8.53 |

| Al2O3 | 3.00 |

| MnO | 2.18 |

| P2O5 | 1.46 |

| TiO2 | 0.56 |

| K2O | 0.54 |

| Na2O | 0.46 |

| OTHER | 7.13 |

| TOTAL | 100.00 |

| Aggregate Type | Limestone | Diorite | Diabase | SSA |

|---|---|---|---|---|

| Alkalinity modulus (M) | 5.45 | 0.09 | 0.35 | 3.22 |

| Reagent | γd | γp | γ |

|---|---|---|---|

| Distilled water | 21.8 | 51.0 | 72.8 |

| Glycerol | 34.0 | 30.0 | 64.0 |

| Formamide | 39.0 | 19.0 | 58.0 |

| Bitumen | 29.1 | 0.37 | 29.47 |

| Aggregate Category | Adhesion Work (Wa-g) | Stripping Work (Wa-s-w) |

|---|---|---|

| Limestone | 26.65 | 151.01 |

| Diorite | 13.64 | 182.98 |

| Diabase | 17.49 | 175.21 |

| SSA | 24.61 | 160.54 |

| PSSA | 45.74 | 125.73 |

| Mixture Type | Bitumen Content (%) | ||||

|---|---|---|---|---|---|

| OAC1 | OACmin | OACmax | OAC2 | OAC | |

| HMA-L | 5.18 | 4.50 | 4.80 | 4.65 | 4.92 |

| HMA-SSA | 5.12 | 5.00 | 5.75 | 5.37 | 5.25 |

| HMA-PSSA | 5.20 | 4.00 | 5.75 | 4.87 | 5.04 |

| Mixture Specimen | Marshall Parameter | ||||||

|---|---|---|---|---|---|---|---|

| Bulk Density (g/cm3) | VV (%) | VMA (%) | VFA (%) | MS (kN) | FL (mm) | T (kN/mm) | |

| HMA-L | 2.433 | 4.5 | 14.42 | 68.79 | 11.79 | 3.60 | 3.275 |

| HMA-SSA | 2.487 | 4.9 | 14.81 | 66.91 | 10.45 | 3.61 | 2.895 |

| HMA-PSSA | 2.472 | 4.1 | 14.25 | 71.23 | 12.06 | 3.44 | 3.506 |

| Requirements (JTG, 2004) | / | 3–6 | ≥13.00 | 65–75 | ≥8 | 1.5–4.0 | / |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Niu, D.; Zhang, Z.; Meng, J.; Yang, Z.; Jing, R.; Liu, X.; Lin, P.; Sheng, Y. Surface Modification of Steel Slag Aggregate for Engineering Application in Asphalt Mixture. Buildings 2023, 13, 16. https://doi.org/10.3390/buildings13010016

Niu D, Zhang Z, Meng J, Yang Z, Jing R, Liu X, Lin P, Sheng Y. Surface Modification of Steel Slag Aggregate for Engineering Application in Asphalt Mixture. Buildings. 2023; 13(1):16. https://doi.org/10.3390/buildings13010016

Chicago/Turabian StyleNiu, Dongyu, Zhao Zhang, Jiandang Meng, Zhengxian Yang, Ruxin Jing, Xueyan Liu, Peng Lin, and Yanping Sheng. 2023. "Surface Modification of Steel Slag Aggregate for Engineering Application in Asphalt Mixture" Buildings 13, no. 1: 16. https://doi.org/10.3390/buildings13010016

APA StyleNiu, D., Zhang, Z., Meng, J., Yang, Z., Jing, R., Liu, X., Lin, P., & Sheng, Y. (2023). Surface Modification of Steel Slag Aggregate for Engineering Application in Asphalt Mixture. Buildings, 13(1), 16. https://doi.org/10.3390/buildings13010016